Introduction: Navigating the Global Market for synthetic shammy leather

In the ever-evolving landscape of the global market, sourcing high-quality synthetic shammy leather presents unique challenges for international B2B buyers. Whether you are looking to meet the demand for automotive detailing products in Europe or exploring versatile applications in Africa and South America, understanding the nuances of this material is crucial. This guide delves into the various types of synthetic shammy leather, their applications across industries, and the key factors to consider when evaluating suppliers.

We will explore the benefits of synthetic materials, which combine traditional chamois qualities with modern performance attributes, such as superior absorbency and durability. Additionally, we will provide insights on effective supplier vetting processes, cost considerations, and the latest trends shaping the market. By equipping yourself with this comprehensive knowledge, you will be empowered to make informed purchasing decisions that align with your business objectives.

Our focus extends beyond mere product specifications; we aim to bridge the gap between suppliers and buyers across diverse regions, including Germany, Brazil, the Middle East, and beyond. The information provided in this guide is designed to enhance your strategic sourcing capabilities, ensuring you select the right synthetic shammy leather products that cater to your specific needs. Embrace the opportunity to elevate your offerings with confidence, knowing you have the insights necessary for success in this competitive market.

Table Of Contents

- Top 6 Synthetic Shammy Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for synthetic shammy leather

- Understanding synthetic shammy leather Types and Variations

- Key Industrial Applications of synthetic shammy leather

- 3 Common User Pain Points for ‘synthetic shammy leather’ & Their Solutions

- Strategic Material Selection Guide for synthetic shammy leather

- In-depth Look: Manufacturing Processes and Quality Assurance for synthetic shammy leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘synthetic shammy leather’

- Comprehensive Cost and Pricing Analysis for synthetic shammy leather Sourcing

- Alternatives Analysis: Comparing synthetic shammy leather With Other Solutions

- Essential Technical Properties and Trade Terminology for synthetic shammy leather

- Navigating Market Dynamics and Sourcing Trends in the synthetic shammy leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of synthetic shammy leather

- Strategic Sourcing Conclusion and Outlook for synthetic shammy leather

- Important Disclaimer & Terms of Use

Understanding synthetic shammy leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Perforated Synthetic Microfiber | Enhanced absorbency with evenly placed perforations | Automotive detailing, marine applications | Pros: Superior drying, machine washable; Cons: May wear out faster than thicker options. |

| PVA Synthetic Chamois | Exclusive PVA material for quick drying and durability | Body shops, cleaning services | Pros: Dries faster than leather, body shop safe; Cons: Higher initial cost. |

| Jumbo-Sized Synthetic Chamois | Larger size for extensive drying, dual-textured surfaces | Commercial vehicle maintenance, pet care | Pros: Covers larger areas quickly; Cons: Bulkier to store and transport. |

| Traditional Synthetic Chamois | Mimics natural chamois feel, often made from blended materials | Household cleaning, automotive care | Pros: Cost-effective, versatile; Cons: May not match the absorbency of premium options. |

| Anti-Microbial Synthetic Chamois | Incorporates antimicrobial properties to prevent odor buildup | Health and hygiene-sensitive environments | Pros: Long-lasting freshness, ideal for sensitive tasks; Cons: Typically more expensive. |

What are the Characteristics of Perforated Synthetic Microfiber Chamois?

Perforated synthetic microfiber chamois are designed to provide exceptional absorbency while allowing for quicker drying times due to their unique perforated structure. These towels are particularly suitable for automotive detailing and marine applications, where a spotless finish is crucial. B2B buyers should consider their durability and ease of cleaning, as these products are often machine washable, enhancing their value over time.

How Does PVA Synthetic Chamois Stand Out?

PVA synthetic chamois are made from a specialized material that dries faster and offers superior durability compared to traditional chamois. This type is widely used in body shops and cleaning services due to its effectiveness on fine finishes. Buyers should weigh the initial investment against the long-term benefits of reduced drying times and increased longevity, making it an attractive option for high-volume users.

Why Choose Jumbo-Sized Synthetic Chamois?

Jumbo-sized synthetic chamois provide extensive drying capabilities, making them ideal for commercial vehicle maintenance and pet care. With a larger surface area and dual-textured sides, these chamois can adapt to various drying tasks, from vehicles to household items. Buyers should consider storage and transport logistics due to their bulkiness, but the time savings they offer can justify the investment.

What Makes Traditional Synthetic Chamois a Versatile Option?

Traditional synthetic chamois are designed to mimic the feel of natural chamois while offering a cost-effective solution for various cleaning tasks. They are widely used in household cleaning and automotive care due to their versatility. Buyers should assess the absorbency levels and overall performance, as they may not match the capabilities of higher-end options, but they remain a popular choice for budget-conscious businesses.

How Do Anti-Microbial Synthetic Chamois Benefit Specific Industries?

Anti-microbial synthetic chamois incorporate technology that prevents odor buildup and microbial growth, making them suitable for health-sensitive environments such as hospitals or food service industries. Their ability to maintain freshness over repeated uses is a significant advantage for B2B buyers focused on hygiene. However, these benefits come at a higher price point, so businesses should evaluate their specific needs and budgets before purchasing.

Key Industrial Applications of synthetic shammy leather

| Industry/Sector | Specific Application of synthetic shammy leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Car detailing and drying | Enhances finish quality and reduces drying time | Durability, absorbency, and ease of cleaning |

| Marine | Boat drying and maintenance | Prevents water spots and enhances surface protection | Resistance to saltwater, UV stability, and longevity |

| Household Cleaning | General cleaning and drying | Efficiently absorbs spills, leaving surfaces streak-free | Softness, non-abrasive properties, and machine washability |

| Industrial Manufacturing | Equipment and surface drying | Reduces downtime and improves operational efficiency | Size, material quality, and compliance with industry standards |

| Sports and Leisure | Gym and sports equipment maintenance | Keeps equipment clean and extends lifespan | Lightweight, absorbency, and antimicrobial properties |

How is Synthetic Shammy Leather Used in the Automotive Sector?

In the automotive industry, synthetic shammy leather is primarily utilized for car detailing and drying. Its high absorbency allows for quick drying of vehicles after washing, preventing water spots and streaks that can detract from the vehicle’s finish. For B2B buyers, sourcing durable and efficient drying materials is crucial. They should look for products that are machine washable and resistant to wear, ensuring long-term cost-effectiveness and maintaining high standards of vehicle presentation.

What Role Does Synthetic Shammy Leather Play in Marine Applications?

In marine applications, synthetic shammy leather is essential for drying boats and maintaining their surfaces. The material’s ability to absorb water quickly helps prevent the formation of water spots, which can lead to corrosion over time. Buyers in this sector, particularly those located in coastal regions, should prioritize sourcing shammy leather that is resistant to saltwater and UV rays, as these factors significantly affect the longevity and performance of the product in marine environments.

How Does Synthetic Shammy Leather Benefit Household Cleaning?

For household cleaning, synthetic shammy leather serves as an effective tool for absorbing spills and drying surfaces. Its non-abrasive nature ensures that delicate surfaces, such as glass and polished wood, remain scratch-free. International buyers should focus on the softness and machine washability of the product, as these features enhance convenience and usability. Additionally, sourcing options that are eco-friendly can appeal to environmentally conscious consumers.

Why is Synthetic Shammy Leather Valuable in Industrial Manufacturing?

In industrial manufacturing, synthetic shammy leather is used for drying equipment and surfaces post-cleaning. This application is crucial for minimizing downtime, as quick drying can lead to faster operational turnaround. B2B buyers in this sector should consider the size and material quality of the shammy leather, ensuring it meets specific industry standards. Compliance with safety and performance regulations is also vital to ensure reliability in high-demand environments.

How is Synthetic Shammy Leather Used in Sports and Leisure Equipment Maintenance?

In the sports and leisure sector, synthetic shammy leather is instrumental for the maintenance of gym and sports equipment. It effectively absorbs moisture and sweat, helping to keep equipment clean and extend its lifespan. When sourcing shammy leather for this application, buyers should look for lightweight options with antimicrobial properties to prevent odor and bacteria buildup. This ensures a hygienic environment for users, particularly in high-traffic areas like gyms and sports facilities.

3 Common User Pain Points for ‘synthetic shammy leather’ & Their Solutions

Scenario 1: Ensuring Consistent Quality in Synthetic Shammy Leather Products

The Problem:

B2B buyers often struggle with inconsistent quality among synthetic shammy leather products. Variability in absorbency, durability, and overall performance can lead to dissatisfaction among end-users, impacting business reputation and customer loyalty. Buyers may find that different batches from the same supplier yield different results, making it difficult to maintain standards across applications, whether in automotive detailing, household cleaning, or industrial use. This inconsistency can result in increased operational costs due to returns, rework, and potential damage to the surfaces being cleaned.

The Solution:

To mitigate quality variability, B2B buyers should establish clear specifications and quality assurance protocols when sourcing synthetic shammy leather. Engage with suppliers who provide detailed product descriptions, including GSM (grams per square meter), material composition, and performance metrics. It’s advisable to request samples from multiple batches before making a bulk order to assess consistency in absorbency and texture. Implementing a supplier evaluation process that includes quality certifications can further ensure that only high-quality materials are sourced. Regularly reviewing product performance and maintaining open communication with suppliers can help address any quality concerns before they escalate.

Scenario 2: Addressing Environmental Concerns with Synthetic Materials

The Problem:

Increasingly, B2B buyers are facing pressure to source eco-friendly products, including synthetic shammy leather. Traditional synthetic materials often raise concerns regarding their environmental impact and sustainability. Buyers may be apprehensive about sourcing products that do not align with their corporate social responsibility goals or the growing consumer demand for environmentally friendly options. This can lead to hesitance in making purchasing decisions, fearing backlash from consumers or stakeholders.

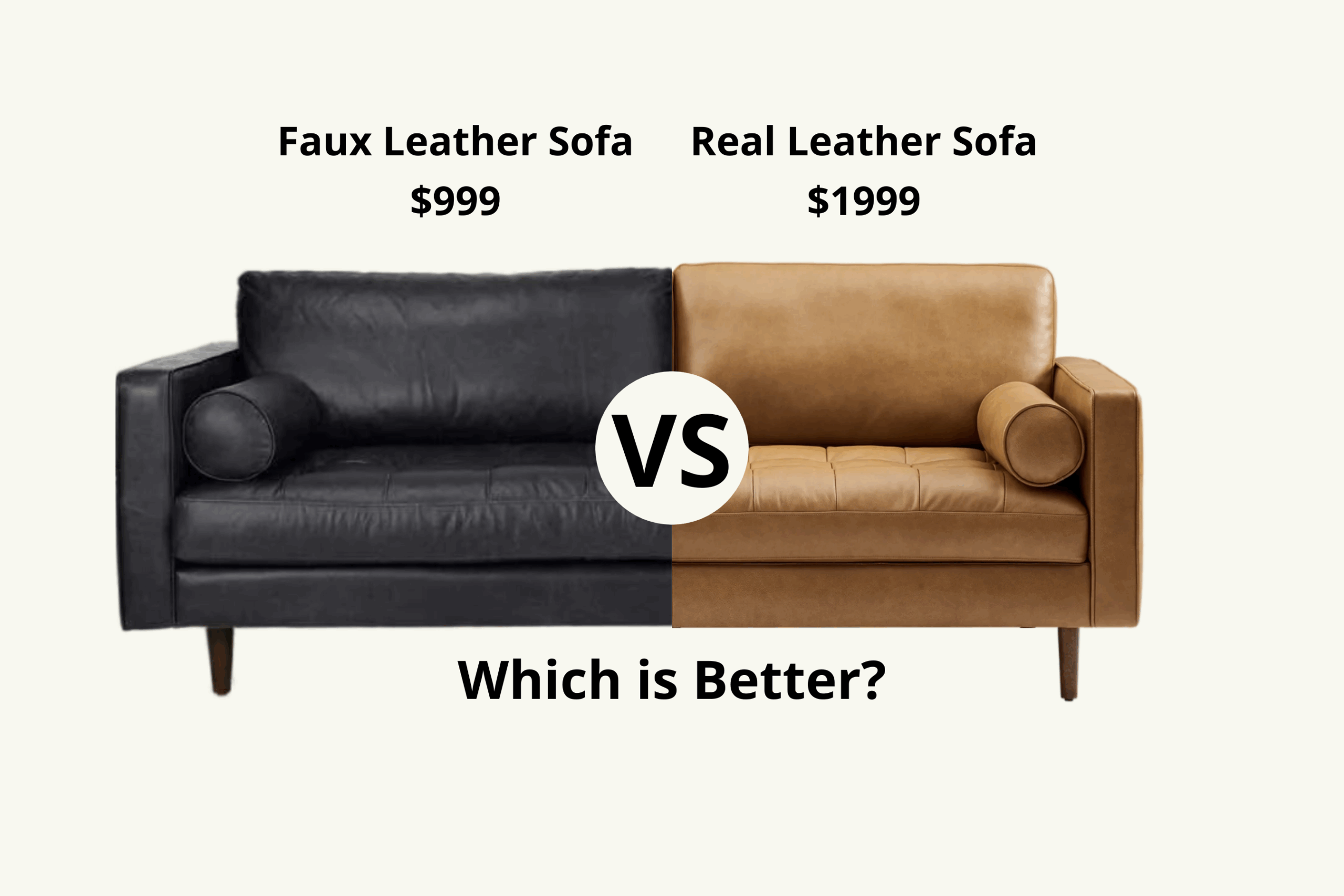

Illustrative image related to synthetic shammy leather

The Solution:

To address these environmental concerns, buyers should actively seek out suppliers who specialize in sustainable synthetic shammy leather. Look for products that are made from recycled materials or produced using eco-friendly manufacturing processes. Certifications such as OEKO-TEX® or similar can indicate that the materials meet certain environmental standards. Additionally, consider implementing a life-cycle assessment (LCA) approach to evaluate the environmental impact of the products being sourced. This not only demonstrates a commitment to sustainability but also positions the buyer as a responsible partner in the supply chain, potentially opening new market opportunities.

Scenario 3: Maximizing Product Lifespan and Performance

The Problem:

Another common challenge faced by B2B buyers is the premature degradation of synthetic shammy leather products, resulting in frequent replacements and increased costs. Many buyers may not fully understand the proper care and maintenance required to extend the lifespan of these materials. Misuse or lack of knowledge regarding washing, drying, and storage can lead to reduced performance, including diminished absorbency and increased wear and tear.

The Solution:

To enhance the longevity and effectiveness of synthetic shammy leather, buyers should invest in proper education regarding product maintenance. Provide training materials or workshops for staff on how to care for these products, emphasizing the importance of washing them according to manufacturer guidelines—typically in cold water and avoiding harsh detergents. Storing the shammy leather in a cool, dry place, away from direct sunlight, can also prevent material degradation. Additionally, consider establishing a regular inspection and replacement schedule based on usage patterns, which can help ensure that only high-performing products are utilized, ultimately saving costs in the long run.

Strategic Material Selection Guide for synthetic shammy leather

When selecting materials for synthetic shammy leather, B2B buyers must consider various factors that impact product performance, durability, and application suitability. Here, we analyze four common materials used in the production of synthetic shammy leather, focusing on their key properties, advantages, disadvantages, and implications for international buyers.

What are the Key Properties of Polyvinyl Alcohol (PVA) in Synthetic Shammy Leather?

Polyvinyl Alcohol (PVA) is a widely used material in synthetic shammy leather due to its excellent absorbency and quick-drying properties. PVA can withstand moderate temperatures and is resistant to various chemicals, making it suitable for automotive and household cleaning applications. Its high tensile strength ensures that PVA-based shammy products can endure repeated use without significant wear.

Pros: PVA is cost-effective and offers superior absorbency, making it ideal for drying applications. Its lightweight nature enhances ease of handling.

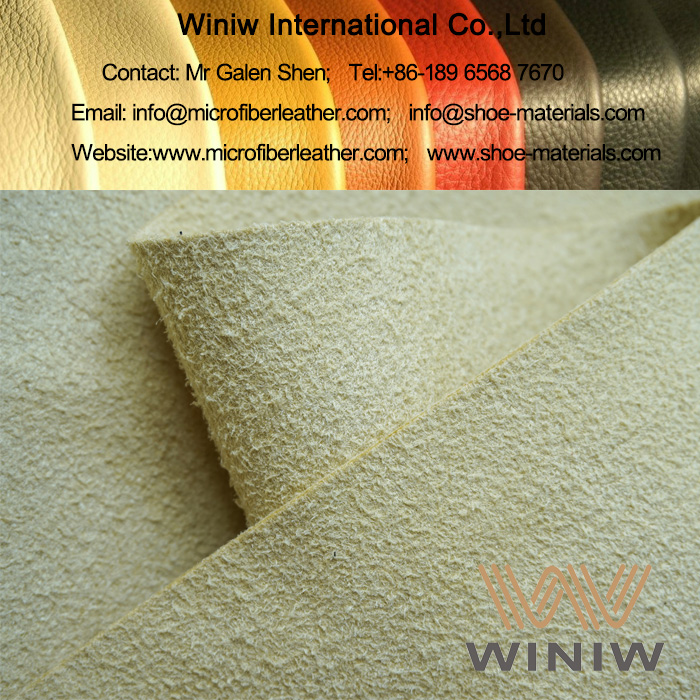

Illustrative image related to synthetic shammy leather

Cons: While PVA is durable, it can degrade when exposed to high temperatures for prolonged periods, limiting its use in certain industrial applications. Additionally, it may require specific care instructions to maintain its performance.

Impact on Application: PVA is particularly compatible with water-based media, making it an excellent choice for cleaning and drying surfaces without leaving streaks or residues.

How Does Microfiber Compare as a Material for Synthetic Shammy Leather?

Microfiber, a blend of polyester and polyamide, is another popular choice for synthetic shammy leather. This material is known for its exceptional softness and high absorbency, allowing it to soak up liquids effectively. Microfiber also offers good resistance to wear and tear, making it suitable for various applications, including automotive, household, and personal care.

Pros: Microfiber is machine washable, which simplifies maintenance. Its versatility allows it to be used for a range of tasks, from drying vehicles to cleaning delicate surfaces.

Illustrative image related to synthetic shammy leather

Cons: The manufacturing process for microfiber can be more complex and costly compared to simpler materials like PVA. Additionally, the environmental impact of synthetic fibers may raise concerns among eco-conscious buyers.

Impact on Application: Microfiber is compatible with both water and oil-based cleaning agents, making it a versatile option for diverse cleaning tasks.

What are the Benefits and Drawbacks of Using Non-Woven Fabrics in Synthetic Shammy Leather?

Non-woven fabrics, often made from synthetic fibers, are engineered for specific applications in synthetic shammy leather. These materials provide a unique combination of softness and durability, making them suitable for high-performance drying tasks.

Illustrative image related to synthetic shammy leather

Pros: Non-woven fabrics are generally more cost-effective to produce and can be designed to meet specific performance criteria. They are lightweight and can be engineered for specific absorbency levels.

Cons: While non-woven fabrics can be durable, they may not offer the same level of absorbency as PVA or microfiber. Their performance can vary significantly based on the manufacturing process.

Impact on Application: Non-woven synthetic shammy leather is often used in industrial settings where cost-efficiency is crucial, but it may not be the best choice for high-end consumer products.

Illustrative image related to synthetic shammy leather

What Role Does Polyurethane Play in Synthetic Shammy Leather Applications?

Polyurethane is a synthetic polymer that offers excellent durability and flexibility, making it a strong contender for synthetic shammy leather. It is resistant to abrasion and can maintain its properties under various environmental conditions, including moisture and temperature fluctuations.

Pros: Polyurethane is exceptionally durable and can withstand extensive use without losing its performance. It is also resistant to mold and mildew, making it ideal for humid environments.

Cons: The cost of polyurethane can be higher than other materials, which may deter some buyers. Additionally, its environmental impact is a consideration, as it is not biodegradable.

Impact on Application: Polyurethane is suitable for applications requiring high durability, such as automotive detailing and industrial cleaning, where longevity and performance are paramount.

Summary Table of Material Selection for Synthetic Shammy Leather

| Material | Typical Use Case for synthetic shammy leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Alcohol | Automotive and household cleaning | Excellent absorbency and quick-drying | Degrades at high temperatures | Low |

| Microfiber | Versatile cleaning tasks | Soft, highly absorbent, machine washable | Higher manufacturing complexity | Medium |

| Non-Woven Fabric | Industrial applications | Cost-effective, customizable performance | Varies in absorbency | Low |

| Polyurethane | High-durability applications | Exceptional durability and moisture resistance | Higher cost, environmental concerns | High |

This strategic material selection guide provides B2B buyers with a comprehensive overview of the materials used in synthetic shammy leather, highlighting their properties and implications for various applications. Understanding these factors is crucial for making informed purchasing decisions that align with specific business needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for synthetic shammy leather

What Are the Main Stages in the Manufacturing Process of Synthetic Shammy Leather?

The manufacturing process for synthetic shammy leather typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets the high standards expected by B2B buyers.

How Is Material Prepared for Synthetic Shammy Leather Production?

The first step in the manufacturing process is the preparation of raw materials. Synthetic shammy leather is primarily made from polyvinyl alcohol (PVA) or polyurethane (PU), both of which are known for their excellent absorbent properties and durability. The selected polymers undergo a thorough quality check to ensure they meet specific requirements, such as viscosity and molecular weight.

Once the raw materials are confirmed to be of high quality, they are mixed with additives to enhance performance characteristics like softness, flexibility, and resistance to wear and tear. This preparation phase is critical, as the quality of the raw materials directly influences the performance of the final product.

What Techniques Are Used in Forming Synthetic Shammy Leather?

After material preparation, the forming process begins. This involves transforming the prepared polymers into sheets or rolls of synthetic shammy leather through a process called extrusion. During extrusion, the polymer blend is heated until it reaches a molten state and then forced through a die to create a flat sheet.

Illustrative image related to synthetic shammy leather

Another technique used in forming is casting, where the polymer mixture is poured into molds to shape it into the desired thickness and size. The choice between extrusion and casting often depends on the specific product requirements and intended applications.

How Is the Assembly of Synthetic Shammy Leather Carried Out?

Once the sheets are formed, they undergo an assembly process where they are cut to size and shaped according to customer specifications. This may involve die-cutting, which allows for precise shapes and sizes, or manual cutting for more intricate designs.

Additionally, some manufacturers may incorporate unique features, such as perforations or texture variations, to enhance the product’s usability. This stage is critical for ensuring that the synthetic shammy leather meets the various applications it is intended for, such as automotive, household cleaning, or personal care.

Illustrative image related to synthetic shammy leather

What Are the Key Steps in the Finishing Process for Synthetic Shammy Leather?

The finishing process is where the synthetic shammy leather is treated to improve its aesthetic appeal and performance. Common finishing techniques include surface treatment to enhance water resistance and softening agents to improve the tactile feel of the product.

Moreover, manufacturers may apply anti-microbial treatments to prevent odor and maintain freshness over time. The final product often undergoes a quality inspection to ensure it meets industry standards before being packaged for distribution.

What Quality Assurance Standards Are Relevant for Synthetic Shammy Leather?

Quality assurance is a critical component in the manufacturing of synthetic shammy leather. B2B buyers should be aware of relevant international standards, such as ISO 9001, which outlines requirements for an effective quality management system. Compliance with ISO standards ensures that the product consistently meets customer and regulatory requirements.

Illustrative image related to synthetic shammy leather

In addition to ISO standards, specific industry certifications like CE marking for products sold in Europe and API standards for automotive applications may also apply. These certifications not only enhance the credibility of the manufacturer but also assure buyers of the product’s quality and safety.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is essential throughout the manufacturing process, with specific checkpoints established to monitor quality at various stages.

-

Incoming Quality Control (IQC): This checkpoint involves testing raw materials upon arrival at the manufacturing facility to ensure they meet predetermined specifications.

-

In-Process Quality Control (IPQC): During the manufacturing stages, various tests are conducted to monitor the production process. This may include checking the viscosity of the polymer mix or the thickness of the extruded sheets.

-

Final Quality Control (FQC): After the assembly and finishing stages, the final product is subjected to rigorous testing to assess performance characteristics such as absorbency, durability, and appearance.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying a supplier’s quality control measures is crucial. Here are several actionable steps to ensure product quality:

-

Supplier Audits: Conducting on-site audits provides insights into the manufacturer’s production processes, quality control protocols, and compliance with industry standards.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality assurance reports, including results from IQC, IPQC, and FQC stages, along with any relevant certifications.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of product quality and compliance with international standards.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several nuances when it comes to quality control:

-

Cultural and Regulatory Differences: Understanding local regulations and cultural attitudes towards quality can help in establishing effective communication with suppliers.

-

Language Barriers: Ensure that all quality documentation is available in a language that is easily understandable to avoid misinterpretations.

-

Logistical Challenges: Consider the logistics involved in shipping and handling, which may impact product quality. Establishing clear guidelines for packaging and transport can help mitigate these risks.

By being proactive in understanding the manufacturing processes and quality assurance measures for synthetic shammy leather, B2B buyers can make informed decisions that align with their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘synthetic shammy leather’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure synthetic shammy leather. Given the diverse applications of synthetic chamois in various industries, including automotive, household cleaning, and personal care, it is essential to follow a structured approach to ensure that the products meet your specific requirements for quality, performance, and cost-effectiveness.

1. Define Your Technical Specifications

Before engaging with suppliers, it’s imperative to clearly outline the technical specifications of the synthetic shammy leather you need. This includes determining factors such as size, weight (GSM), absorbency level, and material composition (e.g., PVA or microfiber). Having well-defined specifications will streamline communication with potential suppliers and help you assess their offerings more effectively.

Illustrative image related to synthetic shammy leather

2. Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the synthetic shammy leather market. Look for companies with a proven track record and positive customer reviews. Utilize platforms like trade shows, industry directories, and online marketplaces to gather a list of potential suppliers. Consider their geographical location and shipping capabilities, especially if you’re sourcing from regions like Asia or Europe.

3. ✅ Verify Supplier Certifications

It’s crucial to ensure that your suppliers comply with relevant industry standards and certifications. Check for certifications such as ISO 9001 for quality management and REACH compliance for chemical safety. These certifications provide assurance of the supplier’s commitment to quality and safety, which is vital for maintaining your brand’s reputation.

4. Request Product Samples

Before making a bulk order, always request samples of the synthetic shammy leather. This allows you to evaluate the product’s texture, absorbency, durability, and overall quality. Assess how the material performs under different conditions, such as drying surfaces or absorbing liquids. This step minimizes the risk of dissatisfaction with the final product.

5. Evaluate Pricing and Payment Terms

Once you have shortlisted suppliers based on quality, it’s time to compare pricing and payment terms. While cost is a significant factor, consider the overall value, including the quality of the product and supplier reliability. Be clear about payment terms, such as upfront deposits and credit terms, to avoid any misunderstandings later on.

6. Discuss Shipping and Logistics

Engage in discussions regarding shipping options and logistics to ensure timely delivery of your order. Understand the lead times, shipping costs, and customs requirements, especially if you’re importing from overseas suppliers. Having clarity on these aspects will help you plan your inventory management effectively and avoid delays in your operations.

7. Establish a Quality Assurance Process

Implement a quality assurance process to monitor the quality of the synthetic shammy leather upon delivery. This could involve third-party inspections or in-house quality checks to ensure that the products meet your specified standards. Establishing this process will help you identify any issues early and maintain a consistent supply of high-quality materials.

By following this checklist, B2B buyers can streamline their sourcing process for synthetic shammy leather, ensuring they select the right suppliers and products to meet their business needs.

Comprehensive Cost and Pricing Analysis for synthetic shammy leather Sourcing

What Are the Key Cost Components in Synthetic Shammy Leather Sourcing?

When sourcing synthetic shammy leather, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The cost of synthetic materials, typically PVA or microfiber, significantly influences the final price. High-quality materials provide better absorbency and durability, which can justify a higher price point.

-

Labor: Labor costs can vary based on the region of production. Countries with lower labor costs may offer competitive pricing, but this may also correlate with varying quality standards.

-

Manufacturing Overhead: This includes expenses associated with running the production facility, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs, impacting pricing.

-

Tooling: Initial tooling costs for creating custom shapes or sizes can be substantial. However, once amortized over larger production runs, these costs can become negligible.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards. Companies that prioritize QC may charge a premium but often deliver higher-quality products.

-

Logistics: Shipping and handling costs, including customs duties and taxes, can significantly affect the total cost, especially for international buyers. Understanding the Incoterms is crucial for managing these expenses effectively.

-

Margin: Suppliers will add a margin to cover their operational costs and profit. This margin can vary widely based on market competition and supplier reputation.

How Do Price Influencers Affect Synthetic Shammy Leather Costs?

Several factors can influence the pricing of synthetic shammy leather, making it essential for buyers to consider these when negotiating.

Illustrative image related to synthetic shammy leather

-

Volume/MOQ: Minimum order quantities (MOQs) can lead to price breaks. Larger orders typically result in lower per-unit costs due to economies of scale.

-

Specifications/Customization: Customized products may incur additional costs. Buyers should balance the need for customization with budget constraints, as unique specifications can significantly affect pricing.

-

Materials Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, environmental certifications) can increase costs. However, they may also enhance the product’s marketability and longevity.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can also impact pricing. Established suppliers with a history of reliability may charge more but can offer better service and quality.

-

Incoterms: Understanding Incoterms is vital for managing shipping costs and responsibilities. Different terms can shift costs between buyer and seller, affecting the total landed cost of the product.

What Are the Best Negotiation Tips for B2B Buyers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation can lead to substantial savings.

-

Conduct Thorough Market Research: Understanding market rates and competitor pricing can provide leverage during negotiations. Buyers should gather as much data as possible about the suppliers and their offerings.

-

Explore Total Cost of Ownership (TCO): Assessing TCO, which includes initial purchase price, maintenance, and operational costs, can help justify higher upfront investments if they lead to lower long-term expenses.

-

Establish Strong Relationships: Building rapport with suppliers can lead to better terms and pricing. Long-term partnerships often yield more favorable pricing structures.

-

Flexibility in Order Size: If feasible, consider adjusting order sizes to meet MOQs that attract better pricing without overcommitting resources.

-

Negotiate Payment Terms: Favorable payment terms can improve cash flow and reduce upfront costs. Discussing options such as staggered payments or extended terms may yield advantageous conditions.

Conclusion

While the synthetic shammy leather market offers a variety of options, understanding the intricate cost structure and pricing influencers is crucial for making informed purchasing decisions. By leveraging negotiation strategies and focusing on total cost considerations, B2B buyers can optimize their sourcing process and enhance their bottom line.

Disclaimer: Prices mentioned are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements.

Alternatives Analysis: Comparing synthetic shammy leather With Other Solutions

Exploring Alternatives to Synthetic Shammy Leather: A Comparative Analysis

In the quest for effective drying solutions, synthetic shammy leather stands out for its unique properties. However, various alternatives exist that may better suit specific needs or preferences. This analysis will compare synthetic shammy leather against two viable alternatives: traditional chamois leather and microfiber towels. The comparison focuses on performance, cost, ease of implementation, maintenance, and best use cases to help international B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Synthetic Shammy Leather | Traditional Chamois Leather | Microfiber Towels |

|---|---|---|---|

| Performance | High absorbency, quick drying | Superior absorbency, natural feel | Excellent absorbency, quick drying |

| Cost | Moderate ($10 – $25 per unit) | Higher ($30 – $50 per unit) | Low ($5 – $20 per unit) |

| Ease of Implementation | Easy to use, lightweight | Requires proper care, heavier | Very easy, available in various sizes |

| Maintenance | Machine washable, low maintenance | Requires special care, hand wash | Machine washable, low maintenance |

| Best Use Case | Automotive drying, versatile usage | Premium car care, fine surfaces | General cleaning, versatile uses |

Detailed Breakdown of Alternatives

Traditional Chamois Leather

Traditional chamois leather is derived from sheepskin and is known for its unmatched absorbency and soft texture. This material can absorb up to six times its weight in water, making it ideal for drying delicate surfaces without scratching. However, it comes at a higher price point and requires careful maintenance, including hand washing and air drying to preserve its properties. While it excels in automotive applications and fine finishes, the investment may not be justified for all businesses, especially those with budget constraints.

Microfiber Towels

Microfiber towels are a popular choice due to their affordability and versatility. They provide excellent absorbency and can dry surfaces quickly, making them suitable for a wide range of applications, from automotive detailing to household cleaning. Additionally, microfiber towels are lightweight, easy to use, and machine washable, allowing for hassle-free maintenance. The primary drawback is that they may not offer the same level of absorbency as traditional chamois leather or synthetic shammy leather in heavy-duty applications. Thus, while they are cost-effective, they might fall short in specialized environments where superior drying performance is critical.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between synthetic shammy leather, traditional chamois leather, and microfiber towels, B2B buyers should consider their specific application needs, budget constraints, and maintenance capabilities. Synthetic shammy leather offers a balanced approach with high absorbency and ease of maintenance, making it ideal for diverse drying tasks. Traditional chamois leather is best suited for premium applications where surface care is paramount, while microfiber towels are perfect for general cleaning tasks where cost-effectiveness is a priority. Understanding these nuances will enable businesses to choose the most appropriate drying solution tailored to their operational requirements.

Essential Technical Properties and Trade Terminology for synthetic shammy leather

What Are the Key Technical Properties of Synthetic Shammy Leather?

When sourcing synthetic shammy leather, understanding its technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

Illustrative image related to synthetic shammy leather

-

Material Composition: Synthetic shammy leather is often made from polyvinyl alcohol (PVA) or microfiber blends. The material grade directly affects durability and absorbency. High-quality PVA materials typically offer superior performance, lasting longer and drying faster than lower-grade alternatives. For B2B buyers, selecting the right material ensures that the product meets performance standards for various applications, from automotive to household uses.

-

Weight (GSM): The weight of synthetic shammy leather is measured in grams per square meter (GSM). A higher GSM often indicates a thicker and more absorbent product. For example, a shammy with a GSM of 300 is generally more effective at soaking up liquids than one with a lower GSM. This property is essential for buyers who prioritize efficiency in drying applications.

-

Size and Dimensions: Synthetic shammy leather comes in various sizes, which can influence its usability. Common dimensions range from 15″x25″ to larger options like 19.6″x37.5″. Larger sizes are particularly beneficial for commercial applications, allowing for quicker drying of larger surfaces. Understanding size specifications helps businesses determine the right product for their specific needs.

-

Edge Type: The edge type of synthetic shammy leather can be either edgeless or finished with seams. Edgeless designs minimize the risk of scratching surfaces during use, making them preferable for high-end applications like automotive detailing. B2B buyers should consider the edge type based on the intended use to prevent damage to sensitive surfaces.

-

Absorbency Rate: This property refers to how much liquid the synthetic shammy can absorb relative to its weight. High-quality synthetic shammies can absorb several times their weight in water, offering superior performance for drying tasks. For businesses, understanding absorbency rates can lead to better product selection that enhances operational efficiency.

What Common Trade Terminology Should B2B Buyers Know?

Navigating the world of synthetic shammy leather also involves familiarity with industry-specific jargon. Here are some common terms that can help streamline the purchasing process:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or products used in another company’s end product. For B2B buyers, understanding OEM relationships is vital for sourcing quality components that meet specific industry standards.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management. Buyers should assess their needs to avoid overstocking or underordering.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a price quote for a specific quantity of goods. For B2B buyers, issuing RFQs can help compare prices and terms, ensuring the best deal is secured.

-

Incoterms (International Commercial Terms): These are standardized terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is crucial for B2B transactions, as they dictate shipping responsibilities, risk management, and cost allocation.

-

PVA (Polyvinyl Alcohol): A synthetic polymer used in the manufacture of shammy leather for its absorbent properties. Understanding PVA’s characteristics helps buyers evaluate the quality and performance of the products they are considering.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing synthetic shammy leather, ensuring that they choose products that align with their operational needs and quality expectations.

Navigating Market Dynamics and Sourcing Trends in the synthetic shammy leather Sector

What Are the Key Drivers and Trends Influencing the Synthetic Shammy Leather Market?

The synthetic shammy leather market is undergoing transformative changes driven by a combination of technological advancements, shifting consumer preferences, and global economic factors. One of the primary drivers is the increasing demand for high-performance cleaning products across various sectors, including automotive, household, and industrial applications. The versatility of synthetic shammies, such as their use in drying vehicles, cleaning surfaces, and even in personal care, makes them highly sought after.

Emerging technologies, particularly in manufacturing processes, are also shaping the market. Innovations in microfiber and polymer blends have led to the development of products that not only offer superior absorbency but also enhanced durability and ease of cleaning. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial for sourcing high-quality products that meet both performance and cost-effectiveness standards.

Moreover, there is a growing trend towards customization and branding in the synthetic shammy leather sector. Suppliers are increasingly offering private label options and tailored solutions to meet the specific needs of businesses, allowing for differentiation in competitive markets. This trend is particularly significant for B2B buyers looking to establish a unique identity in saturated markets.

How Is Sustainability Shaping Sourcing Decisions in the Synthetic Shammy Leather Sector?

Sustainability has become a pivotal consideration for B2B buyers in the synthetic shammy leather market. The environmental impact of production processes and the materials used is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. Synthetic shammies, often made from non-woven synthetic fibers, can be produced with less water and energy compared to traditional leather, offering a more sustainable option for businesses.

Ethical sourcing is also critical, as consumers and corporations alike are increasingly demanding transparency in supply chains. Buyers are encouraged to look for suppliers who hold certifications such as Global Recycled Standard (GRS) or OEKO-TEX, which indicate responsible sourcing and production practices. These certifications not only enhance brand reputation but also align with the growing consumer preference for environmentally friendly products.

In addition, the market is witnessing an uptick in the use of biodegradable materials in synthetic shammy production. As companies strive to reduce their carbon footprint, investing in products that incorporate sustainable materials can provide a competitive edge while meeting regulatory requirements and consumer expectations.

How Has the Synthetic Shammy Leather Market Evolved Over Time?

The evolution of synthetic shammy leather can be traced back to the need for durable and efficient alternatives to traditional leather. Initially, natural chamois leather was the go-to for many applications due to its superior absorbency and softness. However, as industries began to scale and demand increased, the limitations of natural materials became apparent, leading to the exploration of synthetic options.

Since the introduction of synthetic materials in the 20th century, the market has grown exponentially. Early synthetic shammies, often made from basic polymers, have now evolved into advanced microfiber technologies that offer enhanced performance characteristics. Today’s synthetic shammies are not only designed for optimal absorbency but also for durability, ease of maintenance, and cost-effectiveness, catering to a diverse range of applications from automotive care to household cleaning.

This evolution reflects a broader trend in manufacturing, where innovation and sustainability are increasingly prioritized, shaping the future landscape of the synthetic shammy leather sector. For B2B buyers, staying informed about these historical developments can provide insights into product quality and supplier reliability, essential factors for making informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of synthetic shammy leather

-

How do I choose the right supplier for synthetic shammy leather?

Selecting the right supplier involves several key factors. Start by researching suppliers’ reputations and certifications, focusing on those who adhere to international quality standards. Request samples to evaluate material quality, absorbency, and durability. Additionally, consider the supplier’s production capacity and lead times to ensure they can meet your demands. Engaging in direct communication can also reveal their responsiveness and customer service quality, which is crucial for a long-term partnership. -

What is the best type of synthetic shammy leather for automotive applications?

For automotive use, look for synthetic shammy leather made from high-quality PVA (polyvinyl alcohol) materials, known for their superior absorbency and softness. Products that are body shop safe and lint-free are ideal, as they prevent scratches and leave surfaces streak-free. Additionally, perforated designs enhance drying efficiency, making them suitable for drying vehicles quickly and effectively without damaging the paint or finish. -

What are the common customization options available for synthetic shammy leather?

Many manufacturers offer customization options such as size, thickness, color, and branding. You can request specific dimensions to suit your operational needs, as well as unique colors that align with your brand identity. Some suppliers may also allow for logo printing or packaging modifications. Be sure to discuss your requirements upfront to ensure the supplier can accommodate your preferences. -

What is the minimum order quantity (MOQ) for synthetic shammy leather?

Minimum order quantities vary significantly among suppliers and can depend on factors such as product type, customization, and production capabilities. Typically, MOQs can range from a few hundred to several thousand units. It’s advisable to clarify this with your potential suppliers early in the negotiation process to understand their policies and assess whether they align with your purchasing strategy. -

What payment terms should I expect when sourcing synthetic shammy leather internationally?

Payment terms can vary widely based on supplier policies and the buyer’s location. Common terms include upfront payment, a deposit followed by a balance upon delivery, or net payment terms (e.g., Net 30 or Net 60). Be prepared to negotiate these terms to suit your cash flow needs while ensuring the supplier feels secure in the transaction. It’s beneficial to establish clear terms in the contract to avoid misunderstandings. -

How can I ensure quality assurance for synthetic shammy leather products?

To ensure quality, request certifications and testing reports from your supplier that demonstrate compliance with relevant international standards. Consider implementing a quality control process that includes pre-shipment inspections, where you can examine samples for defects and performance. Establishing a clear communication line with your supplier regarding your quality expectations is also essential for maintaining product standards. -

What logistics considerations should I be aware of when importing synthetic shammy leather?

Logistics considerations include shipping methods, import duties, and customs regulations. Choose a reliable shipping partner familiar with international trade to minimize delays. Be aware of the potential tariffs and taxes applicable in your country, as these can impact your overall costs. Additionally, ensure that the supplier provides the necessary documentation for customs clearance to facilitate a smooth import process. -

What environmental factors should I consider when sourcing synthetic shammy leather?

When sourcing synthetic shammy leather, consider the environmental impact of the materials and production processes. Look for suppliers who prioritize sustainability by using eco-friendly materials and processes. Certifications such as ISO 14001 can indicate a commitment to environmental management. Understanding the lifecycle of the product, including its recyclability and disposal methods, can also contribute to your sustainability goals as a business.

Top 6 Synthetic Shammy Leather Manufacturers & Suppliers List

1. Autofiber – Holey Shammy Perforated Synthetic Microfiber Chamois

Domain: autofiber.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “Holey Shammy Perforated Synthetic Microfiber Chamois”, “Size”: “15”x25″”, “Weight”: “300 GSM”, “Material”: “100% Non-Woven Synthetic Microfiber”, “Edge Type”: “Edgeless”, “Country of Origin”: “South Korea”, “SKU”: “TSK300T-P1525-1”, “Features”: [“Exceptional absorbency”, “Fast, spotless, and streak-free finish”, “Machine washable”, “Durable construction”], “Ideal For”: [“Cars”, “…

2. Auto Beauty – Synthetic Chamois

Domain: autobeautyproducts.com

Registered: 2010 (15 years)

Introduction: {“Product Name”: “Synthetic Chamois”, “Code”: “ASE-100”, “Price”: “$25.33”, “Body Shop Safe”: “Yes”, “Size”: “Each”, “Voc Compliant”: “Yes”, “Description”: “Our best seller. Exclusive proven PVA material that gently cleans and dries fine finished surfaces. Lasts longer and dries faster and easier than hide products.”}

3. Chamois – Premium Leather

Domain: chamois.com

Registered: 1996 (29 years)

Introduction: Chamois leather is a unique and natural product made from selected sheepskins, 100% cod oil tanned for a luxurious, golden, soft finish. It can absorb six times its weight in water and is known for its quality and durability. The leather can be cut into regular shapes or left as whole skins, individually sized and graded to meet market requirements. The Pittards Dry-Soft Chamois features a unique …

4. WoollyWormit – Jumbo Sized Synthetic Chamois

Domain: woollywormit.com

Registered: 2016 (9 years)

Introduction: WoollyWormit Jumbo Sized Synthetic Chamois

– Regular Price: $16.95 USD

– Size: 19.6 in x 37.5 in (49.7 cm x 95.2 cm) = 5.1 sq ft (4750 sq cm)

– Material: PVA (Polyvinyl Alcohol)

– Color: Graphite

– Features:

– Super absorbent, engineered for better drying

– Dual surface: one side smooth, one side dimpled

– Non-abrasive, safe for all finishes (cars, furniture, countertops)

– Machine washab…

5. Armor All – Synthetic Chamois

Domain: armorall.com

Registered: 1993 (32 years)

Introduction: Product Name: Armor All® Synthetic Chamois

Description: Ultra-absorbent synthetic car chamois with a unique honeycomb surface that glides easily over wet surfaces without sticking to glass or paintwork.

Key Features:

– Honeycomb design for easy gliding

– Ultra-absorbent

– Fast-drying finish

Usage Instructions: Rinse thoroughly in cold water before first use and wring out excess. Use the honeycomb …

6. 3M – Synthetic PVA Chamois Leather

Domain: avcsl.com

Registered: 2011 (14 years)

Introduction: Product Name: 3M Synthetic PVA Chamois Leather

Brand: 3M

Supplier: AVCSL Advanced Vehicle Cleaning Suppliers Ltd

Price: Current price is £4.01 (original price was £5.00)

Size: 54 x 44 cm

Weight: 0.7 kg

Available Quantities: Pack of 3, Single

Description: Combines the best properties of a real chamois with the convenience of an ordinary car cloth. Increased tolerance to modern chemical cleaners and…

Strategic Sourcing Conclusion and Outlook for synthetic shammy leather

In the evolving landscape of synthetic shammy leather, strategic sourcing remains a vital component for international B2B buyers. The market is characterized by a diverse array of products, from high-performance microfiber chamois to specialized synthetic options that cater to various applications, including automotive and household uses. Understanding the unique features, such as absorbency, durability, and ease of maintenance, empowers buyers to make informed decisions that enhance their operational efficiency.

By prioritizing suppliers who offer innovative solutions and reliable quality, businesses can significantly improve their product offerings and customer satisfaction. The increasing demand for sustainable and high-performance cleaning products presents an opportunity for strategic partnerships that can drive growth in emerging markets across Africa, South America, the Middle East, and Europe.

Illustrative image related to synthetic shammy leather

As we look ahead, the focus on quality and sustainability will shape the future of synthetic shammy leather. Buyers are encouraged to explore new suppliers and technologies, ensuring they stay ahead of market trends. Embrace the advantages of strategic sourcing and position your business to thrive in this dynamic environment. Invest in synthetic shammy leather today to elevate your product line and meet the growing needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.