Introduction: Navigating the Global Market for microfiber gray couch

In the competitive landscape of furniture procurement, sourcing high-quality microfiber gray couches presents a unique challenge for international B2B buyers. The growing demand for stylish, durable, and easy-to-maintain seating options has led to an influx of suppliers and products in the market. This guide serves as a comprehensive resource for navigating the complexities of sourcing microfiber gray couches, addressing key considerations such as product types, applications, supplier vetting processes, and pricing structures.

Understanding the nuances of this market is essential for businesses looking to enhance their offerings or furnish commercial spaces. From exploring different styles and configurations, such as sectionals and loveseats, to evaluating the performance characteristics of microfiber fabric, this guide empowers buyers with the knowledge needed to make informed purchasing decisions.

Particularly for buyers in Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—this resource highlights regional trends, supplier reliability, and logistical considerations that can significantly impact the procurement process. By leveraging insights from this guide, businesses can streamline their sourcing strategies, ensuring they select products that not only meet aesthetic and functional requirements but also align with their budgetary constraints.

Table Of Contents

- Top 3 Microfiber Gray Couch Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for microfiber gray couch

- Understanding microfiber gray couch Types and Variations

- Key Industrial Applications of microfiber gray couch

- 3 Common User Pain Points for ‘microfiber gray couch’ & Their Solutions

- Strategic Material Selection Guide for microfiber gray couch

- In-depth Look: Manufacturing Processes and Quality Assurance for microfiber gray couch

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber gray couch’

- Comprehensive Cost and Pricing Analysis for microfiber gray couch Sourcing

- Alternatives Analysis: Comparing microfiber gray couch With Other Solutions

- Essential Technical Properties and Trade Terminology for microfiber gray couch

- Navigating Market Dynamics and Sourcing Trends in the microfiber gray couch Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of microfiber gray couch

- Strategic Sourcing Conclusion and Outlook for microfiber gray couch

- Important Disclaimer & Terms of Use

Understanding microfiber gray couch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microfiber Sectional | L-shaped or U-shaped, modular arrangements | Hotels, lounges, corporate offices | Pros: Versatile seating, space-saving. Cons: Assembly may require additional labor. |

| Microfiber Sofa | Traditional 2-3 seat designs, various styles | Residential, small businesses | Pros: Classic appeal, easy to clean. Cons: Limited seating capacity compared to sectionals. |

| Reclining Microfiber Couch | Manual or power recline options | Home theaters, entertainment venues | Pros: Enhanced comfort, ideal for relaxation. Cons: May require more maintenance for mechanisms. |

| Microfiber Loveseat | Compact, 2-seat designs, often with storage | Small offices, waiting areas | Pros: Space-efficient, stylish. Cons: Less versatile than larger options. |

| Microfiber Sleeper Sofa | Converts into a bed, often with additional storage | Guest rooms, multi-functional spaces | Pros: Dual functionality, convenient for guests. Cons: May compromise on comfort as a sofa. |

What Are the Key Characteristics of Microfiber Sectionals?

Microfiber sectionals are characterized by their modular designs, allowing for various configurations such as L-shaped or U-shaped arrangements. This flexibility makes them ideal for larger spaces in hotels, lounges, and corporate offices where maximizing seating is crucial. When purchasing, B2B buyers should consider the ease of assembly and the potential need for additional labor, as some models may require professional setup.

Illustrative image related to microfiber gray couch

How Do Microfiber Sofas Differ from Other Types?

Traditional microfiber sofas typically come in 2-3 seat designs and feature a variety of styles, from contemporary to classic. Their broad appeal makes them suitable for residential settings and small businesses. Buyers should focus on the fabric’s durability and ease of maintenance, as these factors are essential for long-term use in high-traffic areas.

What Are the Benefits of Reclining Microfiber Couches?

Reclining microfiber couches, available in both manual and power options, offer enhanced comfort and relaxation, making them perfect for home theaters and entertainment venues. B2B buyers should evaluate the quality of the reclining mechanism, as well as the ease of maintenance, since these features can impact user satisfaction over time. While they provide excellent comfort, potential buyers should be aware that the mechanisms may require more upkeep.

Why Choose Microfiber Loveseats for Smaller Spaces?

Microfiber loveseats are compact, stylish seating options designed for smaller spaces, such as small offices or waiting areas. They often include additional storage, making them practical for environments where space is at a premium. When selecting loveseats, B2B buyers should consider the balance between style and functionality, ensuring that the chosen design complements the overall aesthetic while serving its intended purpose.

How Do Microfiber Sleeper Sofas Enhance Functionality?

Microfiber sleeper sofas serve the dual purpose of providing seating and converting into a bed, making them ideal for guest rooms or multi-functional spaces. While they offer convenience for accommodating guests, buyers should assess the comfort level of the sofa when used for sitting versus sleeping. Additionally, the durability of the sleeper mechanism is critical for ensuring long-term functionality in commercial settings.

Key Industrial Applications of microfiber gray couch

| Industry/Sector | Specific Application of microfiber gray couch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Lounge areas in hotels and resorts | Enhances guest comfort and aesthetic appeal | Durability, stain resistance, and ease of maintenance |

| Corporate Offices | Breakout areas and reception lounges | Promotes a welcoming environment for clients and employees | Ergonomic design, fabric quality, and color versatility |

| Healthcare Facilities | Waiting rooms and patient lounges | Provides comfort and support, improving patient experience | Antimicrobial properties, easy cleaning, and durability |

| Education Institutions | Student lounges and common areas | Offers a comfortable space for relaxation and socializing | Robust construction, maintenance ease, and aesthetic appeal |

| Retail Spaces | Showrooms and customer waiting areas | Creates a welcoming atmosphere that encourages customer engagement | Style compatibility, durability against wear, and color options |

How is the Microfiber Gray Couch Used in the Hospitality Sector?

In the hospitality industry, microfiber gray couches are commonly utilized in lounge areas of hotels and resorts. Their aesthetic appeal and comfort significantly enhance the guest experience, making these spaces more inviting. The durability of microfiber fabric is crucial, as it withstands high traffic and is resistant to stains, ensuring that the furniture remains in excellent condition over time. International buyers should prioritize sourcing couches that meet local climate conditions, ensuring that materials can endure humidity or dry heat without degrading.

Illustrative image related to microfiber gray couch

What is the Role of Microfiber Gray Couches in Corporate Offices?

Microfiber gray couches play a vital role in corporate office environments, particularly in breakout areas and reception lounges. They create a welcoming atmosphere for clients and employees, fostering a sense of comfort and relaxation. Businesses benefit from the ergonomic designs that support long hours of sitting and encourage informal discussions. Buyers from regions like Europe and South America should focus on sourcing couches that reflect their corporate branding while ensuring that the materials used are of high quality and suitable for the office environment.

Why are Microfiber Gray Couches Important in Healthcare Facilities?

In healthcare settings, microfiber gray couches are essential for waiting rooms and patient lounges. They provide comfort and support, which can significantly enhance the overall patient experience. The ability to clean and maintain these couches easily is crucial in healthcare environments where hygiene is paramount. International buyers, particularly from the Middle East, should consider sourcing couches with antimicrobial properties to ensure the safety and comfort of patients while also meeting rigorous health standards.

How Do Education Institutions Benefit from Microfiber Gray Couches?

Educational institutions utilize microfiber gray couches in student lounges and common areas to create comfortable spaces for relaxation and social interaction. These couches help foster a sense of community among students, enhancing their overall experience on campus. Buyers in Africa and South America should prioritize robust construction and maintenance ease, as these factors are essential for high-traffic environments. Additionally, aesthetic appeal can be a deciding factor in how inviting these spaces feel to students.

What is the Significance of Microfiber Gray Couches in Retail Spaces?

In retail environments, microfiber gray couches are strategically placed in showrooms and customer waiting areas to create an inviting atmosphere that encourages customer engagement. The style compatibility with various decor themes, combined with the durability against wear, makes these couches a practical choice for retailers. Buyers should consider sourcing options that offer a variety of color choices and designs to align with their brand image while ensuring that the materials can withstand the demands of a busy retail environment.

3 Common User Pain Points for ‘microfiber gray couch’ & Their Solutions

Scenario 1: Challenges with Stain Resistance and Maintenance

The Problem: B2B buyers in the hospitality or rental industries often face concerns about the durability and maintenance of microfiber gray couches. Given that these couches are frequently used in high-traffic areas, they are susceptible to stains from spills, dirt, and everyday wear and tear. This can lead to dissatisfaction among guests or clients, impacting the overall reputation of the business. Additionally, maintaining a clean and presentable appearance can be labor-intensive, straining operational resources.

Illustrative image related to microfiber gray couch

The Solution: To address these concerns, it is crucial to source microfiber gray couches that are specifically labeled as stain-resistant or treated with protective coatings. When placing orders, buyers should inquire about the fabric’s abrasion resistance and ease of cleaning. It is advisable to establish a routine cleaning protocol that includes regular vacuuming and spot cleaning with appropriate, non-toxic cleaning agents. For more serious stains, buyers should consider investing in professional upholstery cleaning services, which can rejuvenate the couch without damaging the fabric. Additionally, offering training for staff on proper cleaning techniques can enhance the longevity and appearance of the furniture, ensuring a positive experience for all users.

Scenario 2: Sizing and Fit for Various Spaces

The Problem: International buyers often contend with fitting microfiber gray couches into diverse spatial configurations. In markets such as Africa and Europe, where living spaces can vary dramatically in size and layout, selecting a couch that fits both aesthetically and functionally can be challenging. A poorly sized couch can lead to wasted space, obstructed pathways, or a crowded environment, which can deter potential customers or clients.

The Solution: To mitigate sizing issues, buyers should take precise measurements of the intended space before making a purchase. It’s beneficial to choose modular or sectional microfiber gray couches that can be reconfigured to fit different room layouts and dimensions. When sourcing products, buyers should look for detailed product specifications that include dimensions, seat depth, and orientation options. Additionally, offering a range of sizes and styles, including compact models for smaller spaces, can cater to various customer needs. Utilizing augmented reality tools or 3D visualization apps can also help buyers see how different couch options will fit into their designated spaces before making a final decision.

Scenario 3: Quality Perception vs. Cost

The Problem: Cost-conscious B2B buyers often struggle with the perception of quality when sourcing microfiber gray couches at lower price points. There is a common misconception that lower-priced options must sacrifice quality, leading to fears of premature wear, inadequate comfort, or aesthetic appeal. This dilemma is particularly pronounced in competitive markets where buyers are pressured to maintain budget constraints without compromising on quality.

The Solution: To navigate this challenge, buyers should conduct thorough research on manufacturers and suppliers, focusing on their reputation, customer reviews, and warranty offerings. It is essential to request samples of the microfiber fabric to assess its texture and durability firsthand. Buyers can also consider investing in products that offer a commercial warranty, which can provide assurance regarding the couch’s longevity and performance. Engaging in direct communication with suppliers about the materials and construction methods used can yield insights into the product’s value. Additionally, buyers might explore bulk purchasing options that can provide discounts while ensuring they receive high-quality couches that meet their standards. By balancing cost with quality through informed purchasing strategies, buyers can achieve satisfaction and value in their investments.

Illustrative image related to microfiber gray couch

Strategic Material Selection Guide for microfiber gray couch

When selecting materials for microfiber gray couches, it is essential to consider various factors that influence durability, comfort, and aesthetic appeal. The following analysis focuses on four common materials used in the production of microfiber gray couches, providing insights into their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Polyester Microfiber in Couches?

Polyester microfiber is a synthetic material known for its fine fibers, which create a soft and durable fabric. It boasts excellent abrasion resistance, making it suitable for high-traffic areas. Polyester microfiber can withstand temperatures up to 200°F (93°C) without significant degradation, ensuring it maintains its integrity under various conditions. Additionally, it is resistant to mold and mildew, which is crucial for humid climates.

Pros: Polyester microfiber is cost-effective, easy to clean, and highly versatile in design. It can mimic the look of natural fibers while providing superior durability.

Cons: While it is durable, polyester microfiber can be prone to pilling and may not have the same breathability as natural fabrics, potentially leading to discomfort in warmer climates.

Impact on Application: Polyester microfiber is compatible with a wide range of upholstery applications, making it a popular choice for both residential and commercial furniture.

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, should prioritize moisture-resistant fabrics. Compliance with standards like ASTM for flammability may also be necessary.

How Does Polyurethane (PU) Leather Compare for Microfiber Couches?

Polyurethane leather, often used as an alternative to genuine leather, provides a sleek appearance and is easy to maintain. It offers good resistance to wear and tear, withstanding moderate pressure and temperature variations. PU leather is typically rated for 15,000 to 30,000 double rubs, indicating its durability in upholstery applications.

Illustrative image related to microfiber gray couch

Pros: PU leather is more affordable than genuine leather and offers a similar aesthetic appeal. It is also easier to clean and maintain, making it suitable for family-friendly environments.

Cons: Over time, PU leather can crack and peel, especially in high-use settings. It may also have a shorter lifespan compared to genuine leather.

Impact on Application: PU leather is ideal for modern, stylish designs, appealing to consumers looking for a contemporary aesthetic without the high cost of real leather.

Considerations for International Buyers: Compliance with regulations regarding synthetic materials is crucial, particularly in Europe where environmental standards are stringent. Buyers should also consider the climate, as PU leather may not perform well in extreme heat.

What Role Does Cotton Blend Fabric Play in Microfiber Couches?

Cotton blend fabrics combine natural cotton with synthetic fibers, enhancing durability while maintaining comfort. They typically offer good breathability and can handle moderate temperature variations. Cotton blends can endure around 9,000 to 15,000 double rubs, making them suitable for light to moderate use.

Illustrative image related to microfiber gray couch

Pros: These fabrics are soft, comfortable, and often hypoallergenic, making them a great choice for households with allergies.

Cons: Cotton blends may be less durable than pure synthetic options, leading to quicker wear in high-traffic areas. They also require more maintenance to keep them looking fresh.

Impact on Application: Cotton blends are ideal for residential settings where comfort is a priority, but they may not be suitable for commercial applications due to their lower durability.

Considerations for International Buyers: Buyers should ensure that the cotton used is sourced sustainably, as there is a growing demand for eco-friendly materials in Europe and other regions. Compliance with local textile standards is also essential.

How Does Velvet Microfiber Enhance the Aesthetic of Couches?

Velvet microfiber is a luxurious option that adds a rich texture to furniture. It is made from polyester fibers that are woven densely, providing a soft, plush feel. Velvet microfiber can withstand moderate wear and tear, with an abrasion rating similar to that of polyester microfiber.

Pros: The aesthetic appeal of velvet microfiber is unmatched, offering a sophisticated look that can elevate any living space. It is also relatively easy to clean and maintain.

Cons: Velvet can be more susceptible to staining and may require special cleaning products to maintain its appearance. It can also be less durable in high-use environments.

Impact on Application: Velvet microfiber is perfect for upscale residential settings or boutique hotels, where aesthetics are as important as functionality.

Considerations for International Buyers: Buyers should be aware of the cleaning and maintenance requirements, especially in regions with dust or sand, which can affect the fabric’s longevity. Compliance with fire safety standards is also critical.

| Materiaal | Typical Use Case for microfiber gray couch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester Microfiber | Residential and commercial upholstery | Durable and easy to clean | Prone to pilling | Low |

| Polyurethane Leather | Modern furniture designs | Affordable and stylish | Can crack and peel over time | Medium |

| Cotton Blend Fabric | Residential settings | Comfortable and hypoallergenic | Less durable in high-traffic areas | Medium |

| Velvet Microfiber | Upscale residential and boutique hotels | Luxurious aesthetic | Susceptible to staining | Hoog |

In-depth Look: Manufacturing Processes and Quality Assurance for microfiber gray couch

What Are the Key Stages in the Manufacturing Process of Microfiber Gray Couches?

The manufacturing of microfiber gray couches involves several critical stages, each of which contributes to the quality and durability of the final product. Understanding these stages can help B2B buyers assess potential suppliers and ensure they are making informed purchasing decisions.

Material Preparation: What Materials Are Used in Microfiber Gray Couches?

The first step in the manufacturing process is the preparation of materials. Microfiber, a synthetic fabric made from polyester and polyamide, is favored for its softness, durability, and stain resistance. Suppliers typically source high-quality microfiber that meets specific performance standards. Additionally, other materials such as solid wood, engineered wood, or metal for the frame, and various foam types for cushioning, are chosen based on the desired comfort and aesthetic of the couch.

During this stage, suppliers conduct inspections to ensure that all materials meet industry specifications. This includes checking for color consistency, texture uniformity, and compliance with fire safety regulations.

Forming: How Are the Couch Components Shaped?

The forming stage involves cutting and shaping the materials to create the various components of the couch. Advanced cutting techniques, such as laser cutting and CNC machining, are often employed to ensure precision and reduce waste.

For the wooden frames, components are typically assembled using techniques such as doweling or mortise and tenon joints to enhance structural integrity. The upholstery fabric is then cut to size and sewn together, often using double stitching to increase durability.

Assembly: What Techniques Are Used for Couch Assembly?

Assembly is a crucial phase where all individual components come together to form the final product. This involves attaching the frame, cushioning, and upholstery. Quality manufacturers employ skilled labor for this process, ensuring that each couch is assembled with attention to detail.

Techniques such as 8-way hand-tied springs and sinuous springs may be used to provide superior support and comfort. Additionally, features like removable cushions or modular designs are increasingly popular, enhancing the couch’s usability and appeal.

Finishing: How Is the Couch Prepared for Sale?

The finishing stage involves adding final touches that enhance the couch’s aesthetic appeal and functionality. This can include applying protective coatings, adding decorative elements like tufting or nailhead trims, and ensuring all seams are neatly finished.

Before the couches are packaged for shipment, they undergo a thorough cleaning process to remove any dust or debris. This ensures that the product reaches the customer in pristine condition.

What Quality Assurance Practices Are Essential in Couch Manufacturing?

Quality assurance (QA) is vital for ensuring that the final product meets established standards and customer expectations. For B2B buyers, understanding the QA processes can help them evaluate suppliers effectively.

Which International Standards Apply to Microfiber Couch Manufacturing?

International standards such as ISO 9001, which focuses on quality management systems, are crucial for manufacturers to adopt. Compliance with these standards indicates that the manufacturer has processes in place to ensure consistent quality.

Illustrative image related to microfiber gray couch

Additionally, industry-specific certifications like CE marking (indicating compliance with health, safety, and environmental protection standards) and API (American Petroleum Institute) standards may apply, particularly for materials and components used in the manufacturing process.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into three main checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival at the manufacturing facility. Quality inspectors check for defects, dimensions, and compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor the quality of the assembly, stitching, and overall construction. This ensures that any issues are identified and addressed immediately.

-

Final Quality Control (FQC): Once the couches are fully assembled, they undergo a final inspection. This includes checking for aesthetic imperfections, structural integrity, and functionality of features such as reclining mechanisms.

What Testing Methods Are Commonly Used in Couch Quality Assurance?

Common testing methods for microfiber gray couches include:

-

Abrasion Testing: To assess the durability of the microfiber fabric, manufacturers often conduct tests to determine how well the fabric withstands wear and tear over time.

-

Flammability Testing: Compliance with fire safety regulations is crucial, particularly in commercial settings. Manufacturers may subject their products to flammability tests to ensure they meet local and international safety standards.

-

Load Testing: This involves assessing the weight capacity of the couch to ensure it can withstand normal usage without compromising safety or structural integrity.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure the reliability of their products. Here are several actionable steps buyers can take:

-

Supplier Audits: Conducting regular audits of potential suppliers can help buyers assess their manufacturing processes and QC measures. This includes reviewing documentation related to quality standards and certifications.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes, testing results, and compliance with international standards.

-

Third-party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing facility, product quality, and adherence to specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing microfiber gray couches from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, B2B buyers should be aware of certain nuances:

-

Cultural and Regulatory Differences: Different countries may have varying standards and regulations regarding manufacturing and safety. Buyers should familiarize themselves with local requirements to ensure compliance.

-

Logistics and Supply Chain Considerations: International shipping can introduce variables that affect product quality. Ensuring that suppliers have robust logistics strategies in place is crucial for maintaining product integrity during transit.

-

Language and Communication Barriers: Clear communication is essential for effective quality assurance. Buyers should consider working with suppliers who can provide documentation and support in a language that is comfortable for both parties.

By understanding the manufacturing processes and quality assurance practices associated with microfiber gray couches, B2B buyers can make informed decisions that enhance their purchasing strategy and ultimately lead to better product offerings in their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber gray couch’

To assist B2B buyers in procuring a microfiber gray couch, this practical sourcing guide provides a structured checklist. Each step is designed to ensure that the procurement process is efficient, cost-effective, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Begin by establishing clear technical specifications for the microfiber gray couch you wish to procure. Consider factors such as dimensions, seating capacity, and design style (e.g., sectional, loveseat, or sofa). This step is crucial as it aligns your procurement with the intended use, whether for commercial spaces, hotels, or retail environments.

- Key Considerations:

- Size and scale appropriate for your space.

- Desired features such as reclining options or storage capabilities.

Step 2: Research Market Trends

Stay informed about current market trends in the furniture industry, particularly regarding microfiber gray couches. Understanding trends helps you anticipate customer preferences and ensures your offerings remain competitive.

- Focus Areas:

- Popular styles and configurations in your target market.

- Emerging materials or technologies that enhance durability and aesthetics.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making commitments. Request detailed company profiles, including their experience in the industry and examples of past work. This step is vital to ensure the supplier can meet your quality standards and delivery timelines.

Illustrative image related to microfiber gray couch

- Verification Points:

- Supplier’s financial stability and reputation.

- Customer reviews and testimonials from similar industries.

Step 4: Request Samples and Specifications

Before finalizing your order, request physical samples of the microfiber fabric and detailed specifications of the couch. This allows you to assess the quality and feel of the product firsthand, ensuring it meets your expectations.

- What to Look For:

- Color consistency and texture of the microfiber.

- Durability and maintenance requirements of the material.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your shortlisted suppliers to obtain favorable pricing and terms. This step is essential for ensuring that you receive the best value for your investment while considering factors such as volume discounts and payment terms.

- Negotiation Tips:

- Be clear about your budget constraints and desired payment terms.

- Discuss potential long-term partnership benefits for both parties.

Step 6: Verify Compliance with Regulations

Ensure that the selected microfiber gray couch complies with relevant safety and quality standards in your target market. This is particularly important for international procurement, as regulations may vary by region.

- Regulatory Focus:

- Certifications for fire resistance, toxicity, and environmental impact.

- Compliance with import/export regulations specific to your region.

Step 7: Plan for Logistics and Delivery

Coordinate logistics for the delivery of your microfiber gray couches, taking into account lead times and shipping methods. Effective planning helps avoid delays and ensures that your products arrive in good condition.

- Logistical Considerations:

- Determine the best shipping options based on your location.

- Plan for storage and assembly if necessary upon arrival.

By following this checklist, B2B buyers can streamline the procurement process of microfiber gray couches, ensuring that they make informed decisions that align with their business objectives and customer needs.

Comprehensive Cost and Pricing Analysis for microfiber gray couch Sourcing

What Are the Key Cost Components in Sourcing Microfiber Gray Couches?

When sourcing microfiber gray couches, understanding the cost structure is critical for B2B buyers. The primary components include:

-

Materials: The choice of microfiber fabric significantly influences cost. High-quality microfiber, which is both durable and easy to clean, may carry a higher price tag compared to lower-grade options. Additionally, the sourcing of eco-friendly or certified materials can further impact material costs.

-

Labor: Labor costs vary based on the region of manufacturing. Countries with lower labor costs, such as Vietnam, may offer competitive pricing, while European manufacturers may have higher labor costs due to stricter labor laws and higher wage standards.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative expenses associated with production facilities. Efficient operations and economies of scale can help reduce overhead costs.

-

Tooling: Depending on the complexity of the couch design, tooling costs can vary significantly. Custom designs may require specialized molds or tools, increasing initial expenses.

-

Quality Control (QC): Rigorous QC processes ensure that the final product meets specified standards. While this adds to costs, it is essential for maintaining brand reputation and reducing returns.

-

Logistics: Shipping costs depend on the distance from the manufacturer to the buyer, the mode of transportation, and the volume of the order. Bulk orders typically benefit from reduced shipping rates.

-

Margin: Suppliers add a margin to cover their operational costs and profit. The margin can vary based on market competition and perceived value.

How Do Price Influencers Affect Microfiber Gray Couch Sourcing?

Several factors can influence pricing in the B2B market for microfiber gray couches:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to significant discounts. Understanding the MOQ can help buyers negotiate better prices.

-

Specifications and Customization: Customized designs or specific fabric choices can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Quality and Certifications: Products that meet certain certifications (e.g., eco-friendly, fire-resistant) may demand higher prices but can be a selling point in competitive markets.

-

Supplier Factors: The reliability, reputation, and financial stability of suppliers can influence pricing. Established suppliers with proven track records may charge a premium for their products.

-

Incoterms: The terms of delivery (e.g., FOB, CIF) can affect pricing and responsibilities. Understanding these terms is crucial for calculating total landed costs.

What Are Effective Buyer Tips for Negotiating Microfiber Couch Prices?

B2B buyers should adopt strategic approaches to enhance cost-efficiency and secure favorable terms:

-

Negotiation: Leverage volume purchases and long-term contracts to negotiate better pricing. Building a relationship with suppliers can also facilitate more favorable terms.

-

Cost-Efficiency: Consider total cost of ownership, which includes initial purchase price, shipping, potential duties, and maintenance costs. A lower upfront cost may not always result in overall savings.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional price variations due to tariffs, shipping costs, and local market conditions. Understanding these nuances can aid in budgeting and supplier selection.

Are Indicative Prices Available for Microfiber Gray Couches?

While indicative prices can provide a baseline, they can vary widely based on the factors discussed. It is essential for buyers to request detailed quotes from suppliers to understand the pricing structure fully. Prices may range from $500 to over $3,000 depending on materials, design, and customization options. Always seek multiple quotes to ensure competitive pricing and verify the supplier’s credentials.

Illustrative image related to microfiber gray couch

Alternatives Analysis: Comparing microfiber gray couch With Other Solutions

Exploring Alternatives to the Microfiber Gray Couch

When considering the best seating solutions for commercial or residential spaces, the microfiber gray couch stands out due to its blend of comfort, style, and practicality. However, it’s essential for B2B buyers to evaluate other alternatives that may also meet their needs. This analysis provides a comparative overview of the microfiber gray couch against two viable alternatives: leather sofas and fabric sofas.

Comparison Table

| Comparison Aspect | Microfiber Gray Couch | Leather Sofa | Fabric Sofa |

|---|---|---|---|

| Performance | Soft, durable, stain-resistant | High durability, easy to clean | Variety in textures, moderate durability |

| Cost | $500 – $1,500 | $1,000 – $3,500 | $300 – $2,000 |

| Ease of Implementation | Simple assembly | May require professional installation | Usually easy to assemble |

| Maintenance | Spot clean, easy upkeep | Wipe clean, occasional conditioning | Machine washable or spot clean |

| Best Use Case | Living rooms, lounges | High-traffic areas, upscale settings | Casual settings, family rooms |

In-Depth Comparison of Alternatives

Leather Sofa

Leather sofas are known for their luxurious appearance and durability. They typically offer superior resistance to wear and tear, making them ideal for high-traffic environments such as hotels or corporate offices. However, the initial investment is significantly higher compared to microfiber options. While maintenance involves regular conditioning to prevent cracking, cleaning is relatively straightforward with just a wipe-down. The downside is that leather can be sensitive to temperature and may not be as comfortable in extreme heat or cold.

Fabric Sofa

Fabric sofas provide a broad range of aesthetic choices and textures, appealing to diverse consumer preferences. They can be more affordable than leather and may feature machine-washable covers, which enhance their practicality in family settings. However, the durability can vary widely based on the fabric type, and some may not withstand heavy use as effectively as microfiber or leather. Additionally, fabric sofas may require more frequent cleaning to maintain their appearance, especially in environments prone to spills and stains.

Making the Right Choice for Your Needs

In choosing the right seating solution, B2B buyers should carefully consider the specific requirements of their space and clientele. The microfiber gray couch offers a balance of affordability, comfort, and ease of maintenance, making it suitable for various settings. Leather sofas, while more expensive, provide unmatched durability and a premium feel for high-end environments. Fabric sofas, on the other hand, offer versatility and a wide range of styles at a lower cost, though they may require more upkeep.

Ultimately, the decision should align with the intended use, target audience, and budget constraints of the business. By evaluating these alternatives, buyers can make informed decisions that enhance the comfort and aesthetic appeal of their spaces while meeting operational needs.

Essential Technical Properties and Trade Terminology for microfiber gray couch

What Are the Key Technical Properties of Microfiber Gray Couches?

1. Material Composition

Microfiber is a synthetic fabric made from polyester and polyamide fibers, typically finer than silk. This material is known for its softness, durability, and stain resistance, making it suitable for high-traffic areas. For B2B buyers, understanding the material composition helps in assessing the product’s longevity and maintenance needs, which are crucial for customer satisfaction.

2. Abrasion Resistance

This specification indicates how well the fabric can withstand wear and tear. Measured in double rubs, a higher rating signifies better durability. For example, upholstery with an abrasion rating of 30,000 double rubs is classified as extra heavy-duty. B2B buyers should prioritize this property to ensure that the couches can endure the rigors of commercial settings, such as hotels or office lounges.

3. Flame Retardancy

Flame retardant treatments are crucial for meeting safety standards in various markets. Couches that comply with regulations such as the California Bureau of Home Furnishings Technical Bulletin 117 are considered safer for commercial use. B2B buyers must ensure that their products meet local regulations to avoid liability issues and ensure customer safety.

Illustrative image related to microfiber gray couch

4. Stain Resistance

Microfiber couches often come with a stain-resistant finish, making them easier to clean and maintain. This property is particularly important in environments where spills are common, such as restaurants or family-oriented businesses. B2B buyers should seek out options with high stain resistance to reduce maintenance costs and enhance customer satisfaction.

5. Weight Capacity

Understanding the weight capacity of a microfiber gray couch is essential, especially for commercial environments. This property indicates the maximum weight the couch can support without compromising safety or comfort. B2B buyers should assess this specification to ensure that the furniture can accommodate various users, enhancing its appeal in diverse markets.

6. Warranty Terms

A comprehensive warranty can reflect the manufacturer’s confidence in their product’s quality. Warranties typically cover defects in materials and workmanship for a specific period. B2B buyers should consider the warranty terms as a measure of product reliability and customer service support.

What Are Common Trade Terms Relevant to Microfiber Gray Couches?

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of microfiber gray couches, B2B buyers might engage with OEMs to obtain specific designs or fabrications that meet their brand requirements.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it can affect inventory management and cash flow. Understanding MOQ helps buyers negotiate better terms and manage stock levels effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing, delivery, and terms for specific products. B2B buyers use RFQs to compare costs and terms from different suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms that outline the responsibilities of buyers and sellers in international trade. Understanding these terms is essential for B2B buyers to clarify shipping responsibilities, risk management, and cost allocation when importing microfiber gray couches.

5. Upholstery Grade

Upholstery grade refers to the quality and durability of the fabric used in furniture. Higher grades indicate better performance and longevity. B2B buyers should be familiar with upholstery grades to ensure they select products that align with their target market’s expectations.

6. Lead Time

Lead time is the period between placing an order and receiving the product. This term is critical for B2B buyers as it affects inventory planning and customer fulfillment. Understanding lead times allows buyers to manage expectations and streamline operations effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their purchasing strategies and align with market demands.

Navigating Market Dynamics and Sourcing Trends in the microfiber gray couch Sector

What Are the Key Market Dynamics and Sourcing Trends for Microfiber Gray Couches?

The microfiber gray couch market is experiencing robust growth driven by several global factors. Increased urbanization in regions such as Africa and South America is leading to smaller living spaces, creating a demand for multifunctional furniture. Additionally, the rise of e-commerce platforms has transformed how B2B buyers source furniture, facilitating easier access to a variety of styles and price points. International buyers, particularly from Europe and the Middle East, are increasingly looking for customizable options that can meet specific regional tastes and functional needs.

Emerging B2B technology trends are reshaping sourcing strategies. Digital platforms that allow for virtual showrooms and augmented reality (AR) experiences enable buyers to visualize how a microfiber gray couch will fit into their spaces before making a purchase. Furthermore, suppliers are leveraging data analytics to track consumer preferences and inventory levels, ensuring they can meet market demand promptly. This trend is particularly relevant in markets like Vietnam and Germany, where consumer preferences can shift rapidly.

Another significant trend is the increasing focus on product durability and functionality. Buyers are gravitating toward microfiber couches that offer easy maintenance and stain resistance, which are crucial for both residential and commercial applications. As such, suppliers must be aware of these changing preferences and adapt their offerings accordingly to stay competitive.

Illustrative image related to microfiber gray couch

How Is Sustainability Influencing Sourcing Decisions in the Microfiber Gray Couch Market?

Sustainability is becoming a cornerstone of sourcing decisions in the microfiber gray couch sector. As environmental concerns grow, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes sourcing materials that have lower environmental impacts and are produced through ethical supply chains. The use of recycled or sustainably sourced microfiber is gaining traction, as it not only addresses eco-friendly concerns but also appeals to consumers who prioritize sustainability in their purchasing decisions.

Furthermore, certifications such as GREENGUARD and OEKO-TEX are becoming essential criteria for buyers. These certifications guarantee that the materials used in manufacturing microfiber couches meet stringent environmental and health standards. Buyers are encouraged to seek out suppliers who can provide transparent information regarding their sourcing practices and material certifications, ensuring that their purchases align with their sustainability goals.

The importance of ethical supply chains cannot be overstated. International buyers are increasingly scrutinizing the labor practices of manufacturers to ensure fair treatment of workers. This trend is particularly relevant for buyers in regions with strict labor regulations, such as Europe, where consumers are more likely to support brands that are socially responsible.

How Has the Microfiber Gray Couch Evolved to Meet B2B Needs?

The evolution of the microfiber gray couch has been shaped significantly by changing consumer demands and technological advancements. Initially, microfiber was primarily valued for its affordability and ease of cleaning. However, as consumers became more design-conscious, the aesthetic appeal of gray microfiber couches gained prominence. This shift has led to an expansion of styles and configurations, including sectional sofas and customizable options that cater to various tastes and space requirements.

Illustrative image related to microfiber gray couch

Over the years, advancements in textile technology have enhanced the durability and comfort of microfiber, making it a preferred choice for both residential and commercial settings. The introduction of performance fabrics that resist stains and wear has further solidified microfiber’s position in the market. As a result, B2B buyers are increasingly recognizing the value of microfiber gray couches not just as functional pieces, but as stylish investments that can enhance the overall ambiance of living spaces.

In conclusion, understanding these market dynamics, sustainability considerations, and the evolution of microfiber gray couches can provide valuable insights for international B2B buyers looking to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of microfiber gray couch

-

How do I choose the right microfiber gray couch for my business needs?

Choosing the right microfiber gray couch involves evaluating several factors, including size, seating capacity, and design style. Consider the intended use, such as for a waiting area or employee lounge, and ensure the couch complements your existing decor. Additionally, prioritize durability, especially for high-traffic environments, and verify if the fabric is easy to clean and maintain. Reviewing samples from suppliers can help you make an informed decision. -

What is the best way to source high-quality microfiber gray couches?

To source high-quality microfiber gray couches, start by identifying reputable suppliers with positive reviews and a solid track record in the industry. Attend furniture trade shows or explore online B2B marketplaces to connect with manufacturers. Request samples to assess the material quality and craftsmanship. Ensure that suppliers comply with international quality standards and certifications, which can significantly impact product reliability. -

What are the common customization options available for microfiber gray couches?

Customization options for microfiber gray couches often include fabric choice, color variations, dimensions, and additional features like reclining mechanisms or storage compartments. Many manufacturers also offer bespoke designs to fit specific business aesthetics. When discussing customization with suppliers, be clear about your requirements and inquire about minimum order quantities (MOQs) for tailored solutions. -

What are the typical minimum order quantities (MOQs) for purchasing microfiber gray couches?

Minimum order quantities for microfiber gray couches can vary significantly by supplier, typically ranging from 10 to 100 units. Large manufacturers may offer lower MOQs, while smaller or specialized producers might have higher requirements. When negotiating, express your business needs and see if the supplier can accommodate smaller orders, especially for initial trial runs or specific projects. -

What payment terms are common when importing microfiber gray couches?

Payment terms for importing microfiber gray couches typically include options like advance payment, letters of credit, or staggered payments based on production milestones. It’s crucial to clarify these terms upfront to avoid misunderstandings. Many suppliers may request a deposit of 30% to 50% before production, with the remaining balance due prior to shipping. Always ensure that payment methods are secure and provide adequate protection for your transaction. -

How can I ensure the quality of microfiber gray couches before shipment?

To ensure quality before shipment, request a thorough inspection of the couches during the production phase. Many suppliers offer quality assurance (QA) services, where you can either send a representative or hire a third-party inspection service. Check for aspects such as stitching, fabric consistency, and structural integrity. Additionally, consider requesting a pre-shipment sample to evaluate the final product against your specifications. -

What logistics considerations should I keep in mind when importing microfiber gray couches?

When importing microfiber gray couches, consider logistics factors such as shipping methods, freight forwarding, customs clearance, and potential tariffs. Choose a reliable logistics partner experienced in handling furniture to streamline the process. Ensure that your supplier provides the necessary documentation for customs, including invoices and certificates of origin, to avoid delays. Assess the total landed cost, including shipping and duties, to budget effectively. -

What are the best practices for maintaining microfiber gray couches in a commercial setting?

To maintain microfiber gray couches in a commercial setting, regular cleaning is essential. Use a vacuum with a brush attachment to remove dust and debris, and treat stains promptly with a mild detergent and water solution. Avoid harsh chemicals that could damage the fabric. Additionally, consider applying a fabric protector to enhance stain resistance. Schedule periodic deep cleaning by professionals to prolong the life of the couches, ensuring they remain attractive and comfortable for users.

Top 3 Microfiber Gray Couch Manufacturers & Suppliers List

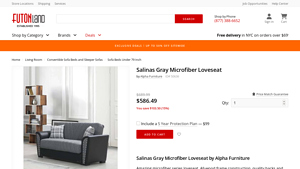

1. Alpha Furniture – Salinas Gray Microfiber Loveseat

Domain: futonland.com

Registered: 1998 (27 years)

Introduction: {‘name’: ‘Salinas Gray Microfiber Loveseat’, ‘brand’: ‘Alpha Furniture’, ‘product_id’: ‘50636’, ‘price’: ‘$586.49’, ‘original_price’: ‘$689.99’, ‘discount’: ‘15%’, ‘dimensions’: {‘width’: ‘61.5’, ‘depth’: ‘31.5’}, ‘bed_dimensions’: {‘width’: ’51’, ‘depth’: ’46’}, ‘material’: ‘Microfiber’, ‘frame_material’: ‘All-wood’, ‘functionality’: ‘Convertible’, ‘color’: ‘Gray’, ‘assembly_required’: ‘Minor ass…

2. Medford – Gray Microfiber Sectional Sofa

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Gray Microfiber Couch, 132″ oversized sectional sofa, microfiber fabric, soft to the touch, easy to clean, ample seating space, includes ottoman, Medford Fabric Sectional, foam seat cushions, padded square arm, sinuous spring suspension, solid wood legs with black finish, light grey modern wood frame L-shaped microfiber sectional sofa with chaise, STENDMAR 3pc 120″ contemporary grey microfiber sof…

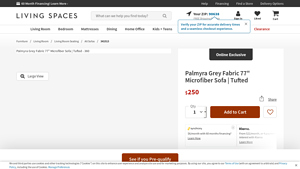

3. Living Spaces – Palmyra Grey Microfiber Sofa

Domain: livingspaces.com

Registered: 1997 (28 years)

Introduction: {“name”:”Palmyra Grey Fabric 77″ Microfiber Sofa”,”color”:”Grey”,”material”:”Microfiber”,”dimensions”:”77 inches”,”style”:”Tufted”,”financing”:”60 Month Financing available”,”shipping”:”Free Next-Day Shipping on Furniture in select areas”}

Strategic Sourcing Conclusion and Outlook for microfiber gray couch

As the demand for microfiber gray couches continues to grow across various international markets, strategic sourcing emerges as a vital component for B2B buyers looking to optimize their purchasing processes. By leveraging data analytics and market insights, businesses can identify reliable suppliers, negotiate better pricing, and ensure product quality that meets consumer expectations. The versatility of microfiber, combined with the timeless appeal of gray, positions these couches as a preferred choice in diverse settings, from residential to commercial applications.

Investing in a well-rounded sourcing strategy not only enhances cost-efficiency but also fosters long-term partnerships with manufacturers, which can be particularly beneficial in regions like Africa, South America, the Middle East, and Europe. Buyers should prioritize suppliers that offer customization options and robust warranties, ensuring that their investments yield high returns over time.

Looking ahead, the microfiber gray couch market holds significant potential for growth, driven by evolving consumer preferences and lifestyle trends. As international buyers, now is the time to act strategically—evaluate your sourcing options, build relationships with trusted suppliers, and position your business to capitalize on the opportunities within this dynamic sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.