Introduction: Navigating the Global Market for customize leather seats

In today’s competitive automotive landscape, sourcing customized leather seats presents a significant challenge for international B2B buyers. The quest for high-quality, durable, and aesthetically pleasing leather upholstery can often feel overwhelming, especially when navigating diverse suppliers across continents. This guide is meticulously designed to empower buyers from regions like Africa, South America, the Middle East, and Europe—such as Nigeria and Brazil—by providing a comprehensive overview of the global market for customized leather seats.

From understanding various types of leather materials and their applications to effective supplier vetting processes, this guide covers all essential aspects of the purchasing journey. It also delves into cost considerations, installation requirements, and maintenance tips, ensuring that buyers make informed decisions that align with their business needs.

By leveraging actionable insights and expert recommendations, this resource aims to simplify the sourcing process, enabling B2B buyers to confidently select suppliers that meet their specific requirements. As the demand for customized leather seats continues to grow, staying informed about market trends and supplier capabilities is crucial for securing the best value and quality in your purchases.

Table Of Contents

- Top 4 Customize Leather Seats Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for customize leather seats

- Understanding customize leather seats Types and Variations

- Key Industrial Applications of customize leather seats

- 3 Common User Pain Points for ‘customize leather seats’ & Their Solutions

- Strategic Material Selection Guide for customize leather seats

- In-depth Look: Manufacturing Processes and Quality Assurance for customize leather seats

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘customize leather seats’

- Comprehensive Cost and Pricing Analysis for customize leather seats Sourcing

- Alternatives Analysis: Comparing customize leather seats With Other Solutions

- Essential Technical Properties and Trade Terminology for customize leather seats

- Navigating Market Dynamics and Sourcing Trends in the customize leather seats Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of customize leather seats

- Strategic Sourcing Conclusion and Outlook for customize leather seats

- Important Disclaimer & Terms of Use

Understanding customize leather seats Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Upholstery Kits | Tailored to specific vehicle make, model, and year; replaces factory upholstery completely. | Automotive customization shops, dealerships | Pros: Factory-like fit, high-quality materials. Cons: Requires professional installation. |

| Preconfigured Packages | Ready-made kits with popular configurations; customizable options available. | Retailers, automotive accessory distributors | Pros: Quick installation, variety of styles. Cons: Limited customization compared to fully custom options. |

| Leather Seat Covers | Slip-on covers designed to fit over existing seats; easier to install. | DIY enthusiasts, budget-conscious buyers | Pros: Affordable, easy to install. Cons: May not fit as well; less durability. |

| Heated and Ventilated Seats | Integration of heating and cooling elements into leather seats. | Luxury vehicle manufacturers, aftermarket upgrades | Pros: Enhanced comfort, attractive for high-end markets. Cons: Higher cost and complexity in installation. |

| Exotic Leather Options | Use of premium materials such as exotic hides; unique textures and colors. | High-end automotive customization, luxury brands | Pros: Distinctive look, high perceived value. Cons: Higher cost and limited availability. |

What Are the Characteristics of Custom Upholstery Kits?

Custom upholstery kits are designed to replace the entire seat cover of a vehicle, providing a seamless, factory-like appearance. These kits are tailored to the specific make, model, and year of the vehicle, ensuring a perfect fit. B2B buyers, such as automotive shops and dealerships, can benefit from these kits as they offer high-quality materials that enhance vehicle aesthetics and comfort. Key purchasing considerations include the quality of leather, warranty options, and the availability of installation services.

Illustrative image related to customize leather seats

How Do Preconfigured Packages Differ from Custom Solutions?

Preconfigured packages consist of popular leather seat designs that are readily available for various vehicle models. While they provide options for customization, such as color and material, they are primarily designed for quick installation. Automotive retailers and accessory distributors often prefer these packages due to their efficiency and appeal to a broad customer base. Buyers should consider the balance between customization options and installation speed when selecting these packages.

What Are the Advantages of Leather Seat Covers?

Leather seat covers are a cost-effective solution for those looking to enhance their vehicle’s interior without a full replacement. These slip-on covers are easy to install and can be a good option for DIY enthusiasts or budget-conscious buyers. However, they may not offer the same durability and fit as custom upholstery kits, which can be a drawback for businesses focused on quality. When considering these products, buyers should weigh installation ease against long-term performance.

Why Are Heated and Ventilated Seats Important in Today’s Market?

Heated and ventilated seats are increasingly popular, particularly in luxury vehicles. This feature enhances passenger comfort, making it an attractive selling point for dealerships and manufacturers. B2B buyers should consider the added value these seats provide, especially in markets where climate control is a significant concern. However, the complexity of installation and higher costs associated with these options are important factors to evaluate.

What Makes Exotic Leather Options Stand Out?

Exotic leather options offer unique textures and colors that appeal to high-end automotive customization markets. These materials can significantly elevate the perceived value of a vehicle, making them ideal for luxury brands and bespoke automotive shops. B2B buyers should consider the sourcing and availability of these materials, as well as the potential for higher profit margins. However, the cost and limited supply can be potential challenges in this niche market.

Key Industrial Applications of customize leather seats

| Industry/Sector | Specific Application of customize leather seats | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom upholstery for luxury and performance vehicles | Enhances vehicle appeal, increases market value | Quality of materials, fitment accuracy, installation support |

| Hospitality | Custom leather seating for hotels and restaurants | Creates a luxurious atmosphere, improves customer experience | Durability, maintenance requirements, design flexibility |

| Transportation Services | Customized seating for taxis and buses | Increases passenger comfort, enhances brand image | Compliance with safety regulations, ease of cleaning, customization options |

| Aviation | Leather seats for private jets and helicopters | Elevates luxury travel experience, attracts high-end clientele | Weight considerations, compliance with aviation standards, customization capabilities |

| Marine | Custom leather seating for yachts and boats | Enhances aesthetics, improves durability in marine environments | Water resistance, UV protection, ease of maintenance |

How Are Customized Leather Seats Used in Automotive Manufacturing?

In the automotive manufacturing sector, customized leather seats are integral to creating luxury and performance vehicles. These seats not only enhance the aesthetic appeal but also significantly increase the market value of the vehicles. International buyers, especially from regions like Africa and South America, often seek high-quality materials that ensure durability and comfort. Sourcing considerations include ensuring the leather’s fitment accuracy to specific vehicle models and the availability of installation support to facilitate seamless integration.

Illustrative image related to customize leather seats

What Role Do Customized Leather Seats Play in the Hospitality Industry?

In the hospitality sector, custom leather seating is pivotal in creating a luxurious atmosphere in hotels and restaurants. This upgrade not only improves the overall customer experience but also reflects the brand’s commitment to quality and comfort. Buyers from the Middle East and Europe may prioritize durability and maintenance requirements, ensuring that the upholstery withstands high traffic while retaining its premium appearance. Flexibility in design is also crucial, allowing businesses to align seating with their unique branding.

How Are Customized Leather Seats Beneficial for Transportation Services?

Transportation services, including taxis and buses, benefit greatly from customized leather seating. Such upgrades enhance passenger comfort and contribute positively to the overall brand image, making services more appealing to customers. For buyers in these sectors, compliance with safety regulations is paramount, along with considerations for ease of cleaning and customization options that cater to diverse passenger needs. This is especially relevant in urban environments across Africa and South America, where comfort can be a key differentiator.

Why Are Customized Leather Seats Important in Aviation?

In the aviation industry, particularly for private jets and helicopters, customized leather seats are synonymous with luxury travel. These seats elevate the travel experience and are essential for attracting high-end clientele. International buyers must consider weight limitations and compliance with aviation standards when sourcing. Additionally, the capability for customization is vital, allowing for a personalized touch that reflects the owner’s style and preferences.

How Do Customized Leather Seats Enhance Marine Applications?

In the marine sector, custom leather seating for yachts and boats not only enhances aesthetics but also improves durability in challenging marine environments. Buyers need to prioritize water resistance and UV protection to ensure longevity. Furthermore, ease of maintenance is a significant consideration, as marine upholstery often faces exposure to elements that can cause wear and tear. This is particularly important for buyers in regions with tropical climates, where the sun and moisture can rapidly degrade materials.

3 Common User Pain Points for ‘customize leather seats’ & Their Solutions

Scenario 1: Difficulty in Matching Vehicle Interiors

The Problem: B2B buyers often encounter challenges when trying to match custom leather seat upholstery to existing vehicle interiors. This issue is particularly pronounced when dealing with a fleet of vehicles that may have varying color and texture specifications, making it difficult to maintain a cohesive aesthetic across all units. Additionally, mismatched colors can lead to dissatisfaction among clients and a potential loss of business.

Illustrative image related to customize leather seats

The Solution: To overcome this challenge, it is crucial for buyers to source leather from suppliers that provide comprehensive color matching services. This can include requesting leather samples before making bulk purchases to ensure consistency in shades and textures. Engaging with a supplier that offers a wide range of materials and color options is essential. Furthermore, utilizing digital configurators provided by manufacturers can help visualize how different leathers will look in specific vehicle models. Consider requesting custom samples that reflect the existing interiors of your fleet, allowing for precise matching. This proactive approach will enhance client satisfaction and uphold the integrity of the brand’s image.

Scenario 2: Installation Complexity and Expertise

The Problem: A common pain point for B2B buyers is the complexity of installing custom leather seats. Many buyers underestimate the technical expertise required for installation, which can result in improper fitting and aesthetic issues. This is particularly relevant for companies that do not have dedicated in-house teams trained in upholstery, leading to costly errors and delays.

The Solution: To address installation complexities, buyers should prioritize working with suppliers that offer professional installation services or training programs. Engaging with manufacturers who have a network of certified installers can significantly reduce the risks associated with DIY installations. Additionally, buyers can invest in comprehensive training for their teams, which can include hands-on workshops or online tutorials provided by the leather seat manufacturers. It is also advisable to create a detailed installation guide that outlines step-by-step procedures, including tools required and common pitfalls to avoid. This investment in training and support will ensure that installations are performed correctly, leading to enhanced product longevity and customer satisfaction.

Illustrative image related to customize leather seats

Scenario 3: Concerns About Durability and Maintenance

The Problem: B2B buyers often worry about the durability and maintenance of custom leather seats, especially in regions with varying climates and usage conditions. Buyers may be apprehensive about investing in leather upholstery that might not withstand extreme temperatures, humidity, or wear and tear, leading to concerns over long-term value.

The Solution: To alleviate these concerns, it is essential for buyers to choose high-quality leather materials that are specifically designed for automotive use. Look for suppliers that offer leather treated with protective coatings to enhance durability against stains, UV rays, and moisture. Additionally, consider investing in maintenance products recommended by the manufacturer, such as conditioners and cleaning agents that can prolong the lifespan of the leather. Implementing a regular maintenance schedule can also help keep the seats in optimal condition, reducing the need for premature replacements. By prioritizing high-quality materials and proper care routines, buyers can ensure that their investment in custom leather seats provides lasting value, even in challenging conditions.

Strategic Material Selection Guide for customize leather seats

What Are the Key Properties of Common Materials Used in Custom Leather Seats?

When selecting materials for custom leather seats, it is essential to consider factors such as durability, comfort, and aesthetic appeal. Below, we analyze four common materials used in this industry: Genuine Leather, Synthetic Leather (PU), Vinyl, and Alcantara. Each material has unique properties and implications for international B2B buyers.

Illustrative image related to customize leather seats

Genuine Leather: What Makes It a Preferred Choice?

Genuine leather is renowned for its luxurious feel and durability. It typically has a high temperature resistance, allowing it to maintain its integrity in varying climates. However, it can be sensitive to moisture and may require regular conditioning to prevent drying and cracking.

Pros: The primary advantage of genuine leather is its durability and aesthetic appeal. It ages well, developing a unique patina over time, which many consumers find desirable. However, it tends to be more expensive and requires specialized care.

Cons: The cost of genuine leather can be prohibitive for some markets, particularly in regions where price sensitivity is high. Additionally, its maintenance requirements can be a drawback for buyers looking for low-maintenance options.

Illustrative image related to customize leather seats

Considerations for International Buyers: Buyers in Africa and South America may need to consider the availability of genuine leather and its compliance with local standards. For example, ensuring that the leather meets the ASTM D-2240 standard for hardness may be crucial for quality assurance.

Synthetic Leather (PU): Is It a Viable Alternative?

Polyurethane (PU) synthetic leather has gained popularity due to its cost-effectiveness and versatility. It offers good resistance to moisture and UV rays, making it suitable for various climates.

Pros: Synthetic leather is generally more affordable than genuine leather and easier to clean, making it a practical choice for commercial applications. It can also be produced in a wide range of colors and finishes.

Cons: While PU leather is durable, it may not have the same longevity as genuine leather. Over time, it can wear down and lose its appearance, particularly in high-use applications.

Considerations for International Buyers: In regions like the Middle East, where high temperatures can affect material performance, ensuring that the synthetic leather complies with relevant standards, such as DIN 53387 for abrasion resistance, is vital.

Illustrative image related to customize leather seats

Vinyl: What Are Its Strengths and Weaknesses?

Vinyl is a synthetic material that is often used in automotive upholstery. It is known for its resistance to moisture and ease of cleaning, making it a popular choice for fleet vehicles and budget-conscious consumers.

Pros: Vinyl is highly durable and resistant to stains, making it suitable for high-traffic environments. Its low cost is another significant advantage for businesses looking to minimize expenses.

Cons: However, vinyl lacks the luxurious feel of leather and can be less comfortable in extreme temperatures. It may also crack over time, especially if exposed to direct sunlight.

Considerations for International Buyers: Buyers in Europe may prefer vinyl for its ease of maintenance and cost-effectiveness. However, they should ensure compliance with EU regulations regarding chemical safety, such as REACH, to avoid potential legal issues.

Alcantara: Is It Worth the Investment?

Alcantara is a premium synthetic material that combines the aesthetics of suede with the durability of synthetic fibers. It is known for its soft texture and is often used in high-end vehicles.

Illustrative image related to customize leather seats

Pros: Alcantara offers excellent breathability and is resistant to fading, making it a stylish choice for luxury applications. It is also easier to maintain than genuine suede.

Cons: The primary downside is its cost, which can be significantly higher than other synthetic materials. Additionally, it may not be as durable as genuine leather in high-wear applications.

Considerations for International Buyers: In markets like Brazil, where luxury vehicles are prevalent, Alcantara could appeal to buyers looking for premium finishes. Buyers should ensure that the material meets local standards for durability and safety.

Summary Table of Material Properties

| Material | Typical Use Case for customize leather seats | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Luxury vehicles, high-end custom interiors | Durability and aesthetic appeal | High cost and maintenance required | High |

| Synthetic Leather (PU) | Mid-range vehicles, commercial applications | Cost-effective and versatile | Less durable over time | Medium |

| Vinyl | Fleet vehicles, budget-friendly options | Stain resistance and low cost | Lacks luxury feel, can crack | Low |

| Alcantara | Luxury vehicles, high-end custom interiors | Soft texture and breathability | High cost and potential durability issues | High |

In-depth Look: Manufacturing Processes and Quality Assurance for customize leather seats

What Are the Main Stages in the Manufacturing Process of Custom Leather Seats?

The manufacturing process for custom leather seats involves several critical stages that ensure high-quality output tailored to specific vehicle models.

Illustrative image related to customize leather seats

-

Material Preparation: The process begins with the careful selection of leather types, which can range from standard to exotic materials. Leather is often sourced from reputable tanneries that adhere to environmental regulations and quality standards. Once selected, the leather undergoes various treatments, including tanning and dyeing, to enhance its durability and aesthetic appeal.

-

Forming: This stage involves cutting the leather into patterns that correspond to the seat design. Precision cutting is essential to minimize waste and ensure a perfect fit. Advanced technologies such as computer-aided design (CAD) and automated cutting machines are commonly employed to achieve high accuracy.

-

Assembly: The individual leather pieces are stitched together using robust sewing techniques. This step often includes the incorporation of additional materials, such as foam padding for comfort and support, as well as heating elements for added luxury. Skilled artisans or automated systems may handle the stitching, ensuring that seams are both durable and visually appealing.

-

Finishing: After assembly, the seats undergo a finishing process that may include applying protective coatings, polishing, and quality checks for any defects. This stage is crucial for enhancing the leather’s longevity and maintaining its visual appeal.

How Do International Standards Influence Quality Assurance in Custom Leather Seat Manufacturing?

Quality assurance (QA) in the manufacturing of custom leather seats is paramount, particularly for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

-

ISO 9001 Certification: Many manufacturers seek ISO 9001 certification, which is an international standard that specifies requirements for a quality management system (QMS). This certification ensures that a company consistently provides products that meet customer and regulatory requirements, thereby enhancing customer satisfaction.

-

Industry-Specific Standards: In addition to ISO standards, certain industry-specific certifications, such as CE marking for products sold within the European Economic Area and API standards for automotive parts, may apply. Compliance with these standards indicates that the manufacturer adheres to safety and quality benchmarks recognized globally.

What Are the Key Quality Control Checkpoints in Custom Leather Seat Manufacturing?

To maintain high-quality standards, manufacturers implement several quality control (QC) checkpoints throughout the production process:

-

Incoming Quality Control (IQC): At this initial stage, raw materials, including leather and components, are inspected for quality and compliance with specifications. This step is essential to prevent defective materials from entering the production line.

-

In-Process Quality Control (IPQC): During the assembly and forming stages, manufacturers conduct regular inspections to ensure that processes are followed correctly. This includes checking the stitching quality, seam alignment, and adherence to design specifications.

-

Final Quality Control (FQC): Before the seats are packaged and shipped, a final inspection is conducted. This includes a comprehensive review of the finished product for any defects, ensuring that it meets all quality standards and customer specifications.

What Common Testing Methods Are Used to Ensure Quality in Custom Leather Seats?

Quality assurance in custom leather seat manufacturing also involves several testing methods to verify the durability and performance of the final products:

-

Physical Testing: This includes tests for tensile strength, abrasion resistance, and colorfastness. These tests help ensure that the leather can withstand wear and tear over time.

-

Environmental Testing: Manufacturers may conduct tests to evaluate how leather responds to environmental factors such as humidity, temperature, and exposure to UV light. This ensures that the leather maintains its integrity and appearance under various conditions.

-

Comfort Testing: Assessing the comfort level of the seats is crucial, especially for long-term use. This may involve ergonomic assessments and user feedback to ensure the final product meets consumer expectations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source custom leather seats should take proactive steps to verify the quality control measures of potential suppliers:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into the manufacturing process, materials used, and adherence to quality standards. This firsthand evaluation can help identify any potential issues before placing a bulk order.

-

Quality Reports: Requesting quality assurance reports, including IQC, IPQC, and FQC documentation, can offer transparency regarding the supplier’s QC processes. Detailed reports should outline testing methods, results, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing facilities and processes. These services often include detailed reports that outline compliance with international standards and any areas for improvement.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, and the Middle East, understanding the nuances of quality control and certification is essential:

-

Customs and Import Regulations: Different countries may have specific import regulations regarding the materials used in manufacturing, particularly leather. Buyers should be aware of any restrictions or certifications required for importing custom leather seats.

-

Cultural Expectations: Quality perceptions may vary by region. Understanding local market expectations for quality and design can help buyers select suppliers that align with their target audience’s preferences.

-

Sustainability Considerations: Increasingly, buyers are focusing on sustainability practices within the supply chain. Suppliers that adhere to environmentally friendly practices and can provide documentation of sustainable sourcing will likely stand out in the global market.

By understanding these manufacturing processes, quality assurance measures, and verification methods, B2B buyers can make informed decisions when sourcing custom leather seats, ensuring they select suppliers that meet their quality and compliance needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘customize leather seats’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure customized leather seats for vehicles. As the demand for premium automotive interiors grows, understanding the sourcing process becomes crucial for making informed decisions. This checklist will help you navigate the complexities of selecting the right suppliers and products, ensuring a successful procurement experience.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly outline the technical specifications for the leather seats you require. This includes details like the vehicle make, model, year, and specific design preferences.

– Considerations: Think about materials (e.g., types of leather or synthetic alternatives), color options, and any additional features such as heating or cooling systems. A well-defined specification will streamline your communication with potential suppliers.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers who specialize in customized leather seat production. Utilize online directories, industry publications, and trade shows to gather a list of potential candidates.

– Key Factors: Look for suppliers with a strong reputation and experience in your target market regions, such as Africa, South America, the Middle East, and Europe. Make sure they have a portfolio showcasing their previous work.

Step 3: Evaluate Supplier Certifications and Standards

Before making any commitments, verify that your shortlisted suppliers meet relevant industry certifications and quality standards.

– Why It Matters: Certifications such as ISO or specific automotive industry standards indicate a commitment to quality and safety. Ensure that suppliers can provide documentation to support their claims.

Step 4: Request Samples and Prototypes

To assess the quality of materials and craftsmanship, request samples or prototypes of the leather seats. This step is crucial in evaluating whether the product meets your expectations.

– What to Look For: Pay attention to the texture, durability, and overall finish. This hands-on evaluation can prevent potential issues during mass production.

Illustrative image related to customize leather seats

Step 5: Check Customer References and Reviews

Reach out to previous customers to gain insights into their experiences with the suppliers you are considering. Customer references can provide valuable information regarding reliability, quality, and service.

– Key Questions: Inquire about the overall satisfaction with the product, the supplier’s responsiveness to issues, and the adherence to delivery timelines.

Step 6: Negotiate Terms and Pricing

Once you’ve narrowed down your options, initiate discussions regarding pricing, payment terms, and delivery schedules.

– Negotiation Tips: Be clear about your budget and expectations. It’s also wise to discuss warranty terms and after-sales support to ensure you are covered post-purchase.

Step 7: Finalize the Contract

Before placing an order, ensure that all agreements are documented in a formal contract. This should detail the specifications, pricing, delivery timelines, and any warranties or guarantees.

– Importance of Clarity: A well-drafted contract protects both parties and sets clear expectations, reducing the likelihood of disputes in the future.

By following these steps, B2B buyers can effectively navigate the sourcing process for customized leather seats, ensuring a successful and satisfactory procurement experience.

Illustrative image related to customize leather seats

Comprehensive Cost and Pricing Analysis for customize leather seats Sourcing

What Are the Key Cost Components in Custom Leather Seat Production?

When sourcing custom leather seats, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The type of leather—be it standard, exotic, or synthetic—plays a significant role in pricing. High-quality leather, such as full-grain or top-grain, tends to be more expensive but offers superior durability and aesthetics.

-

Labor: Skilled labor is essential for the precise cutting, stitching, and assembly of custom leather seats. Labor costs can vary significantly based on the region and the complexity of the design.

-

Manufacturing Overhead: This includes the costs associated with running production facilities, such as utilities, rent, and equipment depreciation. Efficient production processes can help lower overhead costs.

-

Tooling: Custom molds and tools may be necessary for specific designs. These upfront costs can be substantial but are often amortized over larger production runs.

-

Quality Control: Ensuring that the finished products meet industry standards requires investment in QC processes. This can include inspections, testing, and certification, which are critical for maintaining product integrity.

-

Logistics: Transportation costs can vary based on the distance from the supplier to the buyer, as well as the chosen shipping method. International shipping can incur additional customs duties and taxes.

-

Margin: Suppliers typically add a margin on top of their costs to ensure profitability. This margin can vary widely based on market conditions and competition.

How Do Price Influencers Affect Custom Leather Seat Costs?

Several factors influence the pricing of custom leather seats:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts due to economies of scale. Understanding the MOQ can help buyers negotiate better terms.

-

Specifications and Customization: Highly customized designs or unique specifications can increase costs significantly. Clear communication of requirements is essential to avoid unexpected charges.

-

Materials and Quality Certifications: Premium materials and certified quality standards (such as ISO or automotive industry certifications) can justify higher prices but may also enhance the product’s value proposition.

-

Supplier Factors: The supplier’s reputation, location, and financial stability can impact pricing. Established suppliers with a track record of reliability may command higher prices but offer peace of mind.

-

Incoterms: The chosen Incoterms (International Commercial Terms) will define the responsibilities of both the buyer and seller in terms of shipping and handling costs. Understanding these can lead to better negotiation strategies.

What Tips Can Buyers Use to Optimize Costs and Pricing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to optimize costs:

-

Negotiate Effectively: Utilize the information about cost components and pricing influencers to negotiate favorable terms. Be prepared to discuss your volume and specific needs to leverage better pricing.

-

Focus on Total Cost of Ownership (TCO): Rather than just the upfront price, consider the TCO, which includes maintenance, durability, and potential resale value. Investing in higher-quality seats can save costs in the long run.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local labor costs, material availability, and market demand. Familiarizing yourself with these nuances can aid in making informed decisions.

-

Explore Local Suppliers: Consider sourcing from local manufacturers to reduce logistics costs and tariffs. This can also support local economies and may provide faster turnaround times.

-

Request Samples: Before committing to a large order, request material samples to assess quality firsthand. This can prevent costly mistakes and ensure the product meets your expectations.

Disclaimer on Indicative Prices

Prices for custom leather seats can vary widely based on the aforementioned factors. It is essential to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to your specific needs.

Alternatives Analysis: Comparing customize leather seats With Other Solutions

Understanding Alternatives to Customize Leather Seats

When considering options for enhancing vehicle interiors, customize leather seats stand out due to their premium feel and tailored fit. However, B2B buyers should also evaluate viable alternatives that may meet their specific requirements in terms of performance, cost, and ease of implementation. This analysis will compare customize leather seats with two primary alternatives: synthetic leather seats and traditional fabric upholstery.

| Comparison Aspect | Customize Leather Seats | Synthetic Leather Seats | Traditional Fabric Upholstery |

|---|---|---|---|

| Performance | High durability and luxury feel | Good durability; less premium feel | Moderate durability; comfort varies |

| Cost | Higher initial investment | Moderate cost, more affordable | Lowest cost option available |

| Ease of Implementation | Requires professional installation | Can be DIY installed | DIY-friendly, easy to install |

| Maintenance | Requires regular conditioning | Easier to clean, less maintenance | Requires regular cleaning; stains easily |

| Best Use Case | Luxury vehicles, high-end markets | Cost-effective luxury for mid-range vehicles | Budget-conscious vehicles or fleets |

Exploring Synthetic Leather Seats as an Alternative

Synthetic leather seats offer a compelling alternative to customize leather seats. They are manufactured from polyurethane or PVC, providing a look similar to genuine leather at a lower cost. The ease of maintenance is a significant advantage, as they can be wiped clean and are generally resistant to stains. However, synthetic leather may not provide the same level of comfort or breathability as natural leather, which can impact long-term user satisfaction. For B2B buyers focused on cost-effectiveness without sacrificing too much on aesthetics, synthetic leather can be an appealing choice.

Evaluating Traditional Fabric Upholstery

Traditional fabric upholstery is the most budget-friendly option available, making it a suitable choice for fleet vehicles or budget-conscious buyers. It is relatively easy to install, often allowing for DIY projects, which can save on labor costs. However, fabric seats can be less durable and more prone to staining, requiring more frequent cleaning and maintenance. Additionally, they may not provide the luxurious feel that leather options offer, making them less suitable for high-end markets. For businesses prioritizing cost over aesthetics, traditional fabric upholstery can fulfill basic functional needs without significant investment.

Illustrative image related to customize leather seats

Making an Informed Choice: Which Solution is Right for Your Business?

In conclusion, the choice between customize leather seats, synthetic leather seats, and traditional fabric upholstery largely depends on the specific requirements of the B2B buyer. Buyers looking for a premium, long-lasting solution may find customize leather seats to be worth the investment, especially in luxury markets. Conversely, those seeking a balance between cost and quality may prefer synthetic leather, while budget-focused companies might lean towards traditional fabric upholstery. Understanding the pros and cons of each alternative can help businesses select the most appropriate solution for their vehicles, ensuring that their investment aligns with their operational goals and brand image.

Essential Technical Properties and Trade Terminology for customize leather seats

What Are the Key Technical Properties of Customized Leather Seats?

When selecting customized leather seats for vehicles, several technical properties play a crucial role in ensuring quality, durability, and comfort. Understanding these specifications can significantly impact purchasing decisions and long-term satisfaction.

1. Material Grade

The material grade refers to the quality of the leather used in the manufacturing of the seats. Higher-grade leather, such as full-grain or top-grain, is more durable and resistant to wear and tear, offering a luxurious feel. In contrast, lower grades may use bonded or split leather, which could compromise longevity. For B2B buyers, selecting a higher-grade material can result in fewer replacements and enhanced customer satisfaction.

2. Tolerance Levels

Tolerance levels define the acceptable variations in dimensions during the manufacturing process. In the context of customized leather seats, precise tolerances ensure a perfect fit within the vehicle’s interior, preventing issues such as misalignment or discomfort. High tolerance standards are essential for maintaining quality control, making it easier for B2B buyers to trust that products will meet their specifications.

3. Colorfastness

Colorfastness measures the resistance of leather to fading and discoloration when exposed to light, heat, or moisture. This property is particularly vital for customized leather seats, as it affects the aesthetic appeal and longevity of the upholstery. Buyers should prioritize suppliers who provide leather with excellent colorfastness ratings to ensure that their investment remains visually appealing over time.

4. Breathability

Breathability refers to the leather’s ability to allow air circulation, which is essential for comfort, especially in warm climates. High-quality leather with adequate breathability can prevent heat buildup and moisture accumulation, enhancing the user experience. B2B buyers must consider this property, particularly when catering to markets with varying climate conditions, such as Africa and South America.

5. Fire Resistance

Fire resistance is a critical safety feature for automotive upholstery. Customized leather seats should comply with industry standards for flammability to protect occupants in case of an accident. B2B buyers must ensure that their suppliers adhere to these safety regulations to mitigate liability risks and enhance consumer trust.

What Are Common Trade Terms in the Customized Leather Seats Industry?

Navigating the customized leather seats industry requires familiarity with specific jargon and trade terms. Here are some key terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are sold under another brand’s name. In the context of customized leather seats, OEM parts may be preferred for their compatibility and quality assurance. Buyers should consider whether to source OEM products or aftermarket options based on their specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell in a single order. Understanding MOQ is vital for B2B buyers to manage inventory effectively and ensure they meet demand without overcommitting resources. Negotiating MOQs can lead to cost savings, particularly for larger purchases.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Utilizing RFQs can help B2B buyers compare offers and negotiate favorable terms, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, risks, and obligations. Properly defining Incoterms can prevent disputes and streamline the logistics process.

5. Lead Time

Lead time is the time taken from placing an order to the delivery of the product. In the customized leather seats market, understanding lead time is essential for planning inventory and meeting customer demand. B2B buyers should inquire about lead times when placing orders to ensure timely delivery and customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the best customized leather seats for their needs while navigating the complexities of the industry effectively.

Navigating Market Dynamics and Sourcing Trends in the customize leather seats Sector

What Are the Key Market Dynamics and Trends in the Customize Leather Seats Sector?

The global market for customized leather seats is witnessing significant growth, driven by rising consumer demand for personalized automotive interiors and the increasing trend of vehicle customization. In regions like Africa, South America, the Middle East, and Europe, this demand is propelled by a burgeoning middle class and enhanced disposable incomes, allowing consumers to prioritize luxury and comfort in their vehicles. In particular, countries such as Nigeria and Brazil are experiencing rapid urbanization, leading to an increased focus on vehicle aesthetics and functionality.

Emerging technologies are reshaping the sourcing landscape for customized leather seats. Digital platforms that facilitate direct-to-consumer sales are becoming increasingly popular, allowing B2B buyers to source products more efficiently. Additionally, the use of 3D modeling and visualization tools enables customers to customize their designs before purchase, enhancing the buying experience. Integrating advanced manufacturing techniques, such as automated cutting and sewing, is improving lead times and reducing costs, making customization more accessible.

Furthermore, the customization trend is also evident in the choice of materials. Buyers are increasingly looking for unique textures, colors, and finishes, which are often supported by manufacturers offering a wide range of options. The demand for premium features, such as heated and ventilated seats, is also on the rise, emphasizing the need for suppliers to keep pace with evolving consumer preferences.

How Important Is Sustainability and Ethical Sourcing in the Customize Leather Seats Industry?

Sustainability and ethical sourcing are becoming crucial considerations in the customized leather seats sector. The environmental impact of leather production, including deforestation and water usage, has led to increased scrutiny from consumers and regulatory bodies alike. B2B buyers must be aware of these factors when selecting suppliers, as companies that prioritize sustainability are likely to gain a competitive advantage.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly favoring suppliers who demonstrate transparency in their sourcing practices and adhere to ethical labor standards. This includes ensuring fair wages and safe working conditions for all workers involved in the leather production process. Certifications such as the Leather Working Group (LWG) certification can help buyers identify manufacturers committed to sustainable practices.

Illustrative image related to customize leather seats

Moreover, the demand for alternative materials, such as synthetic leathers or plant-based options, is on the rise. These materials not only reduce the environmental footprint but also cater to a growing segment of consumers seeking cruelty-free and eco-friendly choices. B2B buyers should consider integrating these sustainable materials into their product offerings to meet the evolving demands of the marketplace.

What Is the Historical Context of the Customize Leather Seats Market?

The customized leather seats market has evolved significantly over the past few decades. Initially, leather upholstery was considered a luxury reserved for high-end vehicles, primarily due to the high costs associated with sourcing and processing leather. However, as technology advanced and manufacturing processes became more efficient, the market began to open up to a wider audience.

In the early 2000s, the emergence of aftermarket suppliers and manufacturers specializing in customized interiors transformed the landscape. Companies began offering tailored solutions, allowing consumers to personalize their vehicles at a more affordable price. This shift not only democratized access to luxury interiors but also ignited a trend toward individualized vehicle aesthetics.

Today, the market is characterized by a blend of traditional craftsmanship and modern technology, enabling buyers to create unique designs that reflect their personal style. As consumer preferences continue to evolve, the customized leather seats sector is poised for further growth, driven by innovation and an increasing focus on sustainability.

Illustrative image related to customize leather seats

Frequently Asked Questions (FAQs) for B2B Buyers of customize leather seats

-

How do I choose the right supplier for customized leather seats?

Choosing the right supplier involves evaluating their experience, reputation, and product quality. Look for suppliers with a strong portfolio showcasing their work, preferably in your specific market. Request samples of their leather materials to assess quality firsthand. Additionally, check for certifications and customer reviews, which can provide insights into their reliability and service. Establish communication to discuss your specific needs, and ensure they can accommodate international shipping and customs regulations relevant to your region. -

What is the best material for customized leather seats?

The best material for customized leather seats depends on your target market and vehicle type. Full-grain leather is premium and durable, offering a luxurious feel, while top-grain leather provides a balance of quality and cost. For budget-conscious options, synthetic leather can mimic the look of real leather without the high price tag. Consider factors such as climate, intended use, and maintenance ease when selecting materials. Always request samples to ensure the material aligns with your brand’s quality standards. -

What customization options are typically available for leather seats?

Customization options for leather seats can include different colors, textures, stitching patterns, and additional features like heating or cooling elements. Many suppliers offer a configurator tool on their website, allowing you to visualize your choices. You can also request bespoke designs that reflect your brand identity. Ensure that the supplier can accommodate your specific requirements and ask for examples of previous custom projects to gauge their capabilities. -

What are the minimum order quantities (MOQs) for custom leather seats?

Minimum order quantities can vary significantly between suppliers, often depending on the complexity of the customization and materials used. For bulk orders, MOQs might range from a few dozen to several hundred units. When sourcing, it’s crucial to discuss your needs upfront and confirm the MOQ to ensure it aligns with your purchasing capabilities. Some suppliers may offer flexibility for first-time buyers or smaller businesses, so it’s worth negotiating. -

What payment terms should I expect when sourcing customized leather seats?

Payment terms can vary widely among suppliers. Common terms include a deposit upon order confirmation, with the balance due before shipment. Some suppliers may offer net terms, allowing you to pay 30, 60, or 90 days after receiving the goods. Always clarify payment methods accepted (e.g., bank transfer, credit card) and inquire about any financing options available. Ensure that all terms are documented in a formal contract to protect both parties. -

How can I ensure quality assurance for customized leather seats?

To ensure quality assurance, request detailed specifications and samples before full production. Many suppliers will offer a warranty period, which can give you confidence in their product durability. Establish clear quality control checkpoints during production and ask if they conduct regular inspections. Additionally, consider visiting the supplier’s facility if possible or hiring a third-party inspection service to verify compliance with your quality standards before shipment. -

What are the logistics considerations for importing customized leather seats?

Logistics for importing customized leather seats involve understanding shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder with experience in handling automotive parts to manage the logistics process efficiently. Ensure that all documentation, such as invoices and customs declarations, is accurate to prevent delays at customs. Consider the shipping timeframes and costs associated with different transport modes (air vs. sea) to optimize your supply chain. -

How do I handle potential issues with customized leather seats after delivery?

Handling post-delivery issues requires clear communication with your supplier. Establish a process for reporting defects or discrepancies immediately upon receipt of the goods. Ensure that you have documented all specifications and agreements to reference in case of disputes. Many suppliers offer warranty coverage, so inquire about the claims process and timeframes for resolution. Building a strong relationship with your supplier can facilitate smoother problem resolution and foster long-term collaboration.

Top 4 Customize Leather Seats Manufacturers & Suppliers List

1. Tint World – Custom Leather Interiors

Domain: tintworld.com

Registered: 2001 (24 years)

Introduction: Custom Leather Interiors for Cars and Trucks, OEM Quality, 1000+ Patterns, Heating/Cooling Systems, Alea leather interiors, 25 years of experience, meets/exceeds Federal Motor Vehicle Safety Standards (FMVSS), Grade ‘A’ Italian Leather, custom tailor-made for each vehicle, original manufacturer specifications fitment, seat heating and cooling system options, OEM factory approved, complete cloth in…

2. Barbarossa Leather – Custom Leather Colors

Domain: barbarossaleather.com

Registered: 2005 (20 years)

Introduction: Custom Leather Colors available in a full spectrum of options including traditional earth tones and vibrant colors like turquoise, yellow, and lavender. Variegated patterns and textures are also offered. Key colors include: White, Beige, Sepia, Orange, Red, Purple, Blue, Green, Grey, Brown, Black, and Metallic. Specific samples include Abyss, Amazon, Anaconda, Arabesque, Aspen, Aviator, Aztec, Bab…

3. TrimTek Leather – Custom Automotive Interiors

Domain: trimtekleather.com

Registered: 2016 (9 years)

Introduction: Custom leather car and truck interiors made from the finest imported automotive leathers. Engineered to meet or exceed factory performance specifications. Trusted by Chrysler, Dodge, Jeep, and Ford. Custom build leather seats with design ideas provided by customers. On-site expert installation available at dealerships or homes with a mobile installation service. 30 years of experience in the custo…

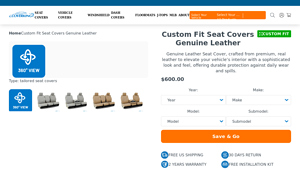

4. Coverking – Genuine Leather Car Seat Covers

Domain: coverking.com

Registered: 1996 (29 years)

Introduction: Genuine Leather Custom Car Seat Covers by Coverking

– Price: $600.00

– Description: Our most luxurious genuine top grain leather.

Strategic Sourcing Conclusion and Outlook for customize leather seats

As the demand for customized leather seats continues to grow across diverse global markets, strategic sourcing emerges as a pivotal element for B2B buyers aiming to capitalize on this trend. By partnering with reputable manufacturers and suppliers who offer tailored solutions, businesses can ensure high-quality products that meet specific client needs. The ability to customize leather upholstery not only enhances vehicle aesthetics but also significantly boosts customer satisfaction and brand loyalty.

Engaging in strategic sourcing allows international buyers from regions such as Africa, South America, the Middle East, and Europe to access a wide array of materials, styles, and installation options. This flexibility empowers businesses to offer unique, high-value products that stand out in competitive markets. Furthermore, leveraging technology to streamline the sourcing process can lead to cost savings and improved supply chain efficiency.

Looking ahead, it is essential for buyers to remain proactive in exploring innovative partnerships and sourcing strategies that align with evolving consumer preferences. By prioritizing quality and customization, businesses can position themselves as leaders in the automotive upholstery sector. Take the next step in transforming your offerings—invest in strategic sourcing for customized leather seats today.

Illustrative image related to customize leather seats

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.