Catalog

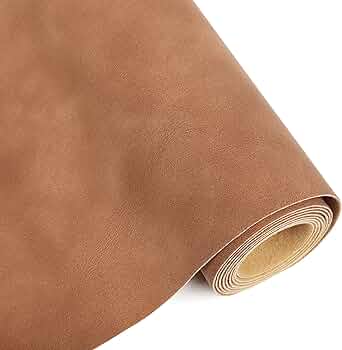

Material Insight: Saude Leather

WINIW B2B Product Guide: Premium Synthetic Leather for Healthcare Applications (Saúde Leather)

Healthcare environments demand materials that prioritize patient safety, practitioner efficiency, and uncompromising hygiene. “Saúde Leather” – high-performance synthetic leather engineered specifically for medical, dental, laboratory, and wellness settings – meets these critical requirements where traditional materials fall short. In spaces where infection control is paramount, surface durability is non-negotiable, and chemical resistance is routine, the choice of upholstery and surface material directly impacts operational success and patient well-being. WINIW, leveraging over 20 years of specialized expertise in advanced synthetic leather development, provides the definitive solution for these demanding applications.

Why Premium Faux Leather is the Essential Choice for Healthcare (Saúde) Applications:

- Superior Hygiene & Infection Control: Unlike porous natural leather or fabric, high-quality faux leather features a fully sealed, non-porous surface. This prevents the absorption of bodily fluids, pathogens, and contaminants, enabling thorough, rapid disinfection with hospital-grade cleaners without material degradation – a fundamental requirement for reducing Healthcare-Associated Infections (HAIs).

- Exceptional Chemical & Stain Resistance: Medical environments expose surfaces to alcohol, iodine, blood, urine, and harsh disinfectants daily. Premium faux leather resists staining, cracking, and deterioration from these aggressive substances, maintaining integrity and appearance far longer than alternatives.

- Enhanced Durability & Longevity: Designed for constant use, high-traffic settings, and frequent cleaning cycles, performance faux leather withstands abrasion, tearing, and punctures significantly better than vinyl or low-grade synthetics, ensuring furniture and equipment maintain functionality and aesthetics over extended service life.

- Ease of Maintenance & Cost Efficiency: The seamless, wipe-clean surface drastically reduces cleaning time and labor costs compared to fabric or leather requiring specialized treatments. Its resilience minimizes replacement frequency, lowering the total cost of ownership for healthcare facilities.

- Consistent Quality & Customization: Synthetic leather offers uniform texture, color, and performance across every batch and hide, eliminating the inconsistencies of natural leather. It can be precisely engineered for specific needs like flame retardancy (critical for medical devices), antimicrobial properties, or specific tactile feels.

Introducing WINIW: Your Trusted Partner in Performance Synthetic Leather

WINIW stands as a global leader in the research, development, and manufacturing of high-performance, eco-conscious synthetic leather solutions, with over two decades of specialized experience serving demanding industrial and professional sectors. We understand that healthcare applications (“Saúde Leather”) require materials engineered beyond basic aesthetics – they demand science-backed performance, unwavering reliability, and commitment to safety.

Our deep expertise translates into synthetic leather that doesn’t just meet, but exceeds, the rigorous standards of the healthcare industry. We combine advanced polymer science with a dedicated focus on sustainability, utilizing water-based PU systems, incorporating recycled content where feasible, and adhering to stringent environmental and safety certifications (REACH, OEKO-TEX® STANDARD 100). WINIW partners with B2B clients to co-develop tailored solutions, ensuring the material properties – from abrasion resistance and flame retardancy to specific hand feel and colorfastness – align perfectly with the unique demands of medical chairs, examination tables, dental units, stretchers, and wellness facility furnishings. When you choose WINIW, you choose a legacy of innovation, uncompromising quality, and a partnership dedicated to advancing material performance for a healthier world.

Technical Performance & Standards

WINIW Saude Leather – B2B Product Technical Guide

WINIW Saude Leather is a premium synthetic leather solution engineered for industrial and commercial applications where performance, sustainability, and cost-efficiency are critical. Designed for B2B clients across furniture, transportation, footwear, and accessories sectors, Saude Leather delivers consistent quality and environmental compliance without compromising on aesthetics or durability.

Technical Advantages

-

Cost-Effective Production

Saude Leather reduces manufacturing costs through high material yield and minimal waste. Its consistent thickness and surface uniformity decrease trimming losses and rework, optimizing production efficiency. Additionally, lower maintenance and longer product life cycles reduce total cost of ownership. -

Superior Durability

Engineered with advanced polyurethane (PU) technology, Saude Leather exhibits exceptional resistance to abrasion, tearing, and flexing. It maintains integrity under high-stress conditions, making it ideal for high-traffic applications such as public seating, automotive interiors, and workwear. -

Customizable Colors & Finishes

WINIW offers full color customization with precise Pantone matching and batch consistency. Clients can select from matte, glossy, soft-touch, or textured finishes to meet brand-specific design requirements. Large-volume orders maintain color uniformity across production runs. -

REACH Compliance

Saude Leather is fully compliant with EU REACH regulations (EC 1907/2006), ensuring the absence of harmful substances such as phthalates, heavy metals, and restricted amines. This makes it safe for consumer goods and eco-sensitive markets. -

ISO 9001-Certified Manufacturing

Produced in ISO 9001-certified facilities, Saude Leather adheres to stringent quality management standards. Every production stage—from raw material sourcing to final inspection—is monitored for consistency, traceability, and performance reliability.

Saude Leather – Technical Specifications

| Property | Specification |

|---|---|

| Base Material | High-performance PU on polyester knit backing |

| Thickness Range | 0.8 mm – 1.5 mm (customizable) |

| Width (Roll) | 137 cm (54 inches) standard |

| Weight | 280 – 350 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale, 500g load) |

| Color Fastness to Rubbing | Grade 4–5 (dry & wet) |

| Light Fastness | ≥4 (Blue Wool Scale) |

| Tensile Strength | ≥80 N/5cm (warp and weft) |

| Tear Strength | ≥15 N (Elmendorf) |

| Cold Crack Resistance | ≤ -20°C |

| Environmental Standards | REACH compliant, free from AZO, PCP, formaldehyde |

| Certifications | ISO 9001, OEKO-TEX® STANDARD 100 (upon request) |

WINIW Saude Leather combines economic efficiency with long-term performance and regulatory compliance, making it a trusted choice for global B2B partners seeking sustainable, high-value synthetic leather solutions.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather for Sustainable Manufacturing

As a leader in advanced material innovation, WINIW provides high-performance synthetic leather solutions engineered for modern manufacturing demands. This guide objectively compares synthetic leather (specifically WINIW’s eco-engineered variants) with traditional real leather across critical business and sustainability metrics. Understanding these differences empowers brands to make informed, future-proof sourcing decisions aligned with ESG goals and operational efficiency.

Key Comparison: Synthetic Leather (WINIW) vs. Real Leather

| Attribute | Synthetic Leather (WINIW) | Real Leather |

|---|---|---|

| Cost | 20-30% lower material cost; consistent pricing with no grade fluctuations. Reduced waste (up to 15% higher yield per sqm). | Higher base cost; significant price volatility due to hide quality, origin, and tannery capacity. Waste rates 10-20% due to natural defects. |

| Durability | Superior abrasion resistance (tested to 20,000+ cycles). Uniform structure ensures consistent performance. Resists cracking, fading, and moisture damage. | Variable durability (dependent on hide grade and tanning). Prone to scratching, water staining, and requires ongoing conditioning. Natural grain may weaken over time. |

| Eco-Friendliness | 60% lower carbon footprint vs. bovine leather. Zero animal sourcing. Water-based PU/PVC options; 30-50% recycled content available. OEKO-TEX® STANDARD 100 certified. Fully traceable supply chain. | High environmental impact: 17,000+ liters water per kg hide, toxic tanning chemicals (chromium), and significant land/water use for livestock. Limited traceability in conventional supply chains. |

Why WINIW Synthetic Leather Delivers B2B Value

- Supply Chain Resilience: Eliminate dependence on volatile hide markets and ethical concerns tied to animal agriculture. Secure consistent material availability with 4-6 week lead times.

- Design & Production Flexibility: Customize thickness, texture, color, and performance properties (e.g., UV resistance, breathability) to exact specifications—unachievable with natural hide variation.

- Compliance & Brand Safety: Meet stringent global regulations (REACH, CA Prop 65) with non-toxic, heavy-metal-free formulations. Avoid reputational risks linked to deforestation or unethical tanning practices.

- Lifecycle Efficiency: Lower maintenance costs for end products; no conditioning required. Recyclable at end-of-life via WINIW’s take-back programs (where available).

WINIW’s synthetic leather is not a compromise—it’s a strategic upgrade for brands committed to scalability, ethical production, and circularity. By choosing WINIW, manufacturers gain a partner invested in co-creating materials that drive both commercial success and planetary stewardship.

Request samples or a technical datasheet to evaluate WINIW’s performance against your specific application requirements.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. Our state-of-the-art manufacturing facility spans 100,000 square meters, making it one of the largest and most advanced production centers in the industry. This expansive infrastructure enables us to maintain high-volume output without compromising on quality or efficiency.

Our competitive advantage lies in our vertically integrated operations and dedicated research and development (R&D) team. Comprised of material scientists and technical experts, our R&D department continuously develops new formulations and finishes to meet evolving market demands, including water-based, solvent-free, and recycled materials that align with global sustainability standards.

Quality control is embedded at every stage of production. WINIW enforces a strict QC system that includes raw material inspection, in-process monitoring, and final product testing. Each batch undergoes rigorous performance evaluations for abrasion resistance, color fastness, tensile strength, and environmental compliance, ensuring consistent product reliability.

Key factory strengths include:

– 100,000 sqm manufacturing facility with automated production lines

– In-house R&D team focused on innovation and eco-conscious material development

– Comprehensive quality control protocols compliant with international standards

– High production capacity supporting large-scale OEM and ODM orders

– Environmentally responsible manufacturing with low-emission processes

WINIW proudly exports to key markets worldwide, including Europe and the USA, where our products are trusted by leading brands in automotive, furniture, apparel, and accessories. Our global logistics network ensures timely delivery and compliance with regional regulatory requirements, reinforcing our reputation as a reliable, long-term partner in sustainable synthetic leather solutions.

Contact Us for Samples

WINIW Microfiber Suede Leather: Premium Sustainable Material for Discerning B2B Applications

WINIW Microfiber Suede Leather represents the pinnacle of eco-conscious innovation in synthetic materials. Engineered for designers and manufacturers committed to uncompromising quality and environmental responsibility, our microfiber suede offers the luxurious hand-feel and aesthetic of premium natural suede—without the ecological burden. Crafted through a closed-loop water-based process, it eliminates harmful solvents, reduces water consumption by 90% versus traditional leather tanning, and utilizes recycled polyester content. This material is certified by OEKO-TEX® STANDARD 100 and meets stringent REACH compliance, ensuring safety for end-users and alignment with global sustainability frameworks.

Key Advantages for Your Production & Brand Value

- Superior Performance: Exceptional abrasion resistance (≥50,000 cycles ISO 12947) and colorfastness (Grade 4-5 ISO 105-B02) ensure longevity in high-use applications.

- Eco-Integrity: Carbon footprint reduced by 65% compared to bovine suede; 100% free of PVC, phthalates, and heavy metals.

- Design Flexibility: Available in 1.0–1.4mm thicknesses, 54 standard colors (custom shades within 15 days), and widths up to 155cm for minimal waste.

- Production Efficiency: Consistent roll-to-roll quality, easy laser cutting, and compatibility with standard sewing/adhesive processes reduce manufacturing downtime.

- End-of-Life Responsibility: Fully recyclable through WINIW’s take-back program, supporting circular economy initiatives.

Performance Specifications at a Glance

| Property | Test Standard | WINIW Suede Result | Industry Avg. (Synthetic) |

|---|---|---|---|

| Tensile Strength | ISO 1766 | ≥25 N/mm² | 18–22 N/mm² |

| Tear Strength | ISO 4674-1 | ≥55 N | 40–50 N |

| Martindale Abrasion | ISO 12947 | ≥50,000 cycles | 30,000 cycles |

| Colorfastness to Rubbing | ISO 105-X12 | Grade 4-5 | Grade 3-4 |

| VOC Emissions | ISO 16000-6 | <10 μg/m³ | 50–200 μg/m³ |

Ideal Applications Across Industries

- Fashion & Accessories: Handbags, footwear uppers, and luxury apparel demanding softness and drape.

- Furniture & Automotive: Seat covers, headliners, and door panels requiring durability and fade resistance.

- Electronics & Lifestyle: Protective cases, watch straps, and premium gadget accessories with scratch resistance.

- Hospitality: Upholstery for high-traffic areas where stain resistance and easy cleaning are critical.

Accelerate your sustainable design cycle with material that meets ethical imperatives without sacrificing performance. WINIW Microfiber Suede Leather empowers your brand to lead in the circular economy while delivering tangible cost savings through reduced waste and streamlined production.

Request Free Samples to Experience the WINIW Difference

Validate quality, texture, and performance for your next collection or product line. Our technical team provides full material data sheets and compliance documentation upon request.

→ Contact WINIW Marketing: MKT88@MicrofiberLeather.com

Samples dispatched within 48 hours. Global logistics support available.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.