Introduction: Navigating the Global Market for how do you make leather soft

In the competitive landscape of leather goods, achieving the right balance between durability and comfort is a significant challenge for B2B buyers. Understanding how to make leather soft is crucial for sourcing products that not only meet aesthetic demands but also provide the comfort and flexibility required in various applications. Whether you are looking to procure leather for upholstery, fashion, or accessories, knowing the nuances of leather types, their tanning processes, and care methods can greatly influence your purchasing decisions.

This comprehensive guide delves into the various types of leather available on the market, highlighting their unique characteristics and applications. From chrome-tanned to vegetable-tanned and oil-tanned leathers, we will explore how each type can be softened effectively without compromising quality. Furthermore, the guide will cover essential aspects such as supplier vetting processes, cost considerations, and best practices for maintaining leather integrity over time.

By empowering international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Germany—this resource aims to equip you with the knowledge necessary to make informed decisions. Whether you are enhancing your product offerings or improving customer satisfaction, understanding the methods to soften leather can lead to significant business advantages and elevate your brand’s reputation in the global marketplace.

Table Of Contents

- Top 6 How Do You Make Leather Soft Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do you make leather soft

- Understanding how do you make leather soft Types and Variations

- Key Industrial Applications of how do you make leather soft

- 3 Common User Pain Points for ‘how do you make leather soft’ & Their Solutions

- Strategic Material Selection Guide for how do you make leather soft

- In-depth Look: Manufacturing Processes and Quality Assurance for how do you make leather soft

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you make leather soft’

- Comprehensive Cost and Pricing Analysis for how do you make leather soft Sourcing

- Alternatives Analysis: Comparing how do you make leather soft With Other Solutions

- Essential Technical Properties and Trade Terminology for how do you make leather soft

- Navigating Market Dynamics and Sourcing Trends in the how do you make leather soft Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do you make leather soft

- Strategic Sourcing Conclusion and Outlook for how do you make leather soft

- Important Disclaimer & Terms of Use

Understanding how do you make leather soft Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable-Tanned | Soft, breathable, and durable; made using natural tannins | Bags, belts, upholstery, high-end leather goods | Pros: Eco-friendly, flexible. Cons: Longer tanning process, may darken over time. |

| Chrome-Tanned | Stiffer, water-resistant, shiny finish; uses chromium sulfate | Footwear, handbags, automotive interiors | Pros: Quick tanning, strong. Cons: Less breathable, potential environmental concerns. |

| Oil-Tanned | Soft, pliable, and water-resistant; treated with oils | Outdoor gear, wallets, belts | Pros: Comfortable, good for heavy use. Cons: Can be more expensive, may require special care. |

| Nubuck | Sanded outer side, velvety texture; luxurious feel | Furniture upholstery, high-end accessories | Pros: Soft, durable, attractive. Cons: Requires careful maintenance, prone to staining. |

| Suede | Soft, velvety finish from the underside of the hide | Apparel, furniture, accessories | Pros: Comfortable, stylish. Cons: Less durable, sensitive to moisture and stains. |

What are the Characteristics and Suitability of Vegetable-Tanned Leather for B2B Buyers?

Vegetable-tanned leather is renowned for its softness, breathability, and durability. The tanning process employs natural tannins derived from tree bark, making it an eco-friendly choice. It is particularly suitable for products requiring flexibility, such as bags, belts, and upholstery. B2B buyers should consider the longer tanning process, which can affect lead times, and the potential for the leather to darken over time, influencing aesthetics.

How Does Chrome-Tanned Leather Stand Out in B2B Applications?

Chrome-tanned leather is recognized for its stiffness, shiny finish, and water resistance, achieved through the use of chromium sulfate. This type of leather is ideal for applications in footwear, handbags, and automotive interiors, where durability is crucial. Buyers should weigh the advantages of quick production and strength against the drawbacks of reduced breathability and potential environmental concerns linked to the tanning process.

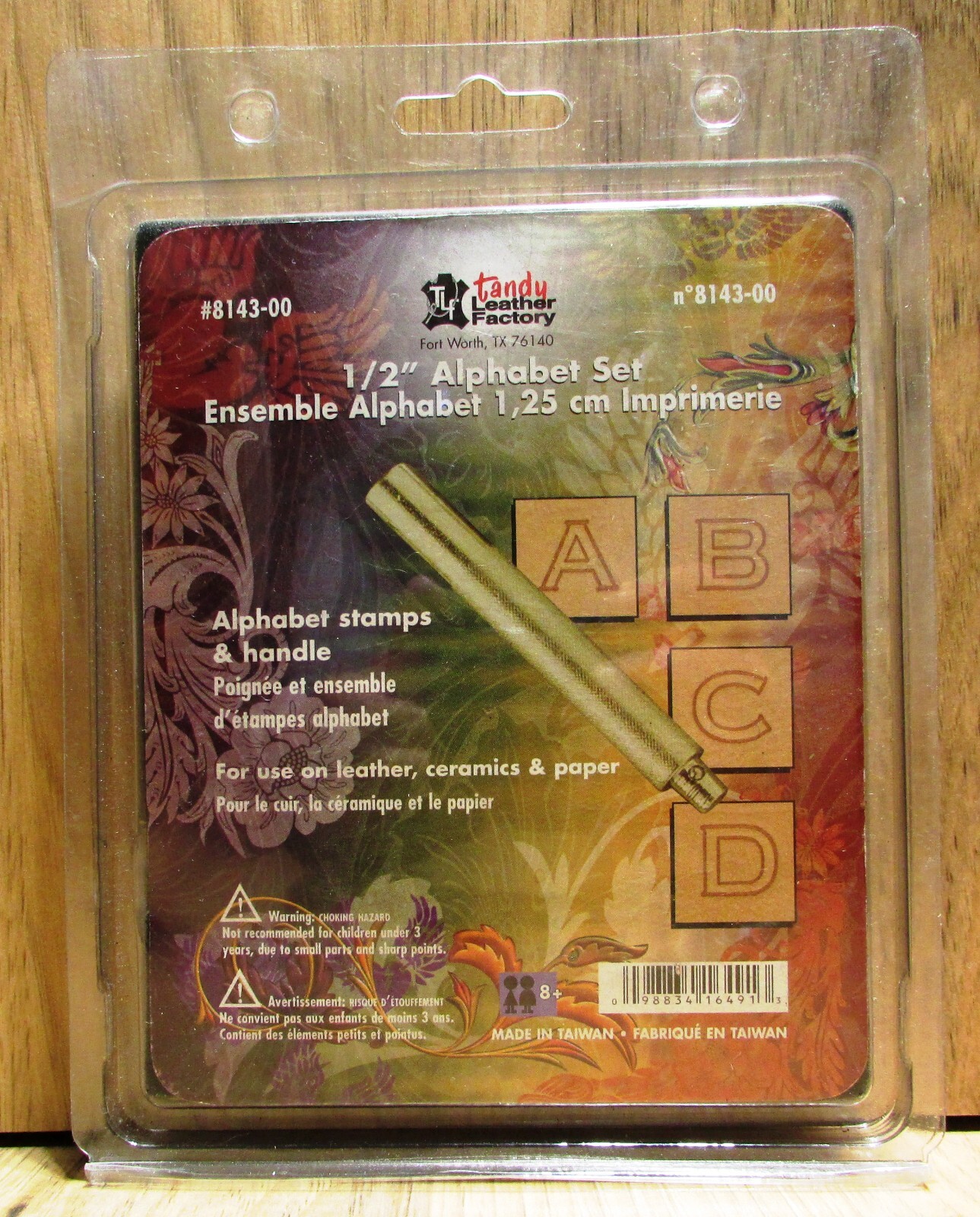

Illustrative image related to how do you make leather soft

What Makes Oil-Tanned Leather a Preferred Choice for Certain B2B Markets?

Oil-tanned leather is characterized by its softness and pliability, treated with oils to enhance its water resistance. It is commonly used in outdoor gear, wallets, and belts, providing comfort and resilience for heavy-use items. B2B buyers may find oil-tanned leather slightly more expensive, but its durability and ease of use can justify the investment. Special care may also be necessary to maintain its quality over time.

Why is Nubuck Leather Considered a Luxury Option for B2B Buyers?

Nubuck leather is crafted from the outer side of cowhide, sanded to create a soft, velvety texture. Its luxurious appearance makes it highly sought after for furniture upholstery and high-end accessories. While it offers durability and aesthetic appeal, B2B buyers must consider the careful maintenance required to prevent staining and the higher cost associated with this premium material.

What Should B2B Buyers Know About Suede Leather’s Applications and Care?

Suede leather, with its soft, velvety finish from the underside of the hide, is popular in apparel and accessories. Its comfort and style make it a favored choice, but its sensitivity to moisture and stains can pose challenges. B2B buyers should ensure they have proper care protocols in place to maintain suede’s quality, as its durability is generally lower than that of other leather types.

Key Industrial Applications of how do you make leather soft

| Industry/Sector | Specific Application of how do you make leather soft | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Softening leather for garments and accessories | Enhances comfort and wearability, improving customer satisfaction | Quality of leather, type of conditioner, environmental impact of tanning processes |

| Furniture & Upholstery | Treatment of leather for sofas and chairs | Increases durability and aesthetic appeal of furniture | Sourcing sustainable leather, compatibility with cleaning products, warranty and maintenance |

| Automotive | Softening leather for car interiors | Improves luxury feel and comfort for passengers | Supplier reputation, adherence to safety regulations, customization options |

| Footwear | Conditioning leather for shoes | Enhances flexibility and comfort, reducing return rates | Material sourcing, durability of softening agents, regional leather quality |

| Leather Goods | Softening leather for bags and wallets | Adds value through premium feel, attracting high-end consumers | Sourcing consistency, compatibility with various finishes, availability of conditioning methods |

How is Leather Softening Used in Fashion & Apparel?

In the fashion industry, softening leather is crucial for creating comfortable and stylish garments and accessories. Stiff leather can lead to discomfort, which may deter customers from purchasing. By employing methods such as conditioning and heat application, businesses can enhance the suppleness of leather, making it more appealing for fashion items. International buyers, particularly from Africa and Europe, should consider the quality of leather and the type of conditioner used to ensure longevity and maintain the product’s luxurious feel.

What are the Benefits of Softening Leather in Furniture & Upholstery?

In furniture manufacturing, softening leather plays a vital role in enhancing the comfort and aesthetic appeal of sofas and chairs. Soft leather not only feels better but also contributes to the overall design and quality of the furniture. Businesses in this sector should prioritize sourcing sustainable leather and consider how the conditioning process may affect compatibility with cleaning products. Buyers from South America and the Middle East should also evaluate warranty and maintenance options to ensure long-term satisfaction.

Illustrative image related to how do you make leather soft

How Does Softening Leather Enhance Automotive Interiors?

In the automotive sector, softening leather is essential for creating luxurious car interiors that enhance the overall passenger experience. Comfortable leather seats significantly contribute to customer satisfaction and brand loyalty. Automotive manufacturers must prioritize sourcing high-quality leather that meets safety regulations while offering customization options. B2B buyers in Europe and Africa should assess supplier reputation and the environmental impact of the tanning processes used.

Why is Softening Leather Important for Footwear?

Softening leather is particularly important in the footwear industry, where comfort and flexibility are paramount. Stiff leather can lead to discomfort and increased return rates, negatively impacting profitability. By conditioning leather effectively, businesses can create shoes that not only look good but also feel good to wear. Buyers should focus on the durability of softening agents and the quality of the leather sourced, especially when operating in diverse markets across Africa and South America.

How Does Softening Leather Benefit Leather Goods Manufacturing?

For manufacturers of leather goods, such as bags and wallets, softening leather adds significant value by providing a premium feel that attracts high-end consumers. Softened leather enhances usability and aesthetic appeal, making products more marketable. Buyers should ensure consistency in sourcing and consider how different softening methods may impact the final product’s finish. Additionally, compatibility with various finishes is crucial, particularly for international buyers from diverse markets in Europe and the Middle East.

3 Common User Pain Points for ‘how do you make leather soft’ & Their Solutions

Scenario 1: Stiff Leather Products Affecting Customer Satisfaction

The Problem: Many B2B buyers, particularly in the fashion and upholstery sectors, encounter stiff leather products that do not meet customer expectations for comfort and usability. This stiffness can result from the type of leather used, the tanning process, or inadequate conditioning. For instance, a furniture manufacturer may receive leather that is too rigid, making the final product uncomfortable for consumers. This can lead to returns, negative reviews, and ultimately damage the brand’s reputation.

The Solution: To mitigate this issue, buyers should prioritize sourcing leather from suppliers who understand the importance of selecting the appropriate tanning process and leather type for their intended use. For instance, opting for vegetable-tanned leather for upholstery applications can provide a softer, more pliable end product. Additionally, implementing a routine conditioning process using high-quality leather conditioners can help maintain the softness and flexibility of the leather over time. Buyers should educate their teams on proper conditioning methods, which include cleaning the leather before application, evenly distributing the conditioner, and allowing ample time for the leather to absorb the product before use. This proactive approach ensures that the leather remains comfortable and retains its aesthetic appeal.

Illustrative image related to how do you make leather soft

Scenario 2: Environmental Factors Leading to Leather Stiffness

The Problem: B2B buyers operating in diverse climates, such as the humid conditions in parts of Africa or the dry heat in the Middle East, often face challenges with leather stiffness caused by environmental factors. Excessive moisture can lead to mold growth, while arid conditions can dry out the leather, making it brittle and inflexible. This variability can significantly impact inventory quality and customer satisfaction, as leather goods may deteriorate faster than anticipated.

The Solution: It is crucial for buyers to establish comprehensive storage and care guidelines tailored to their specific environmental conditions. For humid climates, implementing climate-controlled storage solutions can prevent mold and mildew, while utilizing silica gel packets can help manage moisture levels in storage areas. Conversely, in dry climates, regularly applying a leather conditioner that contains natural oils can help maintain moisture levels in the leather, preventing it from drying out and becoming stiff. Additionally, educating staff on the importance of periodic inspections and proper maintenance can extend the lifespan of leather products and ensure they remain soft and supple.

Scenario 3: Ineffective Softening Techniques Leading to Damage

The Problem: B2B buyers often experiment with various methods to soften leather, including heat application or using household products, which can lead to unintended damage such as cracking or discoloration. This trial-and-error approach not only wastes resources but can also compromise the integrity of the leather, leading to costly replacements and diminished quality control.

The Solution: To avoid damaging leather during the softening process, buyers should adopt a systematic approach based on the leather type and its condition. Consulting with experts or suppliers to identify the most effective softening methods for specific leather types is essential. For instance, oil-tanning techniques can be beneficial for certain leathers, while others may respond better to water-based conditioners. It is advisable to conduct small tests on inconspicuous areas before applying any product to the entire surface. Furthermore, establishing a clear protocol for softening leather—such as the right temperature for heat application, the type of conditioner to use, and the frequency of treatment—can help ensure consistent results and preserve the quality of leather goods. This strategic approach not only enhances product quality but also reinforces brand credibility in the competitive marketplace.

Strategic Material Selection Guide for how do you make leather soft

When considering how to effectively soften leather for various applications, it is essential to analyze the materials and methods available. This guide focuses on four common materials used in the leather softening process: leather conditioners, heat application, natural oils, and alcohol-based products. Each material has unique properties, advantages, and limitations that can significantly impact product performance and suitability.

Illustrative image related to how do you make leather soft

What are the Key Properties of Leather Conditioners?

Leather conditioners are formulated to penetrate the leather fibers, replenishing lost oils and moisture. They typically contain a blend of oils, waxes, and emulsifiers, which help maintain the leather’s suppleness. The temperature stability of these conditioners is generally good, allowing them to perform effectively in various climates, which is particularly relevant for international markets.

Pros and Cons:

The primary advantage of leather conditioners is their ability to restore flexibility without altering the leather’s appearance. However, they can be costly, and the manufacturing complexity varies depending on the formulation. Additionally, some conditioners may not be suitable for all leather types, which could limit their application in diverse markets.

How Does Heat Application Affect Leather Softening?

Applying controlled heat is another method to soften leather. This process involves using heat sources like hairdryers or heat guns to gently warm the leather, making it more pliable. The key property here is the ability to increase the temperature without damaging the leather fibers, which requires careful monitoring.

Illustrative image related to how do you make leather soft

Pros and Cons:

The advantage of heat application is its immediate effect, allowing for quick adjustments during manufacturing. However, excessive heat can lead to irreversible damage, such as cracking or drying out the leather. This method’s complexity also means it requires skilled labor, which may not be readily available in all regions.

What Role Do Natural Oils Play in Softening Leather?

Natural oils, such as coconut or olive oil, are often used to soften leather due to their moisturizing properties. These oils penetrate the leather, replenishing lost oils and enhancing flexibility. They are generally safe for various leather types and have a low environmental impact.

Pros and Cons:

The primary advantage of using natural oils is their cost-effectiveness and ease of application. However, they may not provide long-lasting effects compared to specialized leather conditioners. Additionally, the application process can be labor-intensive, which may affect manufacturing efficiency.

Why Are Alcohol-Based Products Used in Leather Softening?

Alcohol-based products, such as rubbing alcohol or denatured alcohol, can be used to soften leather by breaking down stiff fibers. They evaporate quickly, allowing for rapid drying and flexibility restoration. This method is often favored for its speed and effectiveness.

Illustrative image related to how do you make leather soft

Pros and Cons:

The key advantage of alcohol-based products is their quick action, making them suitable for urgent repairs. However, they can dry out the leather if overused, leading to brittleness. Additionally, their use may not comply with environmental regulations in certain regions, posing challenges for international buyers.

Summary Table of Material Selection for Leather Softening

| Material | Typical Use Case for how do you make leather soft | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather Conditioner | Restoring flexibility in leather goods | Effective replenishment of oils | Can be costly and may not suit all leathers | Medium |

| Heat Application | Immediate softening for manufacturing adjustments | Quick results | Risk of damage if overheated | Low |

| Natural Oils | General softening and conditioning | Cost-effective and environmentally friendly | Labor-intensive application | Low |

| Alcohol-Based Products | Rapid softening for urgent repairs | Fast-acting and effective | Can dry out leather if overused | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to soften leather effectively. Understanding the properties, advantages, and limitations of each material will aid in making informed decisions that align with regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how do you make leather soft

What Are the Key Stages in the Manufacturing Process of Soft Leather?

The journey of transforming raw animal hides into soft leather involves several critical stages. Each stage is essential for achieving the desired softness and quality, making it vital for B2B buyers to understand these processes.

1. Material Preparation: How Are Animal Hides Processed?

The first step in manufacturing soft leather is the preparation of animal hides. This involves several sub-steps:

-

Selection of Hides: The choice of animal hide significantly influences the final softness of the leather. For instance, lambskin and sheepskin are naturally softer compared to cowhide.

-

Curing: This process prevents decomposition. Hides are often salted or dried to preserve them before they undergo tanning.

-

Soaking: After curing, hides are soaked in water to rehydrate them, which prepares them for the tanning process. This step is crucial as it allows for better penetration of tanning agents.

2. What Techniques Are Used in Tanning to Achieve Softness?

Tanning is the core process that determines the softness and flexibility of leather. Various techniques can be employed, each yielding different properties:

Illustrative image related to how do you make leather soft

-

Vegetable Tanning: Utilizing tannins from natural sources like tree bark, this method is slower but results in soft, breathable leather. It is favored for products requiring durability and flexibility.

-

Chrome Tanning: This quicker method uses chromium salts, yielding leather that is initially stiff but can be softened through conditioning. While it offers a shiny finish, it may not always achieve the softness required for high-end applications.

-

Oil Tanning: By treating leather with oils, this method produces an exceptionally soft and pliable product. It is ideal for items like wallets and purses, where comfort is paramount.

-

Heat Treatment: Some manufacturers apply controlled heat during the tanning process to enhance the leather’s softness. This technique must be carefully managed to avoid damaging the leather fibers.

3. How Does the Forming Stage Contribute to Soft Leather Production?

Once the tanning process is complete, the leather enters the forming stage, where it is cut, shaped, and assembled. Key activities include:

-

Cutting: Skilled artisans cut the leather into specific patterns for the intended product. Precision in cutting ensures that the final product maintains the desired softness and flexibility.

-

Molding and Shaping: Depending on the product, leather may be molded to achieve specific contours. Heat and moisture can be applied to aid this process, allowing for better shaping without compromising softness.

4. What Finishing Techniques Enhance Softness and Quality?

The finishing stage is critical for enhancing both the aesthetic appeal and the tactile qualities of leather. Common techniques include:

-

Conditioning: Applying leather conditioners post-tanning helps maintain moisture and softness. Conditioners that are oil-based or wax-based are often preferred for their ability to penetrate deeply.

-

Buffing and Polishing: These techniques enhance the leather’s surface, providing a soft, luxurious feel while also increasing durability.

-

Dyeing: Softening agents may be incorporated into dyes to ensure that the leather retains its softness after coloring.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance is paramount in leather manufacturing, ensuring that the final product meets international standards and buyer expectations.

Illustrative image related to how do you make leather soft

1. What International Standards Are Relevant for Leather Quality?

B2B buyers should be familiar with relevant international quality standards, including:

-

ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality in their processes.

-

CE Marking: Particularly relevant in Europe, CE marking indicates that products meet EU safety and environmental requirements.

-

API Standards: The American Petroleum Institute (API) provides standards that may apply to leather products used in industrial applications.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) should be integrated at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw hides upon arrival. Any subpar hides should be rejected to maintain quality.

-

In-Process Quality Control (IPQC): Throughout the tanning and finishing processes, IPQC ensures that the leather meets specified standards at every stage.

-

Final Quality Control (FQC): Before shipment, FQC is conducted to verify that the finished products meet all specifications and are free from defects.

3. How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must implement due diligence when verifying supplier quality control measures:

-

Supplier Audits: Conducting regular audits of suppliers can help ensure compliance with quality standards and identify areas for improvement.

-

Quality Reports: Requesting detailed quality reports can provide insights into the manufacturing process and any quality issues encountered.

-

Third-Party Inspections: Engaging third-party inspectors can add an extra layer of assurance, offering unbiased evaluations of the leather products.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, must be aware of specific nuances related to quality control and certification:

-

Regional Compliance: Different regions may have unique compliance requirements. For instance, European buyers should ensure that products comply with REACH regulations concerning chemical safety.

-

Cultural Sensitivities: Understanding local market preferences and quality expectations is crucial. For example, certain markets may prioritize environmentally friendly tanning processes.

-

Documentation: Ensure that suppliers provide all necessary documentation, including certificates of compliance and quality assurance reports, to facilitate smoother import processes.

In conclusion, understanding the manufacturing processes and quality assurance practices for leather softening is essential for B2B buyers. By being informed about these stages and quality standards, businesses can make more educated purchasing decisions and ensure that they receive high-quality, soft leather products suitable for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you make leather soft’

Introduction

This practical sourcing guide aims to assist B2B buyers in effectively procuring materials and methods for softening leather. Understanding how to make leather soft is crucial for enhancing the quality and comfort of leather products, thereby meeting customer expectations. This checklist outlines essential steps to ensure you find the right suppliers and methods tailored to your specific needs.

Step 1: Identify Your Leather Type

Recognizing the type of leather you are working with is the first critical step. Different leather types, such as cowhide, lambskin, or suede, require unique softening methods. Each type has its inherent properties and softness levels, which directly influence your choice of conditioning products and techniques.

Illustrative image related to how do you make leather soft

Step 2: Define Your Technical Specifications

Before sourcing, clarify your requirements regarding softness, flexibility, and durability. This ensures you target suppliers who can meet your specific needs. Consider factors such as the intended use of the leather (e.g., apparel, upholstery) and desired finish, as these will affect the softening process.

Step 3: Research Softening Methods

Investigate various methods for softening leather, including natural oils, conditioners, and heat application. Each method has its advantages:

– Natural Oils: Often more environmentally friendly and safe for the leather.

– Commercial Conditioners: May provide a quicker and more uniform softening effect but could contain chemicals that might affect leather integrity.

Understanding these options helps you make informed decisions regarding procurement.

Step 4: Evaluate Potential Suppliers

Thoroughly vet suppliers before making commitments. Look for those with proven expertise in leather treatment and conditioning. Request:

– Company Profiles: Understand their history and specialization.

– Case Studies: Assess their track record with similar leather types or applications.

– References: Speak with other businesses that have utilized their services for insights into reliability and quality.

Step 5: Request Samples and Test Products

Before finalizing your order, ask for samples of the softening products or methods. Testing these samples allows you to evaluate their effectiveness on your specific leather type. Ensure that the samples demonstrate the desired softness and flexibility without compromising the leather’s integrity.

Step 6: Verify Certifications and Compliance

Confirm that suppliers comply with industry standards and environmental regulations. Certifications related to leather processing and treatment methods can indicate a commitment to quality and sustainability. Look for:

– ISO Certifications: Reflects adherence to international quality standards.

– Environmental Certifications: Ensures responsible sourcing and minimal ecological impact.

Illustrative image related to how do you make leather soft

Step 7: Establish Clear Communication Channels

Maintain open lines of communication with your suppliers throughout the procurement process. Clear communication helps address any concerns or adjustments needed during softening treatments. Ensure that suppliers provide detailed instructions and support for the application of their products, enabling you to achieve the best results.

By following this checklist, you can navigate the complexities of sourcing effective leather softening solutions, ensuring that your final products meet the high standards expected in the marketplace.

Comprehensive Cost and Pricing Analysis for how do you make leather soft Sourcing

Understanding the cost structure and pricing nuances associated with sourcing materials and services for softening leather is essential for B2B buyers. This analysis will delve into the various components that contribute to the overall costs, price influencers, and strategic buyer tips, tailored for international buyers from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Softening Leather?

-

Materials: The cost of raw materials is a significant factor in the pricing structure. This includes the type of leather being treated and the softening agents, such as conditioners or oils. High-quality, natural conditioners may command a premium price, while synthetic options could be more affordable but less effective.

-

Labor: Labor costs encompass the workforce needed for the application of softening methods. Skilled workers are often required to ensure the proper treatment of leather, especially in manual conditioning processes. The labor cost can vary significantly based on geographical location and local wage standards.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. The overhead can differ based on the size and efficiency of the manufacturing operation. Companies with advanced technology may have lower overhead per unit due to higher production efficiency.

-

Tooling: Specific tools and machinery may be necessary for conditioning and softening leather. The initial investment in quality tools can be substantial, impacting the overall cost structure. Regular maintenance and updates to tooling are also essential to ensure consistent quality.

-

Quality Control (QC): Implementing rigorous QC processes is crucial to maintain product quality, especially for high-end leather goods. The costs associated with quality inspections, testing materials, and compliance with international standards can add to the overall expense.

-

Logistics: Transportation and shipping costs are critical, particularly for international transactions. Factors such as distance, shipping method, and customs duties can significantly affect the final price. Buyers should consider the most cost-effective logistics solutions to minimize expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely based on market demand, competition, and the perceived value of the service or product.

What Factors Influence Pricing in Leather Softening?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced unit prices due to economies of scale. Understanding the MOQ required by suppliers can help buyers negotiate better pricing.

-

Specifications and Customization: Customized treatments or specific quality requirements may increase costs. Buyers should clearly define their needs to avoid unexpected price hikes.

-

Material Quality and Certifications: The quality of leather and the softening agents used can significantly influence pricing. Certifications for sustainability and quality can also add to costs but may be worth the investment for high-end markets.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven quality may charge more, while newer or less-known suppliers might offer lower prices with varying quality.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is crucial for international buyers. These terms define the responsibilities of buyers and sellers in shipping and can affect total costs significantly.

What Are the Best Practices for Buyers to Optimize Costs?

-

Negotiation: Engaging in negotiations is vital for securing the best prices. Buyers should be prepared with market research and alternative supplier options to leverage during discussions.

-

Cost-Efficiency: Evaluating the Total Cost of Ownership (TCO) is critical. This involves considering not just the purchase price but also maintenance, durability, and potential resale value of leather products.

-

Understanding Pricing Nuances: International buyers should be aware of regional market differences. For instance, suppliers in Africa may offer different pricing structures compared to European counterparts due to local economic conditions.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and more favorable terms over time.

Conclusion

The costs associated with sourcing leather softening solutions are multifaceted, influenced by various components and market dynamics. By understanding these factors and employing strategic purchasing tactics, international B2B buyers can optimize their sourcing decisions and achieve better value for their investments.

Alternatives Analysis: Comparing how do you make leather soft With Other Solutions

Exploring Alternative Solutions for Softening Leather

In the quest to soften leather, various methods and products can be employed, each with its unique advantages and disadvantages. Understanding these alternatives is crucial for B2B buyers, particularly those in industries reliant on leather goods, such as fashion, furniture, and automotive sectors. This section compares the traditional methods of softening leather with other viable alternatives, helping buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | How Do You Make Leather Soft | Natural Oils and Conditioners | Heat Application |

|---|---|---|---|

| Performance | Effective for various leather types; gradual results | Good for conditioning and softening; may take time to see results | Quick results; effective for immediate softening |

| Cost | Moderate (conditioners vary in price) | Generally low-cost (common oils like coconut or olive oil) | Low-cost (requires minimal equipment) |

| Ease of Implementation | Requires several steps (cleaning, applying, buffing) | Simple application process | Requires careful monitoring to avoid damage |

| Maintenance | Regular reapplication needed | Frequent application for best results | Minimal once initial softening is achieved |

| Best Use Case | Ideal for high-quality leather goods requiring long-term care | Suitable for everyday items needing gentle conditioning | Effective for new or stiff leather needing immediate flexibility |

What Are the Benefits and Drawbacks of Natural Oils and Conditioners?

Natural oils and conditioners are popular choices for softening leather due to their accessibility and cost-effectiveness. Oils like coconut and olive provide nourishment to the leather, promoting flexibility and preventing cracking. However, while they are excellent for conditioning, the results may be gradual, requiring multiple applications over time. Additionally, buyers must be cautious about the type of oil used, as some may darken the leather or alter its appearance.

How Does Heat Application Compare to Traditional Softening Methods?

Heat application is another alternative that offers rapid results in softening leather. By carefully applying heat, users can make leather pliable almost immediately. However, this method requires careful monitoring, as excessive heat can damage the leather, leading to irreversible changes. While it is an effective solution for new or particularly stiff leather, it is not recommended for older, delicate pieces that may have already lost some of their natural oils.

Conclusion: Choosing the Right Leather Softening Solution

When selecting the appropriate method for softening leather, B2B buyers should consider the specific requirements of their leather products. For high-quality items that demand long-term care, traditional conditioning methods may be best, providing gradual softening while nourishing the leather. Conversely, for urgent needs or new leather goods, heat application can offer a quick solution, albeit with risks. Natural oils serve as a cost-effective alternative for everyday items but may require consistent reapplication. Ultimately, understanding the nuances of each method will empower buyers to choose the best option to maintain the integrity and softness of their leather goods.

Illustrative image related to how do you make leather soft

Essential Technical Properties and Trade Terminology for how do you make leather soft

When sourcing or manufacturing leather goods, understanding the essential properties and trade terminology related to softening leather is crucial for B2B buyers. This knowledge not only aids in selecting the right materials but also ensures that the final products meet quality standards while catering to market demands.

What Are the Key Technical Properties of Leather for Softening?

1. Tanning Method

The tanning process significantly influences leather’s softness. There are primarily three methods: vegetable tanning, chrome tanning, and oil tanning. Vegetable-tanned leather tends to be softer and more flexible, making it suitable for products requiring comfort. In contrast, chrome-tanned leather is stiffer but water-resistant. Understanding the tanning method allows buyers to choose leather that aligns with their product requirements.

2. Thickness (Gauging)

Leather thickness is measured in ounces or millimeters and impacts its stiffness. Thicker leather is generally more durable but can be less pliable. For instance, garments often require thinner, softer leather, while luggage may utilize thicker options for added durability. B2B buyers must specify the required thickness to ensure the final product meets functional and aesthetic expectations.

3. Grain Type

The grain type refers to the surface texture of the leather, affecting its softness and appearance. Full-grain leather retains the natural texture and is often softer, while corrected grain leather has a uniform finish that may be stiffer. Buyers should assess grain type based on the intended application, as it influences both the product’s feel and longevity.

4. Moisture Content

Leather’s moisture content affects its flexibility and softness. Properly conditioned leather retains moisture, making it supple, while dry leather can become brittle and stiff. Understanding moisture levels is essential for buyers looking to maintain product quality throughout the supply chain.

Illustrative image related to how do you make leather soft

5. Finish Type

Leather finishes, such as aniline or pigmented, can also impact softness. Aniline finishes preserve the leather’s natural feel and softness, while pigmented finishes offer a more durable but potentially stiffer surface. B2B buyers should consider the finish type to align with customer preferences for touch and visual appeal.

What Trade Terminology Should B2B Buyers Understand Regarding Leather?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the leather industry, this term is crucial when sourcing components from suppliers who will customize leather goods according to specific designs or specifications.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest order size a supplier will accept. Understanding MOQ is essential for B2B buyers to manage inventory costs and negotiate favorable terms. It can impact cash flow and inventory management strategies.

3. RFQ (Request for Quotation)

An RFQ is a document issued when a buyer wants to receive price quotes from suppliers. It outlines specifications, including the type of leather, required properties, and quantities. A well-prepared RFQ can streamline the procurement process and facilitate better pricing negotiations.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Understanding these terms is critical for B2B transactions to ensure clarity on shipping, insurance, and risks associated with leather goods.

5. Lead Time

Lead time refers to the duration from order placement to delivery. In the leather industry, lead time can vary based on tanning processes, customization, and shipping logistics. Buyers should factor in lead time when planning production schedules and inventory management.

In conclusion, grasping these essential technical properties and trade terminologies is vital for B2B buyers in the leather industry. This knowledge not only facilitates informed purchasing decisions but also enhances supplier negotiations and overall operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the how do you make leather soft Sector

What Are the Key Market Dynamics and Trends Influencing Leather Softening Techniques?

The leather softening market is witnessing a significant transformation driven by evolving consumer preferences, technological advancements, and the demand for sustainable practices. Globally, buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking leather products that combine durability with comfort. The rise of e-commerce platforms has enabled easier access to diverse leather types and softening products, allowing businesses to explore a wider range of suppliers.

Illustrative image related to how do you make leather soft

Emerging trends in B2B sourcing include the adoption of innovative softening techniques that utilize natural oils and conditioners, catering to the growing demand for environmentally friendly solutions. Technologies such as smart sensors for moisture control and temperature management are also being integrated into leather care practices, ensuring optimal conditions for maintaining leather’s softness and longevity. For instance, suppliers are now offering specialized leather conditioners that not only soften leather but also enhance its resistance to environmental factors, thus prolonging the product’s life cycle.

As international buyers navigate this dynamic market, understanding the specific needs of their customer base is paramount. In regions like Nigeria, where traditional leather goods are prevalent, there is a rising interest in products that reflect both cultural heritage and modern aesthetics. Similarly, European markets are leaning towards premium, artisanal leather goods that emphasize quality and craftsmanship. This interplay of local market demands with global sourcing capabilities defines the current landscape of the leather softening sector.

How Does Sustainability Impact Sourcing Trends in Leather Softening?

Sustainability is increasingly becoming a focal point for B2B buyers in the leather industry. The environmental impact of leather production, particularly concerning water usage and chemical waste, has prompted businesses to seek ethically sourced materials and sustainable practices. Buyers are now prioritizing suppliers who adhere to stringent environmental regulations and employ eco-friendly tanning processes, such as vegetable tanning, which is known for its reduced ecological footprint.

Ethical sourcing is essential not only for compliance with international standards but also for building brand reputation and consumer trust. Companies are increasingly seeking certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification, which assure buyers that the leather products they source are produced sustainably and ethically. This trend is particularly pronounced among European buyers, who often demand transparency in the supply chain and prefer materials that are free from harmful chemicals.

Illustrative image related to how do you make leather soft

The emphasis on sustainability extends to the softening products used in leather care. Many suppliers are now offering biodegradable conditioners and natural oils that align with the ethical values of modern consumers. By choosing sustainable materials and practices, B2B buyers not only contribute to environmental conservation but also tap into a growing market segment that values responsible consumption.

How Has the Leather Softening Industry Evolved Over Time?

The evolution of the leather softening industry is rooted in centuries of craftsmanship, with each era introducing new methods and materials to enhance the properties of leather. Historically, leather was primarily softened through natural processes involving oils and waxes derived from animal fats, which were applied by skilled artisans. However, as industrialization took hold, synthetic tanning and softening agents emerged, offering consistency and cost-effectiveness but often at the expense of environmental health.

In recent decades, there has been a notable shift towards sustainable practices, driven by increased awareness of environmental issues and consumer demand for ethically sourced products. Modern leather softening techniques now blend traditional craftsmanship with innovative technologies, resulting in products that not only meet functional requirements but also align with contemporary values regarding sustainability and ethical production.

This journey reflects the leather industry’s adaptability, responding to changing market dynamics while maintaining its rich heritage. As B2B buyers continue to prioritize quality, sustainability, and ethical sourcing, the leather softening sector is poised to evolve further, embracing new materials and methods that enhance both the product and the planet.

Frequently Asked Questions (FAQs) for B2B Buyers of how do you make leather soft

-

1. How do I solve stiffness in leather products?

To solve stiffness in leather products, start by assessing the type of leather and its condition. Use a high-quality leather conditioner suitable for the specific leather type, applying it evenly after cleaning the surface. For more severe stiffness, consider applying gentle heat to make the leather more pliable. Always test any method on a small, inconspicuous area first to avoid damage. Regular maintenance, such as conditioning and proper storage, will help prevent stiffness in the future. -

2. What is the best method for softening vegetable-tanned leather?

The best method for softening vegetable-tanned leather involves using a specialized leather conditioner that contains natural oils. After cleaning the leather, apply the conditioner generously and allow it to absorb fully. You can also incorporate gentle heat, such as using a hairdryer on a low setting, to help the conditioner penetrate deeper. This method maintains the leather’s breathability and flexibility while preventing it from becoming overly soft or damaged. -

3. Are there specific products recommended for softening leather?

Yes, there are several recommended products for softening leather. Look for leather conditioners that are oil-based, as they effectively nourish and soften the leather. Brands like Lexol and Bickmore offer quality options. Additionally, consider using natural oils like mink oil or neatsfoot oil, which can deeply penetrate and soften tougher leather types. Always check product compatibility with the specific leather type to ensure optimal results. -

4. How can I ensure the quality of leather from international suppliers?

To ensure the quality of leather from international suppliers, conduct thorough research and vetting. Request samples to assess the leather’s texture, flexibility, and finish. Verify the supplier’s certifications, such as compliance with environmental and ethical standards. Engage in direct communication to discuss their tanning processes and sourcing methods, as this will give insight into the quality of the leather provided. -

5. What should I consider when customizing leather orders?

When customizing leather orders, consider the type of leather, thickness, color, and finish that aligns with your product needs. Clearly communicate your specifications, including dimensions and design elements, to the supplier. Be mindful of the minimum order quantities (MOQs) and lead times, as these can vary significantly. It’s also prudent to confirm the supplier’s ability to meet your customization requests without compromising quality. -

6. What are typical payment terms for international leather suppliers?

Typical payment terms for international leather suppliers often range from 30% to 50% upfront, with the balance due upon completion or prior to shipment. Some suppliers may offer net 30 or net 60 terms, allowing buyers to pay after receipt of goods. It’s essential to negotiate terms that suit your cash flow while ensuring you have a reliable contract in place to protect your interests. -

7. How do logistics and shipping impact leather sourcing?

Logistics and shipping significantly impact leather sourcing, as they affect lead times, costs, and product quality. Understand the shipping methods available (air vs. sea) and their associated costs, as air freight is faster but more expensive. Additionally, consider customs regulations and duties in your country, as these can impact overall costs. Establishing a reliable logistics partner can help streamline the process and ensure timely delivery. -

8. How can I manage quality assurance (QA) for leather products?

To manage quality assurance (QA) for leather products, implement a systematic approach that includes regular inspections during production and before shipment. Develop clear quality standards that outline acceptable characteristics such as color, texture, and flexibility. Collaborate closely with your supplier to establish a QA protocol that includes sample testing and detailed reporting on the leather’s properties. Consider third-party inspection services if necessary to ensure compliance with your quality expectations.

Top 6 How Do You Make Leather Soft Manufacturers & Suppliers List

1. Leather Care – Recommended Oils and Conditioners

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Neatsfoot oil – recommended for softening leather. 2. Olive oil – mentioned as an effective alternative. 3. Mink oil – primarily for waterproofing, may leave a sticky surface. 4. Commercial leather conditioners – Lexol was previously favored, but the formula has changed. 5. General advice – oil the leather, let it sit overnight, and wipe off excess with a dry rag. 6. Note that any oil or condit…

2. Vintage Leather – Duffle Bags & Accessories

Domain: vintageleather.store

Registered: 2022 (3 years)

Introduction: Men’s and Women’s Leather Products: Duffle Bags, Messenger Bags, Briefcases, Satchels, Backpacks, Laptop Bags, Camera Bags, Laptop Sleeves, Compendium, Notebook Covers, Toiletry Bags, Sling Bags, Wallets, Leather Journals, Wine Bags, Tobacco Pouches, Passport Wallets, Pencil Cases, Accessories, Glass Cases. Gift options available for Him and Her, with categories for gifts under various price point…

3. OLPR – Leather Waterproof/Repair Cream

Domain: olpr.com

Registered: 2006 (19 years)

Introduction: LEATHER WATERPROOF/REPAIR CREAM BY OLPR. Price: $9.90. Features: Great waterproofing; Powerful restoration; Deeply conditions; Buffs to a beautiful shine; 100% natural & locally sourced; Handmade in the USA. Application: Remove dirt, accumulated grime, and other surface impurities. Apply a tiny amount on a lint-free cloth and rub in a circular motion until the cloth is well coated. When dry, add m…

4. Steel Horse Leather – Weekender & Briefcase Collection

Domain: steelhorseleather.com

Registered: 2019 (6 years)

Introduction: The Dagny Weekender | Large Leather Duffle Bag – $349.00 (was $399.00), The Endre Weekender | Vintage Leather Duffle Bag – $289.00 (was $329.00), The Welch Briefcase | Vintage Leather Messenger Bag – $249.00 (was $279.00), The Hagen Backpack | Vintage Leather Backpack – $249.00 (was $299.00)

5. John Lofgren – Monkey Boots

Domain: thefedoralounge.com

Registered: 2003 (22 years)

Introduction: John Lofgren Monkey Boots Shinki Horsebuttt – $1,136; Grant Stone Diesel Boot Dark Olive Chromexcel – $395; Schott 568 Vandals Jacket – $1,250

6. Manuel Dreesmann – Fiona Bag

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: Fiona Bag: Perfect shoulder bag with zipper. Croissant Bag: Bestseller. Saka Bag: Woven craftsmanship. Small Leather Goods: Wallets, Card & Coin Holders, Key Wallets. Eyewear: Protect your glasses. Device Sleeves: Macbook and iPad sleeves available in any size. Home & Travel Accessories: Range for home and travel. Custom fitted belts and leather bracelets available.

Strategic Sourcing Conclusion and Outlook for how do you make leather soft

In the competitive landscape of leather sourcing, understanding the nuances of how to soften leather is essential for delivering quality products that meet market demands. The key takeaways from this guide emphasize the importance of selecting the appropriate type of leather and employing effective conditioning methods, such as using leather conditioners or applying heat carefully. Each leather type—from chrome-tanned to vegetable-tanned—offers unique benefits and challenges, making it crucial for B2B buyers to match their sourcing strategies with their product goals.

Strategic sourcing not only enhances product quality but also fosters long-term relationships with suppliers who can provide insights into the best practices for leather care and maintenance. By leveraging these insights, businesses can enhance their product offerings and elevate customer satisfaction.

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe should actively seek partnerships with suppliers who prioritize innovation and sustainability in leather treatment. Embrace the opportunity to refine your leather products and gain a competitive edge in your market. Engage with your suppliers today to explore the latest advancements in leather softening techniques and ensure your offerings remain at the forefront of consumer preferences.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.