Introduction: Navigating the Global Market for custom leather boots

In the ever-evolving global market for custom leather boots, sourcing high-quality, comfortable footwear that meets specific industry demands can be a daunting challenge for B2B buyers. With an increasing number of suppliers offering a wide array of custom options, it’s crucial to navigate this landscape effectively to ensure both quality and value. This comprehensive guide delves into various types of custom leather boots, their applications across different sectors, and the intricacies of supplier vetting.

From rugged work boots designed for demanding environments to stylish options suitable for corporate settings, the guide covers essential factors such as material selection, craftsmanship, and customization capabilities. Additionally, we address cost considerations and best practices for negotiating with manufacturers, equipping buyers with the knowledge to make informed purchasing decisions.

This resource is tailored for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, including key markets like Germany and Vietnam. By empowering buyers with actionable insights and strategic recommendations, this guide aims to streamline the procurement process, ensuring that businesses can confidently invest in custom leather boots that enhance their operational efficiency and brand image.

Table Of Contents

- Top 8 Custom Leather Boots Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather boots

- Understanding custom leather boots Types and Variations

- Key Industrial Applications of custom leather boots

- 3 Common User Pain Points for ‘custom leather boots’ & Their Solutions

- Strategic Material Selection Guide for custom leather boots

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather boots

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather boots’

- Comprehensive Cost and Pricing Analysis for custom leather boots Sourcing

- Alternatives Analysis: Comparing custom leather boots With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather boots

- Navigating Market Dynamics and Sourcing Trends in the custom leather boots Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather boots

- Strategic Sourcing Conclusion and Outlook for custom leather boots

- Important Disclaimer & Terms of Use

Understanding custom leather boots Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Work Boots | Heavy-duty construction, steel toe options, slip-resistant soles | Construction, manufacturing, outdoor labor | Pros: High durability, safety features. Cons: Heavier than casual options. |

| Tactical Boots | Designed for military and law enforcement, reinforced support | Security, military, outdoor operations | Pros: Enhanced support, rugged design. Cons: Can be expensive, limited styles. |

| Western Boots | Characteristic pointed toe, decorative stitching, and heel | Ranching, rodeos, country lifestyle | Pros: Unique style, durable leather. Cons: May not suit all professional settings. |

| Motorcycle Boots | Ankle protection, oil-resistant soles, reinforced toe caps | Motorcycling, outdoor activities | Pros: Safety features, stylish. Cons: Bulkier, may lack breathability. |

| Dress Boots | Sleek design, polished finish, often made from finer leather | Corporate, formal events, professional settings | Pros: Stylish, versatile for formal wear. Cons: Less durable for rough use. |

What are the Characteristics and Suitability of Work Boots?

Work boots are engineered for heavy-duty use, featuring robust construction, steel toe options, and slip-resistant soles. They are ideal for industries like construction and manufacturing, where foot protection and durability are paramount. When purchasing, B2B buyers should consider the specific safety standards required for their industry, the comfort level for prolonged use, and the boot’s resistance to various environmental factors. Ensuring a good fit is crucial, as improper sizing can lead to discomfort and decreased productivity.

How Do Tactical Boots Stand Out in Professional Settings?

Tactical boots are designed for military and law enforcement applications, offering reinforced support and rugged durability. These boots often include features such as waterproofing and enhanced ankle support, making them suitable for outdoor operations and security roles. B2B buyers should prioritize the specific needs of their personnel, such as the terrain they will encounter and the level of protection required. Additionally, the weight of the boots and breathability are essential considerations for comfort during extended wear.

Why Choose Western Boots for B2B Applications?

Western boots are recognized for their distinctive pointed toes and decorative stitching, often constructed from high-quality leather. They are primarily used in ranching, rodeos, and country-themed events, appealing to businesses in the agricultural and entertainment sectors. When selecting western boots, buyers should assess the style preferences of their target audience, the boot’s durability, and the ease of maintenance. While they provide a unique aesthetic, western boots may not be suitable for all business environments.

What Makes Motorcycle Boots a Smart Investment?

Motorcycle boots offer essential ankle protection and are typically designed with oil-resistant soles and reinforced toe caps. They cater to the needs of motorcyclists and outdoor enthusiasts, making them a practical choice for businesses involved in recreational activities. Buyers should evaluate the safety features, such as impact resistance and waterproofing, along with the boots’ comfort and flexibility. While they provide significant protection, motorcycle boots can be bulkier, which may not appeal to all consumers.

How Do Dress Boots Fit into Professional Environments?

Dress boots are characterized by their sleek design and polished finish, often made from finer leather. They are suitable for corporate settings, formal events, and professional environments where style is essential. When purchasing dress boots, B2B buyers should focus on the quality of the materials, the craftsmanship, and the versatility of the design for various occasions. While they offer a sophisticated look, dress boots may not provide the same level of durability as more rugged options, making them less suitable for demanding work environments.

Key Industrial Applications of custom leather boots

| Industry/Sector | Specific Application of custom leather boots | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Mining | Heavy-duty work boots for labor-intensive tasks | Enhanced safety, durability, and comfort for workers | Custom fit, material selection (e.g., waterproof), and compliance with safety standards |

| Agriculture & Farming | Custom boots for fieldwork and livestock handling | Protection against harsh conditions and increased mobility | Breathable materials, easy maintenance, and custom sizing options |

| Military & Defense | Tactical boots for personnel in challenging terrains | Improved performance and protection in diverse environments | Durability, lightweight design, and customization for specific missions |

| Firefighting & Rescue | Specialized boots for firefighters and rescue teams | Enhanced safety features, heat resistance, and comfort | Compliance with fire safety regulations and custom fitting for prolonged use |

| Hospitality & Retail | Custom boots for staff in high-traffic environments | Improved employee comfort and brand representation | Stylish designs, ease of cleaning, and custom branding options |

How Are Custom Leather Boots Utilized in the Construction & Mining Industries?

In the construction and mining sectors, custom leather boots are essential for ensuring worker safety and comfort during labor-intensive tasks. These boots are designed to withstand harsh conditions while providing support to prevent injuries. Buyers in this industry often require boots that meet specific safety standards, such as steel-toe protection and slip-resistant soles. Sourcing considerations include selecting durable materials that offer waterproof and breathable features, ensuring the boots can endure extreme environments while providing comfort throughout long shifts.

Illustrative image related to custom leather boots

What Role Do Custom Leather Boots Play in Agriculture & Farming?

Custom leather boots are vital for professionals in agriculture and farming, where workers face varying terrains and weather conditions. These boots provide protection against mud, water, and sharp objects, enabling farmers to perform their duties effectively. Buyers often seek breathable materials that can handle moisture while also being easy to clean. Sourcing considerations also include the need for custom sizing to accommodate different foot shapes, ensuring comfort and reducing fatigue during long hours spent in the field.

Why Are Custom Leather Boots Important for Military & Defense Applications?

In the military and defense sectors, custom leather boots are tailored for personnel operating in challenging terrains. These boots are designed to offer superior support, traction, and protection, essential for various missions. Buyers typically prioritize lightweight designs that do not compromise on durability. Key sourcing considerations include the ability to customize features such as ankle support, waterproofing, and insulation, ensuring boots meet the rigorous demands of diverse operational environments.

How Do Custom Leather Boots Benefit Firefighting & Rescue Teams?

Firefighting and rescue teams rely on specialized custom leather boots that provide enhanced safety features, such as heat resistance and slip protection. These boots are crucial for ensuring the safety of personnel in high-risk situations. Buyers in this sector need to ensure compliance with fire safety regulations while also considering comfort for prolonged wear. Sourcing considerations include the selection of materials that can withstand extreme temperatures and the ability to customize fit for individual needs, ensuring boots perform effectively in critical moments.

What Advantages Do Custom Leather Boots Offer in Hospitality & Retail?

In the hospitality and retail industries, custom leather boots are increasingly used for staff uniforms, providing both functionality and style. These boots enhance employee comfort during long shifts while also contributing to a cohesive brand image. Buyers often look for designs that are easy to clean and maintain, as well as options for custom branding. Key sourcing considerations include ensuring the boots are not only fashionable but also durable enough to withstand daily wear in high-traffic environments, thus promoting employee satisfaction and productivity.

3 Common User Pain Points for ‘custom leather boots’ & Their Solutions

Scenario 1: Sizing and Fit Challenges in Custom Leather Boots

The Problem: One of the most significant challenges B2B buyers face when procuring custom leather boots is ensuring the right fit. Unlike off-the-shelf options, custom boots require precise measurements to cater to individual foot shapes and sizes. Buyers may encounter discomfort and dissatisfaction if the boots do not fit properly, leading to wasted investments and potential returns. This is particularly crucial for businesses in sectors like construction or outdoor work, where comfort and durability are paramount for productivity.

Illustrative image related to custom leather boots

The Solution: To mitigate sizing issues, it’s essential for buyers to work closely with manufacturers who provide comprehensive fitting guides or professional fitting services. Encourage your team to take detailed measurements, including length, width, and arch height, using standardized methods. It’s advisable to select manufacturers that offer customizable options, such as adjustable features and diverse last shapes, which can accommodate a variety of foot profiles. Additionally, request samples or prototypes before finalizing large orders to ensure the fit meets expectations, thus reducing the risk of returns or dissatisfaction.

Scenario 2: Material Quality and Durability Concerns

The Problem: Buyers often struggle with determining the quality of materials used in custom leather boots. With numerous options available, distinguishing between premium and subpar leather can be daunting. Poor-quality materials can lead to rapid deterioration, which is particularly concerning for businesses that rely on boots for heavy-duty tasks. This not only affects employee satisfaction but can also incur additional costs for replacements and repairs.

The Solution: To ensure material quality, prioritize sourcing from established manufacturers known for their craftsmanship and material integrity. Look for certifications or guarantees that validate the leather’s origin and durability. Request detailed information about the leather type, treatment processes, and any sustainability practices involved in production. Additionally, consider establishing long-term relationships with suppliers who offer transparency about their sourcing and manufacturing practices. This proactive approach will help ensure that you invest in boots that withstand the rigors of daily use, ultimately enhancing your brand’s reputation for reliability.

Scenario 3: Long Lead Times and Delivery Issues

The Problem: Custom leather boots often come with longer lead times due to the bespoke nature of their production. B2B buyers may find themselves frustrated by delays, especially when they require boots for specific projects or seasonal work. These delays can disrupt workflows and lead to financial losses, particularly in industries that depend on timely delivery of equipment and safety gear.

Illustrative image related to custom leather boots

The Solution: To combat lead time issues, it’s critical to plan ahead and communicate effectively with suppliers. Establish a clear timeline for orders and ensure that all specifications are finalized early in the process. Consider engaging with manufacturers that offer expedited services or have a proven track record of meeting deadlines. Additionally, maintaining a buffer stock of frequently ordered sizes or styles can help mitigate the impact of lead times on your operations. By implementing these strategies, you can ensure a more reliable supply chain for custom leather boots, allowing your business to operate smoothly without unnecessary interruptions.

Strategic Material Selection Guide for custom leather boots

What Are the Key Properties of Common Materials Used in Custom Leather Boots?

When selecting materials for custom leather boots, it’s essential to consider the specific properties that influence performance, durability, and comfort. Here, we analyze four common materials: full-grain leather, suede, synthetic leather, and rubber.

Full-Grain Leather: The Premium Choice for Durability

Full-grain leather is renowned for its durability and strength, making it a preferred choice for high-quality custom boots. This material retains the natural grain of the hide, providing excellent breathability and moisture resistance. Full-grain leather can withstand temperature variations and is less prone to wear and tear compared to other leather types.

Illustrative image related to custom leather boots

Pros and Cons: While full-grain leather offers exceptional durability and a luxurious appearance, it tends to be more expensive and requires careful maintenance to prevent damage from moisture and dirt. Its manufacturing complexity is higher, as it often involves extensive tanning processes.

Impact on Application: Full-grain leather is ideal for rugged environments, making it suitable for work boots and outdoor applications. However, it may not be the best choice for humid climates unless treated properly.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local leather sourcing regulations. In Europe, adherence to standards such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is crucial for environmental compliance.

Suede: A Versatile and Stylish Option

Suede, a type of leather with a napped finish, is softer and more flexible than full-grain leather. It offers a stylish aesthetic and is often used in fashion-oriented custom boots. Suede is lightweight and provides a comfortable fit, making it suitable for casual wear.

Pros and Cons: The primary advantage of suede is its softness and comfort, but it is less durable than full-grain leather and more susceptible to staining and water damage. Maintenance is critical, as suede requires special cleaning products to preserve its appearance.

Illustrative image related to custom leather boots

Impact on Application: Suede is best suited for lifestyle and casual boots rather than heavy-duty applications. It may not perform well in wet or muddy conditions, limiting its use in certain environments.

Considerations for International Buyers: Suede may not meet the durability expectations in harsher climates, such as those found in the Middle East. Buyers should evaluate local preferences for style versus functionality.

Synthetic Leather: Cost-Effective and Eco-Friendly

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is an increasingly popular choice for custom boots. It mimics the look of real leather while being more affordable and easier to maintain. Synthetic options are often lighter and can offer water resistance.

Pros and Cons: The main advantage is cost-effectiveness, along with ease of cleaning and maintenance. However, synthetic leather may lack the breathability and durability of genuine leather, leading to potential wear issues over time.

Impact on Application: Synthetic leather is suitable for casual and fashion boots but may not perform well in demanding environments. Its compatibility with various media is generally acceptable, but it may not withstand extreme conditions.

Illustrative image related to custom leather boots

Considerations for International Buyers: Buyers from Europe may prefer synthetic options that comply with environmental regulations, while those in Africa and South America might consider the lower cost as a significant advantage in budget-conscious markets.

Rubber: The Functional Choice for Soles

Rubber is primarily used for boot soles due to its excellent traction and durability. It provides a non-slip surface and is resistant to water and various chemicals, making it ideal for work environments.

Pros and Cons: Rubber soles are highly durable and provide good shock absorption, but they can be heavier than other materials. Additionally, the manufacturing process can be complex, especially when integrating rubber with leather.

Impact on Application: Rubber soles are essential for boots designed for outdoor activities, construction, or industrial use. They offer compatibility with various terrains and conditions.

Considerations for International Buyers: Buyers should ensure that rubber materials meet local safety and performance standards, such as ASTM or DIN certifications, particularly in industrial applications.

Illustrative image related to custom leather boots

Summary Table of Material Selection for Custom Leather Boots

| Material | Typical Use Case for custom leather boots | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Work boots, outdoor boots | Exceptional durability and breathability | Higher cost and maintenance required | High |

| Suede | Casual and fashion boots | Softness and comfort | Less durable and susceptible to stains | Medium |

| Synthetic Leather | Casual and fashion boots | Cost-effective and easy to maintain | Lacks breathability and durability | Low |

| Rubber | Industrial and outdoor boots | Excellent traction and water resistance | Heavier and complex manufacturing | Medium |

This strategic material selection guide provides B2B buyers with valuable insights into the properties and applications of common materials used in custom leather boots, facilitating informed purchasing decisions.

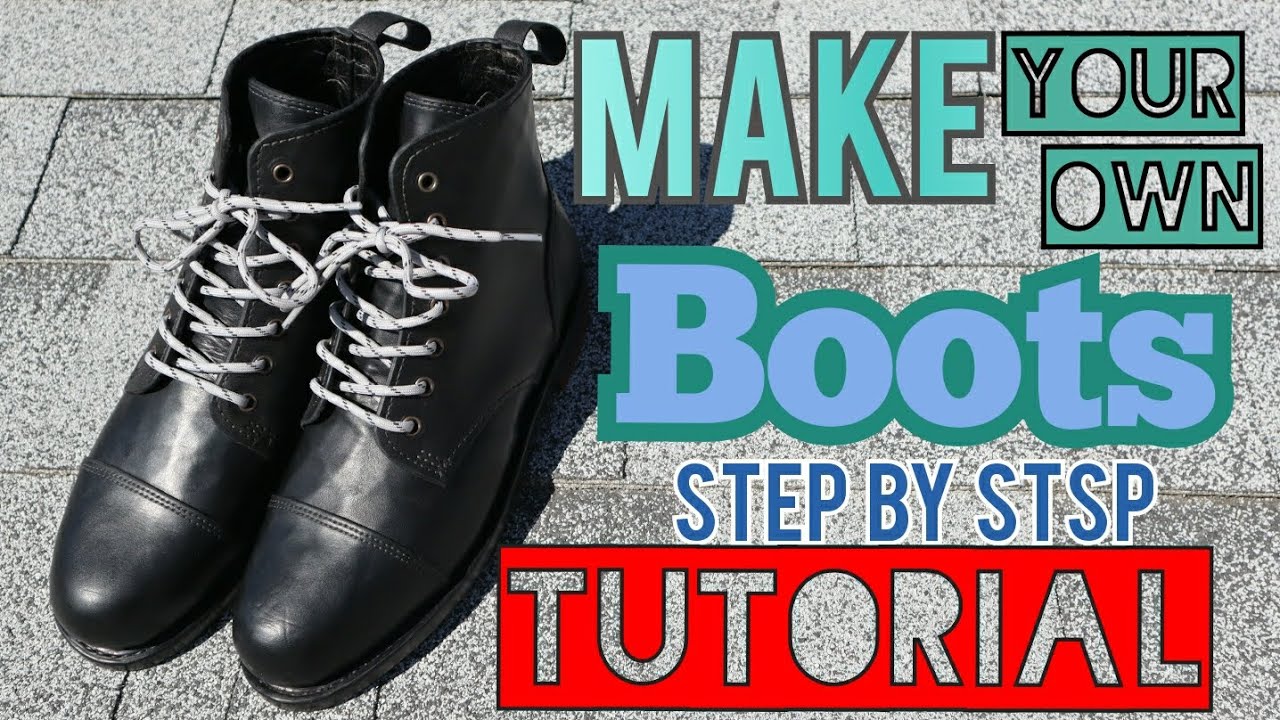

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather boots

What Are the Main Stages of Manufacturing Custom Leather Boots?

The manufacturing of custom leather boots is a meticulous process that involves several key stages: material preparation, forming, assembly, and finishing. Each of these stages is critical in ensuring the final product meets the specific demands of B2B buyers.

Material Preparation: Selecting Quality Leather and Components

The first step in creating custom leather boots involves sourcing high-quality leather and other materials. Various types of leather, such as full-grain, top-grain, and suede, are chosen based on the intended use of the boots. For example, full-grain leather is often selected for work boots due to its durability, while softer leathers may be preferred for fashion boots.

In addition to leather, components such as eyelets, laces, soles, and insoles are also selected. Each material must undergo rigorous inspection to ensure it meets quality standards. Buyers should look for suppliers who provide detailed information on the sourcing and quality of their materials.

Forming: Crafting the Boot Shape

Once the materials are prepared, the next stage is forming. This process involves cutting the leather into patterns that will form the upper part of the boot. Advanced cutting techniques, including laser cutting or die-cutting, are often employed for precision.

The leather pieces are then shaped over a last—a mold that represents the desired foot shape and size. This shaping can be accomplished using heat and moisture to ensure a snug fit. For custom orders, buyers should confirm that the manufacturer can accommodate unique sizing and styling requirements.

Assembly: Stitching and Constructing the Boot

The assembly stage is where the actual boot begins to take form. This involves stitching the upper parts to the sole, typically using techniques such as Goodyear welt construction or Blake stitching. Goodyear welt construction is highly regarded for its durability, allowing the boots to be resoled and extending their lifespan.

During this stage, attention to detail is paramount. The stitching must be consistent and strong, and any decorative elements should be applied with precision. Customization options, such as color choices and styles, should be discussed with the manufacturer at this point to ensure alignment with buyer expectations.

Finishing: Quality Checks and Final Touches

The final stage in manufacturing custom leather boots involves finishing. This includes applying protective coatings, polishing the leather, and conducting quality assurance checks. Finishing not only enhances the aesthetic appeal but also provides protection against wear and environmental factors.

Manufacturers often conduct a final inspection to ensure that the boots meet all specifications before shipping. Buyers should inquire about the specific finishing processes used and the type of protective treatments applied to the leather to ensure longevity.

Illustrative image related to custom leather boots

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance (QA) is a critical aspect of the manufacturing process for custom leather boots. It ensures that products meet international standards and buyer expectations.

What International and Industry-Specific Standards Should Be Considered?

For B2B buyers, understanding the relevant international and industry-specific standards is crucial. The ISO 9001 standard, which focuses on quality management systems, is a common benchmark for manufacturers. Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the intended use of the boots.

Buyers should verify that their suppliers hold these certifications and are compliant with local regulations in their respective regions, particularly if they are sourcing from international markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integral to maintaining the high standards expected in custom leather boot manufacturing. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify any deviations from quality standards early on.

-

Final Quality Control (FQC): A comprehensive assessment of the finished product ensures that it meets all design and quality specifications before delivery.

B2B buyers should ask manufacturers about their specific QA protocols and how they address any issues that may arise during production.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is essential for B2B buyers, particularly when sourcing internationally. Here are several methods to ensure that quality standards are upheld:

What Role Do Audits and Reports Play in Supplier Verification?

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should consider conducting both scheduled and surprise audits to assess compliance with quality standards.

Additionally, suppliers should provide documentation such as quality control reports, inspection checklists, and certifications. This information can help buyers understand the supplier’s commitment to quality and transparency.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further enhance quality assurance efforts. Independent inspectors can assess the manufacturing process and final products to ensure they meet agreed-upon specifications. This is particularly important for buyers in regions where they may not have the capability to conduct on-site inspections.

Illustrative image related to custom leather boots

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must navigate various nuances when it comes to quality control, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding local regulations, cultural differences, and logistical challenges is essential.

How Do Cultural Differences Impact Quality Expectations?

Cultural expectations can influence perceptions of quality and customer service. Buyers should communicate clearly with suppliers about their quality expectations and any specific requirements unique to their market.

What Logistical Challenges Should Be Considered?

Logistics can also pose challenges in ensuring quality. Shipping methods, handling during transit, and storage conditions can all affect the final product. B2B buyers should work closely with suppliers to ensure that quality is maintained throughout the supply chain, from manufacturing to delivery.

By understanding the manufacturing processes and quality assurance measures for custom leather boots, B2B buyers can make informed decisions that align with their business needs and customer expectations. This comprehensive approach not only helps in sourcing high-quality products but also builds long-term relationships with reliable suppliers.

Illustrative image related to custom leather boots

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather boots’

In the competitive landscape of custom leather boot procurement, having a structured sourcing strategy is essential for B2B buyers. This guide provides a step-by-step checklist to streamline your purchasing process and ensure you acquire high-quality, tailored footwear that meets your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear specifications is the first step in sourcing custom leather boots. Consider factors such as material type (e.g., full-grain leather), boot style (e.g., work, tactical, lifestyle), and customization options (e.g., color, size, heel type). This clarity will help you communicate effectively with suppliers and ensure the final product aligns with your expectations.

Step 2: Conduct Market Research on Suppliers

Before approaching suppliers, conduct thorough market research to identify potential partners. Look for manufacturers known for their craftsmanship, reliability, and reputation in the custom leather sector. Utilize online platforms, trade shows, and industry publications to gather information about suppliers who have experience serving businesses in your region.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to their production capabilities, lead times, and quality assurance processes to ensure they can meet your demands.

Illustrative image related to custom leather boots

- Check Certifications: Verify if the supplier holds relevant certifications (e.g., ISO, ethical sourcing) that validate their commitment to quality and sustainability.

- Assess Production Capacity: Ensure the supplier can scale production according to your needs, especially for bulk orders.

Step 4: Request Samples

Requesting samples is an essential step in evaluating the quality of the boots. This allows you to assess the materials, craftsmanship, and overall fit before making a larger commitment. Ensure the samples reflect the specifications you outlined in Step 1.

- Test Fit and Comfort: If possible, have team members try on the samples to provide feedback on comfort and fit.

- Review Material Quality: Examine the leather quality, stitching, and sole construction to gauge durability.

Step 5: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to finalize terms and conditions. Discuss pricing, payment terms, and delivery schedules to avoid misunderstandings later. Establishing a clear contract that outlines these details is crucial for safeguarding your interests.

- Consider Minimum Order Quantities: Be aware of any minimum order requirements and how they impact your budget.

- Clarify Warranty and Return Policies: Ensure you understand the warranty terms and the process for handling defective products.

Step 6: Monitor Production and Quality Control

After placing your order, maintain open lines of communication with the supplier throughout the production process. Request regular updates on progress and any potential delays. Implement a quality control process to ensure that the final products meet your specifications upon delivery.

- Schedule Inspections: If feasible, arrange for on-site inspections during the production phase to address any issues proactively.

- Establish a Feedback Loop: Create a system for providing feedback on the products received to foster a long-term relationship with the supplier.

Step 7: Plan for Ongoing Maintenance and Support

Finally, consider the long-term care and maintenance of your custom leather boots. Discuss with the supplier any recommended care products and services they offer. Establishing a relationship for future orders and maintenance will ensure the longevity of your investment.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing custom leather boots, ensuring a successful procurement process that meets their specific needs and enhances their operational efficiency.

Comprehensive Cost and Pricing Analysis for custom leather boots Sourcing

What are the Key Cost Components in Custom Leather Boot Production?

When sourcing custom leather boots, understanding the cost structure is vital for making informed purchasing decisions. The primary components include:

-

Materials: High-quality leather remains the most significant cost driver. The type of leather (full grain, top grain, or exotic leathers) can substantially impact the price. Additional materials such as linings, insoles, and soles also contribute to overall costs.

-

Labor: Custom boots often require skilled labor for precise fitting and craftsmanship. This includes hand-stitching and specialized techniques, which can elevate labor costs depending on the complexity and customization level.

-

Manufacturing Overhead: This encompasses utilities, equipment depreciation, and facility maintenance. Since custom orders are typically produced in lower volumes compared to mass production, overhead costs per unit can be higher.

-

Tooling: Customization may require unique tools or molds, particularly for bespoke designs. These initial investments add to the cost but can be amortized over multiple orders.

-

Quality Control (QC): Rigorous quality checks ensure that the final product meets specifications. This process incurs additional costs but is essential for maintaining brand reputation, especially in international markets.

-

Logistics: Shipping costs can vary significantly based on the destination, chosen Incoterms, and order size. Import duties and taxes should also be factored in when calculating total logistics costs.

-

Margin: Suppliers typically add a profit margin, which varies based on market conditions, competition, and perceived value of the product.

How Do Price Influencers Impact Custom Leather Boot Sourcing?

Several factors influence the pricing of custom leather boots, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders can lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it beneficial for buyers to consolidate orders.

-

Specifications/Customization: Highly customized designs with specific features will generally incur higher costs. Buyers should evaluate which custom elements are necessary and which can be standardized to control costs.

-

Materials: The choice of leather and other materials can greatly affect the overall price. Buyers should assess whether premium materials are justified based on the intended use and market expectations.

-

Quality and Certifications: Boots that meet certain quality standards or certifications (such as ISO) may come at a premium but can enhance marketability and customer trust.

-

Supplier Factors: The reputation and location of the supplier can influence pricing. Established brands may charge more due to their perceived value, while emerging suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding the implications of different shipping terms (e.g., FOB, CIF) can affect the final landed cost. Buyers should clarify these terms with suppliers to avoid unexpected expenses.

What Buyer Tips Can Help Optimize Costs in Custom Leather Boot Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Building a relationship can lead to better terms and discounts.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as durability, maintenance, and potential resole options. High-quality boots may have a higher upfront cost but lower long-term expenses.

-

Pricing Nuances: Be aware that international shipping can introduce variables like currency fluctuations and customs duties. Obtain quotes that include these potential costs to prevent budget overruns.

-

Supplier Audits: Conduct due diligence on suppliers to assess their production capabilities and quality assurance processes. This can help ensure that you receive a product that meets your specifications without unexpected costs.

Disclaimer

Prices for custom leather boots can vary significantly based on factors outlined above. The figures provided in this analysis are indicative and should be confirmed with suppliers during the sourcing process.

Alternatives Analysis: Comparing custom leather boots With Other Solutions

When considering footwear solutions for industrial, tactical, or lifestyle applications, B2B buyers often weigh the benefits of custom leather boots against alternative options. Understanding these alternatives can aid in making informed purchasing decisions that align with specific requirements and budget constraints.

Illustrative image related to custom leather boots

| Comparison Aspect | Custom Leather Boots | Work Boots | Synthetic Boots |

|---|---|---|---|

| Performance | High durability and comfort; tailored fit for specific tasks. | Good durability; designed for various work environments. | Generally lightweight; suitable for casual use. |

| Cost | Higher initial investment; $400-$900 depending on customization. | Moderate cost; typically ranges from $100-$300. | Lower cost; usually between $50-$150. |

| Ease of Implementation | Requires time for custom fitting and production; typically 4-8 weeks. | Readily available in stores or online; quick delivery. | Readily available; minimal lead time. |

| Maintenance | Requires regular care; can be resoled and repaired. | Low maintenance; often water-resistant materials. | Easy to clean; less frequent maintenance needed. |

| Best Use Case | Ideal for specialized professions requiring durability and comfort. | Suitable for general labor or construction work. | Best for casual wear or light-duty tasks. |

What Are the Benefits and Drawbacks of Work Boots as an Alternative?

Work boots are designed to provide robust protection and comfort for general labor environments. They typically feature reinforced toes, slip-resistant soles, and water-resistant materials, making them suitable for various work settings. The pros of work boots include their moderate price point and availability, allowing for quick procurement. However, they may lack the personalized fit and high durability of custom leather boots, which can lead to discomfort during long hours of wear or specialized tasks.

How Do Synthetic Boots Compare to Custom Leather Boots?

Synthetic boots, often made from materials like nylon or polyurethane, offer a lightweight and cost-effective alternative to custom leather boots. Their lower price and ease of cleaning make them appealing for casual users or those in less demanding environments. However, synthetic materials generally do not provide the same level of durability or comfort as high-quality leather. Over time, synthetic boots may wear out faster and can lack the support needed for prolonged use in demanding situations.

Conclusion: How Can B2B Buyers Choose the Right Footwear Solution?

When selecting the right footwear solution, B2B buyers should assess their specific needs, including the nature of their work, budget constraints, and maintenance capabilities. Custom leather boots are an excellent choice for those requiring high durability and a tailored fit for specialized tasks, while work boots serve well for general labor with quicker availability and lower costs. Synthetic boots may be suitable for casual use but should be avoided for demanding applications. By carefully evaluating these factors, buyers can make informed decisions that enhance comfort, safety, and efficiency in their operations.

Essential Technical Properties and Trade Terminology for custom leather boots

What Are the Key Technical Properties of Custom Leather Boots for B2B Buyers?

When considering custom leather boots for B2B procurement, understanding specific technical properties is crucial. These properties not only affect product quality but also influence buyer decisions and supplier negotiations.

1. Material Grade

The quality of leather used in boot manufacturing is paramount. Common grades include full-grain, top-grain, and corrected grain leather. Full-grain leather, made from the top layer of the hide, offers superior durability and breathability, making it ideal for high-performance boots. Understanding material grade helps buyers assess durability, comfort, and longevity, which are critical for end-users in demanding environments.

2. Construction Method

The construction method refers to how the boot is assembled. Popular methods include Goodyear welt, Blake stitch, and cement construction. Goodyear welted boots, for instance, feature a leather strip (the welt) stitched to both the upper and the sole, allowing for resoling and enhancing durability. Buyers should prioritize construction methods that align with their product longevity and repairability expectations.

3. Tolerance Specifications

Tolerance specifications define acceptable variations in measurements during production. For custom boots, tolerances may apply to dimensions like shaft height, width, and sole thickness. Tight tolerances ensure a better fit and enhance customer satisfaction. Understanding these specifications aids buyers in selecting suppliers who can consistently meet their quality requirements.

4. Comfort Features

Comfort features include aspects such as arch support, cushioning, and moisture-wicking linings. These elements are vital for user satisfaction, especially in sectors requiring prolonged wear, such as construction or outdoor activities. Buyers should seek suppliers that offer customizable comfort features to cater to diverse user needs.

Illustrative image related to custom leather boots

5. Weight Considerations

The weight of the boots can significantly impact user comfort and fatigue levels, particularly in industrial settings. Lighter materials may be preferable for tasks requiring agility, while heavier boots might offer enhanced protection. Evaluating weight considerations helps buyers align products with the specific needs of their workforce.

What Are the Common Trade Terminologies Used in the Custom Leather Boot Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the custom leather boot market.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another brand’s name. In the custom leather boot industry, an OEM may manufacture boots for a retailer who then sells them under their label. Understanding OEM relationships can help buyers navigate supply chains and branding strategies.

Illustrative image related to custom leather boots

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. Knowing the MOQ is critical for buyers to manage inventory and cash flow effectively. Suppliers with lower MOQs may be more accessible for smaller businesses or those just entering the market.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to obtain price quotes for specific products or services. It allows buyers to compare costs and terms across multiple suppliers. Crafting a clear RFQ can lead to better pricing and terms, making it an essential tool for B2B transactions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping agreements. They clarify who is responsible for shipping costs, insurance, and liability during transit. Familiarity with Incoterms is crucial for B2B buyers engaged in international trade, ensuring compliance and risk management.

5. Customization Options

This term refers to the various ways in which products can be tailored to meet specific customer requirements. In the custom leather boot sector, this can include choices in materials, colors, and features. Understanding customization options allows buyers to provide tailored solutions that meet the unique needs of their clientele.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, optimize their procurement processes, and foster successful partnerships in the custom leather boot market.

Navigating Market Dynamics and Sourcing Trends in the custom leather boots Sector

What Are the Key Market Dynamics and Sourcing Trends in the Custom Leather Boots Sector?

The global custom leather boots market is witnessing significant evolution, propelled by a variety of factors that international B2B buyers should be aware of. As consumers increasingly seek personalized products, the demand for custom leather boots is surging, particularly in regions like Africa, South America, the Middle East, and Europe. Key trends include the rising integration of technology in the manufacturing process, such as 3D printing and advanced fitting technologies, which enhance the customization experience. This allows manufacturers to offer a wider range of options, from leather types to sole and heel designs, catering to diverse consumer preferences.

Moreover, sustainability is becoming a critical focus area. Buyers are now looking for suppliers who prioritize environmentally friendly practices, including the use of vegetable-tanned leather and sustainable sourcing methods. The emergence of e-commerce platforms and digital marketplaces is also reshaping the sourcing landscape, making it easier for buyers to connect with manufacturers globally. Additionally, the trend toward direct-to-consumer (DTC) models is enabling brands to offer competitive pricing and improved customer service, which is particularly appealing in emerging markets.

How Is Sustainability Influencing Sourcing Decisions in the Custom Leather Boots Market?

Sustainability and ethical sourcing are increasingly vital in the custom leather boots sector, reflecting a growing consumer awareness of environmental impacts and ethical considerations. The production of leather, particularly when it involves chemical tanning processes, can have detrimental effects on the environment. As a result, B2B buyers are prioritizing suppliers who adopt sustainable practices, such as using eco-friendly tanning methods or sourcing leather from certified sustainable farms.

Illustrative image related to custom leather boots

The importance of transparency in supply chains cannot be overstated. Buyers are encouraged to seek out suppliers who can provide detailed information about their sourcing practices, including the origins of their materials and the treatment of workers involved in the production process. Certifications such as the Leather Working Group (LWG) certification can serve as indicators of a supplier’s commitment to sustainability. Additionally, the use of recycled materials and biodegradable options is becoming more prominent, allowing brands to appeal to environmentally conscious consumers.

What Is the Historical Context Behind the Custom Leather Boots Market?

The custom leather boots market has a rich history that dates back centuries, evolving from handcrafted footwear made by local artisans to a global industry characterized by advanced manufacturing techniques. Historically, boots were tailored to individual needs based on the demands of specific trades, such as logging or military use. This tradition of customization has persisted, with modern manufacturers emphasizing the importance of fit and comfort alongside style.

As the market has expanded, the introduction of new materials and technologies has transformed the landscape. Today, buyers can choose from a plethora of options, ensuring that each pair of boots not only meets functional requirements but also reflects personal style. This evolution underscores the ongoing importance of craftsmanship and quality, which remain at the heart of the custom leather boots sector.

In conclusion, B2B buyers in the custom leather boots market must navigate a landscape shaped by technological advancements, sustainability imperatives, and a deep-rooted tradition of craftsmanship. By understanding these dynamics, buyers can make informed sourcing decisions that align with both market demands and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather boots

-

How do I ensure the quality of custom leather boots from international suppliers?

To ensure the quality of custom leather boots, conduct thorough research on potential suppliers. Request samples to assess materials, craftsmanship, and comfort. Verify their manufacturing processes, including quality control measures and certifications. Establish clear communication regarding your specifications and expectations. Consider visiting the factory if feasible, or engaging a local representative to conduct an on-site inspection. Additionally, seek reviews or testimonials from other B2B buyers who have sourced from the supplier to gauge their reliability and product quality. -

What customization options are available when ordering custom leather boots?

Customization options vary by supplier but often include selecting the type of leather, color, stitching, sole material, and boot style. Some manufacturers allow adjustments to fit, such as width and arch support, and the ability to choose specific features like eyelets, heel height, and toe shape. Make sure to discuss your specific needs and preferences with the supplier to understand the full range of customization options available. This ensures that the final product aligns with your branding and functional requirements. -

What is the minimum order quantity (MOQ) for custom leather boots?

The minimum order quantity (MOQ) for custom leather boots typically ranges from 50 to 100 pairs, depending on the supplier and the complexity of customization. Some manufacturers may offer lower MOQs for specific styles or during promotional periods. It’s essential to clarify the MOQ before placing an order, as it impacts your inventory planning and overall cost. Additionally, inquire about price breaks for larger orders, as this can significantly affect your margins. -

What payment terms should I expect when sourcing custom leather boots?

Payment terms can vary widely among suppliers, but common practices include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipping. Some suppliers may offer flexible payment options, such as letters of credit or payment upon delivery, particularly for established relationships. Always negotiate terms that align with your cash flow needs and ensure you have a clear contract outlining all payment details, including timelines and methods. -

How do I handle logistics and shipping for international orders of custom leather boots?

When managing logistics for international orders, work with a reliable freight forwarder experienced in handling footwear shipments. Discuss options for shipping methods, including air freight for faster delivery or sea freight for cost savings. Ensure you understand customs regulations and duties in both the exporting and importing countries to avoid delays. It’s also wise to track shipments and have contingency plans for potential disruptions in the supply chain. -

What are the typical lead times for custom leather boot orders?

Lead times for custom leather boot orders can vary based on the complexity of the design and the supplier’s capacity. Generally, expect a timeframe of 4 to 12 weeks from order confirmation to delivery. Factors influencing lead times include the availability of materials, the customization process, and production schedules. Always confirm lead times with your supplier and build in extra time for unforeseen delays, particularly for international shipments. -

How can I vet suppliers for custom leather boots effectively?

To effectively vet suppliers, begin by researching their reputation within the industry. Look for certifications that indicate adherence to quality standards, such as ISO or ethical manufacturing practices. Request references from other B2B clients and review their experiences. It’s also beneficial to assess their production capabilities through factory visits or virtual tours. Lastly, ensure they have clear communication protocols and a solid understanding of your market needs. -

What are the best practices for maintaining custom leather boots after purchase?

To extend the lifespan of custom leather boots, implement a regular maintenance routine. Clean the boots with a soft brush or cloth to remove dirt and debris, and apply a quality leather conditioner to keep the material supple. Store boots in a cool, dry place, using boot trees or stuffing to maintain shape. If the soles wear down, consider resoling to prolong their use. Providing proper care not only enhances durability but also preserves the aesthetic appeal of the boots.

Top 8 Custom Leather Boots Manufacturers & Suppliers List

1. Baker’s – Custom Boots

Domain: bakershoe.com

Registered: 1999 (26 years)

Introduction: Custom Boots available from brands like White’s, Wesco, and more. Options include: 1. Baker’s Custom Bounty Hunter White’s Boots – $749.95 2. Custom White’s MP (Military Police) Service Boot – $729.95 3. Custom Smokejumper White’s Boots – $724.95 4. Custom Classic Semi Dress White’s Boots – $739.95 5. Baker’s Custom Horsehide Bounty Hunter White’s Boots – $849.95 6. Custom Boss Wesco Boots – $549….

2. Atitlan Leather – Custom Handmade Boots

Domain: atitlanleather.com

Registered: 2012 (13 years)

Introduction: Custom Made Boots | Handmade Boots Just for You. Regular price for Custom Tall Boots: $229.95, Custom Handmade Lace Up Victorian Boots: $199.95, Custom Chukka Boots: $199.95, Custom Biker Boots: $199.95. Features: handcrafted with a brogue design, handmade leather sole attached using Goodyear welt construction, resoleable, upgraded insoles for comfort. Recommended to use leather balm for maintenan…

3. Whites Boots – Key Products

Domain: whitesboots.com

Registered: 1997 (28 years)

Introduction: Key product details include: 1. Boot Types: Legacy Boots, Lifestyle Boots, Fire Boots, Work Boots, Grande Ronde Series. 2. Featured Products: C350 Chelsea, C350 Cruiser, C350 Cutter, C350-CS, 1972 Perry 6″ Select, The Original 350 Cruiser, The Original 350 Cutter, The Original Packer. 3. Price Range: $430.00 to $750.00 depending on the model. 4. Construction: Hand-sewn stitchdown boots, involving …

4. JK Boots – Handmade Leather Work Boots

Domain: jkboots.com

Registered: 2012 (13 years)

Introduction: This company, JK Boots – Handmade Leather Work Boots, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Jim Green – Custom Made Boots

Domain: jimgreenfootwear.com

Registered: 2020 (5 years)

Introduction: Custom Made Boots from Jim Green offer a variety of options for personalization. Key product details include:

1. **Upper Styles**: Options include AR8, AR08, Razorback, B6, Baobab, AM30, Numzaan, AM31, Stockman, F3, 719, CM719, African Trooper, AR10, African Ranger, AR01, Vellie, V1, Turbo Vellie, S5, Shoellie, AM01, Workhorse Moc Toe, MT01, Meander Moc Toe, MT02.

2. **Last Types**: Various las…

6. Nicks Handmade Boots – Customizable Quality Footwear

Domain: nicksboots.com

Registered: 1997 (28 years)

Introduction: Nicks Handmade Boots offers a variety of boot categories including Work Boots, Heritage Boots, Fire Boots, Tactical Boots, Western Boots, Hiking Boots, and Hunting Boots. Key features include:

– Free size exchanges

– Quick Ship options available

– Customization options for boot designs

– Materials sourced from the USA

– Hand-made craftsmanship

– Specific boot types such as Lace Up, Pull On, …

7. Adelante Shoes – Custom Leather Boots

Domain: adelanteshoes.com

Registered: 2016 (9 years)

Introduction: Made-to-order, custom-sized leather boots for men and women. Extensive range of widths and sizes: Men’s widths from C to EEEEE; Women’s widths from A to EEE. Option for split sizing (right and left foot sizes can be different). Women’s calf widths available from narrow to extra wide. Delivery time approximately 3 weeks. Handcrafted by Guatemalan artisans. Personalization options available.

8. Frank’s Handmade Boots – Originals & Firefighting Work Boots

Domain: franksboots.com

Registered: 2016 (9 years)

Introduction: Frank’s Handmade Boots offers a variety of products including Originals, Wildland Firefighting Work Boots, Casual Boots, and Accessories. They have a limited edition collection called The Patriot Collection, featuring boots made from 7.5 to 8 oz. full grain water resistant leather, designed for various professions such as wildland firefighters, construction workers, and ranchers. The boots feature…

Strategic Sourcing Conclusion and Outlook for custom leather boots

In the realm of custom leather boots, strategic sourcing emerges as a crucial aspect for international B2B buyers. By investing in high-quality, customizable footwear, companies can cater to diverse market demands while ensuring durability and comfort for their end-users. The ability to source bespoke products tailored to specific needs not only enhances customer satisfaction but also strengthens brand loyalty, especially in regions like Africa, South America, the Middle East, and Europe, where unique cultural preferences influence purchasing decisions.

Illustrative image related to custom leather boots

Leveraging partnerships with reputable manufacturers allows businesses to access a wide range of materials, styles, and craftsmanship techniques. This flexibility is essential for meeting the varying requirements of different markets, from rugged work boots to stylish lifestyle options. As the demand for personalized products continues to rise, companies must prioritize strategic sourcing to remain competitive.

Looking ahead, the custom leather boot industry is poised for growth, driven by increasing consumer interest in sustainability and craftsmanship. B2B buyers are encouraged to explore innovative sourcing strategies that emphasize quality and customization. By doing so, they can position themselves as leaders in their respective markets and capitalize on the evolving preferences of global consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to custom leather boots

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.