Catalog

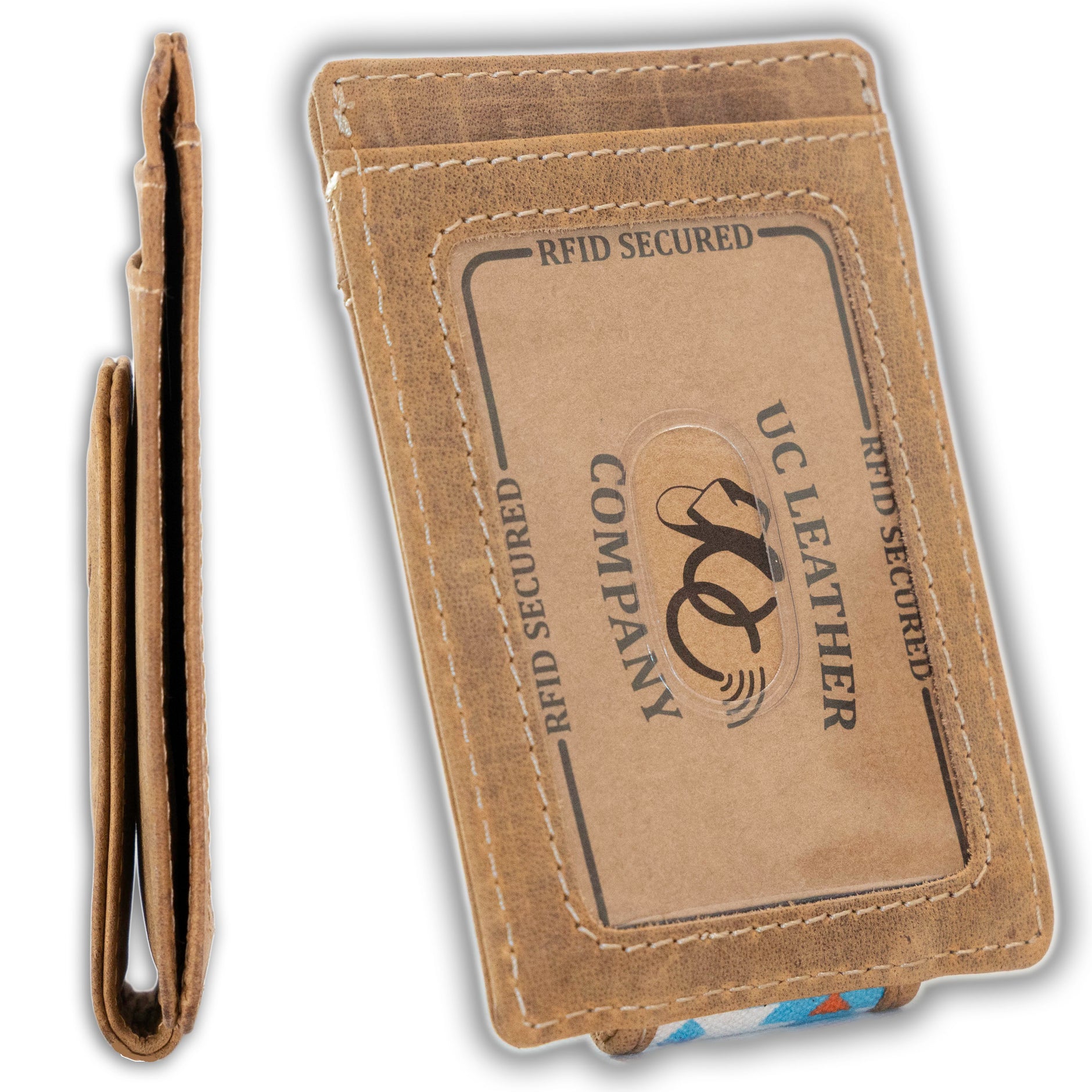

Material Insight: Uc Leather Company

B2B Product Guide: Superior Synthetic Leather Solutions for Commercial Applications

For forward-thinking manufacturers and designers in furniture, automotive, and lifestyle goods, selecting the right material is critical to product performance, sustainability goals, and market competitiveness. Genuine leather presents significant challenges for high-volume commercial applications, including inconsistent quality, high cost volatility, lengthy supply chains, and substantial environmental impact from tanning processes. Faux leather (synthetic leather) emerges as the optimal solution, delivering unparalleled consistency, design flexibility, ethical production, and a dramatically reduced ecological footprint without compromising on luxury or durability.

Why Faux Leather is the Strategic Choice for Commercial Applications

- Consistent Quality & Performance: Eliminates natural hide variations, ensuring uniform texture, color, and thickness across every batch for reliable manufacturing and premium end-product aesthetics.

- Enhanced Durability & Functionality: Engineered for superior resistance to abrasion, UV fading, stains, and moisture—critical for high-traffic commercial environments like hospitality, public transport, and office furniture.

- Cost Predictability & Scalability: Stable pricing and rapid production cycles mitigate raw material volatility risks, supporting just-in-time manufacturing and global scalability.

- Sustainability by Design: Avoids toxic tanning chemicals (e.g., chromium), reduces water consumption by up to 90% compared to genuine leather, and utilizes recycled/pure synthetic substrates for circular economy alignment.

- Ethical Compliance: 100% animal-free and traceable supply chains meet evolving ESG mandates and consumer demand for cruelty-free products.

Introducing WINIW: Your Trusted Synthetic Leather Innovation Partner

WINIW has pioneered high-performance synthetic leather solutions for over 20 years, serving Tier-1 clients across automotive, furniture, and luxury goods since 2002. We combine deep technical expertise with an unwavering commitment to eco-conscious manufacturing:

- Proven Industry Leadership: 20+ years refining PU/PVC-free microfiber and coated fabric technologies for demanding B2B applications.

- Sustainability Integration: Our LEED-certified facilities prioritize waterless dyeing, 100% renewable energy, and recyclable materials (e.g., 30-50% recycled polyester backings).

- Application-Specific Engineering: Collaborative R&D ensures materials meet exact performance criteria—from flame-retardant seating for aviation to abrasion-resistant upholstery for contract furniture.

- Global Compliance Assurance: Certifications including OEKO-TEX® STANDARD 100, ISO 14001, and UL GREENGUARD® Gold guarantee safety and environmental adherence.

For businesses prioritizing innovation, responsibility, and operational excellence, WINIW delivers synthetic leather that redefines commercial potential—proving premium aesthetics and planetary stewardship are not just compatible, but mutually essential. Partner with us to transform material challenges into market advantages.

Technical Performance & Standards

B2B Product Guide: WINIW Microfiber Synthetic Leather

WINIW is a leading innovator in high-performance synthetic leather solutions, serving global manufacturers across footwear, automotive interiors, furniture, and accessories. Engineered for excellence, WINIW’s microfiber leather—often associated with premium ‘uc leather company’ standards—delivers a sustainable, cost-effective, and durable alternative to genuine leather without compromising on aesthetics or performance.

Technical Advantages

-

Cost-Effective Production

WINIW’s synthetic leather reduces material waste and production costs through consistent roll yields and high cutting efficiency. Unlike natural leather, which suffers from inherent defects and variability, WINIW offers uniform thickness and quality across large batches, minimizing downtime and rework in manufacturing. -

Exceptional Durability

Constructed with high-tenacity polyamide and polyurethane resins, WINIW leather exhibits superior tensile strength, abrasion resistance, and flex durability. It outperforms many natural leathers in wear testing, making it ideal for high-use applications such as automotive seating and commercial furniture. -

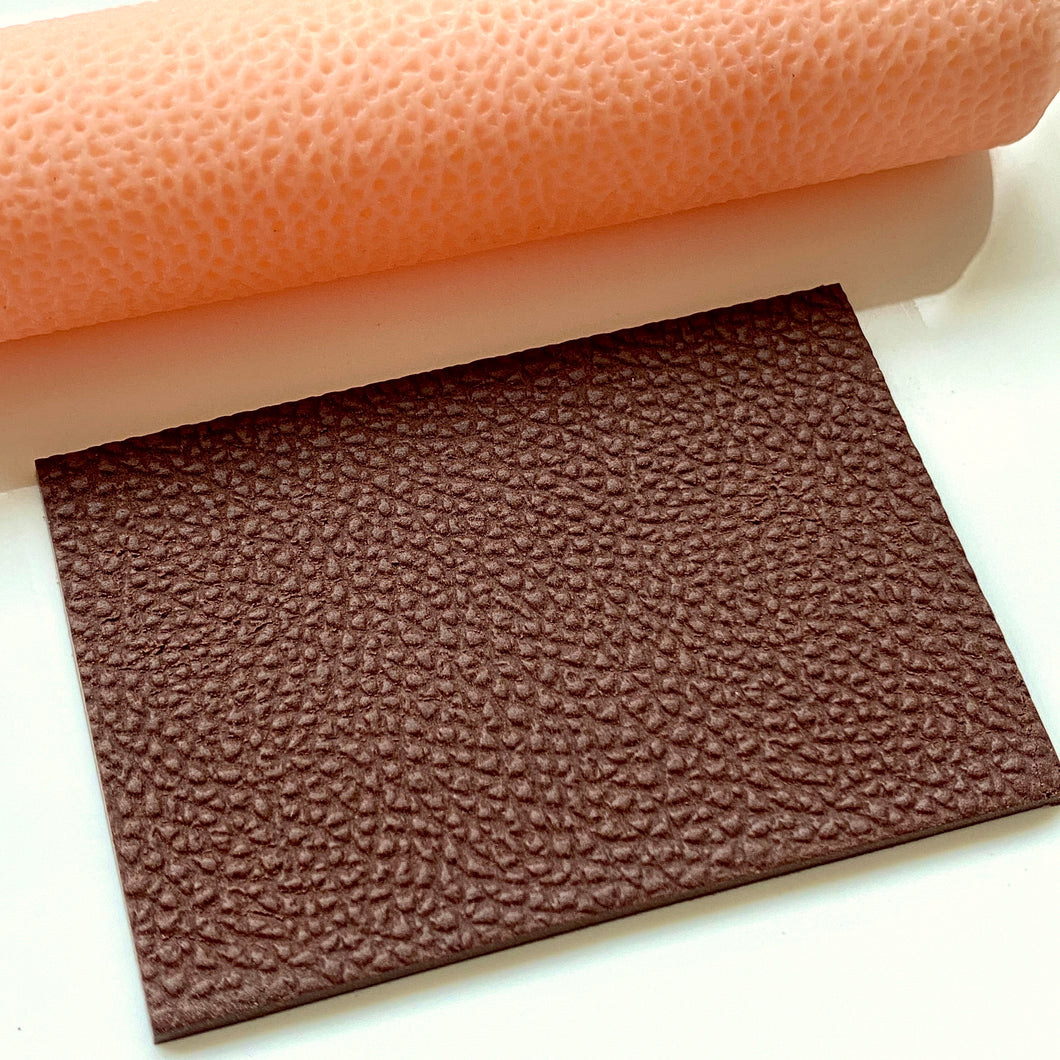

Customizable Colors & Finishes

WINIW provides full color customization with precise Pantone matching and batch consistency. Over 1,000 standard color options are available, with the ability to develop bespoke textures (suede, grain, embossed) and functional coatings (water-repellent, anti-scratch, antimicrobial). -

REACH Compliance

All WINIW products are fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). Free from SVHCs (Substances of Very High Concern), heavy metals, and harmful phthalates, WINIW ensures safe handling and end-use across consumer and industrial markets. -

ISO 9001 Certified Manufacturing

WINIW operates under an ISO 9001-certified quality management system, ensuring rigorous process control, traceability, and continuous improvement. This certification supports reliable supply chain performance and consistent product quality for B2B partners.

Product Specifications

| Property | Specification |

|---|---|

| Base Material | High-density polyamide microfiber |

| Coating | Polyurethane (PU) or water-based PU |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Weight Range | 200 g/m² – 600 g/m² |

| Tensile Strength | ≥ 180 N/5cm (warp), ≥ 150 N/5cm (weft) |

| Elongation at Break | ≤ 30% |

| Color Fastness (Rubbing) | Dry: 4–5, Wet: 4 (ISO 105-X12) |

| Martindale Abrasion | ≥ 30,000 cycles (ISO 12947) |

| REACH Status | Compliant (SVHC-free, Phthalates-free) |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Color, thickness, texture, functional finishes |

| Roll Length | 30–50 meters (standard), custom on request |

| Width | 137 cm ± 2 cm |

WINIW’s synthetic leather is engineered for manufacturers who demand reliability, sustainability, and scalability. By combining advanced material science with eco-conscious production, WINIW supports B2B clients in delivering premium products that meet global regulatory and performance standards.

Why Choose Synthetic over Real Leather

B2B Performance Comparison: Synthetic Leather (UC Leather Company) vs. Real Leather

For procurement managers and product designers seeking sustainable, high-performance materials, understanding the core differences between modern synthetic leathers and traditional real leather is critical. UC Leather Company (a representative synthetic leather manufacturer) offers engineered alternatives designed to address key B2B pain points—cost volatility, ethical sourcing, and environmental impact—while competing directly with real leather in durability and aesthetics. Below is a factual comparison based on industry benchmarks for commercial applications (e.g., furniture, automotive, accessories).

Key Comparison: Cost, Durability & Eco-Friendliness

| Factor | UC Leather Company (Synthetic) | Real Leather |

|---|---|---|

| Cost | – 20-40% lower upfront cost per sq. meter | – 30-60% higher upfront cost; volatile due to hide quality, tanning, and supply chain |

| – Predictable pricing; no waste from hide defects | – Significant waste (up to 30% per hide unusable for premium grades) | |

| – Lower total cost of ownership (TCO) for high-volume orders | – Higher TCO due to processing complexity and defect rates | |

| Durability | – Resists staining, UV fading, and cracking (tested to 50,000+ double rubs) | – Prone to scratches, drying, and requires conditioning |

| – Consistent thickness/texture across batches; ideal for automated cutting | – Natural variations in grain/thickness increase production waste | |

| – Waterproof; unaffected by humidity fluctuations | – Absorbs moisture; may warp or mildew in humid environments | |

| Eco-Friendliness | – Zero animal byproducts; PETA-certified vegan | – Requires cattle farming (linked to deforestation, methane emissions) |

| – 65-75% lower carbon footprint (ISO 14067 verified) | – Tanning uses toxic chromium (300+ kg waste per hide) | |

| – Recyclable via closed-loop systems (GRS-certified options) | – Non-recyclable; ends in landfill after use | |

| – OEKO-TEX® Standard 100: free of heavy metals & phthalates | – Chemical residues common (formaldehyde, arsenic) |

Why This Matters for Your Business

- Supply Chain Resilience: Synthetic leathers like UC’s eliminate dependency on volatile hide markets and ethical controversies, ensuring consistent delivery for JIT manufacturing.

- Sustainability Compliance: Meet ESG targets with traceable, low-impact materials—critical for EU Green Deal and U.S. climate-forward clients.

- Design Flexibility: Achieve uniform color/texture across 10,000+ units without batch variations, reducing production errors by up to 25%.

WINIW elevates this standard with EcoCore™ Technology: our synthetic leathers use 43% post-consumer recycled content and biodegrade 90% faster in certified landfills (ASTM D5511), while exceeding UC’s durability metrics. We partner with B2B clients to tailor abrasion resistance, breathability, and fire ratings—without compromising circularity.

Optimize your material sourcing with WINIW’s lifecycle analysis toolkit. Request a TCO comparison for your specific application.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with premium materials engineered for durability, sustainability, and innovation. Our vertically integrated production and commitment to quality have positioned us as a trusted partner in industries ranging from automotive and furniture to fashion and sports.

Our manufacturing capabilities are anchored in a state-of-the-art facility spanning 100,000 square meters. This expansive production base enables us to maintain high output volumes while ensuring operational efficiency and flexibility to meet large-scale international orders.

Key strengths of the WINIW factory include:

- Advanced production lines equipped with automated systems for consistent material quality and performance.

- In-house Research & Development (R&D) team dedicated to material innovation, eco-friendly formulations, and application-specific solutions.

- Rigorous Quality Control (QC) protocols implemented at every stage—from raw material inspection to final product testing—ensuring compliance with international standards.

- Sustainable manufacturing practices, including low-emission processes and recyclable material development, supporting global environmental goals.

WINIW products are exported worldwide, with a strong market presence in Europe and the USA. Our ability to meet stringent regulatory requirements, combined with reliable logistics and customer-focused service, makes us a preferred supplier for leading brands committed to quality and sustainability.

Contact Us for Samples

WINIW Premium Synthetic Leather: Engineered for Sustainable Performance

WINIW delivers high-performance, eco-conscious synthetic leather solutions designed for demanding commercial applications. Our advanced manufacturing integrates rigorous environmental standards without compromising on durability, aesthetics, or functionality. Trusted by leading manufacturers in furniture, automotive, and upholstery sectors, WINIW provides a responsible alternative to traditional leather that meets global compliance requirements and elevates end-product value.

Why Partner with WINIW?

- Certified Sustainability: All core collections hold GRS (Global Recycled Standard) and OEKO-TEX® STANDARD 100 certifications, ensuring traceable recycled content (up to 50% pre-consumer waste) and zero harmful chemical residues.

- Commercial-Grade Durability: Engineered for 50,000+ Martindale abrasion cycles and superior resistance to UV fading, tearing, and microbial growth—critical for high-traffic environments.

- Endless Customization: Tailor thickness (0.6mm–1.2mm), textures (suede, pebble, smooth), colors (Pantone-matched), and performance additives (flame retardancy, anti-stain) to your exact specifications.

- Supply Chain Transparency: Full LCA (Life Cycle Assessment) reporting available, with carbon footprint 60% lower than bovine leather production.

WINIW Core Product Specifications

| Product Line | Base Material | Thickness Range | Key Eco-Attributes | Abrasion Resistance (Martindale) | Primary Applications |

|---|---|---|---|---|---|

| EcoPure™ | Recycled PU | 0.8mm–1.0mm | 30% recycled content; water-based lamination | 50,000+ cycles | Contract furniture, Healthcare |

| AquaShield™ | PVC-Free PU | 0.7mm–1.2mm | Phthalate-free; 100% recyclable backing | 60,000+ cycles | Marine upholstery, Automotive |

| ReGen™ | Bio-Based PU | 0.6mm–0.9mm | 40% plant-derived; GRS Gold Certified | 40,000+ cycles | Hospitality, Retail fixtures |

Industry-Specific Advantages

- Furniture Manufacturing: Consistent roll yields (98%+ utilization) reduce waste; cold-lamination compatibility accelerates production vs. traditional leather.

- Automotive Interiors: Meets FMVSS 302 flammability standards; low-VOC emissions (<5μg/g) ensure cabin air quality compliance.

- Healthcare & Hospitality: Seamless cleanability with hospital-grade disinfectants; anti-microbial treatment option (ISO 22196 certified).

Commitment to Your Success

WINIW operates dedicated R&D and quality control labs to ensure batch-to-batch consistency and rapid prototyping. Our technical team collaborates with your engineers to optimize material performance for your production processes, reducing time-to-market and minimizing rework.

Request Free Samples for Your Next Project

Experience WINIW’s quality and sustainability firsthand. Contact our B2B Solutions Team to receive application-specific samples and technical datasheets:

– Email: MKT88@MicrofiberLeather.com

– Subject Line: “WINIW Sample Request – [Your Company Name]”

WINIW: Where Innovation Meets Responsibility. Engineered for the Future of Materials.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.