Introduction: Navigating the Global Market for custom leather slings

In the competitive landscape of global trade, sourcing high-quality custom leather slings poses unique challenges for B2B buyers, particularly in diverse markets across Africa, South America, the Middle East, and Europe. With an increasing demand for durable and aesthetically pleasing leather products, decision-makers must navigate a myriad of options to find suppliers that not only meet quality standards but also align with their specific needs. This guide is designed to assist you in making informed purchasing decisions by exploring the various types of custom leather slings, their applications, and the critical factors to consider when vetting suppliers.

The comprehensive scope of this guide includes insights into the different styles and functionalities of custom leather slings, from hunting and sports to tactical applications. We will delve into the nuances of supplier evaluation, emphasizing quality assurance, ethical sourcing, and the importance of reliable customer service. Additionally, we will address cost considerations, enabling you to balance quality with budget constraints effectively.

By leveraging the information provided in this guide, international B2B buyers will be empowered to make confident decisions that enhance their product offerings and meet the expectations of their customers. Whether you’re located in Nigeria, Vietnam, or anywhere in between, this resource aims to simplify your sourcing process, ensuring that your investments in custom leather slings yield the best possible returns.

Table Of Contents

- Top 6 Custom Leather Slings Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather slings

- Understanding custom leather slings Types and Variations

- Key Industrial Applications of custom leather slings

- 3 Common User Pain Points for ‘custom leather slings’ & Their Solutions

- Strategic Material Selection Guide for custom leather slings

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather slings

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather slings’

- Comprehensive Cost and Pricing Analysis for custom leather slings Sourcing

- Alternatives Analysis: Comparing custom leather slings With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather slings

- Navigating Market Dynamics and Sourcing Trends in the custom leather slings Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather slings

- Strategic Sourcing Conclusion and Outlook for custom leather slings

- Important Disclaimer & Terms of Use

Understanding custom leather slings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rifle Slings | Designed for firearms, often padded for comfort. | Hunting, military, law enforcement | Pros: Ergonomic, customizable; Cons: Higher cost for quality. |

| Shotgun Slings | Typically shorter, often with adjustable lengths. | Sporting, hunting, tactical operations | Pros: Lightweight, versatile; Cons: Limited to specific uses. |

| Padded Slings | Extra cushioning for prolonged use, often with anti-slip. | Long-duration hunting, military | Pros: Enhanced comfort, stability; Cons: Bulkier design. |

| Competition Slings | Optimized for accuracy, often with quick-release features. | Competitive shooting, law enforcement | Pros: Precision-focused, reliable; Cons: May lack versatility. |

| Custom Personalized Slings | Unique designs with options for engraving or colors. | Gifts, promotional items, branding | Pros: Distinctive, brand representation; Cons: Longer lead time. |

What are the Characteristics of Rifle Slings and Their Suitability for B2B Buyers?

Rifle slings are primarily designed to support firearms, providing a secure and comfortable carrying option for hunters and military personnel. These slings often come padded for additional comfort during extended use, making them ideal for industries focused on hunting and law enforcement. When purchasing, B2B buyers should consider the ergonomic design and the ability to customize features such as length and attachment style to ensure optimal functionality for their specific applications.

How Do Shotgun Slings Differ from Other Sling Types?

Shotgun slings are typically shorter than rifle slings and can be adjusted to fit various shotgun models. Their lightweight design makes them suitable for fast-paced environments such as sporting events and tactical operations. B2B buyers should evaluate the materials used, as durability and ease of adjustment can significantly impact performance in the field. These slings serve a niche market, so understanding the specific needs of your clientele is crucial for effective procurement.

What Advantages Do Padded Slings Offer for Long-Duration Use?

Padded slings are designed for comfort and stability, often featuring anti-slip materials to prevent movement during use. This makes them particularly beneficial for long-duration hunting trips or military missions where comfort is paramount. B2B buyers should consider the trade-off between added comfort and potential bulkiness when selecting these slings. The right choice can enhance user experience significantly, making them a worthwhile investment for companies focused on outdoor activities.

Why Are Competition Slings Essential for Precision Shooting?

Competition slings are specifically engineered for accuracy, often incorporating quick-release mechanisms to facilitate rapid adjustments during events. These slings are crucial for competitive shooters and law enforcement professionals who require reliable equipment. Buyers in these sectors must assess the precision features and overall construction quality to ensure they meet the rigorous demands of competitive environments. While these slings may not be as versatile as others, their specialized design makes them indispensable for their intended applications.

How Can Custom Personalized Slings Serve B2B Marketing Needs?

Custom personalized slings allow businesses to incorporate unique designs, colors, and engravings, making them ideal for gifts or promotional items. This personalization aspect can enhance brand recognition and customer loyalty, particularly in industries focused on outdoor sports or military commemoratives. However, B2B buyers should be aware of potential lead times and costs associated with customization. The ability to offer distinctive products can set businesses apart in competitive markets, making these slings a valuable addition to any product lineup.

Key Industrial Applications of custom leather slings

| Industry/Sector | Specific Application of custom leather slings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hunting and Outdoor Gear | Custom rifle slings for hunters | Enhanced comfort and durability during long hunts | Sourcing high-quality leather and custom design capabilities |

| Military and Defense | Tactical slings for firearms | Improved weapon handling and quick access in tactical situations | Compliance with military specifications and durability standards |

| Sports and Recreation | Slings for archery and crossbow equipment | Increased performance and user comfort during competitions | Need for lightweight materials and ergonomic design |

| Equestrian and Livestock | Custom leather slings for saddles and gear | Enhanced functionality and style in riding equipment | Consideration for weather resistance and ease of maintenance |

| Fashion and Lifestyle | Luxury leather slings as fashion accessories | Unique branding opportunities and differentiation in the market | Focus on customization options and premium materials |

How Are Custom Leather Slings Used in the Hunting and Outdoor Gear Sector?

In the hunting and outdoor gear industry, custom leather slings are primarily used to support rifles and shotguns, enhancing the comfort and stability for hunters during long excursions. These slings are designed to alleviate shoulder strain and improve weapon accessibility, crucial for quick responses in the field. Buyers in this sector must prioritize sourcing durable leather that can withstand various weather conditions, ensuring longevity and reliability during extensive use.

Illustrative image related to custom leather slings

What Role Do Custom Leather Slings Play in Military and Defense Applications?

In military and defense, custom leather slings are integral to tactical gear, providing soldiers with efficient weapon handling and quick access to firearms. These slings are engineered to meet rigorous military standards, ensuring they can endure harsh environments and demanding conditions. For international buyers, especially from regions like the Middle East, compliance with defense procurement regulations is essential, alongside the need for materials that offer both strength and lightweight characteristics.

How Are Custom Leather Slings Applied in Sports and Recreation?

Within the sports and recreation sector, custom leather slings are utilized for archery and crossbow equipment, enhancing user performance and comfort during competitive events. These slings are tailored to fit specific equipment, allowing for optimal weight distribution and ease of use. Buyers must consider the balance between durability and lightweight design, as well as the need for customization to meet individual athlete preferences, particularly in diverse markets such as Africa and South America.

In What Ways Are Custom Leather Slings Beneficial for Equestrian and Livestock Use?

In the equestrian industry, custom leather slings are often used for saddles and other riding gear, providing both functionality and aesthetic appeal. These slings enhance the rider’s experience by ensuring that equipment is secure and accessible. Buyers in this sector should focus on sourcing weather-resistant materials that require minimal maintenance while also considering the craftsmanship that contributes to the overall style of the gear.

How Do Custom Leather Slings Enhance Fashion and Lifestyle Products?

Custom leather slings are increasingly being incorporated into fashion accessories, offering a unique touch to handbags and other personal items. This application allows businesses to differentiate their products in a competitive market, appealing to consumers looking for bespoke items. For B2B buyers, sourcing high-quality leather and ensuring customization options are vital to meet the evolving demands of fashion-conscious consumers in Europe and beyond.

Illustrative image related to custom leather slings

3 Common User Pain Points for ‘custom leather slings’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Custom Leather Slings

The Problem: B2B buyers often struggle to find suppliers that provide high-quality leather suitable for custom slings. With the market flooded with various grades of leather, distinguishing between genuine, full-grain, and lower-quality options can be challenging. Poor-quality leather can lead to durability issues, affecting both the functionality and reputation of the buyer’s products. Buyers may also encounter inconsistent quality across batches, which can complicate inventory management and lead to customer dissatisfaction.

The Solution: To overcome this challenge, buyers should prioritize sourcing from reputable suppliers known for their craftsmanship and material transparency. When evaluating potential suppliers, request samples of the leather to assess its quality firsthand. Look for detailed specifications on the type of leather used, such as whether it is full-grain or top-grain, and inquire about the tanning process, which greatly influences durability and appearance. Building long-term relationships with suppliers who adhere to strict quality standards can ensure a consistent supply of premium materials. Additionally, consider engaging in audits or site visits to the manufacturing facilities to verify the quality control processes in place.

Scenario 2: Customization Challenges in Design Specifications

The Problem: Many buyers face difficulties in articulating their design specifications for custom leather slings. This can lead to miscommunication with manufacturers, resulting in products that do not meet expectations. Custom features such as engraving, padding, or unique stitching patterns may not be accurately represented if the buyer cannot provide clear guidelines. As a result, this can lead to increased costs due to revisions and wasted materials.

The Solution: To mitigate these issues, buyers should invest time in developing detailed design briefs that include visual references, material specifications, and precise measurements. Utilizing design software or collaborating with a graphic designer can help in creating mock-ups that visually communicate the desired end product. Additionally, establishing a clear communication channel with the manufacturer is essential; this could include regular updates and feedback loops throughout the production process. Establishing a prototype stage can also be beneficial, allowing buyers to review and test the product before final production, ensuring that all specifications are met.

Scenario 3: Addressing Comfort and Ergonomics for End Users

The Problem: A common pain point for buyers is ensuring that custom leather slings are not only aesthetically pleasing but also comfortable and ergonomic for end users. Poorly designed slings can lead to discomfort during use, which can affect customer satisfaction and lead to returns or negative reviews. Buyers may find it challenging to balance the visual appeal of the sling with the necessary ergonomic features, especially when catering to diverse user needs.

Illustrative image related to custom leather slings

The Solution: To tackle this issue, buyers should incorporate user feedback into the design process. Conducting surveys or focus groups with potential users can provide valuable insights into comfort preferences and ergonomic needs. Prioritizing features such as adjustable lengths, padded shoulder sections, and anti-slip materials can significantly enhance user experience. Additionally, buyers should collaborate with ergonomic specialists or product designers who can provide expertise in creating slings that offer both style and comfort. Testing prototypes with actual users in real-world scenarios can also help refine the design and ensure that the final product meets the intended ergonomic standards.

Strategic Material Selection Guide for custom leather slings

What Are the Key Materials for Custom Leather Slings?

When selecting materials for custom leather slings, it is essential to consider various leather types, each with unique properties and performance characteristics. This guide analyzes four common materials used in the production of custom leather slings: full-grain leather, top-grain leather, bonded leather, and synthetic leather. Understanding their properties, advantages, and limitations will help international B2B buyers make informed decisions.

What Are the Properties of Full-Grain Leather?

Full-grain leather is the highest quality leather available, retaining the natural grain and texture of the hide. It is highly durable, resistant to wear and tear, and develops a unique patina over time, enhancing its aesthetic appeal. Full-grain leather is also breathable, making it comfortable for long-term use. However, it can be more expensive due to the quality of the raw material and the manufacturing process involved in creating it.

Pros: Exceptional durability, natural aesthetics, breathability.

Cons: Higher cost, requires maintenance to preserve appearance.

Impact on Application: Suitable for high-end custom slings used in rugged environments.

Considerations for Buyers: Compliance with international leather standards and sourcing from reputable tanneries is critical, especially in regions like Africa and South America where leather quality can vary.

How Does Top-Grain Leather Compare to Full-Grain Leather?

Top-grain leather is slightly less durable than full-grain leather as it is sanded and treated to remove imperfections. This process gives it a more uniform appearance, making it a popular choice for custom leather slings. While it offers good durability and is easier to maintain, it lacks the same level of breathability and aging characteristics as full-grain leather.

Illustrative image related to custom leather slings

Pros: More affordable than full-grain, easier to clean, uniform appearance.

Cons: Less durable, may not develop a patina over time.

Impact on Application: Suitable for everyday use slings that do not require the ruggedness of full-grain leather.

Considerations for Buyers: Ensure that the leather meets local standards for quality and durability, especially in markets like Europe where regulations may be stricter.

What Are the Benefits of Bonded Leather?

Bonded leather is made from leftover scraps of leather that are bonded together with polyurethane or latex. It is a cost-effective option that offers the look of leather without the high price tag. However, its durability is significantly lower than that of full-grain or top-grain leather, making it less suitable for heavy-duty applications.

Pros: Cost-effective, lightweight, easy to work with.

Cons: Lower durability, less water resistance, may not last as long.

Impact on Application: Best for low-cost, decorative slings or for short-term use.

Considerations for Buyers: Important to verify the percentage of genuine leather content to ensure quality, particularly in emerging markets like Vietnam.

Illustrative image related to custom leather slings

How Does Synthetic Leather Perform in Custom Slings?

Synthetic leather, often made from materials like polyurethane or PVC, is designed to mimic the look and feel of real leather. It is highly resistant to water and stains, making it easy to clean and maintain. However, synthetic leather may lack the breathability and aesthetic appeal of natural leather, which can be a drawback for some users.

Pros: Water-resistant, easy to clean, often more affordable.

Cons: Less breathable, may not have the same aesthetic appeal as real leather.

Impact on Application: Ideal for slings used in wet conditions or for users who prioritize easy maintenance.

Considerations for Buyers: Look for certifications regarding environmental impact and compliance with local regulations, especially in regions with strict environmental laws.

Summary of Material Selection for Custom Leather Slings

| Material | Typical Use Case for custom leather slings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end, rugged slings for outdoor use | Exceptional durability and aesthetics | Higher cost, requires maintenance | High |

| Top-Grain Leather | Everyday use slings with a polished look | More affordable, easier to maintain | Less durable than full-grain | Medium |

| Bonded Leather | Decorative or short-term use slings | Cost-effective and lightweight | Lower durability, less water resistance | Low |

| Synthetic Leather | Slings for wet conditions or easy maintenance | Water-resistant and easy to clean | Less breathable, may lack aesthetic appeal | Medium |

This comprehensive analysis of materials will aid international B2B buyers in selecting the most suitable leather for custom slings, ensuring that their products meet both performance and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather slings

What Are the Main Stages of Manufacturing Custom Leather Slings?

The manufacturing process for custom leather slings is intricate, involving several key stages that ensure both functionality and aesthetic appeal.

Illustrative image related to custom leather slings

Material Preparation

The first stage begins with the selection of high-quality leather, which is typically full-grain steer hide due to its durability and natural beauty. The leather is sourced from reputable suppliers who adhere to ethical practices. Once procured, the leather undergoes a conditioning process to enhance its flexibility and strength. This may involve oiling or tanning, which not only preserves the leather but also prepares it for further processing.

Forming the Sling

In the forming stage, the leather is cut into specific patterns using precision tools or automated cutting machines. This stage is crucial as it determines the final shape and dimensions of the sling. Techniques such as die-cutting can be employed for accuracy, ensuring that each piece meets the exact specifications required by the design. Additionally, any personalization options, such as engravings or embossing, are applied during this phase.

Assembly of Components

Once the individual pieces are cut, they move to the assembly stage. Skilled artisans or automated machines stitch the leather parts together, often using high-strength polyester threads to ensure longevity. Solid brass rivets and cast hardware are also incorporated at this stage, providing essential structural support and enhancing the overall aesthetic. The use of reinforced stitching techniques, such as double stitching, ensures that the sling can withstand heavy use without compromising its integrity.

Finishing Touches

The final stage in the manufacturing process is finishing. This includes trimming excess material, applying protective coatings, and conducting a thorough inspection for any defects. The finishing process not only enhances the visual appeal of the sling but also adds a layer of protection against wear and environmental factors. Products are often polished or conditioned to give them a rich, glossy finish.

How Is Quality Assurance Implemented in Custom Leather Sling Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing of custom leather slings, ensuring that each product meets both international standards and customer expectations.

Illustrative image related to custom leather slings

What Are the Relevant International Standards for Quality Assurance?

Many manufacturers adhere to international quality standards, such as ISO 9001, which outlines requirements for quality management systems. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE for European markets or API for American Petroleum Institute standards may apply depending on the intended use of the slings.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials, such as leather and hardware, meet the required specifications before production begins. Suppliers must provide documentation and quality reports to verify compliance.

-

In-Process Quality Control (IPQC): During the assembly and forming stages, inspectors monitor the processes to identify any deviations from the established standards. This may include checking stitching quality, ensuring proper alignment of components, and confirming that personalization options are executed correctly.

-

Final Quality Control (FQC): Once the slings are fully assembled, a final inspection is conducted. This involves checking for defects in stitching, ensuring the finish is uniform, and testing the durability of hardware components. Products that do not meet quality standards are either reworked or discarded.

What Common Testing Methods Are Used?

Manufacturers utilize various testing methods to assess the quality of custom leather slings. These may include:

Illustrative image related to custom leather slings

- Tensile Strength Testing: To evaluate the durability of the leather and stitching under stress.

- Abrasion Resistance Testing: To determine how well the sling can withstand wear and tear over time.

- Weather Resistance Testing: To assess the sling’s performance in various environmental conditions, such as moisture and UV exposure.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is vital for ensuring product reliability.

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed audits and quality reports from suppliers. These documents should outline the manufacturer’s adherence to international standards, along with any relevant certifications. A comprehensive report should include data on IQC, IPQC, and FQC processes, highlighting any corrective actions taken for non-conformance.

How Can Third-Party Inspections Enhance Trust?

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s manufacturing practices. These agencies can conduct on-site audits and testing to ensure compliance with both local and international standards. This step not only enhances trust but also mitigates risks associated with product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers should be aware of specific nuances related to quality control and certification. Different regions may have varying standards and expectations regarding leather quality and manufacturing practices.

Understanding Regional Standards

For example, European buyers may prioritize CE marking for safety, while buyers in the U.S. may focus on compliance with the American National Standards Institute (ANSI) guidelines. Buyers from Africa and South America should also consider local regulations that may influence product quality and safety.

Building Relationships with Suppliers

Establishing strong relationships with suppliers can lead to better communication regarding quality assurance practices. Regular visits to manufacturing sites and open discussions about quality expectations can foster a collaborative environment focused on continuous improvement.

In conclusion, understanding the manufacturing processes and quality assurance protocols for custom leather slings is essential for B2B buyers seeking reliable suppliers. By focusing on detailed inspections, compliance with international standards, and fostering strong supplier relationships, buyers can ensure that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather slings’

Introduction

This sourcing guide aims to equip B2B buyers with a practical checklist for procuring custom leather slings. Given the nuances involved in selecting quality leather goods, this step-by-step approach will help you make informed decisions, ensuring both product quality and supplier reliability.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, outline your specific requirements for the custom leather slings. Consider factors such as material type (e.g., full-grain leather), dimensions, design features (like padding or engraving), and functionality (e.g., hunting, military use). Clearly defined specifications will streamline communication with suppliers and help in assessing product offerings effectively.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in custom leather slings. Look for manufacturers with a strong track record and positive customer reviews. Utilize platforms like trade directories, industry associations, and social media to gather insights into potential partners.

- Tip: Focus on suppliers with experience in your specific market region, as they may have better insights into local preferences and regulations.

Step 3: Evaluate Supplier Capabilities

Once you’ve shortlisted potential suppliers, assess their manufacturing capabilities. Inquire about their production processes, quality control measures, and lead times. Understanding their capacity and efficiency will help ensure they can meet your order volume and timeline.

- Key Consideration: Ask for samples or prototypes to evaluate craftsmanship and material quality, which are critical in leather goods.

Step 4: Verify Supplier Certifications

Confirm that the suppliers adhere to relevant industry standards and certifications. This may include quality management systems, environmental practices, and ethical sourcing certifications. Validating these credentials ensures that you partner with suppliers committed to quality and sustainability.

Illustrative image related to custom leather slings

- Documentation to Request:

- ISO certifications

- Environmental compliance certificates

Step 5: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and delivery conditions. Ensure that you understand the total cost of ownership, including shipping and any potential duties for international transactions. Transparent negotiations will foster a healthier business relationship and prevent misunderstandings later.

- Important Factors to Address:

- Bulk order discounts

- Payment methods (e.g., letters of credit, deposits)

Step 6: Establish Communication Protocols

Create clear communication channels with your selected supplier. Set expectations for updates on production status, quality checks, and delivery timelines. Regular communication is essential for addressing any issues that may arise during the sourcing process.

- Best Practices:

- Schedule regular check-ins via email or video calls.

- Use project management tools to track progress and document changes.

Step 7: Conduct a Final Quality Check

Before finalizing your order, ensure a final quality inspection is conducted. This step is crucial to verify that the products meet your specifications and quality standards. Consider engaging a third-party inspection service, especially for large orders, to provide an unbiased assessment.

- Checklist for Inspection:

- Material quality and finish

- Adherence to design specifications

- Functionality tests (e.g., durability, comfort)

By following these steps, B2B buyers can effectively navigate the complexities of sourcing custom leather slings, ensuring they secure high-quality products that meet their business needs.

Illustrative image related to custom leather slings

Comprehensive Cost and Pricing Analysis for custom leather slings Sourcing

What Are the Key Cost Components for Custom Leather Slings?

When sourcing custom leather slings, understanding the cost structure is crucial for effective budgeting and negotiations. The primary cost components include:

-

Materials: High-quality leather, such as full-grain or top-grain, is essential for durability and aesthetic appeal. The type of leather significantly influences cost, with exotic options like alligator or ostrich being more expensive than standard cowhide. Additionally, hardware components such as buckles and swivels can add to the material costs.

-

Labor: Skilled craftsmanship is required for the production of custom leather slings. Labor costs can vary based on the complexity of the design, the level of personalization (e.g., engraving), and the region of manufacture. Countries with lower labor costs may offer competitive pricing but could compromise on quality.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Companies that maintain high standards of quality and sustainability may have higher overhead costs.

-

Tooling: For custom designs, specific tools and molds may be necessary. This tooling cost can be significant, especially for small batch orders, as the initial investment needs to be amortized over fewer units.

-

Quality Control (QC): Rigorous quality assurance processes are vital to ensure that the slings meet the required standards. QC costs can include inspection, testing, and any rework needed for defective products.

-

Logistics: Shipping costs can vary greatly depending on the destination, weight, and dimensions of the packages. International shipping may also incur customs duties and taxes that need to be factored into the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and generate a profit. This margin can fluctuate based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Custom Leather Sling Costs?

Several factors can influence the pricing of custom leather slings, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Suppliers may be more flexible with pricing for bulk orders, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Unique features, such as personalized engraving or custom colors, can increase costs. Buyers should evaluate whether the added features justify the price increase.

-

Materials and Quality Certifications: Sourcing high-quality materials with certifications (e.g., eco-friendly, fair trade) can impact costs. Buyers should weigh the benefits of certified products against their budgets.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their proven quality and service, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the shipping terms (Incoterms) is crucial for managing costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can determine who bears shipping costs and risks, affecting the overall pricing strategy.

What Are the Best Buyer Tips for Negotiating Custom Leather Sling Prices?

To maximize cost-efficiency when sourcing custom leather slings, international B2B buyers should consider the following strategies:

Illustrative image related to custom leather slings

-

Negotiate: Don’t hesitate to negotiate prices, especially for larger orders. Suppliers may have some flexibility, particularly if you establish a long-term relationship.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term factors like durability and maintenance costs. A higher initial investment in quality may lead to lower replacement costs over time.

-

Understand Pricing Nuances for International Markets: Be aware of local market conditions, currency fluctuations, and regional demand, which can all affect pricing. For buyers from Africa, South America, and the Middle East, understanding local tariffs and trade regulations is also crucial.

-

Request Samples: Before placing a large order, request samples to assess quality and craftsmanship. This can prevent costly mistakes and ensure that the final product meets expectations.

Disclaimer

Prices for custom leather slings can vary significantly based on the factors discussed. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing custom leather slings With Other Solutions

Exploring Alternatives to Custom Leather Slings for B2B Buyers

When evaluating options for carrying and securing rifles, custom leather slings stand out for their quality and craftsmanship. However, businesses seeking to meet diverse operational needs may also consider alternative solutions. This analysis will explore two viable alternatives: synthetic slings and adjustable tactical slings, providing a comprehensive comparison to help B2B buyers make informed decisions.

| Comparison Aspect | Custom Leather Slings | Synthetic Slings | Adjustable Tactical Slings |

|---|---|---|---|

| Performance | High durability and comfort; excellent aesthetic appeal | Good performance; weather-resistant; lightweight | Versatile; adjustable for various uses; often includes tactical features |

| Cost | Generally higher ($85-$245 depending on customization) | Moderate ($30-$100) | Moderate to high ($50-$150) |

| Ease of Implementation | Custom orders may require lead time | Readily available in stores and online | Easy to use; often designed for quick adjustments |

| Maintenance | Requires regular conditioning and care | Low maintenance; easy to clean | Minimal maintenance; can be machine washed in some cases |

| Best Use Case | Ideal for hunters seeking premium aesthetics and comfort | Suitable for diverse environments, including wet conditions | Excellent for tactical applications and varied shooting positions |

What Are the Advantages and Disadvantages of Synthetic Slings?

Synthetic slings offer a practical alternative to custom leather slings, particularly in environments where moisture and wear are concerns. Made from materials like nylon or polyester, these slings are lightweight and often resistant to the elements. They are less expensive than leather options, making them accessible for bulk purchases. However, they may lack the aesthetic appeal and comfort of leather, particularly for long-term use. Additionally, synthetic slings may not provide the same level of durability as high-quality leather options, especially in rugged conditions.

How Do Adjustable Tactical Slings Compare to Custom Leather Slings?

Adjustable tactical slings are designed for versatility and adaptability, catering to a wide range of shooting scenarios. These slings often feature quick-release mechanisms and multiple attachment points, allowing users to customize their setup based on specific needs. While they offer functional advantages for tactical operations, their construction materials may vary, and they might not provide the same level of comfort as leather slings during prolonged use. The cost can also vary widely, depending on the features and brand, but they are generally positioned as a mid-range option.

Conclusion: Which Sling Solution Should B2B Buyers Choose?

For B2B buyers, the choice between custom leather slings, synthetic slings, and adjustable tactical slings ultimately hinges on specific operational requirements. If aesthetics, craftsmanship, and comfort are paramount—especially for high-end markets—custom leather slings are an excellent investment. Conversely, for organizations operating in varied environments or requiring a more tactical approach, synthetic or adjustable tactical slings may provide the necessary functionality at a lower cost. By carefully assessing performance needs, budget constraints, and use cases, buyers can select the sling solution that aligns best with their operational goals.

Essential Technical Properties and Trade Terminology for custom leather slings

What Are the Key Technical Properties of Custom Leather Slings?

When sourcing custom leather slings, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications that international B2B buyers should consider:

-

Material Grade

The grade of leather used in the sling significantly impacts its durability, appearance, and functionality. Full-grain leather, for example, is the highest quality, retaining the natural grain and providing superior strength and longevity. Buyers should prioritize suppliers that use high-grade materials to ensure their slings withstand rigorous use. -

Thickness

The thickness of the leather typically ranges from 1.5 mm to 3 mm. A thicker leather sling may offer more durability and comfort, while a thinner option can be lighter and more flexible. Understanding the specific thickness can help buyers assess the sling’s suitability for their intended applications, such as hunting or tactical use. -

Stitching Quality

The stitching method and thread quality are critical for ensuring the sling’s longevity. Braided polyester or nylon threads are commonly used for their strength and resistance to fraying. Buyers should look for slings that feature double stitching in high-stress areas, which can significantly reduce the risk of failure during use. -

Weight Capacity

Different slings are designed to carry varying weights, often specified in pounds or kilograms. This is particularly important for buyers in hunting or tactical industries, where the sling must securely support the weight of a firearm or other equipment. It’s advisable to confirm the weight capacity to ensure the sling meets operational demands. -

Weather Resistance

Many custom leather slings come with treatments that enhance their weather resistance, making them suitable for outdoor use in various climates. Buyers should inquire about the treatment processes used, such as oiling or waxing, to determine the sling’s ability to withstand moisture, UV exposure, and extreme temperatures.

What Are Common Trade Terms Used in the Custom Leather Sling Industry?

Familiarity with industry jargon helps streamline communication with suppliers and ensures clarity in negotiations. Here are several essential terms:

Illustrative image related to custom leather slings

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of custom leather slings, buyers may engage with OEMs to create proprietary designs that are exclusive to their brand. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers, as it can affect inventory management and cash flow. Suppliers may set different MOQs based on production capabilities or material availability. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. It is an essential step in procurement, allowing buyers to compare costs, delivery times, and conditions before making a purchasing decision. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for understanding cost allocation and liability during shipping. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. Knowing the lead time helps buyers plan their inventory and ensures that they receive their custom leather slings in a timely manner, especially for seasonal demands.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing custom leather slings, ultimately enhancing their procurement strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the custom leather slings Sector

What Are the Current Market Dynamics and Key Trends Influencing Custom Leather Slings?

The global market for custom leather slings is witnessing significant growth, driven by rising consumer demand for personalized and high-quality hunting accessories. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, seek to differentiate their offerings, they are increasingly turning to custom leather products. Key trends shaping this market include the integration of advanced manufacturing technologies such as 3D printing, which allows for rapid prototyping and customization. Additionally, the rise of e-commerce platforms has facilitated easier access to global suppliers, enabling buyers to source unique products with minimal friction.

Another notable trend is the growing popularity of multifunctional designs, with slings that cater not only to traditional hunting but also to tactical and outdoor activities. This versatility appeals to a broader customer base, including hunters, outdoor enthusiasts, and military personnel. As the market expands, buyers should also be aware of fluctuating raw material prices, particularly leather, which can impact profit margins. Collaborating with manufacturers who have established supply chain efficiencies and can offer competitive pricing will be crucial in navigating these dynamics.

Illustrative image related to custom leather slings

How Are Sustainability and Ethical Sourcing Shaping the Custom Leather Sling Industry?

Sustainability and ethical sourcing are increasingly becoming non-negotiable factors for B2B buyers in the custom leather sling market. As environmental awareness rises, buyers are seeking suppliers who prioritize sustainable practices, from sourcing leather to production methods. This includes the use of vegetable-tanned leather, which is less harmful to the environment compared to traditional tanning processes that involve harmful chemicals.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with manufacturers who provide transparency about their sourcing and production practices. Certifications such as the Leather Working Group (LWG) certification can serve as a valuable indicator of a supplier’s commitment to sustainability. By prioritizing suppliers who adhere to these standards, B2B buyers not only enhance their brand image but also cater to a growing market segment that values eco-friendly products.

How Has the Custom Leather Sling Market Evolved Over Time?

The custom leather sling market has evolved significantly over the decades, transitioning from handcrafted artisan pieces to modern, technologically advanced products that meet specific consumer needs. Initially, leather slings were primarily utilitarian, designed for functionality and durability. However, as consumer preferences shifted towards personalization and aesthetics, manufacturers began offering customizable options that cater to individual tastes.

Illustrative image related to custom leather slings

Today, the market is characterized by a blend of traditional craftsmanship and modern innovation. Enhanced materials, such as high-quality synthetic leathers and advanced stitching techniques, now complement traditional leather, providing buyers with a variety of options to meet different price points and performance needs. This evolution reflects broader trends in consumer behavior, where personalization, quality, and ethical considerations are paramount. As the market continues to adapt, international B2B buyers must stay informed about emerging trends to leverage opportunities effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather slings

-

How do I choose the right supplier for custom leather slings?

Selecting the right supplier involves assessing their reputation, quality of materials, and production capabilities. Look for suppliers with a proven track record in manufacturing leather goods and positive reviews from previous clients. Request samples to evaluate craftsmanship and material quality. Additionally, ensure they can meet your specific design requirements and understand the nuances of your target market, especially if you are sourcing from regions like Africa, South America, or the Middle East. -

What are the common customization options available for leather slings?

Customization options for leather slings typically include material selection, color, size, and design elements such as engravings or logos. Suppliers may offer choices between different types of leather, such as full-grain or top-grain, which impact durability and aesthetics. You can also specify hardware types, padding for comfort, and stitching styles. Discuss your specific needs with the supplier to explore all available options and ensure the final product aligns with your brand identity. -

What is the minimum order quantity (MOQ) for custom leather slings?

Minimum order quantities for custom leather slings can vary significantly based on the supplier and the complexity of the design. Generally, MOQs can range from 50 to 200 units. It’s important to confirm this with the supplier upfront, as some may be flexible with smaller orders for new clients or specific projects. Understanding MOQ helps in budget planning and inventory management, particularly for international buyers looking to enter new markets. -

What payment terms should I expect when ordering custom leather slings?

Payment terms can vary among suppliers, but common practices include a deposit of 30-50% upfront with the balance due upon completion or before shipping. Some suppliers may offer credit terms for established businesses. Ensure you clarify payment methods accepted, such as bank transfers or letters of credit, especially for international transactions. It’s advisable to negotiate terms that protect both parties and minimize financial risk. -

How can I ensure quality assurance for my custom leather slings?

To ensure quality assurance, establish clear specifications for materials, craftsmanship, and finishing touches before production begins. Consider implementing a quality control process that includes inspections at various stages of production. Request samples or prototypes to evaluate before full-scale manufacturing. Additionally, inquire if the supplier has certifications or quality management systems in place, such as ISO certifications, which can further assure product quality. -

What logistics considerations should I keep in mind for international shipping?

When shipping custom leather slings internationally, consider factors such as shipping costs, delivery timelines, and customs duties. Work with suppliers that have experience in international logistics and can provide guidance on documentation required for customs clearance. Additionally, choose reliable shipping partners and consider insurance options to protect your investment during transit. Understanding local regulations in your destination country can also prevent delays. -

What are the typical lead times for custom leather sling orders?

Lead times for custom leather sling orders can vary widely based on the complexity of the order and the supplier’s production capacity. Generally, you can expect lead times to range from 4 to 12 weeks. Factors influencing lead times include the availability of materials, customization requirements, and the supplier’s workload. Always confirm lead times upfront and consider including a buffer in your planning to accommodate any unforeseen delays. -

How do I handle disputes or quality issues with my supplier?

Handling disputes or quality issues requires clear communication and a structured approach. Start by documenting the issue with photographs and detailed descriptions. Reach out to your supplier promptly to discuss the problem and seek resolution, whether through replacements, refunds, or corrective actions. Having a written agreement that outlines dispute resolution processes can be beneficial. If necessary, consider third-party mediation or arbitration, especially in international transactions, to resolve conflicts amicably.

Top 6 Custom Leather Slings Manufacturers & Suppliers List

1. Ozark Mountain Leather – Custom Leather Rifle Slings

Domain: ozarkmountainleather.com

Registered: 2013 (12 years)

Introduction: Build Your Own Custom Leather Rifle Sling options include: 1. Design your own Rifle Sling (for a gun with swivels) – Price: $99.00 2. Build your own Leather Rifle Sling (for a gun with swivels) – Price: $99.00 3. Build your own Leather Shotgun Sling (for a gun without swivels) – Price: $115.00 4. YOUTH- Build your own YOUTH Leather Rifle Sling (for a gun with swivels) – Price: $69.00 5. Build your…

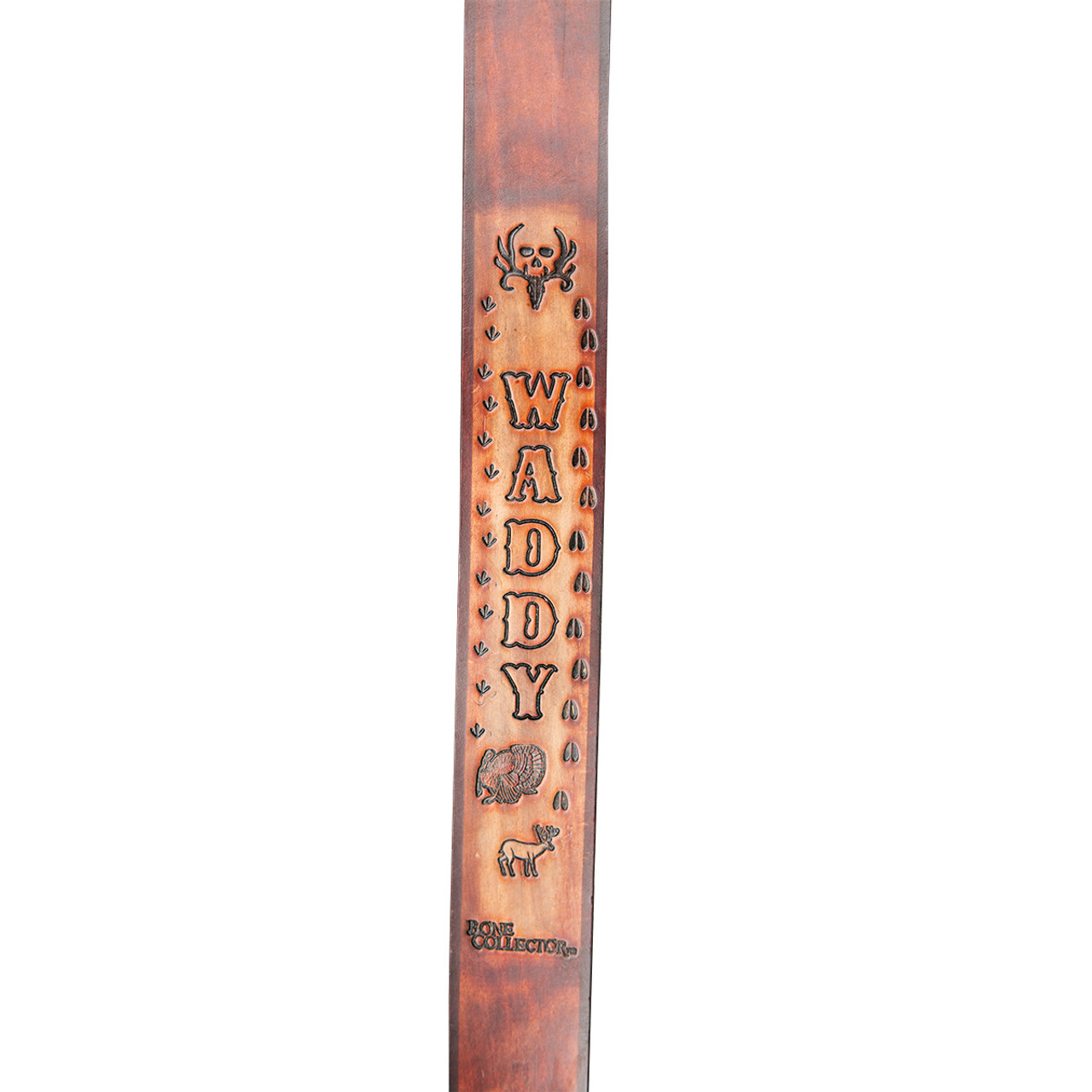

2. Bone Collector – Custom Turkey Tote

Domain: shop.bonecollector.com

Registered: 2000 (25 years)

Introduction: {“products”:[{“name”:”Custom Turkey Tote”,”price”:”$44.99″},{“name”:”Create Your Own BC Sling”,”price”:”$59.99 – $84.99″},{“name”:”Slim Leather Sling – Personalized by Bone Collector”,”price”:”$59.99″},{“name”:”Turkey Tote”,”price”:”$37.00″},{“name”:”Bone Collector Custom Leather Slings”,”price”:”$84.99″}]}

3. Miller Leather – Handmade Rifle Slings

Domain: millersleathershop.com

Registered: 2014 (11 years)

Introduction: This company, Miller Leather – Handmade Rifle Slings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Teton Leather – Handmade Rifle Slings

Domain: tetonleather.com

Registered: 2020 (5 years)

Introduction: Rifle Slings by Teton Leather are handmade custom leather goods designed by hunters for hunters. Key features include:

– Made from high-quality oil stuffed Teton Steer Hide available in brown or black, with a bestselling Dam It sling featuring hand dyed North American beaver tail.

– Solid cast hardware made in America, including both Quick Detach (QD) and standard swivel attachments.

– Premium …

5. Hunter Company – Premium Leather Gun Slings

Domain: huntercompany.com

Registered: 1997 (28 years)

Introduction: Premium Leather Gun Slings from Hunter Company, handmade in the USA since 1952. Key features include: 100% Made in America, Lifetime Guarantee, Handmade, and a 30 Day Risk-Free Trial. Available sling types include Military & Competition Slings, Classic Hunting Slings, and Custom Design Slings. Leather colors offered are Chestnut Tan and Antique Brown. Gun attachment methods include Sling Swivel an…

6. Shokunin USA – Handmade Rifle Slings

Domain: shokuninusa.com

Registered: 2018 (7 years)

Introduction: Rifle & Gun Slings – Leather Sheaths – Handmade & Personalized | Shokunin USA. Custom Handmade Tooled Rifle Sling – Personalized. Regular price: $350.00. Sale price: $146.50 (Save 58%). Availability: In stock (24), Out of stock (2). Artisan Hand Tooled Leather Pancake Holsters – Unique Custom Designs. Regular price: $150.00. Sale price: $118.27 (Save 21%). Artisan Leather Blade Pouch – Ideal for 4…

Strategic Sourcing Conclusion and Outlook for custom leather slings

What Are the Key Takeaways for Sourcing Custom Leather Slings?

In the competitive landscape of custom leather slings, strategic sourcing remains paramount for international buyers. The emphasis on high-quality materials, personalization options, and durability not only enhances product appeal but also meets the specific demands of diverse markets. Buyers should prioritize suppliers that offer customization, ensuring that their products resonate with local tastes and preferences. Furthermore, engaging with manufacturers that maintain ethical sourcing practices can enhance brand reputation and customer loyalty.

Why Is Strategic Sourcing Essential for International Buyers?

For B2B buyers in Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to significant cost savings and improved supply chain efficiency. Establishing strong partnerships with reliable manufacturers can facilitate access to innovative designs and superior craftsmanship. Additionally, understanding regional regulations and market trends is critical for successful product positioning.

What’s Next for Buyers of Custom Leather Slings?

As the demand for custom leather slings continues to rise, international buyers should act decisively. Evaluate potential suppliers based on their commitment to quality, customization capabilities, and sustainability practices. By fostering long-term relationships with reputable manufacturers, businesses can secure a competitive edge in their respective markets. Embrace this opportunity to enhance your product offerings and meet the evolving needs of your customers.

Illustrative image related to custom leather slings

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather slings