Catalog

Material Insight: What Is Artificial Leather Made Of

B2B Product Guide: Understanding Artificial Leather & WINIW’s Sustainable Solution

Artificial leather, also known as faux leather, synthetic leather, or engineered leather, is a high-performance material designed to replicate the look, feel, and functionality of genuine leather without utilizing animal hides. It is fundamentally composed of a fabric backing (typically polyester, cotton, or a blend) coated with a polymer layer. The specific composition and manufacturing process define its quality, durability, and environmental profile:

| Material Type | Primary Components | Key Characteristics |

|---|---|---|

| Polyurethane (PU) | Polymer resin (often water-based for eco-friendliness), fabric backing, pigments | Superior softness, breathability, flexibility, durability, and significantly lower environmental impact than PVC. Dominates modern sustainable offerings. |

| Polyvinyl Chloride (PVC) | PVC resin, plasticizers (often phthalates), fabric backing, stabilizers | Historically common; stiffer, less breathable, contains problematic plasticizers, higher environmental burden during production and disposal. |

Why Faux Leather is the Optimal Choice for Modern B2B Applications

For forward-thinking businesses across furniture, automotive, fashion, and technical textiles, high-quality faux leather presents compelling advantages over both genuine leather and lower-grade synthetics:

- Enhanced Sustainability: Eliminates ethical concerns and the significant land, water, and chemical footprint associated with livestock farming and tanning. Modern PU-based options, especially water-based formulations, drastically reduce VOC emissions and hazardous waste.

- Superior Consistency & Performance: Offers uniform appearance, texture, and thickness across every roll, unlike the natural variations in genuine leather. Engineered for specific performance needs like abrasion resistance, color fastness, seam strength, and UV stability.

- Cost Efficiency & Scalability: Provides predictable pricing unaffected by hide market fluctuations and eliminates waste from hide defects. Enables large-scale, consistent production runs essential for global supply chains.

- Design Versatility: Available in an extensive range of colors, textures, finishes (matte, gloss, embossed), and performance characteristics (e.g., flame retardancy, antimicrobial properties) unattainable with natural materials.

- Durability & Maintenance: Often exhibits superior resistance to cracking, fading, and staining compared to some genuine leathers, while being easier to clean and maintain – a critical factor for commercial and high-use environments.

Introducing WINIW: Your Trusted Partner in Sustainable Synthetic Leather

WINIW stands as a global leader in the research, development, and manufacturing of premium synthetic leather solutions, backed by over 20 years of specialized industry expertise. We are deeply committed to advancing the performance and sustainability of engineered materials. Our focus is on delivering B2B partners like you innovative, high-value PU-based faux leather that meets rigorous quality standards while actively reducing environmental impact. Through continuous investment in R&D and eco-conscious production processes – including leadership in water-based PU technology and exploration of recycled content – WINIW provides the reliable, scalable, and responsible material solutions demanded by today’s discerning markets and conscious consumers. Partner with WINIW for performance you can trust and sustainability you can verify.

Technical Performance & Standards

WINIW Artificial Leather: Technical Advantages and Product Specifications

WINIW specializes in high-performance synthetic leather engineered for industrial and commercial applications. Our artificial leather is designed to deliver superior value across cost, durability, customization, and regulatory compliance. Ideal for furniture, automotive interiors, footwear, and accessories, WINIW’s solutions meet the evolving demands of global B2B clients seeking sustainable, reliable, and scalable materials.

Technical Advantages

-

Cost-Effective Manufacturing

WINIW’s artificial leather reduces material and production costs without sacrificing quality. By optimizing base polymers and production efficiency, we deliver consistent output at competitive price points, helping clients improve margins and scale operations. -

Enhanced Durability

Our synthetic leather features high tensile strength, excellent abrasion resistance, and superior tear performance. Engineered with reinforced polyurethane (PU) or polyvinyl chloride (PVC) coatings and high-density non-woven backings, WINIW leather maintains integrity under stress and prolonged use. -

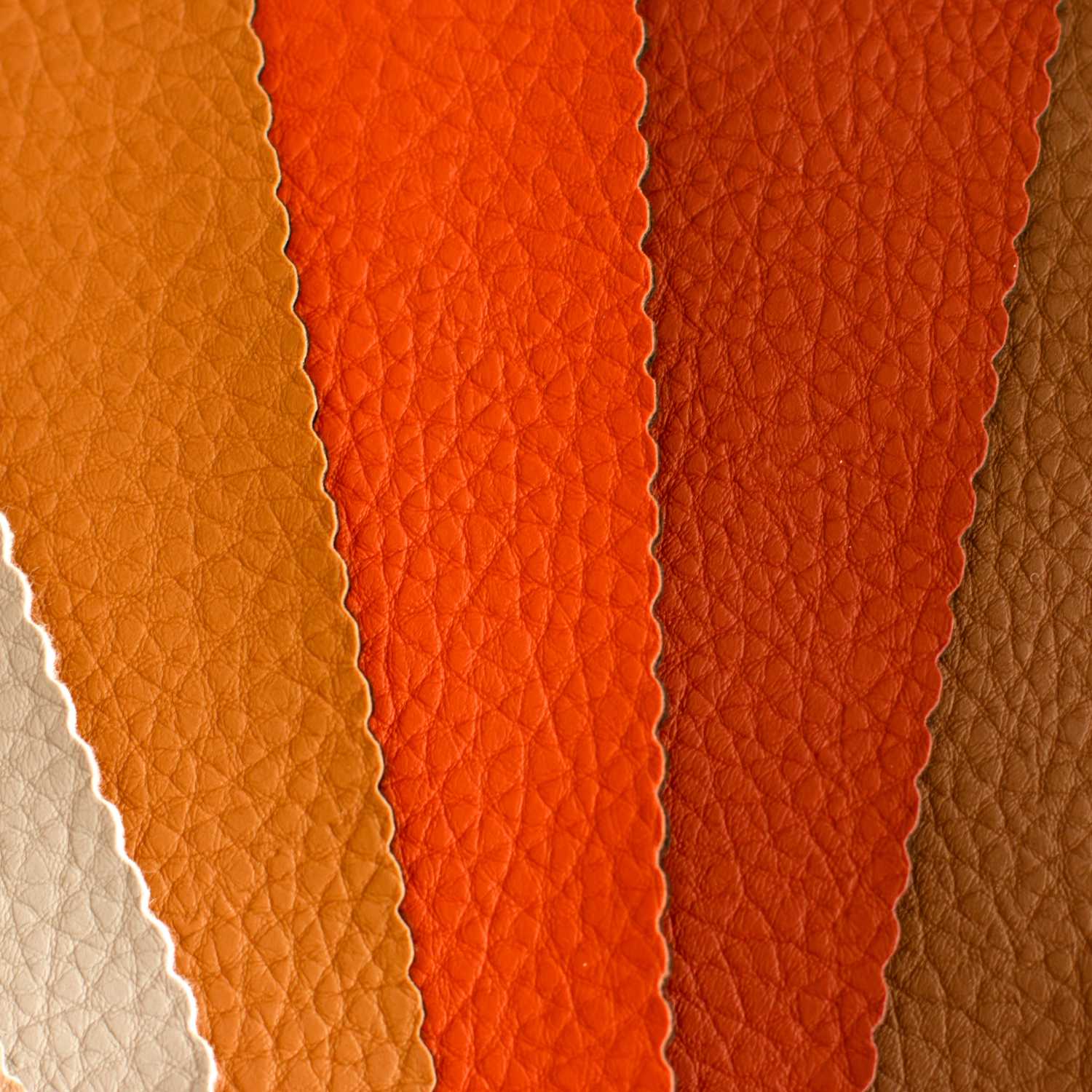

Customizable Colors and Finishes

WINIW offers full color customization with precise Pantone matching and batch consistency. Clients can select from matte, glossy, embossed, or textured finishes to meet brand-specific design requirements. Our digital color management system ensures accurate replication across large-volume orders. -

REACH Compliance

All WINIW artificial leather products are fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). Our materials are free from SVHCs (Substances of Very High Concern) and restricted phthalates, ensuring safety for end users and environmental responsibility. -

ISO9001-Certified Quality Management

WINIW operates under ISO9001-certified processes, guaranteeing consistent product quality, traceability, and continuous improvement. From raw material sourcing to final inspection, every stage adheres to internationally recognized quality standards.

Product Specifications

| Property | Specificatie |

|---|---|

| Base Material | High-density non-woven fabric + PU/PVC coating |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Weight Range | 200 g/m² – 600 g/m² |

| Tensile Strength (MD) | ≥ 60 N/5cm (PU), ≥ 50 N/5cm (PVC) |

| Elongation at Break | ≥ 80% |

| Color Fastness (Rubbing) | Dry: Grade 4–5; Wet: Grade 4 |

| Martindale Abrasion Resistance | ≥ 30,000 cycles (PU), ≥ 20,000 cycles (PVC) |

| Color Options | Full Pantone customization available |

| Certifications | REACH, ISO9001, RoHS (on request) |

| Environmental Profile | Low-VOC, phthalate-free options available |

WINIW’s artificial leather combines advanced material science with sustainable manufacturing practices, providing B2B partners with a reliable, eco-conscious alternative to genuine leather. With scalable production capacity and a focus on technical performance, WINIW supports long-term partnerships in competitive global markets.

Why Choose Synthetic over Real Leather

B2B Product Guide: Artificial Leather vs. Real Leather – Material Composition & Performance Comparison

As a leader in sustainable synthetic materials, WINIW provides this objective comparison to support informed sourcing decisions for designers, manufacturers, and procurement teams. Understanding core material composition is critical for aligning product specifications with environmental goals, durability requirements, and cost efficiency.

Material Composition Breakdown

Artificial Leather (Modern PU-Based Synthetics, e.g., WINIW Eco-Series):

– Primarily engineered from polyurethane (PU) polymer coatings applied to textile backings (typically polyester or recycled PET).

– Backings may incorporate up to 30% post-consumer recycled content in advanced eco-lines.

– Free from PVC, phthalates, and heavy metals in certified sustainable grades.

– Production uses water-based, solvent-free processes to minimize VOC emissions.

– Requires no animal-derived inputs, eliminating agricultural land/water dependencies.

Real Leather:

– Derived from tanned animal hides (bovine, ovine, or exotics), constituting a byproduct of meat/dairy industries.

– Undergoes resource-intensive tanning (chrome or vegetable-based), dyeing, and finishing with chemical additives.

– Natural protein fiber structure (collagen) provides inherent breathability but variable consistency.

– Land, water, and feed demands tied to livestock farming significantly impact upstream sustainability.

Performance & Sustainability Comparison

The table below evaluates key B2B decision factors for industrial applications (e.g., automotive upholstery, furniture, accessories):

| Criteria | Artificial Leather (WINIW Eco-Series) | Real Leather |

|---|---|---|

| Cost | 20-40% lower initial material cost. Consistent pricing unaffected by hide scarcity. Lower waste in cutting (up to 30% yield improvement). | Higher base cost (driven by hide grading, tanning complexity). Price volatility due to livestock market fluctuations. Significant waste in pattern cutting (15-25% average). |

| Duurzaamheid | Superior abrasion resistance (≥50,000 cycles Martindale). Uniform thickness, colorfastness, and stain resistance. No natural defects. Resists cracking in UV/exposure tests (500+ hrs). | Variable durability based on hide grade. Prone to scratches, fading, and moisture damage without intensive maintenance. Natural grain may crack over time (10-15 yr avg. lifespan in commercial use). |

| Eco-Friendliness | 60% lower carbon footprint vs. bovine leather (Higg MSI verified). Zero animal agriculture impact. Recyclable via specialized programs (WINIW Take-Back). Water usage reduced by 90% vs. tanning. | High land/water use (17k L/kg for bovine leather). Tanning effluents risk water pollution (chrome tanning). Biodegradable but slow (decades). Methane emissions from livestock supply chain. |

Strategic Recommendation

For B2B applications prioritizing cost predictability, consistent quality, and verifiable sustainability (e.g., automotive interiors, contract furniture, eco-conscious fashion), modern PU-based artificial leather delivers superior lifecycle value. WINIW’s closed-loop production and recycled content options further future-proof supply chains against tightening ESG regulations. Real leather remains viable for heritage luxury segments but carries escalating environmental liabilities and supply chain risks. Partner with WINIW to access technical data sheets, sample kits, and lifecycle assessments tailored to your product specifications.

WINIW – Engineering Sustainable Performance Since 1986

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. With a strong commitment to sustainability, quality, and cutting-edge technology, WINIW serves industries ranging from automotive and fashion to furniture and sports.

Our manufacturing capabilities are anchored in a state-of-the-art production facility spanning 100,000 square meters. This expansive campus integrates advanced automation, efficient workflows, and environmentally responsible practices to ensure consistent output and scalability for large-volume orders.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 150 technical experts focused on material innovation, durability enhancement, and sustainable development. The team continuously develops new formulations that meet international environmental standards, including REACH, RoHS, and OEKO-TEX certifications.

- In-house testing laboratories equipped to conduct rigorous performance evaluations, including abrasion resistance, color fastness, tensile strength, and environmental aging tests.

- Strict quality control protocols implemented at every stage of production—from raw material inspection to final product verification—ensuring compliance with the highest international standards.

- Full traceability systems and batch control to maintain consistency and support audit readiness for global clients.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our products are trusted by leading brands for their reliability, aesthetic precision, and low environmental impact. By combining industrial scale with technical excellence, WINIW delivers synthetic leather solutions that meet the evolving demands of modern manufacturing.

Contact Us for Samples

WINIW Microfiber Leather Product Guide: Sustainable Performance Materials

WINIW delivers premium synthetic leather solutions engineered for durability, aesthetics, and environmental responsibility. Our microfiber leather technology replaces traditional animal hide and inferior PVC alternatives, offering B2B partners a scalable, ethical material for automotive, furniture, fashion, and technical applications. All WINIW products comply with global eco-standards (REACH, OEKO-TEX®) and prioritize recycled content without compromising performance.

Core Composition of WINIW Artificial Leather

Artificial leather—specifically high-end microfiber leather like WINIW’s—is engineered from advanced polymer systems. Unlike low-tier PVC or basic PU leathers, our material replicates the structure and breathability of genuine leather through a sophisticated multi-layer process:

- Base Layer: Ultra-fine polyester microfibers (0.1–0.3 denier), often incorporating 30–50% recycled PET content, form a non-woven mesh mimicking leather’s collagen structure.

- Binder System: Water-based polyurethane (PU) resins infused with eco-additives permeate the microfiber matrix, creating a supple yet resilient substrate.

- Surface Finish: A proprietary PU or acrylic topcoat provides color, texture (e.g., grain, suede), abrasion resistance, and UV stability. Optional coatings add stain resistance, flame retardancy, or antimicrobial properties.

- Backing: Knitted or woven fabric (polyester/cotton) or foam lamination ensures dimensional stability and ease of processing.

This tri-layer architecture delivers superior tear strength, flexibility, and breathability versus conventional synthetic leathers, while eliminating phthalates, heavy metals, and DMF solvents.

Material Properties Comparison

| Property | WINIW Microfiber Leather | Standard PVC Leather | Basic PU Leather |

|---|---|---|---|

| Eco-Certifications | OEKO-TEX® STANDARD 100, GRS (30%+ recycled) | Rarely certified | Limited certifications |

| Breathability (g/m²/24h) | 8,000–12,000 | <500 | 1,500–3,000 |

| Tensile Strength | 350–450 N/mm² | 150–250 N/mm² | 200–300 N/mm² |

| Abrasion Resistance | 50,000+ cycles (Martindale) | 5,000–15,000 cycles | 15,000–25,000 cycles |

| Recycled Content | 30–50% | 0% | 0–10% |

| End-of-Life | Recyclable via specialized streams | Landfill/toxic incineration | Limited recyclability |

Why Partner with WINIW?

- Sustainability by Design: 37% lower carbon footprint vs. bovine leather (ISO 14040 LCA verified); waterless dyeing processes.

- Performance Tailoring: Customize thickness (0.6–2.0mm), weight (200–600g/m²), colorfastness, and functional properties (e.g., 500+ hour UV resistance).

- Supply Chain Security: ISO 9001/14001-certified production; 95% on-time delivery rate across 40+ countries.

- Regulatory Compliance: Full documentation for EU Ecolabel, California Proposition 65, and automotive OEM specs (e.g., BMW GS 97072).

Discover what artificial leather is made of at a molecular level—and how WINIW’s engineering elevates performance. Request a technical dossier detailing resin chemistry, microfiber alignment science, and lifecycle analysis.

→ Contact WINIW’s Material Science Team:

E-mail MKT88@MicrofiberLeather.com for:

– Free physical samples (specify application: automotive seat, luxury handbag, etc.)

– Custom swatch books with eco-impact metrics

– Compliance documentation for your regional market

WINIW: Engineering the Future of Leather Responsibly.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.