Introduction: Navigating the Global Market for what is synthetic leather made of

In today’s competitive landscape, sourcing high-quality synthetic leather can pose significant challenges for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, including countries like Brazil and Germany. Understanding what synthetic leather is made of, including its components and manufacturing processes, is crucial for making informed purchasing decisions that align with business needs and consumer preferences.

This comprehensive guide delves into the intricacies of synthetic leather, exploring its various types—such as polyurethane (PU) and polyvinyl chloride (PVC)—and their respective applications across industries like fashion, automotive, and furniture. Additionally, it addresses key considerations for supplier vetting, including sustainability practices, regulatory compliance, and quality assurance, which are essential for establishing reliable partnerships.

By equipping international B2B buyers with insights on cost factors, market trends, and product performance, this guide empowers businesses to navigate the complexities of sourcing synthetic leather effectively. The aim is to foster informed decisions that enhance product offerings while meeting the growing demand for ethical and sustainable materials. Whether you’re a procurement manager or a product developer, understanding the nuances of synthetic leather is vital for ensuring your business remains competitive in a rapidly evolving market.

Table Of Contents

- Top 4 What Is Synthetic Leather Made Of Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is synthetic leather made of

- Understanding what is synthetic leather made of Types and Variations

- Key Industrial Applications of what is synthetic leather made of

- 3 Common User Pain Points for ‘what is synthetic leather made of’ & Their Solutions

- Strategic Material Selection Guide for what is synthetic leather made of

- In-depth Look: Manufacturing Processes and Quality Assurance for what is synthetic leather made of

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is synthetic leather made of’

- Comprehensive Cost and Pricing Analysis for what is synthetic leather made of Sourcing

- Alternatives Analysis: Comparing what is synthetic leather made of With Other Solutions

- Essential Technical Properties and Trade Terminology for what is synthetic leather made of

- Navigating Market Dynamics and Sourcing Trends in the what is synthetic leather made of Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is synthetic leather made of

- Strategic Sourcing Conclusion and Outlook for what is synthetic leather made of

- Important Disclaimer & Terms of Use

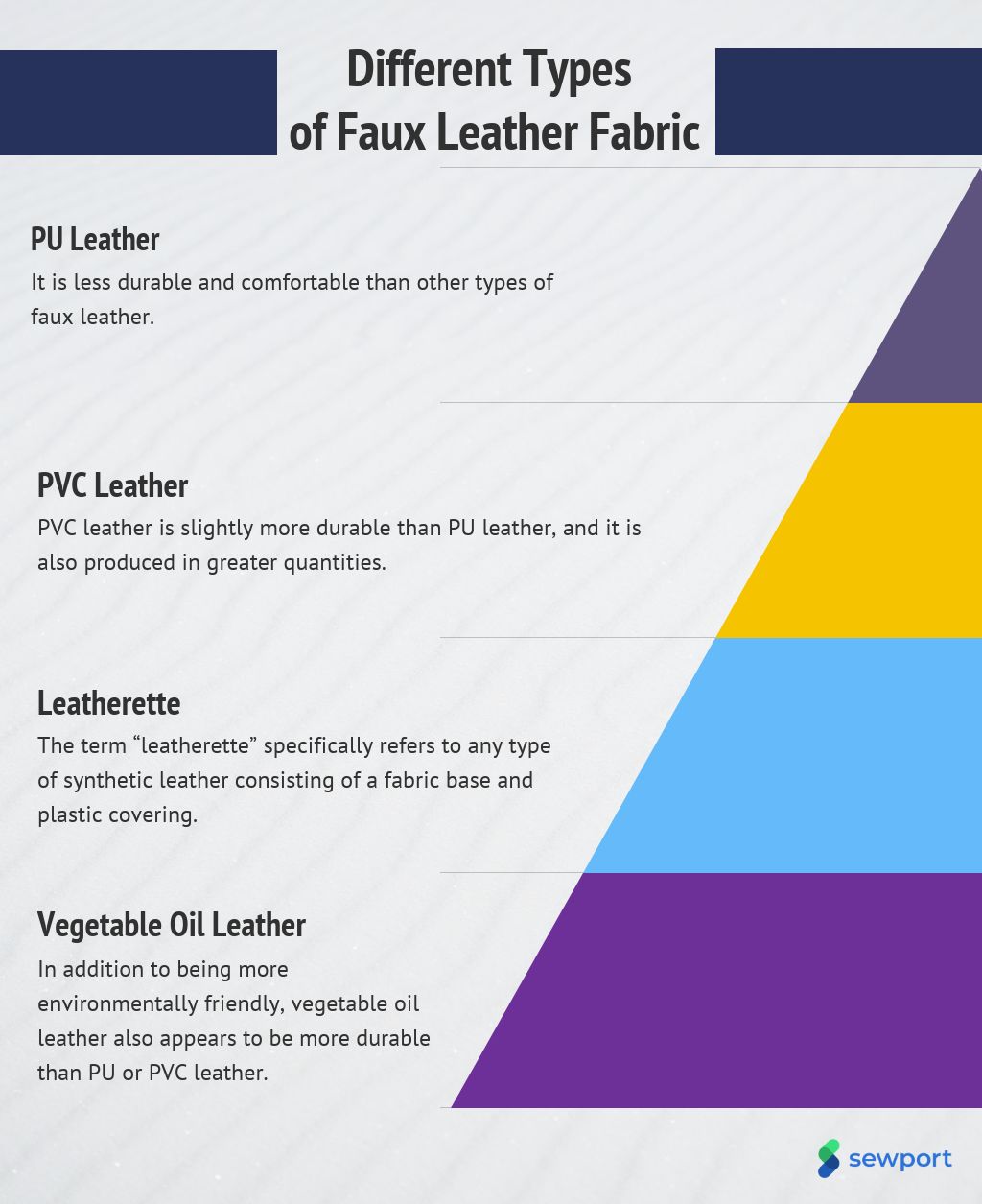

Understanding what is synthetic leather made of Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyurethane (PU) Leather | Soft, flexible, and resembles real leather; often breathable | Upholstery, fashion, automotive interiors | Pros: Eco-friendlier than PVC; Cons: Can be less durable than real leather |

| PVC leer | High durability and water resistance; shiny finish; less breathable | Outdoor furniture, bags, and waterproof clothing | Pros: Cost-effective; Cons: Less environmentally friendly due to chlorine content |

| Microvezel leer | Made from ultra-fine synthetic fibers; breathable and durable | Automotive interiors, high-end upholstery | Pros: High durability and stain resistance; Cons: Can be more expensive than other synthetics |

| Recycled Leather | Composed of recycled leather scraps bonded with synthetic materials; eco-friendly | Fashion, accessories, and upholstery | Pros: Sustainable; Cons: Quality can vary based on the source materials |

| Biodegradable Synthetic Leather | Made from plant-based materials; designed to decompose | Eco-conscious fashion, furniture, and automotive | Pros: Environmentally friendly; Cons: Often more expensive and less readily available |

What are the characteristics and suitability of Polyurethane (PU) Leather for B2B buyers?

Polyurethane (PU) leather is a popular choice among B2B buyers due to its soft texture and flexibility, closely mimicking the look and feel of genuine leather. Its breathability makes it suitable for upholstery in various sectors, including fashion and automotive interiors. When considering PU leather, buyers should evaluate its eco-friendliness compared to PVC options, as it often has a lower environmental impact. However, durability may be a concern, especially in high-wear applications.

How does PVC Leather serve different industries and what are its key features?

PVC leather is known for its high durability and water resistance, making it ideal for applications such as outdoor furniture and waterproof clothing. Its shiny finish is visually appealing for products like bags and accessories. While PVC is cost-effective and widely available, it is important for buyers to consider the environmental implications, as it contains chlorine and may not align with sustainable practices. Overall, PVC leather serves as a reliable option for budget-conscious businesses.

What advantages does Microfiber Leather offer to B2B buyers?

Microfiber leather stands out for its ultra-fine synthetic fibers, which provide exceptional durability and breathability. This makes it a preferred material for high-end upholstery and automotive interiors where both aesthetics and longevity are critical. Buyers should note that while microfiber leather is more expensive than other synthetic options, its stain resistance and overall quality can justify the investment, particularly in premium markets.

Why is Recycled Leather an attractive option for eco-conscious buyers?

Recycled leather, made from scraps and bonded with synthetic materials, presents a sustainable alternative for businesses looking to reduce waste. Its applications span fashion, accessories, and upholstery. Buyers should be aware that while recycled leather is environmentally friendly, the quality can vary significantly based on the source of the materials. This variability necessitates careful supplier selection to ensure that the final product meets their quality standards.

What makes Biodegradable Synthetic Leather a niche market choice?

Biodegradable synthetic leather is increasingly sought after in eco-conscious markets due to its plant-based composition, designed to decompose naturally. It is particularly suitable for fashion, furniture, and automotive applications where sustainability is a priority. However, buyers should consider that biodegradable options may come at a higher price point and are less commonly available than traditional synthetics. As sustainability becomes a key purchasing criterion, this material could see greater demand in the future.

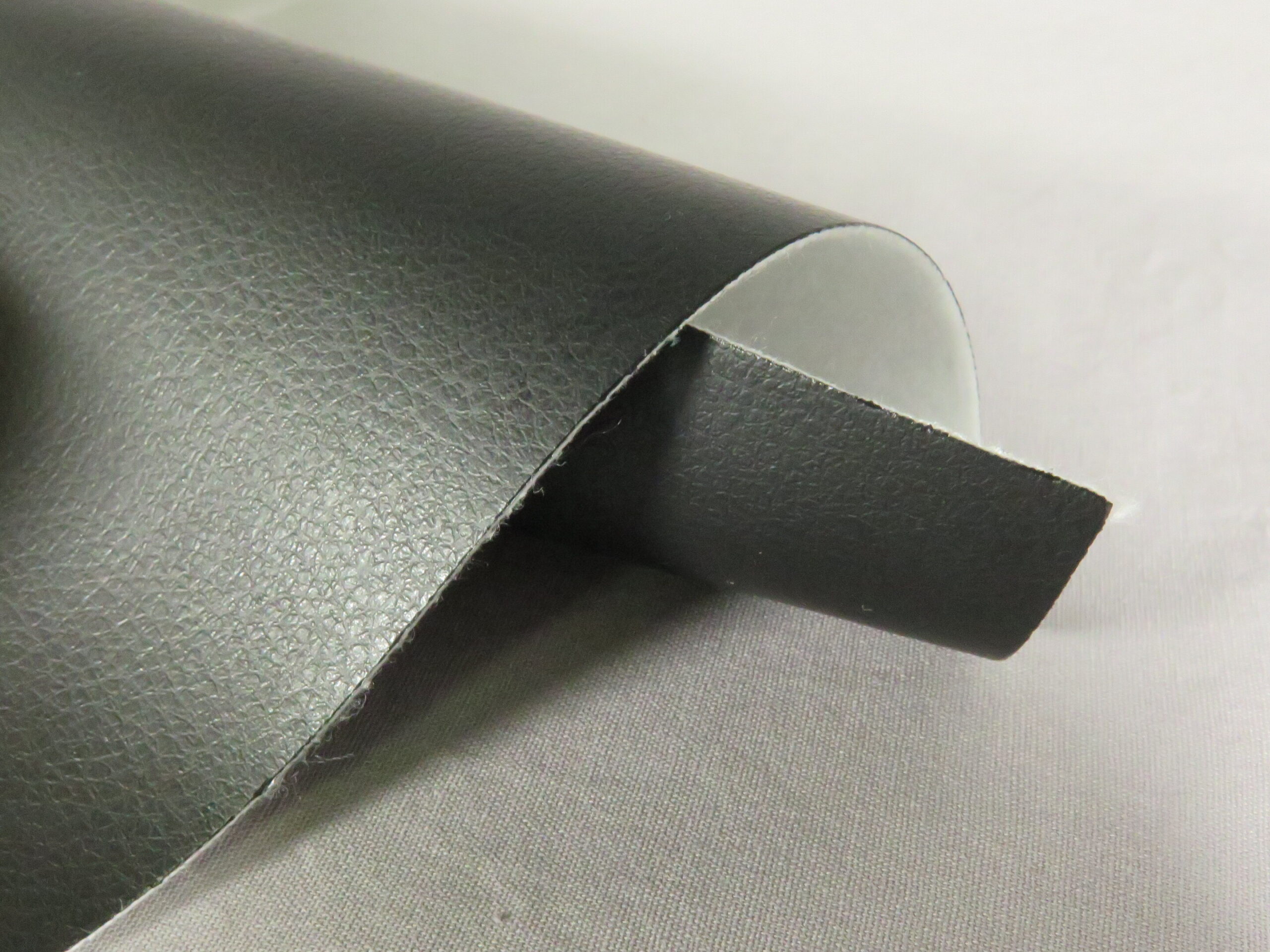

Illustrative image related to what is synthetic leather made of

Key Industrial Applications of what is synthetic leather made of

| Industry/Sector | Specific Application of what is synthetic leather made of | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for car interiors | Cost-effective, lightweight, and customizable options | Compliance with industry standards and durability tests |

| Fashion & Apparel | Clothing and accessories (jackets, bags, shoes) | Eco-friendly alternatives and trendy designs | Material certifications and production capacity |

| Furniture | Sofas and chairs upholstery | Durable and easy-to-clean options for high-traffic areas | Fire resistance and colorfastness requirements |

| Footwear | Shoe manufacturing | Versatile materials that mimic leather aesthetics | Breathability and comfort features |

| Sports Equipment | Gear and apparel for sports teams | Lightweight, water-resistant, and easy to maintain | Performance testing and environmental impact |

How is Synthetic Leather Used in the Automotive Industry?

In the automotive sector, synthetic leather is predominantly used for upholstery in car interiors, including seats, door panels, and dashboards. This material offers a cost-effective alternative to genuine leather while providing a similar aesthetic appeal. International buyers, particularly in regions like Europe and South America, should consider sourcing synthetic leather that meets automotive safety standards, including fire resistance and durability tests, ensuring that the upholstery withstands wear and tear in various climates.

What Role Does Synthetic Leather Play in Fashion & Apparel?

In the fashion industry, synthetic leather serves as a popular material for clothing and accessories, including jackets, bags, and shoes. Its ability to mimic the look and feel of genuine leather makes it an attractive option for eco-conscious consumers. B2B buyers from Africa and the Middle East should prioritize suppliers who offer certified vegan leather options, ensuring compliance with ethical standards while also considering the latest trends and designs that appeal to modern consumers.

Why is Synthetic Leather Important for Furniture?

Synthetic leather is widely used in the furniture industry for upholstering sofas and chairs. Its durability and ease of maintenance make it particularly suitable for high-traffic areas, such as restaurants and hotels. Buyers should focus on sourcing materials that offer fire resistance and colorfastness to ensure longevity and safety in their products. Additionally, understanding the environmental impact of synthetic leather production can aid in making responsible sourcing decisions.

How is Synthetic Leather Beneficial in Footwear Manufacturing?

In footwear manufacturing, synthetic leather is used to create stylish and functional shoes. This material provides versatility, allowing designers to produce a wide range of styles while maintaining a leather-like appearance. B2B buyers should look for synthetic options that offer breathability and comfort features, as these are essential for consumer satisfaction. Additionally, sourcing from suppliers who prioritize sustainable practices can enhance brand reputation in a competitive market.

Illustrative image related to what is synthetic leather made of

What are the Applications of Synthetic Leather in Sports Equipment?

Synthetic leather is increasingly utilized in the production of sports gear and apparel, including uniforms and protective equipment. Its lightweight, water-resistant properties make it ideal for high-performance applications. International buyers should ensure that the materials sourced have undergone rigorous performance testing, meeting the specific demands of various sports. Additionally, understanding the environmental impact of these materials can help brands align with consumer preferences for sustainability in sports equipment.

3 Common User Pain Points for ‘what is synthetic leather made of’ & Their Solutions

Scenario 1: Difficulty Identifying Quality Synthetic Leather

The Problem: B2B buyers often struggle to differentiate between high-quality synthetic leather and lower-grade alternatives. This challenge is exacerbated by the proliferation of terms like “vegan leather” and “pleather,” which can mislead buyers regarding the material’s durability and performance. Buyers may find themselves purchasing products that do not meet their expectations, leading to customer dissatisfaction and increased returns.

The Solution: To effectively source quality synthetic leather, buyers should prioritize transparency in material specifications. Request detailed information about the composition of the synthetic leather, including the specific types of polymers used, such as polyurethane (PU) or polyvinyl chloride (PVC). Engaging with suppliers who provide certifications or test results can also be beneficial. Buyers can look for brands that adhere to established industry standards, such as those set by the Leather Working Group (LWG). Additionally, conducting tactile tests—such as checking the texture, flexibility, and smell—can help identify quality. Always ask for samples before committing to large orders, allowing for a thorough evaluation of the material’s performance characteristics.

Scenario 2: Concerns Over Environmental Impact

The Problem: As sustainability becomes increasingly important, B2B buyers face the challenge of sourcing synthetic leather that aligns with eco-friendly practices. Many synthetic materials are derived from petroleum-based products, raising concerns about their environmental footprint. Buyers are often uncertain about how to evaluate the sustainability of the synthetic leather they intend to purchase, leading to potential reputational risks for their brands.

The Solution: Buyers should seek out synthetic leather options made from sustainable materials, such as bio-based or recycled components. Engage with suppliers who disclose their environmental practices and the life cycle of their products. Look for certifications like Global Recycle Standard (GRS) or OEKO-TEX, which can provide assurance regarding the sustainability claims. Furthermore, consider requesting information about the production processes employed by suppliers to gauge their commitment to minimizing environmental impact. Collaborating with manufacturers that invest in innovative and sustainable alternatives can enhance your brand’s reputation while meeting the growing consumer demand for eco-friendly products.

Illustrative image related to what is synthetic leather made of

Scenario 3: Navigating Regulatory Compliance and Labeling Confusion

The Problem: With varying regulations across different regions, B2B buyers often find it challenging to ensure that the synthetic leather products they source comply with local labeling requirements. In regions like the EU, Brazil, and parts of the Middle East, strict guidelines dictate how synthetic materials can be marketed. Mislabeling can lead to legal ramifications and damage to brand credibility, creating a significant pain point for buyers.

The Solution: Buyers should familiarize themselves with the specific labeling laws relevant to their target markets. This includes understanding how terms like “synthetic leather” or “vegan leather” can be legally used and ensuring that product descriptions accurately reflect the material composition. Engage with suppliers who prioritize compliance and can provide clear, transparent labeling on their products. Conducting regular audits of supplier practices can help ensure adherence to local regulations. Additionally, consider collaborating with legal advisors or industry associations that specialize in material compliance to stay updated on regulatory changes and best practices. This proactive approach will help mitigate risks associated with non-compliance while fostering trust with end consumers.

Strategic Material Selection Guide for what is synthetic leather made of

What Are the Key Materials Used in Synthetic Leather Production?

Synthetic leather, often referred to as faux leather, is primarily made from a variety of materials, each with distinct properties and applications. Understanding these materials is crucial for B2B buyers looking to make informed purchasing decisions. Below, we analyze four common materials used in synthetic leather production: Polyurethane (PU), Polyvinyl Chloride (PVC), Nylon, and Eco-leather.

What Are the Key Properties of Polyurethane (PU) in Synthetic Leather?

Polyurethane (PU) is a versatile polymer that is widely used in the production of synthetic leather. It offers excellent flexibility and durability, making it suitable for a variety of applications, including upholstery, fashion accessories, and automotive interiors. PU synthetic leather can withstand a range of temperatures and is resistant to wear and tear, providing a long-lasting solution for end products.

Illustrative image related to what is synthetic leather made of

Pros: PU synthetic leather is soft, breathable, and has a more natural feel compared to other synthetic options. It is also easier to dye and finish, allowing for a wide range of aesthetic options.

Cons: However, PU can be more expensive than other synthetic materials and may require specific manufacturing processes that could complicate production. It also has lower resistance to certain chemicals compared to PVC.

Impact on Application: PU is compatible with various media, including adhesives and coatings, making it suitable for high-end applications where aesthetics and comfort are paramount.

Considerations for International Buyers: Buyers from regions like Europe and South America should be aware of compliance standards such as REACH regulations in the EU, which govern the use of chemicals in products.

How Does Polyvinyl Chloride (PVC) Compare in Synthetic Leather?

Polyvinyl Chloride (PVC) is another common material used in synthetic leather production. It is known for its durability and resistance to moisture, making it an ideal choice for applications such as outdoor furniture and marine upholstery.

Illustrative image related to what is synthetic leather made of

Pros: PVC synthetic leather is cost-effective and has excellent resistance to abrasion and environmental factors, which makes it suitable for various industrial applications.

Cons: On the downside, PVC is less breathable than PU and can have a plastic-like feel, which may not be desirable for all applications. It also has environmental concerns associated with its production and disposal.

Impact on Application: PVC is often used in applications where moisture resistance is critical, but its lack of breathability can limit its use in clothing and high-comfort items.

Considerations for International Buyers: Buyers should consider compliance with local regulations regarding PVC use, especially in regions like the EU, where stricter environmental regulations are in place.

What Role Does Nylon Play in Synthetic Leather?

Nylon is a synthetic polymer that is sometimes blended with other materials to create synthetic leather. It is known for its strength and durability, making it suitable for high-performance applications.

Pros: Nylon synthetic leather is lightweight, resistant to tearing, and can be treated to enhance its water resistance. It is often used in products that require high durability, such as bags and outdoor gear.

Cons: The primary drawback of nylon is its lower aesthetic appeal compared to PU or PVC, as it may not mimic the look and feel of natural leather as effectively.

Impact on Application: Nylon is particularly effective in applications that require high tensile strength and durability, making it a popular choice in the sports and outdoor sectors.

Considerations for International Buyers: Buyers should be aware of the varying quality standards across regions, such as ASTM in the USA and DIN in Germany, which can affect the suitability of nylon-based synthetic leather for specific applications.

How Is Eco-leather Different in Synthetic Leather Production?

Eco-leather, often made from recycled materials or plant-based components, is gaining traction as a sustainable alternative to traditional synthetic leather.

Pros: Eco-leather is often perceived as more environmentally friendly, appealing to consumers looking for sustainable options. It can be produced with less harmful chemicals and offers a unique aesthetic.

Cons: However, eco-leather can be more expensive and may not offer the same durability as synthetic options like PU or PVC. Its performance can vary significantly based on the manufacturing process and materials used.

Impact on Application: Eco-leather is suitable for products aimed at environmentally conscious consumers, including fashion items and home décor.

Considerations for International Buyers: Buyers should consider certifications related to sustainability, such as Global Organic Textile Standard (GOTS) or similar certifications in their respective regions.

Summary Table of Synthetic Leather Materials

| Materiaal | Typical Use Case for what is synthetic leather made of | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Upholstery, fashion accessories, automotive interiors | Soft, breathable, natural feel | Higher cost, complex manufacturing | Hoog |

| Polyvinyl Chloride (PVC) | Outdoor furniture, marine upholstery | Cost-effective, moisture-resistant | Less breathable, environmental concerns | Low |

| Nylon | Bags, outdoor gear | Lightweight, tear-resistant | Lower aesthetic appeal | Medium |

| Eco-leather | Fashion items, home décor | Environmentally friendly | Higher cost, variable durability | Medium to High |

This detailed analysis provides B2B buyers with essential insights into the materials used in synthetic leather production, helping them make informed decisions that align with their product requirements and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for what is synthetic leather made of

What Are the Key Stages in the Manufacturing Process of Synthetic Leather?

The manufacturing of synthetic leather involves a series of well-defined stages, each critical to ensuring the quality and performance of the final product. Understanding these stages can empower B2B buyers to evaluate suppliers more effectively.

Illustrative image related to what is synthetic leather made of

1. Material Preparation: What Raw Materials Are Used?

Synthetic leather is primarily composed of synthetic polymers such as polyurethane (PU), polyvinyl chloride (PVC), or a blend of both. The first step in the manufacturing process is the preparation of these raw materials.

- Polymer Selection: Manufacturers select high-grade polymers, often considering the end-use of the synthetic leather. For example, PU is often preferred for its breathability and softness, while PVC is chosen for its durability and cost-effectiveness.

- Additives: Various additives are mixed with the polymers to enhance properties such as UV resistance, flexibility, and fire retardancy. This step is crucial in determining the performance characteristics of the synthetic leather.

2. Forming: How Is Synthetic Leather Created?

Once the raw materials are prepared, the next stage is the forming process, which involves several key techniques:

- Coating: The polymer mixture is coated onto a substrate, often made of textile or non-woven materials. This substrate provides structural integrity and a base for the synthetic leather.

- Extrusion: In some cases, polymers are extruded to form sheets that can be further processed. This method is particularly common in PVC production, where sheets are formed and then treated.

- Calendering: This technique involves passing the coated substrate through rollers to achieve the desired thickness and texture. The calendering process is vital for creating the characteristic look and feel of leather.

3. Assembly: What Processes Are Involved in Shaping Synthetic Leather?

After forming, the synthetic leather undergoes assembly processes to create the final product. This includes:

- Cutting: The material is cut into specific shapes and sizes, often using precision cutting machines to ensure accuracy.

- Sewing or Bonding: Depending on the intended use, synthetic leather pieces may be sewn together or bonded using adhesives. This step is critical for ensuring durability and aesthetic appeal in the final product.

4. Finishing: How Is the Final Look Achieved?

The finishing stage adds the final touches to synthetic leather, enhancing its aesthetic and functional properties:

Illustrative image related to what is synthetic leather made of

- Surface Treatment: Various treatments, such as embossing or printing, are applied to create textures or patterns that mimic real leather. This is also the stage where color is added, often through dyeing processes.

- Coating: A protective coating is often applied to improve wear resistance, water repellency, and UV stability. This not only prolongs the life of the synthetic leather but also enhances its appearance.

What Quality Assurance Measures Are Essential in Synthetic Leather Manufacturing?

Quality assurance (QA) is a cornerstone of synthetic leather production, ensuring that products meet international standards and customer expectations.

1. What International Standards Should B2B Buyers Be Aware Of?

Buyers should look for suppliers that comply with recognized international standards, such as:

- ISO 9001: This standard outlines criteria for a quality management system, emphasizing customer satisfaction and continuous improvement.

- CE Marking: Particularly relevant in Europe, CE marking indicates that products meet EU safety, health, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) sets standards that can be relevant for synthetic materials, especially in applications involving heavy-duty use.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials upon arrival. Suppliers should perform inspections to verify that materials meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are essential to ensure compliance with quality specifications. This may include monitoring thickness, texture, and color consistency.

- Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to ensure that all specifications have been met. This includes physical testing, such as abrasion resistance and color fastness.

3. How Can B2B Buyers Verify Supplier Quality Control?

To ensure reliability in the supply chain, B2B buyers can take several steps:

- Audits: Conducting supplier audits helps verify compliance with quality standards. This can include reviewing production processes, quality control procedures, and past performance records.

- Reports: Requesting detailed QC reports from suppliers provides insights into their quality assurance practices and any issues encountered during production.

- Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures and product quality.

What Nuances Should International Buyers Consider in Quality Control?

When sourcing synthetic leather from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances in QC:

- Regulatory Compliance: Different countries have varying regulations regarding synthetic materials. Buyers should ensure that their suppliers comply with local laws regarding labeling, safety, and environmental impact.

- Cultural Expectations: Understanding cultural differences in business practices and quality expectations can enhance buyer-supplier relationships. Establishing clear communication and expectations is key to successful partnerships.

- Sustainability Practices: With a growing focus on sustainability, buyers should inquire about the environmental practices of their suppliers, including waste management and the use of eco-friendly materials.

Conclusion

Understanding the manufacturing processes and quality assurance measures involved in synthetic leather production is essential for B2B buyers. By familiarizing themselves with these aspects, buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs while also aligning with international standards. Investing time in evaluating suppliers based on their manufacturing capabilities and quality assurance practices will ultimately lead to better product quality and more sustainable business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is synthetic leather made of’

Inleiding

This guide serves as a comprehensive checklist for B2B buyers aiming to procure synthetic leather. Understanding the composition and sourcing process of synthetic leather is vital for making informed purchasing decisions, ensuring product quality, and meeting regulatory requirements. Follow these steps to ensure a successful procurement process.

Illustrative image related to what is synthetic leather made of

1. Identify Your Requirements for Synthetic Leather

Begin by clearly defining what you need from synthetic leather. Consider factors such as application (e.g., upholstery, fashion, automotive), desired aesthetics, and performance characteristics.

- Material Composition: Determine if you prefer PU (polyurethane), PVC (polyvinyl chloride), or a blend, as each has different qualities regarding durability, breathability, and environmental impact.

- Certifications: Check if sustainability certifications are essential for your brand or market.

2. Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in synthetic leather. Utilize trade directories, industry associations, and online marketplaces to compile a list of potential partners.

- Reputation: Look for suppliers with positive reviews and a strong presence in the industry.

- Ervaring: Favor suppliers who have experience working in your specific market or region, as they will better understand local regulations and consumer preferences.

3. Verify Supplier Certifications

Before proceeding, ensure that potential suppliers possess relevant certifications. This step is crucial for confirming product quality and compliance with industry standards.

- Kwaliteit: Certifications such as ISO 9001 can indicate a commitment to quality management.

- Environmental Standards: Look for certifications like OEKO-TEX or REACH compliance to ensure that materials are safe and environmentally friendly.

4. Request Sample Materials

Always request samples before making bulk purchases. This allows you to assess the quality, texture, and overall appearance of the synthetic leather firsthand.

- Physical Evaluation: Inspect the samples for consistency in texture and color, as well as for any visible defects.

- Performance Testing: Consider conducting tests for durability, flexibility, and resistance to wear and tear.

5. Inquire About Manufacturing Processes

Understanding how synthetic leather is produced can provide insight into its quality and sustainability. Ask suppliers about their manufacturing techniques and materials used.

Illustrative image related to what is synthetic leather made of

- Production Methods: Learn whether they use environmentally friendly processes or materials, such as vegetable oils instead of petroleum-based products.

- Traceability: Ensure that suppliers can trace the source of their materials to avoid issues with quality or ethical sourcing.

6. Evaluate Pricing and Terms of Sale

Once you have narrowed down your options, compare pricing models and terms of sale. Be cautious of prices that seem too good to be true, as they may indicate lower quality.

- Total Cost of Ownership: Consider not just the unit price but also shipping, duties, and potential return policies.

- Payment Terms: Negotiate favorable payment terms that suit your cash flow requirements.

7. Establish Clear Communication Channels

Finally, set up reliable communication channels with your chosen supplier. Effective communication is essential for addressing concerns, negotiating terms, and ensuring timely deliveries.

- Regular Updates: Request regular updates on order status and production timelines.

- Point of Contact: Designate a specific contact person within the supplier’s organization to streamline communication.

By following these steps, B2B buyers can ensure a thorough and effective sourcing process for synthetic leather, minimizing risks and maximizing quality in their procurement efforts.

Illustrative image related to what is synthetic leather made of

Comprehensive Cost and Pricing Analysis for what is synthetic leather made of Sourcing

What Are the Key Cost Components for Sourcing Synthetic Leather?

When analyzing the cost structure for sourcing synthetic leather, several components must be considered. The primary materials include various synthetic polymers like polyurethane (PU), polyvinyl chloride (PVC), and sometimes biodegradable alternatives made from vegetable oils. Each material has distinct cost implications, with PU typically priced higher due to its favorable properties, such as flexibility and durability.

Labor costs also play a significant role in the overall expense. This includes wages for skilled workers involved in manufacturing and quality control. Manufacturing overhead, which encompasses utilities, rent, and equipment depreciation, can vary greatly depending on the production location. Tooling costs, related to the machinery needed for cutting and shaping the synthetic leather, should not be overlooked, especially for custom designs.

Quality control (QC) processes are essential to ensure the final product meets specified standards, and these can incur additional costs. Logistics, including transportation and warehousing, is another critical factor, especially for international buyers who must consider tariffs, customs duties, and shipping fees. Lastly, profit margins, which can differ by supplier and market conditions, should be factored into the final pricing.

How Do Price Influencers Affect the Sourcing of Synthetic Leather?

Several factors influence the pricing of synthetic leather, making it essential for buyers to understand the nuances involved. Volume and minimum order quantities (MOQ) significantly impact cost; larger orders typically reduce the per-unit price. Custom specifications, such as unique colors or textures, can also lead to increased costs due to additional production steps.

The quality of materials and certifications can affect pricing as well. For instance, products labeled as “eco-friendly” or containing recycled materials may command higher prices due to the sustainable practices involved in their production. Supplier factors, including reputation and reliability, can also play a role in pricing negotiations.

Buyers should also be aware of Incoterms, which define the responsibilities of buyers and sellers in international transactions. The choice of Incoterms can affect the total landed cost, influencing budgeting and pricing strategies.

What Buyer Tips Should International B2B Buyers Consider When Sourcing Synthetic Leather?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should approach the sourcing of synthetic leather with a strategic mindset. Effective negotiation tactics can help secure better pricing. Understanding the total cost of ownership (TCO) is crucial; this includes not just the purchase price but also operational costs, maintenance, and potential disposal fees.

Buyers should also conduct thorough research on suppliers to ensure they offer competitive pricing while maintaining quality standards. Requesting samples before placing large orders can mitigate risks associated with quality discrepancies. Additionally, keeping abreast of market trends and material innovations can provide leverage during negotiations.

Pricing nuances may arise due to regional differences in manufacturing costs and labor availability. For example, suppliers in Brazil may offer more competitive pricing due to lower labor costs, while European suppliers might emphasize quality and certifications, justifying a higher price point.

Illustrative image related to what is synthetic leather made of

Disclaimer on Indicative Prices

Pricing for synthetic leather can fluctuate based on market conditions, supplier negotiations, and raw material availability. Therefore, the figures discussed should be viewed as indicative rather than definitive. Engaging with multiple suppliers and obtaining detailed quotes is advisable to ensure accurate budgeting and planning.

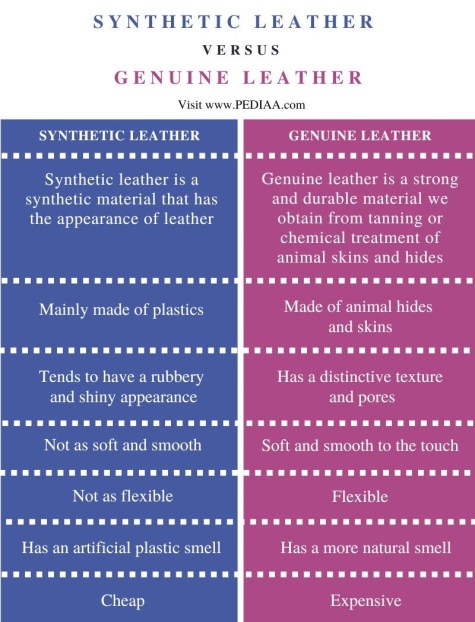

Alternatives Analysis: Comparing what is synthetic leather made of With Other Solutions

Exploring Alternatives to Synthetic Leather: A Comparative Analysis

As the demand for sustainable and ethical materials grows, B2B buyers are increasingly exploring alternatives to synthetic leather. Understanding what synthetic leather is made of—primarily polyurethane (PU), polyvinyl chloride (PVC), and other synthetic components—is crucial for evaluating its suitability against other available materials. This analysis will compare synthetic leather with two viable alternatives: real leather and plant-based leather, providing insights into performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | What Is Synthetic Leather Made Of | Real Leather | Plant-Based Leather |

|---|---|---|---|

| Performance | Moderate durability; water-resistant | High durability; breathable | Varies; generally lower than real leather |

| Cost | Generally lower than real leather | Higher due to sourcing and processing | Moderate; often comparable to synthetic leather |

| Ease of Implementation | Easy to manufacture and source | Requires specialized skills and processing | Can be complex; depends on raw materials |

| Maintenance | Low; easy to clean | Moderate; requires conditioning | Varies; often requires specific care |

| Best Use Case | Fashion, accessories, furniture | High-end goods, automotive | Sustainable fashion, eco-friendly products |

What Are the Advantages and Disadvantages of Real Leather?

Real leather, a natural by-product of the meat industry, offers unmatched durability and breathability, making it ideal for high-end products like luxury handbags and automotive interiors. However, its higher cost and ethical considerations may deter some buyers. The sourcing process also requires specialized skills, which can complicate supply chains. While real leather requires regular conditioning to maintain its quality, it is generally regarded as a long-lasting investment.

How Does Plant-Based Leather Compare?

Plant-based leather, often derived from materials like pineapple leaves (Piñatex) or apple peels, represents an innovative approach to sustainable fashion. This alternative appeals to eco-conscious consumers and brands aiming to reduce their carbon footprint. While it is generally more affordable than real leather, its durability can vary significantly based on the source material. Maintenance requirements can also differ; some plant-based leathers may need specific care to ensure longevity. This option is particularly suitable for brands targeting the growing market for sustainable and ethical products.

Conclusion: Choosing the Right Leather Alternative for Your Business Needs

For B2B buyers, the choice between synthetic leather, real leather, and plant-based leather hinges on several factors, including budget, target market, and sustainability goals. Synthetic leather offers an economical and easy-to-manufacture solution, while real leather provides superior durability and luxury appeal. Plant-based leather stands out as a compelling option for brands prioritizing environmental responsibility. By assessing the unique advantages and drawbacks of each material, businesses can make informed decisions that align with their product offerings and market positioning.

Essential Technical Properties and Trade Terminology for what is synthetic leather made of

What Key Properties Should B2B Buyers Consider for Synthetic Leather?

When sourcing synthetic leather, understanding its technical properties is crucial for making informed purchasing decisions. Here are several key specifications that buyers should consider:

1. Material Composition

Synthetic leather is primarily made from materials such as Polyurethane (PU) and Polyvinyl Chloride (PVC). PU is often preferred for its flexibility, durability, and more environmentally friendly production process compared to PVC. Understanding the material composition helps buyers assess the product’s quality, performance, and suitability for specific applications, such as upholstery, fashion, or automotive interiors.

2. Thickness and Tolerance

The thickness of synthetic leather typically ranges from 0.5mm to 3mm, depending on the intended use. Tolerance refers to the allowable deviation from the specified thickness. For example, a tolerance of ±0.1mm indicates that the actual thickness can vary within this range. Buyers must consider these factors, as they can impact the durability and aesthetics of the final product. Products with consistent thickness are essential for high-quality manufacturing processes.

Illustrative image related to what is synthetic leather made of

3. Breathability and Moisture-Wicking Properties

Breathability is a critical factor, especially in applications where comfort is paramount, such as clothing and footwear. Synthetic leathers generally have low breathability compared to natural leather, which can affect comfort levels. Additionally, moisture-wicking abilities indicate how well the material can manage moisture. For products requiring high performance, such as sportswear or automotive seating, selecting materials with enhanced breathability and moisture management capabilities is vital.

4. Durability and Abrasion Resistance

Durability is often assessed through tests like Martindale or Taber abrasion tests, which measure the material’s resistance to wear and tear. Higher abrasion resistance means longer-lasting products, making it a crucial specification for B2B buyers looking for cost-effective solutions. For instance, synthetic leather used in upholstery should withstand repeated use without significant degradation, ensuring value for money over time.

5. Flame Resistance

Flame resistance is an important property, especially in industries like automotive and aviation. Synthetic leathers can be treated to meet specific fire safety standards, which is crucial for compliance with regulatory requirements. Buyers in these sectors should verify that the materials used in their products adhere to relevant safety standards to mitigate risks.

Illustrative image related to what is synthetic leather made of

What Are Common Trade Terms Used in the Synthetic Leather Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end products. In the synthetic leather industry, buyers may work with OEMs that manufacture synthetic leather goods for brands. Understanding OEM relationships can help buyers secure better pricing and customization options.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan their inventory and budget effectively. Suppliers often set MOQs to ensure production efficiency and profitability.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specified products or services. B2B buyers should use RFQs to compare offers from multiple suppliers, ensuring they receive competitive pricing and favorable terms.

Illustrative image related to what is synthetic leather made of

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is crucial for B2B transactions, as they outline who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers negotiate better shipping terms and reduce potential liabilities.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This is a critical factor in supply chain management, as longer lead times can disrupt production schedules. Buyers should negotiate lead times with suppliers to align with their operational needs.

By understanding these properties and terms, B2B buyers can navigate the synthetic leather market more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the what is synthetic leather made of Sector

What Are the Key Market Dynamics and Trends in the Synthetic Leather Sector?

The synthetic leather market is witnessing a remarkable transformation, driven by evolving consumer preferences and technological advancements. Global demand for synthetic leather is primarily fueled by its application across various industries, including fashion, automotive, and furniture. Notably, the rise of veganism and ethical consumerism has led to increased interest in materials that do not rely on animal products, pushing brands to innovate and offer more sustainable alternatives. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are particularly interested in sourcing synthetic leather that meets both aesthetic and functional requirements.

Emerging technologies in manufacturing processes, such as the use of bio-based polymers and advanced coating techniques, are enhancing the quality and durability of synthetic leather. For instance, the incorporation of plant-based materials in the production process not only reduces reliance on fossil fuels but also appeals to environmentally conscious consumers. Additionally, digital platforms are increasingly becoming vital for B2B transactions, enabling buyers to access a broader range of suppliers and products while facilitating price comparisons and quality assessments.

Regional dynamics also play a crucial role; for example, Europe has stringent regulations on material labeling, which encourages transparency and accountability in sourcing. In contrast, markets in Africa and South America are experiencing growth due to rising disposable incomes and a burgeoning middle class, which is expanding the consumer base for synthetic leather products. As these markets mature, international buyers must remain vigilant about sourcing high-quality materials that align with regional regulations and consumer expectations.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in Synthetic Leather?

Sustainability is becoming a key differentiator in the synthetic leather industry, influencing B2B purchasing decisions across the globe. The environmental impact of synthetic leather production, particularly concerning the use of PVC and other petrochemicals, has raised significant concerns. International buyers are increasingly prioritizing suppliers who adopt eco-friendly practices, such as reducing emissions during production and utilizing sustainable raw materials.

Ethical sourcing is also paramount, as brands face growing pressure to ensure their supply chains are transparent and responsible. Certifications such as the Global Organic Textile Standard (GOTS) and the OEKO-TEX Standard 100 are gaining traction among manufacturers of synthetic leather. These certifications provide assurance to buyers that the materials used are free from harmful substances and produced in a socially responsible manner.

Illustrative image related to what is synthetic leather made of

Moreover, as consumers increasingly demand accountability from brands, B2B buyers must ensure that their suppliers can demonstrate sustainable practices. This includes sourcing materials that minimize waste and energy consumption throughout the production cycle. By aligning with suppliers committed to sustainability, businesses can enhance their brand reputation, meet regulatory requirements, and appeal to a growing segment of eco-conscious consumers.

What Is the Historical Context of Synthetic Leather in the B2B Market?

The journey of synthetic leather began in the early 20th century, primarily as a response to the high costs and ethical concerns associated with real leather. Initially, materials such as PVC were used, which allowed manufacturers to create affordable alternatives. Over time, the production processes evolved, leading to the development of more sophisticated materials like polyurethane (PU) and bio-based options.

By the late 20th century, the rise of environmental awareness began to influence production methods, prompting innovations aimed at reducing the ecological footprint of synthetic leather. The introduction of materials derived from renewable resources, such as plant oils, marked a significant shift in the industry. Today, the synthetic leather market continues to evolve, driven by technological advancements and changing consumer preferences, making it a dynamic sector for international B2B buyers seeking sustainable sourcing solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of what is synthetic leather made of

-

What materials are commonly used to make synthetic leather?

Synthetic leather is primarily composed of materials such as polyurethane (PU), polyvinyl chloride (PVC), and nylon. These materials are engineered to mimic the appearance and texture of real leather while being more cost-effective and often more environmentally friendly. PU is particularly favored for its flexibility and breathability, making it suitable for various applications, including fashion and upholstery. Additionally, some manufacturers are exploring bio-based alternatives that incorporate plant materials, enhancing the sustainability aspect of synthetic leather production. -

How can I differentiate between high-quality synthetic leather and lower-quality alternatives?

High-quality synthetic leather typically features a more realistic grain pattern, better durability, and a more natural feel. When sourcing, examine the texture, smell, and surface finish. Premium products often have a soft, supple feel and a matte finish, while lower-quality options may appear shiny or rubbery. Additionally, inquire about the manufacturing process and materials used, as reputable suppliers will provide transparency regarding their product’s quality and performance. -

What are the common applications for synthetic leather in B2B industries?

Synthetic leather is widely used across various industries, including fashion, automotive, furniture, and accessories. In fashion, it serves as a vegan alternative for bags, shoes, and clothing. The automotive sector utilizes synthetic leather for upholstery, offering a durable and easy-to-clean option. Additionally, in furniture, synthetic leather is often chosen for its aesthetic appeal and resistance to wear, making it ideal for office chairs, sofas, and other furnishings. -

What should I consider when vetting suppliers of synthetic leather?

When vetting suppliers, consider factors such as their production capabilities, material sourcing, and adherence to quality standards. Look for certifications such as ISO or Leather Working Group (LWG) to ensure sustainable and ethical practices. Request samples to assess material quality and performance. Furthermore, evaluate their responsiveness and customer service, as reliable communication is crucial for building a successful long-term partnership. -

What are the typical minimum order quantities (MOQs) for synthetic leather?

Minimum order quantities for synthetic leather can vary significantly based on the supplier and the specific material required. Generally, MOQs can range from 100 meters to several thousand meters. It’s essential to clarify these terms before proceeding with an order, especially if you are testing a new product line. Some suppliers may offer flexibility for smaller orders, particularly for new customers or sample requests, so it’s advisable to discuss your needs directly with potential suppliers. -

What payment terms are commonly offered by synthetic leather suppliers?

Payment terms vary widely among suppliers, but common practices include a 30% deposit upfront with the remaining balance due upon delivery or a net 30 or net 60 payment plan. Some suppliers may offer discounts for early payments or larger orders. It’s important to negotiate terms that align with your cash flow needs and to ensure that the payment method is secure, whether through bank transfers, letters of credit, or other means. -

How can I ensure quality assurance (QA) in my synthetic leather orders?

To ensure quality assurance, establish clear specifications and standards with your supplier before placing orders. Request detailed product descriptions, including material composition, thickness, and performance characteristics. Implement a sampling process where you can review and test materials before full-scale production. Additionally, consider third-party inspections during manufacturing and upon delivery to verify compliance with your quality requirements. -

What logistics considerations should I keep in mind when importing synthetic leather?

When importing synthetic leather, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder experienced in handling textile imports to navigate complex customs procedures. Understand the import duties and taxes applicable in your country, as these can affect overall costs. Additionally, plan for potential delays in shipping, especially during peak seasons, and maintain open communication with your supplier to monitor shipment progress.

Top 4 What Is Synthetic Leather Made Of Manufacturers & Suppliers List

1. Sewport – Faux Leather

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: Faux leather, also known as synthetic leather, is a petroleum-based alternative to genuine leather. It is soft to the touch, water-resistant, and highly resistant to stains, making it easy to clean. While less durable than real leather, it is resistant to abrasions and cuts, ideal for upholstery in homes with children or pets. Faux leather can be produced in various colors, including unconventiona…

2. Buffalo Jackson – Faux Leather Products

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Faux leather, also known as synthetic leather, is made from a fabric base such as polyester, which is then treated with wax, dye, polyvinyl chloride (PVC), or polyurethane to create an imitation leather finish and texture. It is designed to look like real leather but has a uniform surface and feels cold and unnaturally even. Faux leather does not last as long as real leather and does not wear out …

3. Monsieur Chaussure – Synthetic Leather Footwear

Domain: monsieurchaussure.com

Registered: 2010 (15 years)

Introduction: Synthetic leather is a man-made material designed to mimic the appearance and texture of genuine leather. It is often made from polyurethane (PU) or polyvinyl chloride (PVC) and is used in various applications, including clothing, upholstery, and accessories. Synthetic leather is generally more affordable than real leather, easier to clean, and available in a wide range of colors and textures. It …

4. Big Z Fabric – Faux Leather vs. Vinyl

Domain: blog.bigzfabric.com

Registered: 2010 (15 years)

Introduction: Faux Leather: Composite material with a fabric base (polyester, cotton) coated with PU or PVC; better breathability, soft texture, available in various colors; used in apparel, accessories, upholstery. Vinyl: Purely synthetic PVC material; highly durable, moisture-resistant, less breathable, stiffer feel; ideal for outdoor furniture, tablecloths, flooring, car interiors, medical equipment. Price: …

Strategic Sourcing Conclusion and Outlook for what is synthetic leather made of

As the demand for sustainable and ethically sourced materials continues to rise, understanding the composition of synthetic leather is crucial for international B2B buyers. Synthetic leather, often crafted from materials such as polyurethane (PU), polyvinyl chloride (PVC), and even innovative plant-based components, offers a versatile alternative to traditional leather. It’s essential for buyers to recognize the differences in quality, durability, and environmental impact when sourcing these materials.

Strategic sourcing of synthetic leather can unlock significant advantages, such as cost-effectiveness and a reduced carbon footprint. By opting for suppliers who prioritize transparency in their labeling and adhere to strict manufacturing standards, buyers can ensure they are making responsible choices that align with global sustainability goals.

Illustrative image related to what is synthetic leather made of

Looking ahead, the synthetic leather market is poised for growth, particularly in regions like Africa, South America, the Middle East, and Europe. B2B buyers are encouraged to stay informed about evolving trends and innovations in material technology. Engaging with suppliers who demonstrate a commitment to sustainable practices will not only enhance your product offerings but also resonate with increasingly eco-conscious consumers. Now is the time to leverage strategic sourcing to secure a competitive edge in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.