Introduction: Navigating the Global Market for leather work gloves bulk

In the ever-evolving landscape of global commerce, sourcing high-quality leather work gloves in bulk can be a daunting task for international B2B buyers. Companies from diverse regions, including Africa, South America, the Middle East, and Europe (notably Germany and Nigeria), face unique challenges such as fluctuating prices, varying quality standards, and the need for reliable suppliers. This guide is designed to navigate these complexities, providing actionable insights into the bulk purchasing of leather work gloves that meet specific industry needs.

Throughout this comprehensive resource, we will explore various types of leather work gloves, their applications across different sectors, and essential criteria for vetting suppliers. Additionally, we will delve into cost considerations, highlighting how bulk purchasing can lead to significant savings while ensuring quality and durability. By equipping buyers with the knowledge to make informed decisions, this guide serves as a vital tool for businesses looking to enhance their operational efficiency and worker safety.

Whether you’re involved in construction, agriculture, or logistics, understanding the nuances of leather work gloves will empower you to select the right products that align with your operational goals. With a focus on quality, cost-effectiveness, and supplier reliability, this guide is your roadmap to successful bulk procurement in the global market.

Table Of Contents

- Top 5 Leather Work Gloves Bulk Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather work gloves bulk

- Understanding leather work gloves bulk Types and Variations

- Key Industrial Applications of leather work gloves bulk

- 3 Common User Pain Points for ‘leather work gloves bulk’ & Their Solutions

- Strategic Material Selection Guide for leather work gloves bulk

- In-depth Look: Manufacturing Processes and Quality Assurance for leather work gloves bulk

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather work gloves bulk’

- Comprehensive Cost and Pricing Analysis for leather work gloves bulk Sourcing

- Alternatives Analysis: Comparing leather work gloves bulk With Other Solutions

- Essential Technical Properties and Trade Terminology for leather work gloves bulk

- Navigating Market Dynamics and Sourcing Trends in the leather work gloves bulk Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather work gloves bulk

- Strategic Sourcing Conclusion and Outlook for leather work gloves bulk

- Important Disclaimer & Terms of Use

Understanding leather work gloves bulk Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cowhide Leather Gloves | Durable, abrasion-resistant, and often reinforced | Construction, warehouse work | Pros: Strong durability, versatile. Cons: Heavier than some alternatives. |

| Pigskin Leather Gloves | Soft, flexible, and breathable; often water-resistant | Landscaping, agriculture | Pros: Comfortable and breathable. Cons: Less durable than cowhide. |

| Deerskin Leather Gloves | Soft, supple, and dexterous; provides excellent grip | Automotive, assembly tasks | Pros: High dexterity, good for precision work. Cons: Higher cost. |

| Goatskin Leather Gloves | Lightweight, flexible, and resistant to abrasion | General maintenance, light-duty tasks | Pros: Good balance of comfort and durability. Cons: May not withstand heavy-duty tasks. |

| Welding Leather Gloves | Heat-resistant and reinforced; designed for welding applications | Metalworking, fabrication | Pros: High protection against heat and sparks. Cons: Limited versatility for other tasks. |

What Are the Key Characteristics of Cowhide Leather Gloves for B2B Buyers?

Cowhide leather gloves are known for their strength and durability, making them ideal for rigorous applications such as construction and warehouse operations. Their reinforced palms provide extra protection against abrasions, while the keystone thumb design allows for greater flexibility. B2B buyers should consider the weight of these gloves, as they are typically heavier than alternatives, which may affect comfort during extended use. Bulk purchasing can lead to significant savings, especially for businesses with high-volume glove needs.

How Do Pigskin Leather Gloves Stand Out in the Market?

Pigskin leather gloves are celebrated for their softness and breathability, making them suitable for tasks that require prolonged wear, such as landscaping and agricultural work. They also offer water resistance, which is a valuable feature in outdoor environments. When purchasing in bulk, buyers should weigh the comfort against durability, as pigskin may not hold up as well under heavy-duty conditions compared to cowhide options. However, their affordability and comfort make them a popular choice for many businesses.

Illustrative image related to leather work gloves bulk

Why Choose Deerskin Leather Gloves for Precision Tasks?

Deerskin leather gloves are particularly valued for their suppleness and dexterity, allowing workers to handle small tools and perform intricate tasks with ease. This makes them ideal for applications in the automotive and assembly sectors. While they provide an excellent grip, B2B buyers should be aware that deerskin gloves typically come at a higher price point. When sourcing these gloves in bulk, businesses can benefit from reduced costs while ensuring their workforce has the best tools for precision work.

What Makes Goatskin Leather Gloves a Versatile Option?

Goatskin leather gloves are lightweight and flexible, striking a balance between comfort and durability. They are suitable for general maintenance and light-duty tasks, making them a versatile choice across various industries. B2B buyers should consider their specific needs when selecting goatskin gloves, as they may not be appropriate for heavy-duty applications. However, their affordability and comfort make them an attractive option for businesses looking to equip their employees without sacrificing quality.

What Are the Benefits of Using Welding Leather Gloves?

Welding leather gloves are specially designed to withstand high temperatures and provide protection against sparks and molten metal. They are essential for workers in metalworking and fabrication industries. When purchasing welding gloves in bulk, businesses should look for features such as reinforced seams and heat resistance to ensure maximum safety. While these gloves excel in welding applications, their specialized design may limit their use in other tasks, making them a targeted investment for specific operations.

Key Industrial Applications of leather work gloves bulk

| Industry/Sector | Specific Application of leather work gloves bulk | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Site safety and material handling | Enhanced worker safety and productivity | Durability, grip quality, and compliance with safety standards. |

| Agriculture | Crop handling and livestock management | Protection against cuts and abrasions | Breathability, comfort during prolonged use, and resistance to chemicals. |

| Manufacturing | Assembly line work and machinery operation | Improved dexterity and reduced injury risk | Custom fit, material quality, and bulk pricing options. |

| Logistics & Warehousing | Loading, unloading, and sorting goods | Efficient handling of heavy materials | Grip strength, abrasion resistance, and bulk availability. |

| Oil & Gas | Equipment handling and maintenance | Protection from harsh environments and chemicals | Heat resistance, durability, and compliance with industry-specific standards. |

How Are Leather Work Gloves Bulk Utilized in the Construction Industry?

In the construction sector, leather work gloves are essential for site safety and material handling. Workers frequently encounter rough materials, sharp tools, and heavy equipment, making gloves crucial for preventing injuries. Leather gloves provide superior abrasion resistance and durability, ensuring longevity even in demanding conditions. Buyers must consider gloves that comply with local safety regulations and offer a secure fit to enhance grip and control during tasks.

Illustrative image related to leather work gloves bulk

What Role Do Leather Work Gloves Bulk Play in Agriculture?

In agriculture, leather work gloves are used for crop handling and livestock management. They protect workers’ hands from cuts, abrasions, and exposure to chemicals used in farming. The gloves’ durability is vital for tasks such as pruning and planting, where grip and dexterity are essential. Buyers in regions like Africa and South America should prioritize gloves that offer breathability and comfort, as agricultural work often involves long hours outdoors.

How Do Leather Work Gloves Bulk Benefit the Manufacturing Sector?

Manufacturing environments require gloves that enhance dexterity while providing protection during assembly line work and machinery operation. Leather work gloves bulk can significantly reduce the risk of injuries caused by sharp edges or heavy machinery. Buyers should look for gloves with reinforced stitching and ergonomic designs to ensure comfort during extended use. Additionally, sourcing from suppliers who offer bulk pricing can lead to significant cost savings for manufacturing operations.

What Are the Applications of Leather Work Gloves Bulk in Logistics and Warehousing?

In logistics and warehousing, leather work gloves are utilized for loading, unloading, and sorting goods. The gloves help workers handle heavy materials safely and efficiently, reducing the risk of injury. Key considerations for buyers include the gloves’ grip strength and abrasion resistance, as these factors directly impact productivity. Ensuring a steady supply of gloves in bulk can help businesses maintain operations without interruptions.

Why Are Leather Work Gloves Bulk Important in the Oil and Gas Industry?

In the oil and gas sector, leather work gloves are critical for equipment handling and maintenance in harsh environments. These gloves protect against cuts, abrasions, and exposure to chemicals, ensuring worker safety. Buyers should focus on sourcing gloves that are heat-resistant and comply with industry-specific safety standards. The ability to purchase in bulk can also ensure that companies have adequate supplies for their workforce, enhancing operational efficiency.

Illustrative image related to leather work gloves bulk

3 Common User Pain Points for ‘leather work gloves bulk’ & Their Solutions

Scenario 1: Sizing Issues with Bulk Leather Work Gloves

The Problem: When purchasing leather work gloves in bulk, B2B buyers often face the challenge of ensuring the right fit for their workforce. Misjudging glove sizes can lead to discomfort, reduced productivity, and even safety hazards. For instance, a company may order a large quantity of gloves based on the assumption that most employees wear a standard size. However, variations in hand size and shape among workers can render many gloves unusable, resulting in waste and additional costs to reorder.

The Solution: To mitigate sizing issues, B2B buyers should conduct a thorough assessment of their employees’ hand sizes before placing a bulk order. This can be done by distributing a simple sizing guide or conducting a fitting session. Additionally, consider sourcing gloves from manufacturers that offer a range of sizes and styles, including options for men, women, and specific roles (like welding or heavy-duty tasks). When ordering, request samples in different sizes to ensure a proper fit. This proactive approach not only reduces waste but also enhances employee satisfaction and safety on the job.

Scenario 2: Quality Assurance in Bulk Orders

The Problem: Quality inconsistencies can plague bulk orders of leather work gloves, especially when sourced from different suppliers or manufacturers. A B2B buyer may receive gloves that look good on the outside but fail to meet durability or safety standards. For example, gloves that wear out quickly during heavy use can lead to increased operational costs and potential injuries if the gloves do not provide adequate protection.

The Solution: To ensure consistent quality, B2B buyers should establish a clear set of quality standards and specifications before engaging with suppliers. This includes material type, stitching quality, and safety ratings. It’s beneficial to ask for product samples and conduct wear tests under real working conditions before committing to a large order. Additionally, consider partnering with suppliers who have a proven track record and positive reviews within the industry. Regular communication and feedback with suppliers can also help maintain quality control throughout the ordering process.

Scenario 3: Shipping Delays and Inventory Management

The Problem: Shipping delays can significantly impact operations, particularly in industries that rely on leather work gloves for safety and efficiency. A buyer might face a situation where the ordered gloves do not arrive on time, leading to a shortage of essential protective gear. This can disrupt workflows and compromise employee safety, especially in critical situations where gloves are a necessity.

The Solution: To combat potential shipping delays, B2B buyers should plan their orders well in advance, taking into account lead times for production and shipping, especially if ordering from international suppliers. Establishing relationships with multiple suppliers can provide alternative options if one fails to deliver on time. Additionally, consider maintaining a safety stock of gloves based on historical usage rates to buffer against unexpected delays. Leveraging technology, such as inventory management systems, can also aid in tracking stock levels and ensuring timely reordering, thus minimizing disruptions in operations.

Strategic Material Selection Guide for leather work gloves bulk

When selecting leather work gloves in bulk for various applications, understanding the properties and suitability of different leather types is crucial for international B2B buyers. Below, we analyze four common materials used in leather work gloves, focusing on their performance, advantages, disadvantages, and considerations for buyers from diverse regions.

What Are the Key Properties of Cowhide Leather for Work Gloves?

Cowhide leather is one of the most popular materials for work gloves due to its excellent durability and versatility. It offers good abrasion resistance and can withstand a wide range of temperatures, making it suitable for various industrial applications. Cowhide is also relatively resistant to water and oil, which enhances its usability in environments where exposure to such substances is common.

Pros: Cowhide gloves are durable, provide a good grip, and are often more affordable than other leather types. They are suitable for heavy-duty tasks such as construction, automotive work, and outdoor applications.

Illustrative image related to leather work gloves bulk

Cons: While cowhide is tough, it may not be as flexible as softer leathers, which can limit dexterity. Additionally, it may require more maintenance to keep it in optimal condition.

Impact on Application: Cowhide leather gloves are ideal for tasks involving rough handling, such as construction and warehouse work, where durability is paramount.

Considerations for International Buyers: Compliance with standards like ASTM or EN388 is essential. Buyers in regions like Africa and South America should consider local climate conditions, as cowhide can be less breathable in hot environments.

How Does Pigskin Leather Compare for Work Gloves?

Pigskin leather is known for its softness and flexibility, making it an excellent choice for gloves requiring dexterity. It offers good abrasion resistance and is naturally breathable, which can enhance comfort during prolonged use.

Pros: Pigskin gloves are comfortable, flexible, and resistant to water and oil. They are ideal for tasks requiring precision, such as assembly work or detailed craftsmanship.

Illustrative image related to leather work gloves bulk

Cons: While pigskin is durable, it may not withstand heavy-duty applications as well as cowhide. It is generally more expensive due to its quality.

Impact on Application: Pigskin leather gloves are well-suited for tasks in manufacturing, assembly, and maintenance where dexterity and comfort are critical.

Considerations for International Buyers: Buyers should ensure that pigskin gloves meet local safety standards. In Europe, for instance, compliance with EN standards is crucial for market acceptance.

Illustrative image related to leather work gloves bulk

What Are the Advantages of Deerskin Leather for Work Gloves?

Deerskin leather is prized for its exceptional softness and comfort. It provides excellent dexterity and a natural feel, making it a favorite among workers who require precision.

Pros: Deerskin gloves are incredibly comfortable and conform well to the hand, providing a superior fit. They also have good abrasion resistance.

Cons: The main drawback is the higher cost compared to cowhide and pigskin. Additionally, deerskin may not be as durable in extremely rugged applications.

Impact on Application: Deerskin gloves are ideal for tasks such as driving, light construction, and outdoor activities where comfort and dexterity are prioritized.

Considerations for International Buyers: Buyers should be aware of sourcing regulations and animal welfare standards in their respective countries, particularly in Europe, where regulations can be stringent.

What Makes Goatskin Leather a Suitable Option for Work Gloves?

Goatskin leather is known for its softness and strength. It provides excellent abrasion resistance and is often used in gloves that require both durability and dexterity.

Pros: Goatskin gloves are lightweight, flexible, and provide a high level of comfort. They are also resistant to punctures and tears.

Cons: While goatskin is durable, it can be more expensive than cowhide, which may affect bulk purchasing decisions.

Impact on Application: Goatskin gloves are suitable for automotive work, assembly, and other tasks that require a good balance of strength and dexterity.

Illustrative image related to leather work gloves bulk

Considerations for International Buyers: Buyers should check for compliance with relevant safety standards, as goatskin gloves may be subject to different regulations in various regions.

Summary Table of Material Selection for Leather Work Gloves Bulk

| Material | Typical Use Case for leather work gloves bulk | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Heavy-duty tasks (construction, outdoor work) | Durable and abrasion-resistant | Less flexible, requires maintenance | Medium |

| Pigskin | Precision tasks (assembly, manufacturing) | Soft, flexible, breathable | Not as durable for heavy-duty use | High |

| Deerskin | Light construction, driving | Exceptional comfort and dexterity | Higher cost, less rugged | High |

| Goatskin | Automotive work, assembly | Lightweight, puncture-resistant | More expensive than cowhide | Medium to High |

This analysis provides B2B buyers with critical insights into material selection for leather work gloves, helping them make informed purchasing decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for leather work gloves bulk

What Are the Key Stages in the Manufacturing Process of Leather Work Gloves in Bulk?

The manufacturing process for leather work gloves involves several critical stages that ensure the final product meets quality and durability standards. Understanding these stages helps B2B buyers assess the reliability of suppliers and the quality of their products.

1. Material Preparation: What Materials Are Essential for Quality Leather Gloves?

The first step in manufacturing leather work gloves is selecting the right type of leather. Common materials include cowhide, pigskin, and goatskin, each offering different levels of durability, comfort, and flexibility.

Illustrative image related to leather work gloves bulk

Once the leather is selected, it undergoes a tanning process to enhance its durability and resistance to moisture. This step is crucial, as it affects the glove’s lifespan and performance in various working conditions. After tanning, the leather is cut into specific patterns according to the glove design.

2. Forming: How Is the Leather Shaped Into Gloves?

Forming involves shaping the cut leather pieces into glove structures. This process typically employs techniques such as:

- Molding: Leather pieces are shaped using molds that ensure a proper fit and ergonomic design.

- Stitching: Heavy-duty stitching is used to assemble the glove components. Techniques such as double stitching are common to enhance durability, especially in high-stress areas like the palm and fingers.

This stage is vital for ensuring that gloves not only fit well but also provide the necessary protection and flexibility for various tasks.

3. Assembly: What Are the Key Steps in Assembling Leather Gloves?

During assembly, all parts of the glove are put together. This includes attaching components such as:

- Cuffs: Ensuring the glove fits snugly on the wrist.

- Reinforcements: Adding materials to high-wear areas, such as the palms and fingertips, to increase longevity.

Each glove is typically assembled by skilled workers who ensure that every stitch and seam is secure, which is critical for maintaining quality standards.

4. Finishing: What Processes Are Involved in Finalizing the Gloves?

The finishing stage includes several processes that enhance the glove’s aesthetics and functionality:

- Trimming: Excess leather and threads are cut off to create a clean finish.

- Conditioning: Leather conditioners are applied to maintain suppleness and prevent cracking.

- Quality Control: Before packaging, each glove undergoes a final inspection to ensure it meets the required standards.

Finishing not only improves the visual appeal of the gloves but also contributes to their overall performance.

What Quality Control Measures Should B2B Buyers Look For?

Quality assurance is paramount in the manufacturing of leather work gloves. Various international and industry-specific standards ensure that products meet safety and performance requirements.

Relevant International Standards: Which Certifications Should Be Considered?

- ISO 9001: This standard focuses on quality management systems and ensures consistent quality in production processes.

- CE Marking: For gloves sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For gloves used in specific industries such as oil and gas, compliance with American Petroleum Institute standards can be crucial.

Understanding these certifications helps buyers verify that suppliers adhere to high-quality standards.

Illustrative image related to leather work gloves bulk

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected for quality before use.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted during manufacturing to identify issues early.

- Final Quality Control (FQC): Completed gloves undergo a thorough inspection for defects and compliance with specifications before packaging.

These checkpoints help ensure that only high-quality products are delivered to buyers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers:

1. Conducting Supplier Audits: What to Look For?

Requesting audits of suppliers can provide insights into their manufacturing processes and quality control measures. During an audit, buyers should focus on:

- Compliance with relevant standards and certifications.

- Documentation of quality control procedures and testing results.

- Evidence of continuous improvement initiatives.

2. Reviewing Quality Assurance Reports: What Information Is Essential?

Quality assurance reports provide detailed insights into the testing methods and outcomes used throughout the manufacturing process. Buyers should look for:

- Testing methods used (e.g., abrasion resistance, tensile strength).

- Frequency of testing and any historical data indicating consistency in quality.

- Records of customer feedback and how it has been addressed.

3. Engaging Third-Party Inspection Services: Why Is This Important?

Third-party inspections can further validate a supplier’s claims regarding their quality control processes. Engaging an independent service allows buyers to:

- Obtain unbiased assessments of manufacturing practices.

- Ensure that products meet the required specifications before shipment.

- Reduce risks associated with receiving subpar products.

What Quality Control Nuances Should International Buyers Consider?

International buyers must navigate specific quality control nuances that can affect their procurement strategies. For instance:

Illustrative image related to leather work gloves bulk

- Cultural Differences: Understanding regional manufacturing practices and quality expectations can help avoid miscommunications.

- Logistical Challenges: Ensure that quality control measures are consistent across different manufacturing facilities, especially for bulk orders.

- Legal Regulations: Be aware of import regulations and compliance standards in the buyer’s home country, which can vary significantly across regions such as Africa, South America, the Middle East, and Europe.

By addressing these nuances, international buyers can establish more effective partnerships with their suppliers.

Conclusion

The manufacturing processes and quality assurance measures for leather work gloves are integral to delivering high-quality products that meet the demands of various industries. B2B buyers should prioritize understanding these processes and actively engage in verifying quality control practices to ensure they receive durable and reliable gloves that enhance safety and productivity in their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather work gloves bulk’

To effectively source leather work gloves in bulk for your business needs, following a structured approach is essential. This guide outlines key steps to ensure you find the right products and suppliers that meet your requirements.

Step 1: Define Your Technical Specifications

Establishing clear specifications for the leather work gloves you need is crucial. Consider factors such as glove material (e.g., cowhide, pigskin), intended use (e.g., construction, gardening), and necessary features (e.g., reinforced palms, waterproofing). Defining these elements will help you narrow down options and communicate effectively with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies with a strong track record in the leather goods industry. Utilize online platforms, trade shows, and industry directories to compile a list of potential partners. Pay attention to their market presence, customer reviews, and product range.

Step 3: Evaluate Supplier Certifications and Compliance

Before making a commitment, verify that your chosen suppliers comply with relevant industry standards and certifications. This step is vital for ensuring product quality and safety. Look for certifications such as ISO 9001 for quality management and relevant safety standards that apply to leather goods.

Step 4: Request Samples for Quality Assessment

Request samples from shortlisted suppliers to assess the quality of their leather work gloves. This hands-on evaluation is critical for determining whether the gloves meet your specifications regarding durability, comfort, and functionality. Check for stitching quality, thickness of the leather, and overall craftsmanship.

Step 5: Discuss Bulk Pricing and Terms

Engage in discussions about pricing structures, especially for bulk orders. Many suppliers offer tiered pricing based on order quantity, which can lead to significant cost savings. Ensure you understand the payment terms, lead times, and shipping options to avoid any surprises later.

Step 6: Inquire About Customization Options

If your business has specific branding or functional requirements, inquire about customization options. Many suppliers can provide personalized branding, such as logos or colors, which can enhance your company’s visibility. Ensure that any customization does not compromise the gloves’ quality or lead time.

Step 7: Establish Clear Communication Channels

Effective communication is essential throughout the sourcing process. Confirm the preferred communication methods with your supplier and establish regular check-ins. This practice will help address any concerns promptly and ensure that both parties remain aligned on expectations and timelines.

By following these steps, you can streamline your sourcing process for bulk leather work gloves, ensuring that you select high-quality products from reliable suppliers that meet your business needs.

Comprehensive Cost and Pricing Analysis for leather work gloves bulk Sourcing

What Are the Key Cost Components for Bulk Leather Work Gloves Sourcing?

When sourcing leather work gloves in bulk, understanding the cost structure is essential. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of leather significantly impacts the cost. Cowhide, pigskin, and goatskin vary in price, with cowhide typically being more expensive due to its durability and versatility. Additionally, any specialized materials for features like reinforced palms or thermal linings will add to the base cost.

-

Labor: Skilled labor is required for cutting, stitching, and assembling leather gloves. Labor costs can vary widely based on the region. For instance, labor in countries like Germany may be higher than in Nigeria or other developing nations.

-

Manufacturing Overhead: This includes the costs associated with running production facilities, such as utilities, equipment maintenance, and administrative expenses. Overhead can fluctuate based on the location of the manufacturer and the efficiency of their operations.

-

Tooling: Initial tooling costs for molds and machinery can be significant, especially for custom designs. Suppliers may require upfront investments that can influence the final price of bulk orders.

-

Quality Control (QC): Ensuring the gloves meet safety and quality standards incurs additional costs. Certifications (e.g., EN 388 for abrasion resistance) may also necessitate investment in testing and compliance, which can be passed on to buyers.

-

Logistics: Shipping costs are affected by distance, shipping methods, and import/export duties. For international buyers, understanding the implications of Incoterms (e.g., FOB, CIF) is crucial for accurately calculating total logistics costs.

-

Margin: Suppliers will add a profit margin, which can vary based on competition, demand, and the exclusivity of the product. Understanding typical markups in different regions can aid in negotiation.

How Do Price Influencers Impact Bulk Leather Work Gloves?

Several factors influence the pricing of leather work gloves, particularly for bulk orders.

-

Volume/MOQ: The quantity ordered often dictates price breaks. Suppliers typically offer discounts for larger volumes, incentivizing bulk purchases. For example, a supplier may provide a 20% discount for orders of 12-23 pairs and a 24% discount for orders of 24 or more.

-

Specifications and Customization: Custom features such as logo embroidery or specific sizing requirements can increase costs. Buyers should weigh the benefits of customization against the potential increase in price.

-

Quality and Certifications: Higher quality gloves that meet specific safety standards often come at a premium. Buyers should consider the total cost of ownership when evaluating these gloves, as higher upfront costs may lead to reduced replacement rates and better worker safety.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge more, but they also provide peace of mind regarding product consistency and reliability.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They define responsibilities for shipping, insurance, and tariffs, which can significantly impact the overall cost.

What Are the Best Negotiation Tips for International Buyers?

-

Leverage Volume Discounts: Always inquire about bulk pricing and potential discounts. Suppliers are often willing to negotiate on large orders.

-

Consider Total Cost of Ownership: Focus on long-term value rather than just the initial purchase price. This includes assessing durability, safety features, and potential costs associated with replacements.

-

Understand Local Market Dynamics: Familiarize yourself with regional pricing norms and competitor offerings to strengthen your negotiation position.

-

Be Open to Alternative Suppliers: If a supplier is unwilling to negotiate, exploring alternative manufacturers can provide leverage in discussions.

-

Factor in Shipping and Duties: Ensure that any agreed-upon price includes all costs associated with delivery to your location, including tariffs and other fees.

Disclaimer on Indicative Prices

Prices for leather work gloves can fluctuate based on market conditions, material availability, and supplier pricing strategies. Always request the latest quotes and verify details before finalizing any purchase agreements.

Alternatives Analysis: Comparing leather work gloves bulk With Other Solutions

When considering the procurement of protective gear for industrial applications, B2B buyers often explore various solutions to meet their specific needs. Leather work gloves in bulk are a popular choice due to their durability and versatility. However, it’s crucial to evaluate alternative options that may offer comparable benefits. Below, we compare leather work gloves with synthetic gloves and safety mitts, focusing on key performance aspects.

Illustrative image related to leather work gloves bulk

| Comparison Aspect | Leather Work Gloves Bulk | Synthetic Gloves | Safety Mitts |

|---|---|---|---|

| Performance | Excellent abrasion resistance; ideal for heavy-duty tasks. | Good grip and dexterity; suitable for light to medium tasks. | High protection against impacts; less dexterous. |

| Cost | Moderate initial investment; bulk pricing available. | Generally lower cost per unit; ideal for high-volume use. | Higher upfront cost; may require replacement more frequently. |

| Ease of Implementation | Simple to integrate into existing workflows. | Easy to stock and distribute; lightweight. | Requires training for proper use; may need adjustments for specific tasks. |

| Maintenance | Requires occasional cleaning; long-lasting. | Disposable options available; no maintenance needed. | Durable but may need regular inspection for wear and tear. |

| Best Use Case | Construction, agriculture, and outdoor work requiring durability. | Warehousing, assembly lines, and tasks requiring fine motor skills. | High-risk environments where impact protection is critical. |

What Are the Benefits of Using Synthetic Gloves as an Alternative?

Synthetic gloves are a viable alternative for many industries, especially where dexterity is essential. They are often made from materials like nitrile or latex, providing good flexibility and grip. The cost per unit is generally lower than leather gloves, making them suitable for high-volume applications. However, they may not offer the same level of abrasion resistance, making them less ideal for heavy-duty tasks.

How Do Safety Mitts Compare to Leather Work Gloves?

Safety mitts are designed to provide high levels of impact and cut protection, making them suitable for tasks that involve heavy machinery or sharp objects. While they excel in safety features, they often compromise on dexterity and may not be suitable for tasks requiring precision. Additionally, safety mitts can come at a higher cost, which may affect budget considerations for B2B buyers.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate protective gear requires a thorough understanding of specific workplace conditions and requirements. B2B buyers should assess the nature of the tasks their workforce will engage in, the level of protection needed, and budget constraints. While leather work gloves in bulk provide durability and versatility, alternatives like synthetic gloves and safety mitts may better suit specific applications, especially where dexterity or impact protection is prioritized. A comprehensive evaluation will ensure that the chosen solution aligns with safety standards and operational efficiency, ultimately benefiting the workforce and the bottom line.

Illustrative image related to leather work gloves bulk

Essential Technical Properties and Trade Terminology for leather work gloves bulk

What Are the Essential Technical Properties of Leather Work Gloves in Bulk Purchases?

Understanding the critical specifications of leather work gloves is essential for B2B buyers, especially when sourcing in bulk. Here are some key properties that should be considered:

1. Material Grade

Leather work gloves are commonly made from various grades of leather, including cowhide, pigskin, and goatskin. Cowhide is known for its durability and abrasion resistance, making it suitable for heavy-duty tasks. Understanding the material grade helps buyers ensure they are selecting gloves that meet the specific demands of their work environment, such as exposure to harsh conditions or frequent wear.

2. Thickness

The thickness of the leather, typically measured in ounces or millimeters, significantly affects the gloves’ durability and protection level. Thicker gloves offer better abrasion resistance and protection against cuts, but may compromise dexterity. Buyers should balance thickness with the required tactile sensitivity for their workers’ tasks, ensuring safety without sacrificing performance.

3. Stitching Quality

The quality and type of stitching used in leather gloves are indicators of their durability. Heavy-duty stitching, often reinforced at stress points, ensures that the gloves can withstand rigorous use without tearing or coming apart. For B2B buyers, evaluating stitching quality is crucial for ensuring long-term value and reducing replacement costs.

4. Fit and Design Features

Gloves come in various designs, including keystone thumb construction, which allows for better dexterity and comfort. Features such as elastic shirred backs can enhance fit and prevent slipping during use. Choosing the right design is essential for maintaining worker comfort and efficiency, which can directly impact productivity.

5. Abrasion Resistance

This property measures how well the gloves can withstand wear and tear from friction. Gloves with high abrasion resistance are ideal for tasks involving rough surfaces or heavy handling. For companies with specific safety regulations, abrasion resistance can be a critical factor in compliance and risk management.

6. Insulation and Weather Resistance

For outdoor applications, gloves with insulation or weather-resistant properties are essential. Insulated gloves protect workers from cold temperatures, while water-resistant gloves keep hands dry in wet conditions. Buyers in regions with extreme weather conditions should prioritize these features to ensure worker safety and comfort.

What Are the Common Trade Terms Used in the Leather Work Gloves Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential trade terms relevant to B2B buyers:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of leather work gloves, OEMs can provide customized designs or specifications, allowing buyers to brand gloves according to their needs.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for buyers as it can affect inventory levels and cash flow. Buyers should negotiate MOQs to align with their operational needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products. It typically includes details about quantities, specifications, and delivery timelines. A well-prepared RFQ can lead to better pricing and terms from suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms helps buyers assess shipping costs, risks, and responsibilities, ensuring clarity in international transactions.

5. Lead Time

Lead time refers to the time taken from placing an order until its delivery. This is crucial for B2B buyers as longer lead times can impact project timelines and operational efficiency. Buyers should communicate their lead time requirements clearly to suppliers.

6. Certification Standards

These are industry-specific standards that gloves must meet to ensure safety and performance. Common certifications include ANSI/ISEA for cut resistance and EN388 for abrasion resistance. Buyers should verify that the gloves they are sourcing comply with relevant certification standards to ensure they meet safety regulations.

Illustrative image related to leather work gloves bulk

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right leather work gloves for their specific needs while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the leather work gloves bulk Sector

What Are the Current Market Dynamics and Key Trends Influencing the Leather Work Gloves Bulk Sector?

The leather work gloves market is experiencing significant growth driven by increased demand across various industries, including construction, agriculture, and manufacturing. Key global drivers include the rise in workplace safety regulations and a heightened focus on employee protection, which mandates the use of high-quality personal protective equipment (PPE). As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, seek reliable sourcing options, they must navigate an evolving landscape marked by several key trends.

Emerging B2B technology is reshaping the sourcing process, with digital platforms enabling bulk purchases and streamlined supply chain management. E-commerce solutions are becoming essential, allowing buyers to compare products, prices, and suppliers quickly. Additionally, the trend toward customization is gaining traction; businesses are increasingly looking for gloves tailored to specific tasks or industries, which necessitates flexible manufacturing processes from suppliers.

Moreover, sustainability is becoming a crucial factor in purchasing decisions. Buyers are more inclined to partner with manufacturers who demonstrate a commitment to ethical sourcing and environmentally friendly practices. This shift is not only driven by consumer preferences but also by regulatory pressures that demand higher standards in production and supply chain transparency.

How Important Is Sustainability and Ethical Sourcing in the Leather Work Gloves Market?

Sustainability and ethical sourcing are increasingly pivotal in the leather work gloves sector, reflecting broader trends in global supply chains. The environmental impact of leather production, including resource consumption and waste generation, has prompted buyers to seek out suppliers who prioritize sustainable practices. This includes using environmentally friendly tanning processes, minimizing water usage, and ensuring that the leather is sourced from responsible farms that adhere to animal welfare standards.

Ethical supply chains are essential for building brand reputation and customer loyalty. Buyers in regions such as Europe and North America are particularly sensitive to issues related to sustainability, often favoring suppliers who can provide certifications and transparency about their sourcing methods. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming increasingly valuable as they assure buyers of a product’s eco-friendliness and ethical origins.

Furthermore, the demand for ‘green’ materials is on the rise. Innovations in synthetic leather and alternative materials that reduce the environmental footprint are being explored, providing buyers with more options that align with sustainability goals. As the market evolves, those who invest in sustainable practices and ethical sourcing will likely gain a competitive edge.

Illustrative image related to leather work gloves bulk

What Is the Historical Context of Leather Work Gloves in the B2B Sector?

The evolution of leather work gloves has been shaped by both technological advancements and changing labor needs. Historically, leather gloves were primarily handcrafted, focusing on durability and protection for manual laborers. As industries grew and safety regulations emerged in the mid-20th century, the demand for standardized, high-quality gloves surged, prompting manufacturers to adopt mass production techniques.

Over the years, innovations in materials and design have enhanced the functionality and comfort of leather work gloves. Features such as reinforced stitching, ergonomic designs, and moisture-wicking linings have become standard, catering to the diverse needs of various industries. This evolution reflects a broader trend toward increased worker safety and comfort, making leather gloves a staple in many sectors.

Today, as the market continues to adapt to new challenges and opportunities, understanding this historical context can inform B2B buyers about the importance of selecting suppliers who combine tradition with modern technological advancements and sustainability practices.

Frequently Asked Questions (FAQs) for B2B Buyers of leather work gloves bulk

-

1. How do I choose the right leather work gloves for my business needs?

Selecting the appropriate leather work gloves involves assessing the specific tasks and environments your employees will be working in. Consider factors such as the type of leather (cowhide, pigskin, etc.), thickness, and whether you need additional features like reinforced palms or insulation for cold weather. Additionally, evaluate the gloves’ durability and comfort, as well as any industry-specific requirements, such as cut resistance for manufacturing. Always request samples before bulk purchasing to ensure they meet your standards. -

2. What factors should I consider when sourcing leather work gloves from international suppliers?

When sourcing leather work gloves from international suppliers, consider their reputation, manufacturing capabilities, and compliance with safety standards. Verify their certifications, such as ISO or CE marks, to ensure quality and safety. Additionally, assess their ability to meet your order quantities, lead times, and flexibility for customization. It’s advisable to conduct due diligence through references or third-party audits to avoid potential risks associated with international trade. -

3. What are the minimum order quantities (MOQ) for bulk leather work gloves?

Minimum order quantities (MOQ) for bulk leather work gloves can vary significantly based on the supplier and the specific product. Typically, MOQs can range from 100 to several thousand pairs. It’s important to discuss your needs with potential suppliers to negotiate favorable terms. Some suppliers may offer lower MOQs for first-time buyers or for specific styles, while others might have higher thresholds for customized gloves. Always clarify MOQs before placing an order to ensure it aligns with your budget and inventory requirements. -

4. What customization options are available for bulk leather work gloves?

Customization options for bulk leather work gloves often include adding your company logo, selecting specific colors, and choosing materials that meet your operational needs. Some suppliers also offer tailored features, such as different cuff styles or additional padding, to enhance functionality. To explore these options, contact the supplier directly and provide detailed specifications. Customizing gloves can help reinforce brand identity and ensure that the gloves meet the specific requirements of your workforce. -

5. What are typical payment terms for purchasing leather work gloves in bulk?

Payment terms for bulk purchases of leather work gloves can vary widely among suppliers. Common arrangements include partial upfront payments (typically 30-50%) with the balance due upon delivery, or payment in full before shipment. For large orders, suppliers may offer more flexible payment terms, including letters of credit or payment after receipt, depending on your relationship with them. Always clarify payment terms upfront to avoid misunderstandings and ensure a smooth transaction process. -

6. How can I ensure the quality of leather work gloves I purchase in bulk?

To ensure the quality of bulk leather work gloves, request samples before placing a large order to evaluate the fit, comfort, and durability. Look for gloves made from high-quality leather with proper stitching and finishing. Consider suppliers that provide quality assurance guarantees or certifications. Establishing a clear quality control process, including inspections during production and before shipment, can help mitigate risks and ensure that the gloves meet your expectations. -

7. What logistics considerations should I keep in mind when importing leather work gloves?

When importing leather work gloves, consider shipping methods, customs regulations, and potential tariffs in your destination country. Assess the total landed cost, including freight, duties, and taxes, to avoid unexpected expenses. Choose reliable logistics partners who have experience with international shipping and can provide tracking. Planning for lead times and potential delays is also crucial, especially when sourcing from different continents. Proper logistics planning can ensure timely delivery and inventory management. -

8. How do I handle returns or exchanges for bulk orders of leather work gloves?

Handling returns or exchanges for bulk orders of leather work gloves requires understanding the supplier’s return policy. Ensure you have a clear agreement on the conditions under which returns are accepted, such as defective products or incorrect shipments. Document any issues with photos and descriptions to support your case. Communicate promptly with the supplier to initiate the return process and keep records of all correspondence. A well-defined return process can help maintain a good relationship with your supplier while ensuring your operational needs are met.

Top 5 Leather Work Gloves Bulk Manufacturers & Suppliers List

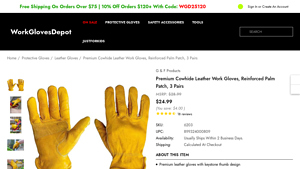

1. Work Gloves Depot – Premium Cowhide Leather Work Gloves

Domain: workglovesdepot.com

Registered: 2005 (20 years)

Introduction: Premium Cowhide Leather Work Gloves, Reinforced Palm Patch, 3 Pairs

– MSRP: $28.99

– Sale Price: $24.99 (You save: $4.00)

– SKU: 6203

– UPC: 899324000809

– Availability: Usually ships within 2 business days

– Features:

– Premium leather gloves with keystone thumb design

– Washable and durable

– Elastic shirred back for secure fit

– Versatile for drivers, utility, warehouse, and outdoor ta…

2. MCR Safety – Premium Gold Elkskin Welder

Domain: shop.mcrsafety.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “Bulk Leather Gloves”, “price”: {“single_pair”: “$12.00”, “dozen”: “$144.00”}, “sizes_available”: [“XL”], “ansi_ratings”: {“abrasion”: 4, “contact_heat”: 5, “puncture”: 5}, “leather_type”: “Elk”, “products”: [{“model”: “P49751”, “description”: “Premium Gold Elkskin Welder”, “sold_by”: “Pair”}, {“model”: “P49750”, “description”: “Premium Pearl Gray Elkskin Welder”, “sold_by”: “Pair…

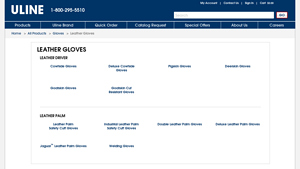

3. ULINE – Leather Gloves

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Leather Gloves, Leather Palm Work Gloves in Stock – ULINE. Types include Leather Driver Cowhide Gloves, Deluxe Cowhide Gloves, Pigskin Gloves, Deerskin Gloves, Goatskin Gloves, Goatskin Cut Resistant Gloves, Leather Palm Safety Cuff Gloves, Industrial Leather Palm Safety Cuff Gloves, Double Leather Palm Gloves, Deluxe Leather Palm Gloves, Jaguar ™ Leather Palm Gloves, Welding Gloves.

4. Safety Gear – Leather Work Gloves

Domain: safetygear.com

Registered: 1999 (26 years)

Introduction: This company, Safety Gear – Leather Work Gloves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Safety Smart Gear – Wholesale Work Gloves

Domain: safetysmartgear.com

Registered: 2006 (19 years)

Introduction: Best Wholesale Work Gloves for the Job. Categories include: High Visibility Clothing, Accessories, Bibs/Overalls, Coveralls, Cold Weather Coveralls, Hoodies, Jackets, Kids Hi Vis Pants, Rain Gear, Safety Vests, Shirts, Sweatshirts, T-Shirts, Women’s Hi Vis, Flame Resistant Clothing, PPE, Ergonomic Supports, Hand Protection, Head Protection, Hearing Protection, Industrial Rain Gear, Lighting Safety…

Strategic Sourcing Conclusion and Outlook for leather work gloves bulk

In conclusion, effective strategic sourcing of leather work gloves in bulk can significantly enhance operational efficiency and cost-effectiveness for businesses across various sectors. By leveraging bulk purchasing options, companies can benefit from substantial discounts, ensuring they receive high-quality gloves while optimizing their budget. The durability and versatility of leather work gloves make them ideal for a range of applications, from construction to agriculture, appealing to diverse international markets.

As global demand for protective gear continues to rise, particularly in regions like Africa, South America, the Middle East, and Europe, international B2B buyers must remain proactive in their sourcing strategies. Engaging with reputable suppliers who offer transparent bulk pricing and reliable shipping options is crucial.

Illustrative image related to leather work gloves bulk

Looking ahead, businesses should prioritize building long-term relationships with suppliers to ensure consistent quality and availability of products. By doing so, they can not only safeguard their workforce but also position themselves competitively in their respective markets. Take the next step in your sourcing strategy—explore the vast options available for bulk leather work gloves and secure the best deals for your organization today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.