Introduction: Navigating the Global Market for custom leather stamping

In the competitive landscape of global trade, sourcing high-quality custom leather stamping solutions presents unique challenges for B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. The need for distinctive branding and product differentiation drives the demand for custom leather stamps, yet navigating the complexities of supplier selection, production timelines, and pricing can be daunting. This guide aims to demystify the process of procuring custom leather stamping services, offering insights into the various types of stamps available, their applications across industries, and essential criteria for vetting suppliers.

From understanding the nuances of materials and design specifications to evaluating cost structures, this comprehensive resource empowers international buyers to make informed decisions. With a focus on practical applications—ranging from small artisanal businesses to large-scale manufacturing operations—this guide addresses the specific needs of diverse markets. Whether you are based in Nigeria, Germany, or elsewhere, the insights provided here will equip you with the knowledge necessary to enhance your product offerings and strengthen your competitive edge in the global marketplace. By leveraging the information contained within, you can confidently engage with suppliers and secure solutions that meet your unique business requirements.

Table Of Contents

- Top 5 Custom Leather Stamping Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather stamping

- Understanding custom leather stamping Types and Variations

- Key Industrial Applications of custom leather stamping

- 3 Common User Pain Points for ‘custom leather stamping’ & Their Solutions

- Strategic Material Selection Guide for custom leather stamping

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamping

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamping’

- Comprehensive Cost and Pricing Analysis for custom leather stamping Sourcing

- Alternatives Analysis: Comparing custom leather stamping With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather stamping

- Navigating Market Dynamics and Sourcing Trends in the custom leather stamping Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamping

- Strategic Sourcing Conclusion and Outlook for custom leather stamping

- Important Disclaimer & Terms of Use

Understanding custom leather stamping Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Brass Stamps | Durable, high-quality brass; suitable for detailed designs | Branding, product labeling, custom gifts | Pros: Long-lasting, excellent detail; Cons: Higher cost compared to other materials. |

| Handheld Steel Stamps | Portable, versatile; can be used for various materials | Small businesses, artisan crafts | Pros: Easy to use, cost-effective; Cons: Limited to smaller designs. |

| Custom Roll Dies | Designed for continuous stamping; ideal for large production runs | Mass production of leather goods | Pros: Efficient for high volume; Cons: Initial setup cost can be high. |

| Heat Embossing Stamps | Utilizes heat for deeper impressions; suitable for delicate designs | High-end leather products, luxury items | Pros: Produces rich, textured results; Cons: Requires additional equipment. |

| Custom CNC Stamps | Precision-engineered using CNC technology; highly customizable | Complex designs, intricate patterns | Pros: High accuracy, fast turnaround; Cons: May require specific file formats. |

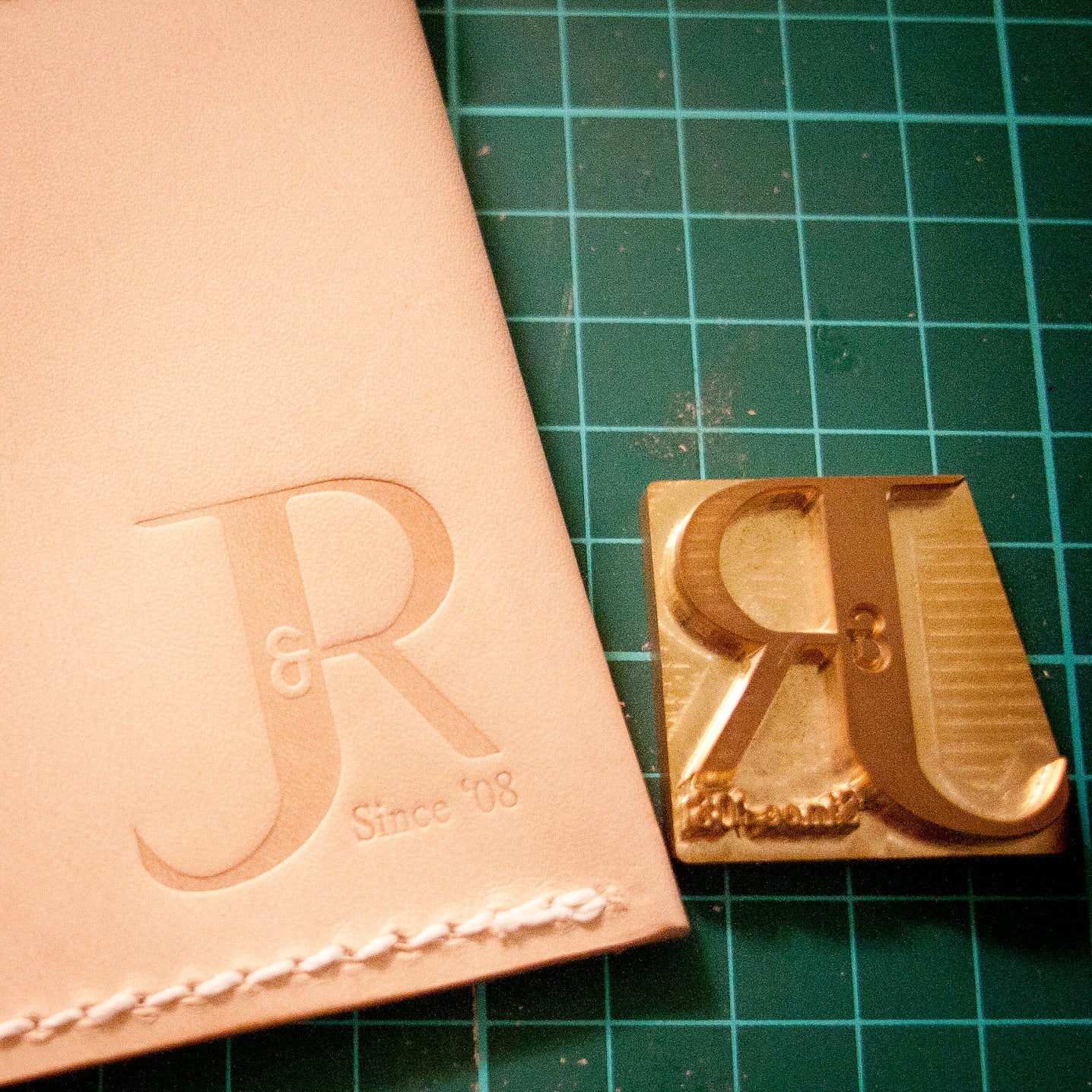

What Are the Characteristics of Custom Brass Stamps?

Custom brass stamps are recognized for their durability and ability to produce intricate designs. Made from high-quality brass, these stamps are ideal for businesses looking to create permanent marks on leather products. They are particularly suited for branding, product labeling, and custom gifts. When considering a purchase, buyers should evaluate the design complexity they require and the longevity of the stamp, as brass offers a longer lifespan compared to other materials.

How Do Handheld Steel Stamps Benefit Small Businesses?

Handheld steel stamps are portable and versatile, making them an excellent choice for small businesses and artisan crafts. These stamps can be used on various materials, including leather, wood, and metal, allowing for a range of applications from personalizing gifts to creating branded merchandise. While they are cost-effective and easy to use, buyers should keep in mind that the size of the designs is limited, which may restrict branding opportunities.

Illustrative image related to custom leather stamping

Why Choose Custom Roll Dies for Mass Production?

Custom roll dies are specifically designed for high-volume stamping, making them an ideal choice for businesses focused on mass production of leather goods. These stamps allow for continuous impressions, significantly increasing efficiency during the manufacturing process. However, the initial setup cost can be high, which may not be suitable for smaller operations. Buyers should assess their production needs and budget to determine if this option aligns with their business goals.

What Are the Advantages of Heat Embossing Stamps?

Heat embossing stamps utilize heat to create deep, textured impressions on leather, making them perfect for high-end leather products and luxury items. This technique enhances the aesthetic appeal of the product, adding perceived value. However, it requires additional equipment like a heat embosser, which can increase the initial investment. Buyers should consider the type of products they intend to create and whether the added texture aligns with their branding strategy.

How Do Custom CNC Stamps Enhance Design Precision?

Custom CNC stamps are engineered using advanced CNC technology, allowing for high precision and intricate designs. These stamps are highly customizable and can accommodate complex patterns that traditional methods may not achieve. They are particularly beneficial for businesses focusing on unique and detailed artwork. However, buyers must ensure they provide the correct file formats, as some manufacturers only accept specific types, which could affect turnaround time.

Key Industrial Applications of custom leather stamping

| Industry/Sector | Specific Application of custom leather stamping | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Branding on leather goods | Enhances brand recognition and adds a premium feel | Quality of materials, precision in design, lead time |

| Automotive | Custom leather interiors | Differentiates products, enhances luxury perception | Durability of stamps, compatibility with leather type |

| Furniture & Décor | Stamping on leather upholstery | Creates unique designs, adds value to furniture pieces | Design complexity, size of stamps, environmental impact |

| Craft & Hobby | DIY leather projects | Empowers creativity, allows for personalized products | Availability of custom designs, ease of use, cost |

| Gift & Promotional | Personalized leather gifts | Increases customer loyalty, enhances gift appeal | Minimum order quantities, shipping options, turnaround time |

How Is Custom Leather Stamping Utilized in the Fashion & Apparel Industry?

In the fashion and apparel sector, custom leather stamping is primarily used for branding leather goods, such as handbags, belts, and wallets. This technique allows businesses to imprint logos or unique designs onto their products, enhancing brand recognition and creating a premium feel. For international B2B buyers, particularly those from Africa and Europe, it’s crucial to consider the quality of materials used for stamping, as well as the precision of the designs. Fast turnaround times can also be a deciding factor, especially in competitive markets.

What Role Does Custom Leather Stamping Play in the Automotive Industry?

The automotive industry utilizes custom leather stamping for branding and enhancing the interiors of vehicles. Stamped leather seats and trim can differentiate a car model, elevating its luxury perception among consumers. For B2B buyers in South America and the Middle East, sourcing durable stamps that can withstand the rigors of vehicle use is essential. Compatibility with various types of leather and the ability to produce intricate designs are also critical factors when selecting a supplier.

How Is Custom Leather Stamping Applied in Furniture & Décor?

In the furniture and décor industry, custom leather stamping is employed to create unique upholstery designs that add value to furniture pieces. Stamped leather can serve as a distinguishing feature that appeals to discerning customers. International buyers, particularly from Europe, should focus on the complexity of the designs they wish to implement and ensure that the stamps can accommodate varying sizes and environmental standards. Sustainability in sourcing materials is increasingly becoming a priority for buyers in this sector.

Why Is Custom Leather Stamping Important for Craft & Hobby Industries?

For the craft and hobby sector, custom leather stamping provides enthusiasts with the tools to create personalized products, such as wallets, keychains, and decorative items. This empowers creativity and allows for unique, one-of-a-kind offerings. B2B buyers in this industry need to consider the availability of custom designs and the ease of use of stamping tools. Cost-effectiveness and the ability to handle small batch orders are also important factors, especially for local artisans.

How Does Custom Leather Stamping Enhance Gift & Promotional Products?

Custom leather stamping is widely used in the gift and promotional products industry to create personalized leather gifts that enhance customer loyalty and appeal. Items like engraved leather notebooks or keychains can leave a lasting impression on clients and customers. For international buyers, particularly in Africa and Europe, minimum order quantities, shipping options, and turnaround times are key considerations when sourcing these products. The ability to customize designs to reflect brand identity can significantly enhance the overall value of promotional efforts.

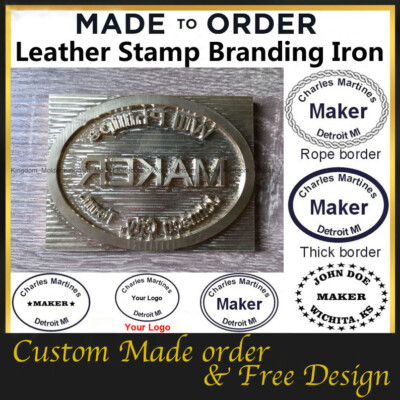

Illustrative image related to custom leather stamping

3 Common User Pain Points for ‘custom leather stamping’ & Their Solutions

Scenario 1: Sourcing Quality Custom Leather Stamps

The Problem: For B2B buyers, especially those in regions such as Africa and South America, sourcing quality custom leather stamps can be a daunting task. Many suppliers may offer low-cost options that compromise on material quality or precision, leading to inferior stamping results. Additionally, buyers may struggle with long lead times and unclear communication, resulting in delays that affect their production schedules.

The Solution: To overcome these challenges, it’s crucial to conduct thorough research before selecting a supplier. Look for manufacturers that offer transparent information about their materials, such as solid brass or high-grade steel, and have positive reviews from other B2B clients. Establish clear communication by asking detailed questions about production timelines and requesting samples of previous work. It’s beneficial to ask for a 3D preview of your custom design to ensure it meets your expectations before proceeding. Utilizing reputable suppliers that provide detailed specifications and guarantees can mitigate risks and ensure you receive high-quality products on time.

Scenario 2: Navigating Design Limitations in Custom Stamping

The Problem: Many B2B buyers face difficulties when it comes to translating intricate designs into effective leather stamps. While custom stamps can be tailored to meet specific branding needs, limitations in the manufacturing process can prevent the reproduction of fine details, leading to disappointment and wasted resources. Buyers may not be aware of the technical specifications that affect their designs, which can result in designs that are either too complex or not feasible for stamping.

The Solution: To address this issue, buyers should familiarize themselves with the technical limitations of the stamping process. When working with suppliers, provide designs in vector format (like .SVG), which allows for greater detail and clarity in production. Before finalizing the order, consider investing in a 3D preview service offered by many suppliers. This will give you a visual representation of how your design will translate into a stamp, allowing for adjustments to be made before production. Additionally, consult with your supplier about the optimal design features that can be effectively stamped, ensuring a balance between creativity and manufacturability.

Illustrative image related to custom leather stamping

Scenario 3: Managing Production Timelines and Rush Orders

The Problem: In the fast-paced B2B environment, delays in production can lead to missed deadlines and dissatisfied customers. Buyers may find themselves in situations where they require custom leather stamps urgently, but many suppliers have standard lead times that can extend beyond acceptable limits. This is particularly problematic for companies that rely on just-in-time inventory systems or have seasonal demands.

The Solution: To manage production timelines effectively, establish relationships with suppliers who offer expedited services. Clearly communicate your deadlines and assess their ability to accommodate rush orders. Some manufacturers provide options for faster turnaround times, often at an additional cost, which can be a worthwhile investment to meet critical deadlines. Additionally, consider ordering stamps in bulk to ensure you have sufficient inventory on hand for future projects, reducing the frequency of rush orders. By proactively planning and collaborating with suppliers, you can ensure that your stamping needs are met promptly, maintaining customer satisfaction and operational efficiency.

Strategic Material Selection Guide for custom leather stamping

What Are the Best Materials for Custom Leather Stamping?

When selecting materials for custom leather stamping, it is crucial to consider their properties, advantages, and limitations. This analysis will focus on four common materials: Brass, Stainless Steel, Aluminum, and Copper. Each material offers unique characteristics that can influence the quality and efficiency of the stamping process.

How Does Brass Perform in Custom Leather Stamping?

Brass is a popular choice for custom leather stamps due to its excellent durability and resistance to corrosion. It can withstand high temperatures and pressures, making it suitable for both heat and cold stamping applications. Brass stamps are known for producing clear, detailed impressions on leather, which is essential for branding and decorative purposes.

Pros: Brass is relatively easy to machine, allowing for intricate designs and custom shapes. It also has a pleasing aesthetic appeal, which can enhance the overall look of the stamped product.

Illustrative image related to custom leather stamping

Cons: The primary drawback of brass is its cost, which can be higher than other materials. Additionally, brass may tarnish over time, requiring periodic maintenance to retain its appearance.

Impact on Application: Brass is compatible with vegetable-tanned leather and other types, making it versatile for various projects. However, care should be taken with softer leathers to avoid damage during stamping.

What Are the Advantages of Stainless Steel for Stamping?

Stainless steel is another widely used material for custom leather stamping. Its high corrosion resistance and strength make it ideal for heavy-duty applications. Stainless steel can withstand extreme temperatures and pressures, ensuring longevity in production environments.

Pros: The durability of stainless steel means that stamps can last longer, reducing the need for replacements. It is also less likely to warp or deform under pressure, ensuring consistent quality in the stamped product.

Cons: The main limitation of stainless steel is its higher manufacturing complexity, which can lead to increased costs. Additionally, it may not produce as fine a detail as brass, depending on the design.

Impact on Application: Stainless steel is suitable for a variety of leather types, including thicker hides. Compliance with international standards like ASTM can also be a consideration for buyers in various regions.

Why Choose Aluminum for Custom Leather Stamping?

Aluminum is a lightweight and cost-effective option for custom leather stamping. It is easy to machine and can be produced quickly, making it an attractive choice for businesses needing rapid turnaround times.

Pros: The lower cost of aluminum makes it accessible for smaller businesses or those just starting in leather stamping. Its lightweight nature also makes it easier to handle during the stamping process.

Cons: However, aluminum is less durable than brass or stainless steel, which can lead to a shorter lifespan for the stamps. It is also more susceptible to deformation under high pressure, which can affect the quality of the stamped impression.

Impact on Application: Aluminum is suitable for lighter applications and can work well with softer leathers. However, it may not be the best choice for high-volume production environments due to its limitations in durability.

What About Copper as a Material for Stamping?

Copper is often used for custom leather stamps due to its excellent conductivity and malleability. It can create sharp impressions and is particularly effective for detailed designs.

Pros: Copper’s malleability allows for intricate designs to be stamped with precision. It also has a unique aesthetic appeal, which can enhance the branding of products.

Cons: The primary drawback of copper is its tendency to tarnish and corrode, which may require regular maintenance. It is also less durable than brass and stainless steel, limiting its use in high-pressure applications.

Impact on Application: Copper is best suited for decorative stamping on vegetable-tanned leather and may not be ideal for heavy-duty applications. International buyers should consider the maintenance requirements when selecting copper stamps.

Summary Table of Material Selection for Custom Leather Stamping

| Material | Typical Use Case for custom leather stamping | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Branding and decorative stamping | Excellent detail and durability | Higher cost, may tarnish over time | High |

| Stainless Steel | Heavy-duty applications | Long lifespan, strong and reliable | Higher manufacturing complexity | High |

| Aluminum | Lightweight and rapid production | Cost-effective, easy to machine | Less durable, may deform under pressure | Low |

| Copper | Decorative impressions | High precision for intricate designs | Tends to tarnish, less durable | Med |

This guide provides a comprehensive overview of the materials available for custom leather stamping, ensuring that international B2B buyers can make informed decisions based on their specific needs and regional standards.

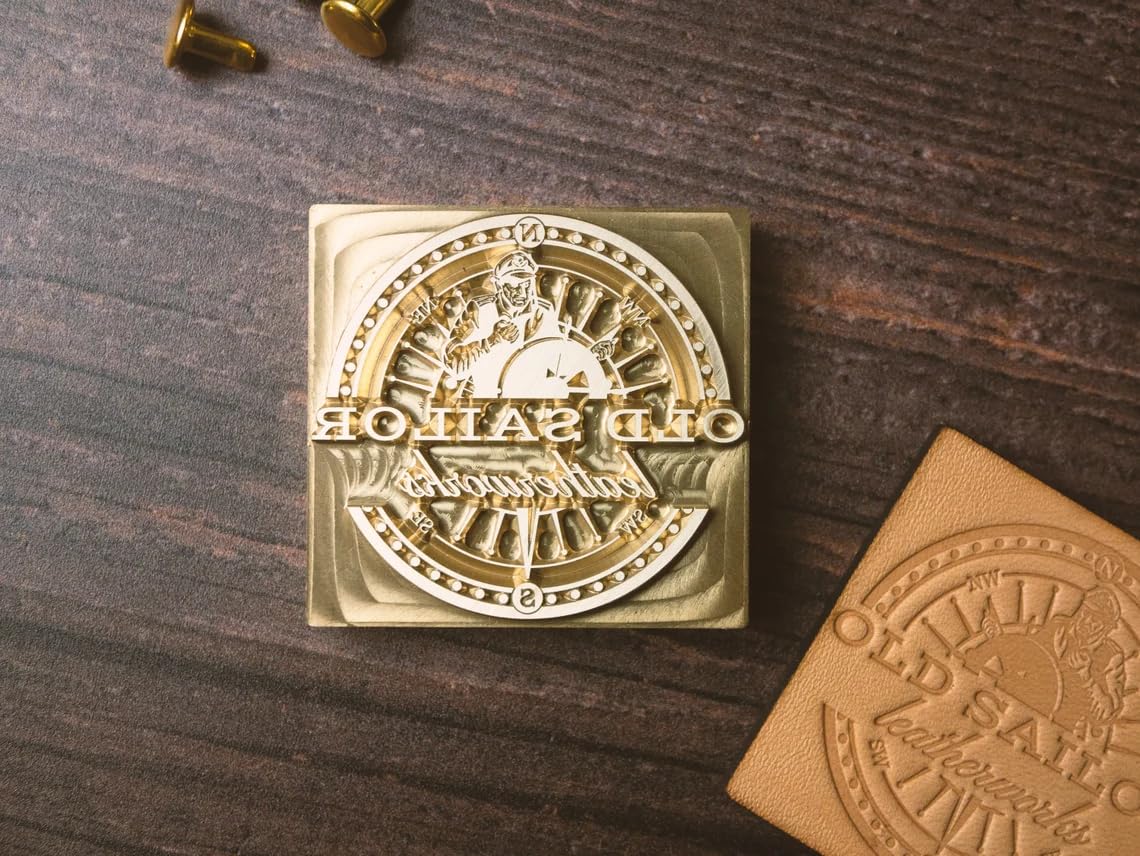

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamping

What Are the Main Stages in the Manufacturing Process for Custom Leather Stamping?

The manufacturing process for custom leather stamping encompasses several stages, including material preparation, forming, assembly, and finishing. Each stage is critical to ensuring the quality and precision of the final product.

Illustrative image related to custom leather stamping

-

Material Preparation: The first step involves selecting high-quality leather, typically vegetable-tanned leather for its durability and ability to hold impressions. The leather is then cut to size, ensuring that it meets the thickness requirements specified by the stamping process, usually a minimum of 4 oz. (1/16″). The leather must be free of defects, ensuring a smooth surface for stamping.

-

Forming: In this stage, custom stamps are created using techniques such as CNC machining or hand engraving, depending on the complexity of the design. For high-precision applications, CNC machines are favored as they can create intricate designs with tight tolerances. The stamps are often made from durable materials like brass or steel, which can withstand repeated use without degrading.

-

Assembly: After the stamps are formed, they may be assembled with handles or presses. For example, larger stamps often require a clicker press for a deep and crisp impression, while smaller stamps may be used with a mallet. This stage also includes ensuring that all components fit together seamlessly for optimal performance.

-

Finishing: The final stage involves quality checks, cleaning, and sometimes applying protective coatings to the stamps. This step ensures that the stamps not only perform well but also maintain their appearance over time. Proper finishing reduces wear and prolongs the lifespan of the stamps.

What Key Techniques Are Employed in Custom Leather Stamping?

Various techniques enhance the quality of custom leather stamping. These include:

-

CNC Machining: This method allows for high precision in creating custom designs and logos. It’s particularly useful for complex patterns where detail is paramount.

-

Hand Engraving: For smaller batches or unique designs, hand engraving remains a viable option, offering a personal touch and artistic flair.

-

Heat Embossing: This technique uses heat along with a stamp to create a raised impression, adding depth and texture to the design. It requires a specialized heat source and is suitable for various types of leather.

-

Foil Stamping: This method involves applying metallic foil to leather, providing an elegant finish that stands out. It’s often used for branding high-end products.

How Is Quality Assurance Implemented in Custom Leather Stamping?

Quality assurance in custom leather stamping is vital to meet the expectations of B2B buyers. International standards, such as ISO 9001, guide manufacturers in establishing effective quality management systems.

-

International Standards: Compliance with ISO 9001 ensures that manufacturers maintain a consistent quality in their processes, from material sourcing to production. Other relevant certifications might include CE marking for products sold in Europe or API standards for specific applications.

-

Quality Control Checkpoints: Manufacturers typically implement several quality control checkpoints, including:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During production, random samples may be taken to monitor ongoing processes and identify any deviations from quality standards.

– Final Quality Control (FQC): Before shipping, the finished products undergo a thorough inspection to verify that they meet all specifications and quality standards.

What Common Testing Methods Are Used in Quality Assurance?

Several testing methods are employed to verify the quality of custom leather stamps:

-

Dimensional Inspection: This checks the physical dimensions of the stamps to ensure they match specifications. Tools like calipers and micrometers are commonly used.

-

Durability Testing: Stamps may undergo tests to assess their wear resistance and the quality of the impressions they produce over time.

-

Visual Inspection: A thorough visual check is performed to identify any cosmetic defects, ensuring the final product meets aesthetic standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, can take several steps to verify supplier quality control:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards. This can be done through on-site visits or third-party audit services.

-

Quality Reports: Requesting quality assurance reports and certifications can help assess the supplier’s commitment to quality. These documents should detail the processes followed and any relevant certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection services before shipment can provide an unbiased assessment of the products. Inspectors can verify compliance with specifications and industry standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances when it comes to quality control:

-

Cultural Differences: Understanding the manufacturing culture in different regions can help buyers set realistic expectations regarding quality and communication.

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers should ensure that their suppliers are compliant with these local regulations.

-

Language Barriers: Clear communication is essential. Buyers should consider language differences that may affect the quality assurance process. Utilizing bilingual staff or translators can help mitigate misunderstandings.

By understanding the manufacturing processes and quality assurance practices in custom leather stamping, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamping’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure custom leather stamping services and products. By following these steps, you can ensure that you select the right supplier and receive high-quality, customized leather stamps that meet your business needs.

Illustrative image related to custom leather stamping

1. Identify Your Specific Needs

Before initiating the procurement process, clearly define your requirements for custom leather stamping. Consider factors such as the type of leather you will be working with, the intended application (e.g., branding, embossing), and the intricacy of your design. This clarity will help you communicate effectively with suppliers and ensure they can meet your specifications.

2. Define Your Technical Specifications

Specify the technical details of the custom stamp you need, including dimensions, materials, and design intricacies. For instance, if you are using vegetable-tanned leather, ensure the stamp is suitable for that material, as different leathers may require varying depths and pressures. Providing precise specifications will help suppliers deliver exactly what you envision.

3. Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the custom leather stamping industry. Look for companies with proven experience, positive customer reviews, and a portfolio showcasing their work. Pay attention to suppliers that cater to international clients, especially those familiar with the regulatory and logistical challenges in your region.

4. Verify Supplier Certifications

Ensure that potential suppliers possess necessary certifications and adhere to industry standards. Certifications can indicate a commitment to quality and sustainability, which can be particularly important for B2B relationships. Ask for documentation that verifies their compliance with relevant regulations and quality assurance processes.

5. Request Samples and Prototypes

Before finalizing your order, request samples or prototypes of the custom stamp. This step allows you to evaluate the quality of materials, craftsmanship, and the precision of the design. Testing samples will help you avoid costly mistakes and ensure that the final product meets your expectations.

6. Discuss Turnaround Times and Shipping Options

Communicate with suppliers about their production timelines and shipping capabilities, especially if you have a tight deadline. Understanding lead times is crucial for planning your production schedule. Inquire about expedited options and shipping methods to avoid delays that could impact your business operations.

7. Establish Clear Communication Channels

Finally, establish effective communication channels with your chosen supplier. This includes discussing the design process, addressing any potential issues, and confirming order details. Clear communication helps build a strong partnership and ensures that any adjustments can be made swiftly throughout the procurement process.

Illustrative image related to custom leather stamping

By following this checklist, you can streamline your procurement of custom leather stamping and foster a successful partnership with your supplier, ultimately enhancing your product offerings and customer satisfaction.

Comprehensive Cost and Pricing Analysis for custom leather stamping Sourcing

What Are the Key Cost Components in Custom Leather Stamping?

When sourcing custom leather stamping, understanding the cost structure is crucial for making informed purchasing decisions. The main cost components include:

-

Materials: The choice of material significantly impacts costs. For example, solid brass is commonly used for stamps, with prices ranging from $68 to $216 depending on size and complexity. Leather quality, such as vegetable-tanned leather or cowhide, also affects pricing.

-

Labor: The labor cost for creating custom stamps varies based on the complexity of the design and the skill level of the workforce. High-precision techniques, such as CNC machining, require more skilled labor, increasing the overall cost.

-

Manufacturing Overhead: This includes expenses related to machinery, utilities, and facility maintenance. Manufacturers may charge higher overhead rates for advanced equipment that allows for intricate designs and faster production times.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. These costs may be amortized over larger order quantities, making them less impactful per unit for bulk orders.

-

Quality Control (QC): Ensuring that each stamp meets quality standards can add to costs. QC processes might include testing for durability and precision, which are crucial for maintaining customer satisfaction.

-

Logistics: Shipping costs vary based on destination, shipping method, and order size. International buyers, particularly from regions like Africa and South America, should consider both shipping fees and potential tariffs.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary widely depending on market demand and competition.

How Do Price Influencers Affect Custom Leather Stamp Costs?

Several factors can influence the pricing of custom leather stamps:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating favorable terms based on anticipated volume can yield significant savings.

-

Specifications and Customization: Unique designs or complex specifications will generally incur higher costs. Buyers should be aware that intricate designs may require more time and resources, impacting the final price.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., eco-friendly or sustainable) may command a premium price. Buyers should weigh the benefits of such materials against their budget constraints.

-

Supplier Factors: Supplier reputation, experience, and location can significantly affect pricing. Established suppliers with a track record of quality may charge more, but they can also offer reliability and superior service.

-

Incoterms: Understanding shipping terms (Incoterms) is vital for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of goods.

What Buyer Tips Can Enhance Cost-Efficiency in Custom Leather Stamping?

To maximize value when sourcing custom leather stamps, consider the following tips:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may have flexibility, especially for larger orders or repeat business.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial costs and consider the TCO, which includes maintenance, durability, and potential reorders. A higher upfront investment in quality may lead to lower long-term costs.

-

Consider Local Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local manufacturers can reduce shipping costs and lead times, enhancing responsiveness to market demands.

-

Request Samples: Before committing to a large order, request samples to evaluate quality. This step can prevent costly mistakes and ensure the final product meets expectations.

-

Stay Informed on Market Trends: Understanding market dynamics and pricing trends can help buyers make strategic sourcing decisions. Keep an eye on material costs and technological advancements that could impact pricing.

Disclaimer on Pricing

Prices for custom leather stamps can vary significantly based on multiple factors. The figures provided herein serve as a general guide and may not reflect current market conditions. Always consult with suppliers for accurate quotes tailored to your specific needs.

Illustrative image related to custom leather stamping

Alternatives Analysis: Comparing custom leather stamping With Other Solutions

Introduction to Alternatives in Custom Leather Stamping

When it comes to branding or personalizing leather goods, custom leather stamping is a widely adopted technique. However, B2B buyers should explore various alternatives that may offer different advantages depending on their specific needs. This analysis compares custom leather stamping with other viable solutions, providing insights into performance, cost, ease of implementation, maintenance, and the best use cases for each method.

Comparison Table

| Comparison Aspect | Custom Leather Stamping | Laser Engraving | Heat Branding |

|---|---|---|---|

| Performance | High durability, clear impressions | Very high precision, intricate designs | Durable, less detailed than engraving |

| Cost | Moderate ($68 – $216) | Higher initial investment ($500+) | Moderate ($100 – $300 for equipment) |

| Ease of Implementation | Requires manual skill and tools | Requires specialized equipment and training | Simple setup, but requires heat source |

| Maintenance | Low (occasional cleaning) | Moderate (equipment upkeep) | Low (minimal maintenance needed) |

| Best Use Case | Small to medium production runs, artisan goods | High volume, intricate designs, logos | Branding or marking larger items |

Detailed Breakdown of Alternatives

Laser Engraving

Laser engraving utilizes high-powered lasers to etch designs onto leather surfaces. This method excels in precision and can produce intricate patterns and logos that are difficult to achieve with traditional stamping. The initial investment for laser engraving equipment can be substantial, often exceeding $500, and may require specialized training to operate effectively. While the maintenance of laser machines can be moderate due to the complexity of the technology, the long-term benefits include high durability and repeatability of designs, making it ideal for high-volume production runs.

Heat Branding

Heat branding involves using a heated metal stamp to imprint designs onto leather. This method offers the advantage of simplicity and can be an excellent choice for marking larger leather items, such as bags or furniture. The initial cost for heat branding equipment is generally moderate, falling between $100 to $300, depending on the equipment’s sophistication. Maintenance is minimal, as the primary requirement is to keep the branding iron clean. However, the level of detail achievable with heat branding may not match that of laser engraving, making it less suitable for intricate designs.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers considering customization options for leather products, the choice between custom leather stamping, laser engraving, and heat branding ultimately depends on specific business needs. Custom leather stamping is ideal for artisans focusing on small to medium production runs and requiring a personal touch. In contrast, laser engraving is best suited for businesses needing high precision and intricate designs for larger production volumes. Heat branding offers a balanced option for those looking for a straightforward method to mark larger leather items without the need for intricate detail. By assessing the performance, costs, and implementation requirements of each method, businesses can select the most effective solution for their leather branding needs.

Illustrative image related to custom leather stamping

Essential Technical Properties and Trade Terminology for custom leather stamping

What Are the Key Technical Properties for Custom Leather Stamping?

When considering custom leather stamping, understanding the technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade: The most commonly used materials for leather stamps include brass and steel. Brass is preferred for its durability and resistance to corrosion, while steel offers a sharper imprint. For B2B buyers, selecting the right material affects both the quality of the stamp and the longevity of the stamped design, impacting overall production costs and efficiency.

-

Stamp Thickness: The thickness of the stamp, often ranging from 6mm to 10mm, is vital for achieving a deep and clear impression on leather. Thicker stamps tend to provide more durability and consistent performance, especially for high-volume production runs. Understanding the implications of stamp thickness ensures that the final product meets the desired aesthetic and functional requirements.

-

Engraving Depth: Typically, the engraving depth for leather stamps varies from 2mm to 5mm. This depth determines how well the design will appear on the leather surface. A deeper engraving is better for thicker leather, ensuring that the design remains visible over time. For B2B buyers, this specification can influence the choice of leather and the intended use of the stamped product.

-

Tolerance Levels: Tolerance refers to the allowable variation in the dimensions of the stamp. In custom leather stamping, maintaining tight tolerances (typically within ±0.1mm) is essential for precision and quality control. This is especially important when producing multiple items with the same design, as even minor discrepancies can lead to significant inconsistencies in the final products.

-

Maximum Impression Dimensions: This specification defines the largest size that can be effectively stamped. Understanding the maximum dimensions helps businesses plan their designs and ensures that the artwork fits within the operational capabilities of the stamping equipment. B2B buyers should confirm these dimensions to avoid costly mistakes in production.

-

Lead Time: The time required to produce and deliver custom stamps can range from a few days to several weeks, depending on the complexity of the design and the manufacturer’s workload. Knowing the lead time is vital for managing inventory and aligning production schedules, particularly in industries where timing is critical.

What Are Common Trade Terms in Custom Leather Stamping?

Familiarity with industry jargon can enhance communication and negotiations. Here are several key terms relevant to custom leather stamping:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce products or components that are purchased by another company and sold under that company’s brand name. In the context of custom leather stamping, OEMs often provide the stamps that businesses use for branding their leather goods.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure that they can meet their production needs without overcommitting financially or in terms of inventory.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to suppliers requesting a quote for specific products or services. In the custom leather stamping industry, submitting an RFQ can help buyers compare prices, lead times, and specifications from multiple suppliers.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help B2B buyers navigate the complexities of international shipping and ensure that their goods arrive safely and on time.

-

Custom Die: This term refers to a specialized tool used to create impressions in materials like leather. Understanding the differences between standard and custom dies can help buyers make informed choices about their stamping needs, especially when unique designs are required.

-

Heat Embossing: A technique that uses heat and pressure to create impressions in leather. This method can enhance the durability and visibility of designs. Knowledge of heat embossing allows buyers to consider various stamping methods based on their product requirements.

By grasping these technical properties and trade terms, B2B buyers in the custom leather stamping market can make better purchasing decisions, streamline their operations, and foster successful partnerships with suppliers.

Navigating Market Dynamics and Sourcing Trends in the custom leather stamping Sector

What Are the Key Market Dynamics and Trends in Custom Leather Stamping?

The custom leather stamping sector is experiencing notable growth driven by increasing demand for personalized leather goods across various industries, including fashion, automotive, and luxury products. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in custom leather applications. This rise is fueled by the consumer desire for unique, bespoke items that stand out in a crowded market. Additionally, advancements in technology, such as CNC machining and 3D printing, are streamlining the production process, enabling quicker turnaround times for custom orders. For instance, suppliers can now produce high-precision custom stamps in as little as 2-3 days, appealing to businesses that prioritize speed and efficiency.

Emerging trends include the integration of digital tools for design and ordering, allowing buyers to visualize their products before manufacturing. Companies are increasingly adopting e-commerce platforms for sourcing, making it easier to compare options and prices globally. Sustainability is also a critical focus, with buyers seeking suppliers who prioritize eco-friendly materials and practices. The rise of ethical sourcing is further influencing purchasing decisions, as companies aim to align with consumers’ values around social responsibility.

How Is Sustainability Shaping the Custom Leather Stamping Supply Chain?

Sustainability has become a cornerstone in the custom leather stamping sector, reflecting a broader industry shift towards environmental responsibility. The environmental impact of leather production is significant, involving resource-intensive processes that can lead to deforestation, water pollution, and high carbon emissions. As B2B buyers become more conscious of these issues, they increasingly seek suppliers who are committed to ethical sourcing and sustainable practices.

Key considerations include the use of vegetable-tanned leather, which is less harmful to the environment compared to conventional tanning methods that often involve toxic chemicals. Additionally, certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) provide assurance of sustainable practices throughout the supply chain. Buyers can enhance their brand reputation by partnering with certified suppliers, which not only meet regulatory requirements but also resonate with environmentally conscious consumers.

The demand for eco-friendly materials and sustainable production methods is reshaping sourcing strategies, making it essential for buyers to evaluate their suppliers’ environmental credentials and ethical practices.

What Is the Historical Context of Custom Leather Stamping Relevant to Today’s B2B Buyers?

The art of leather stamping has a rich history, dating back thousands of years when artisans used rudimentary tools to mark their creations. Originally, these techniques were employed for practical purposes, such as branding livestock or identifying ownership. Over time, the craft evolved into a sophisticated art form used to create intricate designs on leather goods, reflecting cultural significance and personal expression.

In modern times, the advent of technology has revolutionized the custom leather stamping industry. The introduction of CNC machines and advanced engraving techniques has allowed for precision and customization that was previously unattainable. Today, businesses can leverage these advancements to create highly detailed and personalized products, meeting the growing consumer demand for individuality. This historical context is crucial for B2B buyers as it underscores the blend of tradition and innovation in the sector, enabling them to appreciate the value of craftsmanship while capitalizing on modern efficiencies.

By understanding these dynamics, buyers can make informed sourcing decisions that align with market trends, sustainability goals, and historical craftsmanship.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamping

-

How do I choose the right custom leather stamp for my business needs?

When selecting a custom leather stamp, consider the type of leather you will be using, the design complexity, and the intended application. For detailed designs, opt for a stamp that can accurately reproduce intricate features. Evaluate the size of the stamp in relation to your products; larger stamps may be suitable for branding, while smaller ones are better for intricate patterns. Additionally, consult with suppliers who can provide samples or 3D previews to ensure the final product meets your expectations. -

What types of materials are used for custom leather stamps?

Custom leather stamps are typically made from materials like solid brass or steel, known for their durability and ability to create clear impressions. Brass is often preferred for its resistance to corrosion and ability to hold fine details, while steel stamps may offer greater longevity for high-volume applications. When choosing a material, consider the type of leather you will be stamping, as some materials may perform better with specific leather types, such as vegetable-tanned leather. -

What is the typical lead time for custom leather stamp orders?

Lead times for custom leather stamps can vary significantly based on the supplier and the complexity of the design. Generally, you can expect a turnaround time of 5 to 10 business days for standard orders. For urgent requests, many suppliers offer rush options that can reduce the lead time to as little as 2 to 3 working days, albeit at an additional cost. Always confirm the expected delivery time before placing your order, especially for international shipping. -

How do I ensure the quality of custom leather stamps?

To ensure high-quality custom leather stamps, vet suppliers by reviewing their production processes, materials used, and customer feedback. Request samples or a 3D preview of your design to evaluate the quality before finalizing your order. Additionally, inquire about their quality assurance measures, such as inspection protocols and warranty policies. Establishing clear communication about your expectations and specifications can further help in achieving satisfactory results. -

What are the minimum order quantities (MOQs) for custom leather stamps?

Minimum order quantities (MOQs) for custom leather stamps can vary by supplier, often ranging from a single stamp to larger quantities depending on the production capabilities. For bulk orders, some suppliers may offer discounts, making it economically viable to order more than you initially need. Always clarify MOQs during the sourcing process to ensure that your purchase aligns with your production needs and budget constraints. -

What payment terms should I expect when ordering custom leather stamps internationally?

Payment terms for international orders of custom leather stamps can differ by supplier but typically include options like advance payment, partial payment upon order confirmation, and the remainder upon shipping. It’s essential to discuss payment methods accepted (e.g., wire transfer, credit card, PayPal) and any additional fees related to currency conversion or international transactions. Establishing clear terms upfront can help avoid misunderstandings later in the process. -

How can I manage logistics for international shipping of custom leather stamps?

Managing logistics for international shipping involves choosing a reliable shipping partner familiar with customs regulations in your country. Discuss shipping options with your supplier, including express and standard services, to determine the most cost-effective solution. Be aware of potential customs duties and taxes that may apply upon arrival, and ensure that all necessary documentation, such as invoices and customs declarations, is prepared to facilitate smooth delivery. -

What should I include in my design file for custom leather stamps?

When submitting a design for a custom leather stamp, ensure your files are in the preferred format, typically vector files like SVG for precision. Include clear specifications regarding size, engraving depth, and any particular details you want highlighted. If your design contains intricate elements, consider including a 3D preview service to visualize the final product. Providing detailed instructions and high-quality files will help minimize errors and ensure your stamp meets your expectations.

Top 5 Custom Leather Stamping Manufacturers & Suppliers List

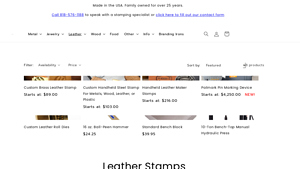

1. Infinity Stamps – Leather Stamping Solutions

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Leather Stamps – Infinity Stamps Inc. offers a variety of leather stamping products including: Handheld Stamps, Plate Stamps, Pin Marking Devices, Roll Dies, Maker Stamps, Hot Stamps, and Steel Type Stamps & Holders. All products are made in the USA and the company has been family-owned for over 25 years. Customers can contact a stamping specialist at 818-576-1188 or fill out a contact form for in…

2. Tandy Leather – Custom Stamps

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Custom Stamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Leather & Custom Brass Stamps by Leather Stamp Maker. All custom stamps ship next business day. Made in the USA. Custom brass stamps, cutting dies, lettersets, and more. Custom stamps are CNC milled from solid brass, available up to 1″ thickness and custom size. Compatible with branding irons and standard presses. Custom leather cutting dies made from solid steel, usable with mechanical, hydraulic…

4. Stamp Leather Co – Premium Leather Crafting Tools

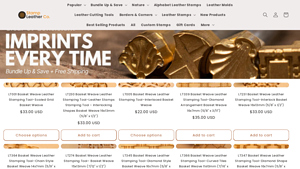

Domain: stampleather.co

Registered: 2023 (2 years)

Introduction: Stamp Leather Co offers a variety of premium leather crafting tools including:

1. **Basket Weave Leather Stamps**:

– LT001: Scaled Grid Basket Weave – $33.00

– LT230: Interlocking Shapes Basket Weave (16x13mm) – $33.00

– LT005: Interlaced Basket Weave – $22.00

– LT339: Diamond Arrangement Basket Weave (16x7mm) – $35.00

– LT231: Interlock Basket Weave (16x13mm) – $33.00

– LT364: …

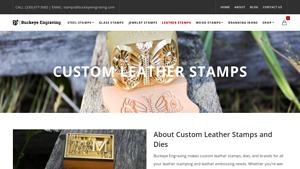

5. Custom Leather Stamps – Premium Quality Options

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

Introduction: Custom leather stamps, dies, and brands for leather stamping and embossing needs. Options available in aluminum, steel, or brass. Aluminum stamps are cost-effective; brass is popular for durability and rust resistance. Customization includes original artwork, high detail engraving, and hand-finishing. Heavy-duty removable steel handle for hand stamps; press stamps include only the engraved face. C…

Strategic Sourcing Conclusion and Outlook for custom leather stamping

In conclusion, the landscape of custom leather stamping presents vast opportunities for B2B buyers across Africa, South America, the Middle East, and Europe. Key takeaways emphasize the importance of understanding the specifications and capabilities of various stamping technologies, such as brass, steel, and heat embossing. Sourcing strategically enables businesses to access high-quality products tailored to their unique branding needs, while ensuring timely delivery and competitive pricing.

Investing in custom leather stamps not only enhances product differentiation but also fosters brand loyalty through unique, personalized items. As global trade continues to evolve, leveraging international suppliers can provide a competitive edge, allowing companies to meet customer demands swiftly and efficiently.

Looking forward, now is the opportune moment for businesses to explore partnerships with established manufacturers who can deliver quality craftsmanship and rapid turnaround times. By prioritizing strategic sourcing, international buyers can position themselves for success in the dynamic market of custom leather stamping. Take action today—connect with reputable suppliers and elevate your brand through distinctive leather products that resonate with your target audience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom leather stamping

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.