Introduction: Navigating the Global Market for leather like fabric

In today’s competitive landscape, international B2B buyers face the pressing challenge of sourcing high-quality leather-like fabric that meets diverse market needs while remaining cost-effective. As businesses across Africa, South America, the Middle East, and Europe seek alternatives to traditional leather, the demand for faux leather and PU leather has surged. This comprehensive guide serves as a valuable resource for navigating the global market for leather-like fabrics, providing insights into various types, applications, and the nuances of supplier vetting.

From upholstery in residential and commercial settings to automotive and marine applications, leather-like fabrics offer versatility that genuine leather often cannot match. This guide explores the latest trends in faux leather, highlights the advantages of sourcing synthetic materials, and outlines key considerations for cost management.

By equipping buyers with actionable insights on product specifications, supplier quality, and market pricing, this guide empowers decision-makers to make informed purchasing choices. Whether you’re looking to enhance your product offerings or seeking sustainable alternatives, understanding the landscape of leather-like fabrics will enable businesses to thrive in an increasingly eco-conscious and price-sensitive marketplace. Dive in to discover how to leverage these materials to meet your operational goals while maximizing value for your customers.

Table Of Contents

- Top 9 Leather Like Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather like fabric

- Understanding leather like fabric Types and Variations

- Key Industrial Applications of leather like fabric

- 3 Common User Pain Points for ‘leather like fabric’ & Their Solutions

- Strategic Material Selection Guide for leather like fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for leather like fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather like fabric’

- Comprehensive Cost and Pricing Analysis for leather like fabric Sourcing

- Alternatives Analysis: Comparing leather like fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for leather like fabric

- Navigating Market Dynamics and Sourcing Trends in the leather like fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather like fabric

- Strategic Sourcing Conclusion and Outlook for leather like fabric

- Important Disclaimer & Terms of Use

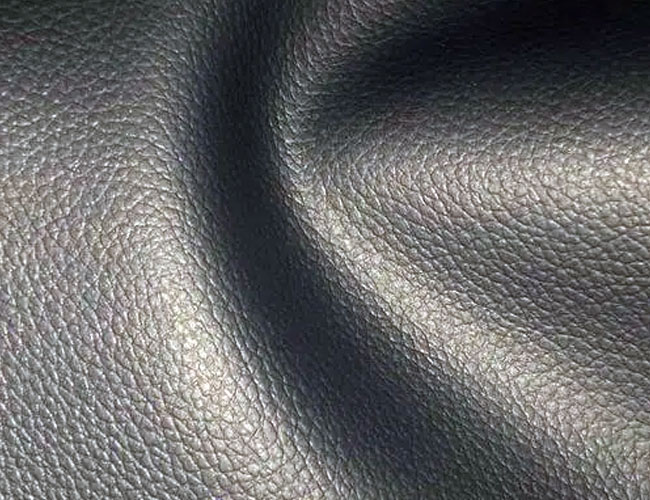

Understanding leather like fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Leather | Soft, supple texture; embossed grain for leather-like appearance | Upholstery for furniture, automotive interiors, marine uses | Pros: Cost-effective, easy to clean, water-resistant. Cons: May not have the same prestige as genuine leather. |

| PVC Leather | Durable and waterproof; often less flexible than PU leather | Commercial upholstery, outdoor furniture | Pros: Affordable, resistant to stains and fading. Cons: Can be less breathable, leading to discomfort. |

| Vegan Leather | Made from synthetic materials; eco-friendly alternatives | Fashion accessories, apparel, and furniture upholstery | Pros: Animal-friendly, available in various textures. Cons: May not have the same durability as traditional leather. |

| Microfiber Leather | Soft, suede-like feel; highly durable and stain-resistant | Automotive interiors, high-end furniture | Pros: Easy to maintain, luxurious appearance. Cons: Higher cost compared to other synthetic options. |

| Suede-like Fabric | Soft texture; resembles traditional suede; often made from polyester | Fashion items, upholstery, and accessories | Pros: Aesthetic appeal, soft touch. Cons: Less water-resistant than other types. |

What are the Characteristics and Suitability of PU Leather for B2B Buyers?

PU leather, or polyurethane leather, is a popular choice due to its soft texture and realistic leather-like appearance. It is highly versatile, making it suitable for various applications such as furniture upholstery, automotive interiors, and marine use. B2B buyers should consider its affordability, as it can be significantly less expensive than genuine leather—up to 75% lower. Additionally, PU leather is easy to clean and maintain, offering durability without the drawbacks of natural leather, such as susceptibility to water damage.

How Does PVC Leather Differ in Applications and Benefits?

PVC leather, or polyvinyl chloride leather, is known for its durability and waterproof properties. This makes it an ideal choice for commercial upholstery and outdoor furniture, where exposure to the elements is a concern. While it is generally more affordable than other options, buyers should be aware that PVC leather may lack the flexibility and breathability of PU leather, which can impact comfort in certain applications. Its resistance to stains and fading makes it a practical option for high-traffic areas.

Illustrative image related to leather like fabric

What Makes Vegan Leather an Attractive Option for B2B Purchasers?

Vegan leather is crafted from synthetic materials and is an appealing alternative for businesses seeking eco-friendly solutions. This type of leather is often used in fashion accessories, apparel, and upholstery, providing a variety of textures and styles. B2B buyers should note that while vegan leather is animal-friendly and increasingly popular, it may not always match the durability of traditional leather. However, its aesthetic appeal and versatility make it a strong contender in the marketplace.

Why Choose Microfiber Leather for High-End Applications?

Microfiber leather offers a luxurious, soft feel and is highly durable, making it a sought-after choice for automotive interiors and high-end furniture. Its stain-resistant properties and ease of maintenance enhance its appeal for B2B buyers looking for premium materials. Although it may come at a higher price point compared to other synthetic options, the long-term benefits of durability and appearance can justify the investment.

What are the Considerations for Suede-like Fabrics in Commercial Uses?

Suede-like fabrics provide a soft texture and aesthetic that appeals to many buyers in the fashion and upholstery markets. While they offer a luxurious look, B2B purchasers should consider their reduced water resistance compared to other synthetic leathers. These fabrics are often made from polyester, making them more affordable but potentially less durable. Businesses should assess their target market and application needs when considering suede-like fabrics for their products.

Key Industrial Applications of leather like fabric

| Industry/Sector | Specific Application of leather like fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for residential and commercial furniture | Cost-effective, durable, and easy-to-clean material | Quality certifications, color and texture variety, bulk pricing options |

| Automotive | Interior seating and trim materials | Lightweight, water-resistant, and customizable designs | Compliance with safety standards, long-term durability, color matching |

| Hospitality | Upholstery for hotel furnishings and restaurant seating | Enhances aesthetic appeal while being low maintenance | Fire-retardant properties, stain resistance, customization options |

| Marine Industry | Upholstery for boats and marine vehicles | Weather-resistant and durable for harsh environments | UV resistance, mildew resistance, and ease of cleaning |

| Fashion and Accessories | Production of bags, shoes, and apparel | Versatile design options and lower production costs | Availability of various textures and colors, ethical sourcing considerations |

How is leather like fabric used in furniture manufacturing?

In the furniture manufacturing sector, leather-like fabric is predominantly used for upholstery in both residential and commercial settings. It offers an aesthetically pleasing alternative to genuine leather, providing similar durability and texture at a fraction of the cost. This fabric is particularly appealing for international buyers in regions like Africa and South America, where cost constraints are significant. Buyers should consider sourcing options that offer a variety of colors and textures to match diverse design preferences, as well as certifications that ensure the quality and longevity of the materials.

What are the applications of leather-like fabric in the automotive industry?

In the automotive sector, leather-like fabric is extensively used for interior seating, trim, and dashboard coverings. Its lightweight nature contributes to overall vehicle efficiency, while its water-resistant properties make it suitable for various climates. International buyers from the Middle East and Europe should focus on suppliers who can provide materials compliant with safety and environmental regulations. Additionally, customization options for colors and finishes can enhance brand identity in the competitive automotive market.

How does leather-like fabric enhance hospitality environments?

The hospitality industry utilizes leather-like fabric for upholstery in hotels and restaurants, where both style and durability are paramount. This material not only enhances the aesthetic appeal of furnishings but also offers low maintenance benefits, which is crucial for high-traffic areas. Buyers in regions like Europe and South America should prioritize sourcing options that include fire-retardant properties and stain resistance to meet safety regulations and maintain a pristine appearance over time.

What role does leather-like fabric play in the marine industry?

In the marine industry, leather-like fabric is used for upholstery on boats and other marine vehicles. Its weather-resistant characteristics make it ideal for outdoor applications, ensuring longevity even in harsh conditions. Buyers from Africa and the Middle East should look for suppliers that offer UV and mildew-resistant options, as these features are essential for maintaining the integrity of marine upholstery. Additionally, ease of cleaning is a significant advantage, as it allows for quick maintenance in a demanding environment.

How is leather-like fabric utilized in the fashion and accessories market?

The fashion and accessories sector employs leather-like fabric in the production of bags, shoes, and apparel, appealing to a market increasingly focused on sustainability and cost-effectiveness. This fabric offers diverse design options without the ethical concerns associated with animal leather, making it attractive to eco-conscious consumers. International buyers should consider sourcing suppliers who provide a wide range of textures and colors, as well as ethical production practices, to align with current consumer trends and preferences.

3 Common User Pain Points for ‘leather like fabric’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: B2B buyers often face the challenge of inconsistent quality when sourcing leather-like fabrics from different suppliers. This can lead to significant issues in production, such as mismatched materials that affect the overall aesthetic and functionality of the final product. For example, a furniture manufacturer may order faux leather from one supplier for a line of chairs, only to discover that the texture, durability, and color of the fabric are not uniform across shipments. Such inconsistencies can jeopardize brand reputation and customer satisfaction.

Illustrative image related to leather like fabric

The Solution: To mitigate the risks associated with quality inconsistencies, B2B buyers should establish strong relationships with a limited number of trusted suppliers. Conduct thorough audits of potential vendors, looking for certifications and industry standards that ensure quality control processes are in place. Buyers can also request samples from multiple batches before placing large orders to verify that the materials meet their specifications. Furthermore, implementing a clear and detailed specification sheet that outlines the desired characteristics of the fabric—such as thickness, texture, colorfastness, and durability—can help align expectations and facilitate better communication with suppliers.

Scenario 2: Difficulty in Sourcing Sustainable Options

The Problem: As sustainability becomes a critical concern for many businesses, B2B buyers are increasingly seeking leather-like fabrics that are environmentally friendly and ethically sourced. However, the market can be saturated with products that claim to be “eco-friendly” without substantial backing. This can leave buyers feeling overwhelmed and uncertain about which options are genuinely sustainable and align with their corporate social responsibility goals.

The Solution: To navigate the complex landscape of sustainable leather-like fabrics, buyers should prioritize suppliers who provide transparency in their sourcing and manufacturing processes. Look for certifications such as Global Recycled Standard (GRS) or OEKO-TEX, which validate the environmental claims of the materials. Engaging in discussions with suppliers about their production methods and the materials used can also reveal insights into their sustainability practices. Additionally, consider sourcing from companies that utilize innovative materials, such as those made from recycled plastics or plant-based substances, which can offer both durability and a reduced environmental impact.

Scenario 3: Challenges in Maintenance and Longevity

The Problem: B2B buyers often encounter difficulties related to the maintenance and longevity of leather-like fabrics. While faux leather is generally marketed as easy to clean and maintain, various products have different levels of durability and stain resistance. For instance, a commercial buyer may find that a specific type of PU leather used in an upholstery project quickly shows signs of wear and tear, which can result in additional costs for replacements and repairs.

Illustrative image related to leather like fabric

The Solution: To ensure the longevity of leather-like fabrics in various applications, buyers should invest time in understanding the specific properties of the materials they are considering. It is essential to review technical specifications, including abrasion resistance, UV stability, and cleaning instructions. When selecting fabrics, opt for those with a higher grade of durability suitable for the intended use, such as commercial or heavy-duty ratings. Buyers can also implement a routine maintenance plan that includes regular cleaning with appropriate products to extend the lifespan of the upholstery. Educating end-users about proper care and maintenance can also significantly reduce wear and increase satisfaction with the product.

Strategic Material Selection Guide for leather like fabric

What Are the Key Properties of PU Leather in B2B Applications?

Polyurethane (PU) leather is a popular choice in the faux leather market, known for its soft texture and durability. It is produced by applying a flexible polymer coating to a fabric backing, which creates a supple material that closely resembles genuine leather. Key properties include excellent water resistance, stain resistance, and mildew resistance, making it suitable for various applications. PU leather can withstand moderate temperature fluctuations and is generally compatible with upholstery, automotive, and marine environments.

Pros of PU leather include its affordability, with costs up to 75% lower than genuine leather, and its ease of maintenance, as it can be cleaned with a simple cloth and warm water. However, a con is that while PU leather is durable, it may not have the same lifespan as high-quality genuine leather in high-stress applications.

Illustrative image related to leather like fabric

How Does PVC Leather Compare in Terms of Performance?

Polyvinyl chloride (PVC) leather, commonly referred to as vinyl, is another widely used synthetic leather. It offers a robust and waterproof surface, making it ideal for outdoor and marine applications. PVC leather is resistant to UV light, which helps prevent fading, and it is also easy to clean.

The advantages of PVC leather include its low cost and high durability, making it suitable for commercial applications such as furniture and automotive upholstery. However, a significant disadvantage is its environmental impact, as PVC production involves harmful chemicals, and it is less breathable than PU leather, which can affect comfort in certain applications.

What Are the Unique Benefits of Microfiber Leather for B2B Buyers?

Microfiber leather is a synthetic material made from ultra-fine fibers, providing a luxurious feel while being highly durable. It is water-resistant and offers excellent stain resistance, making it suitable for high-traffic areas. Its lightweight nature and flexibility allow for versatile applications across various industries.

The key advantage of microfiber leather is its softness and aesthetic appeal, which can closely mimic the look and feel of genuine leather. However, it can be more expensive than other synthetic options, which may be a limitation for budget-conscious buyers. Additionally, microfiber leather may require specific cleaning methods to maintain its appearance.

What Should International Buyers Consider When Selecting Leather-Like Fabrics?

When sourcing leather-like fabrics, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider compliance with local regulations and standards. Familiarity with ASTM, DIN, and JIS standards is crucial, as these can dictate material performance and safety requirements. Additionally, preferences for sustainable and animal-friendly materials are increasingly influencing purchasing decisions, particularly in markets with strong environmental regulations.

Illustrative image related to leather like fabric

Summary Table of Material Selection for Leather-Like Fabrics

| Material | Typical Use Case for leather like fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PU Leather | Upholstery, automotive, marine | Soft texture, affordable | Shorter lifespan than genuine leather | Low |

| PVC Leather | Outdoor furniture, commercial upholstery | High durability, easy to clean | Environmental impact, less breathable | Low |

| Microfiber Leather | High-end furniture, fashion accessories | Luxurious feel, excellent durability | Higher cost, specific cleaning requirements | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for leather like fabric

What Are the Main Stages in the Manufacturing Process of Leather-Like Fabric?

The production of leather-like fabric, commonly known as faux leather, involves several critical stages that ensure the final product meets both aesthetic and functional requirements. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial stage involves selecting the right base fabric, typically polyester or cotton, which is then treated with a polymer coating, such as polyurethane (PU) or polyvinyl chloride (PVC). This process is crucial as it sets the foundation for the fabric’s durability and texture. The coating is often applied using methods like knife-over-roll or gravure printing, allowing for precision in thickness and texture.

-

Forming: Once the base fabric is coated, the next step is forming the leather-like surface. This is achieved through processes such as embossing, where a pattern is pressed onto the surface, mimicking the natural grain of leather. Advanced techniques may include digital printing to create more complex textures and colors, enhancing the visual appeal of the fabric.

-

Assembly: In this stage, the prepared fabric is cut and sewn into various products, ranging from upholstery to fashion items. The assembly process requires skilled craftsmanship to ensure that seams are strong and that the fabric maintains its integrity. This step may also involve additional treatments, such as applying a protective finish to enhance stain resistance and durability.

-

Finishing: The final stage focuses on applying any necessary treatments and coatings to ensure the fabric meets industry standards for performance and aesthetics. This can include adding anti-microbial properties, UV resistance, and water repellency. The finishing process is vital for ensuring that the faux leather can withstand various environmental conditions and usage scenarios.

How Is Quality Assurance Implemented in Leather-Like Fabric Production?

Quality assurance (QA) in the manufacturing of leather-like fabrics is essential to ensure that the final product meets both safety and performance standards. Various international and industry-specific standards guide this process.

-

International Standards: ISO 9001 is the most recognized quality management standard, applicable across various industries, including textile manufacturing. Compliance with ISO 9001 indicates that a supplier adheres to internationally recognized quality management principles, which can help B2B buyers gauge the reliability of potential suppliers.

-

Industry-Specific Certifications: In addition to ISO standards, other certifications may be relevant depending on the end-use of the leather-like fabric. For instance, CE marking ensures compliance with European health, safety, and environmental protection standards, while API standards might apply to materials used in automotive applications.

-

Quality Control Checkpoints: Throughout the manufacturing process, several key quality checkpoints are established:

– Incoming Quality Control (IQC): Materials received are inspected for quality before they enter the production process. This includes testing for fabric strength, colorfastness, and coating integrity.

– In-Process Quality Control (IPQC): Regular inspections during the manufacturing process help identify defects early, minimizing waste and rework.

– Final Quality Control (FQC): A thorough examination of the finished products ensures they meet the required specifications before shipment. This may include testing for physical properties, visual inspections, and compliance with safety regulations.

What Testing Methods Are Commonly Used to Ensure Quality in Leather-Like Fabrics?

B2B buyers should be familiar with common testing methods used to verify the quality of leather-like fabrics. These tests assess various properties, ensuring that the product is fit for its intended use.

-

Tensile Strength Testing: This method measures the fabric’s resistance to tension and helps determine its durability. A higher tensile strength indicates a more robust material.

-

Abrasion Resistance Testing: This test evaluates how well the fabric can withstand wear and tear. Fabrics with higher abrasion resistance are suitable for high-traffic areas and applications requiring longevity.

-

Water Resistance Testing: This assesses the fabric’s ability to repel water, an essential property for upholstery and outdoor applications. Fabrics that pass this test will show minimal absorption when exposed to water.

-

Colorfastness Testing: This measures how well the fabric retains its color when exposed to light, washing, or rubbing. High colorfastness ratings are crucial for maintaining the fabric’s aesthetic appeal over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing leather-like fabrics, B2B buyers must be proactive in verifying the quality control practices of potential suppliers. Here are some effective strategies:

Illustrative image related to leather like fabric

-

Supplier Audits: Conducting audits of a supplier’s manufacturing facility can provide insights into their quality management systems, processes, and adherence to international standards. This hands-on approach allows buyers to assess the supplier’s commitment to quality.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from testing and compliance with relevant standards. Regularly updated quality reports can offer transparency and build trust.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can be particularly valuable for international transactions, where geographical distance may complicate direct oversight.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in leather-like fabric manufacturing is vital. Here are some key considerations:

-

Regional Standards Compliance: Different regions may have varying standards and regulations regarding textile products. Buyers should familiarize themselves with local requirements to ensure compliance and avoid potential legal issues.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary significantly between cultures. Buyers should communicate their specific quality expectations clearly to suppliers, ensuring alignment on product standards.

-

Logistical Considerations: Sourcing from international suppliers may involve additional logistics challenges. Buyers must consider lead times, shipping regulations, and potential tariffs that could affect the cost and quality of the final product.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance practices for leather-like fabrics is crucial for B2B buyers. By focusing on these areas, buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather like fabric’

Introduction

This practical sourcing guide is designed for international B2B buyers looking to procure leather-like fabrics, such as faux leather or PU leather. By following this step-by-step checklist, you can streamline your sourcing process, ensuring you select high-quality materials that meet your specific requirements while optimizing cost and sustainability.

1. Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications of the leather-like fabric you need. This includes the desired thickness, weight, finish, and any specific characteristics such as water resistance or fire retardancy. Having precise specifications helps in receiving accurate quotes and ensures the fabric meets your project’s demands.

2. Identify Your Budget Constraints

Establish a clear budget for your procurement process. Faux leather materials can vary significantly in price, with some options being up to 75% cheaper than genuine leather. Understanding your budget allows you to narrow down suppliers who can provide quality materials within your financial limits, ultimately leading to more informed purchasing decisions.

3. Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in leather-like fabrics. Look for companies with a solid reputation and extensive product offerings. Consider factors such as:

– Product Range: Ensure they offer various textures and colors to meet your design needs.

– Market Presence: Suppliers with a strong international presence may offer better reliability and service.

4. Request Samples for Evaluation

Once you have shortlisted suppliers, request samples of the leather-like fabrics you are interested in. Evaluating physical samples is crucial for assessing quality, texture, and overall appearance. Pay attention to:

– Durability: Check for resistance to wear and tear.

– Cleaning Requirements: Understand the maintenance involved to ensure longevity.

5. Verify Supplier Certifications

Before finalizing any agreements, ensure that potential suppliers possess relevant certifications that verify the quality and safety of their products. Look for certifications such as ISO or compliance with environmental standards. This step is vital for ensuring that the materials meet industry regulations and are ethically sourced.

6. Evaluate Terms and Conditions

Carefully review the terms and conditions provided by suppliers, including payment terms, delivery schedules, and return policies. Understanding these details helps to mitigate risks and ensures that both parties have clear expectations regarding the procurement process.

Illustrative image related to leather like fabric

7. Establish Communication Channels

Effective communication is key to a successful sourcing experience. Establish clear communication channels with your selected supplier, ensuring that you have direct access to representatives who can address any queries or concerns. Regular updates and feedback loops can help prevent misunderstandings and ensure that your project stays on track.

By following these steps, B2B buyers can navigate the complexities of sourcing leather-like fabrics effectively, leading to successful procurement and enhanced project outcomes.

Comprehensive Cost and Pricing Analysis for leather like fabric Sourcing

What are the Key Cost Components in Sourcing Leather-Like Fabric?

When sourcing leather-like fabrics, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The base cost for faux leather, often significantly lower than genuine leather, typically ranges from $5 to $30 per yard depending on the type (PU or PVC) and quality. High-quality PU leather tends to be more expensive due to its superior feel and durability.

-

Labor: Labor costs vary by region and complexity of production. In countries with lower labor costs, such as Vietnam or parts of Africa, manufacturers may offer more competitive pricing. However, specialized labor for high-end finishes may increase costs.

-

Manufacturing Overhead: This includes utilities, rent, and equipment costs. Manufacturers with advanced machinery may have higher overheads, but they can offer better quality and faster turnaround times.

-

Tooling: Custom designs or unique textures may require specific tooling, which can add to initial costs but should be viewed as an investment for potential long-term savings and differentiation in the market.

-

Quality Control (QC): Ensuring that products meet international standards incurs additional costs. Buyers should factor in the expenses associated with rigorous QC processes, especially for exports.

-

Logistics: Transportation costs can vary widely based on distance, shipping methods, and Incoterms. For international buyers, understanding these logistics is essential to avoid unexpected charges.

-

Margin: Supplier margins can differ based on market competition and product exclusivity. Generally, expect margins to range from 10% to 30%, depending on the supplier’s pricing strategy and market positioning.

What Influences the Pricing of Leather-Like Fabrics?

Several factors can influence the pricing of leather-like fabrics:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often lead to discounts. Buyers should assess their needs carefully to leverage better pricing.

-

Specifications and Customization: Customized fabrics or unique specifications can increase the price. Buyers should weigh the benefits of customization against potential cost increases.

-

Materials and Quality Certifications: Fabrics with certifications (e.g., eco-friendly or fire-resistant) may carry a premium. Buyers should evaluate the importance of these certifications based on end-use.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers with a track record of quality may charge more but can offer peace of mind.

-

Incoterms: Understanding the chosen Incoterm (e.g., FOB, CIF) is crucial as it dictates who bears the cost of shipping and insurance, which can significantly affect the total price.

How Can Buyers Negotiate for Better Pricing on Leather-Like Fabrics?

Negotiation is a vital skill in sourcing. Here are some strategies for B2B buyers:

-

Research Market Rates: Knowing average prices for different types of leather-like fabrics helps in negotiating from a position of strength.

-

Leverage Long-Term Relationships: Building rapport with suppliers can lead to better pricing and terms over time.

-

Consider Total Cost of Ownership (TCO): While the initial cost is important, consider long-term factors such as durability and maintenance costs. Presenting a TCO analysis can help justify higher upfront costs for better quality.

-

Explore Multiple Suppliers: Having several potential suppliers can create competition, leading to better pricing and terms.

-

Be Clear About Specifications: Providing detailed specifications can minimize misunderstandings and ensure accurate pricing.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider the following:

-

Currency Fluctuations: Exchange rates can impact costs significantly. Locking in prices in a stable currency can mitigate risks.

-

Import Duties and Taxes: Understanding local import regulations and potential tariffs is essential to avoid unexpected costs.

-

Cultural Negotiation Styles: Be aware of regional negotiation styles; some cultures may prefer direct negotiation while others value relationship-building.

-

Regulatory Compliance: Ensure that the fabric meets the local standards of the importing country to avoid delays or additional costs.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier relationships, and specific buyer requirements. Always request detailed quotes and conduct thorough market research before finalizing purchases.

Illustrative image related to leather like fabric

Alternatives Analysis: Comparing leather like fabric With Other Solutions

Exploring Alternatives to Leather Like Fabric: A Comprehensive Comparison

In the quest for durable, aesthetically pleasing, and cost-effective materials, many businesses consider alternatives to leather-like fabrics. These alternatives vary in terms of performance, cost, ease of implementation, maintenance, and ideal use cases. Understanding these factors can help B2B buyers make informed decisions that align with their specific needs and market demands.

| Comparison Aspect | Leather Like Fabric | Alternative 1: Genuine Leather | Alternative 2: Cork Fabric |

|---|---|---|---|

| Performance | High durability, water-resistant, and easy to clean. | Excellent durability and natural appeal, but requires careful maintenance. | Good durability, lightweight, and water-resistant. |

| Cost | Significantly lower, up to 75% less than genuine leather. | Higher initial investment, often considered a premium material. | Moderate cost, generally lower than genuine leather but higher than synthetic options. |

| Ease of Implementation | Readily available in various colors and textures; easy to source. | Requires sourcing from specific suppliers and may involve higher shipping costs. | Easy to implement; can be sourced from eco-friendly suppliers. |

| Maintenance | Minimal upkeep; can be wiped clean with a damp cloth. | Requires regular conditioning and specialized cleaning products. | Easy to maintain; typically requires just a damp cloth for cleaning. |

| Best Use Case | Ideal for commercial furniture, automotive interiors, and marine applications. | Suited for luxury goods, high-end furniture, and fashion items. | Great for eco-conscious brands and products requiring a unique aesthetic. |

What Are the Advantages and Disadvantages of Genuine Leather?

Genuine leather is revered for its luxury and natural appeal. It boasts excellent durability and develops a unique patina over time, making it highly desirable for high-end products. However, its maintenance requirements can be a drawback, as it necessitates regular conditioning to prevent cracking and drying out. Additionally, genuine leather can be significantly more expensive, which may not align with budget-conscious projects.

How Does Cork Fabric Compare as an Alternative?

Cork fabric presents a unique sustainable option that is gaining popularity in various sectors. It is lightweight, water-resistant, and offers a distinctive texture that appeals to eco-conscious consumers. Cork is also relatively easy to maintain, requiring just a simple wipe-down with a damp cloth. However, it may not provide the same level of durability as leather-like fabrics or genuine leather in high-stress environments, which could limit its application in certain industries.

Making the Right Choice for Your Business Needs

When selecting the right material for your project, consider the specific requirements of your application. If cost efficiency and ease of maintenance are priorities, leather-like fabric is an excellent choice, particularly for commercial applications where durability and aesthetics are paramount. Conversely, if you’re targeting a luxury market, investing in genuine leather may enhance your brand’s perception. For eco-friendly initiatives, cork fabric offers a unique aesthetic while supporting sustainability efforts. Ultimately, your decision should align with your brand values, target market, and operational needs, ensuring you choose a solution that not only meets your requirements but also resonates with your customers.

Essential Technical Properties and Trade Terminology for leather like fabric

What are the Key Technical Properties of Leather-like Fabrics?

When considering leather-like fabrics for commercial applications, understanding their technical properties is vital for making informed purchasing decisions. Here are some essential specifications to keep in mind:

Illustrative image related to leather like fabric

-

Material Composition

Leather-like fabrics are primarily made from synthetic materials such as polyurethane (PU) and polyvinyl chloride (PVC). PU leather is known for its softness and durability, closely mimicking genuine leather, while PVC offers a more cost-effective option with decent durability. Understanding the material composition helps buyers assess the quality and performance of the fabric, ensuring it meets specific project requirements. -

Weight and Thickness

The weight of the fabric, usually measured in grams per square meter (gsm), directly impacts its durability and suitability for various applications. For example, heavier fabrics are often preferred for upholstery in high-traffic areas, while lighter options may be suitable for fashion accessories. Thickness also affects how the fabric drapes and its overall aesthetic, which is crucial for design decisions. -

Abrasion Resistance

Abrasion resistance indicates how well the fabric can withstand wear and tear over time. This property is especially important in commercial settings such as hotels and restaurants where furniture is subject to frequent use. Fabrics that score high on abrasion tests ensure longevity and reduce replacement costs, making them a smart investment for B2B buyers. -

Water and Stain Resistance

Many faux leathers are treated to be water and stain-resistant, which makes them easier to clean and maintain compared to genuine leather. This property is essential for applications in environments prone to spills, such as restaurants and healthcare facilities. Understanding the level of resistance helps buyers select fabrics that will perform well under specific conditions. -

Environmental Compliance

As sustainability becomes a significant concern, many B2B buyers are looking for eco-friendly materials. Leather-like fabrics made from recycled or biodegradable materials can offer a competitive edge. Buyers should inquire about certifications and compliance with environmental regulations to ensure their sourcing aligns with corporate responsibility goals.

What are Common Trade Terms in the Leather-like Fabric Industry?

Understanding industry-specific terminology is crucial for effective communication and negotiation. Here are some common trade terms relevant to leather-like fabrics:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods that are marketed under another company’s brand. In the context of leather-like fabrics, it can indicate suppliers who manufacture materials for furniture or automotive companies. Knowing the OEMs can help buyers identify reliable sources for high-quality products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For leather-like fabrics, MOQs can vary significantly based on the type of material and supplier. Understanding MOQs is critical for buyers to plan their inventory and manage costs effectively. -

RFQ (Request for Quotation)

An RFQ is a formal document that buyers use to request pricing and terms from suppliers. It is particularly useful when sourcing leather-like fabrics in bulk, as it allows buyers to compare offers from multiple suppliers. A well-structured RFQ can streamline the procurement process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping agreements. Understanding these terms helps B2B buyers navigate logistics effectively, ensuring clarity on who is responsible for shipping costs, insurance, and risks during transit. -

Lead Time

Lead time refers to the time it takes from placing an order until the goods are delivered. For businesses relying on leather-like fabrics for production, knowing the lead time is essential for planning and ensuring timely project completion.

By familiarizing themselves with these properties and terms, B2B buyers can make more informed decisions, ultimately enhancing their procurement strategies and ensuring successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the leather like fabric Sector

What Are the Current Market Dynamics and Key Trends in the Leather-Like Fabric Sector?

The leather-like fabric market is witnessing significant growth driven by various global factors. Increasing consumer demand for affordable, stylish, and sustainable alternatives to genuine leather is reshaping sourcing strategies for international B2B buyers. Particularly in regions like Africa, South America, the Middle East, and Europe, the adoption of faux leather is accelerating due to its versatility and lower price point—up to 75% less than genuine leather. Emerging markets, such as Brazil and Vietnam, are becoming pivotal players, offering a diverse range of faux leather products tailored for residential, commercial, and automotive applications.

Technology is also playing a crucial role in this sector. Innovations in manufacturing processes, such as eco-friendly polyurethane (PU) production, are enhancing the quality and sustainability of faux leather. B2B buyers are increasingly leveraging online platforms for sourcing, with many suppliers offering customizable options, allowing businesses to select colors, textures, and specifications that meet their unique project needs. Additionally, the trend towards digitalization is making procurement more efficient, enabling buyers to access a global pool of suppliers while ensuring quality and compliance with international standards.

How Is Sustainability and Ethical Sourcing Impacting the Leather-Like Fabric Market?

Sustainability is at the forefront of the leather-like fabric industry, as consumers and businesses alike become more conscious of their environmental footprint. Faux leather offers a more sustainable alternative to traditional leather, primarily due to its production processes that often consume fewer resources and generate less waste. The significance of ethical sourcing cannot be overstated; businesses are increasingly expected to adopt transparent supply chains that prioritize environmentally friendly practices.

B2B buyers should look for suppliers who offer certified sustainable materials. Green certifications, such as OEKO-TEX and Global Recycled Standard (GRS), indicate compliance with environmental and social responsibility standards. As the demand for eco-friendly products continues to rise, sourcing faux leather that meets these criteria can enhance brand reputation and appeal to environmentally conscious consumers. Emphasizing sustainability in procurement strategies not only helps in mitigating environmental impact but also positions businesses favorably in a competitive market.

What Is the Evolution and Historical Context of Leather-Like Fabrics?

The evolution of leather-like fabrics can be traced back to the early 20th century when synthetic alternatives were first developed to provide a more affordable and versatile option compared to genuine leather. The invention of Naugahyde in 1920 marked a significant milestone, paving the way for various innovations in faux leather production. Over the decades, advancements in textile technology have led to the creation of highly durable and aesthetically pleasing materials, such as polyurethane (PU) leather, which closely resembles genuine leather in texture and appearance.

As consumers’ preferences shifted towards ethical and sustainable products, the faux leather market gained momentum, particularly in the last two decades. This historical context is essential for B2B buyers to understand the trajectory of the market and the ongoing innovations that continue to shape the landscape of leather-like fabrics today.

Frequently Asked Questions (FAQs) for B2B Buyers of leather like fabric

-

How do I choose the right type of faux leather for my project?

When selecting faux leather, consider factors such as the intended use, durability requirements, and aesthetic preferences. For upholstery, PU leather is often recommended for its softness and leather-like appearance, making it suitable for both residential and commercial applications. Additionally, assess the fabric’s resistance to stains, water, and UV light, especially if it will be used outdoors or in high-traffic areas. Don’t hesitate to request samples from suppliers to evaluate the texture and color firsthand. -

What are the benefits of sourcing faux leather from international suppliers?

Sourcing faux leather internationally can provide access to a wider variety of materials, competitive pricing, and unique textures not available locally. Countries like Brazil and Vietnam have established manufacturing capabilities, often resulting in lower production costs. Moreover, international suppliers may offer advanced technologies in faux leather production, ensuring high-quality and sustainable options that align with global trends. Establishing relationships with these suppliers can enhance your product offerings and improve market competitiveness. -

What is the minimum order quantity (MOQ) for faux leather fabrics?

MOQs for faux leather can vary significantly depending on the supplier and the specific fabric type. Typically, MOQs range from 50 to 500 yards, but many suppliers are open to negotiation, especially for repeat customers or larger contracts. When evaluating MOQs, consider your project’s scale and your capacity to store excess inventory. Always discuss the potential for smaller sample orders to assess quality before committing to larger quantities. -

What payment terms should I expect when dealing with international suppliers?

Payment terms can differ based on the supplier’s policies and the nature of the transaction. Common terms include payment upfront, a deposit with the balance due upon shipment, or net payment terms (e.g., net 30 days). Be sure to clarify these terms before placing an order and consider using secure payment methods, such as letters of credit or escrow services, to protect your investment. Understanding the supplier’s currency requirements and exchange rates is also crucial for accurate budgeting. -

How can I ensure the quality of faux leather before purchasing?

To ensure product quality, request certification documents from the supplier, such as ISO certifications or compliance with specific industry standards. Consider conducting a quality assurance (QA) inspection either through third-party services or by visiting the manufacturing site if feasible. Additionally, ask for fabric samples to assess texture, durability, and color fastness. Establishing a clear communication channel with the supplier regarding quality expectations will also help mitigate any potential issues. -

What are the shipping and logistics considerations for sourcing faux leather internationally?

When sourcing faux leather internationally, factor in shipping costs, delivery timelines, and customs duties. Work with suppliers who have experience in international shipping to navigate logistics efficiently. Discuss the preferred shipping methods (e.g., air vs. sea freight) and the potential impact on lead times. It’s advisable to verify the supplier’s ability to provide necessary documentation for customs clearance to avoid delays upon arrival in your country. -

Can I customize faux leather fabrics for my brand?

Many suppliers offer customization options for faux leather, including specific colors, textures, and finishes. Discuss your design requirements with potential suppliers and inquire about their capabilities for custom orders. Keep in mind that minimum order quantities may increase for customized fabrics, and additional lead time may be required for production. Providing detailed specifications and prototypes can help ensure that the final product aligns with your brand’s vision. -

What are the common applications for faux leather in various industries?

Faux leather is versatile and widely used across multiple industries, including furniture upholstery, automotive interiors, fashion accessories, and marine applications. In the hospitality sector, it’s popular for restaurant and hotel furnishings due to its durability and ease of maintenance. Additionally, faux leather serves as a sustainable alternative in fashion, appealing to eco-conscious consumers. Understanding the specific applications within your industry can help you better target your sourcing and marketing efforts.

Top 9 Leather Like Fabric Manufacturers & Suppliers List

1. Decorative Fabrics Direct – PU Leather & Faux Leather

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: PU Leather & Faux Leather | Vinyl Upholstery Fabric. Terms: Free Shipping Coupon Code: SHIPFREE for Most $199 Orders. Available for wholesale purchase by the yard or full roll. Brands include Naugahyde, Omnova Boltaflex, Nassimi, and Spradling. Suitable for furniture, automotive, marine, and commercial projects. Fabric types include Vinyl (PVC), Urethane, and Polycarbonate. Color options include B…

2. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

Introduction: Faux Leather collection by Sallie Tomato includes 66 products, with 65 being Faux Leather and 1 Vinyl. The fabrics are available in various colors including Beige (5), Black (10), Blue (6), Brown (10), Green (6), Grey (6), Navy (4), Orange (1), Pink (4), Purple (2), Red (6), Teal (1), White (2), and Yellow (2). Textures available are Alligator (4), Basket Weave (6), Crocodile (4), Legacy (15), Lim…

3. Reddit – Recommended Fabric Alternatives for Jackets

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Recommended fabrics instead of leather for recreating a jacket include: imitation leather, scuba fabric, faux leather, black duchess satin, waxed canvas, vegan leathers made from plant fibers (like pineapple leaves or discarded mangoes), and heavier cotton options like corduroy or cotton sateen.

4. Rub N Restore – Types of Leather

Domain: rubnrestore.com

Registered: 2010 (15 years)

Introduction: Different types of leather include:

1. Full Grain Leather: Finest quality, fully intact hide, absorbent, may have aniline or pigmented finish.

2. Top Grain Leather: Second best grade, sanded for uniform appearance, repels liquids, often thinner and more flexible.

3. Aniline & Semi-Aniline Leather: Full or top grain, dyed for marbled appearance, absorbent, prone to stains.

4. Pull-up Leather: F…

5. Mood Fabrics – Faux Leather Fabric

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: Faux Leather Fabric by the Yard | Ethical Alternative

6. Rodeo Home – Upholstery Fabrics

Domain: rodeohome.com

Registered: 2003 (22 years)

Introduction: Rodeo Home offers a diverse range of upholstery fabrics, including faux leather, suede, mohair, and bear-like type fabrics. The fabrics are available in medium and heavy weights, ensuring versatility in design. Faux leather provides a sleek look for modern interiors, while suede adds warmth and comfort. Mohair offers plushness and opulence, and bear-like fabrics evoke a cozy, rustic charm. The com…

7. Fabric Warehouse – Faux Leather Upholstery Fabric

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Faux Leather Upholstery Fabric available by the yard. Common names include faux leather, pleather, vegan leather, synthetic leather, and simulated leather. Patterns available include ostrich, peacock, snake, crocodile, alligator, and cow. Fabric width is 54 inches. Suitable for upholstery projects such as stools, benches, and armchairs. Marine vinyl fabric is also available for boat restoration. V…

8. Mitchell Faux Leathers – Lexi Faux Leather

Domain: mitchellfauxleathers.com

Registered: 2011 (14 years)

Introduction: Lexi is a leather-like fabric made of 100% polyurethane, featuring a supple hand and smooth buttery texture. It is suitable for commercial seating applications, particularly effective on soft cushions, bar or gaming rails, pillows, and pillow-back seating. Lexi has a stretch knit backing for easy sewing and boasts superior abrasion resistance (surpassing 100,000 Wyzenbeek cycles), excellent tensil…

9. Sewport – Faux Leather Solutions

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: Faux leather, also known as pleather, vegan leather, Naugahyde, synthetic leather, artificial leather, fake leather, ersatz leather. Fabric composition: PVC or vegetable oils. Fabric breathability: Low. Moisture-wicking abilities: Low. Heat retention abilities: High. Stretchability: Low. Prone to pilling/bubbling: Low. Country where fabric was first produced: United States. Biggest exporting/produ…

Strategic Sourcing Conclusion and Outlook for leather like fabric

In the evolving landscape of leather-like fabrics, strategic sourcing is paramount for international B2B buyers. With the rapid growth of faux leather options such as PU and PVC, businesses can capitalize on significant cost savings—up to 75% less than genuine leather—without sacrificing quality or aesthetics. The versatility of these materials allows for a wide range of applications, from residential and commercial upholstery to automotive and marine uses, making them a smart choice for diverse markets.

Illustrative image related to leather like fabric

Furthermore, the durability and ease of maintenance of faux leather enhance its appeal, particularly in regions facing harsh climates or stringent regulations. Buyers should prioritize suppliers who offer high-quality, sustainable materials that align with current consumer preferences for animal-friendly and eco-conscious products.

As we look to the future, it is essential for B2B buyers in Africa, South America, the Middle East, and Europe to stay informed about emerging trends and innovations in synthetic leather. By engaging with reputable suppliers and leveraging strategic sourcing practices, businesses can position themselves for success in an increasingly competitive market. Embrace the opportunities that leather-like fabrics present and elevate your product offerings today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.