Introduction: Navigating the Global Market for custom leather labels

In today’s competitive landscape, sourcing custom leather labels presents a unique challenge for international B2B buyers. These labels have evolved from mere product identifiers to essential branding tools that convey quality and authenticity. As businesses across Africa, South America, the Middle East, and Europe seek to differentiate their products, understanding the nuances of custom leather labels becomes imperative. This comprehensive guide delves into the various types of leather labels available—ranging from genuine leather to innovative synthetic options—and their diverse applications in fashion, accessories, and beyond.

Navigating the global market also requires astute supplier vetting to ensure quality and reliability. This guide provides actionable insights on evaluating potential suppliers, understanding cost structures, and recognizing the importance of sustainable sourcing practices. With a focus on empowering B2B buyers from regions like Brazil and Nigeria, this resource aims to enhance informed purchasing decisions, ensuring that businesses can effectively leverage custom leather labels to elevate their brand identity and foster lasting consumer connections. By equipping buyers with the knowledge to make strategic choices, this guide serves as a vital tool in the quest for superior branding solutions.

Table Of Contents

- Top 5 Custom Leather Labels Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather labels

- Understanding custom leather labels Types and Variations

- Key Industrial Applications of custom leather labels

- 3 Common User Pain Points for ‘custom leather labels’ & Their Solutions

- Strategic Material Selection Guide for custom leather labels

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather labels

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather labels’

- Comprehensive Cost and Pricing Analysis for custom leather labels Sourcing

- Alternatives Analysis: Comparing custom leather labels With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather labels

- Navigating Market Dynamics and Sourcing Trends in the custom leather labels Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather labels

- Strategic Sourcing Conclusion and Outlook for custom leather labels

- Important Disclaimer & Terms of Use

Understanding custom leather labels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Leather | Made from cowhide or goatskin; natural variations in color and texture | High-end fashion, luxury goods, artisanal products | Pros: Premium look, durability; Cons: Not washable, requires care |

| Faux Leather | Made from PU (polyurethane); washable up to 30°C | Apparel, bags, accessories, eco-friendly products | Pros: Vegan-friendly, easy to clean; Cons: Less luxurious feel, may wear over time |

| WunderPap | Washable paper with a leather-like texture; eco-friendly | Workwear, outdoor clothing, frequently washed items | Pros: Water-repellent, durable; Cons: Lacks the premium feel of real leather |

| Embossed Leather | Custom designs can be embossed or debossed into the leather | Branding for apparel, patches for outerwear | Pros: Unique branding opportunity; Cons: Limited to specific design methods |

| Printed Leather | Features printed designs or logos on leather; less common | Promotional items, merchandise | Pros: High visibility for branding; Cons: Print may fade or wear off over time |

What are the Characteristics and Suitability of Genuine Leather Labels?

Genuine leather labels are crafted from natural cowhide or goatskin, which lends them a unique aesthetic with variations in color and texture. These labels are ideal for high-end fashion brands, luxury goods, and artisanal products where a premium look is essential. When purchasing, buyers should consider the care requirements, as genuine leather is not washable and may require special maintenance to preserve its appearance.

How Do Faux Leather Labels Compare in Terms of Usability?

Faux leather labels, made from polyurethane, offer a washable alternative that is suitable for various applications, including apparel and accessories. They are particularly appealing to brands focused on sustainability and animal welfare, as they are cruelty-free. Buyers should note that while these labels are easier to maintain, they may not provide the same luxurious look as genuine leather and can show signs of wear over time.

What Makes WunderPap Labels a Sustainable Choice?

WunderPap labels are an innovative solution made from washable paper designed to mimic leather’s look and feel. They are ideal for heavy-duty applications such as workwear and outdoor clothing, where durability and frequent washing are necessary. B2B buyers looking for eco-friendly options should consider WunderPap, as it is both water-repellent and tear-resistant, though it lacks the premium touch associated with genuine leather.

How Can Embossed Leather Labels Enhance Brand Identity?

Embossed leather labels offer a unique branding opportunity, allowing businesses to create distinct designs through raised or recessed logos. These labels are often used in patches for outerwear and can significantly enhance a brand’s identity. Buyers should keep in mind that while these labels provide a strong visual impact, the design process may be limited to specific embossing or debossing techniques.

Are Printed Leather Labels Effective for Promotional Use?

Printed leather labels, while less common, provide a way to showcase logos and designs prominently on leather. They are often used for promotional items and merchandise, delivering high visibility for branding efforts. However, buyers should be aware that the print quality may deteriorate over time, potentially affecting the label’s longevity and aesthetic appeal.

Key Industrial Applications of custom leather labels

| Industry/Sector | Specific Application of custom leather labels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Branding on clothing and accessories | Enhances brand identity and product differentiation | Quality of leather, customization options, and durability |

| Footwear | Labels for shoes and boots | Increases perceived value and consumer trust | Material type (genuine vs. faux), attachment methods, design |

| Outdoor Equipment | Tags for backpacks and camping gear | Improves product authenticity and brand recognition | Weather resistance, durability, and eco-friendly materials |

| Home Decor | Labels for furniture and handmade items | Adds a premium touch and personalization | Customization capabilities and material sourcing |

| Automotive | Branding on car interiors and accessories | Enhances luxury perception and brand loyalty | Compatibility with various materials, customization, and size |

How Are Custom Leather Labels Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, custom leather labels serve as a key branding tool. They are often attached to garments, bags, and accessories, providing a tactile and visual representation of quality. By using high-quality leather, brands can convey luxury and craftsmanship, which are essential in competitive markets. International buyers, particularly from regions like Africa and South America, should consider options for customization, such as embossed logos and varied dimensions, to cater to local tastes and preferences.

What Role Do Custom Leather Labels Play in Footwear?

Custom leather labels are commonly used in footwear to enhance branding and provide product information. Labels can be sewn into shoes or attached with rivets, creating a distinctive look that resonates with consumers. In markets like Nigeria and Brazil, where brand loyalty is vital, these labels can significantly influence purchasing decisions. Buyers must ensure that the materials used are durable and suitable for the specific footwear application to withstand wear and tear.

How Are Custom Leather Labels Beneficial for Outdoor Equipment?

For outdoor equipment, custom leather labels are often utilized on backpacks, tents, and camping gear. These labels not only serve branding purposes but also add to the product’s durability and authenticity. Given the rugged nature of outdoor activities, sourcing labels that are weather-resistant and made from durable materials is crucial. International buyers should prioritize suppliers who can offer eco-friendly options, as sustainability is increasingly important in global markets.

In What Ways Do Custom Leather Labels Enhance Home Decor Products?

In the home decor industry, custom leather labels are used on furniture and handmade items to add a personal touch. These labels can elevate the perceived value of products, making them more appealing to consumers who appreciate craftsmanship. Buyers from Europe and the Middle East may look for unique customization options, such as intricate designs or specific color schemes, to align with regional aesthetic preferences. Ensuring the labels are made from high-quality materials will also help in maintaining the integrity of the products.

How Do Custom Leather Labels Impact the Automotive Sector?

In the automotive industry, custom leather labels are often found in car interiors and accessories, providing a sophisticated branding element. These labels can enhance the luxury appeal of vehicles and foster brand loyalty among consumers. Buyers should consider the compatibility of the labels with various materials used in automotive interiors and focus on sourcing options that allow for high-quality customization. This attention to detail can significantly affect the overall consumer experience and brand perception.

3 Common User Pain Points for ‘custom leather labels’ & Their Solutions

Scenario 1: Quality Assurance Concerns with Custom Leather Labels

The Problem: B2B buyers often face significant challenges regarding the quality and durability of custom leather labels. With the increasing demand for premium products, businesses need labels that not only look good but also withstand wear and tear. Buyers may worry about the labels peeling, fading, or losing their shape over time, especially when used in high-stress environments like outdoor apparel or fashion accessories. A lack of clarity regarding the materials and manufacturing processes can lead to costly returns and damage to brand reputation.

The Solution: To mitigate these quality concerns, buyers should prioritize sourcing from reputable manufacturers who provide samples of their products. Requesting samples allows businesses to evaluate the texture, durability, and overall quality before committing to a large order. Additionally, it’s essential to ask for details about the materials used, such as whether they are genuine leather or faux leather, and the manufacturing techniques applied, like laser engraving versus printing. Establishing clear quality assurance metrics with the supplier, including specifications for fade resistance and wear tests, can help ensure that the final product meets expectations. Implementing a robust quality check process upon receiving the labels can further safeguard against defects, ensuring that only high-quality labels are used in production.

Scenario 2: Complexity in Design Customization

The Problem: Customizing leather labels can often be a complex and daunting process, particularly for B2B buyers who may not have a design background. There can be confusion about the options available, such as fonts, colors, and the type of engraving (debossing vs. embossing). This complexity can lead to miscommunication with suppliers, resulting in labels that do not align with the brand’s vision, ultimately wasting time and resources.

The Solution: To streamline the design process, buyers should utilize design tools provided by manufacturers that allow for easy customization of labels. Many suppliers offer online design configurators where businesses can visualize their labels in real-time. This feature can significantly reduce the back-and-forth communication with suppliers. Additionally, collaborating with a graphic designer who understands the brand’s aesthetic can help create a cohesive label design. It’s also beneficial to clearly communicate the brand story and values to the supplier, which can inform the design choices and ensure that the final product aligns with the brand identity. Providing detailed design briefs and requesting mock-ups can further enhance clarity and reduce the likelihood of errors.

Scenario 3: Sourcing Challenges in Different Markets

The Problem: International B2B buyers often encounter difficulties when sourcing custom leather labels due to varying regulations, material availability, and cultural preferences across different regions. For instance, a buyer in Nigeria might struggle to find suppliers that understand local market needs or comply with regional import regulations, which can delay production timelines and increase costs.

Illustrative image related to custom leather labels

The Solution: To effectively navigate these sourcing challenges, buyers should conduct thorough market research to identify reliable suppliers who have experience in their specific region. Establishing partnerships with local distributors can help facilitate smoother transactions and ensure compliance with local regulations. Engaging with trade shows and industry events can also provide valuable networking opportunities, allowing buyers to connect with potential suppliers and gain insights into regional trends and preferences. Furthermore, leveraging online platforms that specialize in B2B transactions can help buyers find suppliers who offer customizable options that cater to diverse markets. Building a strong relationship with suppliers can also foster open communication, making it easier to address any issues related to sourcing, compliance, or production timelines.

Strategic Material Selection Guide for custom leather labels

When selecting materials for custom leather labels, it’s essential to consider the specific properties, advantages, and limitations of each option. This analysis will focus on three common materials: genuine leather, faux leather (PU), and WunderPap. Each material presents unique characteristics that can influence the final product’s performance and suitability for various applications.

What Are the Key Properties of Genuine Leather for Custom Labels?

Genuine leather, typically sourced from cowhide or goatskin, is known for its durability and premium aesthetic. It can withstand a range of temperatures, but care must be taken as it is not washable. The material is resistant to wear and tear, making it suitable for high-end products like apparel, accessories, and handcrafted items. However, its natural variations in color and thickness can affect production consistency.

Pros: Genuine leather offers a luxurious look and feel, providing a unique touch to products. Its long-lasting durability makes it ideal for high-quality items.

Illustrative image related to custom leather labels

Cons: The material is not vegan-friendly, requires special care, and is not suitable for washing, which may limit its application in certain industries.

How Does Faux Leather (PU) Compare for Custom Labels?

Faux leather, made from polyurethane, is a synthetic alternative that mimics the appearance of genuine leather. It is machine washable up to 30°C, making it a practical choice for apparel and accessories that require regular cleaning. The flexibility and versatility of PU leather allow for various applications, from clothing labels to bags.

Pros: This material is cruelty-free and easier to maintain compared to genuine leather. Its washable nature and lower cost make it appealing for mass production.

Cons: Faux leather may not offer the same luxurious feel and can show signs of wear over time, such as peeling or cracking, which might affect brand perception.

What Are the Advantages of Using WunderPap for Custom Labels?

WunderPap is a washable paper material that provides a leather-like appearance while being eco-friendly. It is designed for durability and can withstand washing at higher temperatures, making it suitable for heavy-duty items like workwear and outdoor clothing. Its unique texture develops a crinkled look after washing, adding character to the product.

Pros: WunderPap is water-repellent, tear-resistant, and environmentally friendly, making it ideal for brands focused on sustainability. Its durability in washing conditions makes it a practical choice for frequently laundered items.

Cons: While it offers a unique aesthetic, it lacks the luxurious feel of genuine leather, which may be a drawback for high-end applications.

What Should International B2B Buyers Consider When Selecting Materials?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, compliance with local standards is crucial. Understanding regulations such as ASTM, DIN, or JIS can help ensure that the products meet safety and quality requirements. Additionally, preferences for vegan or eco-friendly materials may influence purchasing decisions, particularly in markets that prioritize sustainability. Buyers should also consider the logistical aspects of sourcing materials, including shipping costs and lead times, which can vary significantly by region.

| Material | Typical Use Case for custom leather labels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end apparel, accessories, handcrafted items | Luxurious look and long-lasting durability | Not washable, requires care, not vegan-friendly | High |

| Faux Leather (PU) | Apparel, bags, accessories | Cruelty-free and machine washable | Less luxurious feel, may wear over time | Medium |

| WunderPap | Workwear, outdoor clothing, frequently washed items | Eco-friendly, durable, and washable | Lacks luxurious feel of real leather | Medium |

In summary, selecting the right material for custom leather labels involves evaluating the specific needs of the product, the target market, and compliance with local standards. By understanding the properties and implications of each material, B2B buyers can make informed decisions that align with their brand values and customer expectations.

Illustrative image related to custom leather labels

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather labels

What Are the Key Stages in the Manufacturing Process of Custom Leather Labels?

The manufacturing process of custom leather labels involves several critical stages that ensure the final product meets quality expectations and customer specifications. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used for Leather Labels?

The first stage in the manufacturing process is material preparation. Custom leather labels can be made from a variety of materials, including genuine leather, faux leather (PU), and alternative materials like WunderPap. Each material has its unique properties that influence the final product’s quality and suitability for different applications.

- Genuine Leather: Typically sourced from cowhide or goatskin, genuine leather is valued for its premium look and durability. It undergoes tanning processes to enhance its longevity and resistance to wear.

- Faux Leather (PU): This synthetic alternative offers a more cost-effective and cruelty-free option. PU leather is easier to clean and maintain, making it suitable for a wider range of products.

- WunderPap: A washable paper that mimics leather, WunderPap is eco-friendly and ideal for items requiring frequent washing.

Once the material is selected, it is cut into the desired shapes and sizes, often using laser cutting for precision.

How Are Custom Leather Labels Formed and Assembled?

The next stage is forming and assembling the labels. This involves several key techniques to ensure that the labels are not only aesthetically pleasing but also functional.

- Laser Engraving: This technique is commonly used to etch logos, text, and designs onto the leather. Laser engraving provides high precision and detail, resulting in a professional finish.

- Embossing and Debossing: These methods create raised or recessed designs on the leather surface, adding texture and depth to the labels. This is particularly effective for branding purposes, as it enhances visibility and recognition.

- Sewing and Attachment: Depending on the design, labels can be sewn onto products or attached using rivets, eyelets, or snaps. Pre-cut holes can be included in the design to facilitate easier attachment.

What Quality Control Measures Should Be Followed During Manufacturing?

Quality control (QC) is a crucial aspect of the manufacturing process, ensuring that each custom leather label meets established standards. Various international and industry-specific standards guide these QC measures.

Which International Standards Apply to Custom Leather Label Manufacturing?

The ISO 9001 standard for quality management systems is widely recognized and applicable across various industries, including leather goods. Compliance with ISO 9001 indicates that the manufacturer has implemented a quality management system that enhances customer satisfaction and meets regulatory requirements.

Additionally, specific certifications like CE marking (for products sold in the European Economic Area) and API standards (for industries involving petroleum and natural gas) may be relevant depending on the end-use of the leather labels.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are essential in identifying defects and ensuring adherence to specifications. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Any discrepancies at this stage can prevent defective products from proceeding through the manufacturing process.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC checks are performed at various points to monitor quality and address any issues in real-time. This can include checking the accuracy of laser engraving or the integrity of the sewing process.

-

Final Quality Control (FQC): The final inspection occurs once the labels are completed. FQC verifies that the labels match the order specifications, including size, color, and design. This step often includes functional tests to ensure durability and usability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Here are actionable steps to ensure compliance and quality assurance:

Illustrative image related to custom leather labels

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control systems, and adherence to international standards. It provides insight into the operational capabilities and commitment to quality.

-

Quality Reports: Request detailed quality reports that outline the results of IQC, IPQC, and FQC. These reports should include metrics on defect rates, compliance with standards, and corrective actions taken for any issues identified.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These services can conduct independent checks on the manufacturing process and final products, ensuring they meet quality standards before shipment.

What Are the Challenges and Considerations for International Buyers in the QC Process?

International buyers face unique challenges when it comes to quality assurance for custom leather labels. Language barriers, differing regulations, and varying quality expectations can complicate the procurement process.

To navigate these challenges, buyers should:

-

Understand Local Regulations: Familiarize themselves with local regulations regarding leather goods in their target market. This ensures that the products comply with necessary legal requirements, such as material safety standards.

-

Establish Clear Communication: Maintain open lines of communication with suppliers. Clearly outline expectations regarding quality standards and delivery timelines to avoid misunderstandings.

-

Leverage Technology: Utilize digital tools for tracking orders, quality reports, and communications. This enhances transparency and allows for better monitoring of the supply chain.

By understanding the manufacturing processes and quality assurance measures for custom leather labels, B2B buyers can make informed decisions, ensuring they partner with suppliers who meet their quality expectations and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather labels’

In the competitive landscape of B2B procurement, sourcing custom leather labels requires careful consideration and strategic planning. This guide provides a step-by-step checklist to ensure that you make informed decisions and secure high-quality products that align with your brand’s values and requirements.

Step 1: Define Your Technical Specifications

Before initiating your sourcing process, clearly outline your technical specifications. This includes the size, shape, material (genuine leather vs. faux leather), and design elements such as logos or text. Establishing these parameters early on helps you communicate effectively with potential suppliers and ensures that you receive samples that meet your criteria.

- Material Type: Decide between genuine leather, faux leather, or alternative materials like WunderPap based on your product’s needs and target audience.

- Design Requirements: Consider the intricacy of your design, as this may affect the manufacturing process and cost.

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is crucial for ensuring product quality and timely delivery. Conduct thorough research to identify potential manufacturers that specialize in custom leather labels.

- Supplier Vetting: Look for suppliers with a proven track record in your industry. Request their company profiles and check for certifications related to quality management.

- Customer Reviews: Explore testimonials and case studies to gauge customer satisfaction and reliability.

Step 3: Request Samples for Evaluation

Once you have a shortlist of suppliers, request samples of their custom leather labels. This step allows you to assess the quality of materials, craftsmanship, and adherence to your specifications.

- Quality Check: Examine the samples for durability, finish, and how well the design translates onto the leather.

- Fit for Purpose: Ensure that the labels are appropriate for the intended use, whether for apparel, accessories, or promotional items.

Step 4: Evaluate Pricing and Minimum Order Quantities

Pricing is a significant factor in your sourcing decision. Compare quotes from different suppliers, but don’t solely focus on the lowest price.

- Total Cost of Ownership: Consider additional costs such as shipping, taxes, and potential import duties, especially if sourcing internationally.

- Minimum Order Quantities (MOQs): Understand the MOQs and assess whether they align with your production needs and budget.

Step 5: Discuss Production Timelines

Establish clear timelines for production and delivery with your selected supplier. Timeliness is essential to meet your market demands and maintain customer satisfaction.

Illustrative image related to custom leather labels

- Lead Times: Ask about the average production time for your order and any factors that could affect these timelines.

- Flexibility: Discuss potential for expedited production if your needs change unexpectedly.

Step 6: Confirm Quality Control Processes

Quality control is paramount when sourcing custom leather labels. Inquire about the supplier’s quality assurance practices to ensure consistency and reliability.

- Inspection Procedures: Understand how the supplier conducts inspections and what standards they adhere to during the production process.

- Return Policies: Familiarize yourself with their policies regarding defective products or unsatisfactory orders.

Step 7: Finalize Terms and Place Your Order

Once you are satisfied with your supplier’s capabilities and have agreed upon terms, finalize the contract. Ensure that all aspects, including pricing, timelines, and quality standards, are documented.

- Clear Communication: Maintain open lines of communication throughout the process to address any concerns promptly.

- Payment Terms: Discuss payment options and terms to avoid misunderstandings later on.

By following this structured approach, B2B buyers can effectively navigate the complexities of sourcing custom leather labels, ensuring a successful procurement process that meets their business needs.

Comprehensive Cost and Pricing Analysis for custom leather labels Sourcing

What Are the Key Cost Components in Custom Leather Labels Sourcing?

When sourcing custom leather labels, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The choice between genuine leather, faux leather, or alternative materials like WunderPap significantly impacts costs. Genuine leather generally commands a higher price due to its durability and premium feel, while faux options may reduce costs but can compromise on luxury appeal.

-

Labor: Labor costs vary based on the complexity of the design and the level of craftsmanship required. Customizations such as embossing or debossing logos can also increase labor expenses.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities and equipment maintenance. Efficient production processes can help minimize these costs.

-

Tooling: Custom tooling for unique label shapes or designs can add to initial costs but may lead to savings in the long run for high-volume orders.

-

Quality Control: Investing in quality control is essential to ensure that the labels meet the required specifications and standards. This can involve additional testing and inspection processes, which will affect the overall cost.

-

Logistics: Shipping costs, especially for international buyers, can vary widely based on distance, shipping method, and customs duties. Understanding Incoterms is vital to navigate these costs effectively.

-

Supplier Margin: Different suppliers will have varying profit margins based on their positioning in the market and the level of service they provide. It’s essential to assess the value offered relative to the price.

How Do Price Influencers Affect Custom Leather Labels?

Several factors influence the pricing of custom leather labels, and buyers should consider these when negotiating and sourcing.

Illustrative image related to custom leather labels

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract lower per-unit costs due to economies of scale. Establishing a strong relationship with suppliers can lead to better terms for MOQs.

-

Specifications and Customization: The more intricate the design, the higher the cost. Buyers should balance their branding needs with budget constraints to find an optimal solution.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., eco-friendly or cruelty-free) can increase costs but may also enhance brand reputation and customer trust.

-

Supplier Factors: The supplier’s location, reputation, and reliability can influence pricing. Established suppliers may charge more due to their quality assurance and service levels, but they can also reduce risks associated with sourcing.

-

Incoterms: Understanding the terms of shipping can significantly affect total costs. Different Incoterms dictate responsibility for costs and risks during transport, impacting the final price.

What Are Essential Buyer Tips for Cost-Efficiency in Custom Leather Labels?

To maximize value and minimize costs, B2B buyers should consider the following strategies:

-

Negotiation Tactics: Engage in open discussions with suppliers about pricing and terms. Highlighting long-term partnership potential can lead to favorable pricing arrangements.

-

Focus on Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, maintenance, and potential replacement costs to evaluate the true value of the labels.

-

Understand Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of additional costs like import duties, taxes, and currency fluctuations that can affect overall pricing.

-

Request Samples: Before committing to large orders, request samples to assess quality and ensure that the product meets your brand’s standards. This can prevent costly mistakes down the line.

Conclusion

Sourcing custom leather labels involves a multifaceted cost structure influenced by various factors. By understanding these components and leveraging negotiation strategies, international B2B buyers can make informed decisions that optimize their investment while enhancing their brand’s identity. Keep in mind that prices can vary widely based on the specifics of your order, so always seek indicative prices and detailed quotes from multiple suppliers.

Alternatives Analysis: Comparing custom leather labels With Other Solutions

When considering branding and product identification, custom leather labels stand out for their aesthetic appeal and durability. However, various alternatives may suit different business needs, especially for international B2B buyers. This section explores the strengths and weaknesses of custom leather labels compared to woven labels and synthetic patches, helping businesses make informed decisions.

| Comparison Aspect | Custom Leather Labels | Woven Labels | Synthetic Patches |

|---|---|---|---|

| Performance | Premium look; laser-engraved for detail | High-quality finish; durable and flexible | Versatile designs; good for branding |

| Cost | Generally higher due to material quality | Moderate cost; bulk options available | Usually lower cost; budget-friendly |

| Ease of Implementation | Requires sewing or rivets for attachment | Easy to attach via sewing or ironing | Simple application with adhesive backing |

| Maintenance | Not washable; care required | Machine washable; low maintenance | Easy to clean; durable with minimal upkeep |

| Best Use Case | High-end products; handmade crafts | Mass-produced clothing; branding | Casual wear; promotional items |

What Are the Advantages and Disadvantages of Woven Labels as an Alternative?

Woven labels provide a cost-effective alternative to custom leather labels, especially for businesses that prioritize mass production. These labels are made from threads woven into a fabric, giving them a soft feel and allowing for intricate designs. They are machine washable, making them suitable for clothing that requires regular cleaning. However, woven labels may lack the premium aesthetic of leather and can fray over time if not properly designed.

Illustrative image related to custom leather labels

How Do Synthetic Patches Compare in Terms of Customization and Use?

Synthetic patches are another viable alternative, crafted from materials like PVC or polyester. They offer excellent customization options, including vibrant colors and complex designs. The adhesive backing makes application straightforward, reducing labor costs during production. While synthetic patches are often more affordable than leather labels, they may not deliver the same high-end appearance and can wear out faster, particularly in high-friction areas.

Conclusion: How to Choose the Right Solution for Your Business Needs?

Selecting the appropriate labeling solution depends on your specific business requirements and target market. Custom leather labels are ideal for premium products where brand perception is critical, while woven labels are excellent for larger production runs with a need for durability and cost-efficiency. Synthetic patches serve as a budget-friendly option for promotional items and casual wear. By assessing the performance, cost, and maintenance requirements of each alternative, B2B buyers can make informed decisions that align with their brand identity and operational goals.

Essential Technical Properties and Trade Terminology for custom leather labels

What Are the Key Technical Properties of Custom Leather Labels?

When sourcing custom leather labels, understanding their essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

The choice between genuine leather, faux leather (PU), or alternatives like WunderPap significantly affects the label’s appearance, durability, and cost. Genuine leather offers a premium look and feel, making it ideal for high-end products, while faux leather is more cost-effective and machine washable. Selecting the right material ensures that the label aligns with the product’s overall quality and brand image.

2. Thickness and Durability

Leather labels come in various thicknesses, typically measured in millimeters. Thicker labels may offer increased durability and resistance to wear and tear, making them suitable for heavy-duty applications. For B2B buyers, understanding the thickness helps in assessing the label’s longevity and appropriateness for specific products, such as apparel or accessories.

3. Tolerance and Precision

Tolerance refers to the allowable deviation in the dimensions and shapes of the labels during production. High precision in cutting and engraving ensures that the labels fit perfectly and maintain a professional appearance. For brands, this is vital as it affects the overall aesthetic and functionality of the label when attached to products.

4. Washability

The ability to wash leather labels varies depending on the material. Genuine leather is generally not washable, while faux leather and WunderPap labels can withstand low-temperature washing. This property is essential for businesses that produce items requiring regular cleaning, as it impacts customer satisfaction and brand reputation.

5. Attachment Options

Custom leather labels can be designed with pre-cut holes for easy attachment using rivets, snaps, or sewing. Understanding the available attachment methods is important for manufacturers and brands to ensure that the labels can be securely affixed to their products, enhancing their overall quality and presentation.

What Are Common Trade Terms in the Custom Leather Label Industry?

Navigating the custom leather label market requires familiarity with specific trade terminology. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of custom leather labels, buyers may work with an OEM to create labels that will be integrated into their branded products. Understanding OEM relationships can help businesses streamline their supply chain and ensure quality.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to produce or sell. This term is significant for B2B buyers as it affects inventory management and production planning. Knowing the MOQ helps businesses assess whether they can meet their demand without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products or services. For custom leather labels, submitting an RFQ allows businesses to compare offers from multiple suppliers, ensuring they obtain the best value and quality.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms is crucial for B2B transactions involving custom leather labels, as they clarify shipping costs, risks, and delivery timelines, aiding in smooth international trade operations.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the final product. This is a critical factor for businesses that rely on timely delivery for product launches or seasonal demands. Understanding lead times helps companies plan their production schedules and inventory levels effectively.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom leather labels, ultimately enhancing their product offerings and brand image in competitive markets.

Navigating Market Dynamics and Sourcing Trends in the custom leather labels Sector

What Are the Current Market Dynamics and Key Trends in Custom Leather Labels?

The custom leather labels market is experiencing significant growth driven by increasing consumer demand for quality and authenticity in products. Global trends indicate a shift towards personalization and branding, with businesses seeking unique identifiers that enhance their product appeal. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, the ability to customize leather labels to reflect brand identity is paramount. Buyers are leveraging advancements in digital design technology, allowing for precise customization options that cater to various aesthetic preferences.

Emerging technologies such as 3D printing and laser engraving are revolutionizing the production of custom leather labels, offering businesses the ability to produce intricate designs with high efficiency. Moreover, the growing trend towards e-commerce has accelerated the demand for small-batch productions, enabling brands to maintain exclusivity while catering to niche markets. B2B buyers are increasingly looking for suppliers that can offer flexibility in order sizes, rapid turnaround times, and a variety of materials, including genuine leather and eco-friendly alternatives.

How Is Sustainability and Ethical Sourcing Impacting the Custom Leather Labels Sector?

Sustainability and ethical sourcing have become critical considerations for businesses in the custom leather labels sector. With growing awareness around environmental issues, buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. The environmental impact of leather production, particularly in terms of water usage and chemical pollution, has led to a rise in demand for eco-friendly materials and processes.

Illustrative image related to custom leather labels

Many manufacturers are now offering alternatives such as PU leather and washable paper, which provide a sustainable option without compromising on the aesthetic appeal of traditional leather. B2B buyers are encouraged to seek out suppliers who possess ‘green’ certifications, indicating adherence to environmental standards and ethical labor practices. Certifications like the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) can guide buyers in selecting suppliers that align with their sustainability goals.

Establishing ethical supply chains not only enhances brand reputation but also resonates with consumers who are increasingly making purchasing decisions based on a brand’s environmental and social responsibility.

How Have Custom Leather Labels Evolved Over Time?

The evolution of custom leather labels reflects broader trends in consumer goods and branding. Initially serving a purely functional purpose, leather labels have transformed into key branding tools that convey a product’s quality and craftsmanship. Historically, leather was reserved for high-end products; however, advancements in production techniques have made it accessible for various market segments.

Today, custom leather labels can be found in a wide array of products, from luxury fashion items to everyday apparel. This shift has been fueled by the growing consumer desire for authenticity and a personal touch in their purchases. Furthermore, the introduction of digital design technologies has empowered brands to experiment with innovative designs, fostering a culture of creativity and differentiation in the market. As a result, custom leather labels are not only identifiers but also a canvas for expressing brand values and narratives.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather labels

-

How do I choose the right material for custom leather labels?

Selecting the right material for your custom leather labels depends on the intended use and desired aesthetic. Genuine leather provides a premium look and durability, ideal for high-end products. Faux leather (PU) is more affordable and washable, suitable for everyday items. If your products require frequent washing, consider WunderPap, a washable paper that mimics leather. Assess your product’s requirements, your target market’s preferences, and your budget to make an informed choice. -

What customization options are available for leather labels?

Customization options for leather labels include size, shape, color, and design. Most suppliers offer laser engraving for logos, text, and symbols, providing high precision and clarity. You can also choose from various attachment methods such as rivets, snaps, or sewing holes. Some companies allow you to upload your artwork or use design templates, ensuring your labels align with your brand identity. Always confirm the customization capabilities with your supplier before placing an order. -

What is the minimum order quantity (MOQ) for custom leather labels?

The MOQ for custom leather labels varies by supplier, often ranging from 5 to 50 pieces. Lower MOQs may be available for specific materials or during promotional periods. When sourcing, inquire about bulk order discounts, as larger quantities typically result in cost savings. Consider your inventory turnover and production needs to determine the optimal order size that balances cost-effectiveness with your demand. -

How can I ensure quality when sourcing custom leather labels internationally?

To ensure quality when sourcing custom leather labels, begin by vetting suppliers thoroughly. Request samples to evaluate material quality and craftsmanship. Look for certifications or compliance with international standards. Additionally, reading customer reviews and testimonials can provide insights into reliability and product quality. Establish clear communication regarding your quality expectations and consider implementing a quality assurance process to monitor production. -

What payment terms should I expect when sourcing leather labels?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (usually 30-50%) with the balance due upon completion or before shipment. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established buyers. Always clarify payment methods accepted, such as credit cards, wire transfers, or letters of credit, and review any transaction fees that may apply. -

What logistics considerations should I keep in mind when importing leather labels?

When importing leather labels, consider shipping costs, delivery times, and customs regulations. Choose a shipping method that balances speed and cost, such as air freight for urgent orders or sea freight for larger shipments. Familiarize yourself with import duties and taxes applicable in your country to avoid unexpected costs. Collaborate with a reliable logistics provider experienced in handling international shipments to streamline the process. -

How can I track the status of my order for custom leather labels?

Most reputable suppliers provide order tracking capabilities. After placing an order, you should receive an order confirmation along with a tracking number once the order is shipped. If tracking information is not provided, reach out to your supplier’s customer service for updates. Regular communication is crucial, especially for international orders, to ensure timely delivery and address any potential issues. -

What are common uses for custom leather labels in various industries?

Custom leather labels are versatile and used across multiple industries, including fashion, furniture, and promotional products. In the fashion industry, they serve as branding elements on apparel, bags, and accessories. Furniture manufacturers use them for branding and quality assurance. Additionally, custom leather labels can enhance promotional items, providing a tactile and luxurious feel that sets products apart in competitive markets. Understanding your target market’s preferences can help you leverage leather labels effectively.

Top 5 Custom Leather Labels Manufacturers & Suppliers List

1. Wunderlabel – Leather Labels

Domain: wunderlabel.com

Registered: 2015 (10 years)

Introduction: Leather Labels: 1. Genuine Leather: – Price: From 5 pieces for $12.95 – Material: 100% genuine leather – Features: Different dimensions & shapes, not washable, laser-engraved with custom text/symbol/logo, optional holes for attachment. 2. Faux Leather: – Price: From 5 pieces for $12.95 – Material: 100% PU (Polyurethane) – Features: Different sizes & shapes, washable (cold), laser-engraved with cus…

2. New York Custom Labels – Custom Leather Patches

Domain: newyorkcustomlabels.com

Registered: 2009 (16 years)

Introduction: Custom leather patches are a popular alternative for traditional embroidered patches that can be sewn onto baseball caps, beanies, jackets, and other types of outerwear. Smaller size leather patches are used as clothing labels on shirts and shoes. Custom leather patch designs can be embossed (raised) or debossed (pressed) into genuine leather color. Options include adding a print color to the pres…

3. The Nifty Knitter Shop – Custom Leather Tags

Domain: theniftyknittershop.com

Registered: 2016 (9 years)

Introduction: Custom Leather Tags from $12.95; available in several colors and styles including Handmade Knitted Heart, Handmade Seal, Handmade Seal with Washing Instructions, and Button options; color options include Medium and Dark.

4. Best Labels – Custom Leather Labels

Domain: bestlabels.eu

Introduction: Genuine leather labels | Custom Leather Labels for jeans, pants, jackets, sweatshirts, sweaters, hats, bags, etc. Premium quality with exceptional finishes, colors, and textures. Customization available via online design tool. Manufacturing process includes digital engraving, laser cutting, hot/cold embossing, and quality control. Examples of models include:

– Model EP-M69: 15x40mm, 42 EUR / 50 p…

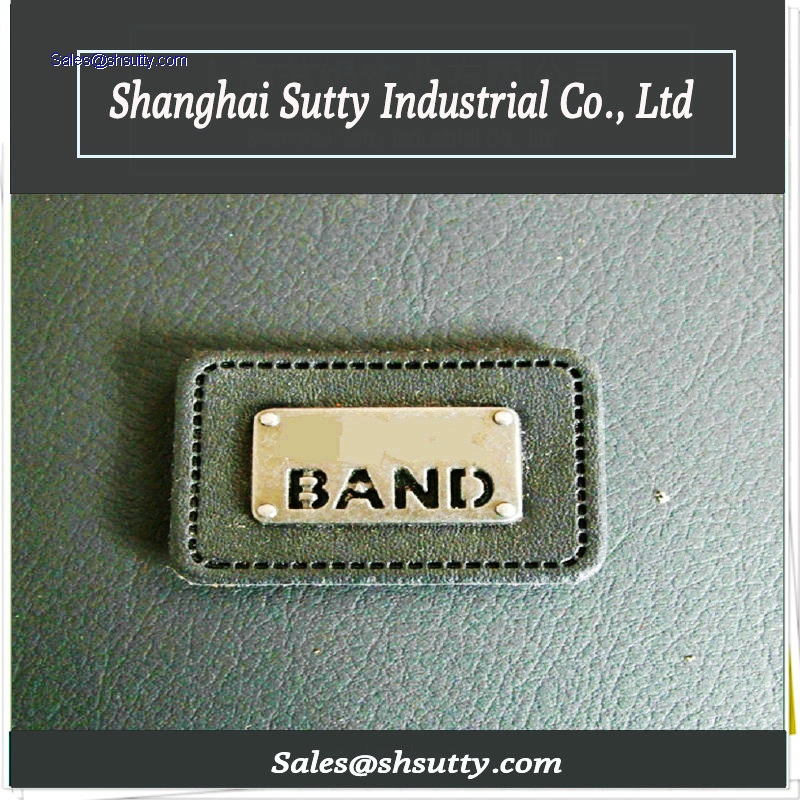

5. Best Labels – Custom Faux Leather Labels

Domain: bestlabels.us.com

Introduction: Faux leather labels, also known as synthetic leather, made of polyurethane (PU) material. Customizable with logos or brand names. Available in various shapes, sizes, and colors. Suitable for clothing items such as jeans, jackets, sweatshirts, hats, and bags. Cost-effective and eco-friendly options available. Key models include:

– Model EP-M169: 15x40mm, 30 EUR / 50 pcs, price per piece: 0.199 – 0…

Strategic Sourcing Conclusion and Outlook for custom leather labels

What Are the Key Insights for B2B Buyers of Custom Leather Labels?

As the demand for custom leather labels continues to grow, international B2B buyers must prioritize strategic sourcing to enhance brand identity and consumer trust. Custom leather labels, whether made from genuine leather or high-quality faux options, serve as powerful branding tools that communicate quality and craftsmanship. By selecting the right materials and customization options, businesses can create unique identifiers that resonate with their target markets.

The strategic sourcing of custom leather labels not only involves choosing the right supplier but also understanding the nuances of production processes and material characteristics. Buyers from regions like Africa, South America, the Middle East, and Europe should consider factors such as lead times, shipping logistics, and the environmental impact of materials. Leveraging these insights can lead to more sustainable and cost-effective sourcing strategies, ultimately boosting profit margins.

How Can You Position Your Brand for Future Success?

Looking ahead, the integration of innovative designs and sustainable materials in custom leather labels will play a crucial role in differentiating brands in competitive markets. By investing in quality and creativity, businesses can foster lasting customer relationships and enhance brand loyalty. Now is the time for B2B buyers to explore partnerships with reliable suppliers and capitalize on the growing trend of personalized branding. Embrace the future of custom leather labels and elevate your brand’s identity today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to custom leather labels

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.