Introduction: Navigating the Global Market for furniture upholstery material

In the dynamic landscape of global commerce, sourcing high-quality furniture upholstery materials can be a daunting challenge for B2B buyers, especially those seeking to meet diverse consumer preferences across markets like Nigeria, Brazil, and Europe. With an overwhelming array of options—from luxurious velvets to durable synthetics—the task of selecting the right fabric is not just about aesthetics but also about performance, longevity, and cost-effectiveness. This guide is designed to illuminate the complexities of the upholstery materials market, providing insights into various fabric types, their applications, and the key factors to consider when making a purchase.

International buyers will find comprehensive information on how to vet suppliers effectively, ensuring that the materials sourced not only meet quality standards but also align with local regulations and market trends. We delve into critical aspects such as pricing strategies, shipping logistics, and sustainability practices, equipping buyers with the knowledge they need to navigate the competitive landscape. By empowering B2B buyers with actionable insights and expert recommendations, this guide serves as a vital resource for making informed purchasing decisions in the ever-evolving global market for furniture upholstery materials.

Table Of Contents

- Top 8 Furniture Upholstery Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for furniture upholstery material

- Understanding furniture upholstery material Types and Variations

- Key Industrial Applications of furniture upholstery material

- 3 Common User Pain Points for ‘furniture upholstery material’ & Their Solutions

- Strategic Material Selection Guide for furniture upholstery material

- In-depth Look: Manufacturing Processes and Quality Assurance for furniture upholstery material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘furniture upholstery material’

- Comprehensive Cost and Pricing Analysis for furniture upholstery material Sourcing

- Alternatives Analysis: Comparing furniture upholstery material With Other Solutions

- Essential Technical Properties and Trade Terminology for furniture upholstery material

- Navigating Market Dynamics and Sourcing Trends in the furniture upholstery material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of furniture upholstery material

- Strategic Sourcing Conclusion and Outlook for furniture upholstery material

- Important Disclaimer & Terms of Use

Understanding furniture upholstery material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather | Durable, luxurious, develops a unique patina | High-end furniture, automotive interiors | Pros: Durable, easy to clean; Cons: High cost, sensitive to scratches. |

| Fabric | Wide variety of textures and patterns, breathable | Residential and commercial upholstery | Pros: Affordable, versatile; Cons: Can stain easily, less durable than leather. |

| Vinyl | Water-resistant, easy maintenance, cost-effective | Hospitality, marine applications | Pros: Affordable, durable; Cons: Less breathable, can crack over time. |

| Velvet | Soft, plush texture, luxurious appearance | Luxury furniture, decorative items | Pros: Elegant look, comfortable; Cons: Requires special care, can be expensive. |

| Microfiber | Synthetic, soft, stain-resistant, durable | Residential upholstery, pet-friendly options | Pros: Affordable, easy to clean; Cons: Can attract dust and lint, less breathable. |

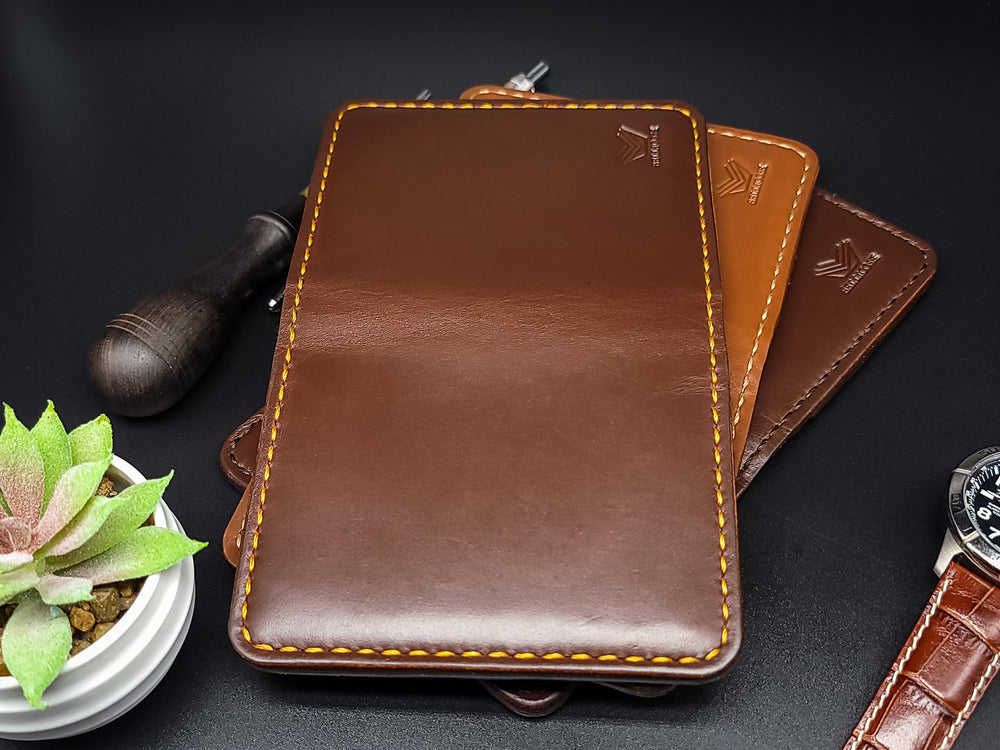

What are the Characteristics of Leather Upholstery?

Leather upholstery is renowned for its durability and luxurious feel. It is available in various grades, from full-grain to bonded leather, each offering distinct qualities. Leather develops a unique patina over time, enhancing its aesthetic appeal. Its primary B2B applications include high-end furniture and automotive interiors, where durability and elegance are paramount. When considering leather, buyers should weigh its higher cost against its longevity and ease of maintenance, as it can be easily wiped clean.

Why Choose Fabric Upholstery for Your Business Needs?

Fabric upholstery encompasses a broad range of textiles, including cotton, linen, and blends. This type of upholstery offers a plethora of colors and patterns, making it highly versatile for various applications, from residential to commercial furniture. While fabric is generally more affordable than leather, it can be prone to staining and may not withstand wear as effectively. B2B buyers should consider the intended use and traffic levels when selecting fabric, as some materials are better suited for high-use environments.

Illustrative image related to furniture upholstery material

What Makes Vinyl an Ideal Choice for Specific Applications?

Vinyl upholstery is a synthetic option known for its water resistance and ease of maintenance. It is commonly used in the hospitality industry and marine applications due to its durability and affordability. While vinyl is less breathable than natural materials, it offers a cost-effective solution for businesses looking for resilient upholstery. Buyers should consider the potential for cracking over time, particularly in environments with extreme temperature fluctuations.

How Does Velvet Upholstery Enhance Furniture Aesthetics?

Velvet upholstery is characterized by its soft, plush texture and luxurious appearance, making it a popular choice for high-end furniture and decorative items. The fabric is available in various colors and patterns, allowing for creative design possibilities. However, velvet requires special care to maintain its appearance and can be more expensive than other options. B2B buyers should assess the maintenance capabilities of their clientele when considering velvet for their offerings.

Why is Microfiber a Practical Option for B2B Buyers?

Microfiber upholstery is a synthetic material known for its softness, durability, and stain resistance, making it an excellent choice for residential upholstery and pet-friendly applications. It is often more affordable than natural fabrics and is easier to clean, appealing to budget-conscious buyers. However, it can attract dust and lint, which may require regular maintenance. Businesses should evaluate the target market’s needs for practicality and aesthetics when selecting microfiber upholstery.

Key Industrial Applications of furniture upholstery material

| Industry/Sector | Specific Application of Furniture Upholstery Material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Upholstery for Hotels and Restaurants | Enhances guest experience and brand image | Durability, stain resistance, and aesthetic appeal |

| Healthcare | Upholstery for Medical Furniture | Ensures hygiene, comfort, and ease of maintenance | Antimicrobial properties and compliance with health standards |

| Automotive | Upholstery for Vehicle Interiors | Improves passenger comfort and vehicle aesthetics | Material durability, fire resistance, and design flexibility |

| Office Furniture | Upholstery for Office Chairs and Workstations | Promotes employee comfort and productivity | Ergonomic design, stain resistance, and color options |

| Retail | Upholstery for Display Furniture | Attracts customers and enhances product presentation | Customization options and durability for high traffic environments |

How is Furniture Upholstery Material Used in the Hospitality Sector?

In the hospitality industry, furniture upholstery material is critical for enhancing the aesthetic appeal and comfort of hotels and restaurants. Upholstered seating and furnishings contribute significantly to the guest experience, influencing their perception of the brand. Buyers must prioritize durability and stain resistance, as high foot traffic can lead to rapid wear and tear. Additionally, the choice of colors and patterns should align with the brand’s theme to create a cohesive atmosphere.

Illustrative image related to furniture upholstery material

What Role Does Upholstery Material Play in Healthcare Settings?

In healthcare, upholstery materials are used for medical furniture, including chairs, beds, and waiting room furniture. The primary focus is on hygiene and comfort, as these factors are paramount in patient care. Upholstery materials must have antimicrobial properties to prevent the spread of infections and be easy to clean and maintain. International buyers should ensure that the materials comply with health standards specific to their region, which may vary between Africa, South America, the Middle East, and Europe.

How is Upholstery Material Utilized in the Automotive Industry?

In the automotive sector, furniture upholstery material enhances the interior of vehicles, providing comfort and aesthetic appeal. Upholstered seats and panels not only improve passenger experience but also contribute to the overall design of the vehicle. Buyers in this sector must consider the material’s durability and fire resistance, as well as its ability to withstand varying climates. The flexibility in design is crucial for customization, allowing manufacturers to meet diverse consumer preferences.

Why is Upholstery Material Important for Office Furniture?

Office furniture upholstery is essential for creating a comfortable and productive work environment. High-quality upholstery on chairs and workstations can significantly enhance employee comfort, leading to improved focus and productivity. Buyers should look for materials that are ergonomically designed and resistant to stains, as office environments can be prone to spills and wear. A variety of color options can also help align with corporate branding, making a positive impression on clients and visitors.

How Does Upholstery Material Impact Retail Environments?

In retail settings, upholstered display furniture plays a key role in attracting customers and showcasing products effectively. The right upholstery can enhance the visual appeal of merchandise while providing a comfortable shopping experience. Buyers should consider customization options that reflect their brand identity and ensure that the materials are durable enough to withstand high traffic. Additionally, the choice of upholstery should be made with an eye toward easy maintenance, as cleanliness is vital in retail environments.

3 Common User Pain Points for ‘furniture upholstery material’ & Their Solutions

Scenario 1: Sourcing Quality Upholstery Material for Diverse Markets

The Problem: B2B buyers often struggle to find high-quality upholstery materials that meet the diverse needs of various markets, particularly when sourcing for regions with different climate conditions and consumer preferences. For instance, a buyer in Nigeria might require fabrics that are resistant to high humidity and heat, while a buyer in Europe may prioritize durability and luxury aesthetics. This challenge is compounded by the lack of transparent information regarding fabric origins, performance characteristics, and supplier reliability.

The Solution: To effectively source upholstery materials tailored to specific market needs, buyers should engage in a multi-faceted approach. Start by conducting thorough research on potential suppliers, focusing on those with a proven track record in international markets. Request samples to evaluate not only the aesthetic appeal but also the fabric’s durability and suitability for local climate conditions. Establish clear specifications based on the intended use—such as residential versus commercial applications—and communicate these requirements to suppliers. Additionally, consider forming partnerships with local distributors who understand regional consumer behavior, as they can provide valuable insights into the most suitable materials.

Scenario 2: Managing Inventory and Reducing Waste in Upholstery Fabrics

The Problem: Another pain point for B2B buyers is managing inventory effectively, particularly when dealing with a wide range of upholstery materials. Overstocking can lead to increased holding costs and wasted resources, while understocking can result in delays and missed sales opportunities. Buyers often find it difficult to predict demand accurately, especially in fluctuating markets.

Illustrative image related to furniture upholstery material

The Solution: Implementing a data-driven inventory management system can significantly alleviate this issue. Utilize sales data analytics to forecast demand trends based on historical purchasing patterns and market conditions. Establish a just-in-time (JIT) inventory model that allows for smaller, more frequent orders, reducing the need for large stockpiles. Additionally, collaborate closely with suppliers to establish flexible ordering agreements that allow for quick replenishment of popular items without incurring excess inventory. By adopting these practices, buyers can optimize their inventory levels, reduce waste, and ensure they have the right materials on hand when needed.

Scenario 3: Ensuring Compliance with International Standards and Regulations

The Problem: B2B buyers often face the challenge of ensuring that their upholstery materials comply with various international standards and regulations. This is particularly relevant for businesses operating in regions with stringent environmental and safety regulations, such as the EU. Non-compliance can lead to costly penalties, product recalls, and reputational damage.

The Solution: To navigate compliance issues effectively, buyers should familiarize themselves with relevant regulations in their target markets. This includes understanding flammability standards, chemical safety requirements, and environmental certifications (such as OEKO-TEX or GREENGUARD). Work closely with suppliers to obtain certifications and documentation that demonstrate compliance with these standards. Additionally, consider investing in training for procurement teams on regulatory requirements and conducting regular audits of suppliers to ensure ongoing compliance. By proactively addressing these issues, buyers can mitigate risks and enhance their product offerings, ensuring they meet both regulatory requirements and consumer expectations.

Illustrative image related to furniture upholstery material

Strategic Material Selection Guide for furniture upholstery material

What Are the Key Properties of Common Upholstery Materials?

When selecting upholstery materials for furniture, it is essential to consider their key properties, which directly impact product performance. Common materials include polyester, leather, cotton, and vinyl, each offering unique characteristics that cater to different applications.

Polyester is a synthetic fabric known for its durability and resistance to wrinkles and fading. It has a high temperature rating, making it suitable for various environments. Polyester is also resistant to mildew and abrasion, which is beneficial for high-traffic areas. However, it can be less breathable compared to natural fibers, potentially leading to discomfort in hot climates. For international buyers, compliance with standards such as ASTM D5034 (for tearing strength) is crucial, especially in regions with varying climate conditions.

Leather is a premium upholstery material that exudes luxury and elegance. Its natural properties provide excellent durability and resistance to wear and tear, making it ideal for high-end furniture. Leather is also easy to clean, which is a significant advantage for commercial applications. However, it can be costly and requires more complex manufacturing processes, including tanning and finishing. Buyers should be aware of local preferences for leather types, such as full-grain or top-grain, and ensure compliance with environmental regulations regarding tanning processes.

Cotton is a versatile natural fiber that offers comfort and breathability. It is available in various designs and colors, making it suitable for diverse aesthetic requirements. While cotton is relatively affordable, it is less durable than synthetic options and may require more frequent replacement in high-use settings. For international buyers, understanding local standards for fabric flammability and durability (like BS 5852 in the UK) is essential, particularly in regions with stringent safety regulations.

Illustrative image related to furniture upholstery material

Vinyl is a synthetic alternative that mimics the look of leather but at a lower cost. It is highly resistant to moisture and stains, making it suitable for environments where spills are common, such as restaurants and healthcare facilities. Vinyl is also easy to maintain, which is a significant advantage for commercial applications. However, it can lack the breathability and comfort of natural materials, leading to potential discomfort in warmer climates. Buyers should consider the environmental impact of vinyl production and ensure compliance with regulations regarding phthalates and other chemicals.

Summary Table of Upholstery Materials

| Material | Typical Use Case for furniture upholstery material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Office chairs, residential sofas | Durable and resistant to fading | Less breathable than natural fibers | Medium |

| Leather | High-end furniture, luxury vehicles | Elegant, easy to clean | Expensive and complex manufacturing | High |

| Cotton | Residential sofas, decorative pillows | Comfortable and breathable | Less durable, may require frequent replacement | Low |

| Vinyl | Commercial seating, healthcare furniture | Moisture-resistant and easy to maintain | Lacks breathability, potential discomfort | Medium |

This strategic material selection guide provides a comprehensive overview of common upholstery materials, highlighting their properties, advantages, and limitations. By understanding these factors, international B2B buyers can make informed decisions that align with their specific market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for furniture upholstery material

What Are the Key Stages in the Manufacturing Process of Furniture Upholstery Material?

The manufacturing process of furniture upholstery material involves several critical stages, each designed to ensure the final product meets aesthetic, functional, and durability standards. The main stages include material preparation, forming, assembly, and finishing.

1. Material Preparation

The initial stage focuses on sourcing and preparing raw materials, which may include natural fibers like cotton, linen, and wool, as well as synthetic options such as polyester and vinyl. Quality assurance begins at this stage, where suppliers must provide documentation confirming the material’s compliance with international standards such as ISO 9001.

Key techniques in this phase include:

- Fabric Sourcing: Establishing relationships with reliable suppliers who adhere to ethical sourcing practices.

- Pre-Treatment Processes: Involves cleaning, dyeing, and finishing treatments to enhance the fabric’s properties, such as stain resistance and colorfastness.

2. Forming

Once the materials are ready, they undergo forming processes. This stage transforms the raw materials into usable fabric through various techniques.

- Weaving and Knitting: Techniques such as warp and weft weaving create different fabric structures, while knitting offers elasticity.

- Printing and Dyeing: Advanced printing technologies, including digital printing, allow for customized designs, while dyeing processes ensure color uniformity and vibrancy.

3. Assembly

In the assembly phase, the prepared fabric is cut and sewn into the desired shapes for upholstery. This stage often requires skilled labor to ensure precision and quality.

- Cutting: Automated cutting machines are commonly used to ensure accuracy and minimize waste.

- Sewing: High-quality stitching techniques are essential for durability, particularly in high-use furniture.

4. Finishing

The finishing stage enhances the fabric’s appearance and functionality. This can include processes such as:

- Coating and Laminating: Applying protective coatings improves durability and resistance to wear and tear.

- Quality Control Checks: Visual inspections and tests for defects are conducted to ensure the fabric meets specified standards before packaging.

How Is Quality Assurance Implemented in Upholstery Fabric Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet both customer expectations and regulatory requirements. Various international and industry-specific standards guide these practices.

Relevant International Standards for Upholstery Material Quality

B2B buyers should be familiar with the following standards that govern quality assurance in upholstery manufacturing:

Illustrative image related to furniture upholstery material

- ISO 9001: Focuses on quality management systems and continuous improvement processes.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Specifications: Specific to the petroleum and natural gas industry, relevant for synthetic upholstery materials derived from petrochemicals.

What Are the Key Quality Control Checkpoints in Upholstery Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure each stage meets predefined standards. The common QC checkpoints include:

1. Incoming Quality Control (IQC)

At this initial stage, incoming materials are inspected for compliance with quality standards. This includes checking for defects, verifying supplier certifications, and ensuring that materials meet specifications.

2. In-Process Quality Control (IPQC)

During the manufacturing process, ongoing inspections are conducted to monitor the quality of fabric production. This includes:

Illustrative image related to furniture upholstery material

- Monitoring Production Conditions: Ensuring machines are calibrated correctly and that processes adhere to specified parameters.

- Spot Checks: Random inspections of fabric samples for defects or inconsistencies.

3. Final Quality Control (FQC)

Once the upholstery materials are completed, a final quality control inspection is performed. This stage involves:

- Visual Inspections: Checking for color consistency, fabric weight, and overall appearance.

- Testing for Durability: Common tests include abrasion resistance, colorfastness, and tensile strength to ensure the upholstery can withstand regular use.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are practical steps to consider:

1. Conduct Supplier Audits

Regular audits can provide insights into a supplier’s manufacturing processes and quality control measures. Buyers should request documentation of previous audits and any corrective actions taken.

2. Review Quality Control Reports

Request detailed QC reports, including test results and compliance certificates. This information can help verify that the supplier meets international standards.

Illustrative image related to furniture upholstery material

3. Engage Third-Party Inspectors

Employing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. This is especially important for international transactions, where distance can complicate direct oversight.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate several nuances in quality control specific to their regions:

- Regulatory Compliance: Understanding local regulations related to product safety and quality is crucial, especially in regions with stringent import requirements.

- Cultural Considerations: Different cultures may have varying expectations regarding product quality and durability. Buyers should communicate their quality standards clearly to avoid misunderstandings.

- Logistics and Supply Chain Management: Ensuring that quality is maintained throughout the supply chain, from production to delivery, is vital. Buyers should establish clear protocols for quality checks at each stage of the supply chain.

By paying close attention to the manufacturing processes and quality assurance practices, B2B buyers can ensure they source high-quality upholstery materials that meet their business needs and customer expectations. This thorough approach not only minimizes risks but also enhances the overall value of the final products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘furniture upholstery material’

Introduction

Navigating the procurement of furniture upholstery materials can be complex, particularly for international B2B buyers. This step-by-step checklist is designed to streamline your sourcing process, ensuring you make informed decisions that align with your business needs and quality standards.

1. Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring that the upholstery materials meet your project requirements. Consider factors such as fabric type (e.g., leather, synthetic, natural fibers), durability (measured in double rubs), and suitability for specific applications like residential or commercial use. Documenting these specifications will provide a solid foundation for evaluating suppliers.

2. Research Market Trends and Material Options

Stay informed about current market trends in upholstery materials. This includes understanding popular fabrics, colors, and textures that appeal to your target audience. Investigate options such as eco-friendly materials or innovative textile technologies that may offer competitive advantages in your market.

Illustrative image related to furniture upholstery material

3. Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, certifications, and references from previous clients in similar industries or regions. Look for suppliers with a proven track record of quality and reliability, and consider their ability to meet your volume requirements.

- Supplier Credentials: Verify certifications related to quality management systems (e.g., ISO certification) and sustainability (e.g., OEKO-TEX).

- Client Testimonials: Seek testimonials or case studies that demonstrate the supplier’s capabilities and reliability.

4. Request Samples for Quality Assessment

Always request samples before finalizing your order. Examining fabric samples allows you to assess texture, color accuracy, and overall quality firsthand. This step is crucial in preventing costly mistakes and ensuring the material aligns with your design vision.

5. Negotiate Pricing and Terms

Engage in discussions about pricing, payment terms, and delivery schedules with your chosen suppliers. Understanding the total cost of ownership, which includes shipping and potential tariffs, is vital for budgeting. Be prepared to negotiate to secure the best possible deal without compromising on quality.

6. Review and Understand Shipping Logistics

Consider the logistics involved in transporting upholstery materials to your location. Evaluate shipping options, lead times, and potential customs regulations that may affect delivery. Collaborating with suppliers who have experience in international shipping can mitigate delays and ensure smooth transactions.

Illustrative image related to furniture upholstery material

7. Establish a Quality Control Process

Implement a quality control process to ensure that received materials meet your specifications. This may involve setting up inspections upon delivery or establishing a return policy for defective products. Having a robust quality assurance strategy will help maintain your brand’s reputation and customer satisfaction.

By following this checklist, B2B buyers can navigate the complexities of sourcing furniture upholstery materials effectively, ensuring they make well-informed decisions that support their business objectives.

Comprehensive Cost and Pricing Analysis for furniture upholstery material Sourcing

What Are the Key Cost Components in Furniture Upholstery Material Sourcing?

Understanding the cost structure in furniture upholstery material sourcing is crucial for B2B buyers looking to optimize their procurement processes. The primary cost components include:

-

Materials: The type of fabric—be it linen, velvet, or synthetic—significantly influences the cost. Specialty fabrics may come with a premium price due to their unique properties or sourcing challenges.

-

Labor: Labor costs encompass the wages paid to skilled workers for cutting, sewing, and finishing upholstery. This can vary by region; for instance, labor may be cheaper in countries in Africa compared to Europe.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment depreciation, and maintenance. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial setup costs for machinery and tools, especially for customized orders, can be substantial. Buyers should consider whether these costs can be amortized over larger orders to minimize impact.

-

Quality Control (QC): Ensuring that the upholstery materials meet specific standards involves costs related to testing and inspection. High-quality fabrics may require more rigorous QC processes, affecting overall pricing.

-

Logistics: Transportation and handling costs can vary widely depending on the origin of the materials and the destination. International shipping, customs duties, and local distribution costs should all be factored into the total cost.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. This margin can vary based on competition, market demand, and the supplier’s positioning.

How Do Price Influencers Affect Furniture Upholstery Material Costs?

Several factors influence the pricing of upholstery materials, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger volumes often leads to discounted rates. Buyers should negotiate MOQs that align with their consumption rates to optimize costs.

-

Specifications and Customization: Custom designs or specific fabric requirements can drive up costs. Buyers should clearly define their specifications upfront to avoid unexpected expenses later.

-

Material Quality and Certifications: Higher-quality materials or those that meet specific certifications (like eco-friendliness or fire resistance) tend to come at a premium. Understanding the value of these certifications can justify higher prices.

-

Supplier Factors: The reputation, reliability, and service level of suppliers can impact pricing. Long-term relationships with trusted suppliers can lead to better pricing and terms.

-

Incoterms: The choice of Incoterms (International Commercial Terms) determines the responsibilities of buyers and sellers in shipping costs and risks. Understanding these terms can lead to more favorable agreements.

What Are Effective Buyer Tips for Negotiating Upholstery Material Prices?

International B2B buyers should consider the following tips to enhance their negotiation strategies and achieve cost-efficiency:

-

Leverage Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with the upholstery material, including maintenance, durability, and potential waste. This perspective can lead to better investment decisions.

-

Negotiate Terms: Engage suppliers in discussions about payment terms, delivery schedules, and potential discounts for early payment or bulk orders. Flexible terms can significantly impact cash flow.

-

Research Market Trends: Stay informed about market conditions, fabric trends, and competitor pricing. This knowledge can empower buyers during negotiations and help them identify fair pricing.

-

Build Relationships: Cultivating strong relationships with suppliers can yield benefits such as improved pricing, priority service, and access to exclusive products.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, tariffs, and logistics. Buyers from Africa, South America, the Middle East, and Europe should be particularly mindful of these factors when sourcing upholstery materials internationally.

Disclaimer

The prices and cost components discussed are indicative and can vary based on specific circumstances, market conditions, and supplier agreements. Always conduct thorough due diligence when sourcing upholstery materials.

Alternatives Analysis: Comparing furniture upholstery material With Other Solutions

Exploring Alternatives to Furniture Upholstery Material

In the competitive landscape of furniture manufacturing, businesses are often faced with the challenge of selecting the most suitable material for upholstery. While traditional upholstery fabrics offer a classic approach, various alternatives can provide unique benefits. This analysis compares furniture upholstery material with two viable alternatives: synthetic leather and modular upholstery systems. Each option presents distinct advantages and limitations that can influence purchasing decisions for B2B buyers.

Illustrative image related to furniture upholstery material

| Comparison Aspect | Furniture Upholstery Material | Synthetic Leather | Modular Upholstery Systems |

|---|---|---|---|

| Performance | Durable and versatile, suitable for various settings | Water-resistant and easy to clean | Offers customization and easy replacement |

| Cost | Moderate to high, depending on fabric quality | Generally lower than high-quality fabrics | Initial investment can be high but cost-effective long-term |

| Ease of Implementation | Requires skilled labor for installation | Simple to cut and apply, can be DIY | Requires professional installation for optimal results |

| Maintenance | Regular cleaning and care needed | Low maintenance, wipe-clean surface | Easy to clean, but components may need replacement |

| Best Use Case | Ideal for luxury furniture and long-term use | Suitable for budget-friendly options and high-traffic areas | Excellent for modern spaces needing flexibility in design |

What Are the Pros and Cons of Synthetic Leather as an Upholstery Alternative?

Synthetic leather, commonly known as faux leather, is made from materials such as polyurethane or polyvinyl chloride (PVC). One of its primary advantages is its cost-effectiveness; synthetic leather is typically less expensive than high-quality upholstery fabrics. Additionally, it is water-resistant and easy to clean, making it suitable for environments prone to spills, such as dining areas or lounges. However, synthetic leather may not offer the same durability and aesthetic appeal as natural fabrics, leading to potential wear and tear over time.

How Do Modular Upholstery Systems Compare to Traditional Upholstery Materials?

Modular upholstery systems consist of pre-fabricated components that can be easily assembled or disassembled, allowing for greater flexibility in design. These systems are advantageous for businesses that frequently change their interior layouts or styles, as they enable quick and easy updates. While the initial investment may be higher than traditional upholstery, the long-term savings on maintenance and replacement can be significant. However, the requirement for professional installation can be a drawback for companies seeking to minimize labor costs.

Choosing the Right Upholstery Solution for Your Business Needs

When selecting the right upholstery solution, B2B buyers should carefully assess their specific needs, including the intended use of the furniture, budget constraints, and desired aesthetic. Furniture upholstery materials remain a strong choice for businesses seeking durability and a luxury feel, while synthetic leather may be more appropriate for cost-sensitive projects. On the other hand, modular upholstery systems provide innovative options for dynamic spaces, albeit with higher initial costs. By weighing the pros and cons of each alternative, buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for furniture upholstery material

What Are the Key Technical Properties of Furniture Upholstery Materials?

Understanding the essential technical properties of furniture upholstery materials is crucial for B2B buyers. These specifications not only impact the performance and longevity of the upholstery but also influence sourcing decisions and cost-effectiveness. Here are some critical properties to consider:

-

Material Grade

Material grade refers to the quality and type of fabric used in upholstery. Fabrics can be categorized into grades based on factors like fiber content, durability, and finish. Higher-grade materials typically offer better performance, such as resistance to wear and fading, making them ideal for high-traffic environments. Buyers should evaluate the grade to align with their target market’s expectations and budget. -

Durability (Double Rubs)

Durability is often quantified by double rubs, which measures the fabric’s resistance to abrasion. A higher double rub count indicates that the fabric can withstand more friction before showing signs of wear. For commercial applications, such as in hotels or offices, selecting fabrics with at least 30,000 double rubs is advisable to ensure longevity and reduce replacement costs. -

Flammability Ratings

Flammability ratings assess how easily a fabric ignites and how it burns. Compliance with industry standards, such as the NFPA (National Fire Protection Association) or CAL117, is essential for upholstery in public spaces. Understanding these ratings helps buyers meet safety regulations and avoid liability issues. -

Colorfastness

Colorfastness indicates how well a fabric retains its color when exposed to light, washing, or rubbing. Fabrics with high colorfastness ratings are critical for maintaining the aesthetic appeal of furniture over time. Buyers should prioritize colorfast materials, especially in regions with intense sunlight or humid conditions, to avoid premature fading. -

Moisture Resistance

Moisture resistance refers to a fabric’s ability to repel water or resist staining from spills. Upholstery materials with moisture-resistant properties are particularly valuable in settings prone to spills, such as cafes or family homes. This property enhances the fabric’s usability and minimizes cleaning efforts. -

Weight and Thickness

The weight and thickness of upholstery fabric can influence its application. Heavier fabrics are often more durable and suitable for high-traffic areas, while lighter fabrics may be ideal for decorative purposes. Buyers should consider the intended use to select the appropriate weight and thickness for their upholstery projects.

What Are Common Trade Terms in the Upholstery Industry?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In upholstery, an OEM might manufacture fabric or components that are integrated into finished furniture. Understanding OEM relationships helps buyers identify quality suppliers and streamline sourcing processes. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it can impact cash flow and inventory management. Negotiating favorable MOQs can lead to better pricing and supply chain efficiency. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. This is a critical step in the procurement process, allowing buyers to compare costs and terms across different suppliers. Crafting a detailed RFQ can result in more accurate quotes and better supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including delivery points and shipping costs. Familiarity with these terms helps buyers avoid misunderstandings and ensures clarity in contracts. For instance, terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the risk at various points in the shipping process. -

Lead Time

Lead time refers to the time taken from placing an order until it is delivered. Understanding lead times is essential for effective inventory planning and meeting customer demands. Buyers should consider lead times when evaluating suppliers to ensure timely project execution. -

Certification Standards

Certification standards indicate that a fabric meets specific quality or safety requirements, such as eco-friendliness or hypoallergenic properties. Certifications can enhance a product’s marketability and appeal, particularly in regions with strict regulations or consumer preferences for sustainable materials.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their sourcing strategies and ultimately improve their product offerings.

Navigating Market Dynamics and Sourcing Trends in the furniture upholstery material Sector

What Are the Key Market Dynamics and Trends Impacting the Furniture Upholstery Material Sector?

The global furniture upholstery material market is experiencing significant transformation driven by a confluence of factors, including evolving consumer preferences, technological advancements, and sustainability imperatives. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigate these dynamics, several key trends emerge.

Illustrative image related to furniture upholstery material

Firstly, the demand for diverse fabric options continues to grow, with buyers seeking materials that blend functionality and aesthetics. Innovations in textile technology, such as digital printing and smart fabrics, are enabling manufacturers to offer customized solutions that cater to specific design needs. Additionally, the rise of e-commerce platforms has made it easier for B2B buyers to access a wider range of suppliers, facilitating better price comparisons and sourcing decisions.

Emerging markets, particularly in Africa and South America, are seeing increased investment in furniture production, driven by urbanization and a growing middle class. This shift is creating a demand for high-quality upholstery materials that can withstand varying climatic conditions. In the Middle East, luxury and high-end fabrics are gaining traction, aligning with the region’s penchant for opulent interiors.

Furthermore, the COVID-19 pandemic has accelerated the need for durable and easy-to-clean materials, prompting buyers to prioritize fabrics that can withstand frequent sanitization without compromising on style.

How Is Sustainability and Ethical Sourcing Shaping the B2B Landscape in Furniture Upholstery Materials?

Sustainability is no longer a mere trend but a core consideration for B2B buyers in the upholstery material sector. As environmental concerns grow, buyers are increasingly seeking materials that minimize ecological impact. This includes sourcing fabrics made from recycled materials, organic fibers, and those certified by recognized sustainability standards.

Ethical sourcing practices are becoming paramount, with buyers demanding transparency in supply chains. This trend is particularly pronounced among buyers from Europe, where regulations around sustainability and ethical labor practices are stringent. Suppliers who can demonstrate compliance with these standards not only enhance their marketability but also build trust with their clients.

Illustrative image related to furniture upholstery material

The importance of ‘green’ certifications cannot be overstated. Certifications such as Global Organic Textile Standard (GOTS), OEKO-TEX, and the Forest Stewardship Council (FSC) provide assurance to buyers that the materials they are sourcing have been produced responsibly. As sustainability becomes a decisive factor in purchasing decisions, suppliers who align with these values are likely to gain a competitive edge.

What Is the Historical Context of the Furniture Upholstery Material Market?

The evolution of the furniture upholstery material market is closely linked to broader trends in interior design and consumer behavior. Historically, upholstery materials were predominantly natural fibers, such as cotton and linen, which were favored for their comfort and durability. With the advent of synthetic fibers in the mid-20th century, the market saw a significant shift towards materials like polyester and nylon, which offered enhanced performance and cost-effectiveness.

The late 20th century marked a turning point as globalization facilitated the rise of diverse fabric options from various regions, enriching the market landscape. Today, the sector is characterized by a blend of traditional craftsmanship and modern manufacturing techniques, allowing for a rich tapestry of choices that cater to the diverse needs of B2B buyers worldwide.

In summary, as international B2B buyers navigate the complexities of the upholstery materials market, understanding these dynamics, prioritizing sustainability, and recognizing the historical context will be crucial for making informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of furniture upholstery material

-

How do I choose the right upholstery material for my business needs?

Selecting the appropriate upholstery material involves assessing several factors, including durability, aesthetics, and maintenance requirements. Consider the intended use of the furniture, as high-traffic areas may require more robust fabrics like commercial-grade vinyl or heavy-duty polyester. Additionally, evaluate the design and color palette that aligns with your brand identity. Request samples from suppliers to ensure the material meets your quality expectations before making a bulk purchase. -

What types of upholstery fabrics are best for commercial use?

For commercial upholstery, fabrics such as heavy-duty polyester, vinyl, and treated cotton are ideal due to their durability and ease of maintenance. These materials are designed to withstand high usage and resist stains and wear. Fabrics with a higher rub count, such as those tested for over 30,000 double rubs, are recommended for longevity in busy environments. Always check the fabric’s specifications to ensure it meets your business’s operational demands. -

What is the minimum order quantity (MOQ) for upholstery materials?

MOQs vary by supplier and can range from as low as 10 yards to several hundred. It is essential to confirm the MOQ before initiating a purchase, as this can significantly affect your budgeting and inventory management. Some suppliers may offer lower MOQs for specific materials or during promotional periods. Establishing a relationship with your supplier can also lead to more favorable terms, especially for recurring orders. -

How can I vet upholstery material suppliers for quality and reliability?

To effectively vet suppliers, start by researching their industry reputation, customer reviews, and case studies. Request samples to assess the fabric’s quality firsthand. Additionally, inquire about their production processes, certifications, and compliance with international standards. Establish clear communication regarding lead times, return policies, and after-sales support to ensure a reliable partnership. Building a strong rapport with suppliers can facilitate smoother transactions and better service. -

What payment terms should I expect when sourcing upholstery materials internationally?

Payment terms can vary widely based on the supplier’s policies and the nature of the transaction. Common options include upfront payments, net 30 or net 60 days, or letter of credit for larger orders. It’s crucial to negotiate terms that protect your cash flow while ensuring the supplier is compensated fairly. Always clarify payment methods accepted, such as bank transfers or credit cards, and be aware of any additional fees that may apply to international transactions. -

How do I ensure quality assurance for my upholstery materials?

Quality assurance can be maintained by establishing clear specifications and standards with your supplier. Request certificates of compliance and conduct regular inspections of the materials upon delivery. Implement a sampling process where you test a small batch before full-scale production. Building a strong relationship with your supplier can also encourage them to prioritize quality and address any issues proactively. -

What logistics considerations should I keep in mind when importing upholstery materials?

When importing upholstery materials, consider shipping costs, transit times, and customs regulations for your destination country. Collaborate with logistics experts to navigate import duties and tariffs effectively. Ensure your supplier can provide necessary documentation, such as bills of lading and certificates of origin, to facilitate smooth customs clearance. Planning ahead for potential delays can help you maintain project timelines and avoid unexpected costs. -

Can I customize upholstery materials for my brand?

Yes, many suppliers offer customization options, including fabric patterns, colors, and even material composition. This can enhance your brand’s identity and differentiate your products in the market. Discuss your customization needs early in the sourcing process to ensure the supplier can meet your requirements. Be prepared to review prototypes or samples before finalizing orders to ensure the end product aligns with your vision.

Top 8 Furniture Upholstery Material Manufacturers & Suppliers List

1. King Cotton – Upholstery Fabrics Collection

Domain: kingcottonfabrics.com

Registered: 2011 (14 years)

Introduction: Upholstery Fabrics collection includes 832 products. Categories include Abstract, Animals, Animal Prints, Birds, Floral, Geometric (Dots, Herringbone, Houndstooth), High Performance, Imported Linen, Linen, Matelasse’, Metallic, Solid, Stripes, Plaids, Checks, Textured & Tweed, Toile, Velvet. Fabrics available in various colors such as White, Ivory, Natural, Brown, Grey, Black, Red, Pink, Orange, Y…

2. Top Fabric – Velvet Upholstery Fabric

Domain: topfabric.com

Registered: 2003 (22 years)

Introduction: This company, Top Fabric – Velvet Upholstery Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Fabric Wholesale Direct – Upholstery Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Upholstery Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Fabric Warehouse – Upholstery Fabric By The Yard

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Upholstery Fabric By The Yard – All Brands, Themes, Colors. SHIPS FREE OVER $100. Categories include Outdoor Fabric, Vinyl, Marine & Auto Upholstery, Curtain, Leather, Utility Supplies. Available options: Remnants Vs Yards, Colors (Beige, Black, Blue, Bronze, Brown, Gold, Gray, Green, Ivory, Khaki, Orange, Pink, Purple, Red, Silver), Fabric Weight (Extra Heavy, Heavy, Lightweight, Medium, Very Lig…

5. Revolution Fabrics – Stain Resistant Upholstery Fabrics

Domain: revolutionfabrics.com

Registered: 2015 (10 years)

Introduction: This company, Revolution Fabrics – Stain Resistant Upholstery Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Decorative Fabrics Direct – Upholstery Fabric

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Upholstery Fabric available for home decor, sold by the yard. Wide range of designs, colors, and fabric types. Categories include: Interior Upholstery, Outdoor Upholstery, Drapery, and Curtain Lining. Fabric types include Chenille, Cotton Duck, Crypton, Damask, Embroidered, Faux Silk, Jacquard, Linen, Velvet, and more. Brands include Covington, Crypton Home, Magnolia Home Fashions, Sunbrella, and …

7. KOVI Fabrics – Upholstery Fabric Selection

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Upholstery Fabric – KOVI Fabrics offers a wide selection of upholstery fabrics including brocades, velvet, prints, linens, denims, cotton blends, natural fabrics, outdoor upholstery fabric, and faux and genuine leathers. Key features include:

– Shop by Color: Black, Grey and Silver, White, Beige, Tan and Neutral, Brown, Gold, Red and Burgundy, Orange and Coral, Yellow, Green, Teal and Aqua, Blue,…

8. Kincaid Furniture – Bedroom Essentials

Domain: kincaidfurniture.com

Registered: 1997 (28 years)

Introduction: {“categories”: {“bedroom”: [“beds”, “chests”, “dressers”, “upholstered beds”, “nightstands”, “benches”], “dining_room”: [“upholstered dining”, “dining storage”, “dining room tables”, “dining room chairs”, “bar & counter stools”], “living_room”: [“sectionals”, “ottomans”, “chairs and accents”, “sofas”, “coffee tables”, “chairside tables”, “entertainment end tables”], “accents”: [“accent tables”, “b…

Strategic Sourcing Conclusion and Outlook for furniture upholstery material

What Are the Key Insights for International B2B Buyers in Upholstery Materials?

In today’s competitive market, strategic sourcing of furniture upholstery materials is crucial for businesses looking to enhance product offerings and maximize profitability. By understanding the diverse range of materials—from luxurious velvets to durable linens—buyers can make informed decisions that align with consumer preferences and emerging design trends. The emphasis on sustainability and ethical sourcing is also gaining momentum, particularly in regions such as Africa and South America, where environmentally conscious consumers are becoming increasingly influential.

Illustrative image related to furniture upholstery material

How Can Strategic Sourcing Drive Value in Upholstery Material Procurement?

Investing in strategic sourcing not only reduces costs but also fosters long-term supplier relationships that can lead to innovation and improved product quality. Engaging with suppliers who provide comprehensive product information and transparency about material origins can significantly enhance your brand’s credibility and appeal. This approach is particularly vital for international buyers navigating diverse markets, such as those in the Middle East and Europe, where consumer expectations vary widely.

What Should B2B Buyers Do Next for Future Success?

As we move forward, the upholstery materials market will continue to evolve, influenced by trends in design, sustainability, and consumer behavior. International buyers should actively seek out partnerships with reliable suppliers who prioritize quality and innovation. By staying informed and agile, businesses can position themselves for success in a dynamic marketplace. Embrace the opportunity to explore new materials and designs that resonate with your target audience, and take the next step towards elevating your product line today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.