Introduction: Navigating the Global Market for custom leather stamping dies

In the fast-evolving landscape of leather goods manufacturing, sourcing high-quality custom leather stamping dies poses a significant challenge for international B2B buyers. As businesses from Africa, South America, the Middle East, and Europe (including countries like Saudi Arabia and Nigeria) strive to enhance product differentiation and branding, the need for precision-engineered stamping dies becomes paramount. This comprehensive guide addresses the complexities involved in sourcing these essential tools, covering various types, applications, and the nuances of supplier vetting.

Buyers will explore the distinctions between materials such as brass, steel, and aluminum, and how each affects the longevity and effectiveness of stamping. Additionally, this guide delves into the specific applications of custom leather stamping dies, from embossing to branding, ensuring that businesses can select the right tools for their unique projects. Understanding cost factors and logistical considerations is crucial for making informed purchasing decisions in a global market.

Equipped with actionable insights and expert recommendations, this guide empowers B2B buyers to navigate the intricacies of sourcing custom leather stamping dies. By enhancing their understanding of the market, buyers can confidently partner with suppliers that align with their operational needs, ensuring quality and efficiency in their leather production processes.

Table Of Contents

- Top 5 Custom Leather Stamping Dies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather stamping dies

- Understanding custom leather stamping dies Types and Variations

- Key Industrial Applications of custom leather stamping dies

- 3 Common User Pain Points for ‘custom leather stamping dies’ & Their Solutions

- Strategic Material Selection Guide for custom leather stamping dies

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamping dies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamping dies’

- Comprehensive Cost and Pricing Analysis for custom leather stamping dies Sourcing

- Alternatives Analysis: Comparing custom leather stamping dies With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather stamping dies

- Navigating Market Dynamics and Sourcing Trends in the custom leather stamping dies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamping dies

- Strategic Sourcing Conclusion and Outlook for custom leather stamping dies

- Important Disclaimer & Terms of Use

Understanding custom leather stamping dies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Leather Hand Stamps | Made from brass, steel, or aluminum; suitable for hand stamping; high detail engraving | Branding, embossing, and marking leather | Pros: Versatile, customizable; Cons: May require manual effort for large batches. |

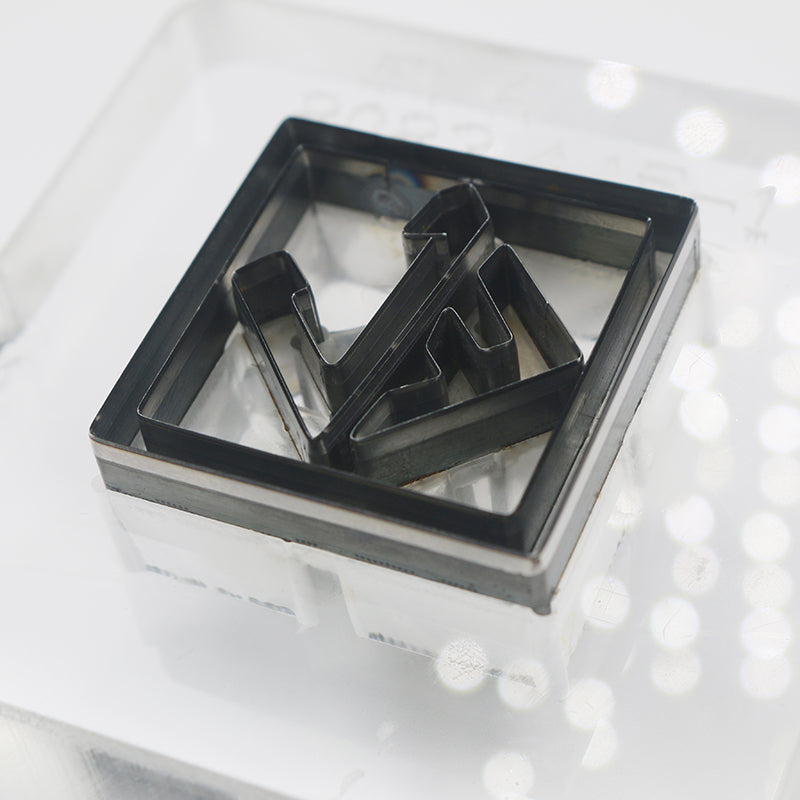

| Leather Cutting Dies | Sharp edges for cutting shapes; can be custom designed; compatible with various materials | Crafting, prototyping, production runs | Pros: Precise cuts, efficient for mass production; Cons: Initial investment can be high. |

| Custom Roll Dies | Designed for repetitive stamping; available in brass or steel; interchangeable segments | Continuous patterns on belts or straps | Pros: Ideal for high-volume production; Cons: Limited to specific machinery types. |

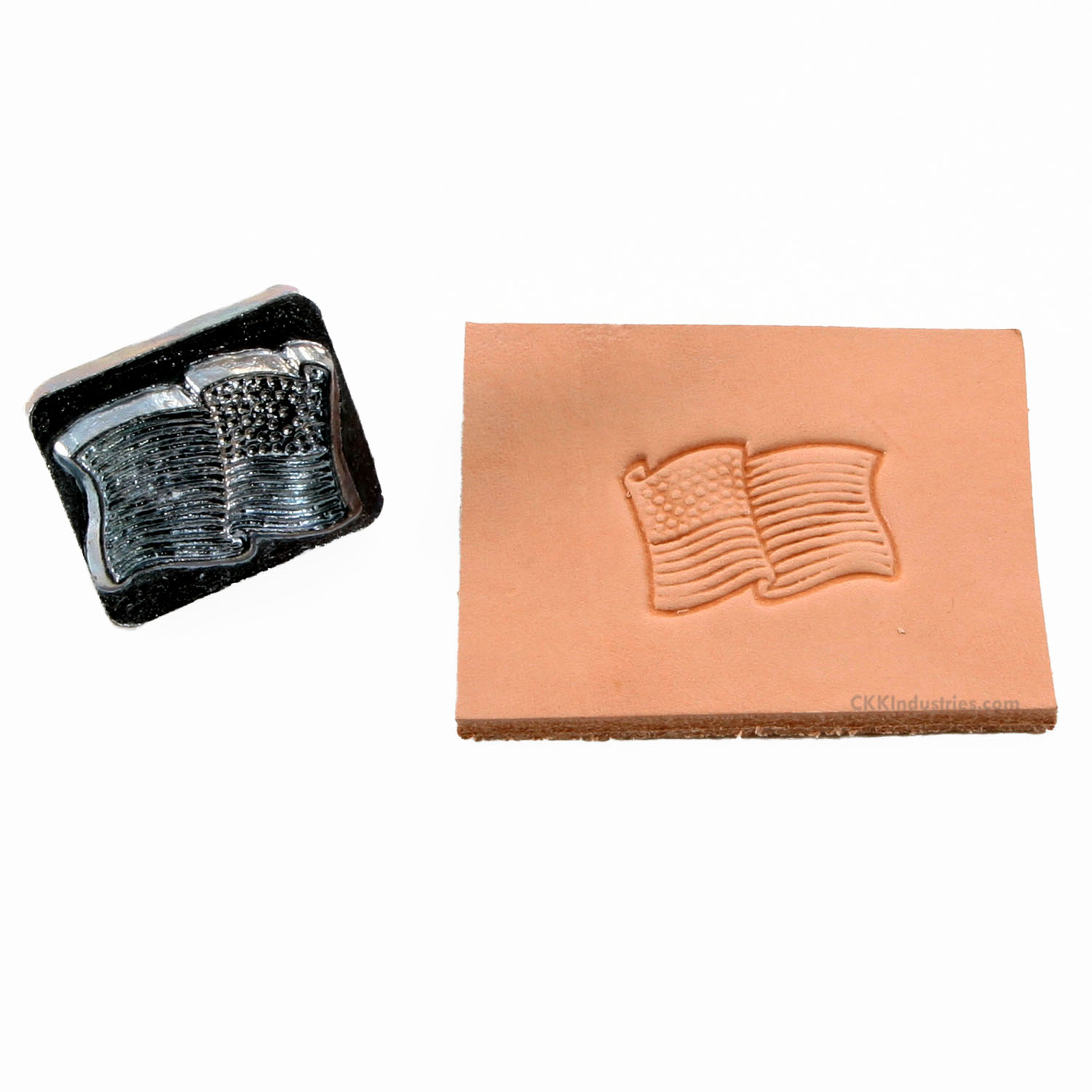

| Branding Irons | Suitable for heat application; made from durable materials; can mark various leather types | Branding on leather goods | Pros: Creates a permanent mark; Cons: Requires heat source and may need specific handling. |

| Embossing Dies | Creates raised designs; suitable for detailed logos; can be used with various leather types | Decorative applications, luxury goods | Pros: Enhances aesthetics; Cons: May not be suitable for all leather types. |

What are the Characteristics and Suitability of Custom Leather Hand Stamps?

Custom leather hand stamps are crafted from materials such as brass, steel, or aluminum, each offering unique benefits. They are particularly effective for branding, embossing, and marking leather items. B2B buyers should consider the level of detail required for their projects, as these stamps can be finely engraved to create intricate designs. While they offer flexibility and customization options, buyers should be aware that manual stamping may require additional labor for larger production volumes.

How Do Leather Cutting Dies Enhance Production Efficiency?

Leather cutting dies are engineered with sharp edges to create precise shapes, making them essential for crafting, prototyping, and large-scale production runs. They can be tailored to specific designs, allowing businesses to achieve consistent results across multiple products. When purchasing, B2B buyers should evaluate the initial investment against the potential for increased efficiency and reduced labor costs in their manufacturing processes.

What Are the Advantages of Custom Roll Dies for High-Volume Production?

Custom roll dies are specifically designed for repetitive stamping, making them ideal for applications requiring continuous patterns, such as on belts or straps. Made from durable brass or steel, these dies can include interchangeable segments for added versatility. For B2B buyers, the primary consideration should be the compatibility of the die with existing machinery, as this can significantly impact production capabilities and costs.

Why Choose Branding Irons for Leather Marking?

Branding irons are designed for heat application, allowing businesses to create permanent marks on various leather types. They are particularly useful for branding leather goods, providing a high-quality finish that can enhance product appeal. Buyers should consider the need for a heat source and the specific handling requirements, as these factors can influence the overall usability and effectiveness of the branding process.

What Role Do Embossing Dies Play in Decorative Leather Applications?

Embossing dies create raised designs on leather, adding a decorative element that is particularly valuable in luxury goods. These dies can accommodate detailed logos and custom designs, making them suitable for various leather types. B2B buyers should assess the compatibility of embossing dies with their specific leather materials, as some types may not yield the desired results. The aesthetic enhancement provided by embossing can significantly contribute to a product’s marketability.

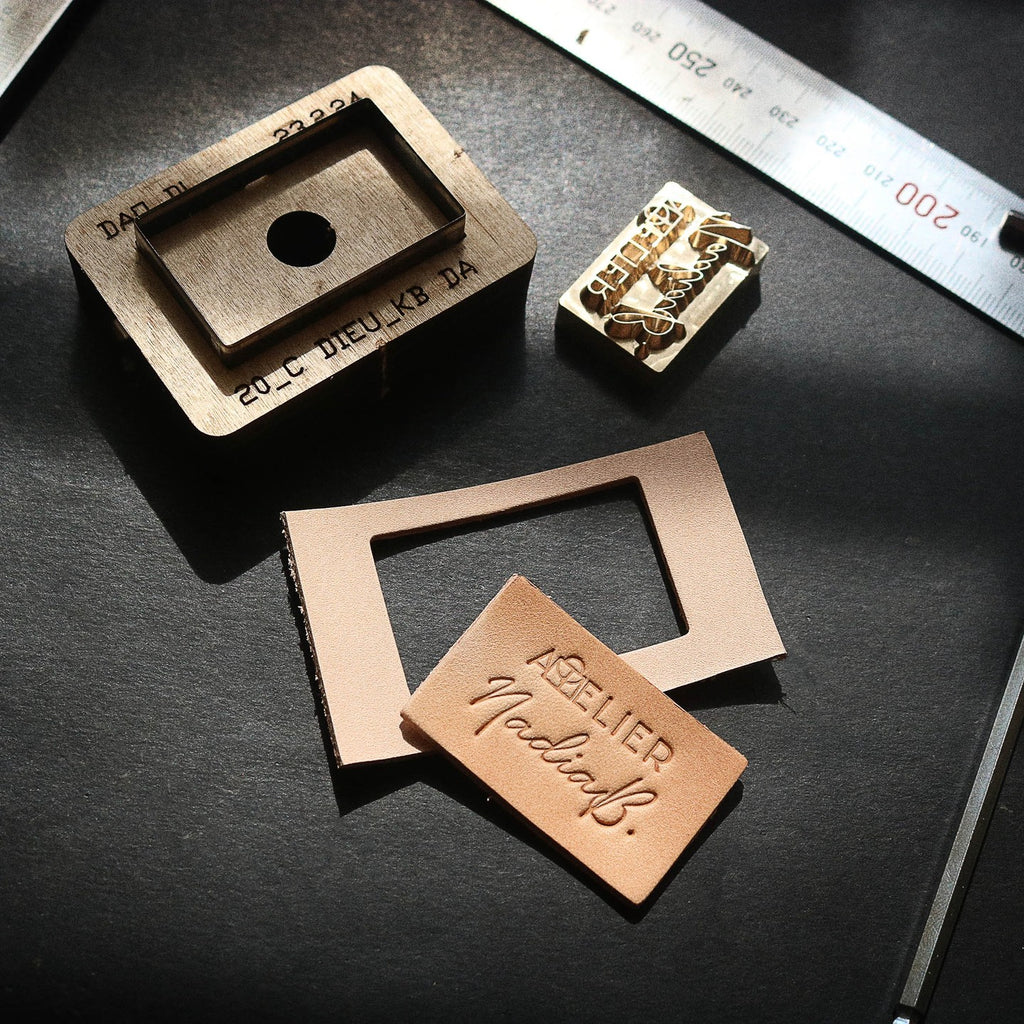

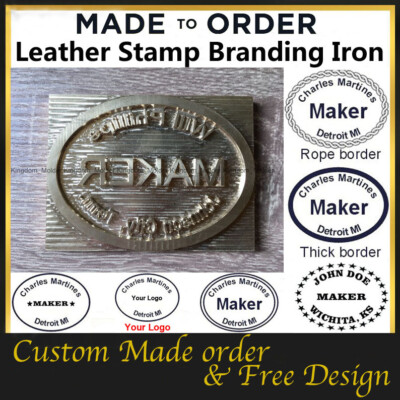

Illustrative image related to custom leather stamping dies

Key Industrial Applications of custom leather stamping dies

| Industry/Sector | Specific Application of custom leather stamping dies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Accessories | Branding and logo stamping on leather bags and belts | Enhances brand recognition and product value | Material quality (brass vs. steel), customization options |

| Automotive | Custom leather stamping for car interiors and upholstery | Adds luxury appeal and personalization | Compatibility with various leather types, durability requirements |

| Footwear | Stamping designs on leather shoes and boots | Unique product differentiation and enhanced aesthetics | Precision in design replication, turnaround time for orders |

| Furniture | Embossing logos or patterns on leather furniture | Elevates brand identity and craftsmanship appeal | Customization capabilities, size and complexity of designs |

| Craft and Hobby | Custom dies for DIY leather crafting projects | Supports creativity and personalization for artisans | Availability of various die sizes and shapes, ease of use |

How Are Custom Leather Stamping Dies Used in Fashion Accessories?

In the fashion accessories industry, custom leather stamping dies are essential for branding and logo applications on products like bags and belts. These dies allow manufacturers to imprint unique designs that enhance brand recognition and add perceived value to their products. For international buyers, particularly in regions such as Africa and South America, sourcing high-quality brass or steel dies ensures durability and a professional finish, which is critical for competing in the global market. Buyers should consider the die’s compatibility with their leather types and the intricacies of their designs to achieve the desired aesthetic.

What Role Do Custom Leather Stamping Dies Play in the Automotive Sector?

In the automotive sector, custom leather stamping dies are used to create luxurious interiors by embossing logos and patterns on leather upholstery. This process not only adds a touch of sophistication but also allows for personalization, which is increasingly demanded by consumers. For businesses in the Middle East and Europe, sourcing dies that can accommodate various leather types and withstand the rigors of automotive use is vital. Ensuring that the dies are made from durable materials will prevent wear and tear, maintaining the quality of the finished product over time.

How Are Custom Leather Stamping Dies Beneficial for Footwear Manufacturers?

Footwear manufacturers utilize custom leather stamping dies to imprint intricate designs on shoes and boots, helping to differentiate their products in a crowded market. This application enhances the aesthetic appeal of footwear, making them more attractive to consumers. For B2B buyers in regions like Saudi Arabia and Nigeria, sourcing dies that offer precision in design replication is crucial to maintaining brand integrity. Additionally, understanding the lead times for custom orders can help businesses plan their production schedules effectively.

In What Ways Are Custom Leather Stamping Dies Used in Furniture Design?

In the furniture industry, custom leather stamping dies are employed to emboss logos or decorative patterns onto leather upholstery, elevating the craftsmanship and brand identity of furniture pieces. This application can significantly enhance the perceived value of the product, appealing to high-end markets. Buyers from Europe and South America should focus on sourcing dies that allow for a variety of customization options, ensuring they can meet specific design requirements. The capability to produce dies that are tailored to complex designs will also be a key consideration.

Illustrative image related to custom leather stamping dies

How Do Custom Leather Stamping Dies Support Craft and Hobby Businesses?

Custom leather stamping dies are particularly valuable for craft and hobby businesses, enabling artisans to create personalized leather goods. These dies allow for a range of creative applications, from unique patterns to custom logos, supporting the artistic expression of crafters. For international buyers, particularly in emerging markets, sourcing versatile dies that can handle various sizes and shapes is essential for maximizing creativity. Additionally, ensuring that the dies are user-friendly will facilitate easier integration into crafting processes, making them accessible to a wider range of artisans.

3 Common User Pain Points for ‘custom leather stamping dies’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision and Consistency in Stamping

The Problem: A common issue faced by B2B buyers, especially those involved in large-scale production, is achieving the desired precision and consistency with custom leather stamping dies. This challenge can lead to significant production delays and wasted materials, as poorly stamped designs may not meet quality standards. Buyers may find that their stamping dies do not hold up to repeated use, resulting in inconsistent impressions that can tarnish the reputation of their brand.

The Solution: To overcome this problem, buyers should prioritize sourcing high-quality materials and precision engineering when selecting custom leather stamping dies. Opting for dies made from durable materials like brass or steel can ensure longevity and consistent performance. When placing an order, it is essential to provide detailed specifications, including the intended leather type, thickness, and desired design intricacies. Working closely with manufacturers who offer design support can also help refine the artwork, ensuring the final product meets expectations. Additionally, conducting test runs with the dies on sample leather before full-scale production can help identify any potential issues and allow for adjustments.

Scenario 2: Uncertainty in Selecting the Right Die Type for Various Leather Types

The Problem: Many buyers struggle with the uncertainty of choosing the appropriate type of custom leather stamping die for different leather materials. For instance, using a die that is too harsh for softer leather can result in damage, while a die that is not suitable for thicker leather may fail to make a clear impression. This lack of clarity can lead to costly errors, wasted materials, and dissatisfaction among customers.

The Solution: To effectively navigate this challenge, buyers should invest time in understanding the characteristics of the leather they are working with and the corresponding stamping methods. Collaborating with suppliers who have expertise in leather types and stamping techniques is crucial. When placing an order, buyers should specify the leather type (e.g., vegetable-tanned, chrome-tanned, or suede) and any unique requirements. Suppliers can provide valuable insights on which dies are best suited for specific applications, ensuring that the end result aligns with quality standards. Additionally, utilizing sample pieces of the intended leather for testing different dies can provide practical insights and enhance decision-making.

Scenario 3: Long Lead Times and Communication Gaps in Custom Orders

The Problem: International buyers, particularly those in regions like Africa and South America, often face long lead times and communication barriers when ordering custom leather stamping dies. This can be frustrating, especially when tight production schedules are involved. Miscommunications about design specifications or timelines can lead to further delays and affect overall project delivery.

The Solution: To mitigate these issues, buyers should establish clear communication channels with their suppliers from the outset. Providing comprehensive design files (preferably in vector format) and discussing timelines upfront can help set realistic expectations. Choosing suppliers who offer digital proofs before production can also minimize misunderstandings regarding design details. Furthermore, considering suppliers with a proven track record of timely deliveries and responsive customer service can enhance the overall ordering experience. By fostering a collaborative relationship with suppliers, buyers can ensure smoother transactions and more efficient project timelines, ultimately leading to higher satisfaction and reduced stress.

Strategic Material Selection Guide for custom leather stamping dies

What Are the Key Materials for Custom Leather Stamping Dies?

When selecting materials for custom leather stamping dies, it is crucial to consider the properties, advantages, and limitations of each option. The most common materials used for these dies include steel, brass, aluminum, and tool steel. Each material has distinct characteristics that can impact the performance of the stamping process and the quality of the final product.

How Does Steel Perform for Custom Leather Stamping Dies?

Steel is a widely used material for custom leather stamping dies due to its strength and durability. It can withstand high temperatures and pressures, making it suitable for various stamping applications. Steel dies are resistant to wear and can produce crisp, clear impressions on leather. However, they can be prone to rust if not properly maintained, which may be a concern for buyers in humid environments.

Pros: High durability, excellent for high-volume production, and produces detailed impressions.

Cons: Heavier than other materials, potential for rust, and higher manufacturing complexity.

For international buyers, particularly in regions with high humidity like parts of Africa and the Middle East, it is essential to consider the need for proper storage and maintenance to prevent corrosion.

What Are the Advantages of Brass for Leather Stamping Dies?

Brass is another popular choice for leather stamping dies, favored for its excellent thermal conductivity and resistance to rust. Brass dies are particularly effective for wet stamping applications, as they do not corrode when exposed to moisture. This material is also easier to machine, which can reduce manufacturing complexity and costs.

Pros: Corrosion-resistant, good thermal properties, and produces high-quality impressions.

Cons: Generally more expensive than aluminum, softer than steel, which may lead to wear over time.

For B2B buyers in regions like Europe and South America, where quality and durability are paramount, brass may be the preferred choice despite its higher cost.

Why Choose Aluminum for Custom Leather Stamping Dies?

Aluminum is often considered a cost-effective option for custom leather stamping dies. It is lightweight and easy to handle, making it suitable for smaller projects or for companies just starting with leather stamping. However, aluminum is less durable than steel or brass and may not provide the same level of detail in impressions.

Pros: Lower cost, lightweight, and easy to machine.

Cons: Less durable, prone to wear, and not suitable for high-pressure applications.

International buyers should be aware that while aluminum may save costs upfront, it may not be the best long-term investment for high-volume production.

Illustrative image related to custom leather stamping dies

What Role Does Tool Steel Play in Leather Stamping Dies?

Tool steel is designed for high-performance applications and is known for its hardness and wear resistance. It can withstand high temperatures and is less likely to deform under pressure, making it ideal for custom leather stamping dies. However, tool steel can be more expensive and may require specialized machining processes.

Pros: Exceptional durability, high resistance to wear, and maintains sharp edges.

Cons: Higher cost, requires specialized machining, and can be heavier.

For B2B buyers in regions with stringent manufacturing standards, such as Europe, tool steel may be the ideal choice for high-quality leather stamping applications.

Summary Table of Material Selection for Custom Leather Stamping Dies

| Material | Typical Use Case for custom leather stamping dies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-volume production and detailed impressions | High durability and wear resistance | Prone to rust without maintenance | High |

| Brass | Wet stamping applications and high-quality impressions | Corrosion-resistant and good thermal properties | Softer than steel, may wear over time | Medium |

| Aluminum | Small projects and cost-sensitive applications | Lightweight and cost-effective | Less durable and prone to wear | Low |

| Tool Steel | High-performance applications requiring durability | Exceptional hardness and wear resistance | Higher cost and requires specialized machining | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions regarding custom leather stamping dies. Understanding the properties and implications of each material can significantly impact the quality and efficiency of leather stamping projects.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamping dies

When considering the procurement of custom leather stamping dies, understanding the manufacturing processes and quality assurance measures is crucial for B2B buyers. The quality of these dies directly impacts the efficiency and effectiveness of your leather stamping operations. Below is a detailed exploration of the typical manufacturing stages, key techniques employed, and quality control measures that ensure your investment meets international standards.

What are the Main Stages in the Manufacturing Process of Custom Leather Stamping Dies?

The manufacturing process for custom leather stamping dies generally involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring that the final product meets specific requirements and performs reliably in various applications.

Material Preparation: What Materials are Commonly Used?

The choice of materials is foundational to the performance of leather stamping dies. Common materials include:

- Steel: Known for its strength and durability, steel is often used in high-volume production settings.

- Brass: Valued for its excellent thermal conductivity and resistance to rust, brass is the preferred choice for many leather makers.

- Aluminum: While lighter and more cost-effective, aluminum is typically used for lower-demand applications.

The selected material undergoes rigorous inspection to ensure it meets the required specifications before moving to the next stage.

Illustrative image related to custom leather stamping dies

Forming: What Techniques are Used in Creating the Die?

The forming stage utilizes advanced techniques to create the die shape, including:

- CNC Machining: Computer Numerical Control (CNC) machining offers high precision in cutting and engraving designs onto the die. This method is essential for achieving intricate details and consistent quality across batches.

- Die Casting: For certain designs, die casting may be employed, allowing for rapid production of complex shapes.

- Laser Engraving: This technique is often used for creating detailed designs, logos, or text on the dies.

Each technique has its advantages, and the choice often depends on the specific requirements of the project, including design complexity and production volume.

Assembly: How are Custom Dies Assembled?

Once the components are formed, they are carefully assembled. This may involve:

- Fitting Components Together: Ensuring that all parts align correctly for optimal performance.

- Installing Handles and Holders: Many dies come with ergonomic handles or holders to facilitate ease of use during stamping.

The assembly process includes thorough checks to confirm that the die operates smoothly and meets design specifications.

Finishing: What Quality Enhancements are Applied?

Finishing processes enhance the durability and aesthetics of the dies. Common finishing techniques include:

- Polishing: To remove any burrs or rough edges, ensuring a smooth stamping surface.

- Coating: Applying protective coatings to prevent corrosion and extend the lifespan of the die.

Quality checks during the finishing stage are crucial to ensure that the die will perform reliably under various conditions.

What Quality Assurance Measures are Typically Implemented?

Quality assurance is a vital component of the manufacturing process for custom leather stamping dies. It ensures that products meet international standards, providing confidence to B2B buyers.

Which International Standards are Relevant for Quality Assurance?

International standards such as ISO 9001 play a significant role in quality management systems. Compliance with these standards indicates that a manufacturer has established processes to ensure consistent quality. Additionally, certifications like CE or API may be relevant depending on the specific application of the dies.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are essential in identifying any defects or inconsistencies during the manufacturing process. Key checkpoints include:

Illustrative image related to custom leather stamping dies

- Incoming Quality Control (IQC): Assessing raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring production processes to identify and rectify any deviations in real-time.

- Final Quality Control (FQC): Conducting comprehensive inspections of finished products before shipment.

These checkpoints help maintain quality throughout the manufacturing process, ensuring that only products that meet stringent standards reach the buyer.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are several methods to do so:

- Supplier Audits: Conducting on-site audits of the manufacturing facility can provide insights into the quality management practices employed.

- Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s adherence to quality standards and any corrective actions taken in case of deviations.

- Third-Party Inspections: Engaging independent inspectors to evaluate the manufacturing process and final products can offer an unbiased assessment of quality.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of specific quality control nuances that may affect their procurement process. These include:

- Cultural Differences: Understanding local manufacturing practices and quality perceptions can influence negotiations and expectations.

- Regulatory Compliance: Different regions may have varying regulatory requirements that must be adhered to, impacting the design and material choices for custom dies.

- Logistical Considerations: The geographical distance can affect lead times and the ability to conduct quality inspections before shipment.

By understanding these nuances, B2B buyers can make more informed decisions, ensuring they select suppliers who can meet their quality requirements effectively.

Illustrative image related to custom leather stamping dies

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures for custom leather stamping dies is essential for B2B buyers. By focusing on material selection, production techniques, and rigorous quality control practices, buyers can ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamping dies’

To effectively source custom leather stamping dies, it’s essential to follow a structured approach that ensures quality, compatibility, and cost-effectiveness. This checklist will guide you through the necessary steps to make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Identify the types of leather you will be using, the required sizes of the stamps, and the specific designs or logos you need. This clarity helps suppliers understand your requirements and provide accurate quotes.

- Consider the material of the dies (e.g., brass, steel, aluminum) based on durability and application.

- Determine the engraving depth and precision necessary for your design.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in custom leather stamping dies. Look for companies with a proven track record in your region or industry.

Illustrative image related to custom leather stamping dies

- Assess their portfolio for examples of previous work to gauge quality.

- Read customer reviews and testimonials to understand their service reliability and product performance.

Step 3: Request Samples and Prototypes

Before placing a bulk order, request samples or prototypes of the stamping dies. This step allows you to evaluate the quality and effectiveness of the dies in real-world applications.

- Test the samples on various leather types to ensure compatibility.

- Check for the clarity of the impressions and overall durability of the dies.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers adhere to international quality standards and certifications. This verification is crucial for maintaining product quality and consistency.

- Look for certifications relevant to manufacturing and product safety, such as ISO certifications.

- Confirm that the supplier has experience in exporting to your target regions, particularly if you are sourcing internationally.

Step 5: Discuss Customization Options

Engage in discussions with suppliers about potential customization options. Many suppliers offer tailored solutions to fit unique project requirements, including design alterations and material preferences.

- Inquire about the minimum order quantities for custom designs and any associated costs.

- Ensure that the supplier can accommodate specific branding needs, such as logo placements or special characters.

Step 6: Evaluate Pricing and Payment Terms

Compare pricing structures among different suppliers to ensure you are getting competitive rates. However, don’t just focus on the lowest price; consider the overall value, including quality and service.

Illustrative image related to custom leather stamping dies

- Clarify payment terms, including deposits, payment methods, and any financing options.

- Be aware of potential additional costs for shipping, customs, and taxes if sourcing internationally.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear channels for discussing specifications, timelines, and any issues that may arise.

- Utilize email, phone calls, or video conferences for direct communication.

- Set expectations for response times and updates on order progress to avoid misunderstandings.

By following these steps, you can streamline your sourcing process for custom leather stamping dies, ensuring you choose the right supplier and receive products that meet your exact specifications.

Comprehensive Cost and Pricing Analysis for custom leather stamping dies Sourcing

What Are the Key Cost Components for Custom Leather Stamping Dies?

When sourcing custom leather stamping dies, several cost components must be considered. Understanding these will help international B2B buyers effectively budget and negotiate with suppliers.

-

Materials: The choice of materials significantly impacts the price. Brass and steel are common materials for stamping dies, with brass generally being more popular due to its durability and resistance to rust when wet. Aluminum offers a lower-cost alternative but may not provide the same longevity. Prices typically range from $2 to $300 depending on the size and material selected.

-

Labor: The complexity of the design directly affects labor costs. Custom designs that require high precision, such as intricate logos or lettering, demand skilled labor, which can increase overall costs. Additionally, the production location plays a role; labor costs in regions like North America may be higher compared to those in Asia or South America.

-

Manufacturing Overhead: This includes the costs associated with maintaining production facilities, utilities, and administrative expenses. Suppliers often factor these overhead costs into the pricing, which can vary widely depending on the country of manufacture.

-

Tooling: Custom dies may require unique tooling setups, which can lead to additional charges. Tooling costs can be significant for complex designs that necessitate specialized machinery or processes.

-

Quality Control (QC): Ensuring that dies meet specified tolerances requires an investment in quality control processes. Buyers should inquire about the QC measures employed by suppliers, as these can impact pricing. Higher quality assurance often results in a higher price but may reduce long-term costs related to product defects.

-

Logistics: The cost of shipping and handling can be substantial, especially for international orders. Factors such as distance, shipping method, and customs duties need to be considered. Incoterms can also affect logistics costs, so understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) is essential.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can vary based on market demand, competition, and the supplier’s business strategy. Understanding the market landscape can help buyers negotiate better pricing.

How Do Price Influencers Affect Custom Leather Stamping Dies?

Several factors influence the pricing of custom leather stamping dies, particularly for international buyers.

Illustrative image related to custom leather stamping dies

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract bulk discounts. Buyers should assess their needs carefully; ordering beyond MOQ can lead to significant savings per unit.

-

Specifications and Customization: Custom features, such as size, engraving depth, and material choices, can alter pricing. Buyers should be clear about their requirements to receive accurate quotes.

-

Quality and Certifications: Suppliers offering higher quality dies may charge more. Certifications (e.g., ISO standards) can also influence pricing, as they indicate a commitment to quality.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: The agreed-upon Incoterms can influence total costs. Terms like DDP (Delivered Duty Paid) mean the supplier covers all shipping costs, while EXW (Ex Works) places more responsibility on the buyer.

What Are the Best Negotiation Tips for B2B Buyers in International Markets?

-

Research and Compare: Understand market prices and supplier offerings in different regions. This knowledge can empower buyers during negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial price but the long-term costs associated with the dies, including maintenance, durability, and potential reorders.

-

Leverage Volume: If possible, negotiate for lower prices based on order volume or future business commitments. Suppliers often appreciate the promise of repeat business.

-

Be Clear About Expectations: Clearly communicate design specifications, quality requirements, and delivery timelines to avoid misunderstandings that could lead to increased costs.

-

Understand Currency Fluctuations: For international transactions, currency exchange rates can impact overall costs. Consider locking in rates or negotiating payments in a stable currency.

Conclusion: Navigating the Pricing Landscape

The pricing of custom leather stamping dies is multifaceted, influenced by material choices, labor, tooling, and logistics, among other factors. By understanding these elements and employing strategic negotiation tactics, international B2B buyers can optimize their sourcing strategies and achieve cost-effective solutions. Always remember to request quotes and verify the total cost of ownership to ensure the best value for your investment.

Alternatives Analysis: Comparing custom leather stamping dies With Other Solutions

In the realm of leather crafting, custom leather stamping dies are a popular choice for businesses looking to imprint designs, logos, or patterns onto leather products. However, there are alternative solutions available that can also fulfill similar needs. Understanding these alternatives can help businesses make informed decisions based on their specific requirements, such as cost, performance, and ease of use.

| Comparison Aspect | Custom Leather Stamping Dies | Heat Branding Irons | Laser Engraving Systems |

|---|---|---|---|

| Performance | Excellent for detailed designs and deep impressions | Good for clear, crisp branding; limited detail | High precision with intricate designs and multiple materials |

| Cost | Moderate to high, depending on customization | Moderate, with lower initial investment | High initial cost, but cost-effective for large runs |

| Ease of Implementation | Requires setup and manual operation | Easy to use, especially for branding | Requires technical knowledge for operation and setup |

| Maintenance | Low; durable materials but can wear over time | Low; occasional cleaning required | Moderate; requires software updates and maintenance |

| Best Use Case | Ideal for embossed designs on thick leather | Best for branding logos on thinner or softer leather | Suitable for detailed designs on various materials, including leather |

What Are the Pros and Cons of Heat Branding Irons?

Heat branding irons provide a viable alternative to custom leather stamping dies, especially for businesses looking for a straightforward branding solution. They are generally more affordable and simpler to operate, making them accessible for smaller workshops or startups. However, their limitations in detail and design complexity mean they may not be suitable for all branding needs. Heat branding works best on thinner leather, and while it produces a clean mark, it may lack the depth and intricacy that stamping dies can achieve.

How Do Laser Engraving Systems Compare?

Laser engraving systems offer a cutting-edge alternative to traditional stamping methods. They excel in precision and detail, allowing for intricate designs that can be replicated consistently across various materials, including leather. However, the initial investment is higher compared to custom stamping dies and heat branding irons. Additionally, operating a laser engraving machine requires a certain level of technical knowledge, which may necessitate training for staff. For businesses that prioritize detail and versatility, the return on investment can be significant, especially for larger production runs.

Illustrative image related to custom leather stamping dies

How Should B2B Buyers Choose the Right Solution?

When selecting the right solution for leather branding or stamping, B2B buyers should consider their specific operational needs, budget constraints, and the desired outcome of their leather products. Custom leather stamping dies are well-suited for businesses that require durable, deep impressions and detailed designs. In contrast, heat branding irons are ideal for simpler branding tasks on thinner leather. Meanwhile, laser engraving systems cater to those looking for high precision and versatility across multiple materials. By evaluating these factors, businesses can choose the most effective solution that aligns with their branding objectives and production capabilities.

Essential Technical Properties and Trade Terminology for custom leather stamping dies

What Are the Essential Technical Properties of Custom Leather Stamping Dies?

Understanding the technical specifications of custom leather stamping dies is crucial for B2B buyers in making informed purchasing decisions. Here are some key properties to consider:

-

Material Grade

The most common materials for leather stamping dies are brass, steel, and aluminum. Brass is preferred for its durability and resistance to rust, making it ideal for wet stamping applications. Steel offers superior strength and longevity, while aluminum is a cost-effective option for less demanding applications. Selecting the right material can significantly impact the quality and lifespan of the die. -

Tolerance

Tolerance refers to the permissible limit of variation in dimensions and specifications. High-precision dies often have tighter tolerances, which are essential for achieving clean and accurate impressions. For B2B buyers, understanding tolerance levels is vital, as tighter tolerances can lead to higher costs but can also improve the quality of the finished product, reducing the need for rework. -

Engraving Depth

The engraving depth affects how deeply the design is imprinted on the leather. A typical engraving depth ranges from 2mm to 5mm, depending on the application and type of leather being used. Deeper engravings are suitable for thicker leather, while shallower engravings are better for finer materials. Buyers should specify their needs based on the leather type to ensure optimal results. -

Heat Resistance

For applications involving heat stamping, the die material must withstand high temperatures without degrading. Brass and steel are generally suitable for heat applications, while aluminum may not perform as well under extreme heat. Understanding heat resistance is critical for buyers looking to implement branding techniques that require temperature control. -

Customizability

Many manufacturers offer customizable dies that can be tailored to specific designs and requirements. This includes options for interchangeable segments, which allow users to switch designs without needing a new die. Customizability is a significant advantage for businesses looking to create unique branding or product designs efficiently. -

Compatibility with Press Types

Different leather stamping dies are designed to work with various types of presses (e.g., arbor, clicker, hydraulic). Ensuring that the selected die is compatible with existing equipment is crucial for efficient production. B2B buyers should communicate their press specifications to manufacturers to avoid compatibility issues.

What Are Common Trade Terms Used in Custom Leather Stamping Dies?

Familiarizing yourself with industry jargon can enhance communication with suppliers and streamline the purchasing process. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of leather stamping dies, OEM suppliers can provide customized solutions tailored to specific production requirements. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest order quantity that a supplier is willing to accept. Understanding MOQ is essential for B2B buyers, as it can affect inventory costs and production planning. Suppliers may have different MOQs based on material type and custom designs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. B2B buyers should use RFQs to obtain competitive quotes and ensure they are comparing similar offerings from different manufacturers. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and risks during the shipping process. -

Debossing vs. Embossing

Debossing refers to creating an impression that is recessed into the leather, while embossing creates a raised design. Understanding the difference is crucial for buyers looking to achieve specific branding effects on their leather products. -

Production Lead Time

This term indicates the time it takes from placing an order to the delivery of the finished product. Knowing the production lead time is vital for effective project management and meeting deadlines, especially in industries with tight schedules.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing custom leather stamping dies more effectively, ensuring they select the right products to meet their business needs.

Illustrative image related to custom leather stamping dies

Navigating Market Dynamics and Sourcing Trends in the custom leather stamping dies Sector

What are the Key Trends Driving the Custom Leather Stamping Dies Market?

The custom leather stamping dies market is witnessing significant growth, driven by various global factors. Increasing demand for personalized leather goods across industries—from fashion to automotive—has spurred the need for custom stamping dies. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking for high-quality, durable products that can withstand diverse applications.

Emerging trends include the rise of digital technologies such as CAD (Computer-Aided Design) for die design, which allows for greater precision and customization. Buyers are also gravitating towards suppliers who offer quick turnaround times, often facilitated by advancements in manufacturing processes, such as CNC machining. Furthermore, the advent of e-commerce platforms has made it easier for international buyers to access a broader range of suppliers, streamlining the sourcing process.

Another noteworthy trend is the growing preference for materials that enhance the longevity and performance of stamping dies. Brass and steel are favored for their durability, while aluminum is chosen for cost-effective solutions. As buyers become more discerning, they are increasingly inclined to seek out manufacturers that can provide detailed specifications and customization options tailored to their unique needs.

How is Sustainability Shaping the Custom Leather Stamping Dies Sector?

The conversation around sustainability is becoming increasingly important in the custom leather stamping dies sector. Environmental impacts from leather production and die manufacturing are under scrutiny, prompting businesses to adopt more sustainable practices. B2B buyers are now prioritizing suppliers who can demonstrate a commitment to ethical sourcing and sustainability.

One key aspect is the use of eco-friendly materials and processes. Buyers are encouraged to seek out suppliers that utilize responsibly sourced leather and sustainable production methods. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the trend towards recycling and upcycling in the leather industry is gaining traction, with many companies exploring ways to repurpose leather waste into new products. By choosing suppliers who align with these ethical standards, international buyers not only contribute to a more sustainable industry but also enhance their brand image in markets that value corporate responsibility.

What is the Historical Context of Custom Leather Stamping Dies in B2B Markets?

Historically, custom leather stamping dies have been integral to the leatherworking industry, evolving from simple hand tools to sophisticated machinery. In the early days, artisans crafted dies manually, limiting the complexity and precision of designs. However, the industrial revolution brought about mechanization, allowing for mass production and the introduction of various die materials, including brass and steel, which are now industry standards.

The late 20th century saw a technological leap with the introduction of CNC machining, significantly enhancing the precision and efficiency of die manufacturing. This evolution not only improved the quality of stamping dies but also expanded their applications across different sectors, from luxury fashion to automotive interiors. Today, as global demand for customized leather goods continues to rise, the market for custom leather stamping dies is poised for further growth, driven by innovation and a commitment to sustainability.

In summary, the custom leather stamping dies market is navigating a landscape shaped by technological advancements, sustainability considerations, and an ever-increasing demand for personalized products. B2B buyers in diverse regions must remain vigilant and proactive in sourcing from suppliers that align with these evolving market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamping dies

-

How do I choose the right custom leather stamping die for my project?

Selecting the appropriate custom leather stamping die involves understanding your specific application and requirements. Consider the type of leather you will be using, as different materials (e.g., vegetable-tanned or chrome-tanned leather) may require different stamping techniques. Additionally, think about the design complexity, desired depth of impression, and whether you need a hand stamp or a die for a press. Communicating your needs clearly to suppliers will help them recommend the best options tailored to your projects. -

What is the typical lead time for custom leather stamping dies?

The lead time for custom leather stamping dies can vary significantly based on the supplier and the complexity of your design. Generally, you can expect a timeframe of 10 to 15 business days from the approval of your design proof. Some suppliers may offer expedited services for an additional fee, allowing for quicker turnaround times, sometimes as fast as 2-3 days for simpler designs. Always confirm lead times with your supplier before placing an order, especially if you have tight project deadlines. -

What factors should I consider when vetting suppliers for custom leather stamping dies?

When vetting suppliers, evaluate their experience in the industry, quality of materials used, and customer reviews. Look for suppliers that provide detailed information about their manufacturing processes and materials, such as whether they use brass, steel, or aluminum. Ask for samples of their work to assess the quality of their dies. Additionally, consider their ability to offer customization and support throughout the design process, as well as their responsiveness to inquiries. -

What are the minimum order quantities (MOQ) for custom leather stamping dies?

Minimum order quantities for custom leather stamping dies can vary by supplier. Some manufacturers may have an MOQ of just one die, while others might require larger orders to offset production costs. It’s essential to clarify the MOQ with potential suppliers early in your discussions to ensure it aligns with your project needs. If you require a smaller quantity, consider looking for suppliers who specialize in small-batch production or those willing to accommodate your request. -

What payment terms are commonly offered by suppliers of custom leather stamping dies?

Payment terms can vary widely among suppliers, but many will require a deposit upfront, typically ranging from 30% to 50% of the total order value. The remaining balance is often due upon completion or before shipment. Some suppliers may also offer net payment terms, allowing payment within a specific period after delivery. Always review and negotiate payment terms before finalizing your order, and consider using secure payment methods to protect your transaction. -

How can I ensure the quality of custom leather stamping dies?

To ensure the quality of your custom leather stamping dies, request a proof or sample before full production. This allows you to verify the design, depth, and overall quality. Additionally, inquire about the supplier’s quality assurance processes and whether they offer guarantees or warranties on their products. Regular communication throughout the production process can also help identify any potential issues early on, ensuring that the final product meets your specifications. -

What shipping options are available for international orders of custom leather stamping dies?

Shipping options for international orders typically include standard and expedited services, with costs varying based on weight, destination, and delivery speed. Common carriers include DHL, FedEx, and UPS, which provide tracking and insurance options. It’s crucial to discuss shipping terms with your supplier, including customs duties and import taxes, to avoid unexpected costs. Additionally, confirm estimated delivery times to ensure your dies arrive when needed for your production schedule. -

What should I do if I need modifications to my custom leather stamping die after ordering?

If you need modifications to your custom leather stamping die after placing your order, contact your supplier as soon as possible. Many manufacturers will allow changes if they haven’t started production, but modifications may incur additional costs or extend lead times. Clear communication is key; provide specific details about the changes needed and confirm any adjustments to pricing and timelines. Establishing a good relationship with your supplier can facilitate smoother modifications and enhance collaboration for future projects.

Top 5 Custom Leather Stamping Dies Manufacturers & Suppliers List

1. Leather Stamp Maker – Custom Steel Leather Cutting Dies

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Steel Leather Cutting Dies by Leather Stamp Maker, Made in the USA. Custom Leather Cutting Dies available. Full Letter Sets include: trio of each letter A-Z, three copies of numbers 0-9, special characters (period, comma, at symbol, ampersand, hash, slash, dash, exclamation mark), four blank spacers, stamping handle, 4-inch holder, packaged in a box. Mini Font Sets include: full set of 26 uppercas…

2. Custom Leather Stamps – High-Detail Engraving

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

Introduction: Custom leather stamps, dies, and brands for leather stamping and embossing needs. Made from aluminum, steel, or brass. Aluminum for lower cost, brass for durability and rust resistance. High detail engraving, hand-finished, and made in the USA. Heavy-duty removable steel handle for hand stamps; press leather stamps include custom engraved stamp face. Custom branding irons available for thinner or …

3. Infinity Stamps – Custom Leather Roll Dies

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Custom Leather Roll Dies from Infinity Stamps, Inc. Made in the USA. Family owned for over 25 years. Contact available via phone (818-576-1188) or contact form. Suitable for various stamping applications including leather. Part of a larger range of stamping products including metal, wood, and jewelry stamps.

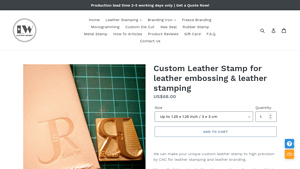

4. LW Leathers – Custom Leather Stamp

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: Custom Leather Stamp for leather embossing & leather stamping\nRegular price: US$68.00\nSize options: Up to 1.25 x 1.25 inch (3 x 3 cm), Up to 1.5 x 1.5 inch (4 x 4 cm), Up to 2 x 2 inch (5 x 5 cm), Up to 3 x 3 inch (7.5 x 7.5 cm), Up to 4 x 4 inch (10 x 10 cm)\nProduction lead time: 2-5 working days (rush orders available)\nMaterial: Solid Brass\nStamp thickness: 8mm\nEngraving depth: 3mm\nApplic…

5. Weaver Leather Supply – Clicker Dies & Sets

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Clicker Dies & Sets from Weaver Leather Supply include high-impact polycarbonate leather cutting dies designed for efficiency and precision in leather crafting. Key features include:

– Variety of sizes available (1″, 2″, 2-5/8″, 3-5/8″)

– Custom Polycarb Leather Cutting Dies available upon request

– Ideal for mass production, saving time and ensuring consistency

– Popular in-stock options incl…

Strategic Sourcing Conclusion and Outlook for custom leather stamping dies

In the competitive landscape of custom leather stamping dies, strategic sourcing emerges as a critical driver of success for international B2B buyers. By selecting suppliers who offer high-quality materials such as brass and steel, businesses can ensure durability and precision in their stamping operations. Understanding the nuances of customization, including design specifications and the types of leather being used, allows buyers to tailor their orders to meet specific project needs effectively.

Furthermore, leveraging local manufacturers can provide advantages such as reduced shipping times and costs, which is especially beneficial for companies in regions like Africa, South America, the Middle East, and Europe. As buyers continue to prioritize sustainability and ethical sourcing, partnering with manufacturers committed to eco-friendly practices can enhance brand reputation and customer loyalty.

Looking ahead, the demand for innovative and customizable stamping solutions is set to grow. International B2B buyers are encouraged to engage proactively with suppliers to explore new technologies and designs that can elevate their product offerings. By doing so, businesses can not only meet current market demands but also position themselves as leaders in the evolving leather industry.

Illustrative image related to custom leather stamping dies

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather stamping dies