Catalog

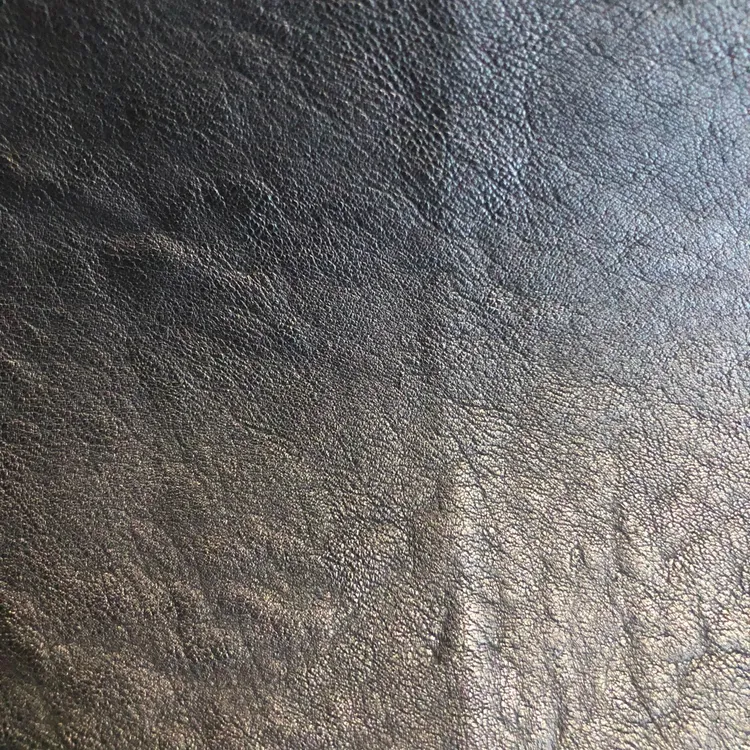

Material Insight: Pu Leatehr

B2B Product Guide: PU Leather Solutions by WINIW

Polyurethane (PU) leather, commonly known as faux leather, is a high-performance synthetic material engineered to replicate the look, feel, and durability of genuine leather—without the environmental and ethical concerns. Made by applying a polyurethane coating to a fabric backing, PU leather offers exceptional versatility, making it ideal for industries ranging from furniture and automotive to fashion and electronics.

Faux leather stands out as the best choice for modern manufacturing applications due to its consistent quality, cost-efficiency, and sustainable profile. Unlike genuine leather, PU leather can be precisely tailored to meet specific requirements for thickness, texture, color, and performance—ensuring batch-to-batch uniformity critical in large-scale production. It is also more environmentally responsible, requiring significantly less water and energy to produce and avoiding the harmful byproducts associated with traditional tanning processes. With superior resistance to abrasion, UV light, and microbial growth, PU leather delivers long-lasting performance in demanding environments.

WINIW is a trusted leader in synthetic leather innovation, with over 20 years of experience in research, development, and manufacturing. Headquartered in China and serving global markets, WINIW specializes in high-quality PU leather solutions that combine advanced technology with eco-conscious practices. Our state-of-the-art production facilities utilize low-VOC formulations, recyclable substrates, and water-based processes to minimize environmental impact while maximizing product performance.

- We offer a comprehensive range of PU leather products tailored for diverse industrial applications.

- Our materials meet international standards for safety, durability, and sustainability, including REACH, RoHS, and OEKO-TEX®.

- WINIW partners with B2B clients to deliver custom solutions—from texture and color matching to performance enhancements.

With a commitment to innovation, quality, and environmental stewardship, WINIW empowers manufacturers to build better products with smarter materials.

Technical Performance & Standards

WINIW PU Leather: Advanced Synthetic Solution for Demanding Applications

WINIW PU Leather delivers a superior balance of performance, sustainability, and economic value for B2B manufacturing partners. Engineered for industrial scalability without compromising environmental responsibility, our material provides a reliable alternative to traditional leather and inferior synthetics. Below are the core technical advantages driving ROI for global clients.

Key Technical Advantages

-

Cost-Effective Production

Optimized resin formulation and high-yield manufacturing reduce material costs by 15–25% versus standard PU leathers. Consistent thickness tolerance (±0.05mm) minimizes cutting waste, while rapid thermoforming compatibility accelerates production cycles. -

Exceptional Durability

Reinforced polyester backing and cross-linked polyurethane matrix achieve >50,000 cycles Martindale abrasion resistance (ASTM D4966). Resists cracking at -20°C, maintains integrity under 100,000+ flex cycles (ASTM D2095), and exhibits <5% tensile elongation loss after 1,000 hrs UV exposure (ISO 105-B02). -

Precision Color Customization

Pantone®-matched pigmentation system supports 1,200+ standard colors with Delta-E <1.0 color consistency. Custom color development turnaround: 7–10 days. Batch-to-batch variance controlled to ΔE <0.5 via spectrophotometric QC. -

Full REACH Compliance

Zero SVHCs (Substances of Very High Concern) per ECHA guidelines. Phthalate-free plasticizers, heavy metal content <10ppm (Cd, Pb, Hg, Cr⁶⁺), and VOC emissions <50μg/m³ (EN ISO 12219-3). Comprehensive compliance documentation available. -

ISO 9001-Certified Quality

End-to-end process control from raw material sourcing to shipment. Real-time in-line thickness monitoring, 100% visual inspection, and quarterly third-party validation ensure ≤0.5% defect rate.

Technical Specifications Overview

| Property | Standard Value | Test Method |

|---|---|---|

| Thickness Range | 0.6 mm – 1.2 mm | ISO 2418 |

| Tensile Strength | ≥ 25 N/mm² | ISO 1767 |

| Tear Strength | ≥ 45 N | ISO 3377-2 |

| Colorfastness (Rubbing) | Grade 4–5 (Dry/Wet) | ISO 105-X12 |

| Martindale Abrasion | ≥ 50,000 cycles | ASTM D4966 |

| Lightfastness | ≥ 6 (Blue Wool Scale) | ISO 105-B02 |

| Hydrolysis Resistance | Pass (500 hrs) | ISO 1419 (Type B) |

| Formaldehyde Content | < 20 ppm | EN ISO 17226-1 |

WINIW PU Leather integrates circular design principles with industrial robustness, enabling partners to meet stringent sustainability targets without sacrificing performance. Our dedicated technical team collaborates on material adaptation for automotive interiors, furniture, luggage, and technical textiles—ensuring optimal processing and end-product excellence. Request a sample kit with full compliance dossier to validate performance against your specifications.

Why Choose Synthetic over Real Leather

B2B Product Guide: PU Leather vs. Real Leather

In the manufacturing and design sectors, selecting the right material is crucial for balancing performance, cost, and sustainability. Two widely used materials in footwear, upholstery, automotive interiors, and fashion accessories are PU (polyurethane) leather and real (genuine) leather. Below is a detailed comparison to support informed B2B decision-making.

Overview of Materials

-

PU Leather: A synthetic alternative made by applying a polyurethane coating to a fabric backing. It mimics the texture and appearance of real leather without using animal hides. WINIW’s advanced PU leather solutions are engineered for high performance, offering consistent thickness, color fastness, and enhanced breathability.

-

Real Leather: Derived from animal hides (commonly bovine), real leather undergoes tanning and finishing processes to preserve and enhance its natural properties. It is valued for its authenticity, longevity, and premium tactile feel.

Key Differences

-

Composition: PU leather is 100% synthetic and animal-free, making it suitable for vegan and cruelty-free product lines. Real leather is a natural material with inherent variations in grain and texture.

-

Consistency: PU leather offers uniform appearance and thickness across batches, simplifying production planning and quality control. Real leather may have natural imperfections and variations, requiring more grading and sorting.

-

Customization: PU leather can be easily colored, embossed, and textured to meet specific design requirements. Real leather customization is more limited due to its natural structure.

-

Maintenance: PU leather is generally easier to clean and more resistant to staining and fading under UV exposure when formulated with protective topcoats. Real leather requires conditioning to prevent drying and cracking.

-

Sustainability: PU leather production avoids animal agriculture, reducing land and water use. Modern microfiber PU leathers, such as those developed by WINIW, are designed for recyclability and lower environmental impact. Real leather relies on the meat industry, but tanning processes (especially chrome tanning) can generate hazardous waste if not managed responsibly.

Performance Comparison

| Criteria | PU Leather | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher due to raw material and processing |

| Durability | Good resistance to cracking and fading; lifespan of 3–5 years with proper care | High durability; can last 10+ years with maintenance |

| Eco-friendliness | Higher; lower carbon footprint, no animal sourcing, recyclable options available | Moderate; uses by-products of meat industry but tanning can be polluting |

Conclusion

For B2B partners prioritizing cost-efficiency, design flexibility, and environmental responsibility, PU leather presents a compelling alternative to real leather. WINIW’s eco-conscious PU leather solutions are engineered to meet rigorous industrial standards while supporting sustainable supply chains. Real leather remains a premium choice for luxury markets where natural origin and aging characteristics are valued. The optimal material choice depends on the product application, target market, and sustainability goals.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered Excellence for Global Partners

WINIW stands as a leader in sustainable synthetic leather manufacturing, delivering premium materials to discerning B2B clients worldwide. Our vertically integrated operations combine scale, innovation, and uncompromising quality control to meet the rigorous demands of international markets, particularly Europe and North America.

Core Manufacturing Strengths

- Advanced Production Capacity: Operate a state-of-the-art facility spanning 100,000+ sqm, enabling high-volume output with agile scalability for custom orders.

- Innovation-Driven R&D: Maintain a dedicated team of 50+ specialists focused on material science, eco-process development, and performance enhancement. Our lab pioneers water-based PU/PVC formulations, recycled content integration (up to 40% PCR), and bio-based alternatives.

- Rigorous Quality Assurance: Implement a 4-stage QC protocol (raw material screening, in-process monitoring, finished product validation, and shipment verification) aligned with ISO 9001 standards. Every batch undergoes 12+ physical performance tests (abrasion, colorfastness, tear strength) and chemical compliance screening.

- Global Compliance Expertise: Certifications include OEKO-TEX® STANDARD 100, REACH, CPSIA, and SGS-tested phthalate-free production. Tailored documentation supports seamless customs clearance in the EU and USA.

Global Market Reach

WINIW consistently supplies Tier-1 clients across key sectors:

| Region | Key Industries Served | Compliance Highlights |

|————–|——————————–|————————————-|

| Europe | Automotive, Luxury Goods, Furniture | REACH SVHC, EU Ecolabel, ZDHC MRSL |

| North America| Footwear, Apparel, Healthcare | CPSIA, Prop 65, LEED-compatible |

| APAC | Electronics, Transportation | JIS L 1081, GB/T 22892-2009 |

Our logistics network ensures <30-day lead times for container shipments to major ports in Rotterdam, Los Angeles, and New York, backed by dedicated regional support teams. By prioritizing closed-loop water systems, solar energy integration, and zero-VOC processes, WINIW delivers not just performance, but a verifiable reduction in environmental footprint—proven through annual third-party lifecycle assessments. Partner with us for synthetic leather solutions where ethical manufacturing meets industrial excellence.

Contact Us for Samples

B2B Product Guide: WINIW® PU Leather Solutions

WINIW is a leading innovator in synthetic leather manufacturing, specializing in high-performance, eco-conscious polyurethane (PU) leather for global B2B clients. Our advanced production technology ensures consistent quality, durability, and sustainability—making WINIW the preferred choice for industries ranging from automotive and furniture to fashion and footwear.

Our PU leather is engineered to meet rigorous international standards, offering excellent abrasion resistance, color fastness, and flexibility. With a focus on environmental responsibility, WINIW’s PU leather is free from hazardous substances and produced using low-impact processes, aligning with global sustainability goals.

Key Advantages of WINIW PU Leather:

- Superior softness and texture, closely mimicking genuine leather

- High resistance to wear, cracking, and fading

- Eco-friendly formulation with REACH and RoHS compliance

- Customizable thickness, color, finish, and backing fabric

- Cost-effective alternative to genuine leather with consistent batch quality

- Suitable for a wide range of applications including upholstery, bags, apparel, and interiors

Technical Specifications (Standard Grade):

| Property | Specification |

|---|---|

| Thickness | 0.6mm – 2.0mm (customizable) |

| Width | 137cm / 54” (standard roll width) |

| Weight | 200g – 400g per linear meter |

| Abrasion Resistance | >20,000 cycles (Martindale) |

| Color Fastness | ≥ Grade 4 (Xenon arc test) |

| Environmental Standards | REACH, RoHS, OEKO-TEX® compliant |

Why Partner with WINIW?

We support bulk manufacturing with short lead times, global shipping, and dedicated R&D for custom solutions. Our team collaborates closely with clients to match material performance with brand values—especially in sustainability and innovation.

Request Free Samples

Experience the quality of WINIW PU leather firsthand. Free samples are available for qualified B2B partners.

Contact us today:

MKT88@MicrofiberLeather.com

Subject: Request for PU Leather Sample & Catalog

Elevate your product line with sustainable, high-performance PU leather from WINIW.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.