Introduction: Navigating the Global Market for how to make leather boots waterproof

In the fast-paced global market, ensuring the durability and reliability of leather boots, particularly in challenging environments, is a critical concern for B2B buyers. As businesses across Africa, South America, the Middle East, and Europe seek to source high-quality leather boots, understanding how to make leather boots waterproof becomes imperative. Waterproofing not only enhances the longevity of these investments but also safeguards workers’ comfort and performance in varied climates, from the humid jungles of Brazil to the arid deserts of Saudi Arabia.

This comprehensive guide delves into the diverse methods and products available for waterproofing leather boots, including waxes, oils, and sprays, while also addressing the specific needs of various leather types. Buyers will gain insights into the best practices for application, the importance of routine maintenance, and the right timing for treatment to ensure optimal performance. Additionally, the guide covers essential considerations for supplier vetting, cost analysis, and potential ROI, equipping businesses with the knowledge to make informed purchasing decisions.

By leveraging this guide, international B2B buyers can confidently navigate the complexities of waterproofing leather boots, ensuring they select the best solutions that align with their operational needs and environmental challenges. With an emphasis on actionable insights and expert recommendations, this resource empowers buyers to enhance their product offerings and improve customer satisfaction in an increasingly competitive marketplace.

Table Of Contents

- Top 6 How To Make Leather Boots Waterproof Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make leather boots waterproof

- Understanding how to make leather boots waterproof Types and Variations

- Key Industrial Applications of how to make leather boots waterproof

- 3 Common User Pain Points for ‘how to make leather boots waterproof’ & Their Solutions

- Strategic Material Selection Guide for how to make leather boots waterproof

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather boots waterproof

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather boots waterproof’

- Comprehensive Cost and Pricing Analysis for how to make leather boots waterproof Sourcing

- Alternatives Analysis: Comparing how to make leather boots waterproof With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make leather boots waterproof

- Navigating Market Dynamics and Sourcing Trends in the how to make leather boots waterproof Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather boots waterproof

- Strategic Sourcing Conclusion and Outlook for how to make leather boots waterproof

- Important Disclaimer & Terms of Use

Understanding how to make leather boots waterproof Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wax Sealing | Durable, often made from beeswax; requires warming for application | Outdoor work boots, heavy-duty footwear | Pros: Long-lasting protection; enhances leather appearance. Cons: Can impair resoling; may darken leather. |

| Waterproofing Sprays | Easy to apply, silicone-based; requires frequent reapplication | Hiking boots, casual leather footwear | Pros: Quick application; suitable for various leathers. Cons: Less durable; requires regular maintenance. |

| Oil Treatments | Conditioning oils like mink or neatsfoot; penetrates leather | Work boots, outdoor footwear | Pros: Nourishes leather; improves flexibility. Cons: Can darken leather; may require multiple applications. |

| Seam Sealers | Urethane-based adhesives; applied to seams for extra protection | All types of leather footwear | Pros: Effective for preventing leaks; enhances durability. Cons: Additional step; may require drying time before main treatment. |

| DWR (Durable Water Repellent) | Factory-applied finish; needs periodic renewal | Hiking boots, performance footwear | Pros: Initial protection against water; maintains breathability. Cons: Effectiveness diminishes over time; requires regular monitoring. |

What are the Characteristics and Suitability of Wax Sealing for Waterproofing Leather Boots?

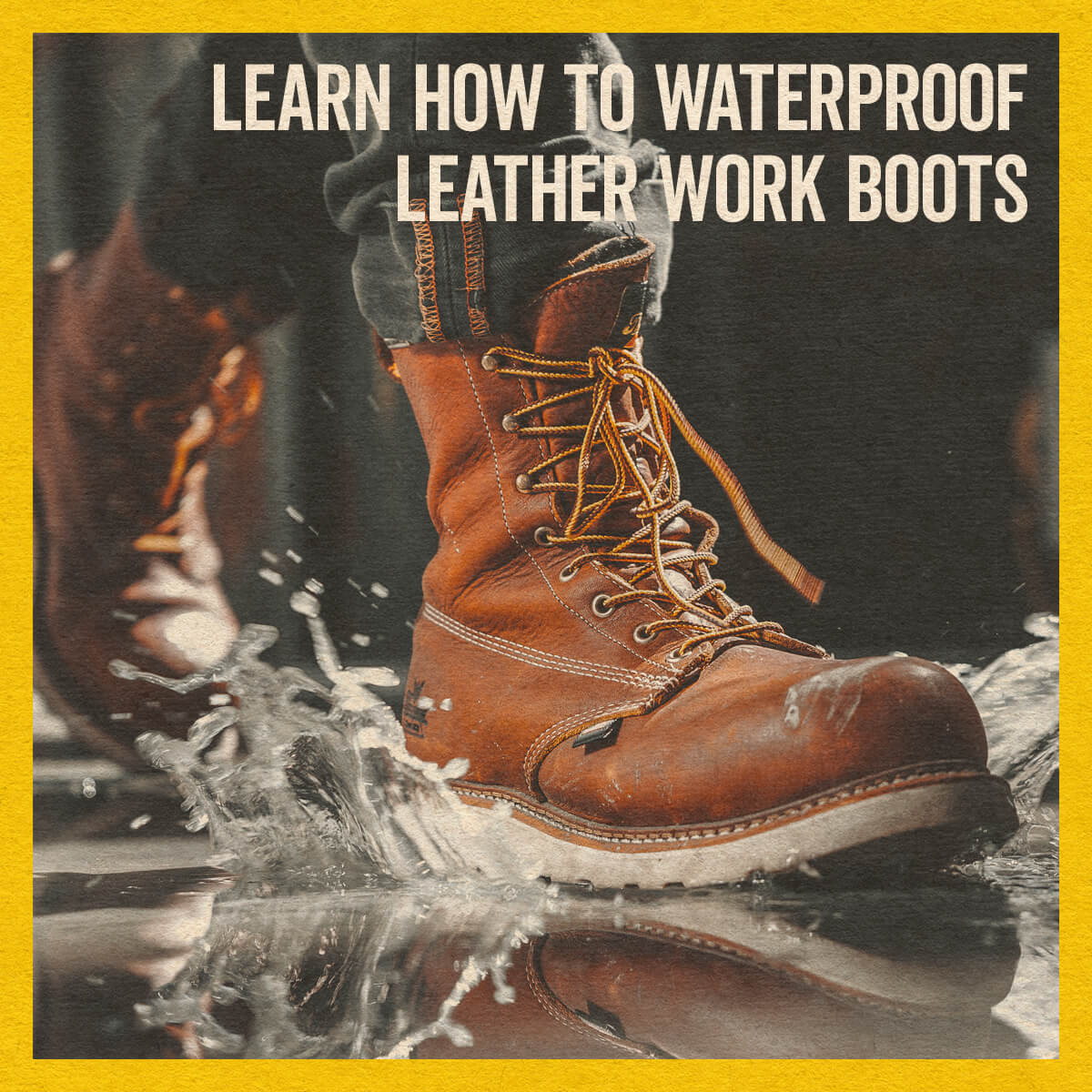

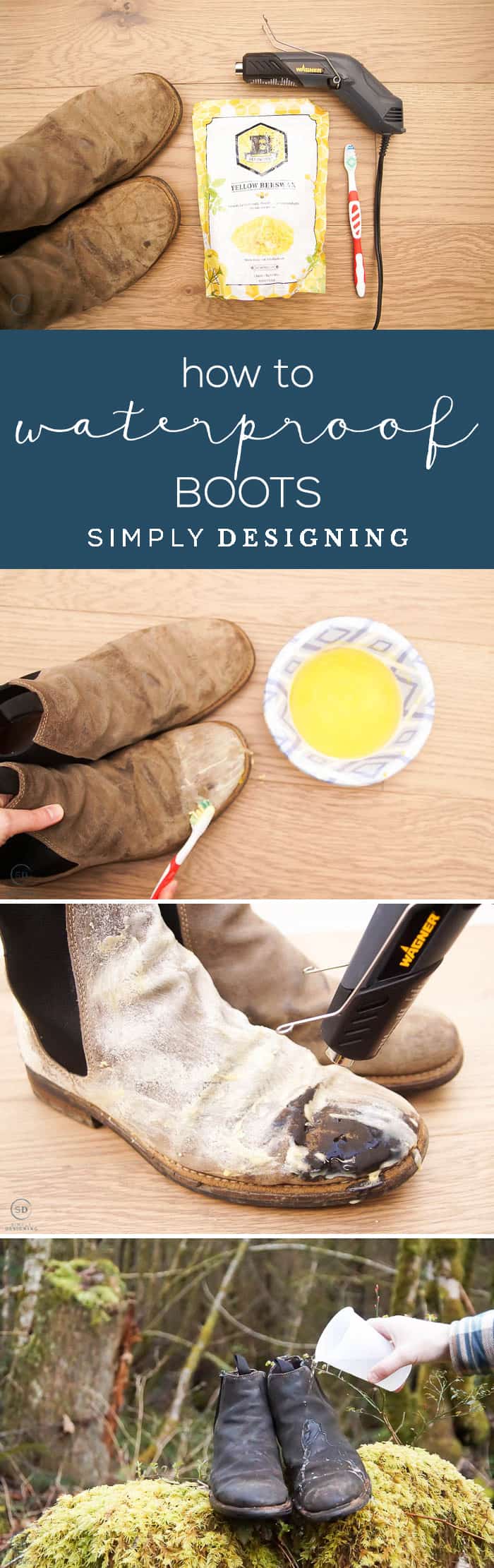

Wax sealing is a traditional method utilizing beeswax to create a durable waterproof barrier. This technique is particularly effective for heavy-duty footwear used in outdoor environments, providing long-lasting protection against moisture while enhancing the leather’s natural appearance. However, businesses should note that wax can impair the ability to resole boots, making it less suitable for footwear that requires frequent resoling. Buyers should weigh the longevity of protection against the potential need for future repairs.

How Do Waterproofing Sprays Work and Where are They Best Applied?

Waterproofing sprays are typically silicone-based solutions that offer a quick and easy application process. They are ideal for casual leather footwear and hiking boots but require regular reapplication, especially after exposure to water. This method is advantageous for businesses looking for a user-friendly solution that does not require extensive preparation. However, the less durable nature of sprays means that they may not provide the same level of long-term protection as other methods, necessitating a commitment to ongoing maintenance.

Illustrative image related to how to make leather boots waterproof

What Are the Benefits of Using Oil Treatments for Leather Boots?

Oil treatments, such as mink or neatsfoot oil, are excellent for conditioning leather while providing a level of water resistance. This method is particularly suitable for work boots and outdoor footwear, as it nourishes the leather and enhances its flexibility. However, businesses should be aware that oil treatments can darken the leather and may require multiple applications to achieve desired results. This option is best for companies focused on maintaining the health and longevity of their leather products.

Why Should Businesses Consider Seam Sealers for Enhanced Waterproofing?

Seam sealers are urethane-based adhesives designed to reinforce the seams of leather boots, which are often the most vulnerable points for water intrusion. This additional layer of protection is beneficial for all types of leather footwear, enhancing overall durability. While seam sealing adds an extra step to the waterproofing process, it significantly reduces the risk of leaks and extends the lifespan of the footwear. Companies should consider this method when investing in high-quality leather boots for demanding environments.

What is the Role of DWR in Waterproofing Leather Boots?

DWR, or Durable Water Repellent, is a factory-applied finish that provides initial protection against water while allowing the leather to breathe. This treatment is commonly found in hiking and performance footwear, making it suitable for businesses focused on outdoor activities. However, the effectiveness of DWR diminishes over time, requiring periodic renewal and monitoring. Companies should factor in the need for ongoing maintenance when choosing this method, ensuring their footwear remains functional in wet conditions.

Key Industrial Applications of how to make leather boots waterproof

| Industry/Sector | Specific Application of how to make leather boots waterproof | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Waterproofing work boots for site safety | Reduces worker injuries from wet conditions, prolongs boot lifespan | Ensure compatibility with various leather types, consider bulk purchasing options for cost efficiency |

| Agriculture | Protecting leather boots for farming and livestock care | Enhances durability in muddy conditions, reduces maintenance costs | Look for eco-friendly waterproofing solutions suitable for agricultural environments |

| Outdoor Recreation | Waterproofing hiking boots for adventure tourism | Increases customer satisfaction and safety, reduces gear replacement costs | Source treatments that are easy to apply and effective in diverse climates |

| Oil & Gas | Waterproofing boots for field operations | Protects employees from hazardous conditions, improves productivity | Consider heavy-duty waterproofing options that withstand extreme environments |

| Military & Defense | Ensuring waterproof boots for soldiers in various terrains | Enhances operational effectiveness, increases boot longevity | Focus on high-performance, durable solutions that meet military specifications |

How is Waterproofing Leather Boots Applied in the Construction Industry?

In the construction sector, waterproofing leather work boots is critical for ensuring worker safety. Wet conditions can lead to slips and falls, causing injuries and downtime. By treating boots with durable waterproofing agents, businesses can prolong the life of their footwear, reducing replacement costs. Buyers should focus on products that are compatible with multiple leather types and consider bulk purchasing options for cost efficiency, especially in regions like Africa and the Middle East where construction activities are booming.

What Role Does Waterproofing Play in Agriculture?

For agricultural workers, waterproofing leather boots is essential for maintaining comfort and safety while working in muddy or wet conditions. Waterproof treatments enhance the durability of boots, allowing them to withstand harsh environments, which ultimately reduces maintenance costs. Buyers in South America and Africa should prioritize eco-friendly waterproofing solutions that are safe for use around livestock and crops, ensuring compliance with agricultural standards.

How Does Waterproofing Impact Outdoor Recreation?

In the outdoor recreation industry, particularly for hiking and adventure tourism, waterproofing leather boots is vital for customer satisfaction. Waterproof boots keep feet dry and comfortable, which is crucial for long hikes or multi-day treks. Businesses can benefit from sourcing easy-to-apply waterproofing treatments that are effective across various climates. International buyers should seek products that offer long-lasting protection, especially in regions with diverse weather patterns, such as Europe and South America.

Why is Waterproofing Important in the Oil & Gas Sector?

In the oil and gas industry, waterproofing leather boots is crucial for field operations where workers are exposed to wet and hazardous environments. Waterproofed boots protect employees from moisture-related injuries and enhance productivity by keeping feet dry. Buyers should consider heavy-duty waterproofing options that can withstand extreme conditions, focusing on suppliers that offer products meeting industry-specific safety standards.

Illustrative image related to how to make leather boots waterproof

How Does Waterproofing Benefit Military Operations?

In military applications, ensuring that soldiers have waterproof boots is vital for operational effectiveness in diverse terrains. Waterproofing treatments help maintain the integrity of boots, prolonging their lifespan and ensuring soldiers remain focused on their missions rather than dealing with wet feet. Buyers in the defense sector should prioritize high-performance waterproofing solutions that meet stringent military specifications, particularly for operations in regions with challenging climates like the Middle East.

3 Common User Pain Points for ‘how to make leather boots waterproof’ & Their Solutions

Scenario 1: The Challenge of Inconsistent Waterproofing Results

The Problem: Many B2B buyers face challenges when trying to ensure that their leather boots consistently repel water. This inconsistency can arise from using various waterproofing products that may not be compatible with the specific type of leather. For instance, applying a wax-based treatment on boots designed for a breathable membrane can lead to impaired functionality, causing premature moisture penetration. Additionally, buyers may find that even after proper application, the waterproofing wears off too quickly, especially in harsh environmental conditions prevalent in regions like Africa and the Middle East.

The Solution: To overcome these issues, B2B buyers should first assess the specific type of leather used in their boots—whether it’s full-grain, suede, or nubuck—and select a waterproofing treatment that is explicitly designed for that material. Products such as silicone-based sprays or oil treatments tend to offer better durability for heavy-use environments. It’s crucial to follow a standardized waterproofing protocol: clean the boots thoroughly, apply the treatment evenly, and allow ample drying time in a well-ventilated area to ensure complete absorption. Regular maintenance and reapplication based on usage and exposure can further enhance the longevity of the waterproofing effect.

Illustrative image related to how to make leather boots waterproof

Scenario 2: The Impact of Environmental Conditions on Boot Longevity

The Problem: B2B buyers operating in regions with extreme weather conditions—such as heavy rains in South America or the arid, dusty environments of the Middle East—often find that their leather boots deteriorate quickly. Moisture can lead to mold and mildew growth, while dust can create abrasions that compromise the leather’s integrity. This wear not only affects comfort and performance but also significantly shortens the lifecycle of the boots, leading to increased replacement costs.

The Solution: To address these environmental challenges, buyers should implement a proactive waterproofing strategy that includes selecting high-quality, environmentally-suited waterproofing products. For instance, a combination of seam sealers and waterproofing sprays can provide a robust defense against both moisture and dust. Regular cleaning and conditioning of the leather using specialized cleaners and conditioners will also help maintain flexibility and prevent cracking. Buyers should consider investing in training for their teams on proper boot care techniques and the importance of routine inspections to catch wear and tear early, ultimately extending the lifespan of their footwear investments.

Scenario 3: The Cost of Downtime Due to Boot Failures

The Problem: In industries where mobility and safety are paramount—such as construction and agriculture—B2B buyers face significant challenges when leather boots fail to keep moisture out. Wet boots not only lead to discomfort but can also result in workplace injuries, decreased productivity, and increased downtime for employees. The financial implications of having to replace boots frequently can also add up, particularly for organizations that maintain large inventories of workwear.

The Solution: To mitigate these risks, buyers should establish a comprehensive waterproofing and maintenance program. This program should include the purchase of high-quality waterproofing agents and regular training sessions for employees on how to properly apply these products. Additionally, implementing a schedule for inspecting and maintaining boots can prevent moisture-related issues before they lead to failure. For organizations operating in wet or variable climates, investing in boots with built-in waterproof membranes can also reduce the need for frequent treatments and enhance overall employee safety and comfort.

Strategic Material Selection Guide for how to make leather boots waterproof

What Are the Key Materials for Waterproofing Leather Boots?

When it comes to waterproofing leather boots, selecting the right materials is crucial for performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the waterproofing process, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Wax-Based Waterproofing Work for Leather Boots?

Key Properties: Wax-based waterproofing treatments, typically made from natural beeswax or synthetic alternatives, create a barrier that repels water while allowing the leather to breathe. They are effective in preventing moisture penetration and can withstand varying temperatures.

Pros & Cons: Wax treatments are durable and provide excellent waterproofing. However, they can be labor-intensive to apply, requiring warming and careful buffing to achieve the best results. Additionally, they may darken the leather and are not ideal for boots that may require resoling, as wax can interfere with adhesive bonding.

Impact on Application: Wax treatments are particularly effective in environments with moderate moisture exposure but may not perform as well in extreme wet conditions. They are suitable for casual wear and light work environments.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local climate conditions, as wax may not be as effective in extremely humid environments. Compliance with local regulations regarding chemical content is also essential.

What Are the Benefits of Using Waterproofing Sprays?

Key Properties: Waterproofing sprays are typically silicone or fluoropolymer-based, providing a thin, protective layer over the leather. They are designed for quick application and can be used on various types of leather, including suede and nubuck.

Pros & Cons: The main advantage of sprays is their ease of use and quick application. However, they are generally less durable than wax treatments and require frequent reapplication, especially in high-moisture environments. They may also offer limited protection against abrasion.

Illustrative image related to how to make leather boots waterproof

Impact on Application: Sprays are ideal for light-duty applications and casual wear but may not withstand heavy-duty use. They are effective in regions with sporadic rain but may not be suitable for consistently wet conditions.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure that the sprays comply with EU chemical regulations. Additionally, understanding the local market’s preference for ease of use versus durability can guide purchasing decisions.

How Do Oil Treatments Enhance Leather Boot Waterproofing?

Key Properties: Oil treatments, such as mink oil or neatsfoot oil, penetrate the leather to condition and provide a water-resistant barrier. They enhance the leather’s natural properties and improve flexibility.

Pros & Cons: Oils are excellent for conditioning leather and preventing it from drying out, which prolongs the life of the boots. However, they can darken the leather and may require more frequent reapplication than other methods. The oil application process can also be messy and time-consuming.

Illustrative image related to how to make leather boots waterproof

Impact on Application: Oil treatments are suitable for environments where flexibility and conditioning are essential, such as in outdoor work settings. However, they may not provide adequate protection in extremely wet conditions.

Considerations for International Buyers: In regions like Saudi Arabia, where high temperatures can affect leather, oil treatments can help maintain the material’s integrity. Buyers should be aware of the potential for color change and ensure that oils meet local environmental standards.

What Role Do Seam Sealers Play in Waterproofing Leather Boots?

Key Properties: Seam sealers are urethane-based adhesives that provide an additional layer of protection against moisture ingress at the seams, which are often the weakest points in leather boots.

Pros & Cons: Seam sealers are highly effective at preventing leaks and can be used in conjunction with other waterproofing methods. However, they require careful application and drying time, adding complexity to the waterproofing process.

Impact on Application: Seam sealers are essential for heavy-duty boots used in wet conditions, ensuring that seams remain watertight. They are particularly beneficial for work boots exposed to rain and puddles.

Illustrative image related to how to make leather boots waterproof

Considerations for International Buyers: Buyers should ensure that seam sealers meet international standards for durability and flexibility. In regions with varying climates, such as Europe, understanding the local conditions can help determine the best sealing products.

Summary Table of Materials for Waterproofing Leather Boots

| Material | Typical Use Case for how to make leather boots waterproof | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wax-Based Treatments | Light work and casual wear | Excellent waterproofing and durability | Labor-intensive application, may darken leather | Medium |

| Waterproofing Sprays | Casual wear and light-duty applications | Quick and easy application | Less durable, frequent reapplication needed | Low |

| Oil Treatments | Outdoor work and conditioning leather | Conditions leather, prolongs lifespan | Can darken leather, messy application | Medium |

| Seam Sealers | Heavy-duty boots in wet conditions | Prevents leaks at seams | Requires careful application and drying | Medium |

This guide provides actionable insights for international B2B buyers, enabling informed decisions when selecting materials for waterproofing leather boots. Understanding the properties and implications of each material can significantly enhance product performance and customer satisfaction.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather boots waterproof

What Are the Key Manufacturing Processes for Making Leather Boots Waterproof?

To produce high-quality waterproof leather boots, manufacturers typically engage in a series of well-defined processes. Each stage plays a crucial role in ensuring that the final product meets the required standards of durability and water resistance. Below is an overview of the main stages involved in the manufacturing process.

How Is Material Prepared for Waterproof Leather Boots?

The first stage of production involves material preparation, which includes sourcing and selecting the appropriate leather. Full-grain leather is often preferred due to its natural breathability and durability. The leather undergoes tanning, which not only preserves it but also enhances its water resistance.

Additionally, manufacturers may treat the leather with a Durable Water Repellent (DWR) finish during this stage. This chemical treatment helps to repel water at the surface level, providing an initial layer of protection. The quality of the leather and the effectiveness of the DWR treatment can significantly influence the boot’s overall waterproofing capabilities.

What Techniques Are Used in Forming Leather Boots?

Once the materials are prepared, the next step is forming. This stage involves cutting the leather into specific shapes and sizes, which is often done using precision cutting machines. Manufacturers utilize patterns to ensure consistency across batches.

After cutting, the leather pieces are shaped into the boot’s upper using techniques such as lasting, where the leather is stretched over a mold to create the desired form. This process is critical for ensuring a snug fit, which is essential for preventing water from entering the boot.

How Are Waterproof Leather Boots Assembled?

The assembly stage is where various components of the boot are brought together. This includes attaching the upper to the sole, which is done using durable adhesives or stitching, depending on the design specifications. Seam sealing is often employed during this stage to further enhance waterproofing. This technique involves applying a waterproof adhesive along the seams, which are common points of water ingress.

Manufacturers may also incorporate additional waterproof membranes, such as Gore-Tex, during assembly. These membranes provide a breathable barrier that prevents water from penetrating while allowing moisture from sweat to escape.

What Finishing Techniques Are Applied to Ensure Waterproof Quality?

Finishing techniques involve the application of final treatments that enhance both the appearance and functionality of the boots. This may include applying waxes or oils that provide additional waterproofing and conditioning. Such treatments not only protect the leather but also improve its aesthetic qualities, ensuring that the boots remain visually appealing to customers.

Illustrative image related to how to make leather boots waterproof

Final inspections are conducted at this stage to ensure that the boots meet all quality standards before packaging and shipping.

What Quality Assurance Standards Are Relevant for Waterproof Leather Boots?

Quality assurance is an integral part of the manufacturing process, especially for products intended for international markets. Various standards govern the manufacturing and quality control of waterproof leather boots.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate their commitment to quality and consistency in production. Additionally, for products sold in the European market, compliance with CE marking requirements is essential. CE marking indicates that the boots meet EU safety, health, and environmental protection standards.

For certain markets, particularly in the Middle East and Africa, buyers may also look for compliance with region-specific standards, which can vary significantly. Understanding these requirements helps buyers ensure they are sourcing products that meet the legal and safety standards of their target market.

How Are Quality Control Checkpoints Implemented During Manufacturing?

Quality control (QC) checkpoints are critical for maintaining high standards throughout the manufacturing process. Several key checkpoints are commonly established:

What Are the Different QC Checkpoints in the Manufacturing Process?

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival at the manufacturing facility. It ensures that only high-quality leather and components are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor adherence to quality standards. This includes checking the integrity of seams, the application of waterproofing treatments, and the overall assembly quality.

-

Final Quality Control (FQC): Before the boots are packaged, a thorough final inspection is performed. This step verifies that all specifications have been met, ensuring that the product is free from defects and ready for distribution.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control measures of suppliers is crucial to ensuring the reliability and performance of waterproof leather boots. Here are some effective strategies:

What Strategies Can Buyers Use to Assess Supplier QC?

-

Conducting Audits: Regular audits of manufacturing facilities can provide insights into the quality control processes and adherence to international standards. Buyers should request audit reports and documentation of compliance with relevant standards.

-

Reviewing QC Reports: Suppliers should provide detailed QC reports that outline inspection results, including any issues identified and corrective actions taken. This transparency helps buyers gauge the supplier’s commitment to quality.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. This is particularly important for international buyers who may not be able to visit the manufacturing site.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers need to be aware of specific nuances related to quality control and certification. Different regions may have varying expectations regarding compliance and certification, which can affect trade and market entry.

How Do Regional Differences Impact Quality Assurance?

For instance, products entering the European market must comply with strict CE marking requirements, while Middle Eastern countries may have their own certification processes that differ significantly. Buyers from Africa and South America should also consider local regulations and standards that may influence product acceptance.

Understanding these regional nuances allows B2B buyers to make informed decisions about their sourcing strategies, ensuring that the products they purchase meet the necessary quality and regulatory standards for their specific markets.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for waterproof leather boots is essential for B2B buyers. By focusing on these areas, buyers can make informed decisions, ensuring they source high-quality products that meet international standards and regional requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather boots waterproof’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking effective methods to waterproof leather boots. Protecting leather footwear is essential for maintaining product quality and extending the lifespan of the boots, particularly in regions prone to wet conditions. This checklist outlines key steps to source and implement waterproofing solutions, ensuring your investments remain protected.

Step 1: Assess Your Material Requirements

Understanding the type of leather used in the boots is critical. Different leather types, such as full-grain, nubuck, or suede, require specific waterproofing treatments. Ensure that the solutions you consider are compatible with the leather’s characteristics to avoid damaging the material.

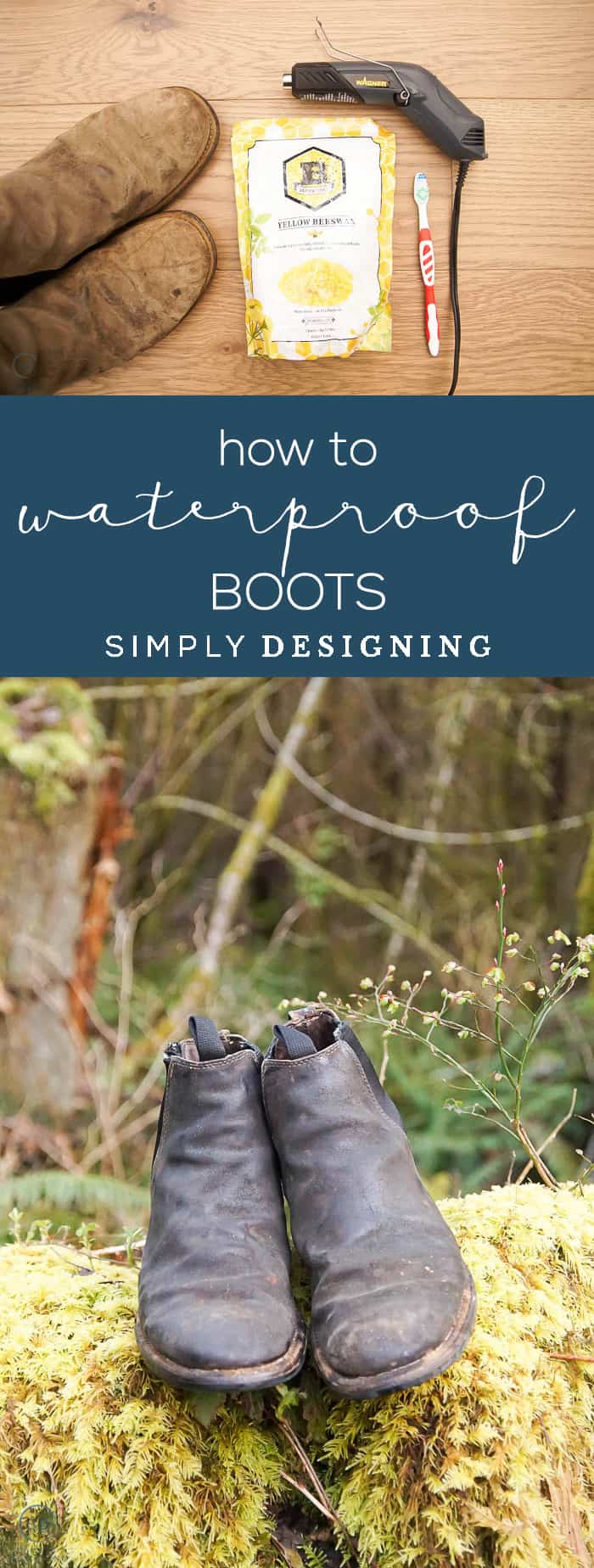

Step 2: Research Waterproofing Product Options

Explore a variety of waterproofing treatments available in the market. Options may include wax-based coatings, waterproof sprays, and oil treatments. Each product type has its own application method, durability, and effect on leather appearance, so choose one that aligns with your boots’ intended use and aesthetic.

Illustrative image related to how to make leather boots waterproof

- Wax-based treatments: Provide a durable finish but may darken the leather.

- Spray treatments: Easy to apply but require more frequent reapplication.

Step 3: Evaluate Supplier Credentials

Before purchasing, ensure that your suppliers have a solid reputation in the industry. Review their certifications, customer testimonials, and case studies to gauge their reliability. This step is vital as it minimizes the risk of sourcing subpar products that could compromise the quality of your leather boots.

Step 4: Request Product Samples

Obtaining samples of the waterproofing treatments you are considering is essential. Conduct tests on the leather to see how each product performs in terms of water resistance and any potential changes to the leather’s color or texture. This hands-on evaluation can prevent costly mistakes down the line.

Step 5: Establish Application Guidelines

Define clear application protocols for the waterproofing treatments. This includes the proper cleaning methods prior to application and drying times for each product. Providing detailed guidelines ensures consistency in application across your team, which is crucial for achieving optimal waterproofing results.

Illustrative image related to how to make leather boots waterproof

- Cleaning: Boots should be thoroughly cleaned to remove dirt and grime before applying any treatment.

- Drying: Allow sufficient drying time to ensure the treatment adheres properly and maintains effectiveness.

Step 6: Monitor and Schedule Regular Maintenance

Implement a schedule for periodic waterproofing treatments based on the usage and environmental conditions the boots are exposed to. Regular maintenance extends the life of the leather and maintains its performance. Keep records of when treatments are applied to ensure timely reapplication.

Step 7: Provide Training for Staff

Training staff on the importance of waterproofing and the correct application methods is crucial. This not only ensures adherence to best practices but also fosters a culture of quality assurance within your organization. Knowledgeable staff are more likely to take care of the boots, prolonging their durability and performance.

By following these steps, B2B buyers can effectively source and implement waterproofing solutions for leather boots, ensuring they remain durable and high-performing in various conditions.

Illustrative image related to how to make leather boots waterproof

Comprehensive Cost and Pricing Analysis for how to make leather boots waterproof Sourcing

When analyzing the costs associated with making leather boots waterproof, several key components must be considered. Understanding the cost structure will enable B2B buyers to make informed sourcing decisions and negotiate better deals.

What Are the Key Cost Components for Waterproofing Leather Boots?

-

Materials: The primary materials involved in waterproofing leather boots include specialized waterproofing agents such as waxes, sprays, and oils. The costs for these materials can vary significantly based on the quality and effectiveness of the product. For instance, premium waxes made from beeswax or silicone sprays often come at a higher price point but offer better longevity and protection.

-

Labor: Labor costs will encompass the time taken for application and any necessary preparation, such as cleaning and conditioning the leather. Depending on the complexity of the waterproofing process and whether it’s done in-house or outsourced, labor costs can fluctuate. Skilled labor may command a premium, especially in regions where expertise is scarce.

-

Manufacturing Overhead: This includes indirect costs related to the production process, such as utilities, rent, and equipment depreciation. These costs can be especially relevant for manufacturers who produce waterproofing agents at scale, impacting the overall pricing structure.

-

Tooling: For companies that manufacture their waterproofing products, tooling costs can represent a significant investment. This includes the cost of machinery and equipment needed to create the waterproofing agents or to apply them effectively to the boots.

-

Quality Control (QC): Ensuring that waterproofing treatments are effective requires rigorous quality control processes. Costs associated with QC can include testing materials for durability and effectiveness, which can drive up overall expenses.

-

Logistics: Transportation and shipping costs also play a crucial role in the overall pricing structure. Import duties and tariffs can significantly affect international sourcing, particularly for buyers in Africa, South America, the Middle East, and Europe.

-

Margin: Finally, the profit margin set by suppliers will influence the final price. This margin can vary based on competition, demand, and the supplier’s positioning in the market.

How Do Price Influencers Impact Waterproofing Leather Boots?

-

Volume/MOQ: The minimum order quantity (MOQ) can impact pricing significantly. Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should assess their demand forecasts to negotiate favorable pricing.

-

Specifications and Customization: Customized waterproofing solutions may incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected price increases.

-

Material Quality and Certifications: Higher-quality materials often come with certifications that ensure efficacy and compliance with industry standards. These certifications can add to the cost but may be essential for certain markets.

-

Supplier Factors: The reputation and reliability of suppliers can also influence pricing. Established suppliers may charge more due to their perceived reliability and product quality.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, all of which can impact the total cost.

What Are the Best Buyer Tips for Cost-Efficiency in Waterproofing Leather Boots?

-

Negotiate: Always seek to negotiate pricing, especially when dealing with large orders. Suppliers may offer discounts for bulk purchases or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance costs, durability, and the effectiveness of the waterproofing solution over time. A higher upfront cost may lead to lower long-term expenses.

-

Research and Compare Suppliers: Take the time to compare multiple suppliers. This helps in understanding the market rate and leveraging competition to secure better pricing.

-

Stay Informed on Market Trends: Understanding market dynamics can provide leverage in negotiations. For instance, fluctuations in raw material prices may affect supplier costs, providing an opportunity for buyers to negotiate lower prices.

-

Factor in Regional Considerations: Buyers from different regions may face unique challenges, such as import tariffs or regional regulations. Understanding these factors can assist in making more informed purchasing decisions.

In conclusion, a comprehensive understanding of the cost structure and pricing influencers related to waterproofing leather boots is vital for B2B buyers. By leveraging this knowledge, buyers can negotiate better deals, ensure quality, and ultimately enhance their product offerings.

Alternatives Analysis: Comparing how to make leather boots waterproof With Other Solutions

Introduction: Exploring Alternatives to Waterproofing Leather Boots

When it comes to protecting leather boots from moisture, various methods exist beyond traditional waterproofing techniques. Each method has its own set of advantages and disadvantages, making it essential for B2B buyers to evaluate their options carefully. This comparison will analyze how to make leather boots waterproof against alternative solutions such as breathable waterproof membranes and synthetic waterproof materials, providing insights into performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | How To Make Leather Boots Waterproof | Breathable Waterproof Membranes | Synthetic Waterproof Materials |

|---|---|---|---|

| Performance | Effective against water penetration; requires regular maintenance for optimal results | Excellent moisture management; allows sweat to escape while keeping water out | Highly effective; can be fully waterproof and durable |

| Cost | Moderate, dependent on product choice and frequency of application | Higher initial investment; long-term savings due to durability | Generally lower cost; varies by material quality |

| Ease of Implementation | Requires cleaning and multiple application steps; ongoing maintenance needed | Installed during manufacturing; little to no maintenance required | Easy to implement; typically ready-to-wear |

| Maintenance | Regular reapplication necessary; can be time-consuming | Minimal maintenance; occasional cleaning required | Low maintenance; resistant to wear and tear |

| Best Use Case | Ideal for outdoor work environments where boots are exposed to wet conditions | Suitable for hiking and outdoor activities with varying weather | Best for general wear or environments with high moisture exposure |

Detailed Breakdown of Alternatives

Breathable Waterproof Membranes: What Are Their Benefits and Limitations?

Breathable waterproof membranes, such as Gore-Tex, are designed to keep water out while allowing moisture from sweat to escape. This technology is particularly beneficial for users engaged in high-intensity activities, as it promotes comfort and reduces the risk of overheating. However, the initial cost of boots featuring these membranes can be significantly higher than traditional leather waterproofing methods. Additionally, while they require minimal maintenance, the performance can degrade over time if the outer fabric becomes worn or dirty, necessitating careful upkeep.

Synthetic Waterproof Materials: Are They a Cost-Effective Solution?

Synthetic waterproof materials are engineered to provide a high level of water resistance and durability. They are often lighter than leather and come in a variety of styles, making them appealing for everyday wear. The cost-effectiveness of these materials is a significant advantage, as they tend to be less expensive than leather boots, especially when considering the long-term durability. However, they may lack the classic aesthetic and breathability of leather, which could be a drawback for those seeking a traditional look or requiring high breathability for extended outdoor use.

Illustrative image related to how to make leather boots waterproof

Conclusion: How Should B2B Buyers Choose the Right Waterproofing Solution?

Choosing the right waterproofing solution for leather boots depends on specific business needs and environmental conditions. For companies in industries requiring robust outdoor performance, breathable waterproof membranes may offer the best combination of comfort and protection. In contrast, businesses seeking a budget-friendly option might find synthetic waterproof materials to be more suitable, particularly for casual or less intensive work environments. Ultimately, B2B buyers should consider factors such as performance expectations, maintenance capabilities, and cost implications to make informed decisions that align with their operational requirements.

Essential Technical Properties and Trade Terminology for how to make leather boots waterproof

When considering waterproofing leather boots, understanding the essential technical properties and trade terminology can significantly enhance decision-making for B2B buyers. Here’s a detailed overview of critical specifications and common jargon relevant to this industry.

What Are the Key Technical Properties of Waterproofing Leather Boots?

-

Material Grade

– Definition: Material grade refers to the quality and type of leather used in boot production, such as full-grain, top-grain, or suede.

– Importance: Higher-grade leathers offer better water resistance and durability. For B2B buyers, selecting boots made from full-grain leather ensures longevity and performance, particularly in demanding environments. -

Waterproof Rating (e.g., IPX Rating)

– Definition: This rating system measures the degree of water resistance, typically expressed in terms of pressure (e.g., IPX-3 indicates resistance to water spray).

– Importance: Understanding the waterproof rating helps buyers ensure that the boots meet specific operational requirements, especially in industries where exposure to wet conditions is frequent. -

Durable Water Repellent (DWR) Treatment

– Definition: DWR is a surface treatment applied to fabrics and leather that causes water to bead up and roll off.

– Importance: A good DWR treatment prolongs the life of waterproofing. Buyers should look for boots with a high-quality DWR finish, as this adds an essential layer of protection against moisture. -

Breathability

– Definition: This property refers to the ability of the leather to allow moisture vapor from sweat to escape while preventing water from entering.

– Importance: Breathable boots enhance comfort during extended wear, reducing the risk of overheating and moisture buildup. This is crucial for workers in hot and humid climates. -

Seam Sealing

– Definition: Seam sealing involves applying a waterproof sealant to the stitching areas of the boots to prevent water ingress.

– Importance: Since seams are common failure points for waterproofing, effective seam sealing is critical for ensuring the overall integrity of the boot. B2B buyers should prioritize boots with reinforced seam sealing for maximum protection.

What Are Common Trade Terms in the Waterproof Boot Industry?

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Buyers often engage with OEMs to ensure that the components used in waterproof boots meet specific quality standards and specifications. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ is essential for B2B buyers when negotiating purchases, as it affects inventory management and cash flow. -

RFQ (Request for Quotation)

– Definition: An RFQ is a business process where buyers request pricing and other details from suppliers for specific products or services.

– Relevance: This term is vital for buyers seeking to compare costs and terms from different suppliers in the waterproof boot market. -

Incoterms (International Commercial Terms)

– Definition: These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Relevance: Familiarity with Incoterms is crucial for B2B transactions, especially for international buyers, to avoid misunderstandings related to delivery and liability. -

Lead Time

– Definition: Lead time is the duration between the initiation of an order and its completion.

– Relevance: For B2B buyers, understanding lead time is critical for planning inventory and ensuring that products arrive in time for operational needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing waterproof leather boots, ensuring they meet their specific needs and standards.

Navigating Market Dynamics and Sourcing Trends in the how to make leather boots waterproof Sector

What Are the Key Market Dynamics and Trends in the Leather Boot Waterproofing Sector?

The global market for waterproof leather boots is driven by various factors, including the increasing demand for outdoor activities and the growing awareness of the importance of quality footwear. In regions such as Africa, South America, the Middle East, and Europe, the need for durable and waterproof footwear is accentuated by diverse climatic conditions and the prevalence of outdoor work. For B2B buyers, understanding the sourcing trends is crucial; there is a noticeable shift towards innovative waterproofing technologies, such as advanced coatings that enhance durability and breathability.

Illustrative image related to how to make leather boots waterproof

Emerging technologies, like nanotechnology and hydrophobic treatments, are gaining traction, providing significant advantages over traditional methods. Additionally, buyers are increasingly looking for suppliers who can offer customized solutions tailored to specific market needs, ensuring that products meet local demands. Moreover, the trend towards e-commerce platforms has simplified the procurement process, allowing international buyers to access a wider range of waterproofing products and treatments.

As the market continues to evolve, it’s essential for B2B buyers to stay informed about the latest developments in waterproofing methods, as well as the performance characteristics of various materials. This knowledge will enable them to make informed purchasing decisions and maintain a competitive edge in their respective markets.

How Is Sustainability Shaping the Leather Boot Waterproofing Industry?

The environmental impact of traditional leather production and treatment processes has led to a growing emphasis on sustainability and ethical sourcing within the leather boot waterproofing sector. International B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices, including the use of eco-friendly waterproofing agents and responsibly sourced materials.

Sustainable waterproofing solutions often involve the use of biodegradable or non-toxic chemicals, reducing the ecological footprint of leather boot production. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) provide assurance to buyers that products are manufactured in an environmentally conscious manner.

Additionally, the demand for transparency in supply chains is rising, prompting manufacturers to adopt ethical sourcing practices that ensure fair labor conditions and minimize environmental degradation. Buyers who align with suppliers committed to sustainability can enhance their brand reputation and appeal to increasingly environmentally conscious consumers, thereby driving sales in competitive markets.

What Is the Historical Context of Waterproofing Leather Boots for B2B Buyers?

The evolution of waterproofing techniques for leather boots can be traced back centuries, with early methods relying on natural oils and waxes derived from animal fats. These traditional practices laid the groundwork for contemporary waterproofing technologies.

In the mid-20th century, advancements in synthetic materials led to the development of more effective waterproofing agents, including polyurethane and silicone-based treatments. These innovations not only improved the performance of leather boots but also expanded their applications across various industries, from outdoor recreation to industrial work environments.

As the demand for durable, weather-resistant footwear has increased, manufacturers have continued to refine waterproofing techniques, leading to the sophisticated products available today. For B2B buyers, understanding this historical context can provide valuable insights into product development and innovation, informing their procurement strategies as they seek high-quality waterproof leather boots that meet the needs of modern consumers.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather boots waterproof

-

How do I choose the right waterproofing treatment for leather boots?

Selecting the appropriate waterproofing treatment depends on the type of leather your boots are made of. Full-grain leather typically benefits from wax-based treatments, while suede and nubuck require specialized sprays or oils. Always read the product specifications to ensure compatibility. Additionally, consider the intended use of the boots; heavier-duty options may be necessary for work environments with high moisture exposure. Finally, remember to test any new product on a small, inconspicuous area of the boot to assess its effect on color and texture. -

What is the best method to waterproof leather boots for industrial use?

For industrial applications, a combination of seam sealing and wax or oil treatments offers the best protection. Start by applying a seam sealer to vulnerable areas, as seams are prone to leaks. Follow this with a high-quality wax or oil treatment that suits the leather type. Regular maintenance is crucial; reapply treatments every few weeks, especially if the boots are frequently exposed to water. This approach not only enhances waterproofing but also prolongs the lifespan of the leather. -

How often should I waterproof leather boots to maintain their quality?

The frequency of waterproofing depends on usage conditions. For boots used in wet or muddy environments, a treatment every 2-4 weeks is recommended. If you notice water no longer beading on the surface or if the boots appear dirty, it’s time for a fresh application. Boots that are less frequently used or kept in dry conditions may require treatment only once or twice a season. Regular inspections and upkeep can significantly extend the life of the boots. -

What are the key factors to consider when sourcing waterproofing products for leather boots?

When sourcing waterproofing products, consider the product’s effectiveness, compatibility with different leather types, and environmental regulations in your target market. Look for suppliers who provide detailed product specifications and testing results. Additionally, assess the supplier’s reputation, responsiveness, and ability to offer samples or trials. Certifications, such as eco-friendliness or compliance with safety standards, can also be significant in decision-making, especially for international trade. -

What are the minimum order quantities (MOQ) for waterproofing products?

Minimum order quantities can vary significantly by supplier and product type. For bulk purchases, MOQs might range from 100 to 1,000 units, depending on the supplier’s production capacity and inventory strategy. When negotiating terms, consider your storage capabilities and projected usage rates. It’s also wise to discuss flexibility in MOQs, especially if you’re testing a new product or entering a new market. Building a strong relationship with suppliers can lead to better terms. -

What payment terms should I expect when sourcing waterproofing products internationally?

Payment terms for international transactions typically vary by supplier and may include options like advance payment, net 30, or payment upon delivery. Common methods include wire transfers, letters of credit, and online payment platforms. It’s essential to clarify these terms upfront to avoid misunderstandings. Additionally, consider the currency exchange rates and potential transaction fees, as these can impact overall costs. Establishing a good rapport with your supplier can lead to more favorable payment arrangements. -

How can I ensure quality assurance (QA) for waterproofing products?

To ensure quality assurance for waterproofing products, request samples for testing before placing a bulk order. Establish clear specifications and performance metrics that the product must meet. Additionally, inquire about the supplier’s QA processes, including any certifications or third-party testing they conduct. Regular audits and communication can help maintain standards. If possible, build a long-term partnership with suppliers who consistently demonstrate high-quality products and reliable service. -

What logistics considerations should I keep in mind when importing waterproofing products?

When importing waterproofing products, consider shipping methods, lead times, and customs regulations in your target country. Sea freight is often cost-effective for bulk orders, but air freight may be necessary for urgent needs. Verify the supplier’s ability to provide necessary documentation for customs clearance, such as certificates of origin and compliance. Additionally, factor in potential tariffs and taxes that could affect the total landed cost. Collaborating with experienced logistics partners can streamline the import process.

Top 6 How To Make Leather Boots Waterproof Manufacturers & Suppliers List

1. Thorogood – Waterproof Leather Work Boots

Domain: thorogoodusa.com

Registered: 2013 (12 years)

Introduction: Thorogood offers a variety of waterproof leather work boots designed to withstand outdoor conditions. Key product categories include: Moc Toe Work Boots, Safety Toe Work Boots, Composite Toe Work Boots, Steel Toe Work Boots, Waterproof Work Boots, Insulated Work Boots, and Women’s Work Boots. Popular series include Genesis Series, American Heritage Series, Hammerhead Series, and Logger Series. Rec…

2. Durango – Steel Toe Chukkas

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Durango Steel Toe Chukkas; waterproofing methods discussed include kiwi silicon waterproof spray, mink oil paste, leather honey, and Sno-Seal; recommended maintenance includes conditioning and waxing; waterproofing process should be done monthly in winter; silicone spray is not ideal for leather boots; leather is porous and requires conditioning to enhance water resistance.

3. REI – Waterproofing Treatments for Hiking Boots

Domain: rei.com

Registered: 1996 (29 years)

Introduction: Waterproofing treatments for hiking boots are designed for either full-grain leather or rough leathers like suede or nubuck. Wax-based treatments are less common now and can impair resoling. Boots with Gore-Tex® or similar membranes do not require treatment in those areas. The waterproofing process involves cleaning the boots, ensuring they are damp, applying the treatment, and drying them properl…

4. Instructables – Waterproof Leather Boots

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Waterproof boots made of real leather, treated with wax for water repellency. Requires candle (or wax), heat source (hair dryer or heat gun), and the process involves rubbing wax on the boots, heating to melt the wax, and applying multiple layers for effective coverage. The boots are not originally designed to be waterproof but can provide splash protection.

5. Carolina & Matterhorn – Key Work Boots

Domain: overlookboots.com

Registered: 2014 (11 years)

Introduction: Sale price $199.99 Carolina Men’s Anchor 10″ Waterproof Composite Square Toe Roper Work Boot – CA8536; Sale price $239.99 Matterhorn Men’s Max 8″ Composite Toe Waterproof Logger Work Boot Brown MT2560; Sale price $229.99 Carolina Men’s 28 Series 8” Waterproof Composite Toe Work Boot – Kharthoum Cigar – CA8528; Sale price $294.99 Carolina Men’s Coppice 12″ Composite Toe Waterproof Logger Work Boot-…

6. Nikwax – Key Waterproofing Products

Domain: ukhillwalking.com

Registered: 2007 (18 years)

Introduction: 1. Nikwax Liquid – Easy and quick to apply, maintains leather and adds waterproofing. Used since mid-1980s. 2. Nikwax Solid Wax – Not preferred due to difficulty in application. 3. Neatsfoot Oil – Recommended by a bootmaker for feeding leather, prevents drying out. 4. SNO-SEAL – Beeswax-based, effective but not commonly found in the UK. 5. Grangers G-Wax – Highly recommended for waterproofing leat…

Strategic Sourcing Conclusion and Outlook for how to make leather boots waterproof

In conclusion, the waterproofing of leather boots represents a critical area of focus for international B2B buyers seeking to enhance product durability and customer satisfaction. Key takeaways include the importance of selecting appropriate waterproofing treatments tailored to specific leather types, maintaining regular upkeep to prolong the life of the boots, and understanding the environmental factors that may affect waterproofing efficacy. By prioritizing strategic sourcing, businesses can ensure access to high-quality materials and products, thereby minimizing returns and maximizing customer loyalty.

Illustrative image related to how to make leather boots waterproof

Investing in effective waterproofing solutions not only protects the integrity of the leather but also safeguards the investment made by businesses in their footwear offerings. As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, there is an increasing demand for reliable and durable leather products.

Now is the time for B2B buyers to explore innovative waterproofing technologies and treatments, thereby positioning themselves as leaders in a competitive marketplace. Collaborate with trusted suppliers and manufacturers to enhance your product offerings and meet the growing expectations of your customers. Together, let’s pave the way for a future where quality and performance in leather footwear are paramount.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to how to make leather boots waterproof

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.