Catalog

Material Insight: Waht Is Pu Leather

Understanding PU Leather: The Engineered Alternative for Modern Business Applications

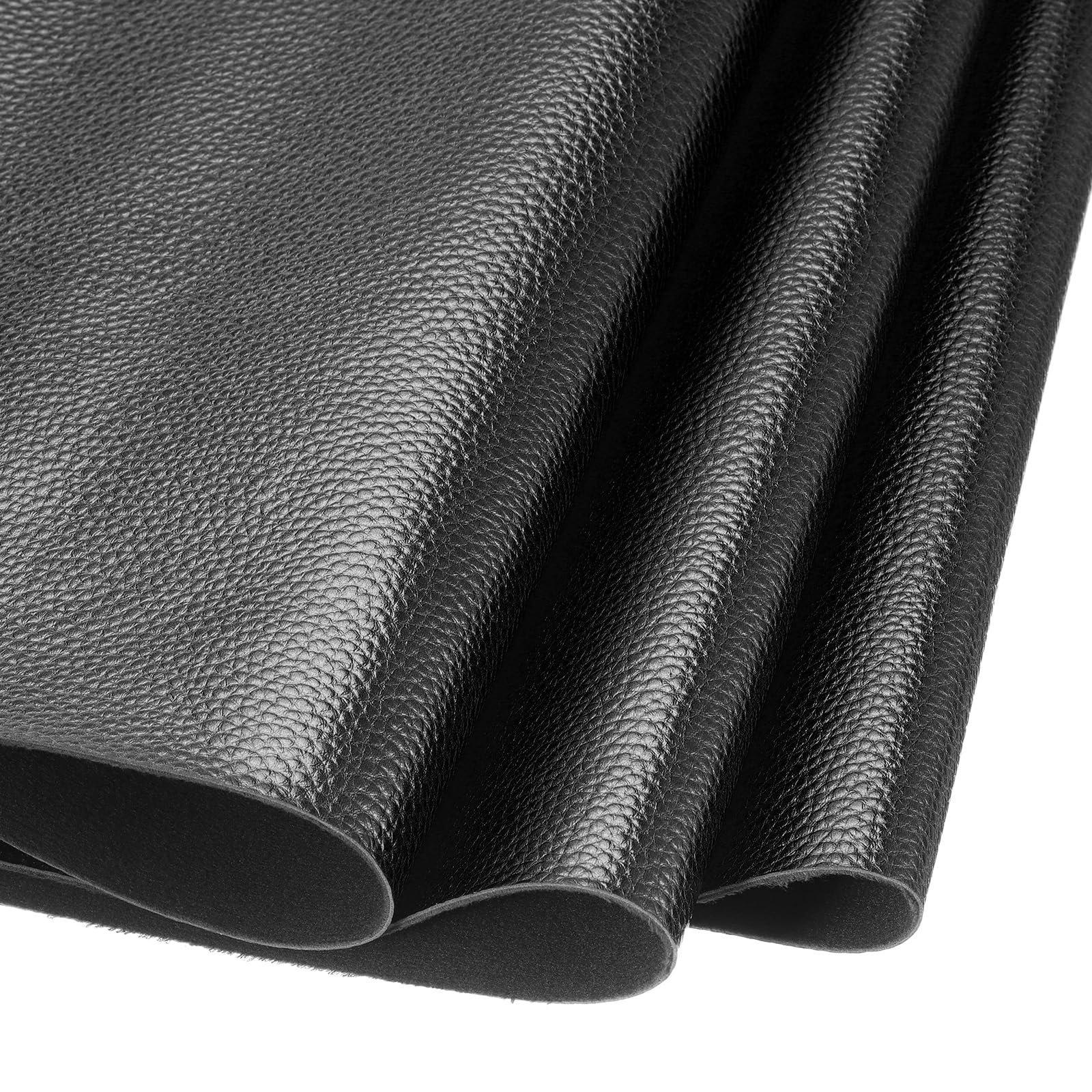

Polyurethane (PU) leather, also known as synthetic leather or faux leather, is a high-performance material created by applying a polyurethane resin coating onto a textile base (typically polyester or cotton). Unlike traditional PVC leather, PU leather contains no chlorine-based plastics, offering superior breathability, flexibility, and environmental safety. It replicates the aesthetic and tactile qualities of genuine leather while eliminating ethical concerns, inconsistent sourcing, and high maintenance costs associated with animal hides. Engineered for precision, PU leather delivers uniform texture, color fastness, and enhanced durability tailored to rigorous commercial demands.

Why PU Leather Outperforms Alternatives in Commercial Applications

- Cost Efficiency: Eliminates the 30-50% cost volatility of genuine leather with consistent pricing, reducing budget uncertainty for large-scale production.

- Durability & Maintenance: Resists cracking, fading, and staining 2-3x longer than genuine leather in high-traffic environments (e.g., hospitality seating, automotive interiors), cutting replacement costs.

- Ethical & Regulatory Compliance: 100% animal-free and phthalate-free, meeting EU REACH, OEKO-TEX® standards, and corporate sustainability mandates without supply chain traceability risks.

- Design Flexibility: Customizable thickness (0.6mm–1.2mm), textures (suede, grain, exotic), and colors in 2-3 weeks—versus months for leather—accelerating time-to-market.

- Eco-Performance: Uses 65% less water and generates 50% lower CO₂ emissions than leather tanning, with recyclable backing options supporting circular economy goals.

WINIW: Precision Engineering for Sustainable Business Solutions

For over 20 years, WINIW has pioneered next-generation synthetic leather solutions trusted by global leaders in automotive, furniture, and luxury goods manufacturing. Our vertically integrated production—spanning R&D, coating, and finishing—ensures uncompromising quality control and rapid scalability (up to 500,000 meters monthly). We specialize in creating application-specific formulations that balance eco-credentials (GRS-certified, solvent-free processes) with performance metrics critical to B2B success: abrasion resistance (50,000+ double rubs), lightfastness (Grade 7+), and fire safety (FMVSS 302, CAL 117). Partner with WINIW to transform sustainability targets into competitive advantage, without sacrificing durability or design excellence.

Technical Performance & Standards

WINIW B2B Product Guide: Understanding PU Leather

Polyurethane (PU) leather is a high-performance synthetic leather engineered to deliver the look and feel of genuine leather with enhanced functionality, sustainability, and cost-efficiency. At WINIW, our PU leather is developed for industrial and commercial applications where durability, aesthetics, and compliance are critical. Designed for B2B partners in furniture, automotive, apparel, and accessories, WINIW’s PU leather combines advanced material science with eco-conscious manufacturing.

Technical Advantages of WINIW PU Leather

-

Cost-Effective Alternative

WINIW PU leather offers a significantly lower total cost of ownership compared to genuine leather. It eliminates the variability and high sourcing costs associated with animal hides while maintaining a premium appearance. Reduced waste during cutting and processing further enhances cost efficiency in large-scale production. -

Superior Durability

Our PU leather is engineered for high abrasion resistance, excellent tensile strength, and outstanding flexibility. It maintains integrity under repeated stress, making it ideal for high-use environments such as automotive interiors and commercial furniture. Resistant to cracking, fading, and peeling, WINIW PU leather ensures long-term product performance. -

Customizable Colors and Finishes

WINIW offers full color customization with precise color matching (Pantone, RAL, or customer-provided samples). Our advanced coating and embossing technologies enable a wide range of textures—from matte and glossy to natural grain and exotic patterns—supporting brand-specific design requirements. -

REACH Compliance

WINIW PU leather is fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). Our products are free from harmful substances such as phthalates, heavy metals, and AZO dyes, ensuring safety for end-users and alignment with global environmental standards. -

ISO 9001 Certified Production

Manufactured in ISO 9001-certified facilities, WINIW PU leather adheres to rigorous quality management systems. This ensures consistent product quality, traceability, and continuous improvement across all production batches, providing reliability for B2B supply chains.

Technical Specifications – WINIW PU Leather

| Property | Specificatie |

|---|---|

| Base Material | Polyester fabric (scrim or knit) |

| Coating Material | Thermoplastic polyurethane (TPU) |

| Thickness Range | 0.6 mm – 1.8 mm (customizable) |

| Width Range | 137 cm – 150 cm (standard roll width) |

| Weight | 280 – 450 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale test) |

| Color Fastness to Rubbing | Grade 4–5 (dry), Grade 3–4 (wet) |

| Light Fastness | >4 (Blue Scale, 72 hrs UV exposure) |

| Tensile Strength | ≥ 50 N/5cm (warp & weft) |

| Tear Strength | ≥ 3.5 N |

| Cold Crack Resistance | Passes at -20°C |

| Environmental Compliance | REACH, RoHS,不含偶氮染料 (AZO-free) |

| Certifications | ISO 9001, OEKO-TEX® (on request) |

| Customization Options | Color, thickness, texture, backings, roll length |

WINIW PU leather is engineered for performance-driven industries seeking a sustainable, reliable, and customizable material solution. By combining affordability with industrial-grade durability and full regulatory compliance, WINIW supports B2B partners in delivering high-value products to competitive markets.

Why Choose Synthetic over Real Leather

B2B Product Guide: PU Leather vs. Real Leather Comparison

PU Leather Defined

Polyurethane (PU) leather is a high-performance synthetic material engineered to replicate the look, feel, and functionality of genuine leather. At WINIW, our PU leather utilizes advanced polymer technology, often incorporating recycled content (e.g., PET bottles) and water-based, solvent-free production processes. It offers consistent texture, color fastness, and resistance to cracking or fading, making it ideal for furniture, automotive interiors, fashion accessories, and tech accessories where controlled aesthetics and ethical sourcing are priorities.

Real Leather Defined

Real leather is a natural material derived from tanned animal hides (typically bovine, ovine, or porcine). Its production involves resource-intensive processes: hide sourcing, chemical tanning (often using chromium), dyeing, and finishing. While valued for its unique grain patterns and aging characteristics, real leather exhibits natural inconsistencies in texture and thickness. Its environmental footprint includes significant land/water use, greenhouse gas emissions from livestock, and chemical pollution risks from tanneries.

Comparative Analysis: Key Attributes for Commercial Procurement

| Attribute | PU Leather (WINIW Standard) | Real Leather |

|---|---|---|

| Cost | – 30–50% lower upfront cost – Reduced waste in cutting (consistent grain) – Lower logistics weight = reduced shipping costs |

– Higher raw material cost – Significant price volatility (hide market) – Up to 20% waste due to natural defects |

| Duurzaamheid | – Superior resistance to UV fading & moisture – Uniform strength (no weak spots) – Resists cracking in temperature extremes – Typical lifespan: 5–8 years (commercial use) |

– Prone to drying/cracking without conditioning – Vulnerable to water stains & mold – Lifespan highly variable (3–15+ years) – Susceptible to insect damage |

| Eco-Friendliness | – WINIW Advantage: 40–60% recycled content options – Zero animal sourcing – Water-based production (near-zero VOC emissions) – 70% lower CO₂e vs. bovine leather (Higg MSI data) |

– High water consumption (15,000–20,000 L/kg) – Chromium pollution risk in tannery effluent – Land use/deforestation for grazing – Non-biodegradable in landfills |

Strategic Considerations for B2B Buyers

- Sustainability Compliance: WINIW PU leather aligns with EU Ecolabel, REACH, and LEED criteria, supporting ESG reporting and circular economy initiatives. Real leather struggles with Scope 3 emissions tracking and chemical regulation compliance.

- Supply Chain Resilience: PU leather offers stable lead times and batch consistency; real leather faces hide scarcity and ethical certification complexities (e.g., Leather Working Group audits).

- End-of-Life: WINIW’s mono-material PU is increasingly recyclable via closed-loop systems; real leather tanning chemicals complicate biodegradation and recycling.

WINIW’s engineered PU leather delivers cost efficiency, performance reliability, and verifiable sustainability—enabling brands to meet market demands without compromising ethical or environmental commitments. Partner with us to develop custom solutions aligned with your sustainability roadmap.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with premium materials engineered for durability, sustainability, and aesthetic excellence. Our vertically integrated production ecosystem ensures consistent quality, rapid innovation, and reliable delivery for partners across industries.

- Our state-of-the-art manufacturing facility spans 100,000 square meters, making it one of the largest synthetic leather production bases in Asia. This extensive capacity supports high-volume orders while maintaining precision and efficiency.

- A dedicated R&D team of over 150 technical experts drives continuous innovation, developing eco-friendly materials such as water-based PU, recycled content leathers, and bio-based solutions tailored to client specifications.

- Strict quality control protocols are implemented at every stage—from raw material selection to final inspection. Our QC system complies with international standards, including REACH, RoHS, and OEKO-TEX, ensuring safe, consistent, and compliant products.

- WINIW maintains advanced testing laboratories on-site to evaluate physical properties, color fastness, abrasion resistance, and environmental compliance, providing full traceability and certification documentation.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our products are trusted by automotive, furniture, footwear, and fashion brands committed to sustainability and performance.

- Longstanding partnerships with global distributors and tier-one manufacturers underscore our reputation for reliability and premium quality.

- Our logistics network ensures timely delivery to international clients, supported by multilingual customer service and technical support teams.

By combining scale, innovation, and rigorous quality assurance, WINIW delivers synthetic leather solutions that meet the evolving demands of environmentally conscious, high-standard industries worldwide.

Contact Us for Samples

WINIW B2B Product Guide: Understanding Premium PU Leather

PU leather (Polyurethane Leather) is a high-performance synthetic material engineered to replicate the aesthetics, texture, and functionality of genuine leather while addressing critical sustainability and cost-efficiency demands in modern manufacturing. At WINIW, we specialize in advanced microfiber-based PU leather solutions designed for durability, eco-compliance, and seamless integration into diverse product lines—from automotive interiors and furniture to fashion accessories and electronics.

Key Properties of WINIW PU Leather

- Eco-Conscious Composition: Formulated without PVC, phthalates, or heavy metals, meeting global standards like REACH, OEKO-TEX® STANDARD 100, and ISO 14001.

- Superior Durability: Resists abrasion, tearing, and UV degradation (tested to 50,000+ Martindale cycles), ensuring longevity in high-use applications.

- Customizable Performance: Tailored thickness (0.6mm–2.0mm), textures (suede, grain, embossed), and color matching (Pantone® certified) for brand-specific needs.

- Resource Efficiency: 60% lower carbon footprint vs. genuine leather and 40% lighter weight vs. PVC alternatives, reducing shipping emissions.

- Ease of Processing: Compatible with standard cutting, sewing, and laminating equipment—minimizing production retooling costs.

Technical Comparison: WINIW PU Leather vs. Alternatives

| Feature | WINIW PU Leather | PVC leer | Genuine Leather |

|---|---|---|---|

| Base Material | Microfiber + PU resin | PVC + plasticizers | Animal hide |

| Eco-Certifications | REACH, OEKO-TEX® 100 | Limited | Varies |

| Weight (g/m²) | 300–800 | 500–1,000 | 800–1,500 |

| Water Resistance | Excellent (hydrophobic) | Moderate (degrades) | Poor (requires seal) |

| Recyclability | Partially recyclable | Non-recyclable | Limited |

| Lead Time | 15–20 days | 20–30 days | 60+ days |

Why WINIW Stands Apart in Sustainable Innovation

Our closed-loop production system recovers 95% of solvents during manufacturing, eliminating toxic emissions. All collections—including our award-winning EcoLuxe™ and AeroWeave™ lines—use bio-based PU resins (up to 30% plant-derived content) without compromising tensile strength or flexibility. We partner with global brands to replace conventional materials while accelerating progress toward Science-Based Targets (SBTi) and circular economy goals.

Ready to Elevate Your Product Line?

Discover how WINIW PU leather reduces environmental impact without sacrificing performance or aesthetics. Request free samples to test our materials in your production workflow—and validate their fit for your sustainability commitments.

Contact our B2B Solutions Team:

MKT88@MicrofiberLeather.com

Free samples available for qualified businesses. Specify your application, volume requirements, and sustainability targets for a tailored proposal.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.