Introduction: Navigating the Global Market for custom leather holster makers

In the ever-evolving landscape of the global market, sourcing high-quality custom leather holsters presents unique challenges for international B2B buyers. Whether you’re catering to law enforcement, the military, or civilian markets, finding reliable suppliers who deliver craftsmanship, durability, and design innovation can be daunting. This comprehensive guide aims to equip buyers from diverse regions—including Africa, South America, the Middle East, and Europe (notably Germany and Vietnam)—with the insights needed to make informed purchasing decisions in the realm of custom leather holster makers.

Throughout this guide, we will delve into various aspects essential for successful sourcing. From exploring the types of holsters available—such as inside-the-waistband (IWB), outside-the-waistband (OWB), and shoulder holsters—to understanding their specific applications in different markets, buyers will gain a holistic view of what to expect. We will also cover critical factors such as supplier vetting processes, cost considerations, and emerging trends in customization and materials.

By providing actionable insights and strategic guidance, this guide empowers B2B buyers to navigate the complexities of the custom leather holster market effectively, ensuring they align their procurement strategies with the demands of their target audiences. Ultimately, informed decisions can lead to enhanced product offerings and improved customer satisfaction.

Table Of Contents

- Top 7 Custom Leather Holster Makers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather holster makers

- Understanding custom leather holster makers Types and Variations

- Key Industrial Applications of custom leather holster makers

- 3 Common User Pain Points for ‘custom leather holster makers’ & Their Solutions

- Strategic Material Selection Guide for custom leather holster makers

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather holster makers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather holster makers’

- Comprehensive Cost and Pricing Analysis for custom leather holster makers Sourcing

- Alternatives Analysis: Comparing custom leather holster makers With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather holster makers

- Navigating Market Dynamics and Sourcing Trends in the custom leather holster makers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather holster makers

- Strategic Sourcing Conclusion and Outlook for custom leather holster makers

- Important Disclaimer & Terms of Use

Understanding custom leather holster makers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| IWB (Inside the Waistband) | Designed for concealed carry, fits inside the waistband | Law enforcement, personal defense | Pros: Excellent concealment, comfort; Cons: May require adjustment for fit. |

| OWB (Outside the Waistband) | Sits outside the waistband, offers quicker access | Tactical operations, open carry markets | Pros: Easy access, stability; Cons: Less concealment, bulkier. |

| Shoulder Holsters | Suspended from shoulders, distributes weight evenly | Professional security, law enforcement | Pros: Comfort for heavy firearms, easy concealment; Cons: Bulkiness, requires cover garment. |

| Crossdraw Holsters | Positioned for drawing across the body | Hunting, tactical applications | Pros: Quick access while seated; Cons: Less secure for active movement. |

| Custom Fit Holsters | Tailored to specific firearm models | High-end retail, collectors | Pros: Perfect fit, enhanced retention; Cons: Longer wait times, higher costs. |

What Are the Characteristics of IWB Holsters?

IWB holsters are designed to be worn inside the waistband, providing a discreet carry option that is ideal for personal defense and law enforcement applications. Their compact nature allows for excellent concealment, making them suitable for daily carry. B2B buyers should consider the comfort and adjustability of these holsters, as fit can vary significantly between different body types and clothing styles.

Why Choose OWB Holsters for Tactical Operations?

OWB holsters are positioned outside the waistband, allowing for quick access to the firearm. They are particularly popular in tactical operations and open carry markets. Buyers should evaluate the stability and ease of access these holsters provide, especially in high-stress situations. However, their bulk can make them less suitable for concealed carry.

How Do Shoulder Holsters Offer Comfort?

Shoulder holsters distribute the weight of the firearm across the shoulders, which can be beneficial for carrying heavier guns. They are commonly used in professional security and law enforcement settings due to their comfort and concealment capabilities. When purchasing, B2B buyers should consider the need for a cover garment, as these holsters can be bulkier than other options.

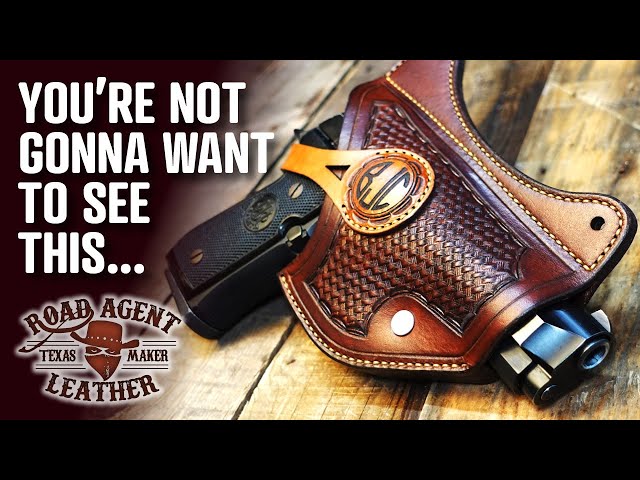

Illustrative image related to custom leather holster makers

What Are the Benefits of Crossdraw Holsters?

Crossdraw holsters allow for drawing the firearm across the body, which can be advantageous in seated positions, such as in a vehicle. This type of holster is often favored in hunting and tactical applications. Buyers should weigh the benefits of quick access against the potential for less secure retention during active movement.

Why Invest in Custom Fit Holsters?

Custom fit holsters are tailored to specific firearm models, ensuring a perfect fit and enhanced retention. They are particularly appealing to high-end retail buyers and collectors who prioritize quality and craftsmanship. While these holsters often come with higher costs and longer wait times, the investment can lead to superior performance and satisfaction in the long run.

Key Industrial Applications of custom leather holster makers

| Industry/Sector | Specific Application of custom leather holster makers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Custom holsters for duty weapons | Enhanced safety and accessibility for officers in the field | Compliance with local regulations, durability, and customization options |

| Military | Tactical holsters for firearms | Improved operational efficiency and weapon retention | Material strength, adaptability to various weapons, and ergonomic design |

| Sporting Goods | Holsters for competitive shooting | Increased performance and comfort for shooters | Weight, fit for specific firearms, and aesthetic appeal |

| Outdoor Recreation | Holsters for hunting and outdoor activities | Practicality and ease of access during outdoor adventures | Weather resistance, customization for different firearm types, and comfort |

| Fashion and Lifestyle | Custom leather holsters as fashion accessories | Unique branding opportunities and customer engagement | Quality of leather, craftsmanship, and design versatility |

How Are Custom Leather Holsters Used in Law Enforcement?

Custom leather holsters are pivotal in law enforcement, providing officers with secure and accessible storage for their duty weapons. These holsters are designed to facilitate quick access while ensuring the firearm is safely retained, which is crucial during high-stress situations. International buyers, particularly from regions with stringent firearm regulations, must consider the compliance of these holsters with local laws, ensuring they meet durability standards and can be customized for specific duty requirements.

What Role Do Custom Holsters Play in Military Operations?

In military applications, custom leather holsters are essential for tactical operations. They are crafted to accommodate various firearms while ensuring that soldiers can easily access their weapons during missions. The holsters must be robust and adaptable to different environments, which is particularly important for international buyers from diverse geographical regions. Key considerations include the material’s strength, the holster’s ergonomic design, and compatibility with military gear.

How Are Custom Leather Holsters Beneficial in Competitive Shooting?

In the sporting goods sector, custom leather holsters enhance performance in competitive shooting events. They are tailored to provide comfort and allow for rapid draws, which can significantly impact a shooter’s success. Buyers from regions with a vibrant shooting culture, such as Europe and South America, should prioritize sourcing holsters that offer lightweight designs and fit specific firearm models, ensuring they meet the demands of competitive environments.

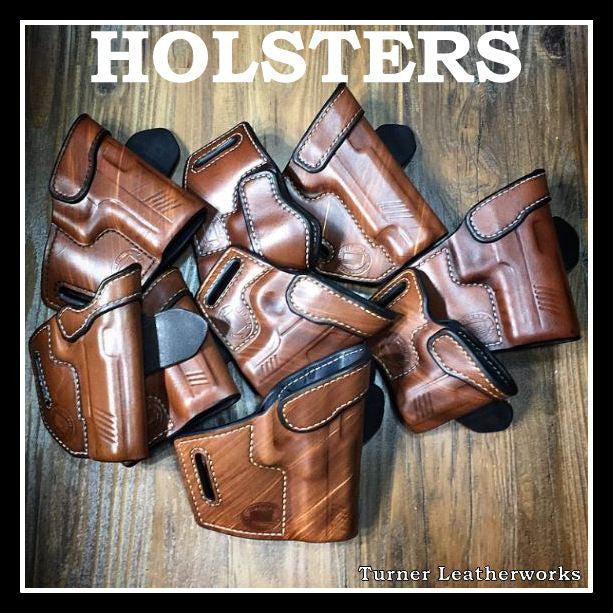

Illustrative image related to custom leather holster makers

What Applications Exist for Holsters in Outdoor Recreation?

For outdoor enthusiasts, custom leather holsters serve as practical solutions for carrying firearms during hunting and other recreational activities. These holsters are designed to provide easy access while ensuring comfort during extended wear. When sourcing these products, international buyers need to consider factors like weather resistance, the ability to customize for different firearm types, and overall comfort to ensure a satisfying outdoor experience.

How Do Fashion and Lifestyle Markets Utilize Custom Leather Holsters?

In the fashion and lifestyle sectors, custom leather holsters are increasingly seen as stylish accessories. They offer unique branding opportunities for businesses looking to engage customers through aesthetically pleasing designs. Buyers in this space should focus on the quality of leather, craftsmanship, and the versatility of designs to cater to diverse consumer preferences, particularly in markets like Europe and the Middle East, where fashion trends can significantly influence purchasing decisions.

3 Common User Pain Points for ‘custom leather holster makers’ & Their Solutions

Scenario 1: Inconsistent Quality Across Orders

The Problem: B2B buyers often face challenges with the quality of custom leather holsters. When placing bulk orders for various clients or markets, buyers may receive products that vary in craftsmanship, leather quality, and finishing. This inconsistency can lead to dissatisfaction among end customers and damage the buyer’s reputation, particularly in markets where quality is paramount.

The Solution: To mitigate the risk of inconsistent quality, buyers should establish a detailed quality assurance (QA) process before placing large orders. This includes requesting product samples that align with the intended specifications, such as leather type, stitching, and finishing. Additionally, buyers should consider setting up regular communication with the holster maker to discuss production standards and expectations. Implementing a clear set of quality metrics can help both parties understand the required standards. Conducting periodic site visits or audits can also be beneficial to ensure that the manufacturer adheres to the agreed-upon quality benchmarks throughout the production cycle.

Scenario 2: Long Lead Times Affecting Inventory Management

The Problem: One of the significant pain points for B2B buyers is the long lead times associated with custom leather holster manufacturing. When trying to manage inventory for seasonal demand or unexpected spikes, extended wait times can result in stock shortages, affecting sales and customer satisfaction. This is particularly critical in regions where buyers rely on timely deliveries to meet local market demands.

The Solution: To navigate long lead times, buyers should work closely with custom leather holster makers to establish a transparent timeline for production. This includes understanding the factors that contribute to lead times, such as material sourcing or production capacity. Buyers can negotiate for faster production schedules by providing forecasts of their needs or committing to long-term partnerships that ensure priority in manufacturing. Additionally, implementing a just-in-time inventory system can help mitigate the impact of delays, allowing buyers to maintain lower stock levels while ensuring product availability.

Scenario 3: Difficulty in Customization and Design Communication

The Problem: Customization is a core aspect of working with leather holster makers, but B2B buyers often struggle with effectively communicating their design requirements. This can lead to misunderstandings about the desired features, size, and aesthetics of the holster, resulting in products that do not meet market expectations. In diverse markets like Africa or South America, cultural nuances in design preferences can further complicate this issue.

The Solution: To enhance communication and ensure accurate customization, buyers should invest in creating comprehensive design briefs. These briefs should include detailed specifications, drawings, and even examples of preferred styles or features. Utilizing digital tools for mockups can facilitate better visualization for both parties. Additionally, establishing a feedback loop where initial designs can be reviewed and revised based on buyer input will foster a collaborative approach. Engaging in regular check-ins throughout the design process can also help address any issues early on, ensuring that the final product aligns with the buyer’s expectations and market demands.

Illustrative image related to custom leather holster makers

Strategic Material Selection Guide for custom leather holster makers

What Are the Key Materials Used in Custom Leather Holster Manufacturing?

When selecting materials for custom leather holsters, manufacturers typically consider various types of leather and synthetic alternatives. Each material offers distinct properties that can influence the performance, durability, and overall appeal of the final product. Below, we analyze four common materials used in the industry.

1. Full-Grain Leather

Key Properties: Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain pattern, providing exceptional strength and breathability. This material can withstand temperature fluctuations and is resistant to wear and tear.

Pros & Cons: The durability of full-grain leather is unmatched, making it ideal for holsters that require longevity. However, it comes at a higher cost compared to other leather types, which may not be feasible for all manufacturers. The manufacturing process can be complex, requiring skilled artisans to achieve the desired finish.

Illustrative image related to custom leather holster makers

Impact on Application: Full-grain leather is compatible with various climates, making it suitable for international markets. Its natural properties allow it to mold to the firearm over time, enhancing user comfort.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local leather sourcing regulations. Preferences for natural materials may favor full-grain leather in these markets, aligning with traditional craftsmanship values.

2. Top-Grain Leather

Key Properties: Top-grain leather is slightly less durable than full-grain, as it has been sanded and treated to remove imperfections. It offers a more uniform appearance while still providing good breathability and flexibility.

Illustrative image related to custom leather holster makers

Pros & Cons: This material is more affordable than full-grain leather, making it a popular choice for mid-range holsters. However, it may not offer the same level of durability, especially under heavy use. The manufacturing process is less complex than that of full-grain leather, allowing for quicker production times.

Impact on Application: Top-grain leather is suitable for everyday carry holsters, providing a balance between aesthetics and functionality. It can withstand moderate wear, making it a viable option for casual users.

Considerations for International Buyers: In Europe, top-grain leather is often preferred for its aesthetic appeal. Buyers should verify that the leather meets EU regulations on chemical treatments to ensure safety and compliance.

Illustrative image related to custom leather holster makers

3. Synthetic Leather (e.g., Kydex)

Key Properties: Synthetic leather, such as Kydex, is a thermoplastic material known for its rigidity and resistance to moisture and chemicals. It can withstand high temperatures and offers excellent retention properties.

Pros & Cons: The primary advantage of synthetic leather is its durability and ease of maintenance. It is also less expensive than genuine leather. However, it lacks the aesthetic appeal of natural leather and may not mold to the firearm as well over time.

Impact on Application: Synthetic leather is ideal for tactical holsters that require quick access and retention. Its weather-resistant properties make it suitable for outdoor use in various climates.

Considerations for International Buyers: Buyers from South America and Africa may find synthetic options appealing due to their affordability and low maintenance. However, they should consider local preferences for traditional materials and ensure that the synthetic products comply with regional environmental regulations.

4. Suede Leather

Key Properties: Suede leather, made from the underside of the hide, is soft and flexible. It offers a unique texture and aesthetic appeal but is less durable than other leather types.

Pros & Cons: Suede provides a comfortable fit and is often lighter than full-grain or top-grain leather. However, it is more susceptible to staining and damage from moisture, which limits its use in certain applications. The manufacturing process is straightforward, but care must be taken to maintain its appearance.

Impact on Application: Suede is suitable for holsters designed for occasional use or as fashion accessories. Its softness enhances comfort for users who prioritize aesthetics over ruggedness.

Considerations for International Buyers: In Europe, suede may be favored for its luxurious feel. Buyers should ensure that suede products are treated to resist moisture and comply with local environmental standards.

Illustrative image related to custom leather holster makers

Summary Table of Material Selection for Custom Leather Holster Makers

| Material | Typical Use Case for Custom Leather Holster Makers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Premium holsters for everyday carry | Exceptional durability and breathability | Higher cost and complex manufacturing | High |

| Top-Grain Leather | Mid-range holsters for casual use | Affordable and aesthetically pleasing | Less durable than full-grain | Medium |

| Synthetic Leather | Tactical holsters for quick access | Weather-resistant and low maintenance | Lacks aesthetic appeal | Low |

| Suede Leather | Fashionable holsters for occasional use | Soft and comfortable | Susceptible to stains and moisture | Medium |

This strategic material selection guide aims to assist B2B buyers in making informed decisions about the materials used in custom leather holster manufacturing, considering both performance and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather holster makers

What Are the Key Stages in the Manufacturing Process for Custom Leather Holsters?

The manufacturing process for custom leather holsters involves several key stages that ensure the final product meets the expectations of quality and functionality. Each stage is critical in creating durable and aesthetically pleasing holsters.

Material Preparation: How Is Leather Selected and Prepared?

The first step in the manufacturing process is the selection of high-quality leather. Custom holster makers often choose full-grain leather, known for its durability and natural characteristics. The leather is carefully inspected for imperfections and graded based on its quality.

Once selected, the leather is prepared through processes such as cutting and conditioning. The cutting must be precise to ensure each piece fits together seamlessly during assembly. Conditioning involves treating the leather to enhance its pliability and longevity, which may include oiling or applying wax.

Forming: What Techniques Are Used to Shape the Leather?

The forming stage involves molding the leather to the desired shape of the holster. This is typically achieved through techniques such as wet forming or vacuum forming. In wet forming, the leather is moistened and then shaped around a mold to create a perfect fit for the firearm it is designed to hold.

Vacuum forming utilizes suction to draw the leather around a mold, providing a more uniform shape and contour. This step is crucial as it determines how well the holster will secure the firearm while allowing for easy access.

Assembly: How Are the Components Joined Together?

Once the leather pieces are shaped, they are assembled. This stage involves stitching, riveting, and sometimes gluing the components together. Skilled artisans often use heavy-duty sewing machines and high-strength threads, ensuring that the seams are robust and can withstand wear and tear.

Attention to detail during assembly is vital. Each holster should be tested for fit and functionality as it is constructed, with adjustments made as necessary to ensure optimal performance.

Finishing: What Processes Enhance the Holster’s Durability and Aesthetics?

The finishing stage includes dyeing, sealing, and polishing the holster. Custom leather holster makers often use eco-friendly dyes to achieve rich colors while maintaining the leather’s integrity. The edges of the leather are sanded and burnished to create a smooth finish, which not only enhances aesthetics but also prevents moisture absorption.

Illustrative image related to custom leather holster makers

A protective coating is typically applied to safeguard against scratches and environmental damage, ensuring that the holster remains functional and visually appealing over time.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance (QA) is integral to the manufacturing process of custom leather holsters. Buyers should be aware of various international standards and industry-specific certifications that indicate a commitment to quality.

Which International Standards Are Relevant for Leather Holster Manufacturing?

ISO 9001 is a widely recognized quality management standard that outlines criteria for a quality management system. Manufacturers certified under ISO 9001 demonstrate a commitment to consistent quality and customer satisfaction.

Illustrative image related to custom leather holster makers

In addition to ISO standards, B2B buyers should also look for compliance with specific industry standards such as CE marking for products sold in Europe, which indicates that the product meets EU safety, health, and environmental requirements.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are essential for ensuring that each holster meets the required standards. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials, such as leather and hardware, upon arrival to ensure they meet specified quality criteria.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor compliance with design specifications and quality standards.

-

Final Quality Control (FQC): Before shipment, the finished products undergo a thorough inspection to ensure they meet all quality and safety standards.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. Here are several methods to consider:

What Audit Processes Are Effective for Ensuring Quality?

Conducting on-site audits can provide invaluable insights into a supplier’s manufacturing processes and quality control practices. During these audits, buyers can evaluate the supplier’s adherence to quality standards, the condition of their facilities, and the qualifications of their staff.

Additionally, requesting documentation of past audits and certifications can help assess a supplier’s reliability and commitment to quality.

How Can Third-Party Inspections Ensure Compliance with Quality Standards?

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. These organizations can conduct random inspections during various stages of production and provide detailed reports on compliance with international standards.

What Are the Common Testing Methods for Quality Assurance in Leather Holsters?

Testing methods play a crucial role in confirming the durability and functionality of leather holsters. Common testing methods include:

Illustrative image related to custom leather holster makers

-

Tensile Strength Tests: These assess the strength of the leather and stitching to ensure it can withstand pulling and stress without tearing.

-

Water Resistance Tests: To evaluate how well the holster performs in wet conditions, manufacturers may test the leather’s resistance to moisture.

-

Wear and Tear Tests: Simulating everyday use helps to determine how the holster will perform over time and under various conditions.

How Do Quality Control Nuances Affect International B2B Buyers?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control that may affect their purchasing decisions.

What Should Buyers Consider Regarding Regional Standards?

Different regions may have varying regulations and standards for leather products. Buyers should familiarize themselves with local requirements and ensure that their suppliers are compliant. This may involve additional certifications or adjustments in manufacturing processes to meet regional demands.

How Can Buyers Mitigate Risks Related to Quality Control?

To mitigate risks associated with quality control, buyers should consider establishing long-term relationships with trusted suppliers. Regular communication and ongoing quality assessments can foster transparency and reliability in the supply chain, ultimately leading to better product outcomes.

Illustrative image related to custom leather holster makers

In conclusion, understanding the manufacturing processes and quality assurance practices of custom leather holster makers is essential for B2B buyers. By focusing on key stages of production and relevant quality control measures, buyers can make informed decisions that align with their business needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather holster makers’

Introduction

This practical sourcing guide serves as a checklist for B2B buyers looking to procure custom leather holster makers. By following these steps, you can ensure that you partner with suppliers who meet your quality standards and can fulfill your specific needs. This guide will help you navigate the complexities of sourcing in the custom leather industry, ensuring a successful collaboration.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the custom leather holsters you need. This includes dimensions, types of leather, color preferences, and any specific design features. Establishing these parameters will guide your search and help potential suppliers understand your requirements.

Illustrative image related to custom leather holster makers

- Consider the intended use: Are the holsters for everyday carry, competitive shooting, or tactical purposes?

- Identify material quality: Specify the grade of leather required, as this affects durability and aesthetics.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential leather holster makers. Look for companies with a solid reputation in the industry, particularly those that specialize in custom solutions.

- Utilize online platforms: Explore B2B marketplaces and industry-specific forums.

- Check reviews and testimonials: Customer feedback can provide insight into product quality and supplier reliability.

Step 3: Evaluate Supplier Capabilities

Before committing to any supplier, assess their production capabilities and quality control processes. Ensure they can produce the volume and quality you require.

- Request samples: Examine the craftsmanship and materials used in their previous work.

- Inquire about lead times: Understand their production timelines to align with your project schedule.

Step 4: Verify Compliance and Certifications

Ensure that your chosen suppliers comply with relevant industry standards and hold necessary certifications. This can include quality management systems or environmental certifications.

- Ask for documentation: Request proof of certifications and compliance with regulations, especially if sourcing from different regions.

- Check for ethical practices: Verify that the supplier adheres to ethical sourcing standards, particularly concerning animal welfare.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms early in the process. Understanding costs upfront can prevent misunderstandings later.

Illustrative image related to custom leather holster makers

- Compare pricing models: Evaluate whether prices are per unit, bulk, or based on custom features.

- Negotiate payment terms: Discuss deposits, payment schedules, and any warranties or guarantees offered.

Step 6: Establish Communication Channels

Effective communication is vital for a successful partnership. Establish clear lines of communication with your chosen supplier to facilitate collaboration.

- Set expectations for updates: Agree on how often you will receive progress reports and updates on production.

- Utilize multiple channels: Use emails, video calls, and messaging apps to maintain ongoing discussions.

Step 7: Finalize the Contract and Terms

Once you have selected a supplier, formalize the agreement with a detailed contract. This should outline all terms, including delivery schedules, payment terms, and quality expectations.

- Include penalties for non-compliance: Ensure that there are clauses that protect your interests in case of delays or quality issues.

- Review all terms carefully: Make sure both parties understand and agree to the contract before proceeding.

By following this checklist, you can confidently source custom leather holster makers that align with your business objectives and quality standards.

Comprehensive Cost and Pricing Analysis for custom leather holster makers Sourcing

What Are the Key Cost Components in Custom Leather Holster Manufacturing?

When sourcing custom leather holsters, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

Illustrative image related to custom leather holster makers

-

Materials: The quality of leather significantly influences the overall cost. Premium American leather, known for its durability and aesthetics, typically commands a higher price. Additionally, hardware components such as buckles and fasteners can vary in cost depending on their source and quality.

-

Labor: Skilled artisans are required for the meticulous craftsmanship involved in making custom holsters. Labor costs can vary based on the region and the level of expertise required. In countries with higher labor costs, such as Germany, expect to pay more for skilled craftsmanship.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs, but they still play a significant role in the final pricing.

-

Tooling: Custom tooling for specific designs or unique features adds to the initial investment. This can be a substantial cost for low-volume orders but becomes more manageable with larger runs.

-

Quality Control (QC): Ensuring that each holster meets quality standards incurs additional costs. Rigorous QC processes are critical, especially for international buyers who may have specific certification requirements.

-

Logistics: Shipping costs can vary widely based on the destination and chosen Incoterms. These terms dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect overall costs.

-

Margin: Manufacturers typically apply a markup to cover overhead and profit. This margin can vary depending on the manufacturer’s reputation, the exclusivity of the design, and market demand.

How Do Pricing Influencers Impact Custom Leather Holster Costs?

Several factors can influence the pricing of custom leather holsters:

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing. Larger orders usually result in lower per-unit costs due to economies of scale. Conversely, small orders can incur higher prices due to the fixed costs of production.

-

Specifications/Customization: Customization options, including size, color, and additional features, can increase costs. The more complex the design, the higher the labor and material costs.

-

Material Quality/Certifications: Higher-quality materials and certifications (such as eco-friendly or sustainable sourcing) can elevate prices. Buyers should assess whether these features align with their target market and brand positioning.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers with a proven track record may charge premium prices for their expertise and reliability.

-

Incoterms: Understanding the implications of Incoterms is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost, impacting overall pricing strategies.

What Tips Can Help Buyers Optimize Costs When Sourcing Custom Leather Holsters?

When navigating the sourcing landscape, consider the following tips for effective negotiation and cost management:

-

Negotiate Wisely: Building a relationship with suppliers can lead to better pricing terms. Be prepared to discuss volume commitments or longer-term contracts in exchange for favorable rates.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the TCO, which includes shipping, potential tariffs, and future maintenance costs. This broader perspective can help identify the most cost-effective options.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, local regulations, and import duties that can affect pricing. Additionally, ensure that the supplier can meet specific legal and compliance requirements for your region.

-

Seek Flexible Terms: If possible, negotiate for flexible payment terms or installment options to manage cash flow better, especially for larger orders.

-

Request Samples: Before committing to a large order, request samples to assess quality and craftsmanship. This will help avoid costly mistakes and ensure that the product meets your expectations.

By understanding the cost components, pricing influencers, and employing strategic negotiation tactics, B2B buyers can effectively source high-quality custom leather holsters that meet their specific needs while managing costs efficiently.

Alternatives Analysis: Comparing custom leather holster makers With Other Solutions

Understanding Alternatives to Custom Leather Holster Makers

When considering the best way to procure holsters for firearms, B2B buyers have various options beyond custom leather holster makers. Each alternative presents unique advantages and drawbacks, impacting factors such as performance, cost, and usability. This analysis compares custom leather holster makers with two viable alternatives: Synthetic Holster Manufacturers and Kydex Holster Producers.

Illustrative image related to custom leather holster makers

Comparison Table

| Comparison Aspect | Custom Leather Holster Makers | Synthetic Holster Manufacturers | Kydex Holster Producers |

|---|---|---|---|

| Performance | High durability and comfort; tailored fit for specific firearms | Moderate durability; may lack custom fit | High durability; retains shape well |

| Cost | Typically higher ($130 – $700) for premium craftsmanship | Moderate cost ($50 – $150) | Affordable ($30 – $120) |

| Ease of Implementation | Longer lead times due to customization | Quick turnaround; mass-produced | Fast production; limited customization options |

| Maintenance | Requires regular conditioning and care | Low maintenance; usually water-resistant | Minimal maintenance; easily cleaned |

| Best Use Case | Ideal for collectors and those valuing aesthetics and tradition | Suitable for everyday carry and budget-conscious buyers | Great for tactical applications and law enforcement |

Detailed Breakdown of Alternatives

Synthetic Holster Manufacturers

Synthetic holster manufacturers produce holsters using materials like nylon or polymer, which offer a balance between cost and functionality. The primary advantage of synthetic holsters is their affordability and lightweight nature, making them suitable for everyday carry. However, they may lack the aesthetic appeal and customization options that leather holsters provide. Additionally, synthetic options may not offer the same level of comfort and fit as custom leather, especially for those who carry their firearm regularly.

Kydex Holster Producers

Kydex is a thermoplastic material known for its durability and ability to retain its shape under stress. Kydex holsters are often molded specifically for individual firearm models, providing a secure fit and easy re-holstering. These holsters are especially popular among law enforcement and tactical users due to their lightweight and rugged design. However, Kydex holsters may not offer the same level of comfort as leather options, particularly during extended wear, and can lack the classic aesthetic that some users prefer.

Conclusion: Choosing the Right Holster for Your Needs

In selecting the right holster solution, B2B buyers must evaluate their specific needs against the advantages and disadvantages of each option. Custom leather holsters are ideal for those seeking high-quality craftsmanship, aesthetic appeal, and a personalized fit, making them suitable for collectors and enthusiasts. In contrast, synthetic and Kydex alternatives may be more appropriate for budget-conscious buyers or tactical applications requiring durability and ease of maintenance. Ultimately, understanding the unique characteristics of each solution allows buyers to make informed decisions that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for custom leather holster makers

What Are the Key Technical Properties Important for Custom Leather Holster Makers?

Understanding the essential technical properties of custom leather holsters is crucial for B2B buyers. These properties not only determine the quality and functionality of the holsters but also impact customer satisfaction and long-term durability.

1. Material Grade

The grade of leather used in holster manufacturing is paramount. High-quality leather, such as full-grain or top-grain, ensures durability, aesthetic appeal, and comfort. Full-grain leather, for instance, retains the natural grain and texture, providing a robust finish that ages beautifully. B2B buyers should prioritize suppliers that use premium leather, as it reflects the craftsmanship and longevity of the product.

Illustrative image related to custom leather holster makers

2. Stitching Technique

The stitching method employed in holster construction significantly influences its strength and reliability. Double stitching, for example, is commonly used to reinforce critical stress points, preventing wear and tear over time. This technique is especially important for holsters designed for heavy use, as it enhances durability and ensures that the holster maintains its shape and function under various conditions.

3. Tolerance and Fit

Precise tolerances in design and manufacturing are vital for ensuring that each holster fits the intended firearm perfectly. A well-fitted holster allows for secure retention while enabling quick access. B2B buyers should verify that manufacturers utilize advanced measurement techniques and tools to achieve these tolerances, ensuring that the final product meets exact specifications.

4. Finish and Treatment

The finish applied to the leather affects both aesthetics and functionality. Various treatments can enhance water resistance, reduce friction, and prevent staining. Understanding the types of finishes used, such as oil or wax-based, can help buyers assess the suitability of a holster for specific environments or usage scenarios.

Illustrative image related to custom leather holster makers

5. Weight-Bearing Capacity

Holsters need to support the weight of the firearm securely. This property is particularly crucial for holsters designed for larger firearms or additional accessories. Buyers should inquire about the weight-bearing specifications to ensure the holster can accommodate their products without compromising safety or comfort.

What Are Common Trade Terms Used in the Custom Leather Holster Industry?

Familiarity with industry-specific terminology can facilitate smoother transactions and clearer communication between buyers and manufacturers.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of custom leather holsters, B2B buyers may engage with OEMs to create bespoke solutions that meet specific market demands. Understanding OEM relationships can help buyers leverage quality and innovation.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to produce or sell. This term is critical for B2B buyers as it directly impacts inventory management and cost efficiency. Buyers should negotiate MOQs that align with their business models to ensure they can meet market demands without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. This tool is essential for B2B buyers seeking competitive pricing and evaluating multiple suppliers. Crafting a detailed RFQ can lead to better responses and more favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is vital for B2B transactions, especially in international markets, as they clarify who is responsible for costs and risks during transit.

5. Customization Options

This term refers to the various ways a buyer can personalize a product to meet specific needs, such as size, color, or additional features. Knowing the customization options available can enhance buyer satisfaction and ensure that the product aligns with their brand or operational requirements.

By grasping these technical properties and trade terms, B2B buyers in the custom leather holster market can make informed decisions that bolster their business objectives and enhance their product offerings.

Navigating Market Dynamics and Sourcing Trends in the custom leather holster makers Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Holster Makers Sector?

The global custom leather holster market is experiencing significant growth, driven by increasing consumer demand for personalized firearm accessories and a surge in outdoor activities, including hunting and shooting sports. Key markets in Africa, South America, the Middle East, and Europe are witnessing a rise in gun ownership, which directly correlates with the demand for high-quality, durable holsters. Notably, European countries like Germany have stringent regulations that encourage gun owners to invest in reliable and well-crafted holsters, enhancing safety and compliance.

Emerging B2B technology trends, such as e-commerce platforms and digital customization tools, are transforming the sourcing landscape. International buyers are increasingly leveraging online marketplaces to connect with manufacturers, allowing for direct communication and customization options. These platforms also facilitate access to a broader range of products, enabling buyers from diverse regions to find specific styles and materials that meet their market preferences. Additionally, the use of augmented reality (AR) in product visualization is gaining traction, helping buyers make informed decisions before purchasing.

How Important Is Sustainability and Ethical Sourcing in the Custom Leather Holster Makers Sector?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the custom leather holster sector. The environmental impact of leather production, including deforestation, water usage, and chemical waste, necessitates a shift toward more sustainable practices. Buyers are increasingly seeking suppliers that prioritize eco-friendly materials and processes, such as vegetable-tanned leather, which minimizes the use of harmful chemicals.

Furthermore, ethical supply chains are essential for fostering transparency and accountability. Many businesses are now adopting ‘green’ certifications and sustainability standards to appeal to environmentally conscious consumers. Buyers should look for manufacturers that are committed to ethical practices, such as fair labor conditions and sourcing from responsible suppliers. This not only enhances brand reputation but also aligns with the growing consumer demand for sustainable products.

Illustrative image related to custom leather holster makers

What Is the Brief Evolution and History of Custom Leather Holster Making?

The craft of leather holster making has its roots in traditional artisan practices, with origins dating back centuries. Initially, holsters were made for practical purposes, primarily for military and law enforcement use. Over time, as firearms became more accessible to the general public, the demand for personalized and aesthetically pleasing holsters grew.

The mid-20th century marked a significant turning point, particularly in the United States, where custom leather holster makers began to emerge, emphasizing craftsmanship and quality. Companies like Kirkpatrick Leather, established in 1950, have set the standard for bespoke leather goods, blending traditional techniques with modern design. This evolution reflects a broader trend in the B2B landscape, where buyers are increasingly valuing craftsmanship, customization, and sustainability in their sourcing decisions.

In summary, the custom leather holster market is evolving in response to changing consumer preferences and technological advancements. By understanding market dynamics, prioritizing sustainability, and appreciating the craft’s rich history, international B2B buyers can make informed decisions that align with their business goals and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather holster makers

-

How do I ensure the quality of custom leather holsters from a supplier?

To ensure the quality of custom leather holsters, start by requesting samples of their products. Evaluate the craftsmanship, materials, and durability. Check for reviews or testimonials from other B2B clients. It’s also wise to visit the supplier’s facility if possible, or conduct a virtual tour to assess their production process. Finally, inquire about their quality assurance protocols, such as materials sourcing and stitching techniques, to confirm they meet industry standards. -

What are the key customization options available for leather holsters?

Custom leather holsters can be tailored in various ways, including size, shape, and color. Additionally, you can specify features such as retention systems, belt attachments, and decorative elements like embossing or engraving. Discussing your specific needs with the manufacturer will help you identify available options. Ensure that the supplier has experience with the firearm models you need holsters for, as this can impact fit and functionality. -

What is the minimum order quantity (MOQ) for custom leather holsters?

The MOQ for custom leather holsters varies by manufacturer, typically ranging from 10 to 100 units. Factors influencing MOQ include production capacity, material availability, and customization complexity. It’s advisable to discuss your needs with potential suppliers to negotiate terms that work for both parties. Be aware that larger orders may lead to better pricing and faster turnaround times. -

What payment terms should I expect when ordering custom leather holsters?

Payment terms can vary significantly among suppliers. Common practices include upfront payments, deposits (typically 30-50%), and balance payments upon delivery. Some manufacturers may offer credit terms based on your business relationship and order size. Clarifying these terms before placing an order is crucial to avoid misunderstandings and ensure a smooth transaction. -

How can I vet a supplier of custom leather holsters effectively?

Vetting a supplier involves several steps. Start by researching their reputation through online reviews and industry references. Requesting a portfolio of previous work can provide insight into their capabilities. It’s also beneficial to check their certifications and compliance with international trade regulations. If possible, arrange a meeting to discuss their production process, lead times, and commitment to quality. -

What logistics considerations should I be aware of when importing leather holsters?

When importing leather holsters, consider shipping methods, customs duties, and import regulations specific to your region. Choose a reliable logistics partner experienced in handling international trade. Ensure that your supplier can provide all necessary documentation, such as commercial invoices and certificates of origin. Planning for lead times and potential delays due to customs is essential for timely delivery. -

What are the common quality assurance practices for custom leather holsters?

Quality assurance in the production of custom leather holsters typically includes material inspections, in-process checks, and final product evaluations. Suppliers often follow specific guidelines to ensure consistency in craftsmanship, such as standardized stitching techniques and material grading. Inquire about the manufacturer’s QA processes and whether they conduct any third-party inspections to validate their products. -

How do I handle issues with my order of custom leather holsters?

If you encounter issues with your order, promptly contact your supplier to discuss the problem. Document any defects or discrepancies with photos and detailed descriptions. Most reputable manufacturers will have a returns or corrections policy in place. Open communication is key; a good supplier will work with you to resolve issues efficiently, whether through replacements, repairs, or refunds.

Top 7 Custom Leather Holster Makers Manufacturers & Suppliers List

1. Galco Gunleather – Leather Holsters & Accessories

Domain: galcogunleather.com

Registered: 1998 (27 years)

Introduction: Galco Gunleather offers a variety of leather gun holsters, belts, slings, and accessories. Key product categories include:

– Holsters: Types include shoulder/chest holster systems, shoulder holster components, ankle holsters, and more.

– Ammo/Accessory Carriers: Various carriers designed to match holsters.

– Belts: High-quality leather belts for gun carry.

– Outdoor Gear: Tactical and outdoor …

2. Diamond D Custom Leather – Handcrafted Alaskan Holsters

Domain: diamonddcustomleather.com

Registered: 2010 (15 years)

Introduction: Handcrafted Alaskan Leather Holsters, including: Guides Choice® Chest Holster, Alaska Hunter Hip Holster, Leather Gun Holster-HH12, Pancake Holster, Alaska EDC Leather Belt Slide, Alaska Urban Defender Inside the Waistband Holster, Leather Shoulder Holster-SSR, Henry Mare’s Leg & Axe Scabbard. Leather Belts: “Alaska Tough” Leather Belt, Alaskan Souvenir Leather Belts. Holster Accessories: Alaska H…

3. Mernickle – Custom Handmade Leather Holsters

Domain: mernickleholsters.com

Registered: 1999 (26 years)

Introduction: Custom Handmade in the USA Leather Holsters for Everyday Carry. Categories include: Everyday Carry Holsters (Outside the Waist Band, Inside the Waist Band, Cross Draw), Law Enforcement/Duty Holsters, New Shoulder/Chest Holsters, Field Hunting Holsters, Cowboy Holsters (Cowboy/Western Holsters, Cowboy Fast Draw Holsters), Classic Hollywood/Movie Inspired Holsters, Wild Bunch Holsters, The Walking D…

4. Tucker Gun Leather – High-Quality Concealed Carry Holsters and Belts

Domain: tuckergunleather.com

Registered: 2001 (24 years)

Introduction: Tucker Gun Leather offers a variety of high-quality, durable, and aesthetically pleasing concealed carry leather holsters and gun belts. Key product features include:

– Types of Holsters: Inside the waistband (IWB), Outside the waistband (OWB), Appendix, Deep Carry, Revolver, Pocket, Chest, Shoulder, Ankle, and Field Holsters.

– Customization: Options for colors, decorative stamping designs, and…

5. Mitch Rosen – Premium Leather Gun Holsters

Domain: mitchrosen.com

Registered: 1997 (28 years)

Introduction: Premium IWB & OWB Leather Gun Holsters, Handmade in the USA, Express Line and Full Detail Line available, various holster types including OWB, IWB, Shoulder, Pocket, and Ankle Holsters. Products designed for multiple gun models including Glock, Sig Sauer, 1911 Variants, Smith & Wesson, Beretta, Springfield, and Ruger. Express Line offers faster turnaround with a 1½” belt slot. Delivery time for Fu…

6. Paradise Valley Leather – Custom Holsters

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Paradise Valley Leather – Custom Holsters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Bulman Gunleather – Custom Leather Holsters

Domain: bulman-gunleather.com

Registered: 2020 (5 years)

Introduction: Bulman Gunleather offers a range of custom leather holsters and accessories, including: IWB (Inside-The-Waistband) Holsters, OWB (Outside-The-Waistband) Holsters, Kydex Holsters, Shoulder Holsters, Ankle Holsters, and Pocket Holsters. They also provide accessories such as magazine and light carriers, apparel, and gun belts. Key products include the Professional Dual Clip ($145.00), DJ Special ($17…

Strategic Sourcing Conclusion and Outlook for custom leather holster makers

In the competitive landscape of custom leather holster manufacturing, strategic sourcing emerges as a vital component for success. B2B buyers should prioritize partnerships with reputable suppliers who emphasize quality craftsmanship, sustainable materials, and innovative design. By leveraging these partnerships, businesses can ensure they are offering products that not only meet but exceed customer expectations, enhancing brand loyalty and market position.

As international markets expand, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for high-quality custom leather holsters is on the rise. Buyers should focus on suppliers that combine traditional techniques with modern functionality, ensuring their products cater to diverse consumer preferences and regulatory requirements.

Looking ahead, the integration of advanced manufacturing technologies and sustainable practices will shape the future of this industry. B2B buyers are encouraged to seek out suppliers who are committed to innovation and ethical sourcing. By doing so, they can position themselves as leaders in the market while delivering exceptional value to their customers. Now is the time to invest in strategic sourcing relationships that will drive growth and success in the custom leather holster sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.