Introduction: Navigating the Global Market for leather and polyurethane

In today’s competitive landscape, sourcing high-quality leather and polyurethane products can present significant challenges for B2B buyers, especially those aiming to meet diverse consumer demands across regions such as Africa, South America, the Middle East, and Europe. As businesses strive to balance aesthetics, functionality, and sustainability, understanding the intricacies of materials like genuine leather and PU leather becomes essential. This comprehensive guide delves into the various types of leather and polyurethane, their applications across multiple industries, and key considerations for supplier vetting and cost analysis.

With a focus on actionable insights, this guide equips international B2B buyers with the knowledge needed to make informed purchasing decisions. Whether you’re looking to enhance your product line with luxurious leather goods or exploring innovative, cost-effective polyurethane solutions, we provide a detailed framework for evaluating options based on quality, sustainability, and market trends. By addressing critical aspects such as durability, maintenance, and ethical sourcing, this resource empowers businesses to select the right materials that align with their operational goals and consumer preferences.

Navigating the global market for leather and polyurethane is not just about choosing between two materials; it’s about strategically positioning your brand to meet the evolving expectations of today’s consumers. This guide is your roadmap to mastering the complexities of sourcing and leveraging these materials effectively.

Table Of Contents

- Top 5 Leather And Polyurethane Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather and polyurethane

- Understanding leather and polyurethane Types and Variations

- Key Industrial Applications of leather and polyurethane

- 3 Common User Pain Points for ‘leather and polyurethane’ & Their Solutions

- Strategic Material Selection Guide for leather and polyurethane

- In-depth Look: Manufacturing Processes and Quality Assurance for leather and polyurethane

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather and polyurethane’

- Comprehensive Cost and Pricing Analysis for leather and polyurethane Sourcing

- Alternatives Analysis: Comparing leather and polyurethane With Other Solutions

- Essential Technical Properties and Trade Terminology for leather and polyurethane

- Navigating Market Dynamics and Sourcing Trends in the leather and polyurethane Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather and polyurethane

- Strategic Sourcing Conclusion and Outlook for leather and polyurethane

- Important Disclaimer & Terms of Use

Understanding leather and polyurethane Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Leather | Made from animal hides; unique grain and texture; durable | Luxury goods, high-end furniture | Pros: Long-lasting, develops character over time. Cons: Higher cost, requires maintenance. |

| PU Leather | Synthetic, water-resistant, available in various colors | Upholstery, fashion accessories | Pros: Cost-effective, easy to clean. Cons: Less durable, can crack and fade over time. |

| Bicast Leather | Combination of genuine leather and a polyurethane coating | Budget furniture, automotive interiors | Pros: Affordable, retains some leather characteristics. Cons: Limited lifespan, may not be fully vegan. |

| Split Leather | Made from the fibrous part of animal hides, often coated | Budget-friendly furniture and bags | Pros: Cost-effective, offers some leather feel. Cons: Less durable, can wear out quickly. |

| Bonded Leather | Reconstituted leather made from leather scraps and resin | Affordable furniture, accessories | Pros: Eco-friendly, low cost. Cons: Not as durable, may lack the appearance of real leather. |

What Are the Key Characteristics of Genuine Leather for B2B Buyers?

Genuine leather is derived from animal hides, offering a unique texture and natural imperfections that enhance its aesthetic appeal. This material is highly valued in luxury markets, such as high-end furniture and fashion accessories, due to its durability and ability to develop a rich patina over time. For B2B buyers, investing in genuine leather means selecting a product that not only has longevity but also appeals to consumers seeking quality. However, the higher price point and the need for regular maintenance must be considered.

How Does PU Leather Compare in Terms of Applications and Suitability?

PU leather, or polyurethane leather, is a synthetic alternative that mimics the look of genuine leather while being water-resistant and easier to clean. It is widely used in upholstery for commercial settings, such as restaurants and offices, as well as in fashion items. B2B buyers appreciate PU leather for its affordability and versatility, allowing for a range of colors and styles. However, it is essential to note that PU leather may not offer the same durability as genuine leather, leading to potential long-term costs associated with replacements.

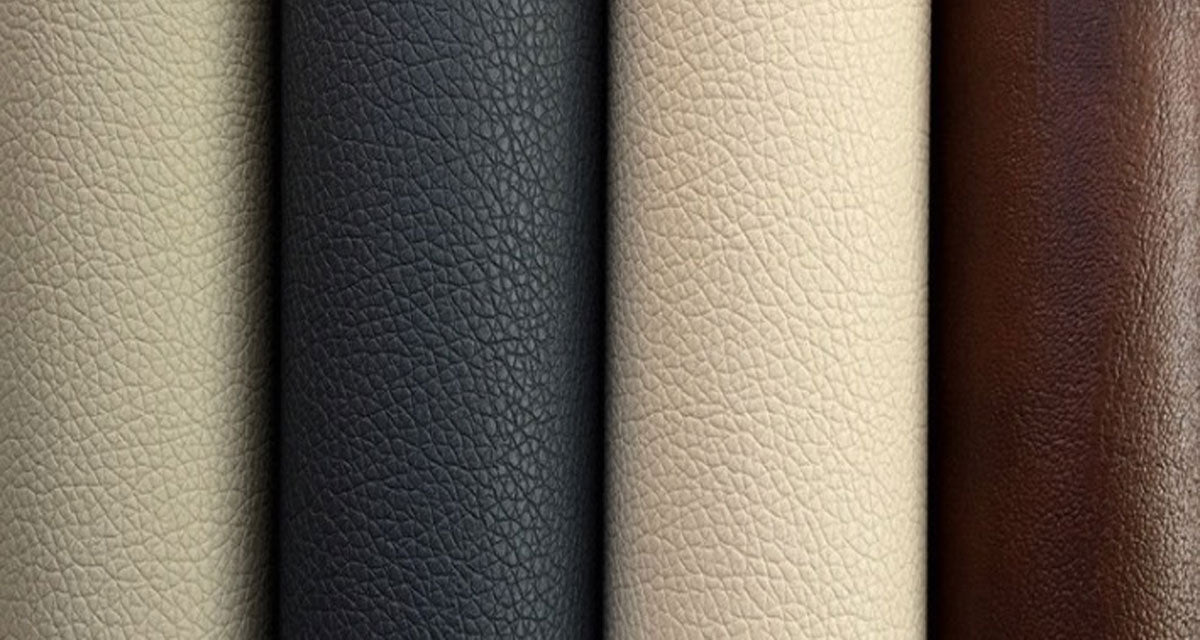

Illustrative image related to leather and polyurethane

What Are the Benefits and Drawbacks of Bicast Leather in Commercial Use?

Bicast leather combines genuine leather and a polyurethane coating, making it a budget-friendly option for businesses. It is commonly used in automotive interiors and budget furniture, providing a balance between cost and quality. While it retains some characteristics of genuine leather, such as texture, it is important for B2B buyers to be aware that its lifespan may be shorter, and it may not be fully vegan. Understanding these trade-offs can help businesses make informed purchasing decisions.

Why Consider Split Leather for Economical Solutions?

Split leather is derived from the fibrous layer of animal hides and is often coated to enhance its appearance. This type of leather is a cost-effective solution for businesses looking to provide a leather-like experience without the premium price tag. It is commonly found in budget-friendly furniture and bags. However, B2B buyers should consider its limited durability compared to higher-quality leathers, as it may wear out more quickly, impacting long-term value.

What Makes Bonded Leather an Eco-Friendly Choice for B2B Buyers?

Bonded leather is created from leftover leather scraps that are bonded together with resin, making it an environmentally conscious choice for businesses. It is often used in affordable furniture and accessories. B2B buyers can benefit from its lower cost and reduced waste; however, it is essential to keep in mind that bonded leather may lack the durability and aesthetic appeal of full-grain leather. Understanding these factors can help businesses align their purchasing decisions with sustainability goals while meeting budget constraints.

Key Industrial Applications of leather and polyurethane

| Industry/Sector | Specific Application of leather and polyurethane | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for seats and interiors | Enhances aesthetics and comfort while being durable | Ensure compliance with regional automotive standards and regulations. Look for suppliers who offer eco-friendly PU options. |

| Furniture | Upholstery for sofas, chairs, and headboards | Provides a stylish, durable, and easy-to-clean finish | Verify the quality of materials and inquire about warranty policies for wear and tear. |

| Fashion and Accessories | Handbags, clothing, and shoes | Offers a vegan alternative while allowing for diverse styles and colors | Seek suppliers with a reputation for ethical manufacturing and those who can provide customization options. |

| Home Décor | Wall coverings, cushions, and decorative items | Adds luxury and personalization to interior spaces | Consider the environmental impact of materials and the availability of sustainable sourcing options. |

| Sports and Leisure | Gear and apparel, such as gloves and jackets | Combines functionality with comfort and style | Assess the durability and performance under various conditions, ensuring compliance with safety standards. |

How is Leather Used in the Automotive Industry?

In the automotive sector, leather is predominantly utilized for upholstery in seats and interiors, enhancing the vehicle’s aesthetic appeal and comfort. Leather provides a luxurious feel that is often associated with high-end vehicles, while its durability ensures longevity even under heavy use. International buyers should prioritize suppliers who comply with local automotive standards and regulations, particularly in regions like Europe and the Middle East, where quality and environmental considerations are paramount. Additionally, sourcing eco-friendly options, such as sustainable leather alternatives, can appeal to environmentally conscious consumers.

What Are the Applications of Leather and Polyurethane in Furniture?

In the furniture industry, leather and polyurethane are extensively used for upholstery on sofas, chairs, and headboards. PU leather, in particular, offers a cost-effective alternative that is easy to maintain and clean, making it suitable for both residential and commercial applications. For B2B buyers, verifying the quality of materials is essential to ensure durability and longevity. It is also important to inquire about warranty policies that cover wear and tear, especially when sourcing products for high-traffic areas or commercial spaces.

Illustrative image related to leather and polyurethane

How Do Fashion Brands Use Leather and Polyurethane?

Fashion and accessories brands leverage leather and polyurethane for a variety of products, including handbags, clothing, and shoes. PU leather provides a vegan alternative that allows brands to cater to a growing demographic of environmentally conscious consumers. Buyers should seek suppliers known for ethical manufacturing practices and those who can offer customization options to meet specific design needs. This is especially relevant in markets across Africa and South America, where unique styles and cultural influences play a significant role in consumer preferences.

What Are the Benefits of Leather in Home Décor?

Leather and polyurethane are increasingly popular in home décor applications, such as wall coverings, cushions, and decorative items. These materials add a touch of luxury and personalization to interior spaces, enhancing aesthetic appeal. B2B buyers should consider the environmental impact of the materials they source, particularly in Europe, where sustainability is a key concern. It is also advisable to explore suppliers who offer sustainable sourcing options to align with consumer demand for eco-friendly products.

How Are Leather and Polyurethane Used in Sports and Leisure?

In the sports and leisure industry, leather and polyurethane are commonly found in gear and apparel, such as gloves and jackets. These materials combine functionality with comfort, providing athletes with the necessary performance characteristics while ensuring durability. Buyers should assess the durability and performance of these materials under various conditions, ensuring compliance with safety standards. This is crucial for international buyers who operate in diverse climates and conditions, particularly in regions like the Middle East and Africa, where outdoor sports are prevalent.

Illustrative image related to leather and polyurethane

3 Common User Pain Points for ‘leather and polyurethane’ & Their Solutions

Scenario 1: Navigating Quality Discrepancies in Leather and Polyurethane

The Problem: B2B buyers often encounter significant challenges when sourcing leather and polyurethane products due to varying quality standards. For instance, when purchasing upholstery for commercial spaces, a buyer may receive products that look appealing but fail to meet durability expectations. Inconsistent quality can lead to customer dissatisfaction, increased replacement costs, and damage to the buyer’s reputation, particularly in industries like hospitality or automotive, where high standards are crucial.

The Solution: To mitigate quality discrepancies, buyers should establish clear specifications that outline the desired properties of leather and polyurethane materials. Conduct thorough research on suppliers, focusing on those with established reputations and transparent quality control processes. Request samples of the materials and conduct performance tests, such as abrasion resistance and color fastness, to ensure they meet your requirements. Additionally, consider integrating third-party certifications that guarantee the quality of the materials, as this can provide an added layer of assurance for your purchases. By taking these proactive steps, buyers can significantly reduce the risk of quality-related issues and enhance their procurement processes.

Scenario 2: Addressing Sustainability Concerns in Material Choices

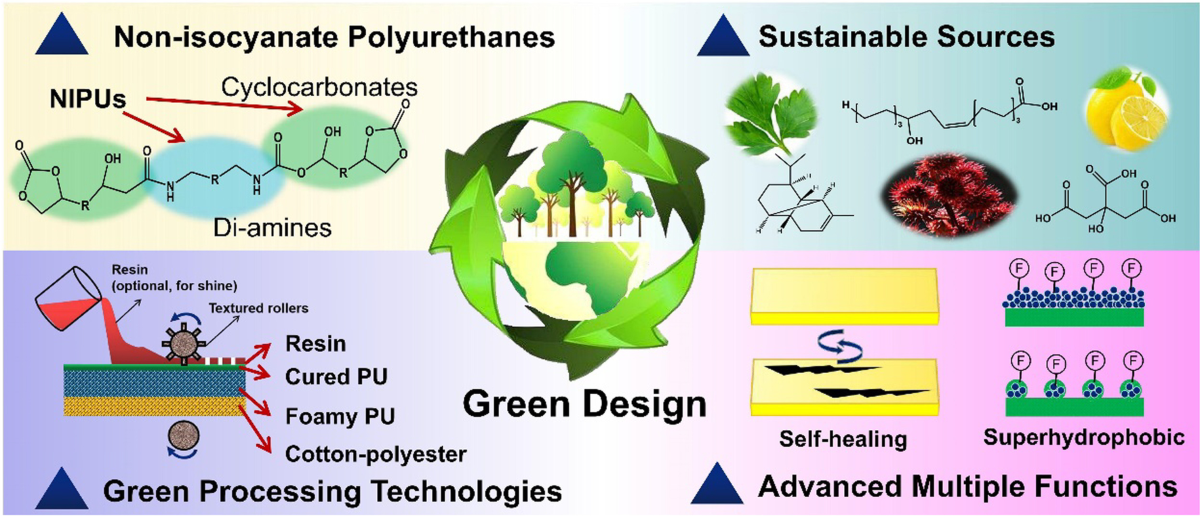

The Problem: As global sustainability standards rise, B2B buyers face increasing pressure to choose environmentally friendly materials. The challenge lies in the perception that polyurethane products are less sustainable due to their plastic content. Buyers in industries such as furniture manufacturing or automotive may struggle to reconcile the demand for aesthetic appeal with the need for sustainable practices, risking backlash from environmentally conscious consumers.

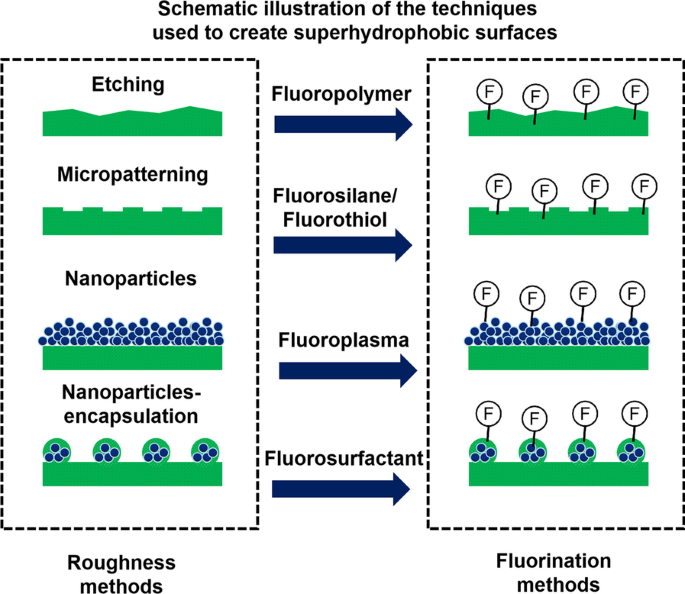

The Solution: Buyers can address sustainability concerns by opting for high-quality PU leather that utilizes eco-friendly production processes. Look for suppliers who prioritize sustainability in their operations, such as those using water-based adhesives and low-emission manufacturing techniques. Additionally, explore recycled polyurethane options, which can significantly reduce the environmental footprint of your products. Educating your team on the benefits of these materials and communicating your sustainability initiatives to customers can also enhance your brand image. By making informed choices and promoting sustainable practices, buyers can position themselves as leaders in the eco-conscious market.

Illustrative image related to leather and polyurethane

Scenario 3: Overcoming Misconceptions About PU Leather Durability

The Problem: Many B2B buyers mistakenly believe that polyurethane leather is a short-lived, inferior alternative to genuine leather. This misconception can lead to hesitance in investing in PU products, especially in sectors where durability and longevity are paramount, such as automotive interiors or high-traffic commercial settings. As a result, buyers may miss out on the benefits of PU leather, including cost savings and ease of maintenance.

The Solution: To counter misconceptions about PU leather durability, buyers should focus on education and transparency. When sourcing PU leather, inquire about the specific grades and formulations used, as higher-quality PU options can offer enhanced durability and resistance to wear and tear. Request case studies or testimonials from suppliers that demonstrate the longevity of their PU products in similar applications. Additionally, provide training for your procurement and sales teams to better articulate the benefits of PU leather to clients, emphasizing its water resistance and low maintenance requirements. By fostering a better understanding of PU leather’s capabilities, buyers can confidently include these materials in their offerings, leading to improved client satisfaction and reduced costs.

Strategic Material Selection Guide for leather and polyurethane

What Are the Key Properties of Genuine Leather and Polyurethane?

Genuine Leather: Understanding Its Properties and Applications

Genuine leather is a natural material derived from animal hides, primarily cattle. Its key properties include excellent durability, breathability, and the ability to develop a unique patina over time. This makes it ideal for high-end applications such as luxury furniture, automotive interiors, and fashion accessories. Genuine leather can withstand a wide range of temperatures and pressures, making it suitable for various environments.

Pros and Cons of Genuine Leather

The primary advantage of genuine leather is its longevity and aesthetic appeal, which enhances with age. However, it comes at a higher cost and requires more complex manufacturing processes, including tanning and finishing. Additionally, genuine leather is less resistant to water and stains compared to synthetic options, which may limit its use in certain applications.

Illustrative image related to leather and polyurethane

Impact on Application

Genuine leather is compatible with a variety of media, including water and oils, but it requires proper care to maintain its appearance and functionality. For international buyers, compliance with standards such as ASTM for leather quality may be essential, particularly in regions like Europe where regulations are stringent.

Polyurethane Leather: Analyzing Its Properties and Suitability

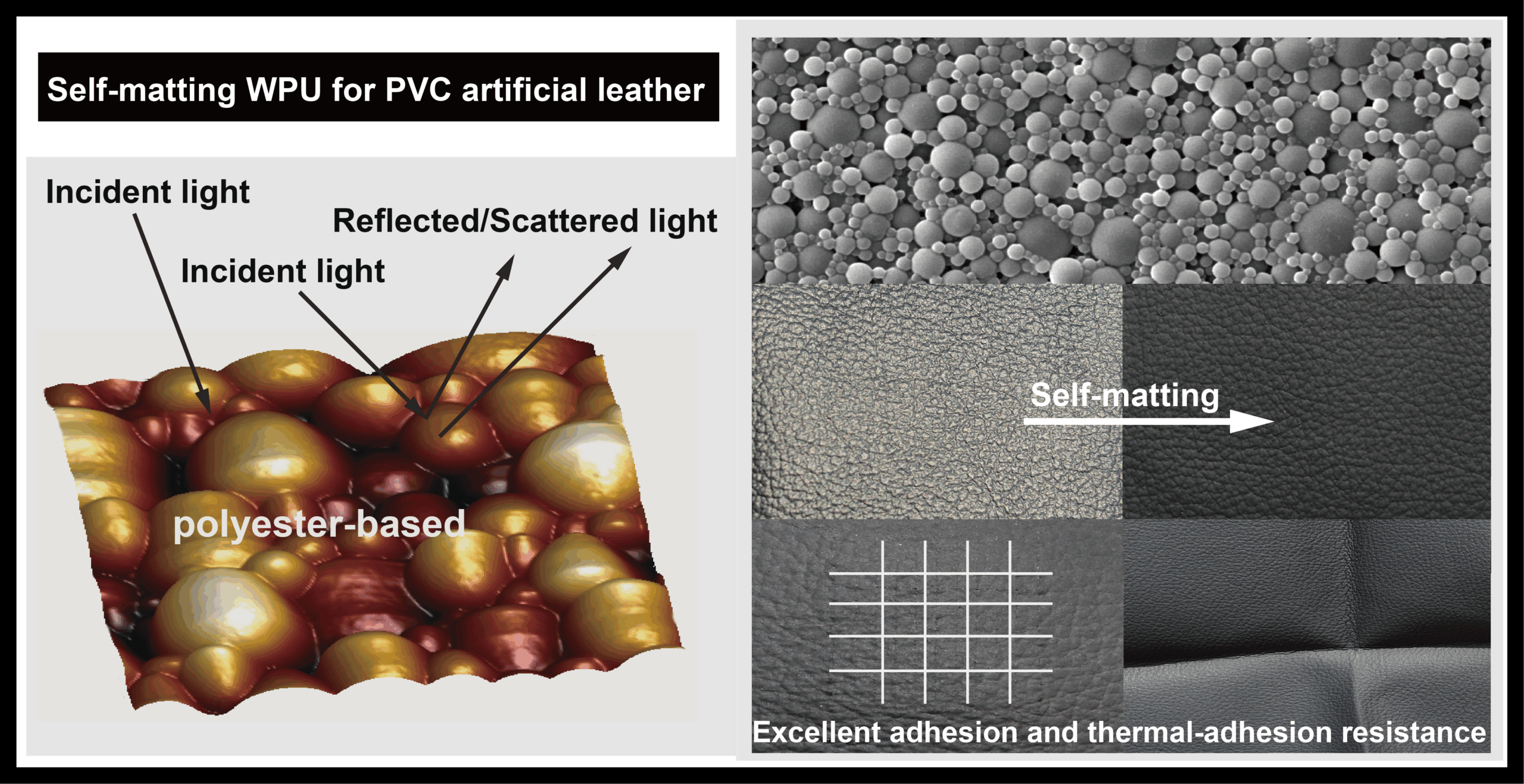

Polyurethane leather, or PU leather, is a synthetic alternative to genuine leather made from thermoplastic polymers. It is known for its water resistance and ease of maintenance, making it suitable for applications in environments like kitchens, bars, and automotive upholstery. PU leather can be produced in various colors and textures, offering flexibility in design.

Pros and Cons of Polyurethane Leather

The main advantage of PU leather is its affordability and ease of production, which allows for a wide range of styles. However, it lacks the durability and aesthetic qualities of genuine leather, often leading to cracking and fading over time. Additionally, while PU leather is marketed as vegan, some variants contain leather remnants, which could be a concern for ethically-minded consumers.

Impact on Application

PU leather is less breathable than genuine leather, which may affect comfort in applications like seating. Its compatibility with various cleaning agents makes it suitable for high-traffic areas. International buyers should be aware of the varying standards for synthetic materials, such as DIN in Europe, to ensure compliance with local regulations.

Illustrative image related to leather and polyurethane

What Are the Considerations for B2B Buyers in Different Regions?

When selecting between genuine leather and polyurethane leather, B2B buyers from Africa, South America, the Middle East, and Europe must consider several factors. Compliance with local standards, such as ASTM or JIS, is crucial, especially in markets like Germany and Saudi Arabia, where quality assurance is paramount. Additionally, understanding consumer preferences for sustainability and ethical sourcing can influence purchasing decisions.

Summary Table of Material Selection for Leather and Polyurethane

| Material | Typical Use Case for leather and polyurethane | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Luxury furniture, automotive interiors, fashion accessories | Durability and unique patina | Higher cost and requires maintenance | High |

| Polyurethane Leather | Upholstery for kitchens, bars, automotive interiors | Affordability and easy maintenance | Less durable, prone to cracking | Low |

This guide provides a comprehensive overview of the strategic material selection for leather and polyurethane, helping B2B buyers make informed decisions based on their specific application needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for leather and polyurethane

What Are the Main Stages in the Manufacturing Process of Leather and Polyurethane?

The manufacturing processes for leather and polyurethane (PU) involve several distinct stages, each critical to ensuring product quality and durability. Understanding these stages can empower B2B buyers to make informed decisions when sourcing materials.

Material Preparation: How Are Raw Materials Processed?

For leather, the process begins with the selection of high-quality hides, usually sourced from cattle. These hides undergo curing, where they are treated with preservatives to prevent decay. The curing process may involve salting, drying, or using chemicals like chromium salts. The choice of curing method can significantly impact the leather’s characteristics, including its flexibility and resistance to moisture.

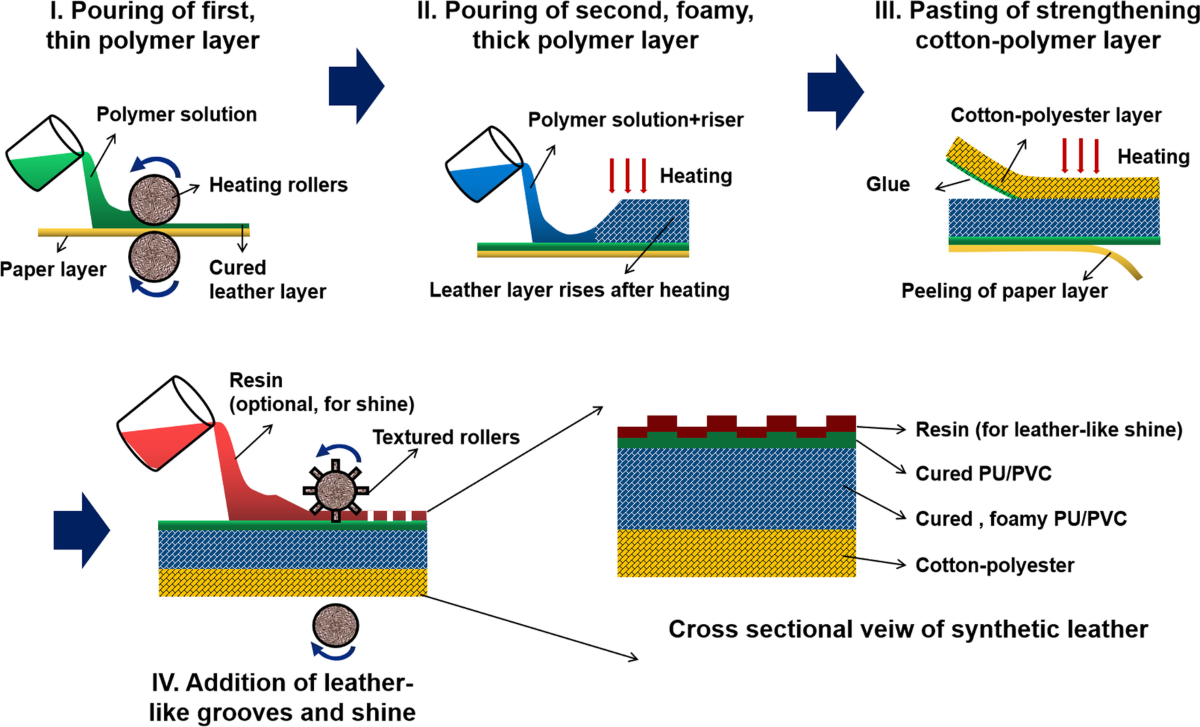

In contrast, PU leather manufacturing starts with the production of polyurethane, a synthetic polymer. The primary components—polyols and isocyanates—are combined in a controlled environment to create a thermoplastic material. This mixture is then processed into sheets, which can be layered over a fabric backing for added strength. Understanding the raw material sourcing is essential, as it can affect both quality and sustainability.

Illustrative image related to leather and polyurethane

What Techniques Are Used in Forming and Assembling Leather and PU Products?

After material preparation, the next phase is forming. For leather, this involves cutting the hides into specific shapes using die-cutting or laser cutting. This precision ensures that the pieces fit together seamlessly during assembly. Techniques like stitching, riveting, or gluing are employed to join the pieces, with stitching often considered the most durable option.

In the case of PU leather, the sheets are also cut into the desired shapes. The PU material is often adhered to a fabric backing to enhance durability and flexibility. This process may utilize heat and pressure to bond the materials effectively. Assembly techniques can include sewing or ultrasonic welding, which creates strong, seamless joints.

How Is the Finishing Stage Important in the Production of Leather and PU Products?

Finishing is a crucial stage that determines the final look and feel of the product. For leather, this may involve dyeing, polishing, or applying protective coatings. The finishing process enhances the leather’s aesthetic appeal and can improve its durability against wear and tear.

For PU leather, finishing typically includes embossing to mimic the texture of genuine leather and applying surface coatings to enhance water resistance and colorfastness. The finishing stage is vital for both materials, as it significantly influences the product’s marketability and longevity.

What Are the Key Quality Control Measures in the Leather and PU Manufacturing Process?

Quality assurance is integral to maintaining high standards in leather and PU production. International standards such as ISO 9001 are often adopted to ensure consistent quality management systems. Specific industry standards, such as CE marking for safety or API standards for automotive applications, may also be relevant depending on the end-use of the products.

What Are the Common Quality Control Checkpoints in Manufacturing?

Quality control in leather and PU manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage checks the raw materials upon arrival. For leather, this may include assessing the quality of hides, while for PU, it involves verifying the purity of the polymer components.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure adherence to specifications. This may involve checking the dimensions of cut pieces or monitoring the bonding process in PU leather.

-

Final Quality Control (FQC): Before products are packaged for shipment, a thorough inspection is performed. This includes checking for defects, ensuring proper finishing, and testing durability through methods like wear and tear assessments or water resistance tests.

How Can B2B Buyers Verify Supplier Quality Control Standards?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are several actionable steps:

-

Conduct Supplier Audits: Regular audits can help assess compliance with international quality standards. These audits should evaluate the entire production process, from raw material sourcing to final product inspection.

-

Request Quality Control Reports: Suppliers should provide documentation detailing their quality control measures, including inspection results and compliance with relevant standards. These reports offer insight into the reliability of the supplier’s processes.

-

Engage Third-Party Inspection Services: Hiring independent inspectors can provide an objective assessment of the supplier’s manufacturing practices. These inspectors can conduct on-site evaluations and perform product testing to ensure compliance with specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing leather and PU products from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, several nuances should be considered:

Illustrative image related to leather and polyurethane

-

Cultural Differences in Standards: Quality expectations may vary significantly across regions. It is essential to establish clear communication regarding quality standards and specifications.

-

Regulatory Compliance: Different regions may have specific regulations governing the use of materials and manufacturing processes. B2B buyers should be aware of these regulations to ensure compliance and avoid potential legal issues.

-

Sustainability Concerns: Increasingly, buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices. This may include sourcing eco-friendly materials, minimizing waste, and ensuring fair labor practices.

In conclusion, understanding the manufacturing processes and quality assurance measures for leather and polyurethane is vital for B2B buyers looking to make informed purchasing decisions. By focusing on these areas, buyers can ensure they partner with suppliers who meet their quality standards and align with their business values.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather and polyurethane’

Introduction

This sourcing guide is designed to assist B2B buyers in effectively procuring leather and polyurethane products. By following this step-by-step checklist, you will be better equipped to identify reliable suppliers, assess product quality, and make informed purchasing decisions tailored to your specific business needs.

Step 1: Define Your Technical Specifications

Clearly outline your requirements for leather and polyurethane products. This includes understanding the specific types (e.g., genuine leather vs. PU leather) and characteristics (e.g., durability, texture, color) that meet your business needs.

– Consider the end use: Will the products be used in high-traffic areas or require enhanced water resistance?

– Identify material preferences: Different applications may call for different grades of leather or polyurethane.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in leather and polyurethane. Look for companies with a strong reputation in the market.

– Check their experience: Suppliers with a proven track record in your industry are more likely to understand your specific needs.

– Utilize online platforms: Use B2B marketplaces and industry forums to gather insights and reviews from other buyers.

Step 3: Evaluate Product Quality

Before making any commitments, assess the quality of the leather and polyurethane products offered by potential suppliers. Request samples to evaluate their properties firsthand.

– Inspect durability: Check for signs of wear, flexibility, and resistance to cracking.

– Assess aesthetics: Ensure the texture and color align with your brand’s standards.

Step 4: Verify Supplier Certifications

Ensure that suppliers have the necessary certifications that align with industry standards and sustainability practices. This is crucial for maintaining compliance and quality assurance.

– Look for ISO certifications: These indicate adherence to international quality management standards.

– Check for eco-friendly certifications: If sustainability is a priority, verify that the supplier follows environmentally responsible practices.

Step 5: Request Transparent Pricing and Terms

Obtain detailed pricing information and payment terms from shortlisted suppliers. Transparency in pricing helps avoid hidden costs later in the procurement process.

– Inquire about minimum order quantities: Understand how this might impact your purchasing strategy.

– Negotiate terms: Don’t hesitate to discuss payment schedules and discounts for bulk orders.

Step 6: Assess Logistics and Delivery Capabilities

Evaluate the supplier’s logistics and delivery capabilities to ensure they can meet your timelines and distribution needs.

– Confirm shipping options: Are they able to ship internationally? What are the lead times?

– Understand return policies: Ensure that the supplier has a clear process for handling defective products or unsatisfactory orders.

Illustrative image related to leather and polyurethane

Step 7: Establish Communication Channels

Open lines of communication with your selected supplier to facilitate ongoing dialogue throughout the procurement process.

– Designate contacts: Establish who will be your point of contact for inquiries and issues.

– Set expectations: Clearly outline communication protocols for updates on order status and any potential delays.

By following this checklist, you will enhance your sourcing strategy for leather and polyurethane products, ensuring you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for leather and polyurethane Sourcing

What Are the Key Cost Components in Sourcing Leather and Polyurethane?

When sourcing leather and polyurethane (PU), understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to leather and polyurethane

-

Materials: The cost of raw materials is the most significant factor. Genuine leather costs significantly more than PU due to its sourcing and tanning processes. For instance, high-quality leather from Europe can command premium prices, while PU, being a synthetic product, generally has lower material costs.

-

Labor: Labor costs can vary widely depending on the region and the complexity of the production process. Countries with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality. Skilled artisans are often required for high-end leather goods, which can increase labor costs.

-

Manufacturing Overhead: This includes expenses related to the facility, utilities, and equipment maintenance. In regions with higher operational costs, such as Germany, manufacturing overhead can significantly affect the final price of both leather and PU products.

-

Tooling: The initial setup costs for molds and machinery can be substantial, especially for customized products. Investing in high-quality tooling is critical for ensuring product quality and consistency, which can influence pricing.

-

Quality Control: Ensuring that products meet quality standards incurs additional costs. This is particularly crucial in the leather industry, where defects can lead to substantial financial losses. Implementing stringent QC processes can add to the overall cost but is essential for maintaining brand reputation.

-

Logistics: Transportation and shipping costs can fluctuate based on the distance, mode of transport, and current fuel prices. Incoterms also play a vital role in determining how costs are allocated between buyers and suppliers. For international buyers, understanding these terms is crucial to avoid unexpected expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on market demand and competition.

What Factors Influence Pricing for Leather and Polyurethane Products?

Several factors can influence the pricing of leather and PU products, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often come with significant discounts. Suppliers may have a MOQ that can affect pricing flexibility for smaller buyers.

-

Specifications and Customization: Customized products generally incur higher costs due to the need for specialized materials and processes. Standardized products usually have more predictable pricing.

-

Material Quality and Certifications: Higher-quality materials or those with sustainability certifications can lead to increased prices. Buyers should assess whether the added cost aligns with their product requirements.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may charge more but offer better quality assurance.

-

Incoterms: The choice of Incoterms affects the distribution of costs and responsibilities between buyers and suppliers. Familiarity with terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can prevent misunderstandings and unexpected costs.

How Can Buyers Negotiate for Better Prices on Leather and Polyurethane?

Effective negotiation strategies can lead to better pricing and terms:

-

Research and Benchmarking: Buyers should gather market intelligence on pricing and supplier capabilities. This knowledge can empower them during negotiations.

-

Focus on Total Cost of Ownership (TCO): Rather than just the upfront cost, consider the long-term costs associated with maintenance, durability, and potential returns on investment.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to more favorable terms and pricing flexibility over time.

-

Leverage Volume: If possible, consolidate orders or collaborate with other buyers to increase order size, which can lead to bulk discounts.

-

Be Transparent About Needs: Clear communication about expectations and requirements can help suppliers provide more accurate quotes and potentially reduce costs.

Conclusion: What Should International B2B Buyers Consider?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing leather and PU is critical. Factors such as local market conditions, transportation logistics, and currency fluctuations can greatly influence pricing. It is advisable to conduct thorough due diligence and maintain open lines of communication with suppliers to secure the best possible terms.

Disclaimer: Prices mentioned in this analysis are indicative and can vary based on market conditions and supplier negotiations. Always seek quotes from multiple sources to ensure competitive pricing.

Alternatives Analysis: Comparing leather and polyurethane With Other Solutions

Understanding Alternatives to Leather and Polyurethane

As businesses explore sustainable and cost-effective materials, the demand for alternatives to traditional leather and polyurethane (PU) is growing. This analysis compares leather and PU against two viable alternatives: recycled polyester and bio-based leather. Each alternative presents unique benefits and challenges that can significantly impact purchasing decisions for international B2B buyers.

Illustrative image related to leather and polyurethane

| Comparison Aspect | Leather And Polyurethane | Recycled Polyester | Bio-Based Leather |

|---|---|---|---|

| Performance | Durable, long-lasting, develops unique patina over time; PU is water-resistant but less durable. | Good durability but less luxurious feel; can be water-resistant. | Comparable to genuine leather in terms of aesthetics and durability, but varies by production method. |

| Cost | Higher cost for genuine leather; PU is more affordable. | Generally lower cost due to recycling processes. | Mid-range cost; can vary based on sourcing and production techniques. |

| Ease of Implementation | Requires specific manufacturing processes and skilled labor, especially for genuine leather. | Easier to implement as it often uses existing textile manufacturing infrastructure. | Moderate complexity; requires new production methods but is increasingly becoming mainstream. |

| Maintenance | Requires conditioning and care to maintain appearance; PU is easier to clean but can wear out faster. | Easy to clean; however, may not withstand heavy wear as well as leather. | Requires similar care to genuine leather; durability can depend on the specific product. |

| Best Use Case | High-end products, luxury items, furniture, automotive interiors. | Casual wear, eco-friendly products, sportswear, and upholstery. | Fashion items, accessories, and furniture aiming for sustainability without compromising aesthetics. |

What Are the Advantages and Disadvantages of Recycled Polyester?

Recycled polyester, often derived from plastic bottles, offers a sustainable solution that reduces waste while providing good durability. Its cost-effectiveness makes it appealing for mass production, particularly in sectors like fashion and upholstery. However, it lacks the premium feel of genuine leather and may not be suitable for high-end applications where appearance is crucial. Additionally, while it can be water-resistant, it might not perform as well under heavy wear compared to leather.

How Does Bio-Based Leather Compare to Traditional Options?

Bio-based leather, made from natural materials such as plant fibers, presents an innovative alternative that closely mimics the look and feel of genuine leather. This material is appealing for its sustainability credentials, as it reduces reliance on fossil fuels and animal products. However, the production processes can be complex and vary widely, which may lead to inconsistencies in quality. Additionally, while it is generally more sustainable, the costs can fluctuate based on the sourcing of raw materials.

Making the Right Choice for Your Business Needs

When selecting between leather, polyurethane, and their alternatives, B2B buyers should consider their specific application and target market. For high-end products where durability and aesthetics are paramount, genuine leather remains the gold standard. However, for brands focusing on sustainability and cost-effectiveness, alternatives like recycled polyester and bio-based leather may provide the right balance of performance and environmental responsibility. Ultimately, the decision will depend on the company’s values, budget constraints, and the expectations of their customer base.

Illustrative image related to leather and polyurethane

Essential Technical Properties and Trade Terminology for leather and polyurethane

What Are the Key Technical Properties of Leather and Polyurethane for B2B Buyers?

Understanding the critical technical properties of leather and polyurethane is essential for B2B buyers, especially when making informed purchasing decisions. Here are some key specifications that play a vital role in product selection.

1. Material Grade

Material grade refers to the quality and classification of leather or polyurethane used in manufacturing. For leather, grades can include full-grain, top-grain, and corrected grain, each indicating the level of processing and durability. In polyurethane, material grades can vary based on the thickness and type of polymer used. For buyers, knowing the material grade is crucial as it directly affects the product’s durability, appearance, and cost.

2. Tolerance Levels

Tolerance levels define the acceptable variations in dimensions and physical properties of leather and polyurethane products. This specification is vital in ensuring that components fit together properly in applications such as furniture or automotive interiors. A tight tolerance level often indicates higher quality, which is essential for maintaining brand reputation and customer satisfaction.

3. Abrasion Resistance

Abrasion resistance measures a material’s ability to withstand wear from friction. This property is especially important for upholstery and automotive applications, where surfaces are subject to constant use. High abrasion resistance translates to longer-lasting products, which can reduce replacement costs and enhance customer loyalty.

4. Water Resistance

Water resistance is a critical property, particularly for polyurethane, which is often marketed as a more durable and easy-to-clean alternative to leather. Understanding the level of water resistance can help B2B buyers determine the suitability of a material for specific environments, such as kitchens or outdoor settings, where spills and moisture exposure are common.

5. Breathability

Breathability refers to the material’s ability to allow air circulation, which is a significant factor for comfort in upholstery and clothing. Genuine leather typically offers better breathability compared to polyurethane, which can lead to discomfort in warmer conditions. Buyers should consider the end-use of their products when evaluating this property.

6. Color Fastness

Color fastness measures how well a material retains its color when exposed to various conditions, such as light, washing, or rubbing. This property is particularly important for products designed for long-term use in visible areas. High color fastness ensures that products maintain their aesthetic appeal over time, which is critical for branding and customer satisfaction.

What Are Common Trade Terms in the Leather and Polyurethane Industry?

Familiarity with industry jargon can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are several common terms relevant to the leather and polyurethane market.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products or components that are purchased by another company and sold under that company’s brand name. Understanding OEM relationships can help buyers assess the quality and reliability of the products they are sourcing.

Illustrative image related to leather and polyurethane

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it impacts inventory management and cash flow. Knowing the MOQ can help buyers negotiate better terms or determine the feasibility of a purchase.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. Issuing an RFQ allows buyers to compare prices and conditions from multiple suppliers, ensuring they secure the best deal.

4. Incoterms

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help B2B buyers understand shipping costs, risks, and delivery timelines, which are essential for effective supply chain management.

5. Lead Time

Lead time refers to the period from placing an order to receiving the goods. Understanding lead times is crucial for inventory planning and ensuring that products are available when needed, especially in industries with fluctuating demand.

6. Certification Standards

Certification standards refer to the industry-specific qualifications that products must meet to ensure safety, quality, and environmental compliance. Awareness of certification standards can help buyers ensure that the products they source align with their quality assurance processes and regulatory requirements.

By grasping these essential technical properties and trade terminology, B2B buyers can make more informed decisions regarding leather and polyurethane products, leading to successful sourcing and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the leather and polyurethane Sector

What Are the Current Market Dynamics Affecting Leather and Polyurethane Sourcing?

The leather and polyurethane (PU) market is witnessing transformative changes driven by global economic factors, consumer preferences, and technological advancements. Key trends include the rising demand for sustainable materials, the shift towards online B2B marketplaces, and innovations in manufacturing processes. For international buyers from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

One of the most significant drivers is the increasing consumer awareness surrounding sustainability and ethical production. Buyers are increasingly favoring suppliers who demonstrate environmentally responsible practices and transparency in their supply chains. Additionally, digital transformation is reshaping how businesses engage with suppliers, with e-commerce platforms becoming vital for sourcing and procurement processes. Buyers can now access a broader range of suppliers, compare prices, and evaluate product quality with ease.

Emerging technologies like AI and blockchain are also playing a pivotal role in enhancing supply chain efficiency and traceability. For instance, blockchain can provide real-time insights into the sourcing and production processes, ensuring that buyers are aware of the environmental impact of their purchases. Furthermore, the rise of smart manufacturing is enabling more customized leather and PU products, catering to specific market needs.

Illustrative image related to leather and polyurethane

How Is Sustainability Influencing Leather and PU Sourcing Practices?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the leather and polyurethane sectors. The environmental impact of traditional leather production, which often involves significant water consumption and chemical use, has led to a growing demand for more sustainable alternatives. Buyers are now seeking suppliers who offer eco-friendly materials and practices, such as vegetable-tanned leather or recycled PU, which reduce the ecological footprint.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers to ensure fair labor practices and humane treatment of animals in the case of genuine leather. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® are becoming essential for verifying the sustainability claims of suppliers. These certifications assure buyers that the materials meet stringent environmental and social criteria.

Incorporating sustainable practices not only enhances a company’s brand reputation but also aligns with the growing consumer expectation for environmentally responsible products. As international buyers prioritize sustainability, they can leverage these values to differentiate themselves in competitive markets.

What Is the Historical Context of Leather and PU Development for B2B Buyers?

The history of leather and polyurethane dates back several centuries, with leather being one of the oldest materials used by humans. Traditional leather crafting has evolved significantly, with advancements in tanning and finishing techniques improving product quality and durability. The introduction of PU leather in the mid-20th century offered a synthetic alternative, catering to a growing demand for affordable and versatile materials.

Initially, PU leather was perceived as a low-cost substitute for genuine leather. However, advancements in technology have improved its quality, leading to its acceptance in various applications, from fashion to automotive upholstery. Today, PU leather is recognized for its advantages, such as water resistance and ease of maintenance, making it a popular choice among manufacturers and consumers alike.

Understanding the evolution of these materials helps B2B buyers appreciate the diverse options available in the market and the factors influencing their sourcing decisions. By staying informed about historical developments, buyers can better navigate the complexities of the current market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of leather and polyurethane

1. How do I solve the challenge of sourcing high-quality leather and polyurethane?

To source high-quality leather and polyurethane, start by identifying reputable suppliers with a proven track record in the industry. Conduct thorough research, including reading reviews, checking certifications, and asking for samples. Building relationships with suppliers through direct communication can provide insights into their manufacturing processes and quality assurance measures. Additionally, attending trade shows can help you connect with potential suppliers and evaluate their products firsthand.

2. What is the best type of polyurethane leather for commercial applications?

The best type of polyurethane leather for commercial applications is typically full-synthetic PU leather, as it is entirely vegan and offers superior water resistance and durability. It is ideal for high-traffic areas such as restaurants and offices, where ease of cleaning and maintenance are essential. Ensure that the PU leather has been tested for wear and tear, and consider options with a protective coating for added longevity, especially in environments with heavy use.

3. How can I determine the authenticity of leather products when sourcing?

To determine the authenticity of leather products, perform a visual inspection and check for imperfections and natural grain patterns, which are characteristic of genuine leather. Conduct a water test by placing a few drops on the material; genuine leather will absorb water, while PU leather will not. Additionally, request documentation from suppliers that verifies the material’s origin and composition, ensuring it meets your quality standards.

4. What factors should I consider when negotiating payment terms with suppliers?

When negotiating payment terms with suppliers, consider factors such as your cash flow, the order size, and the supplier’s payment policies. Aim for terms that provide flexibility, such as a percentage upfront and the balance upon delivery. Be clear about currency and payment methods, as international transactions may involve additional fees. Establishing trust and a good relationship with suppliers can lead to more favorable terms in the long run.

5. What are the minimum order quantities (MOQ) typically required for leather and polyurethane?

Minimum order quantities (MOQ) for leather and polyurethane can vary significantly depending on the supplier and the type of material. Generally, MOQs for PU leather are lower than for genuine leather due to the lower production costs. It’s advisable to discuss MOQs upfront during negotiations, and if you need smaller quantities, inquire about the possibility of bulk purchasing or combining orders with other buyers to meet the MOQ.

6. How do I ensure quality assurance when sourcing leather and polyurethane products?

To ensure quality assurance when sourcing leather and polyurethane products, establish clear specifications and standards before placing an order. Request samples for evaluation and conduct factory visits if possible. Implement a quality control process that includes inspections at various production stages. Additionally, consider third-party quality assurance services that can provide independent verification of product quality before shipment.

Illustrative image related to leather and polyurethane

7. What logistics considerations should I keep in mind when importing leather and polyurethane?

When importing leather and polyurethane, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. Choose reliable freight forwarders experienced in handling similar materials to minimize delays. Ensure that all necessary documentation, including invoices, packing lists, and certificates of origin, is in order for smooth customs clearance. Additionally, factor in potential tariffs and taxes that may affect your overall costs.

8. How can I customize leather and polyurethane products to meet my specific needs?

To customize leather and polyurethane products, communicate your requirements clearly with suppliers, including specifications such as color, texture, and dimensions. Many suppliers offer customization options, but it’s crucial to discuss minimum order quantities and any additional costs involved. Request prototypes or samples of customized products before finalizing orders to ensure they meet your expectations. A good supplier will be open to collaboration and provide insights on feasible customization options.

Top 5 Leather And Polyurethane Manufacturers & Suppliers List

1. Manuel Dreesmann – PU Leather Solutions

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: This company, Manuel Dreesmann – PU Leather Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. HowStuffWorks – PU Leather

Domain: home.howstuffworks.com

Registered: 1998 (27 years)

Introduction: PU (Polyurethane) leather is an artificial leather made from polyurethane, a type of plastic. It is 100% vegan, with no animal skin involved. There are two types of PU leather: full-synthetic (completely vegan) and semi-synthetic (which has a natural leather base). PU leather is water-resistant, easy to clean, and available in a wide variety of colors. However, it lacks the authentic look and feel…

3. Diffen – Leather vs Polyurethane Comparison

Domain: diffen.com

Registered: 2007 (18 years)

Introduction: Leather vs Polyurethane Comparison:

1. **Material**:

– Leather: Animal hide treated with chemicals.

– Polyurethane: Plastic, often used as faux leather (PU leather).

2. **Durability**:

– Leather: Very durable (10-15 years with maintenance), used in rugged conditions, fades in sunlight, degrades with age.

– Polyurethane: Very durable but susceptible to cracking and UV damage.

3. **Co…

4. Carl Friedrik – PU Leather

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: PU leather, also known as artificial or imitation leather, is made from polyurethane, a type of plastic. It is created by applying a PU resin coating to natural fabrics like nylon, cotton, or vinyl. 100% PU leather is vegan-friendly as it contains no animal by-products, while PU leather made from split leather is not vegan. Benefits include being softer, lighter, and more UV resistant than animal …

5. Rahui – PU Leather

Domain: rahui.com

Registered: 2015 (10 years)

Introduction: This company, Rahui – PU Leather, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for leather and polyurethane

As the global market for leather and polyurethane evolves, international B2B buyers must prioritize strategic sourcing to navigate the complexities of these materials. Genuine leather offers durability and a unique aesthetic, making it a premium choice for high-end applications. However, the rising demand for PU leather reflects a shift towards cost-effective, sustainable alternatives that cater to diverse consumer preferences. Understanding the differences between full-synthetic and semi-synthetic PU leather is crucial for making informed purchasing decisions.

For buyers in Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can enhance supplier relationships and optimize procurement processes. By evaluating the environmental impact and longevity of these materials, businesses can align their sourcing strategies with sustainability goals while meeting market demands.

Illustrative image related to leather and polyurethane

Looking ahead, consider diversifying your supplier base to include manufacturers who prioritize ethical practices and innovative production techniques. As consumer awareness grows, the demand for high-quality, sustainable leather alternatives will continue to rise. Engage with your suppliers now to ensure you are well-positioned to meet future market needs and capitalize on emerging trends.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.