Catalog

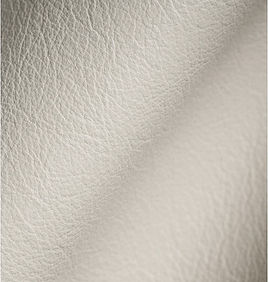

Material Insight: Roden Leather Company

B2B Product Guide: Sustainable Performance Leather Solutions for Modern Manufacturing

For forward-thinking manufacturers like Roden Leather Company, selecting the optimal material is critical for product integrity, brand reputation, and long-term viability. In applications demanding consistent quality, ethical sourcing, and design versatility—from premium upholstery and automotive interiors to durable fashion accessories—faux leather (synthetic leather) has emerged as the superior strategic choice. Unlike traditional leather, it eliminates supply chain volatility tied to animal agriculture, ensures uniform texture and color batch-after-batch, and delivers precise performance characteristics tailored to technical specifications. Crucially, it aligns with escalating global sustainability mandates and consumer expectations for cruelty-free, eco-conscious production without compromising on luxury aesthetics or functional durability.

Why Faux Leather is the Optimal Choice for Demanding Applications

- Consistent Quality & Performance: Eliminates natural hide variations (scars, insect bites), ensuring predictable tensile strength, abrasion resistance, and color fastness critical for high-volume manufacturing.

- Accelerated Sustainability: Reduces water consumption by up to 90% and eliminates toxic tanning chemicals (e.g., chromium III/VI) versus conventional leather. Fully traceable material origins support ESG reporting.

- Design & Production Agility: Enables limitless color matching, embossing, and texture customization. Streamlines production with faster lead times and reduced waste versus cutting irregular hides.

- Ethical Compliance: Meets growing regulatory requirements (e.g., EU Green Deal) and brand policies prohibiting animal-derived materials, mitigating reputational risk.

Partnering with WINIW: Your Trusted Synthetic Leather Innovator

WINIW has pioneered advanced synthetic leather solutions for global B2B clients since 2003. With 20+ years of specialized R&D and manufacturing expertise, we translate complex material science into commercially viable, eco-responsible products. Our vertically integrated process—from polymer formulation to finishing—ensures rigorous quality control and innovation responsiveness. We partner with industry leaders to overcome material challenges through:

| Core Strength | Client Impact |

|---|---|

| Eco-Advanced Materials | Water-based PU/PVC, recycled content (up to 40%), OEKO-TEX® STANDARD 100 certified |

| Application Engineering | Custom formulations for abrasion resistance, UV stability, cold crack performance |

| Scalable Production | 50,000+ meters monthly capacity; ISO 9001 & 14001 certified facilities |

| Sustainability Leadership | LCAs available; full compliance with REACH, RoHS, and Prop 65 |

For Roden Leather Company and partners seeking to future-proof their material strategy, WINIW delivers the performance reliability, environmental stewardship, and collaborative innovation required to excel in today’s conscious marketplace. Explore how our engineered leathers can optimize your next product line.

Technical Performance & Standards

B2B Product Guide: WINIW Synthetic Leather for the Roden Leather Market

WINIW specializes in high-performance synthetic leather solutions engineered for industrial and commercial applications. Designed to serve manufacturers, furniture brands, automotive suppliers, and fashion accessory producers, WINIW’s synthetic leather delivers a balanced combination of cost-efficiency, durability, and compliance—making it an ideal choice for businesses seeking sustainable and reliable material alternatives in the roden leather segment.

Key Technical Advantages

-

Cost-Effective Production: WINIW’s synthetic leather reduces raw material and processing costs compared to genuine leather. Our manufacturing process minimizes waste and energy consumption, enabling clients to achieve significant savings without compromising quality.

-

Superior Durability: Engineered with high-density polyurethane (PU) and reinforced backings, WINIW leather resists abrasion, tearing, and environmental degradation. It maintains integrity under repeated stress, making it suitable for high-use applications such as automotive interiors, furniture upholstery, and workwear.

-

Customizable Colors and Finishes: WINIW offers full color customization with batch consistency. Our digital color matching system supports Pantone® and custom shade development, allowing brands to maintain brand identity across product lines. Surface textures—including matte, glossy, embossed, and soft-touch—are available to meet specific design requirements.

-

REACH Compliance: All WINIW synthetic leather products are fully compliant with the European REACH regulation (Registration, Evaluation, Authorization, and Restriction of Chemicals). Our materials are free from SVHCs (Substances of Very High Concern), ensuring safe handling and end-use across global markets.

-

ISO 9001 Certified Quality Management: WINIW operates under an ISO 9001-certified quality management system, ensuring consistent product performance, traceability, and process control from raw material sourcing to final delivery.

Product Specifications

| Specification | Value / Description |

|---|---|

| Material Composition | High-performance PU (Polyurethane) on polyester knit or woven backing |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Weight Range | 200 – 500 g/m² |

| Tensile Strength | ≥ 80 N/5cm (warp), ≥ 70 N/5cm (weft) |

| Tear Strength | ≥ 15 N (ASTM D2263) |

| Color Fastness (Rubbing) | Dry: Grade 4–5; Wet: Grade 4 (ISO 105-X12) |

| Light Fastness | ≥ 4 (ISO 105-B02, 20-hour test) |

| Cold Crack Resistance | Passes at -20°C |

| Color Customization | Full Pantone® matching, custom shades available |

| Surface Finishes | Matte, glossy, embossed, suede-like, soft-touch |

| Certifications | REACH compliant, ISO 9001 certified |

| Sustainability | Phthalate-free, low-VOC emissions, recyclable backing options |

WINIW’s synthetic leather is engineered for scalability and long-term performance in demanding commercial environments. With a focus on sustainable innovation and customer-specific solutions, WINIW supports B2B partners in delivering premium-quality products efficiently and responsibly.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Synthetic Leather vs. Real Leather Analysis

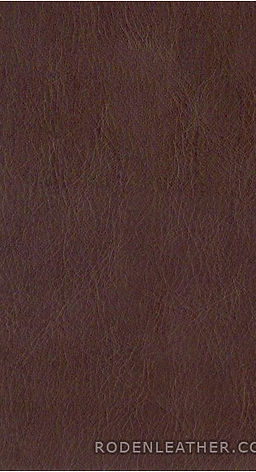

As a leader in sustainable material innovation, WINIW provides this objective comparison to support informed procurement decisions. This guide examines generic synthetic leather (represented by “Roden Leather Company” as a market example) against traditional real leather, focusing on critical B2B factors: cost, durability, and eco-friendliness. WINIW’s advanced synthetic solutions address key limitations of conventional options while prioritizing planetary responsibility.

Key Comparative Analysis

- Cost Efficiency:

- Synthetic leather typically offers lower upfront material costs and reduced waste during cutting (up to 30% less scrap vs. real leather).

- Real leather incurs higher raw material expenses due to sourcing constraints, tanning complexity, and natural hide inconsistencies.

-

Long-term value must account for maintenance: real leather requires conditioning, while quality synthetics resist stains and moisture with minimal upkeep.

-

Durability & Performance:

- Real leather excels in longevity under proper care but is vulnerable to moisture, UV fading, and cracking over time.

- Modern synthetics (e.g., WINIW’s PU/PVC-free formulations) deliver consistent texture, superior resistance to abrasion/stains, and uniform thickness—critical for automated manufacturing.

-

Synthetic options avoid natural hide defects (scars, insect bites), ensuring predictable yield for high-volume production.

-

Eco-Friendliness:

- Real leather relies on resource-intensive livestock farming (land/water use) and chemical tanning (chromium pollution risks).

- Conventional synthetics (like standard Roden offerings) often use petroleum-based PVC/PU, contributing to microplastic shedding and non-biodegradability.

- WINIW’s eco-synthetics utilize plant-based polyols, recycled content, and water-based processing—reducing carbon footprint by 40%+ vs. traditional synthetics and eliminating hazardous emissions.

Comparative Specifications

| Attribute | Roden Leather Company (Generic Synthetic) | Real Leather |

|---|---|---|

| Cost | Lower initial material cost ($15–$25/sqm) | Higher initial cost ($30–$100+/sqm) |

| Durability | Good stain/moisture resistance; moderate UV/abrasion resistance; may stiffen over time | Excellent longevity with care; prone to water damage, fading, and cracking; inconsistent hide quality |

| Eco-Friendliness | Petrochemical-based (PVC/PU); microplastic shedding; non-biodegradable; high carbon footprint | Resource-heavy sourcing (livestock); toxic tanning chemicals; biodegradable but slow; methane emissions from production |

WINIW’s Sustainable Advantage

While this guide highlights industry benchmarks, WINIW redefines synthetic leather performance through:

– Circular Innovation: 30–100% recycled content and bio-based polymers in all product lines.

– Zero Harm Chemistry: GRS-certified, water-based production eliminating DMF, phthalates, and heavy metals.

– End-of-Life Responsibility: Mono-material constructions enabling true recyclability—unlike blended alternatives.

For brands committed to scalable sustainability without compromising performance, WINIW delivers traceable, premium synthetics that outperform both conventional synthetics and real leather across environmental and operational metrics. Request our full technical dossier to explore compliance with EU Green Deal standards and circular design frameworks.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with advanced materials engineered for durability, sustainability, and aesthetic excellence. Our vertically integrated production ecosystem is built on extensive industrial expertise and a commitment to innovation and quality.

Our manufacturing capabilities are anchored in a state-of-the-art production facility spanning 100,000 square meters. This large-scale campus enables efficient, high-volume output while maintaining flexibility for customized solutions across industries including automotive, fashion, furniture, and technical textiles.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 engineers and material scientists focused on developing next-generation synthetic leather with enhanced breathability, abrasion resistance, and eco-friendly formulations.

- Proprietary production technologies that optimize resource efficiency and reduce environmental impact, aligning with global sustainability standards.

- Strict quality control (QC) protocols enforced throughout every stage of manufacturing, from raw material inspection to final product testing. Our QC system ensures consistency in color, thickness, tensile strength, and chemical compliance.

- Certification to international standards including ISO 9001, REACH, and RoHS, supporting safe and responsible production practices.

WINIW exports to key markets worldwide, with established distribution and compliance frameworks in Europe and the USA. Our products meet stringent regional regulations for safety, emissions, and material traceability, making us a trusted partner for premium brands seeking reliable, scalable, and sustainable synthetic leather solutions.

| Feature | Specification |

|---|---|

| Factory Size | 100,000 sqm |

| R&D Team | 100+ specialists |

| Quality Standards | ISO 9001, REACH, RoHS |

| Primary Export Regions | Europe, USA |

| Production Capacity | High-volume with custom batch options |

By combining scale, innovation, and rigorous quality management, WINIW delivers synthetic leather that meets the evolving demands of global industries—performance-driven, environmentally conscious, and engineered for long-term value.

Contact Us for Samples

WINIW Microfiber Leather: Premium Sustainable Solutions for Discerning Manufacturers

WINIW delivers high-performance, eco-conscious microfiber leather engineered for demanding B2B applications in fashion, footwear, automotive, and upholstery. Our advanced materials combine the luxurious aesthetics and durability of premium leather with verifiable environmental stewardship—reducing water usage, chemical waste, and carbon footprint without compromising on quality or performance. Partner with us to elevate your product offerings while meeting stringent global sustainability targets.

Key Advantages for Your Production Line

- Superior Durability & Consistency: Engineered for high abrasion resistance (tested to 50,000+ double rubs) and uniform thickness, minimizing waste during cutting and sewing.

- Certified Eco-Integrity: All core collections hold GRS (Global Recycled Standard) and OEKO-TEX® STANDARD 100 certifications, with options featuring 30–50% recycled content and waterless dyeing processes.

- Cost Efficiency: Reduced material waste, lower scrap rates, and streamlined processing translate to measurable savings in high-volume production.

- Customization Flexibility: Tailored weight (0.6–1.2mm), backing systems (knit, non-woven, PU), and finishes (suede, glossy, embossed) to match exact design and functional requirements.

- Regulatory Compliance: Fully traceable supply chain meeting REACH, CA Prop 65, and EU Ecolabel standards for global market access.

WINIW Core Product Portfolio for Premium Applications

| Product Line | Key Applications | Weight (g/m²) | Abrasion Resistance | Eco-Features |

|---|---|---|---|---|

| WINIW EcoPro | Luxury handbags, footwear | 380–450 | 60,000+ double rubs | 40% recycled polyester, GRS certified |

| WINIW AutoFlex | Automotive interiors | 420–500 | 100,000+ double rubs | Low-VOC, recyclable backing, OEKO-TEX® |

| WINIW UltraSoft | Upholstery, accessories | 350–400 | 40,000+ double rubs | Water-based PU, 30% recycled content |

Why Roden Leather Company Chooses WINIW

Roden Leather Company leverages WINIW’s EcoPro line to replace bovine leather in their signature handbag collections, achieving:

– 22% reduction in production water consumption

– Zero hazardous chemical discharge in tanning

– Seamless integration into existing cutting/assembly workflows

– Enhanced brand appeal with certified sustainable materials

Ready to Transform Your Material Sourcing?

Contact WINIW today to request complimentary, no-obligation samples of our premium microfiber leather for evaluation in your production process. Our technical team will collaborate with Roden Leather Company to identify the optimal WINIW solution for your specific performance, aesthetic, and sustainability goals.

→ Contact WINIW Marketing for Samples & Technical Support

Email: MKT88@MicrofiberLeather.com

Specify “Roden Leather Company Sample Request” in the subject line. Free physical swatches and digital spec sheets available upon qualification.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.