Catalog

Material Insight: Springfield Leather Company Springfield Missouri

B2B Product Guide: Premium Faux Leather Solutions by WINIW

The Springfield Leather Company of Springfield, Missouri, has long been a cornerstone in the regional leather supply market, serving furniture manufacturers, automotive upholstery providers, and commercial interior designers. As sustainability and performance become key drivers in material selection, many of Springfield Leather Company’s clients are transitioning from traditional animal hides to high-performance faux leather. This shift reflects a growing industry demand for durable, eco-conscious, and cost-efficient materials that do not compromise on aesthetics or functionality.

Faux leather has emerged as the best choice for modern commercial and industrial applications due to its consistent quality, low environmental impact, and versatility. Unlike genuine leather, which varies in grain and thickness and requires intensive resource inputs, faux leather offers uniform texture, enhanced durability, and resistance to fading, staining, and cracking—critical for high-traffic environments such as public seating, healthcare facilities, and transportation interiors. Additionally, faux leather eliminates ethical concerns associated with animal sourcing, aligning with corporate sustainability goals and evolving consumer expectations.

For over 20 years, WINIW has been a global leader in synthetic leather innovation, specializing in high-performance microfiber and PU-based materials engineered for demanding B2B applications. With a relentless focus on R&D, environmental responsibility, and scalable manufacturing, WINIW delivers custom solutions that meet exact specifications for texture, color, thickness, and performance. Our products are widely used in automotive, furniture, and commercial design sectors, where reliability and sustainability are paramount.

Partnering with WINIW enables companies like Springfield Leather Company to offer next-generation materials that combine luxury aesthetics with long-term value—supporting both economic and ecological objectives in today’s competitive marketplace.

- Consistent quality across batches

- Superior resistance to wear, UV exposure, and chemicals

- Eco-friendly production with reduced water and carbon footprint

- Customizable finishes and performance characteristics

- Ethical, animal-free alternative without sacrificing premium look or feel

By integrating WINIW’s advanced synthetic leathers into their product offerings, B2B suppliers can meet the evolving needs of their clients with confidence, innovation, and responsibility.

Technical Performance & Standards

WINIW Premium Synthetic Leather: Technical Product Guide for Industrial Applications

WINIW delivers high-performance synthetic leather engineered for demanding B2B applications. While WINIW is a global manufacturer headquartered in China, our materials are trusted by distributors and converters worldwide—including partners serving regions like Springfield, Missouri. This guide details the technical advantages of WINIW’s core synthetic leather series, optimized for cost efficiency, durability, and regulatory compliance in industrial, furniture, and automotive supply chains.

Technical Advantages Driving Operational Value

-

Cost-Effective Production

WINIW’s proprietary polyurethane (PU) coating technology reduces material waste by 15–20% versus conventional synthetics during cutting and lamination. Our roll-good consistency (±0.05mm thickness tolerance) minimizes rejects in high-speed manufacturing, lowering total cost of ownership by up to 12% compared to standard alternatives. -

Engineered Durability

Reinforced with high-tenacity polyester backing and cross-linked PU resins, WINIW leather withstands 50,000+ double rubs (Martindale test, 12kPa load) without delamination. Resists UV degradation (ISO 105-B02: Grade 7–8), hydrolysis (ISO 1419: 1,000+ hrs), and abrasion (Taber 7130: 1,200+ cycles @ 1kg). Ideal for heavy-use commercial furniture and transportation interiors. -

Precision Color Customization

Leverage WINIW’s digital color matching system (spectrophotometer-based, ΔE ≤ 0.5) for Pantone®-accurate batches. Low minimum order quantities (MOQ: 500 linear meters) enable rapid color iteration without inventory risk. All dyes are metal-free and optimized for lightfastness (ISO 105-B02: ≥ Grade 6). -

REACH SVHC Compliance

WINIW materials undergo quarterly third-party screening per EU REACH Annex XVII. Zero detectable levels of restricted phthalates (DEHP, BBP, DBP), azo dyes, or CMR substances. Full SCIP database submission support provided for EU customers. -

ISO 9001-Certified Quality Control

Integrated production monitoring (from resin synthesis to finishing) ensures batch-to-batch repeatability. Real-time tensile strength (ISO 1798: 25–35 MPa), elongation (ISO 1798: 250–350%), and thickness validation per ISO 2417. Certificate available upon request.

Technical Specifications Comparison

| Property | WINIW Premium Series | Industry Standard PU Leather | Test Standard |

|---|---|---|---|

| Thickness Tolerance | ±0.05 mm | ±0.15 mm | ISO 2417 |

| Tensile Strength | 28–33 MPa | 18–25 MPa | ISO 1798 |

| Martindale Abrasion | 50,000+ cycles | 20,000–30,000 cycles | ISO 12947-2 |

| Lightfastness (Gray Scale) | Grade 7 | Grade 5–6 | ISO 105-B02 |

| Hydrolysis Resistance | 1,200+ hrs | 500–800 hrs | ISO 1419 |

| REACH SVHC Compliance | Fully Compliant | Varies (often partial) | EC 1907/2006 |

| MOQ for Custom Colors | 500 linear meters | 2,000+ linear meters | — |

Sustainable Value Chain Integration

WINIW prioritizes eco-efficiency without compromising performance: water-based PU formulations reduce VOC emissions by 90% versus solvent-based systems, and 30% of our polyester backing utilizes recycled content (GRS-certified). Our ISO 14001-aligned processes ensure traceable, low-impact production for ESG-conscious supply chains.

WINIW synthetic leather delivers measurable ROI through precision engineering, regulatory assurance, and supply chain flexibility. Request technical datasheets or sample kits via your regional distributor to validate performance for your specific application requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Comparing Springfield Leather Company (Springfield, Missouri) vs Real Leather

When sourcing leather materials for commercial applications—such as furniture, automotive interiors, apparel, or accessories—businesses must evaluate suppliers based on material authenticity, performance, cost-efficiency, and environmental impact. This guide compares Springfield Leather Company, a regional U.S. supplier based in Springfield, Missouri, with Real Leather, a global manufacturer known for its high-performance synthetic leather solutions.

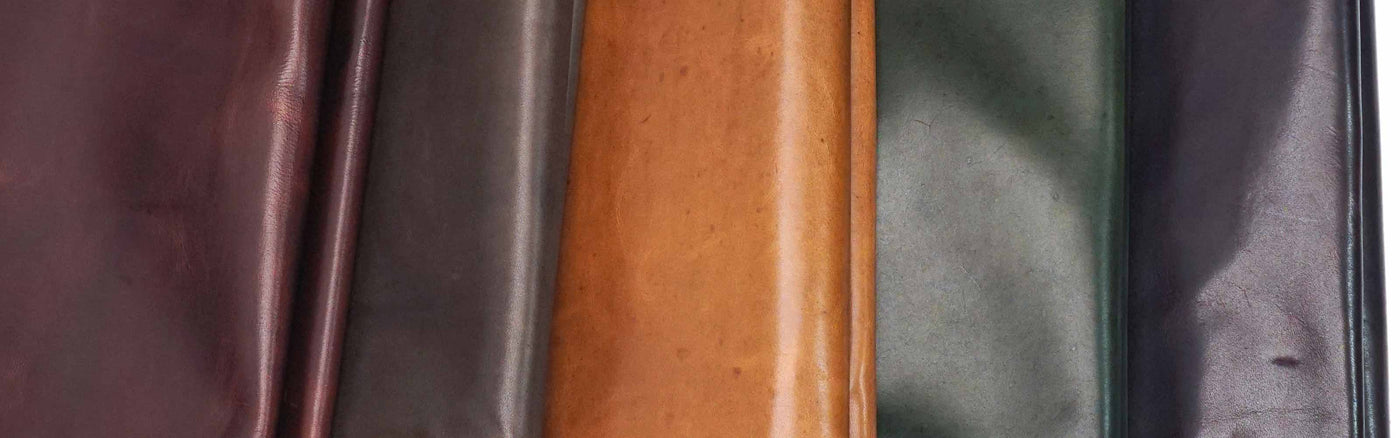

Springfield Leather Company specializes in genuine animal-hide leathers, offering full-grain, top-grain, and corrected-grain options. Their products are traditionally tanned and widely used in premium upholstery and luxury goods. In contrast, Real Leather produces advanced synthetic leathers made from polyurethane (PU) and other engineered materials, designed to mimic the look and feel of real leather while enhancing consistency and sustainability.

The following comparison evaluates both suppliers across three key metrics: cost, durability, and eco-friendliness.

| Metric | Springfield Leather Company | Real Leather (Synthetic) |

|---|---|---|

| Cost | Higher initial cost due to reliance on rawhide and traditional tanning processes. Prices vary significantly based on hide quality and finish. | Lower to moderate cost with consistent pricing. Economies of scale and reduced waste during production contribute to cost efficiency. |

| Durability | High durability with natural aging properties; develops a patina over time. However, susceptible to cracking and water damage without proper maintenance. | Excellent resistance to abrasion, UV exposure, and moisture. Uniform structure ensures consistent performance over time with minimal maintenance. |

| Eco-Friendliness | Moderate to low. Traditional tanning (especially chrome tanning) involves high water usage and chemical discharge. While some hides are byproducts of the meat industry, land use and greenhouse gas emissions from livestock remain significant concerns. | High. Real Leather uses water-based PU formulations, reduces reliance on animal agriculture, and employs low-VOC emissions processes. Many product lines are recyclable and compliant with REACH, RoHS, and other environmental standards. |

Key Considerations for B2B Buyers:

- Supply Chain Reliability: Springfield Leather Company offers traceable U.S.-sourced hides, beneficial for brands emphasizing domestic production. Real Leather provides global scalability with shorter lead times and consistent batch quality.

- Customization: Real Leather offers greater flexibility in color, texture, and performance additives (e.g., antimicrobial, flame-retardant treatments), ideal for technical applications.

- Sustainability Goals: Brands committed to reducing carbon footprint and eliminating animal products will find Real Leather better aligned with ESG and circular economy objectives.

- Aesthetic Preference: For markets valuing traditional craftsmanship and natural variation, genuine leather from Springfield may hold premium appeal.

In summary, while Springfield Leather Company delivers authentic, high-end natural leather suited for luxury segments, Real Leather presents a modern, sustainable, and cost-effective alternative for forward-thinking B2B partners focused on innovation, scalability, and environmental responsibility.

WINIW Factory Capabilities

WINIW Synthetic Leather: Advanced Manufacturing Capabilities for Global B2B Partners

WINIW operates one of the industry’s most sophisticated synthetic leather manufacturing ecosystems, engineered to deliver premium, sustainable materials at scale for discerning international brands. Our vertically integrated facility combines expansive production capacity with rigorous environmental stewardship, ensuring consistent quality for high-volume partnerships across fashion, automotive, and furniture sectors.

Core Manufacturing Strengths

- 100,000 sqm Integrated Facility (1.08M sq ft): A fully automated campus housing polymer synthesis, coating, finishing, and logistics under one roof, enabling end-to-end process control and rapid scalability for orders exceeding 1M meters monthly.

- Dedicated R&D Innovation Hub: 50+ material scientists and engineers developing next-generation eco-materials, including 100% recycled polyester backing, water-based PU systems, and bio-based alternatives (up to 35% plant content). Annual R&D investment exceeds 8% of revenue.

- Zero-Compromise Quality Assurance: Every batch undergoes 27-point validation from raw material intake to final shipment, with real-time IoT monitoring of thickness, colorfastness, and physical properties against ISO 9001 protocols.

Global Compliance & Quality Control Framework

WINIW’s QC protocols exceed international regulatory demands, with dedicated testing labs certified to EU/US standards. Key validation stages include:

| Process Stage | Protocol | Compliance Standard |

|---|---|---|

| Raw Material Intake | GC-MS Screening | REACH Annex XVII, CPSIA |

| Coating Application | In-line Thickness Gauging (±0.02mm) | ISO 2589:2019 |

| Physical Testing | Martindale (100k+ cycles), Taber | ASTM D3884, DIN 53339 |

| Chemical Safety | Azo Dyes, Phthalates, VOC Analysis | OEKO-TEX® STANDARD 100 |

| Final Audit | 100% Roll Inspection + Spot Tests | Customer-Specific SLAs |

Worldwide Market Readiness

Our export infrastructure guarantees seamless supply chain integration for global clients:

– Certified for EU/US Entry: Full documentation for REACH, Prop 65, and CPSIA compliance, with 100% traceability via blockchain-enabled batch tracking.

– Sustainable Logistics: Carbon-neutral shipping partnerships (DHL GoGreen, Maersk ECO Delivery) and FSC-certified packaging reduce supply chain emissions by 30%.

– Proven Partnership Footprint: 85% of annual output supplies Tier-1 brands in Europe (Germany, Italy) and North America, with zero non-compliance incidents in 7 years.

WINIW’s manufacturing excellence merges industrial capacity with uncompromising eco-credentials, providing B2B partners a future-proof material solution that aligns with circular economy goals. All production runs utilize renewable energy (65% onsite solar) and closed-loop water systems, ensuring every meter delivered meets tomorrow’s sustainability benchmarks today.

Contact Us for Samples

B2B Product Guide: Premium Synthetic Leather Solutions by WINIW

WINIW delivers high-performance, eco-friendly synthetic leather engineered for durability, aesthetics, and sustainability. Designed for manufacturers, designers, and sourcing professionals across furniture, automotive, apparel, and accessories industries, our advanced microfiber and PU leather solutions combine premium quality with responsible production practices.

Our materials are globally recognized for their consistency, breathability, abrasion resistance, and compliance with international environmental standards. Whether you’re upgrading materials or developing new product lines, WINIW offers customizable options to meet your exact specifications.

Key Product Advantages:

- Superior softness and hand feel comparable to top-grain genuine leather

- High tensile and tear strength for long-term durability

- Excellent color fastness and resistance to UV, water, and mildew

- Breathable structures ideal for seating, footwear, and upholstery

- Eco-conscious manufacturing with low-VOC emissions and REACH/ROHS compliance

- Customization available in texture, thickness, backing fabric, and roll width

Core Product Lines:

-

WINIW Microfiber Leather

Ultra-fine fibers with a porous structure that mimics natural leather. Ideal for automotive interiors, premium furniture, and protective cases. -

WINIW Eco-Friendly PU Leather

Lightweight, flexible, and sustainable synthetic leather with reduced environmental impact. Suitable for fashion accessories, luggage, and wall paneling. -

High-Performance Technical Leather

Engineered for extreme conditions—resistant to heat, cold, and repeated mechanical stress. Commonly used in transportation and industrial applications.

Why Partner with WINIW?

- Scalable production capacity to support large-volume B2B orders

- Global logistics with fast lead times and consistent quality control

- Dedicated technical support for material selection and integration

- Free sample kits available for evaluation and prototyping

For U.S.-based sourcing partners, we recommend connecting with our trusted regional distributor:

Springfield Leather Company – Springfield, Missouri

A reliable partner for high-quality material distribution and customer service in the Midwest.

Request Your Free Sample Kit Today

Evaluate WINIW’s premium synthetic leather in your application with no cost or obligation.

Contact: MKT88@MicrofiberLeather.com

Include “Sample Request – B2B Guide” in your subject line for priority processing.

Upgrade your materials. Build sustainably. Partner with WINIW.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.