Introduction: Navigating the Global Market for black faux leather fabric

In the ever-evolving landscape of global trade, sourcing high-quality black faux leather fabric presents both opportunities and challenges for international B2B buyers. As industries increasingly shift towards sustainable and ethical materials, the demand for faux leather has surged, compelling businesses to navigate a diverse market filled with various suppliers, product types, and applications. This guide aims to demystify the complexities surrounding black faux leather fabric, offering insights into its myriad uses—from upholstery and fashion to automotive applications—and the essential factors to consider when selecting suppliers.

Buyers from Africa, South America, the Middle East, and Europe, including key markets like Vietnam and Saudi Arabia, will find this resource invaluable. We delve into critical aspects such as product specifications, quality assurance, cost analysis, and supplier vetting processes. By equipping you with actionable insights and best practices, this guide empowers you to make informed purchasing decisions that align with your business needs and sustainability goals. Whether you are seeking to enhance your product line or ensure consistent quality in your supply chain, understanding the nuances of black faux leather fabric is essential for maintaining a competitive edge in today’s market.

Table Of Contents

- Top 5 Black Faux Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for black faux leather fabric

- Understanding black faux leather fabric Types and Variations

- Key Industrial Applications of black faux leather fabric

- 3 Common User Pain Points for ‘black faux leather fabric’ & Their Solutions

- Strategic Material Selection Guide for black faux leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for black faux leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘black faux leather fabric’

- Comprehensive Cost and Pricing Analysis for black faux leather fabric Sourcing

- Alternatives Analysis: Comparing black faux leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for black faux leather fabric

- Navigating Market Dynamics and Sourcing Trends in the black faux leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of black faux leather fabric

- Strategic Sourcing Conclusion and Outlook for black faux leather fabric

- Important Disclaimer & Terms of Use

Understanding black faux leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vinyl Faux Leather | Waterproof, durable, flexible, and easy to clean. | Upholstery, apparel, outdoor gear. | Pros: Cost-effective, high durability. Cons: Can be less breathable than natural leather. |

| PU Faux Leather | Soft texture, high-end look, and often more eco-friendly. | Fashion apparel, accessories, home decor. | Pros: Mimics real leather closely, versatile. Cons: May not be as durable as vinyl. |

| Embossed Faux Leather | Textured surface resembling exotic skins (e.g., gator, snake). | Fashion items, luxury upholstery. | Pros: Unique aesthetics, high perceived value. Cons: Higher cost, may require more care. |

| Distressed Faux Leather | Vintage look with a worn appearance, soft feel. | Fashion, bags, and furniture. | Pros: Stylish, trendy appearance. Cons: May not suit all applications due to aesthetic. |

| Marine Faux Leather | Resistant to water and UV rays, ideal for outdoor use. | Boat upholstery, outdoor furniture. | Pros: Durable in harsh conditions, easy maintenance. Cons: Limited color options compared to other types. |

What are the Characteristics of Vinyl Faux Leather?

Vinyl faux leather is highly regarded for its waterproof and durable properties, making it suitable for both indoor and outdoor applications. This type of fabric is easy to clean, which is essential for B2B buyers in industries such as upholstery and outdoor gear. When considering vinyl faux leather, businesses should evaluate its flexibility and resistance to tearing and wrinkling, ensuring it meets their specific project needs. Its cost-effectiveness is a significant advantage, particularly for large-scale purchases.

How Does PU Faux Leather Compare to Other Types?

PU (polyurethane) faux leather is known for its soft texture and high-end appearance, often preferred in fashion and home decor. It is considered more eco-friendly than other synthetic options, appealing to environmentally conscious brands. B2B buyers should consider the versatility of PU faux leather, as it can be used in various applications, from clothing to accessories. However, its durability may not match that of vinyl, which could be a deciding factor for high-usage scenarios.

What are the Benefits of Embossed Faux Leather?

Embossed faux leather features a textured surface that mimics exotic skins, such as gator or snake, providing a unique aesthetic that is highly sought after in the fashion industry. This type of fabric is often used in luxury upholstery and high-end fashion items. B2B buyers should weigh the perceived value of embossed faux leather against its higher cost, as the distinctive look can justify a premium price point. Additionally, buyers should consider the care requirements, as embossed textures may require more attention to maintain their appearance.

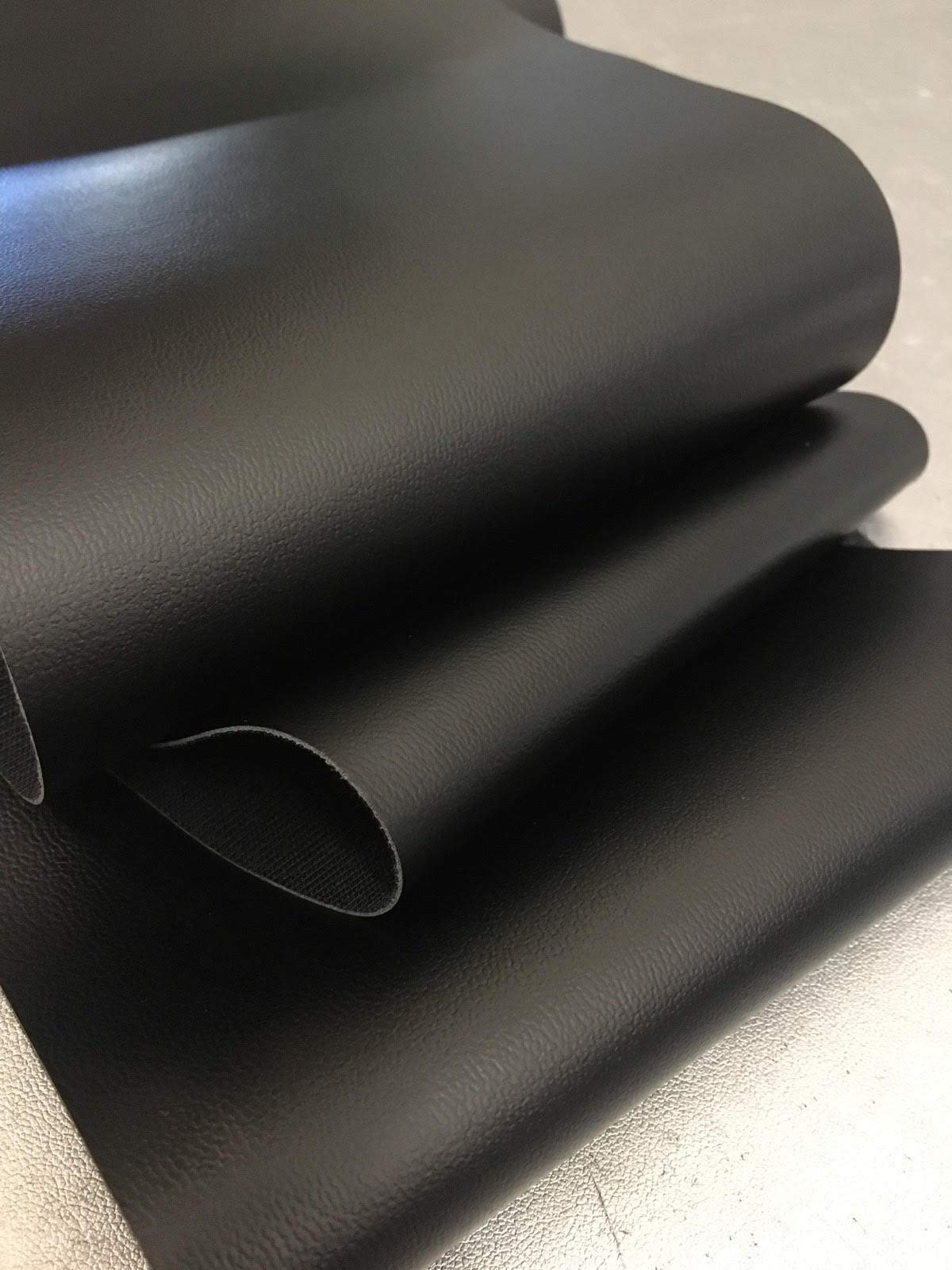

Illustrative image related to black faux leather fabric

Why Choose Distressed Faux Leather for Fashion?

Distressed faux leather offers a vintage look with a soft, worn appearance, making it a popular choice for fashion items, bags, and furniture. Its trendy aesthetic appeals to consumers seeking a rustic or retro style. For B2B buyers, the key consideration should be the balance between style and application; while distressed faux leather can enhance product appeal, it may not suit all market segments. Additionally, the unique appearance can lead to higher production costs, which should be factored into pricing strategies.

What Makes Marine Faux Leather Ideal for Outdoor Use?

Marine faux leather is specifically designed to withstand exposure to water and UV rays, making it ideal for outdoor applications such as boat upholstery and outdoor furniture. Its durability in harsh conditions is a significant selling point for B2B buyers in marine and outdoor industries. When selecting marine faux leather, businesses should consider the limited color options available, as this may affect design flexibility. The ease of maintenance is another advantage, allowing for quick cleaning and upkeep, which is crucial for outdoor environments.

Key Industrial Applications of black faux leather fabric

| Industry/Sector | Specific Application of black faux leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior upholstery for vehicles | Enhances aesthetic appeal and provides durability | Look for UV resistance and ease of cleaning |

| Fashion | Apparel production (jackets, skirts, etc.) | Cost-effective alternative to genuine leather | Consider fabric weight, stretch, and color options |

| Furniture | Upholstery for sofas and chairs | Offers high-end look while being easy to maintain | Ensure compliance with flammability standards |

| Hospitality | Decorative elements in hotels and restaurants | Creates a luxurious ambiance at a lower cost | Evaluate durability and cleaning ease |

| Sports Equipment | Gear and accessories (bags, protective gear) | Lightweight and resistant to wear and tear | Assess flexibility, tear resistance, and waterproofing |

How is Black Faux Leather Fabric Used in the Automotive Industry?

In the automotive sector, black faux leather fabric is primarily utilized for interior upholstery, including seats, door panels, and dashboards. This material not only enhances the aesthetic appeal of vehicles but also provides durability against wear and tear. For international buyers, especially in regions like the Middle East and Africa, sourcing options should emphasize UV resistance to withstand harsh sunlight and easy cleaning properties to maintain a pristine interior.

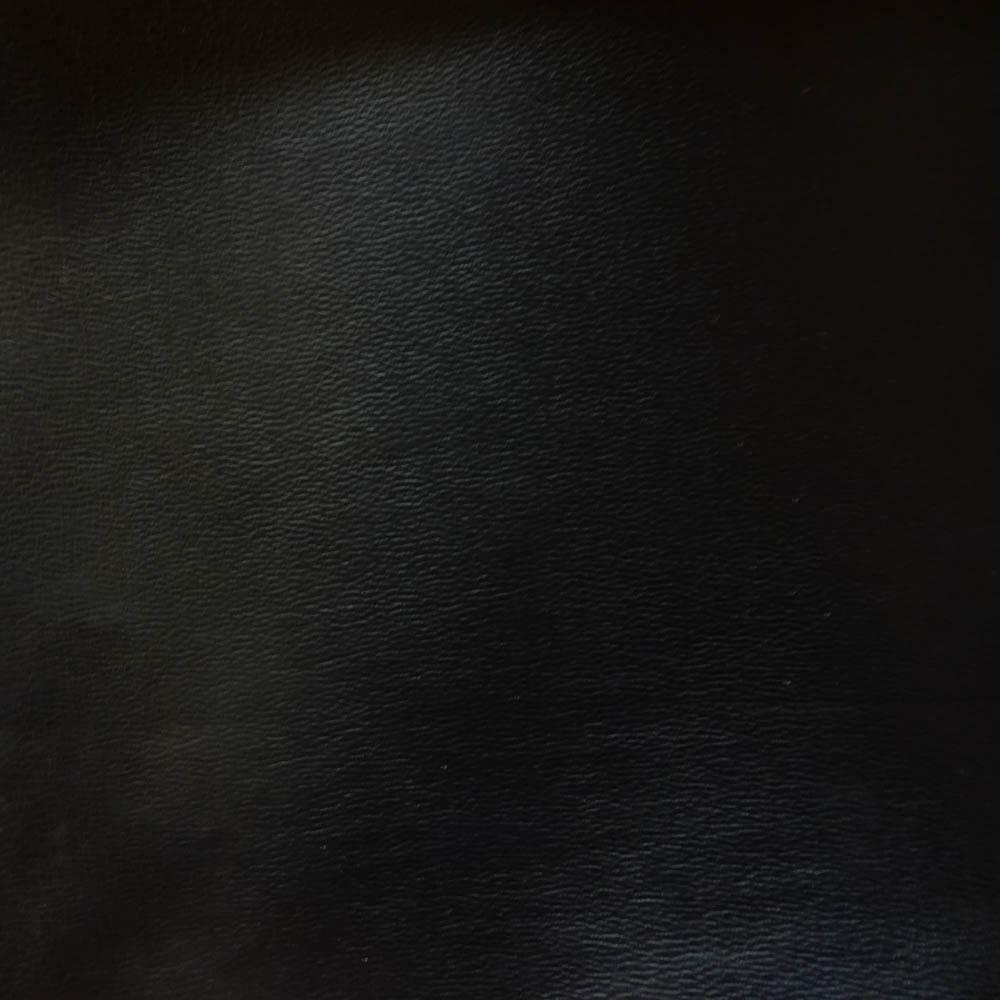

Illustrative image related to black faux leather fabric

What are the Applications of Black Faux Leather Fabric in Fashion?

In the fashion industry, black faux leather fabric is a popular choice for producing various apparel items such as jackets, skirts, and pants. It serves as a cost-effective alternative to genuine leather while still offering a stylish appearance. B2B buyers must consider fabric weight and stretchability to ensure the final products meet the desired fit and comfort levels. Additionally, color consistency is crucial for bulk orders to maintain brand integrity.

How is Black Faux Leather Fabric Beneficial for Furniture Upholstery?

Black faux leather fabric is extensively used in furniture upholstery, particularly for sofas and chairs, due to its luxurious appearance and ease of maintenance. This material provides a high-end look without the associated costs of genuine leather. When sourcing for this application, businesses should prioritize materials that comply with flammability standards to ensure safety in commercial settings. Durability is also a key factor, as furniture is subjected to regular use.

What Role Does Black Faux Leather Fabric Play in the Hospitality Sector?

In the hospitality industry, black faux leather fabric is commonly used for decorative elements such as wall coverings, restaurant seating, and decorative cushions. It helps create a luxurious ambiance while being a cost-effective solution compared to traditional materials. For international buyers, evaluating the durability and ease of cleaning is essential, especially in high-traffic areas where maintenance can be challenging.

How is Black Faux Leather Fabric Applied in Sports Equipment?

Black faux leather fabric is increasingly used in the production of sports equipment, including bags, protective gear, and accessories. Its lightweight nature combined with resistance to wear and tear makes it an ideal choice for active use. B2B buyers should assess the fabric’s flexibility and tear resistance to ensure the performance of the final products. Additionally, waterproofing features can enhance the longevity of gear used in outdoor environments.

3 Common User Pain Points for ‘black faux leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Black Faux Leather Fabric

The Problem: Many B2B buyers face significant challenges when sourcing black faux leather fabric that meets their quality and durability standards. Discrepancies in material specifications, such as thickness, texture, and resistance to wear, can lead to unsatisfactory products that may not withstand the intended use, especially in high-demand environments like furniture upholstery or fashion. This can result in increased costs due to returns, wasted materials, and the need for reordering, which disrupts production timelines.

The Solution: To overcome sourcing challenges, B2B buyers should establish clear specifications before engaging with suppliers. This includes defining the required rub count (a measure of durability), weight, and finish type. Additionally, it is beneficial to request samples from multiple suppliers to evaluate the material’s quality firsthand. Engaging with reputable suppliers who provide transparency in their sourcing practices and material certifications can ensure that the faux leather meets industry standards. Buyers should also consider forming long-term relationships with a select few suppliers to streamline the procurement process and ensure consistent quality in future orders.

Scenario 2: Addressing Environmental Concerns with Faux Leather Fabric

The Problem: In today’s market, environmental sustainability is a growing concern for businesses. B2B buyers of black faux leather fabric may struggle with the perception that synthetic materials are harmful to the environment. This concern can hinder sales, especially in industries focusing on eco-friendly products. Buyers need to navigate the complexities of sourcing materials that align with sustainable practices while still meeting aesthetic and functional requirements.

The Solution: B2B buyers can mitigate these concerns by opting for faux leather made from recycled materials or those that are certified as eco-friendly. Engaging with suppliers who offer transparency about their manufacturing processes can help buyers select products that reduce their carbon footprint. Additionally, providing education to customers about the benefits of faux leather, such as lower environmental impact compared to real leather, can enhance the product’s appeal. Highlighting these features in marketing materials can reassure consumers that their purchases are contributing to a more sustainable future.

Scenario 3: Ensuring Proper Care and Maintenance of Faux Leather Products

The Problem: Another common issue faced by B2B buyers is the care and maintenance of products made from black faux leather fabric. Many end-users are unaware of how to properly clean and maintain faux leather, leading to damage, deterioration, and unsatisfactory performance over time. This lack of knowledge can result in negative customer experiences, product returns, and increased warranty claims.

The Solution: To address this challenge, B2B buyers should invest in creating comprehensive care guides and training materials for their customers. These resources should cover proper cleaning techniques, such as using mild soap and water, and avoiding harsh chemicals that can damage the material. Including care instructions with products upon delivery can enhance customer satisfaction and prolong the lifespan of the items. Additionally, providing workshops or online tutorials on faux leather maintenance can empower users with the knowledge they need, reducing the likelihood of damage and fostering brand loyalty. By actively supporting customers in their product care, B2B buyers can differentiate themselves in a competitive market and enhance overall customer satisfaction.

Illustrative image related to black faux leather fabric

Strategic Material Selection Guide for black faux leather fabric

What Are the Key Materials Used in Black Faux Leather Fabric?

Black faux leather fabric is primarily made from various synthetic materials, each with unique properties and applications. Understanding these materials is essential for B2B buyers looking to make informed decisions based on performance, cost, and compliance with international standards.

1. PVC (Polyvinyl Chloride)

Key Properties:

PVC is known for its durability and flexibility, making it suitable for various applications. It can withstand temperatures ranging from -10°C to 60°C and has a high resistance to moisture and UV light.

Pros & Cons:

PVC faux leather is cost-effective and easy to clean, making it ideal for upholstery and fashion items. However, it can be less breathable than other materials, which may affect comfort in clothing applications. Additionally, PVC can be less environmentally friendly due to its production process.

Impact on Application:

PVC is commonly used in upholstery, automotive interiors, and fashion accessories. Its water-resistant properties make it suitable for outdoor applications, although it may not perform well in extreme temperatures.

Considerations for International Buyers:

Buyers should ensure that PVC products comply with local regulations regarding chemical safety and environmental impact. Standards such as ASTM D-2047 for slip resistance may be relevant for upholstery applications.

2. PU (Polyurethane)

Key Properties:

PU faux leather offers excellent abrasion resistance and is more breathable than PVC. It can endure temperatures from -20°C to 70°C, making it versatile for various climates.

Pros & Cons:

PU is often perceived as a higher-quality alternative to PVC, providing a more authentic leather feel. However, it tends to be more expensive and may require more complex manufacturing processes. While it is durable, it may not be as water-resistant as PVC.

Illustrative image related to black faux leather fabric

Impact on Application:

PU is widely used in high-end fashion, upholstery, and automotive applications due to its luxurious appearance and feel. It is suitable for items requiring a soft touch, such as jackets and bags.

Considerations for International Buyers:

Buyers from regions with stringent environmental regulations, such as Europe, should verify that PU products meet compliance standards like REACH. Additionally, understanding the local market’s preferences for material quality is crucial.

3. Recycled Materials

Key Properties:

Recycled faux leather is made from post-consumer waste, often featuring a blend of materials like recycled PVC or PU. It can exhibit varying durability based on the source materials used.

Pros & Cons:

Using recycled materials can significantly reduce environmental impact and appeal to eco-conscious consumers. However, the variability in quality can pose challenges in consistency and performance.

Impact on Application:

Recycled faux leather is suitable for fashion items and upholstery, particularly in markets that prioritize sustainability. It may not have the same durability as virgin materials, which could limit its use in high-wear applications.

Considerations for International Buyers:

Buyers should assess the certifications of recycled materials to ensure they meet local environmental standards. Awareness of consumer trends towards sustainability can also guide purchasing decisions.

Summary Table of Material Properties for Black Faux Leather Fabric

| Material | Typical Use Case for black faux leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Upholstery, automotive interiors | Cost-effective and easy to clean | Less breathable, less eco-friendly | Low |

| PU | High-end fashion, luxury upholstery | Authentic leather feel, durable | Higher cost, complex manufacturing | Med |

| Recycled Materials | Fashion items, eco-friendly upholstery | Environmentally friendly | Variable quality, less durable | Med |

This guide equips B2B buyers with actionable insights into the materials used in black faux leather fabric, enabling them to make informed purchasing decisions that align with their specific needs and regional compliance standards.

Illustrative image related to black faux leather fabric

In-depth Look: Manufacturing Processes and Quality Assurance for black faux leather fabric

What Are the Key Stages in the Manufacturing Process of Black Faux Leather Fabric?

The manufacturing process of black faux leather fabric involves several critical stages that ensure the final product meets high-quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The process begins with the selection of high-quality synthetic materials, primarily PVC (polyvinyl chloride) or PU (polyurethane). These materials are chosen for their durability, flexibility, and ability to mimic the texture and appearance of real leather. Suppliers often utilize advanced blending techniques to ensure the materials possess the desired properties, such as water resistance and tear strength. The selected materials are then cut into manageable sizes for the subsequent processes. -

Forming

The forming stage involves shaping the faux leather material. This can be achieved through various techniques, including calendering, where the material is passed through rollers to achieve the desired thickness and texture. Embossing techniques may also be applied to create patterns that enhance the aesthetic appeal of the fabric. Additionally, the application of coatings or finishes during this stage can enhance the material’s resistance to UV light, making it suitable for both indoor and outdoor applications. -

Assembly

In the assembly phase, the prepared sheets of faux leather are cut into specific patterns and shapes required for various applications such as upholstery, apparel, or accessories. Advanced cutting technologies, such as laser cutting or die-cutting, ensure precision and reduce material waste. This stage may also include sewing, where pieces are stitched together to create finished products, ensuring structural integrity and aesthetic appeal. -

Finishing

The finishing process is crucial for providing the final touch to the fabric. This includes additional treatments that enhance durability and aesthetics, such as applying protective coatings to improve water resistance and stain repellency. The finished fabric is then rolled or folded and prepared for distribution.

How Is Quality Assurance Implemented in Black Faux Leather Fabric Production?

Quality assurance (QA) is vital in the manufacturing of black faux leather fabric to ensure that the final products meet international standards and customer expectations. QA processes generally follow established protocols, including adherence to ISO 9001 standards and other industry-specific certifications.

-

International Standards and Certifications

For B2B buyers, understanding the relevant international standards is essential. ISO 9001 outlines requirements for a quality management system and is widely recognized across industries. Additionally, certifications such as CE mark for safety and compliance in European markets or API standards for durability may also be relevant depending on the end-use of the fabric. -

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated throughout the manufacturing process to monitor quality at various stages:

– Incoming Quality Control (IQC): Materials received from suppliers are inspected for compliance with specifications and quality standards before they enter the production line.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages, where samples may be taken for testing to ensure consistency and quality.

– Final Quality Control (FQC): Once the faux leather fabric is completed, it undergoes a final inspection to assess its appearance, texture, and performance characteristics, ensuring it meets the required standards before shipping. -

Common Testing Methods for Faux Leather

Various testing methods are employed to evaluate the quality of black faux leather fabric. Common tests include:

– Tensile Strength Testing: Measures the fabric’s strength and durability under stress.

– Rub Test: Assesses the fabric’s abrasion resistance, ensuring it can withstand regular use.

– Water Resistance Testing: Evaluates how well the material repels water, which is crucial for outdoor applications.

– Flammability Testing: Ensures the fabric meets safety standards regarding fire resistance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source black faux leather fabric must ensure that their suppliers maintain high-quality standards. Verification can be achieved through several methods:

-

Supplier Audits

Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Audits allow buyers to assess compliance with international standards and verify the implementation of QA protocols. -

Quality Control Reports

Requesting detailed QC reports from suppliers can help buyers evaluate their quality assurance practices. These reports should include information on testing results, compliance with standards, and any corrective actions taken in case of deviations. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can occur at various stages of production, ensuring that the fabric meets the agreed-upon specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital for successful sourcing of black faux leather fabric:

-

Regional Compliance Standards

Different regions may have specific compliance requirements that suppliers must meet. Buyers should familiarize themselves with local regulations and certifications necessary for their markets. -

Cultural Differences in Quality Perception

Quality perception can vary significantly across cultures. Understanding these differences can aid in establishing effective communication with suppliers and ensuring that expectations are aligned. -

Logistical Considerations

Shipping and logistics play a crucial role in maintaining quality. Buyers should consider how transportation conditions may affect the integrity of the fabric and ensure that suppliers employ appropriate packaging methods to mitigate risks during transit.

By focusing on the manufacturing processes and quality assurance practices outlined above, B2B buyers can make informed decisions when sourcing black faux leather fabric, ensuring they receive high-quality products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘black faux leather fabric’

This guide is designed to assist B2B buyers in efficiently sourcing black faux leather fabric. By following this practical checklist, you can ensure that your procurement process is streamlined and effective, ultimately leading to a successful acquisition that meets your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring that the faux leather fabric meets your project requirements. Consider factors such as thickness, weight, and intended use, whether for upholstery, fashion, or accessories. A well-defined specification helps you communicate effectively with suppliers and avoid misunderstandings.

Illustrative image related to black faux leather fabric

- Key Considerations:

- Desired texture (e.g., smooth, embossed).

- Performance requirements (e.g., water resistance, durability).

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in black faux leather fabric. Utilize online directories, industry trade shows, and referrals from other businesses to compile a list of potential partners. A diversified supplier pool can help you negotiate better terms and ensure quality.

- Action Points:

- Check supplier ratings and reviews.

- Assess their market presence and experience.

Step 3: Evaluate Supplier Certifications

Before engaging with a supplier, verify their certifications and compliance with industry standards. Certifications related to environmental practices, product safety, and quality management systems (like ISO 9001) are indicators of a reliable supplier. This step is crucial for ensuring the fabric’s quality and sustainability.

- What to Look For:

- Certifications relevant to your industry (e.g., REACH compliance in Europe).

- Evidence of ethical sourcing and manufacturing practices.

Step 4: Request Samples for Quality Assessment

Always request samples before making a bulk order. This allows you to assess the fabric’s quality, feel, and appearance firsthand. Ensure that the samples reflect the specifications you require, as variations can occur in production.

Illustrative image related to black faux leather fabric

- Important Aspects:

- Check for consistency in color and texture.

- Test durability through stretch and tear assessments.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations to determine pricing and other contractual terms. Be prepared to discuss minimum order quantities, payment terms, and delivery timelines. Establishing clear agreements can prevent future disputes and ensure a smooth transaction.

- Negotiation Tips:

- Leverage multiple supplier quotes for better pricing.

- Clarify return policies and warranty conditions.

Step 6: Confirm Logistics and Shipping Arrangements

Finalize the logistics of your order, including shipping methods and delivery schedules. Consider the geographical location of your supplier in relation to your business to optimize shipping times and costs. Effective logistics planning is vital for timely project execution.

- Logistics Considerations:

- Choose reliable shipping partners with a good track record.

- Understand customs regulations, especially for international shipping.

Step 7: Monitor Order Fulfillment and Quality Control

After placing your order, maintain communication with the supplier to monitor the fulfillment process. Implement quality control measures upon receipt of the fabric to ensure it meets your specifications and standards. This proactive approach helps in quickly addressing any issues that may arise.

- Quality Control Steps:

- Inspect the fabric for defects or discrepancies.

- Document findings for future reference and supplier evaluations.

By following these steps, B2B buyers can navigate the complexities of sourcing black faux leather fabric effectively, ensuring that their procurement process aligns with their business objectives and quality standards.

Comprehensive Cost and Pricing Analysis for black faux leather fabric Sourcing

What Are the Key Cost Components in Sourcing Black Faux Leather Fabric?

When sourcing black faux leather fabric, international B2B buyers must consider several critical cost components. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The cost of the fabric itself, which can vary significantly based on the type of faux leather (e.g., PVC, PU, or specialty blends). Premium materials often come at a higher price but offer improved durability and aesthetics.

-

Labor: Labor costs can fluctuate based on the region of sourcing. In countries with lower labor costs, such as Vietnam, manufacturing costs may be lower, but this can sometimes lead to compromises in quality.

-

Manufacturing Overhead: This encompasses all the indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: If custom specifications are required, tooling costs can add significantly to the overall price. This includes the cost of molds and machinery setup tailored to specific product designs.

-

Quality Control (QC): Implementing strict QC measures ensures that the final product meets the required standards. While this may increase upfront costs, it ultimately reduces the risk of returns and dissatisfaction.

-

Logistics: Shipping and handling costs vary depending on the distance from the supplier to the buyer. Incoterms will play a crucial role in determining who bears these costs, with some terms potentially offering cost savings.

-

Margin: Suppliers will include their profit margin in the final price. Understanding the typical margins in the industry can help buyers negotiate better terms.

How Do Price Influencers Affect Black Faux Leather Fabric Costs?

Several factors influence the pricing of black faux leather fabric in the B2B market:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating minimum order quantities (MOQs) to maximize their cost efficiency.

-

Specifications/Customization: Custom designs or specific quality certifications can increase costs. Buyers should assess whether these enhancements are necessary for their target market.

-

Materials: The choice of materials will significantly impact price. Sustainable or high-performance materials typically command higher prices but may appeal to environmentally conscious consumers.

-

Quality/Certifications: Fabrics that meet certain industry certifications (e.g., fire resistance, eco-friendliness) may cost more but can provide a competitive advantage in specific markets.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more due to their proven track record of quality and service.

-

Incoterms: Understanding Incoterms is vital for budgeting. They define the responsibilities of buyers and sellers regarding transportation costs, which can affect the total landed cost of goods.

What Buyer Tips Should Be Considered for Cost-Efficiency?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should keep the following tips in mind:

-

Negotiation: Don’t hesitate to negotiate pricing, especially for bulk orders. Building a long-term relationship with suppliers can lead to better pricing and terms over time.

-

Cost-Efficiency Analysis: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, customs, and potential returns. A lower upfront cost may not always equate to better value.

-

Pricing Nuances: Be aware of regional pricing variations. Factors such as tariffs, local demand, and currency fluctuations can impact prices for buyers in different markets.

-

Supplier Research: Conduct thorough research on potential suppliers. Look for reviews, case studies, and testimonials to ensure they can meet your quality and delivery expectations.

-

Long-Term Partnerships: Establishing long-term relationships with suppliers can yield better pricing and priority service, particularly important for consistent product availability.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence before finalizing any purchasing agreements.

Alternatives Analysis: Comparing black faux leather fabric With Other Solutions

Exploring Alternatives to Black Faux Leather Fabric

In the competitive landscape of textiles, black faux leather fabric stands out as a popular choice for various applications, particularly in upholstery and fashion. However, there are several alternatives that may also meet the needs of B2B buyers. Understanding these alternatives allows businesses to make informed decisions based on performance, cost, and specific use cases.

| Comparison Aspect | Black Faux Leather Fabric | Genuine Leather | Faux Suede | Vinyl |

|---|---|---|---|---|

| Performance | Durable, waterproof, and flexible; good resistance to tearing and wrinkling | Highly durable, authentic look; more breathable | Soft and matte finish; less durable than leather | High-shine finish; excellent durability; waterproof |

| Cost | Moderate (approx. $11.19 per yard) | High (varies widely) | Moderate (approx. $10-$20 per yard) | Low to moderate (approx. $5-$20 per yard) |

| Ease of Implementation | Easy to cut and sew; available by the yard | Requires specialized tools for cutting and stitching | Easy to sew but may need special care | Very easy to work with; can be glued or sewn |

| Maintenance | Low maintenance; easy to clean with mild soap and water | Requires regular conditioning and care to maintain | Spot clean only; not as resistant to stains | Low maintenance; easy to wipe clean |

| Best Use Case | Upholstery, fashion accessories, automotive interiors | High-end fashion, luxury upholstery | Casual wear, home decor | Outdoor furniture, budget-friendly fashion |

What Are the Pros and Cons of Genuine Leather Compared to Black Faux Leather Fabric?

Genuine leather offers an authenticity and durability that faux leather cannot match. It has a luxurious feel and breathability, making it ideal for high-end applications such as luxury fashion and premium upholstery. However, genuine leather comes with a high price tag and requires more maintenance, including conditioning to prevent drying and cracking. Additionally, it raises ethical concerns regarding animal welfare, which may not align with every brand’s values.

How Does Faux Suede Stack Up Against Black Faux Leather Fabric?

Faux suede presents a softer, matte alternative to black faux leather fabric. It mimics the look and feel of suede without the use of animal products, making it an ethical choice. However, it is generally less durable and more prone to staining and wear over time compared to black faux leather. Faux suede is best used in applications where softness and comfort are paramount, such as casual wear and home decor, but it may not withstand the rigors of high-traffic environments.

Illustrative image related to black faux leather fabric

What Advantages Does Vinyl Offer Over Black Faux Leather Fabric?

Vinyl is an alternative that provides a high-shine finish and excellent durability. It is waterproof and resistant to wear, making it a suitable option for outdoor furniture and budget-friendly fashion items. Vinyl is typically less expensive than both black faux leather and genuine leather, which can be appealing for cost-conscious buyers. However, it lacks the texture and aesthetic appeal of black faux leather, which may limit its use in upscale applications.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate fabric for a project, B2B buyers should consider the specific requirements of their applications, including performance, cost, and maintenance. For high-end products where authenticity and luxury are paramount, genuine leather may be the best choice despite its higher cost and maintenance needs. Conversely, black faux leather fabric is ideal for those seeking a balance between aesthetics, durability, and ease of care. For applications requiring a budget-friendly option, vinyl offers functionality without compromising on durability. Ultimately, understanding the unique characteristics of each material will guide buyers in making an informed choice tailored to their business objectives.

Essential Technical Properties and Trade Terminology for black faux leather fabric

What Are the Key Technical Properties of Black Faux Leather Fabric?

When sourcing black faux leather fabric, understanding its technical specifications is crucial for making informed purchasing decisions. Here are some key properties to consider:

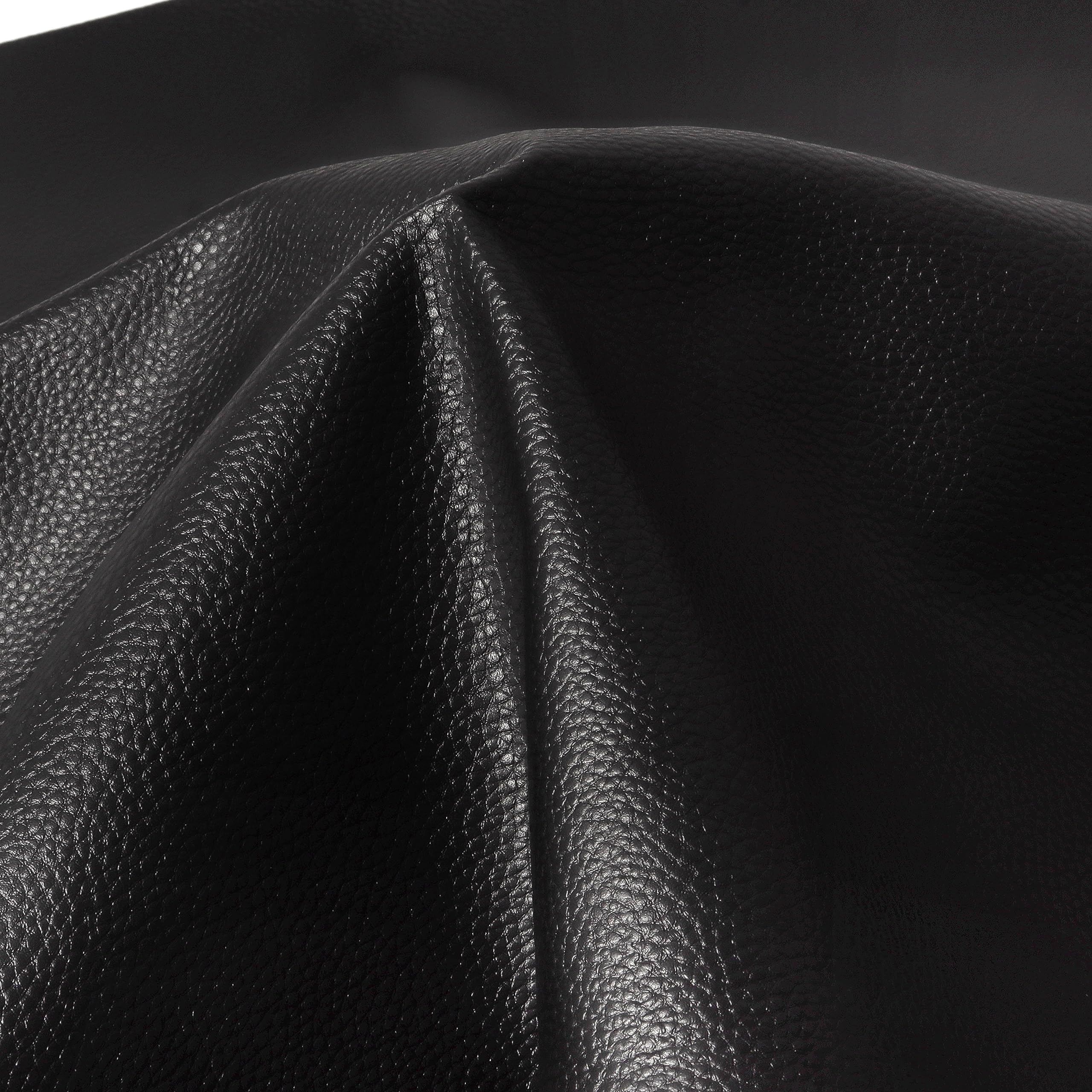

1. Material Composition

Black faux leather is typically composed of polyvinyl chloride (PVC) or polyurethane (PU). PVC is known for its durability and resistance to moisture, while PU offers a softer feel and a more environmentally friendly option. B2B buyers should evaluate the material based on the intended use—whether for upholstery, apparel, or accessories—to ensure compatibility with their product lines.

2. Weight and Thickness

The weight of faux leather fabric is measured in grams per square meter (gsm) or ounces per yard. A heavier fabric, often over 300 gsm, indicates durability, making it suitable for high-traffic applications like furniture upholstery. Conversely, lighter weights are more appropriate for fashion items. Understanding weight helps buyers assess the fabric’s application and longevity.

Illustrative image related to black faux leather fabric

3. Durability Rating

Durability is often quantified through the Martindale rub test, which measures how well a fabric withstands wear and tear. A higher rub count (e.g., 50,000 rubs) signifies greater durability, making the fabric suitable for items that will see frequent use. Buyers should prioritize this rating to avoid premature fabric failure in their products.

4. Water Resistance

Most black faux leather fabrics are water-resistant, which is a significant advantage for both indoor and outdoor applications. This characteristic ensures that items made from faux leather can withstand spills and moisture, making it ideal for various climates. B2B buyers should inquire about the specific water resistance capabilities of the fabric to meet regional demands.

5. Fire Retardancy

Fire safety is a crucial consideration, especially in commercial applications. Many faux leather fabrics are treated to meet specific fire safety standards. B2B buyers must ensure that the materials comply with local regulations, particularly for products used in public spaces or commercial establishments.

Illustrative image related to black faux leather fabric

What Are Common Trade Terms Related to Black Faux Leather Fabric?

Navigating the world of B2B transactions involves familiarizing oneself with industry jargon. Here are several essential terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers find reliable suppliers who can deliver high-quality faux leather fabric that meets specific design requirements.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and cash flow. Knowing the MOQ can help businesses plan their purchases and avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specific products. For B2B buyers looking to procure black faux leather fabric, submitting an RFQ can streamline the procurement process and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, risks, and delivery responsibilities associated with importing faux leather fabric.

Illustrative image related to black faux leather fabric

5. Lead Time

Lead time refers to the duration between placing an order and receiving the goods. This term is essential for supply chain planning, as longer lead times can impact production schedules. Buyers should communicate clearly with suppliers to establish realistic lead times for their fabric orders.

Understanding these technical properties and trade terms can empower B2B buyers to make more informed decisions when sourcing black faux leather fabric, ultimately leading to more successful procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the black faux leather fabric Sector

What Are the Key Trends Shaping the Black Faux Leather Fabric Market?

The global market for black faux leather fabric is experiencing significant transformation driven by various factors. A primary driver is the increasing demand for sustainable and cruelty-free materials, particularly among consumers in Europe, North America, and emerging markets in Africa and South America. The rise of eco-consciousness has led to greater interest in synthetic alternatives that mimic the aesthetic of genuine leather while offering durability and lower maintenance costs.

Illustrative image related to black faux leather fabric

Current B2B sourcing trends reflect a shift towards digital platforms that facilitate easier access to suppliers and manufacturers. E-commerce platforms and marketplaces are becoming the go-to avenues for international buyers seeking bulk purchases. This trend is particularly pronounced in regions such as the Middle East and Southeast Asia, where buyers are leveraging technology for price comparisons, product reviews, and supplier ratings.

Moreover, customization is gaining traction in the faux leather sector. Buyers are increasingly looking for unique textures, finishes, and colors to differentiate their products in the competitive fashion and upholstery markets. Suppliers who can offer a diverse range of options—including embossed patterns and varying weights—are better positioned to meet these evolving demands.

How Does Sustainability and Ethical Sourcing Impact the Black Faux Leather Fabric Sector?

Sustainability is at the forefront of discussions surrounding the black faux leather fabric industry. The environmental impact of traditional leather production has prompted many businesses to explore more sustainable options. Faux leather, typically made from PVC or polyurethane, presents a more eco-friendly alternative, particularly when produced using sustainable practices.

Illustrative image related to black faux leather fabric

Ethical sourcing is becoming a crucial consideration for international B2B buyers. Companies are increasingly seeking suppliers who can demonstrate transparency in their supply chains and adherence to ethical labor practices. Certifications such as OEKO-TEX and Global Recycled Standard are gaining importance as they provide assurance that materials have been produced with minimal environmental impact and without exploitation of workers.

Furthermore, the market is witnessing a rise in innovative materials that incorporate recycled plastics and bio-based alternatives. These advancements not only reduce the carbon footprint associated with faux leather production but also appeal to a growing demographic of environmentally conscious consumers. For B2B buyers, aligning with suppliers who prioritize sustainable practices can enhance brand reputation and foster customer loyalty.

How Has the Black Faux Leather Fabric Market Evolved Over Time?

The evolution of the black faux leather fabric market reflects broader societal shifts towards sustainability and innovation. Initially, faux leather was seen as a budget-friendly substitute for genuine leather, often lacking in quality and aesthetic appeal. However, advancements in technology have dramatically improved the look and feel of synthetic materials, making them more competitive in both fashion and upholstery markets.

In recent years, the rise of ethical consumerism has further propelled the demand for faux leather. As brands strive to align with consumer values, many are transitioning away from animal-based materials towards high-quality, synthetic alternatives. This shift not only meets market demands but also opens new avenues for creativity and design, allowing manufacturers to experiment with colors, patterns, and finishes that were previously unattainable with traditional leather.

Overall, the black faux leather fabric sector is poised for continued growth, driven by consumer preferences, technological advancements, and a collective push towards sustainability and ethical sourcing practices. B2B buyers who adapt to these changes will find ample opportunities for innovation and differentiation in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of black faux leather fabric

-

How do I select the right black faux leather fabric for my project?

Choosing the right black faux leather fabric involves understanding the specific requirements of your project, such as the intended use (upholstery, apparel, etc.) and the desired aesthetic. Consider factors like weight, texture, and durability. For instance, if you need a fabric for outdoor furniture, opt for a waterproof and UV-resistant option. Additionally, check the rub count, which indicates durability; a higher rub count (e.g., 50,000+) is ideal for high-traffic areas. -

What is the best black faux leather fabric for upholstery?

The best black faux leather fabric for upholstery is one that balances durability with comfort. Look for heavyweight options made from PVC or PU, which offer a leather-like feel while being easy to maintain. Fabrics with a rub count of 50,000 or more are suitable for high-use areas. Ensure the fabric is also easy to clean and resistant to tearing, as these qualities will enhance the longevity of your upholstered furniture. -

What are the minimum order quantities (MOQs) for black faux leather fabric?

Minimum order quantities can vary significantly between suppliers. Generally, MOQs for black faux leather fabric range from 10 to 100 yards, depending on the manufacturer and the type of fabric. It’s advisable to discuss your project needs with potential suppliers to negotiate favorable terms, especially if you are looking for a specific color or texture. Some suppliers may offer flexibility for first-time buyers or larger projects. -

What payment terms should I expect when sourcing black faux leather fabric internationally?

Payment terms in international B2B transactions often include options like wire transfers, letters of credit, or payment through platforms like PayPal. Many suppliers require a deposit (typically 30% to 50%) upfront, with the balance due before shipment or upon delivery. Always clarify the payment terms during negotiations to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees in your budgeting. -

How can I ensure the quality of black faux leather fabric before purchasing?

To ensure quality, request samples of the black faux leather fabric before placing a bulk order. Evaluate the samples for texture, durability, and color consistency. You can also ask for certifications or test reports that indicate the fabric’s compliance with industry standards for flammability and durability. Conducting a quality assurance check upon delivery can help confirm that the received materials meet your specifications. -

What shipping options are available for black faux leather fabric?

Shipping options for black faux leather fabric typically include air freight for faster delivery or sea freight for more economical shipping on larger orders. Depending on your location and supplier, you may also have the option for express courier services. Be sure to discuss shipping costs, estimated delivery times, and whether the supplier provides tracking information for your order. -

How do I vet suppliers of black faux leather fabric?

Vetting suppliers involves researching their reputation, history, and customer feedback. Look for suppliers with positive reviews and a track record of reliability in fulfilling orders. Request references from previous clients and inquire about their production processes and quality control measures. Additionally, consider visiting the supplier’s facility or arranging virtual meetings to assess their operations and ensure they align with your business values. -

Can I customize black faux leather fabric for my brand?

Many manufacturers offer customization options, including color, texture, and pattern for black faux leather fabric. When discussing customization, provide clear specifications and any design files you have. Be aware that custom orders may have higher MOQs and longer lead times. It’s essential to communicate your branding needs effectively to ensure the final product aligns with your vision.

Top 5 Black Faux Leather Fabric Manufacturers & Suppliers List

1. Hobby Lobby – Black Faux Leather Fabric

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {‘name’: ‘Black Faux Leather Fabric’, ‘SKU’: ‘1533819’, ‘discounted_price’: ‘$11.19’, ‘original_price’: ‘$15.99’, ‘discount’: ‘30% Off’, ‘fabric_type’: ‘Fabric By The Yard’, ‘available_increments’: ‘1-yard increments’, ‘average_bolt_size’: ‘approximately 9 yards’, ‘width’: ’55 inches’, ‘vertical_repeat’: ‘8.66 inches’, ‘horizontal_repeat’: ‘8.66 inches’, ‘color’: ‘Black’, ‘weight’: ‘Heavyweight’, …

2. Mood Fabrics – Faux Leather Fabric

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: Faux Leather Fabric by the Yard | Ethical Alternative

3. Online Fabric Store – Vinyl & Leather Fabrics

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: Vinyl & Leather fabrics available for various applications including apparel, décor, and utility. The collection features a range of colors such as white, ivory, natural, tan, gold, yellow, orange, brown, green, pink, red, blue, purple, gray, and black. Product types include basic and designer fabrics, with characteristics like flame retardant, water repellent, and outdoor suitability. The materia…

4. Naugahyde – Black Faux Leather Upholstery Vinyl

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Black Faux Leather Upholstery Vinyl

– Distributor Wholesale

– Free Shipping Coupon Code: SHIPFREE for Most $199 Orders

– Available by the yard or roll at wholesale prices

– Brands: Naugahyde, Boltaflex, Omnova

– Uses: Automotive, Furniture, Marine

– Various styles and colors available

– Example Products:

1. LDR01 LANDERS BLACK – $14.95 per yard, 45 yards in stock

2. RU930 Naugahyde ROGUE II – …

5. Fabric Wholesale Direct – Faux Leather Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Faux Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for black faux leather fabric

As the demand for black faux leather fabric continues to rise across various industries, strategic sourcing becomes increasingly crucial for B2B buyers aiming to remain competitive. The versatility and durability of this material make it an ideal choice for applications ranging from upholstery to fashion, allowing businesses to meet diverse customer preferences while maintaining cost efficiency. Key takeaways include the importance of selecting high-quality suppliers that offer a range of options, including waterproof and easy-to-clean variants, which cater to both aesthetic and practical needs.

In light of evolving market trends, it is essential for international buyers—particularly those from Africa, South America, the Middle East, and Europe—to stay informed about innovations in faux leather technology. This material not only aligns with sustainable practices but also offers a high-end appearance without the associated costs of genuine leather.

Looking ahead, B2B buyers should actively seek partnerships with suppliers who prioritize quality and ethical sourcing. By doing so, they can enhance their product offerings and ensure customer satisfaction. Embrace the opportunities presented by black faux leather fabric to drive growth and innovation in your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.