Introduction: Navigating the Global Market for fabric and leather adhesive

In today’s competitive landscape, sourcing high-quality fabric and leather adhesive can present significant challenges for international B2B buyers. With a myriad of options available globally, it becomes crucial to identify adhesives that not only meet industry standards but also suit specific applications, whether for upholstery, fashion, or industrial uses. This guide serves as a comprehensive resource, providing insights into various types of fabric and leather adhesives, their applications, and the key factors to consider when selecting the right product for your needs.

Throughout this guide, we will explore the distinct characteristics of popular adhesive options, from quick-drying solutions to those offering permanent bonds, ensuring that your purchasing decisions are well-informed. Additionally, we will delve into supplier vetting processes, cost considerations, and regional market trends, specifically tailored for B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, such as Brazil and Germany.

By equipping you with the knowledge to navigate the complexities of the fabric and leather adhesive market, this guide aims to empower your business with the tools necessary to make strategic purchasing decisions. Ultimately, a well-informed approach to sourcing adhesives can enhance product quality and durability, driving greater satisfaction for your customers and fostering long-term business success.

Table Of Contents

- Top 5 Fabric And Leather Adhesive Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric and leather adhesive

- Understanding fabric and leather adhesive Types and Variations

- Key Industrial Applications of fabric and leather adhesive

- 3 Common User Pain Points for ‘fabric and leather adhesive’ & Their Solutions

- Strategic Material Selection Guide for fabric and leather adhesive

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric and leather adhesive

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric and leather adhesive’

- Comprehensive Cost and Pricing Analysis for fabric and leather adhesive Sourcing

- Alternatives Analysis: Comparing fabric and leather adhesive With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric and leather adhesive

- Navigating Market Dynamics and Sourcing Trends in the fabric and leather adhesive Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric and leather adhesive

- Strategic Sourcing Conclusion and Outlook for fabric and leather adhesive

- Important Disclaimer & Terms of Use

Understanding fabric and leather adhesive Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Water-Based Adhesives | Fast grab, dries clear, remains flexible | Upholstery, leather repairs, clothing | Pros: Non-toxic, easy cleanup; Cons: May not bond well with non-porous materials. |

| Instant Adhesives | Quick-drying, strong, permanent bond | Fabric and leather repairs, crafts | Pros: Rapid application, durable; Cons: Limited working time before set. |

| Contact Adhesives | Strong initial tack, requires bonding surfaces to be pressed together | Industrial applications, heavy-duty repairs | Pros: Excellent for large surface areas; Cons: Requires precise application. |

| Heat-Activated Adhesives | Bond formed with heat application | Specialty leather goods, automotive interiors | Pros: Creates robust bonds; Cons: Requires heat source, longer application time. |

| Eco-Friendly Adhesives | Non-toxic, biodegradable materials | Sustainable fashion, eco-conscious products | Pros: Meets green certifications; Cons: May have lower performance in extreme conditions. |

What Are the Key Characteristics of Water-Based Adhesives?

Water-based adhesives are known for their fast grab and flexibility, making them ideal for a variety of applications in upholstery, leather repairs, and clothing manufacturing. These adhesives typically dry clear, ensuring that aesthetic qualities are maintained after application. B2B buyers should consider the non-toxic nature of these products, which allows for easier cleanup and safer handling. However, it is crucial to note that their bonding effectiveness may diminish on non-porous surfaces, which could limit their use in certain industrial applications.

How Do Instant Adhesives Benefit B2B Buyers?

Instant adhesives, such as Tear Mender, are favored for their quick-drying capabilities and strong, permanent bonds. They are particularly suitable for fabric and leather repairs, as well as various crafting applications. The rapid application process allows businesses to minimize downtime, making it a valuable asset in production settings. However, buyers should be aware of the limited working time before the adhesive sets, which necessitates careful planning during the application process.

What Are the Advantages of Using Contact Adhesives?

Contact adhesives are characterized by their strong initial tack and bonding capabilities, especially when both surfaces are pressed together. They are commonly used in industrial applications, such as heavy-duty repairs and large surface area bonding. The robustness of contact adhesives makes them suitable for demanding environments. Buyers should consider that precise application is essential, as misalignment can lead to ineffective bonds, potentially resulting in wasted materials and increased costs.

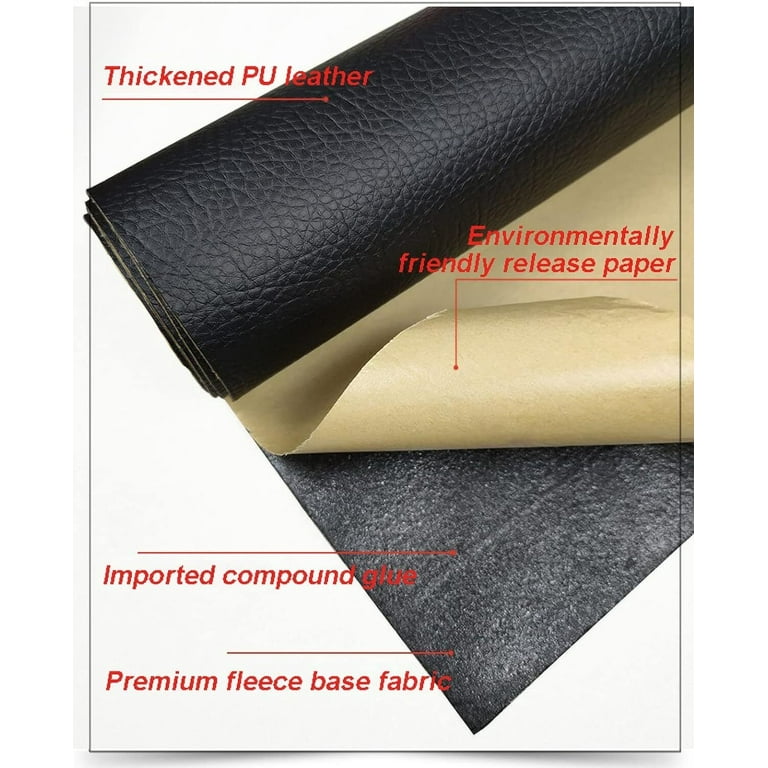

Illustrative image related to fabric and leather adhesive

When Should B2B Buyers Consider Heat-Activated Adhesives?

Heat-activated adhesives are specialized products that require a heat source for bonding. They are particularly effective for applications in specialty leather goods and automotive interiors, where a strong, durable bond is essential. While these adhesives create robust connections, they necessitate additional equipment for application, which can increase initial investment costs. B2B buyers should evaluate whether the benefits of strength and durability outweigh the complexities of application.

Why Choose Eco-Friendly Adhesives for Sustainable Practices?

Eco-friendly adhesives are formulated from non-toxic and biodegradable materials, making them an excellent choice for businesses focused on sustainability. They are increasingly popular in sustainable fashion and eco-conscious product lines. While these adhesives often meet green certifications, buyers should keep in mind that they may not perform as well under extreme conditions compared to traditional options. This consideration is crucial for businesses aiming to balance environmental responsibility with product performance.

Key Industrial Applications of fabric and leather adhesive

| Industry/Sector | Specific Application of Fabric and Leather Adhesive | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery repair and customization | Enhances vehicle aesthetics and longevity | Durability, heat resistance, and flexibility are critical. |

| Fashion & Apparel | Seamless garment repairs and alterations | Reduces waste and extends product life | Eco-friendly formulations and quick-drying properties are essential. |

| Furniture Manufacturing | Upholstery and leather furniture assembly | Ensures product durability and customer satisfaction | Adhesive strength and compatibility with various materials are key. |

| Footwear Production | Sole attachment and leather repairs | Improves product quality and reduces returns | Waterproof and flexible adhesives are crucial for long-lasting wear. |

| Marine Industry | Repair of boat covers and upholstery | Enhances safety and prolongs equipment life | UV resistance and waterproof capabilities are vital for outdoor applications. |

How is Fabric and Leather Adhesive Used in the Automotive Industry?

In the automotive sector, fabric and leather adhesives are essential for upholstery repair and customization. These adhesives are used to bond various materials, such as leather seats and fabric linings, ensuring a seamless finish. By using high-quality adhesives, manufacturers can enhance vehicle aesthetics and extend the lifespan of interior components. International buyers should prioritize sourcing adhesives that exhibit durability, heat resistance, and flexibility to withstand the rigors of automotive environments.

What Role Does Fabric and Leather Adhesive Play in Fashion and Apparel?

In the fashion and apparel industry, fabric and leather adhesives facilitate seamless garment repairs and alterations. They enable designers and manufacturers to quickly fix tears, reinforce seams, and create unique designs without the need for traditional sewing methods. This not only reduces waste but also extends the life of garments, appealing to eco-conscious consumers. Buyers should look for eco-friendly formulations that offer quick-drying properties to streamline production processes.

How is Fabric and Leather Adhesive Applied in Furniture Manufacturing?

Furniture manufacturers utilize fabric and leather adhesives for upholstery and furniture assembly. These adhesives ensure a strong bond between various materials, contributing to the durability and aesthetic appeal of the final product. By employing reliable adhesives, businesses can enhance customer satisfaction and reduce product returns. When sourcing, manufacturers should consider the adhesive’s strength and compatibility with different materials to ensure optimal performance.

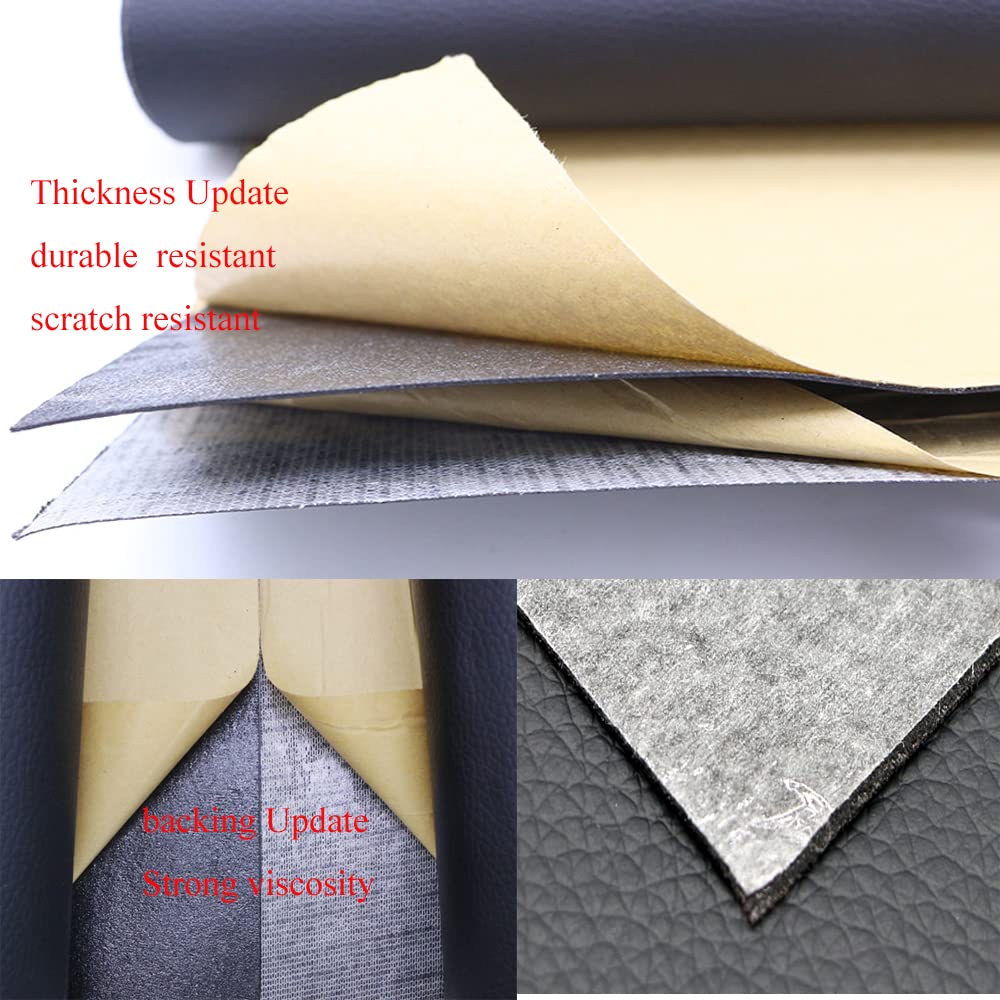

Illustrative image related to fabric and leather adhesive

In What Ways Do Footwear Producers Benefit from Fabric and Leather Adhesive?

In footwear production, fabric and leather adhesives are crucial for attaching soles and repairing leather components. These adhesives provide a strong, flexible bond that can withstand the demands of daily wear. By improving product quality and reducing return rates, manufacturers can enhance their reputation in a competitive market. Buyers should prioritize waterproof and flexible adhesives to ensure long-lasting performance in footwear applications.

How is Fabric and Leather Adhesive Utilized in the Marine Industry?

The marine industry employs fabric and leather adhesives for the repair of boat covers, upholstery, and other fabric-based components. These adhesives help maintain safety and prolong the life of marine equipment by providing strong, waterproof bonds. International buyers should focus on adhesives that offer UV resistance and durability to withstand harsh marine environments, ensuring reliable performance in outdoor applications.

3 Common User Pain Points for ‘fabric and leather adhesive’ & Their Solutions

Scenario 1: Rapid Repairs for High-Volume Production

The Problem: In industries such as fashion manufacturing or upholstery, B2B buyers often face the challenge of needing rapid repairs on products to meet production deadlines. A torn seam or damaged leather can halt the production line, causing delays and increased costs. Buyers are often frustrated with adhesives that take too long to cure or do not provide a strong enough bond for high-stress applications, leading to rework and wasted materials.

Illustrative image related to fabric and leather adhesive

The Solution: To address this pain point, buyers should seek out fast-acting adhesives specifically designed for high-volume production settings. For instance, Tear Mender’s instant fabric and leather adhesive offers a quick-setting time of just three minutes, allowing for immediate handling and further processing. When sourcing these adhesives, buyers should look for products that are both waterproof and flexible to ensure durability in varying conditions. Additionally, conducting a thorough testing phase with different materials can help determine the most effective adhesive for specific applications, ensuring that repairs are not only quick but also reliable.

Scenario 2: Compatibility with Diverse Materials

The Problem: Many B2B buyers encounter issues when trying to bond different materials, such as leather to fabric, or fabric to metal. The challenge lies in finding an adhesive that effectively works across multiple substrates without compromising the integrity of either material. This can lead to product failures, increased returns, and a damaged reputation.

The Solution: To overcome this compatibility challenge, buyers should opt for versatile adhesives like those that are specifically labeled for use on a variety of materials, including leather, textiles, and synthetics. Products such as Tear Mender are engineered to create strong bonds on porous and non-porous surfaces alike. Buyers should also consider using a patch method for repairs, where a piece of the same material is placed beneath the damaged area, ensuring better adhesion and strength. For best results, it’s advisable to conduct preliminary tests on small samples to evaluate adhesion before full-scale application, minimizing risks associated with material incompatibility.

Scenario 3: Ensuring Long-Term Durability in Outdoor Applications

The Problem: B2B buyers involved in outdoor product manufacturing, such as marine upholstery or outdoor gear, face the challenge of ensuring that their adhesive choices can withstand harsh environmental conditions. Many adhesives fail when exposed to moisture, UV rays, or extreme temperatures, leading to product degradation and customer dissatisfaction.

Illustrative image related to fabric and leather adhesive

The Solution: To ensure durability in outdoor applications, buyers should prioritize adhesives that are specifically formulated to be UV resistant and waterproof. Products like Tear Mender not only provide a quick-drying and flexible bond but are also designed to withstand outdoor conditions. When selecting an adhesive, buyers should verify the manufacturer’s specifications regarding temperature and moisture resistance. Implementing a rigorous quality control process, including real-world testing of adhesives in outdoor environments, will help to validate their performance. Regularly reviewing supplier options and staying updated on the latest advancements in adhesive technology can also enhance product longevity and customer satisfaction.

Strategic Material Selection Guide for fabric and leather adhesive

What Are the Key Materials for Fabric and Leather Adhesives?

When selecting adhesives for fabric and leather applications, understanding the properties and implications of various materials is crucial for international B2B buyers. Here, we analyze four common materials used in fabric and leather adhesives, focusing on their key properties, advantages, disadvantages, and specific considerations for global markets.

What Are the Key Properties of Water-Based Adhesives?

Water-based adhesives are popular in fabric and leather applications due to their versatility and ease of use. They typically feature a flexible bond that can withstand moderate temperature variations, making them suitable for various climates.

Pros: Water-based adhesives are non-toxic and eco-friendly, which aligns with the growing demand for sustainable products. They are also easy to clean up with water, reducing manufacturing complexity.

Cons: However, their durability may be lower than solvent-based options, particularly in high-stress applications. They may also require longer curing times, which can affect production schedules.

Impact on Application: These adhesives are compatible with a wide range of porous materials, making them ideal for textiles and leather. However, they may not perform well on non-porous surfaces.

Considerations for International Buyers: Compliance with environmental regulations is crucial, especially in Europe, where stringent standards like REACH apply. Buyers should also be aware of local preferences for sustainable products.

How Do Solvent-Based Adhesives Compare?

Solvent-based adhesives offer strong bonds and excellent durability, making them suitable for heavy-duty applications. They can withstand high temperatures and pressures, which is vital for products exposed to extreme conditions.

Pros: Their quick-drying nature allows for faster production cycles, making them a preferred choice for manufacturers needing efficiency.

Cons: The main drawback is their potential toxicity and environmental impact, which may lead to regulatory challenges. Additionally, they can be more expensive due to the cost of raw materials and compliance measures.

Impact on Application: Solvent-based adhesives are effective for both porous and non-porous materials, broadening their usability in diverse applications.

Considerations for International Buyers: Buyers in regions like the Middle East and Africa should ensure compliance with local safety regulations, as well as international standards such as ASTM and DIN.

What Are the Benefits of Hot Melt Adhesives?

Hot melt adhesives provide a strong, flexible bond that sets quickly upon cooling. They are ideal for applications requiring immediate handling, such as in the automotive and furniture industries.

Pros: Their fast curing time enhances production efficiency, and they can bond a variety of materials, including leather and textiles.

Cons: However, their performance can be affected by temperature fluctuations, as they may soften in high heat. This limits their application in environments with extreme temperatures.

Impact on Application: Hot melt adhesives are particularly effective for layered materials and can provide a waterproof seal, making them suitable for outdoor applications.

Illustrative image related to fabric and leather adhesive

Considerations for International Buyers: Buyers should consider the thermal stability of hot melt adhesives in their specific climate conditions, especially in warmer regions. Compliance with relevant standards is also necessary.

How Do Contact Adhesives Function in This Context?

Contact adhesives are known for their strong initial tack and flexibility, making them suitable for bonding leather to fabric. They require application on both surfaces before joining.

Pros: They offer excellent resistance to heat and moisture, making them ideal for products that will be exposed to various environmental conditions.

Cons: The complexity of application can be a drawback, as it requires precise alignment and timing. Additionally, the fumes can pose health risks, necessitating proper ventilation during use.

Illustrative image related to fabric and leather adhesive

Impact on Application: Contact adhesives are particularly effective for heavy-duty applications where a strong bond is critical, such as in upholstery and automotive interiors.

Considerations for International Buyers: Buyers must ensure that the adhesives comply with local regulations regarding VOC emissions, especially in regions with strict environmental laws.

Summary Table of Material Properties

| Material | Typical Use Case for fabric and leather adhesive | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Water-Based Adhesives | General fabric and leather bonding | Eco-friendly and easy cleanup | Lower durability in high-stress applications | Low |

| Solvent-Based Adhesives | Heavy-duty bonding in extreme conditions | Strong bond and quick drying | Potential toxicity and higher costs | High |

| Hot Melt Adhesives | Automotive and furniture applications | Fast curing and flexible bond | Performance affected by temperature | Medium |

| Contact Adhesives | Upholstery and automotive interiors | Excellent resistance to heat and moisture | Complex application process | Medium |

This strategic material selection guide provides B2B buyers with essential insights into fabric and leather adhesives, enabling informed decisions that align with their operational needs and regional compliance requirements.

Illustrative image related to fabric and leather adhesive

In-depth Look: Manufacturing Processes and Quality Assurance for fabric and leather adhesive

What Are the Main Stages in the Manufacturing Process of Fabric and Leather Adhesives?

The manufacturing of fabric and leather adhesives encompasses several critical stages, each designed to ensure that the final product meets stringent performance and safety standards. Understanding these stages can help B2B buyers assess the capabilities of their suppliers.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing fabric and leather adhesives is material preparation. This involves sourcing high-quality raw materials, including polymers, solvents, and additives. The choice of materials directly impacts the adhesive’s properties, such as flexibility, drying time, and resistance to environmental factors. For instance, water-based polymers are commonly used for their eco-friendly properties and ease of use.

During this stage, suppliers typically conduct thorough checks on the quality of raw materials, ensuring they comply with international standards such as ISO 9001. B2B buyers should inquire about the sourcing and specifications of these materials to ensure that they align with their own quality requirements.

Forming: How Is the Adhesive Mixture Created?

The forming stage involves mixing the prepared raw materials in precise ratios. This process often employs advanced mixing technology to achieve a homogeneous mixture, crucial for ensuring consistent adhesive performance. Key techniques during this phase include:

- High-Shear Mixing: This method is used to blend materials thoroughly, reducing the risk of clumping and ensuring uniformity in viscosity.

- Temperature Control: Maintaining specific temperature ranges during mixing can enhance the properties of the adhesive, such as curing speed and bonding strength.

B2B buyers should confirm that their suppliers utilize modern mixing technologies, as this can significantly impact product quality.

Assembly: What Steps Are Taken to Package the Adhesive?

Once the adhesive has been mixed, it is transferred to the assembly stage. Here, the adhesive is packaged into various formats, such as tubes, bottles, or bulk containers, depending on the intended use. This stage may also involve the addition of safety seals and labels that comply with regulatory requirements.

Quality checks are essential during assembly to ensure that the packaging is secure and that the adhesive is free from contamination. Buyers should look for suppliers that have robust assembly processes, as packaging can affect shelf life and usability.

Finishing: How Is the Adhesive Prepared for Distribution?

The finishing stage involves final inspections and testing before the adhesive is ready for distribution. This includes:

Illustrative image related to fabric and leather adhesive

- Labeling: Ensuring that all products are accurately labeled with safety information and usage instructions.

- Quality Control Tests: Conducting various tests, such as viscosity measurements and bonding strength evaluations, to confirm that the adhesive meets specified performance criteria.

In this stage, B2B buyers should ask about the specific tests performed and the results, as these can provide insights into the adhesive’s reliability.

What Quality Assurance Practices Are Essential for Fabric and Leather Adhesives?

Quality assurance (QA) is a critical aspect of the manufacturing process for fabric and leather adhesives. Effective QA practices help ensure that products consistently meet performance standards and regulatory requirements.

What International Standards Should B2B Buyers Consider?

For B2B buyers, understanding the relevant international standards is crucial for ensuring product quality. Key standards include:

Illustrative image related to fabric and leather adhesive

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming for consistent quality in their products.

- CE Marking: In Europe, products must comply with CE marking regulations, indicating that they meet safety and health standards.

- API Standards: For adhesives used in specific applications, such as automotive or aerospace, adherence to API (American Petroleum Institute) standards may be necessary.

B2B buyers should verify that their suppliers comply with these standards to mitigate risks associated with product quality.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are critical for maintaining product integrity throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to monitor consistency and quality.

- Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to ensure all specifications are met.

B2B buyers can enhance their supply chain reliability by asking suppliers about their quality control procedures and how they handle discrepancies.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

Verifying a supplier’s quality assurance practices is essential for B2B buyers looking to ensure consistent product quality. Here are some strategies:

What Role Do Audits and Reports Play?

Regular audits of suppliers can provide valuable insights into their manufacturing processes and quality control practices. Buyers should request:

- Quality Assurance Audits: These audits assess compliance with ISO and other relevant standards.

- Performance Reports: Suppliers should provide documentation detailing quality metrics, such as defect rates and testing results.

By reviewing these reports, buyers can gain confidence in their suppliers’ capabilities and reliability.

How Important Are Third-Party Inspections?

Engaging third-party inspectors can further enhance quality assurance. These independent entities can conduct assessments of the manufacturing process and product quality, providing an unbiased evaluation. B2B buyers should consider including third-party inspections in their procurement process to ensure adherence to quality standards.

What Nuances Should International Buyers Consider?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, should be aware of specific nuances when evaluating adhesive suppliers:

- Regulatory Differences: Each region may have different regulatory requirements for adhesives, so it’s essential to ensure that suppliers comply with local regulations.

- Cultural Differences in Quality Standards: Expectations regarding quality and performance may vary by region, affecting how suppliers approach manufacturing and quality assurance.

By understanding these nuances, international buyers can make more informed decisions and foster successful partnerships with their suppliers.

Conclusion

The manufacturing processes and quality assurance practices for fabric and leather adhesives are complex yet critical for ensuring product reliability. By understanding these processes and actively engaging with suppliers about their quality assurance measures, B2B buyers can enhance their procurement strategies and ensure they receive high-quality adhesives that meet their specific needs.

Illustrative image related to fabric and leather adhesive

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric and leather adhesive’

To assist B2B buyers in the procurement of fabric and leather adhesives, this guide provides a structured approach to ensure informed decision-making. By following these steps, you can identify the best products for your needs while minimizing risks and ensuring quality.

Step 1: Define Your Technical Specifications

Start by determining the specific requirements for your adhesive. Consider factors such as the materials you’ll be bonding (fabric types, leather grades), the intended use (indoor vs. outdoor applications), and performance characteristics (waterproof, flexible, UV resistant). Clearly defined specifications help streamline the sourcing process and align your needs with supplier offerings.

Step 2: Research Market Trends and Product Innovations

Stay informed about the latest advancements in adhesive technologies. Trends such as eco-friendly formulations and quick-drying properties are gaining traction globally. Understanding these trends allows you to choose products that not only meet current performance standards but also appeal to environmentally conscious consumers.

Step 3: Evaluate Potential Suppliers

Before making any commitments, thoroughly vet potential suppliers. Look for established companies with a proven track record in the adhesive market. Request company profiles, product samples, and case studies from other businesses in your industry. This step is essential to gauge the reliability and quality of the adhesive products you’re considering.

Step 4: Verify Certifications and Compliance

Ensure that the adhesives meet relevant industry standards and regulations, especially if your products will be exported or used in sensitive applications. Check for certifications such as ISO, ASTM, or REACH compliance. Compliance not only assures quality but also helps avoid legal complications in your target markets.

Step 5: Request Samples for Testing

Always ask for product samples before placing a bulk order. Conduct in-house testing to evaluate the adhesive’s performance based on your specific requirements, such as bond strength, drying time, and flexibility. This hands-on approach can reveal potential issues and help you make an informed decision.

Step 6: Negotiate Pricing and Terms

Once you’ve selected a supplier, it’s time to negotiate pricing and terms. Consider factors like bulk discounts, payment terms, and shipping options. A clear agreement protects both parties and ensures you receive the best value for your investment.

Step 7: Establish a Quality Assurance Process

Finally, implement a quality assurance process to monitor the adhesive’s performance over time. Regularly review supplier performance and product quality to ensure they continue to meet your specifications. This proactive approach will help mitigate risks associated with adhesive failures and maintain product integrity.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing fabric and leather adhesives, ensuring they select high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for fabric and leather adhesive Sourcing

What Are the Key Cost Components for Fabric and Leather Adhesive?

When sourcing fabric and leather adhesive, understanding the cost structure is crucial for effective budgeting and procurement strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of base chemicals significantly influences the cost. For instance, eco-friendly, non-toxic adhesives may come at a premium compared to conventional options. Prices can range from $6.50 to $32.99 per unit, depending on the formulation and size.

-

Labor: Labor costs vary based on the region and the complexity of the adhesive production process. In regions with higher wage standards, labor can account for a larger portion of the total cost.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs, making it essential to evaluate suppliers’ operational efficiencies.

-

Tooling: Initial setup costs for specialized machinery can be significant. Custom adhesives may require unique tooling, which could lead to higher upfront costs but potentially lower unit costs for larger orders.

-

Quality Control: Ensuring product consistency and reliability is vital, particularly for B2B applications. QC processes may add to costs but are necessary to maintain standards and avoid costly returns or rework.

-

Logistics: Shipping and handling costs can fluctuate based on the distance from the manufacturer to the buyer, as well as the shipping method chosen. Understanding Incoterms is essential to clarify who bears these costs.

-

Margin: Supplier margins will vary based on competition, brand reputation, and the perceived value of the product. Buyers should assess if the margin aligns with the product’s quality and performance.

How Do Price Influencers Impact Sourcing Decisions for Fabric and Leather Adhesive?

Several factors can influence the pricing of fabric and leather adhesives, making it essential for international buyers to consider these elements during their sourcing process.

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Negotiating favorable terms based on anticipated usage can lead to significant savings.

-

Specifications and Customization: Custom formulations tailored to specific applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Adhesives that meet specific industry standards or possess certifications (e.g., eco-friendly, non-toxic) may have higher costs. Buyers should weigh these benefits against their project requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and customer service can significantly impact pricing. Establishing long-term relationships with suppliers may also yield better pricing and terms.

-

Incoterms: Understanding shipping terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is vital. These terms affect overall pricing and the responsibilities of both the buyer and seller regarding logistics costs.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing Fabric and Leather Adhesive?

Navigating the B2B market for fabric and leather adhesives can be challenging, particularly for buyers from regions like Africa, South America, the Middle East, and Europe. Here are several strategies to enhance cost-efficiency:

-

Negotiation: Always engage in negotiations with suppliers. Leverage bulk purchasing, long-term contracts, and competitive quotes from multiple suppliers to obtain the best possible pricing.

-

Total Cost of Ownership (TCO): Consider not just the purchase price, but also logistics, storage, and potential waste or rework costs when evaluating options. A cheaper adhesive may lead to higher TCO if it requires more frequent replacements or results in lower quality outcomes.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, adhesives sourced within Europe may carry higher shipping costs to Africa or South America. Understanding these nuances can inform sourcing decisions.

-

Supplier Evaluation: Regularly assess supplier performance and product quality. Building a rapport with reliable suppliers can lead to improved pricing and priority service during peak demand periods.

In conclusion, careful analysis of cost components, price influencers, and strategic sourcing tips can empower international B2B buyers to make informed decisions in the fabric and leather adhesive market. Always remember that prices may fluctuate, and it’s advisable to obtain indicative quotes before finalizing any sourcing agreements.

Alternatives Analysis: Comparing fabric and leather adhesive With Other Solutions

Understanding Alternatives to Fabric and Leather Adhesive

In the realm of materials repair, particularly for fabric and leather, various adhesive solutions are available. While fabric and leather adhesives offer specific advantages, it is essential for B2B buyers to explore alternative methods that might better suit their operational needs, budget constraints, or application contexts. This section presents a comparison of fabric and leather adhesive against two viable alternatives: sewing and using heat-activated adhesives.

Comparison Table

| Comparison Aspect | Fabric And Leather Adhesive | Sewing | Heat-Activated Adhesive |

|---|---|---|---|

| Performance | Strong, flexible bond; quick drying | Durable, but time-consuming | Strong bond, but requires heat source |

| Cost | Moderate ($6.50 – $10.95) | Higher (thread, needle, labor) | Moderate to high (depends on equipment) |

| Ease of Implementation | Easy; minimal tools required | Requires skill and time | Moderate; requires heat source and technique |

| Maintenance | Low; generally permanent | Moderate; may need resewing | Low; permanent bond once set |

| Best Use Case | Quick repairs, diverse fabrics | Heavy-duty applications, structural repairs | Applications needing seamless finishes |

Pros and Cons of Alternatives

What Are the Advantages and Disadvantages of Sewing?

Sewing is a traditional method that provides a robust and durable repair for fabric and leather. Its primary advantage lies in its strength; sewn seams can withstand significant stress and strain. However, this method is time-intensive and requires specialized skills, making it less feasible for quick repairs. Additionally, sewing may not be suitable for all types of fabric, particularly those that are delicate or prone to fraying. For B2B buyers focusing on high-stress applications, sewing might be the best choice despite its increased labor costs.

Illustrative image related to fabric and leather adhesive

How Does Heat-Activated Adhesive Compare?

Heat-activated adhesives offer a unique bonding solution that involves applying heat to activate the adhesive layer, creating a strong and permanent bond. This method is particularly advantageous for applications requiring a seamless appearance, such as upholstery or high-end fashion. However, it necessitates additional equipment, such as heat presses, which can elevate initial costs and complexity. Furthermore, the reliance on heat means that it may not be suitable for all environments, especially where electrical sources are limited. For businesses focused on aesthetics and high-quality finishes, heat-activated adhesives can provide a compelling solution.

How to Choose the Right Solution for Your Needs

When determining the best adhesive solution for fabric and leather repairs, B2B buyers should consider their specific operational requirements, including the nature of the repairs, budget, and available resources. Fabric and leather adhesives are ideal for quick fixes and diverse materials, while sewing offers unmatched durability for structural repairs. Heat-activated adhesives, although requiring additional tools, can provide a polished finish for high-end applications. By weighing these factors, businesses can select the most appropriate solution that aligns with their goals and operational capabilities.

Essential Technical Properties and Trade Terminology for fabric and leather adhesive

What Are the Key Technical Properties of Fabric and Leather Adhesives?

When sourcing fabric and leather adhesives, B2B buyers should be aware of several critical specifications that impact performance and suitability for various applications. Here are some essential properties to consider:

-

Bonding Strength

Bonding strength refers to the adhesive’s ability to hold materials together under stress. This property is vital for applications where durability is paramount, such as in upholstery or automotive interiors. Buyers should inquire about the shear and tensile strength ratings to ensure the adhesive can withstand operational demands. -

Drying Time

The drying time of an adhesive is crucial for operational efficiency. Fast-drying adhesives enable quicker production cycles and minimize downtime. For example, products like Tear Mender can bond in as little as three minutes, allowing for immediate handling and further processing. Understanding drying time helps businesses plan their production schedules effectively. -

Flexibility

Flexibility is essential in applications where the bonded materials may experience movement or stress. Adhesives that remain flexible after curing are less likely to crack or break under tension. This is particularly important in leather goods and clothing, where the materials must maintain their integrity during use. -

Water Resistance

Water resistance indicates an adhesive’s ability to withstand moisture without losing its bonding properties. This is crucial for applications in outdoor gear, marine fabrics, or upholstery exposed to spills. B2B buyers should verify the adhesive’s waterproofing capabilities to ensure long-lasting performance in various environments. -

Non-Toxicity and Eco-Friendliness

In an increasingly environmentally conscious market, non-toxic and eco-friendly adhesives are gaining importance. These adhesives are safer for workers and consumers and may comply with regulations in different regions. This property can enhance a brand’s reputation and appeal to eco-aware customers. -

Shelf Life

Shelf life refers to the period an adhesive remains effective while stored. For B2B buyers, understanding the shelf life is crucial for inventory management and ensuring that products are used within their optimal time frame. Adhesives with longer shelf lives reduce waste and increase cost efficiency.

What Are Common Trade Terms Related to Fabric and Leather Adhesives?

Navigating the B2B landscape requires familiarity with industry jargon. Here are several common terms that buyers should know:

Illustrative image related to fabric and leather adhesive

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end products. In the adhesive industry, understanding OEM specifications can help buyers ensure compatibility with their manufacturing processes. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for buyers to avoid excess inventory and manage cash flow effectively. Buyers should negotiate MOQs that align with their production needs and storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers asking for price quotes for specific products. This term is essential for B2B buyers looking to compare pricing and terms across different suppliers for fabric and leather adhesives, ensuring they secure the best deals. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and delivery responsibilities, which is particularly important when sourcing adhesives from global suppliers. -

TDS (Technical Data Sheet)

A TDS provides detailed information about an adhesive’s properties, application methods, and safety precautions. Buyers should review TDS documents to ensure the selected adhesive meets their technical requirements and safety standards. -

MSDS (Material Safety Data Sheet)

An MSDS outlines the hazards associated with a chemical product, including handling and storage guidelines. It is crucial for ensuring workplace safety and regulatory compliance, especially when dealing with adhesives that may contain hazardous materials.

Understanding these technical properties and trade terminology equips B2B buyers with the knowledge needed to make informed decisions, ensuring that they select the right fabric and leather adhesives for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the fabric and leather adhesive Sector

What Are the Key Trends Shaping the Fabric and Leather Adhesive Market?

The fabric and leather adhesive market is undergoing significant transformation driven by several global factors. Increasing demand for durable, high-performance adhesives is largely fueled by the booming fashion, upholstery, and automotive industries. As international buyers from regions like Africa, South America, the Middle East, and Europe (e.g., Brazil, Germany) seek reliable solutions, companies are responding with innovations that enhance product performance, such as waterproof, UV-resistant, and quick-drying adhesives.

Emerging technologies, including digital platforms for sourcing and procurement, are reshaping how businesses engage with suppliers. Buyers now have access to a wealth of information on product specifications, customer reviews, and price comparisons, allowing for more informed decision-making. Moreover, the rise of e-commerce has made it easier for companies to source adhesives directly from manufacturers, often at competitive prices.

Sustainability is also becoming a key driver in the market. As consumers and businesses alike prioritize eco-friendly practices, manufacturers are developing adhesives that are non-toxic, biodegradable, and made from renewable resources. This shift not only addresses environmental concerns but also aligns with regulatory pressures in various regions.

How Is Sustainability Influencing the Sourcing of Fabric and Leather Adhesives?

The environmental impact of traditional adhesives is prompting a shift towards sustainability in sourcing practices. Many adhesives contain harmful solvents and chemicals, which can have adverse effects on both health and the environment. B2B buyers are increasingly prioritizing suppliers who can demonstrate a commitment to sustainability through ethical sourcing practices and eco-friendly product offerings.

Ethical supply chains are becoming a critical consideration for international buyers. Companies are seeking suppliers who can provide transparency regarding their sourcing methods and labor practices. Certifications such as ISO 14001 (Environmental Management) and Cradle to Cradle can serve as indicators of a supplier’s commitment to sustainable practices.

Furthermore, the demand for ‘green’ materials is driving innovation in the adhesive sector. Manufacturers are exploring alternative raw materials, such as plant-based polymers and water-based formulations, which minimize environmental impact. As more buyers prioritize sustainability, suppliers who can offer these innovative, eco-friendly adhesives are likely to gain a competitive edge.

What Is the Historical Context Behind Fabric and Leather Adhesives?

The evolution of fabric and leather adhesives dates back to ancient times, where natural substances like animal glues and plant resins were used for bonding materials. Over the centuries, advancements in chemistry led to the development of synthetic adhesives, significantly enhancing performance and versatility.

The late 20th century saw a boom in the production of water-based adhesives, which offered a safer and more environmentally friendly alternative to solvent-based options. This shift was largely driven by stricter regulations and growing awareness of health and environmental issues. Today, the market continues to evolve, with a strong emphasis on innovation, sustainability, and meeting the diverse needs of various industries. As the landscape of fabric and leather adhesives continues to change, B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric and leather adhesive

-

How do I choose the right adhesive for fabric and leather applications?

Choosing the right adhesive depends on the specific materials and the intended use. For fabric-to-fabric bonding, look for quick-drying, flexible adhesives that can withstand washing and wear. For leather, opt for adhesives that provide a strong, permanent bond and are resistant to moisture. Consider factors such as drying time, flexibility, and whether the adhesive is non-toxic and eco-friendly, especially if the end products will be used in sensitive environments or by consumers in regions with strict regulations. -

What is the best adhesive for repairing leather goods?

The best adhesive for leather repairs is one that offers a strong, flexible bond and is resistant to moisture and temperature changes. Water-based adhesives, like those that dry clear and remain flexible, are ideal for leather goods. Brands like Tear Mender provide effective options that are quick-drying and washable, allowing for immediate use post-repair. Always test a small area first to ensure compatibility with the specific leather type. -

What are the minimum order quantities (MOQs) for fabric and leather adhesives?

Minimum order quantities can vary significantly between suppliers, often ranging from 100 to 1,000 units, depending on the adhesive type and manufacturer. It’s advisable to discuss MOQs directly with suppliers during the negotiation phase to find options that fit your budget and inventory needs. Some suppliers may offer flexibility on MOQs for first-time orders or if you are willing to commit to future purchases. -

What payment terms should I expect when sourcing adhesives internationally?

Payment terms can vary widely depending on the supplier and the country of origin. Common terms include net 30 or net 60, where payment is due within 30 or 60 days of invoice. For international transactions, suppliers may request upfront payments or a letter of credit to mitigate risk. Always clarify payment terms before finalizing orders to ensure alignment with your cash flow and financial capabilities. -

How do I vet suppliers for fabric and leather adhesives?

Vetting suppliers involves assessing their credibility, quality standards, and reliability. Start by checking their certifications, customer reviews, and product samples. Request references from previous clients and verify their production capabilities and compliance with international standards. Engaging in direct communication can also provide insights into their operational practices and customer service approach, ensuring they align with your business expectations. -

What quality assurance measures should I look for in adhesive products?

Quality assurance measures to look for include compliance with relevant international standards, such as ISO certifications, and adherence to safety regulations. Suppliers should provide documentation regarding the adhesive’s performance characteristics, such as adhesion strength, flexibility, and resistance to environmental factors. Regular quality checks and transparent reporting can indicate a supplier’s commitment to maintaining high product standards. -

What are the logistics considerations when importing adhesives from abroad?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Understand the supplier’s shipping capabilities and whether they handle logistics or if you need to engage a freight forwarder. Ensure compliance with import regulations in your country, including any necessary documentation and tariffs. Timely communication with your supplier can help mitigate delays and ensure a smooth import process. -

Can I customize adhesive formulations for specific applications?

Many suppliers offer customization options for adhesive formulations to meet specific application needs. This may include variations in viscosity, drying time, or chemical composition. Discuss your requirements with potential suppliers, and inquire about their ability to develop tailored solutions. Be prepared to provide detailed specifications and possibly conduct testing to ensure the customized adhesive meets your performance expectations.

Top 5 Fabric And Leather Adhesive Manufacturers & Suppliers List

1. Tear Mender – Instant Fabric and Leather Adhesive

Domain: outfitterssupply.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Tear Mender Instant Fabric and Leather Adhesive”, “sizes_available”: [“6 oz”, “16 oz”], “sku”: “WLF115-06”, “price”: “$10.95 USD”, “description”: “For use on clothing, leather, upholstery, home decor, sport, marine, indoor/outdoor fabrics. Tear Mender is waterproof, flexible, permanent, quick-drying, UV resistant, eco-friendly, non-toxic, and acid-free. The strongest repairs util…

2. Tear Mender – Fabric & Leather Adhesive

Domain: tearmender.com

Registered: 1998 (27 years)

Introduction: Tear Mender Fabric & Leather Adhesive bonds to porous materials in 3 minutes. It is non-toxic, washable, flexible, and UV resistant. Available in two sizes: 32 oz. bottle for $32.99 (Item No. TG-32) and 2 oz. bottle for $8.99 (Item No. TM-1-EA).

3. Atom Adhesives – Leather-Bond

Domain: atomadhesives.com

Registered: 2013 (12 years)

Introduction: [{‘name’: ‘Leather-Bond’, ‘description’: ‘Leather-Bond is a two part, heat-resistant and low exotherm, epoxy adhesive formulation. It is a 100% solid epoxy adhesive.’, ‘cure_time’: ‘Hardens Within 24 hours’, ‘msrp’: ‘$1.99 – $120.99’}, {‘name’: ‘Leather-Bond 1’, ‘description’: ‘Leather-Bond 1 is an exceptional epoxy formulation recommended for lower temperature or wet industrial bonding applicatio…

4. Reddit – Flexible Contact Glue

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Contact glue, flexible, long life-span, resistant to serious cold, suitable for leather and fabric applications.

5. Weldwood – Contact Cement & E6000 – Adhesive

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: 1. Weldwood Contact Cement: Highly recommended for leather-to-leather and leather-to-fabric applications. Noted for its strong adhesion and low VOC (odor). Users suggest applying thinly to avoid soaking through fabric.

2. E6000: Described as extremely strong, requiring significant force to separate glued pieces. It takes longer to cure compared to contact cements, making it suitable for applicat…

Strategic Sourcing Conclusion and Outlook for fabric and leather adhesive

In the ever-evolving landscape of fabric and leather adhesive solutions, the importance of strategic sourcing cannot be overstated. As international B2B buyers navigate diverse markets across Africa, South America, the Middle East, and Europe, understanding the unique properties of adhesives—such as waterproofing, flexibility, and drying times—can significantly enhance product offerings and customer satisfaction.

Investing in high-quality adhesives not only improves product durability but also fosters brand loyalty among consumers who value long-lasting repairs. By prioritizing eco-friendly and non-toxic options, businesses can align with growing sustainability trends, appealing to conscientious consumers and partners alike.

Looking ahead, the demand for innovative adhesive solutions is set to rise. Buyers should leverage strategic partnerships with reputable manufacturers to ensure a reliable supply chain and access to the latest technologies. By staying informed on market trends and consumer preferences, B2B buyers can make informed decisions that will strengthen their competitive advantage.

Illustrative image related to fabric and leather adhesive

Now is the time to take action—evaluate your sourcing strategies, explore new suppliers, and invest in adhesive solutions that meet the diverse needs of your customers. Embrace the future of fabric and leather adhesives, and position your business for success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.