Introduction: Navigating the Global Market for custom patches for leather vest

In today’s competitive landscape, sourcing high-quality custom patches for leather vests presents a unique challenge for international B2B buyers. As the demand for personalized and distinctive motorcycle gear grows, companies must navigate a myriad of options while ensuring that their selections align with brand identity and customer preferences. This comprehensive guide addresses these complexities by detailing various types of custom patches, their applications, and the critical factors to consider when vetting suppliers.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including markets in Saudi Arabia and Vietnam—will find invaluable insights into the intricacies of the custom patches market. This guide not only outlines the diverse styles available, from embroidered logos to intricate designs, but also explores the cost implications, production timelines, and quality assurance processes that can significantly impact purchasing decisions.

By empowering buyers with actionable knowledge and strategic sourcing tactics, this guide aims to streamline the procurement process and foster successful partnerships with reliable suppliers. Whether you are looking to enhance your product offerings or establish a unique brand presence, understanding the global landscape of custom patches for leather vests is essential for making informed decisions that resonate with your target market.

Table Of Contents

- Top 7 Custom Patches For Leather Vest Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom patches for leather vest

- Understanding custom patches for leather vest Types and Variations

- Key Industrial Applications of custom patches for leather vest

- 3 Common User Pain Points for ‘custom patches for leather vest’ & Their Solutions

- Strategic Material Selection Guide for custom patches for leather vest

- In-depth Look: Manufacturing Processes and Quality Assurance for custom patches for leather vest

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom patches for leather vest’

- Comprehensive Cost and Pricing Analysis for custom patches for leather vest Sourcing

- Alternatives Analysis: Comparing custom patches for leather vest With Other Solutions

- Essential Technical Properties and Trade Terminology for custom patches for leather vest

- Navigating Market Dynamics and Sourcing Trends in the custom patches for leather vest Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom patches for leather vest

- Strategic Sourcing Conclusion and Outlook for custom patches for leather vest

- Important Disclaimer & Terms of Use

Understanding custom patches for leather vest Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Embroidered Patches | High durability, intricate designs, and vibrant colors | Motorcycle clubs, fashion brands, promotional events | Pros: Long-lasting, customizable. Cons: Higher production cost. |

| Woven Patches | Flat, detailed designs with a smooth finish | Corporate branding, team uniforms | Pros: Cost-effective, lightweight. Cons: Less durable than embroidered. |

| Leather Patches | Made from genuine leather, offering a rugged aesthetic | High-end fashion, custom apparel | Pros: Unique look, premium feel. Cons: Higher material costs, limited design complexity. |

| PVC Patches | Flexible, waterproof, and colorful | Outdoor gear, sports apparel | Pros: Weather-resistant, easy to clean. Cons: Less traditional appearance. |

| Sublimation Patches | Full-color prints on fabric, ideal for complex designs | Promotional items, event giveaways | Pros: Unlimited color options, high detail. Cons: Limited to lighter fabrics. |

What Are Embroidered Patches and Their B2B Suitability?

Embroidered patches are a staple in the custom patch market, known for their durability and intricate designs. Typically made from threads stitched onto fabric, these patches can incorporate detailed logos or artwork. They are highly suitable for motorcycle clubs and fashion brands looking to establish a strong visual identity. When purchasing, B2B buyers should consider the production cost, as embroidered patches can be pricier than other types, but they offer longevity and a premium feel that justifies the investment.

Why Choose Woven Patches for Corporate Branding?

Woven patches are characterized by their flat designs, which allow for fine detailing while maintaining a smooth finish. They are particularly popular in corporate branding and team uniforms due to their cost-effectiveness and lightweight nature. B2B buyers should evaluate the intended use and budget, as woven patches provide a balance between quality and affordability, making them an excellent choice for companies looking to enhance their brand visibility without significant expenditure.

What Are the Benefits of Leather Patches?

Leather patches offer a rugged aesthetic that is often associated with high-end fashion and custom apparel. Made from genuine leather, these patches are not only stylish but also durable, appealing to brands that emphasize quality. B2B buyers should be aware of the higher material costs and limited design complexity, which may restrict the use of colors and intricate patterns. However, the unique look of leather patches can significantly elevate a product’s appeal in a competitive market.

Illustrative image related to custom patches for leather vest

How Do PVC Patches Stand Out in Outdoor Gear?

PVC patches are a modern alternative, made from flexible, waterproof materials that are ideal for outdoor gear and sports apparel. Their vibrant colors and ability to withstand various weather conditions make them popular among brands targeting adventure enthusiasts. B2B buyers should consider the trade-off between traditional aesthetics and the practical benefits of PVC patches. While they may lack the classic look of embroidered options, their resilience and ease of cleaning make them a practical choice for specific applications.

Why Are Sublimation Patches Ideal for Promotional Items?

Sublimation patches utilize a printing process that allows for full-color designs on fabric, making them perfect for promotional items and event giveaways. These patches can achieve high detail and unlimited color options, appealing to brands that want to make a bold statement. However, they are best suited for lighter fabrics, which may limit their application in certain contexts. B2B buyers should assess the fabric type and desired visual impact when considering sublimation patches for their marketing efforts.

Key Industrial Applications of custom patches for leather vest

| Industry/Sector | Specific Application of custom patches for leather vest | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Clubs | Custom patches for club affiliation and identity | Enhances community identity and member loyalty | Quality of embroidery, durability, and design flexibility |

| Fashion Retail | Unique branding elements for leather apparel | Distinguishes products in a competitive market | Customization options, lead times, and minimum order quantities |

| Military and Tactical Gear | Identification and morale patches | Boosts unit cohesion and enhances brand visibility | Compliance with military specifications and material durability |

| Promotional Merchandise | Branded patches for events and giveaways | Increases brand visibility and customer engagement | Cost-effectiveness, design complexity, and production timelines |

| Custom Apparel Manufacturing | Patches as design elements for bespoke leather vests | Adds unique value and personalization to products | Material compatibility, production scalability, and turnaround time |

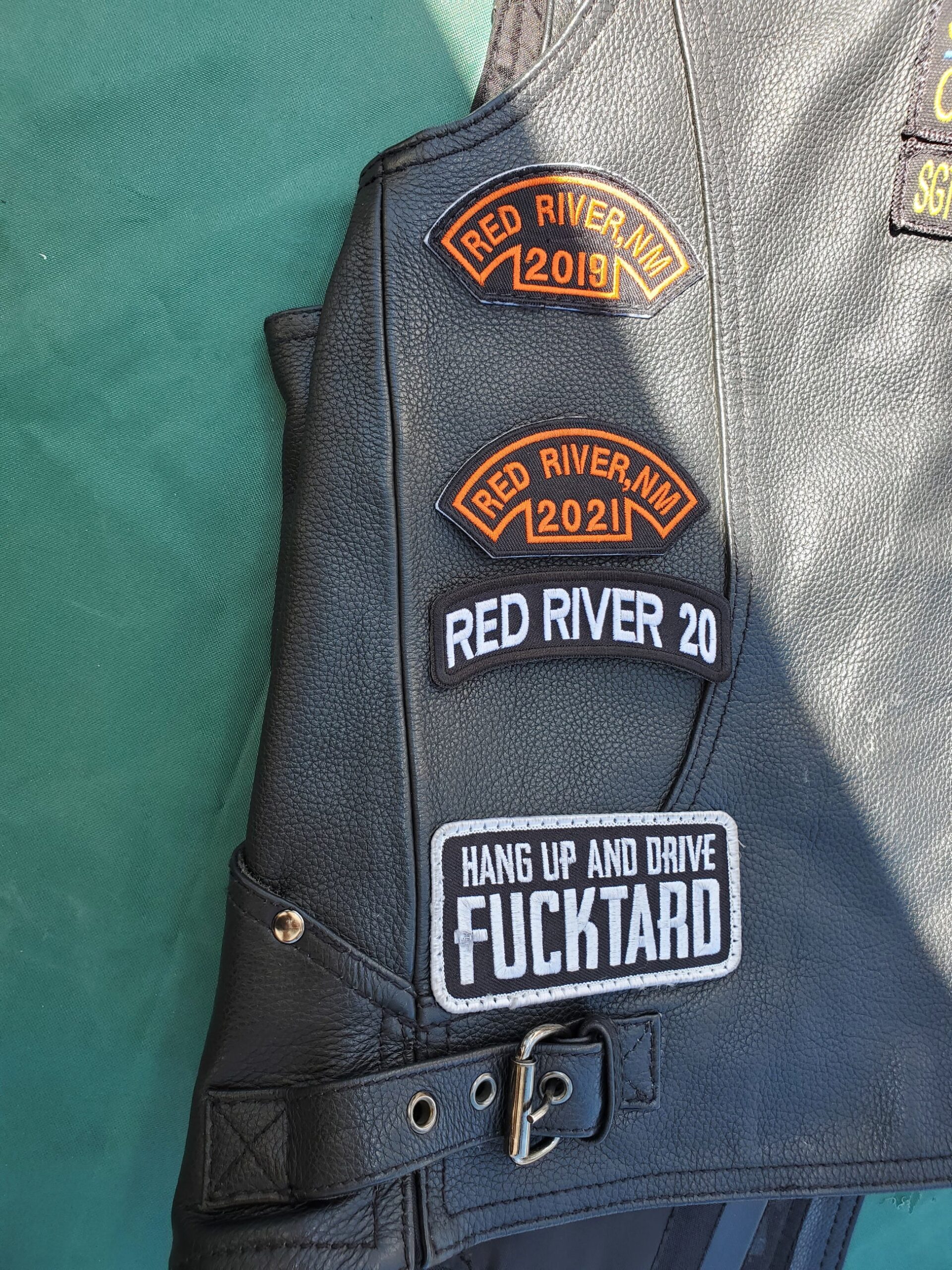

How Are Custom Patches Used in Motorcycle Clubs?

In motorcycle clubs, custom patches serve as a vital means of expressing group identity and camaraderie among members. These patches often display club logos, slogans, and ranks, solidifying the bond between members. For international buyers, particularly from regions like Africa and Europe, sourcing high-quality patches is crucial. They must ensure that the patches are durable enough to withstand various environmental conditions while maintaining vibrant colors and intricate designs. Additionally, understanding local regulations regarding the use of certain symbols can be essential for compliance.

What Role Do Custom Patches Play in Fashion Retail?

Fashion retailers utilize custom patches to enhance their leather apparel offerings, creating unique branding elements that set them apart in a saturated market. These patches can represent brand logos or seasonal themes, adding a distinctive flair to products. For B2B buyers, particularly in South America and the Middle East, it’s important to consider factors like customization options and lead times. Retailers often seek patches that can be easily integrated into existing designs without compromising the overall aesthetic or quality of the leather.

How Are Custom Patches Beneficial for Military and Tactical Gear?

In the military and tactical sectors, custom patches are used for identification, morale, and branding. Patches can denote rank, unit affiliation, or special achievements, fostering a sense of pride and unity among personnel. For businesses supplying these patches, especially those catering to international military contracts, compliance with specific military specifications is critical. Buyers must also prioritize the durability of materials, ensuring that patches can withstand rigorous use in diverse environments.

What Advantages Do Custom Patches Offer for Promotional Merchandise?

Custom patches are increasingly popular in promotional merchandise, allowing businesses to enhance brand visibility during events and giveaways. They serve as cost-effective marketing tools that can be attached to bags, clothing, or accessories, creating memorable brand impressions. For international B2B buyers, it’s essential to evaluate the cost-effectiveness of production and the complexity of design. A focus on timely delivery and the ability to meet bulk order requirements can significantly impact promotional success.

How Do Custom Patches Enhance Custom Apparel Manufacturing?

In custom apparel manufacturing, patches are a key element that adds value and personalization to leather vests. They allow manufacturers to create bespoke pieces that cater to individual customer preferences, enhancing the overall product appeal. For buyers in Europe and Asia, it’s vital to assess material compatibility with leather and the scalability of production. Ensuring a quick turnaround time can also be a decisive factor in meeting market demands and maintaining competitive advantage.

3 Common User Pain Points for ‘custom patches for leather vest’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Custom Patches

The Problem:

B2B buyers often struggle to find reliable suppliers who can provide high-quality materials for custom patches that will withstand wear and tear, particularly for leather vests. Many buyers face issues with inconsistencies in patch quality, leading to dissatisfaction from their customers. Additionally, cultural differences in design preferences can complicate the sourcing process, especially for international buyers from regions like Africa and the Middle East, where local tastes may differ significantly from Western markets.

The Solution:

To overcome these challenges, buyers should conduct thorough research to identify reputable suppliers with a proven track record in producing durable custom patches. Start by requesting samples from potential vendors to assess material quality firsthand. Look for suppliers who can provide patches made from high-grade thread and backing materials that can withstand outdoor conditions.

Engaging in a transparent dialogue with suppliers about your specific needs—such as design intricacies and cultural considerations—can also help. For instance, if your target market favors vibrant colors or specific motifs, communicate these preferences clearly. Additionally, consider utilizing local suppliers who understand regional trends and customer expectations, which can enhance both the quality and appeal of the final product.

Scenario 2: Navigating Design Specifications and Customization Limits

The Problem:

Buyers frequently encounter limitations when customizing patch designs due to strict vendor guidelines or technical constraints. This can lead to frustration, especially when trying to create unique patches that reflect the brand’s identity or the cultural significance of the target market. For example, intricate designs may not translate well into embroidery, resulting in a final product that does not meet the buyer’s expectations.

The Solution:

To mitigate this issue, buyers should work closely with their chosen vendors to understand the specific limitations of different customization options. Before finalizing designs, engage in collaborative discussions with the vendor’s design team. This will allow you to gain insights into what can be realistically achieved within the scope of the chosen materials and production methods.

Illustrative image related to custom patches for leather vest

Utilize design software that allows for mock-ups and visual previews to better communicate your vision to suppliers. This proactive approach ensures that both parties are aligned before production begins. Additionally, consider creating a tiered design plan that includes variations of your initial concept—this way, if certain elements cannot be produced as intended, alternative designs can be quickly adapted without starting from scratch.

Scenario 3: Ensuring Timely Delivery for Seasonal Orders

The Problem:

Timeliness is critical, especially for B2B buyers who need to align patch deliveries with specific seasonal promotions or events. Delays in production or shipping can result in missed opportunities for sales and affect customer satisfaction. Buyers often find it challenging to communicate urgent timelines to suppliers, particularly when dealing with international shipping logistics.

The Solution:

To ensure timely delivery, establish clear timelines and expectations from the outset of the sourcing process. Communicate your deadlines explicitly during initial discussions with suppliers. Implement a project management tool that allows for tracking progress and deadlines throughout the production cycle.

Additionally, consider building a buffer into your timeline by placing orders well in advance of peak seasons. This not only accommodates potential delays but also allows for any unexpected design revisions or quality checks. When negotiating with suppliers, inquire about their capacity to handle rush orders and discuss any expedited shipping options that may be available. By fostering a strong partnership with suppliers, you can create a more responsive supply chain that meets your urgent needs without compromising quality.

Illustrative image related to custom patches for leather vest

Strategic Material Selection Guide for custom patches for leather vest

What Are the Key Materials for Custom Patches for Leather Vests?

When selecting materials for custom patches designed for leather vests, several options are commonly utilized, each with unique properties and implications for performance, durability, and cost. Understanding these materials is crucial for B2B buyers looking to make informed decisions that align with their specific market needs, especially in diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Properties of Embroidered Fabric Patches?

Embroidered fabric patches are a popular choice for custom patches due to their aesthetic appeal and versatility. Typically made from polyester or cotton threads, these patches are stitched onto a fabric backing.

- Key Properties: Embroidered patches are durable and can withstand washing and wear. They have a temperature resistance that allows them to maintain integrity under varying conditions.

- Pros & Cons: They offer excellent color retention and can be produced in intricate designs, making them visually appealing. However, they may not be as durable as other materials when subjected to extreme conditions, such as heavy abrasion or harsh weather. The manufacturing process can be complex, leading to higher costs.

- Impact on Application: These patches are suitable for casual wear and motorcycle gear, providing a classic look. However, they may not be ideal for environments where heavy-duty performance is required.

- Considerations for International Buyers: Buyers should consider compliance with local textile standards and preferences for sustainable materials, particularly in Europe and South America, where eco-friendly practices are increasingly valued.

How Do PVC Patches Compare for Custom Applications?

PVC (Polyvinyl Chloride) patches are another viable option for custom patches, particularly for those seeking a waterproof and durable alternative.

- Key Properties: PVC patches are resistant to water, chemicals, and UV light, making them suitable for outdoor applications.

- Pros & Cons: They are highly durable and can withstand extreme weather conditions, which is beneficial for motorcycle riders. However, they can be less flexible than fabric patches and may not offer the same level of detail in designs. The production process can also be more expensive due to the material’s nature.

- Impact on Application: Ideal for rugged outdoor use, these patches can endure harsh conditions, making them popular among bikers and outdoor enthusiasts.

- Considerations for International Buyers: Compliance with environmental regulations concerning PVC usage is essential, particularly in regions with stringent plastic regulations, such as Europe.

What Are the Benefits of Leather Patches for Custom Vest Applications?

Leather patches offer a classic and premium look, making them a favored choice for high-end custom vests.

Illustrative image related to custom patches for leather vest

- Key Properties: Leather is inherently durable and can withstand wear and tear, maintaining its appearance over time.

- Pros & Cons: They provide a luxurious aesthetic and can be embossed or debossed for added texture. However, leather patches can be more expensive and require careful maintenance to prevent damage from moisture or sunlight.

- Impact on Application: Leather patches are particularly suited for motorcycle vests, contributing to a rugged, authentic biker look. However, they may not be suitable for all weather conditions without proper treatment.

- Considerations for International Buyers: Buyers should be aware of sourcing regulations regarding animal products and ensure compliance with local standards, particularly in regions sensitive to animal welfare issues.

How Do Woven Patches Fit into the Custom Patch Landscape?

Woven patches are created by weaving threads together, resulting in a flat, detailed design.

- Key Properties: They are lightweight and can capture intricate designs with high precision.

- Pros & Cons: Woven patches can be produced at a lower cost compared to embroidered patches and are less bulky. However, they may not be as durable as embroidered options and can fray over time.

- Impact on Application: These patches are suitable for promotional items and casual wear but may not hold up as well in demanding environments.

- Considerations for International Buyers: Buyers should consider the production methods and sustainability of materials used in woven patches, as this is becoming increasingly important in many markets.

Summary Table of Material Options for Custom Patches

| Material | Typical Use Case for custom patches for leather vest | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Embroidered Fabric | Casual wear, motorcycle gear | Excellent color retention | Less durable in extreme conditions | Medium |

| PVC | Outdoor applications, rugged use | Waterproof and UV resistant | Less flexible, higher production cost | High |

| Leather | High-end vests, premium applications | Luxurious aesthetic | Expensive, requires maintenance | High |

| Woven | Promotional items, casual wear | Lightweight, intricate designs | Less durable, can fray over time | Low |

This analysis provides a comprehensive overview of the materials available for custom patches, enabling B2B buyers to make strategic decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for custom patches for leather vest

What Are the Key Stages in the Manufacturing Process of Custom Patches for Leather Vests?

The production of custom patches for leather vests involves a series of well-defined stages, each critical to ensuring the final product meets quality standards and customer specifications. The primary stages of the manufacturing process include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Custom Patches?

The journey begins with the selection of high-quality materials, typically including various types of leather and fabric for the patches, along with thread and backing materials. Suppliers often source these materials from reputable manufacturers to ensure durability and aesthetic appeal. The preparation stage may involve pre-treating leather to enhance its resistance to wear and tear, as well as dyeing or printing fabric to achieve the desired colors and designs.

Illustrative image related to custom patches for leather vest

What Techniques Are Used in Forming Custom Patches?

Once the materials are prepared, they undergo forming, which includes cutting and shaping the patches according to the specified designs. Advanced technologies such as laser cutting can be employed for precision, allowing for intricate designs that would be difficult to achieve with traditional methods. Additionally, embroidery machines are used to stitch logos or patterns onto the patches, ensuring that every detail is captured accurately. This stage is crucial, as any errors in cutting or stitching can lead to wasted materials and increased production costs.

How Are Custom Patches Assembled?

After the patches are formed, the assembly stage involves attaching any additional elements, such as iron-on or Velcro backing, which allows for easy application onto leather vests. This process may also include sewing patches onto leather, which requires skilled labor to ensure that the patches are securely affixed without damaging the vest material. Quality control checks should be integrated into this stage to catch any assembly errors early.

What Finishing Techniques Enhance the Quality of Custom Patches?

The finishing stage is where the patches receive their final touches. This may involve heat-setting designs to ensure they are durable and resistant to fading, as well as trimming any excess material to achieve a clean finish. Final inspection is vital at this stage to ensure that each patch meets the established quality standards before they are packaged for shipment.

Illustrative image related to custom patches for leather vest

What Quality Assurance Measures Are Essential in Custom Patch Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for custom patches, ensuring that products not only meet customer specifications but also comply with international standards. Implementing a robust QA system involves adhering to various standards such as ISO 9001, which focuses on quality management systems, and CE marking for products sold in Europe.

How Do Manufacturers Implement Quality Control Checkpoints?

Quality control checkpoints are established throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the production process helps identify and rectify issues before they escalate. This may include random sampling of patches at various stages of production.

- Final Quality Control (FQC): Before shipment, a final inspection is conducted to ensure that all patches meet quality specifications in terms of design, stitching, and durability.

What Testing Methods Are Commonly Used for Custom Patches?

Common testing methods for custom patches include tensile strength tests to assess the durability of the stitching and adhesive properties tests for iron-on patches. Additionally, colorfastness tests are conducted to ensure that colors do not fade when exposed to light or washing. These tests are crucial for maintaining the reputation of both the manufacturer and the buyer.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential. Here are some actionable steps:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into the quality management processes in place. This can be done by the buyer or through third-party audit services.

- Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from IQC, IPQC, and FQC stages.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the quality of patches before shipment. This is particularly important for buyers in regions with stringent quality regulations.

What Are the Unique Quality Assurance Considerations for International Buyers?

International buyers must also be aware of the nuances in quality assurance that may vary by region. For instance, certain markets may have specific regulatory requirements that affect product safety and compliance. Buyers should familiarize themselves with these regulations to ensure that their patches not only comply with international standards but also local laws.

Illustrative image related to custom patches for leather vest

Furthermore, understanding the cultural significance of certain designs or symbols is crucial when dealing with patches that might represent local clubs or affiliations. Ensuring that these designs are treated with respect and produced accurately can enhance buyer-supplier relationships and customer satisfaction.

Conclusion: Ensuring Quality in Custom Patch Manufacturing

In summary, the manufacturing process for custom patches for leather vests is intricate, requiring careful attention to detail at each stage—from material preparation to finishing. Quality assurance practices, aligned with international standards, are essential for maintaining the integrity of the final product. By understanding these processes and engaging in thorough verification practices, B2B buyers can ensure they partner with reliable suppliers who deliver high-quality custom patches that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom patches for leather vest’

Introduction

Sourcing custom patches for leather vests involves a careful evaluation of suppliers, materials, and designs to ensure that the final product aligns with your business needs. This checklist provides a structured approach to streamline the procurement process, minimizing risks while maximizing quality and value.

Illustrative image related to custom patches for leather vest

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the patches you intend to source. This includes size, color, design intricacies, and attachment methods (sewn or ironed). Providing detailed specifications helps suppliers understand your requirements, ensuring that the final product meets your expectations and branding guidelines.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in custom patches. Use online platforms, trade shows, and industry contacts to gather a list of potential vendors. Prioritize suppliers who demonstrate experience in producing high-quality patches and have a portfolio showcasing their work, particularly in the leather goods sector.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Assess their production capacity, lead times, and ability to handle your order volume. Additionally, inquire about the types of materials they use and their customization options to ensure they align with your desired quality and durability standards.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to evaluate the quality of the patches firsthand, including stitching, material integrity, and color accuracy. Examine how well the patches adhere to leather, as this will impact their longevity and appearance on vests.

Step 5: Verify Certifications and Compliance

Ensure that potential suppliers comply with international quality standards and regulations. Check for certifications that indicate adherence to safety and quality benchmarks, particularly if you’re sourcing from regions with varying manufacturing standards. Certifications such as ISO or compliance with environmental regulations can provide additional assurance of quality.

Step 6: Understand Pricing and Payment Terms

Discuss pricing structures and payment terms upfront to avoid any surprises later. Look for transparency in pricing, including any additional costs for customization or shipping. Consider negotiating terms that work for both parties, such as discounts for bulk orders or flexible payment schedules.

Step 7: Establish Communication Protocols

Set clear communication channels and expectations with your chosen supplier. Define how often you will check in on the order’s progress and ensure that both parties are aligned on timelines and deliverables. Good communication is key to resolving any issues that may arise during production, keeping your project on track.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom patches for leather vests with confidence, ensuring they select the right suppliers and receive products that enhance their brand’s identity.

Comprehensive Cost and Pricing Analysis for custom patches for leather vest Sourcing

What are the Key Cost Components in Custom Patches for Leather Vests?

When sourcing custom patches for leather vests, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall cost. High-quality fabrics such as twill, felt, or leather can range from $2 to $10 per patch, depending on the complexity and durability required.

-

Labor: Labor costs encompass the wages paid for both skilled and unskilled workers involved in the design and production process. Customization work, such as embroidery or specialized sewing techniques, can add approximately 15-30% to the labor costs.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Overhead can typically add 10-20% to the total production cost.

-

Tooling: For custom designs, initial tooling costs can be significant, particularly for molds or specialized machinery. These costs can vary greatly, often starting around $500 and increasing based on complexity and quantity.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add another 5-10% to the cost. This is essential for maintaining standards, especially for international markets.

-

Logistics: Shipping and handling costs must also be factored in, especially for international shipments. Depending on the destination, logistics can add 5-15% to the overall cost.

-

Margin: Finally, suppliers typically add a profit margin, which can range from 10% to 30%, based on market conditions and competitive pricing strategies.

How Do Price Influencers Impact Custom Patches for Leather Vests?

Several factors influence the pricing of custom patches:

-

Volume/MOQ: Larger orders usually benefit from economies of scale, resulting in lower per-unit costs. Suppliers often set Minimum Order Quantities (MOQs), which can range from 50 to 500 patches, affecting pricing.

-

Specifications/Customization: The level of customization requested (e.g., size, design complexity, special features) directly impacts the cost. More intricate designs or specific requests can increase the price significantly.

-

Materials Quality/Certifications: Higher-quality materials or those with specific certifications (e.g., eco-friendly, hypoallergenic) can lead to increased costs but may offer better long-term value.

-

Supplier Factors: The reputation, location, and reliability of the supplier can also affect pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: Understanding shipping terms (like FOB, CIF, DDP) is essential for determining who bears shipping costs and risks, which can influence the final price.

What Buyer Tips Can Enhance Cost Efficiency in Custom Patch Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiate: Always negotiate on pricing, especially for larger orders. Suppliers may be willing to lower prices to secure a bulk deal.

-

Focus on Total Cost of Ownership (TCO): Assess not just the initial price but the long-term costs associated with quality, durability, and potential returns. A cheaper patch may result in higher costs if it wears out quickly.

-

Understand Pricing Nuances: Be aware of regional pricing variations and currency fluctuations that may impact costs. Engage suppliers who can provide fixed pricing or favorable terms to mitigate these risks.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce shipping costs and lead times, providing a more efficient solution for urgent needs.

-

Request Samples: Before committing to a large order, request samples to evaluate quality and ensure it meets your specifications.

Conclusion

The cost and pricing landscape for custom patches for leather vests is multifaceted. By understanding the various cost components and price influencers, B2B buyers can make informed decisions that align with their business needs. Always remember that the cheapest option may not always offer the best value, so focus on quality and reliability when selecting suppliers.

Alternatives Analysis: Comparing custom patches for leather vest With Other Solutions

Understanding Alternatives for Custom Patches for Leather Vests

When considering ways to personalize leather vests, custom patches are a popular choice among bikers and motorcycle enthusiasts. However, there are alternative solutions that can achieve similar outcomes, each with unique advantages and drawbacks. This analysis provides a comparative overview of custom patches against other viable options to assist B2B buyers in making informed decisions.

| Comparison Aspect | Custom Patches For Leather Vest | Iron-on Transfers | Embroidered Logos |

|---|---|---|---|

| Performance | High durability; withstands wear and tear | Moderate durability; can peel over time | Very durable; withstands frequent washing |

| Cost | Moderate pricing; varies by design and size | Lower cost; generally cheaper than patches | Higher cost; requires professional setup |

| Ease of Implementation | Requires sewing or heat application | Easy to apply with heat; minimal skill needed | Requires professional embroidery service |

| Maintenance | Low maintenance; long-lasting | Moderate; may need replacement if peeling occurs | Low; durable and resistant to fading |

| Best Use Case | Ideal for personalization and club affiliation | Suitable for quick, temporary designs | Best for branding and formal applications |

What Are Iron-on Transfers and Their Pros and Cons?

Iron-on transfers offer a quick and user-friendly alternative to custom patches. They can be applied with a household iron and are often less expensive than patches. However, their durability is a concern; they may peel or fade after multiple washes, making them less suitable for rugged use. While they are perfect for short-term applications or promotional events, they might not hold up as well in the long term compared to custom patches, especially for those who frequently wear their leather vests.

How Do Embroidered Logos Compare to Custom Patches?

Embroidered logos represent a more premium option for personalizing leather vests. This method involves stitching the design directly onto the vest, which results in a very high-quality finish that is durable and resistant to fading. However, the cost of embroidered logos tends to be higher than that of custom patches, and the implementation often requires professional services. While embroidered logos are ideal for businesses looking to establish a strong brand presence, they may not be as flexible or personal as custom patches, which allow for more unique designs and club affiliations.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right solution for personalizing leather vests depends on various factors, including budget, desired durability, and application method. For B2B buyers, understanding the specific context of use is crucial. If longevity and a strong personal statement are priorities, custom patches may be the best option. However, for temporary designs or cost-sensitive projects, iron-on transfers could suffice. Conversely, if high-quality branding is the goal, investing in embroidered logos might be the way to go. Assessing these alternatives in relation to your specific requirements will lead to a more satisfying and effective investment.

Essential Technical Properties and Trade Terminology for custom patches for leather vest

What Are the Key Technical Properties of Custom Patches for Leather Vests?

When selecting custom patches for leather vests, understanding the technical specifications is crucial for ensuring quality and durability. Here are several critical properties to consider:

Illustrative image related to custom patches for leather vest

-

Material Composition

The most common materials used for patches include polyester, cotton, and nylon. Polyester offers durability and resistance to fading, while cotton provides a more traditional feel. The choice of material affects not only the patch’s longevity but also its aesthetic appeal, making it essential for branding and style. -

Stitch Density

Stitch density refers to the number of stitches per square inch in an embroidered patch. Higher stitch density results in more intricate designs and better durability. For B2B buyers, a higher stitch count can justify premium pricing, as it often signifies superior quality and a longer lifespan in harsh conditions. -

Backing Type

There are various backing options for patches, including heat-sealed, adhesive, and Velcro. Heat-sealed patches are ideal for a permanent application, while adhesive backings allow for easy application without sewing. Understanding the backing type is important for determining the patch’s intended use and how it will adhere to the leather vest. -

Size and Shape Tolerance

Tolerance refers to the allowable variation in the dimensions of the patch. Custom patches can come in various shapes and sizes, but it’s crucial to ensure they fit well on the intended leather vest. Accurate size specifications prevent production issues and ensure customer satisfaction. -

Colorfastness

This property indicates how well the colors in the patch resist fading due to exposure to sunlight and washing. For B2B buyers, patches with high colorfastness ratings are critical for maintaining the brand’s image over time. Choosing patches that can withstand the elements is essential, especially for outdoor or rugged use. -

Embellishment Options

Patches can be embellished with additional features like sequins, studs, or reflective materials. These embellishments not only enhance the aesthetic appeal but can also serve functional purposes, such as increasing visibility for safety. Understanding these options can help buyers differentiate their products in a competitive market.

What Are Common Trade Terminology and Concepts Related to Custom Patches?

Navigating the world of custom patches requires familiarity with specific industry jargon. Here are key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are used in another company’s end products. In the context of custom patches, working with an OEM can streamline production and ensure that patches meet specific quality standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units that a supplier is willing to produce. Understanding MOQ is vital for B2B buyers to assess cost-effectiveness and inventory management. It can impact cash flow and storage considerations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For buyers seeking custom patches, issuing an RFQ can help compare costs, quality, and delivery times, allowing for informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs, risk, and delivery. Familiarity with Incoterms is essential for B2B buyers to understand their obligations and mitigate potential disputes. -

Lead Time

This term refers to the time it takes from placing an order until it is delivered. For custom patches, lead time can vary based on complexity and production capacity. Understanding lead times helps buyers plan their inventory and meet market demands effectively. -

Sampling

Sampling involves creating a prototype of the patch before full-scale production. This step allows buyers to assess quality, design, and functionality. Sampling is crucial for ensuring that the final product aligns with expectations and reduces the risk of costly errors during large-scale production.

By familiarizing themselves with these properties and terms, B2B buyers can make more informed decisions regarding custom patches for leather vests, ultimately enhancing their product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the custom patches for leather vest Sector

What Are the Key Market Trends Influencing the Custom Patches for Leather Vest Sector?

The global market for custom patches for leather vests is experiencing notable growth, driven by several factors. The rise of motorcycle culture, particularly in regions such as Africa, South America, the Middle East, and Europe, has led to an increased demand for personalized and distinctive fashion statements. Custom patches serve not only as a form of self-expression but also as a means of club affiliation, enhancing their appeal among motorcycle enthusiasts.

Technological advancements are also shaping sourcing trends in this sector. Digital printing and embroidery technologies are enabling manufacturers to produce high-quality, intricate designs with shorter lead times. B2B buyers are increasingly leveraging e-commerce platforms to streamline their procurement processes, enabling them to access a wider range of products from global suppliers. Moreover, data analytics tools are becoming essential for understanding consumer preferences and tailoring product offerings accordingly.

Illustrative image related to custom patches for leather vest

Emerging trends such as the integration of augmented reality (AR) for virtual try-ons and customization are providing unique opportunities for businesses to engage customers. The focus on aesthetic appeal combined with functionality in patches—such as weather resistance and durability—has become a key market dynamic. As buyers seek quality and personalization, suppliers must be agile in their offerings to remain competitive.

How Important Is Sustainability and Ethical Sourcing in the Custom Patches for Leather Vest Industry?

Sustainability has become a significant consideration for B2B buyers in the custom patches sector. The environmental impact of textile production, including the use of synthetic materials and the processing of leather, has prompted businesses to reevaluate their sourcing practices. Ethical supply chains are not just a regulatory requirement but a competitive advantage, particularly in markets that prioritize corporate social responsibility.

Buyers are increasingly seeking suppliers who employ sustainable practices, such as using eco-friendly dyes and materials certified by recognized environmental standards. Certifications like Global Organic Textile Standard (GOTS) and Oeko-Tex are gaining traction, as they assure buyers that the products meet stringent environmental criteria.

Furthermore, the demand for recycled and upcycled materials is rising, reflecting a shift toward circular economy principles. Implementing sustainable practices can enhance brand reputation and customer loyalty, especially among environmentally conscious consumers. For B2B buyers, partnering with suppliers that prioritize sustainability can lead to long-term benefits and a stronger market position.

What Is the Historical Context Behind Custom Patches for Leather Vests?

The tradition of using patches on leather vests dates back to the early motorcycle culture of the 20th century. Initially adopted by military personnel and biker gangs, patches became symbols of identity, camaraderie, and rebellion. Over time, the custom patch phenomenon evolved, with motorcycle clubs using them to signify membership, achievements, and affiliation.

In the late 20th century, the rise of counter-culture movements further popularized the use of patches, with designs reflecting individualistic values and artistic expression. Today, custom patches are not only a staple in biker fashion but have transcended into mainstream apparel, appealing to a broader audience. This evolution underscores the significance of patches in contemporary fashion, making them a valuable asset for B2B buyers looking to tap into a diverse market.

Illustrative image related to custom patches for leather vest

By understanding these historical roots, international B2B buyers can better appreciate the cultural significance of custom patches and leverage this knowledge in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of custom patches for leather vest

-

How do I choose the right supplier for custom patches for leather vests?

Choosing the right supplier involves evaluating their experience, quality of materials, and customer reviews. Request samples to assess the quality of their patches, including stitching and fabric durability. Additionally, verify their production capabilities and lead times to ensure they can meet your demands. It’s also beneficial to inquire about their compliance with international trade regulations, especially if you’re sourcing from regions like Africa or South America. A reputable supplier will be transparent about their processes and willing to provide references. -

What is the minimum order quantity (MOQ) for custom patches?

MOQs for custom patches can vary significantly by supplier. Many manufacturers may set an MOQ between 50 to 100 patches, while others may offer lower or higher quantities depending on customization complexity. When sourcing internationally, consider the costs of shipping and import duties as these can affect overall pricing. It’s advisable to discuss your specific needs with potential suppliers to negotiate a suitable MOQ that aligns with your budget and inventory plans. -

What customization options are available for leather vest patches?

Customization options typically include size, shape, color, design, and backing type (iron-on or sew-on). Some suppliers may offer additional features such as reflective materials or unique stitching techniques. When selecting customization options, consider your target market’s preferences and the intended use of the patches. Providing your supplier with high-resolution artwork or detailed specifications can help ensure the final product meets your expectations. -

What payment terms should I expect when sourcing custom patches?

Payment terms can vary by supplier but commonly include options like upfront deposits (20-50%) with the balance due upon completion or shipment. Some suppliers may accept letters of credit or other secure payment methods, especially for larger orders. Always clarify payment terms and conditions before finalizing any agreements. This transparency can help avoid misunderstandings and ensure a smooth transaction process. -

How can I ensure quality assurance for my custom patches?

To ensure quality assurance, request a detailed quality control process from your supplier. This should include pre-production samples for approval and inspections at various production stages. Establishing clear quality standards and specifications upfront can help maintain consistency. Additionally, consider incorporating third-party inspections, especially for large orders, to verify that the patches meet your quality expectations before shipment. -

What are the logistics considerations for shipping custom patches internationally?

Logistics considerations include understanding shipping costs, delivery times, and customs regulations in your country. Choose a reliable shipping partner that can provide tracking and insurance options. Be aware of any import duties or tariffs that may apply to your shipment, as these can significantly impact overall costs. Collaborating with your supplier to optimize packaging and shipping methods can also help reduce costs and ensure timely delivery. -

How can I manage the risks associated with sourcing from international suppliers?

Managing risks involves thorough supplier vetting, including checking references and reviewing their track record. Establish clear contracts that outline responsibilities, quality standards, and timelines. Consider using escrow services for payments to protect both parties. Regular communication throughout the production process can help address issues promptly and foster a collaborative relationship, minimizing potential risks associated with international sourcing. -

What trends should I be aware of in the custom patch market?

Current trends include the increasing demand for eco-friendly materials and sustainable production practices, as consumers become more environmentally conscious. Additionally, personalized and unique designs are gaining popularity, especially among younger demographics. Keep an eye on cultural influences and regional preferences, as these can affect design choices and market demands in different areas, including Africa and South America. Staying updated on these trends can help you position your offerings effectively in a competitive market.

Top 7 Custom Patches For Leather Vest Manufacturers & Suppliers List

1. Hot Leathers – Biker Patches

Domain: hotleathers.com

Registered: 1996 (29 years)

Introduction: Biker Patches available at Hot Leathers include various styles such as large back patches, rocker patches, officer patches, and reflective patches. The collection features patches for different themes including military and patriotic designs, fun and novelties, and ladies patches. Popular styles include animals, eagles, religious themes, and first responders. The patches are designed for bikers an…

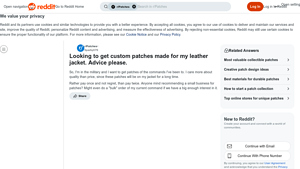

2. MakeMyPatch – Custom Biker Vest Patches

Domain: makemypatch.com

Registered: 2018 (7 years)

Introduction: Custom Patches Set for Biker Vest

Price: $17.50 (originally $55.00)

Measurements (W x H):

– Top Rocker: 13 x 5 in (33 x 12.7 cm)

– MC Patch: 3 x 3 in (7.62 x 7.62 cm)

– Name Tags: 4 x 1 in (10.16 x 2.54 cm)

– Bottom Rocker: 13 x 5 in (33 x 12.7 cm)

Features:

– Iron-on patches

– High quality embroidered

– Degressive pricing available

Shipping: Worldwide delivery, estimated delivery time 15 to 20 …

3. Wizard Patch – Custom Embroidered Badges

Domain: wizardpatch.com

Registered: 2011 (14 years)

Introduction: Custom embroidered badges and patches, personalized emblems, volume-based pricing, various categories including custom patches, biker patches, military patches, music/band patches, apparel and accessories, trending products, and featured products. Specific items include: Custom Embroidered Single Bar Name Tag Strip, Top Gun Flight Suit Name Tag, Custom Bar Tags, Custom Top & Bottom Rockers, MC Pat…

4. Lazer Designs – Custom Leather Patches

Domain: lazerdesigns.com

Registered: 2002 (23 years)

Introduction: Custom leather patches for jackets, personalized options available.

5. Tactical Gear Junkie – Custom Biker Vest Patch

Domain: tacticalgearjunkie.com

Registered: 2012 (13 years)

Introduction: Custom Biker Vest Patch – Top and Bottom Arch Style Tab and Rocker – Sew On. Measures roughly 12.5 inches from end to end. Made to be sewn-on (no hook fastener backing). Maximum of 35 characters per patch. Made by Tactical Gear Junkie in the USA. Price: $32.54. Customization requires entering text in a provided text box, with all text capitalized. Production time is 3-7 business days.

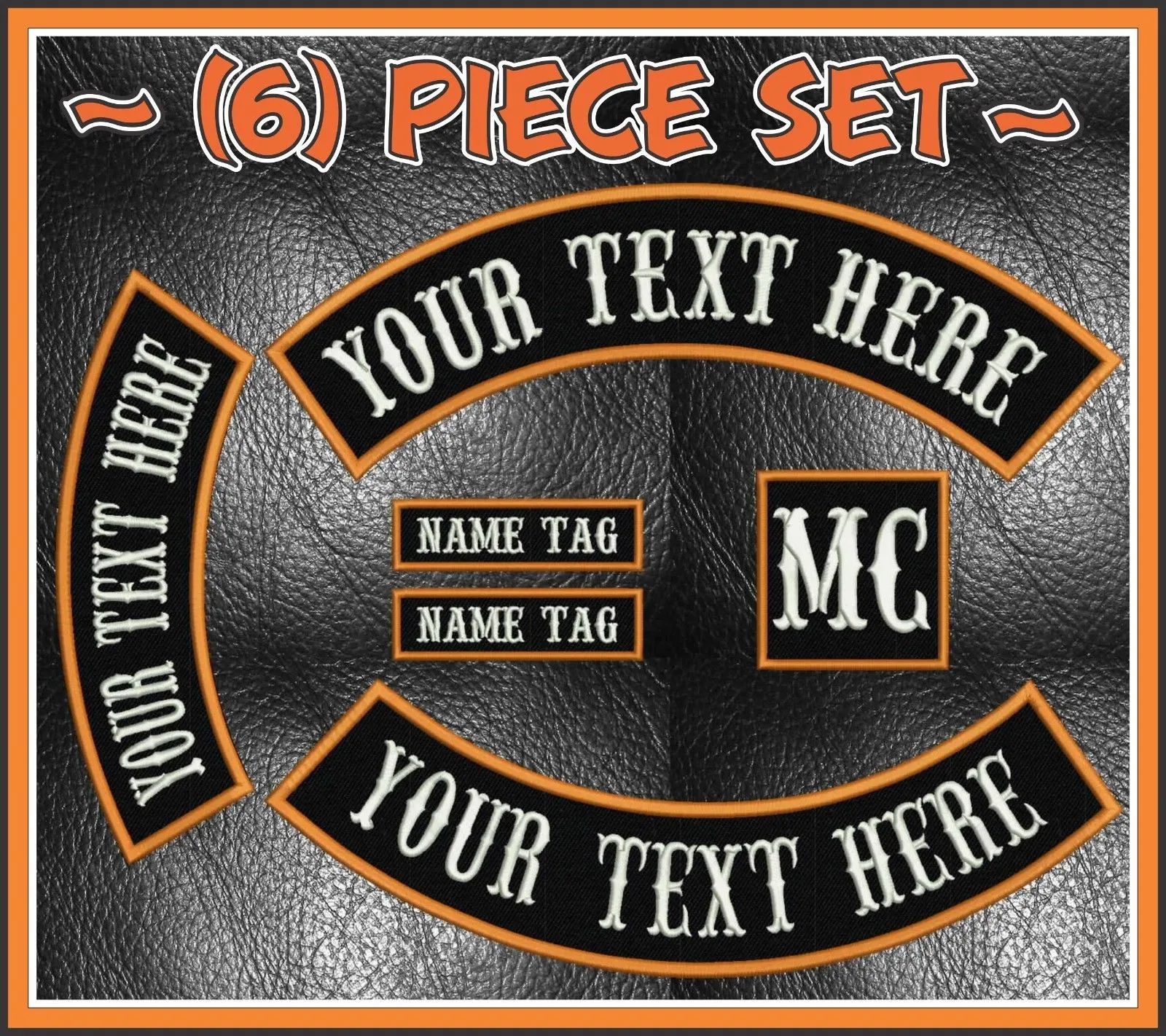

6. Reddit – Custom Leather Jacket Patches

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom patches for a leather jacket, focusing on quality over price, with a potential bulk order for military commands.

7. Melon Patches – Custom Embroidered Biker Vest Patches

Domain: melonpatches.com

Registered: 2018 (7 years)

Introduction: Custom embroidered biker vest patches designed for bikers, available in various styles including small rectangles and full back patches. Made with high-quality materials and state-of-the-art embroidery machines. 100% satisfaction guaranteed with free replacement for defects. The design process includes submitting your design, receiving an artist’s proof for approval, and final production of the pa…

Strategic Sourcing Conclusion and Outlook for custom patches for leather vest

In navigating the competitive landscape of custom patches for leather vests, strategic sourcing emerges as a critical factor for success. By prioritizing quality, supplier reliability, and cost-effectiveness, international B2B buyers can enhance their product offerings and meet the diverse demands of their markets. Collaborating with manufacturers who emphasize craftsmanship and customization will not only bolster brand identity but also foster customer loyalty.

Investing in strong supplier relationships enables businesses to adapt to changing trends and consumer preferences. As the market for personalized and unique motorcycle gear continues to expand, buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in countries like Saudi Arabia and Vietnam—must remain agile. This adaptability will ensure that they are well-positioned to seize emerging opportunities.

Looking ahead, the potential for growth in the custom patches sector is significant. By leveraging strategic sourcing practices, companies can stay ahead of the competition and cater to the evolving tastes of their clientele. It’s time to take action—explore partnerships that align with your vision and drive your business forward in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.