Introduction: Navigating the Global Market for how to make a leather scabbard

In the dynamic landscape of leather craftsmanship, navigating the intricacies of making a leather scabbard presents unique challenges for international B2B buyers. Sourcing high-quality materials and skilled artisans is critical, particularly for businesses in regions like Africa, South America, the Middle East, and Europe, where craftsmanship standards may vary significantly. This guide not only delves into the various types of leather scabbards available—ranging from traditional designs to modern adaptations—but also examines their applications across different markets, ensuring you can meet diverse customer needs.

Furthermore, we provide actionable insights into supplier vetting processes, helping you identify reputable manufacturers and artisans who can deliver consistent quality. Understanding the cost structures involved in the production of leather scabbards is equally essential, as it directly impacts your pricing strategy and competitive positioning. By equipping you with this comprehensive knowledge, this guide empowers you to make informed purchasing decisions that align with your business objectives.

Whether you are looking to enhance your product offerings or establish long-term partnerships with suppliers, our insights will help you navigate the global market effectively. Embrace the art of leather craftsmanship and elevate your business with expertly crafted scabbards that resonate with your customers’ expectations and cultural preferences.

Table Of Contents

- Top 5 How To Make A Leather Scabbard Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather scabbard

- Understanding how to make a leather scabbard Types and Variations

- Key Industrial Applications of how to make a leather scabbard

- 3 Common User Pain Points for ‘how to make a leather scabbard’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather scabbard

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather scabbard

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather scabbard’

- Comprehensive Cost and Pricing Analysis for how to make a leather scabbard Sourcing

- Alternatives Analysis: Comparing how to make a leather scabbard With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather scabbard

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather scabbard Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather scabbard

- Strategic Sourcing Conclusion and Outlook for how to make a leather scabbard

- Important Disclaimer & Terms of Use

Understanding how to make a leather scabbard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Wood Core | Utilizes a carved wooden core, typically poplar or similar, covered with leather. | Custom sword manufacturers, historical reenactments | Pros: Durable, authentic appearance. Cons: Labor-intensive, requires skilled craftsmanship. |

| Slat Method | Composed of thin wooden slats bent around the blade, often using steam or soaking. | Artisanal scabbard makers, bespoke leather goods | Pros: Flexible design, lightweight. Cons: More complex assembly, may require specialized tools. |

| Simple Slot Design | Features a basic slot for the blade with minimal shaping of the core. | Mass production, budget-friendly options | Pros: Quick to produce, lower costs. Cons: Less secure fit, may lack aesthetic appeal. |

| Custom Molded Leather | Leather is molded directly around the blade, often using heat and moisture. | High-end custom scabbard producers, luxury markets | Pros: Perfect fit, high customization. Cons: Longer production time, requires experience. |

| Decorative Scabbard | Incorporates intricate designs, embossing, or tooling on the leather surface. | Specialty retailers, collectors, and gift shops | Pros: Unique aesthetic, high market demand. Cons: Higher price point, can be time-consuming to produce. |

What Are the Characteristics of Traditional Wood Core Scabbards?

Traditional wood core scabbards are characterized by their robust structure, made from carved wooden cores that provide shape and durability. Typically constructed from poplar, the wood is shaped to fit the sword snugly before being wrapped in leather. This method is ideal for custom sword manufacturers and historical reenactors who value authenticity. Buyers should consider the craftsmanship required and the potential for higher costs due to the labor-intensive nature of this method.

How Does the Slat Method Differ from Other Techniques?

The slat method utilizes thin wooden slats that are either steamed or soaked to allow bending around the sword blade. This technique provides flexibility and a lightweight design, making it suitable for artisanal scabbard makers and bespoke leather goods. When purchasing, businesses should assess the complexity of assembly and the need for specialized tools, which may impact production timelines and costs.

What Are the Advantages of Using a Simple Slot Design?

The simple slot design features a straightforward approach, with a basic slot cut into the wood for the blade. This method is quick to produce and cost-effective, making it ideal for mass production and budget-friendly options. However, buyers should be aware that while the production speed and lower costs are appealing, this design may offer less security for the blade and might lack aesthetic appeal compared to more intricate methods.

Why Choose Custom Molded Leather Scabbards?

Custom molded leather scabbards are made by shaping leather directly around the blade, often through heat and moisture techniques. This method allows for a perfect fit and high levels of customization, appealing to high-end custom scabbard producers and luxury markets. Businesses should consider the longer production time and the need for skilled artisans, which can influence pricing and availability.

What Makes Decorative Scabbards Unique in the Market?

Decorative scabbards stand out due to their intricate designs, embossing, or tooling on the leather surface. They cater to specialty retailers, collectors, and gift shops, capitalizing on the demand for unique and aesthetically pleasing products. While they can command a higher price point due to their detailed craftsmanship, buyers should factor in the time-consuming production process and ensure they are targeting the right market segment for these premium items.

Key Industrial Applications of how to make a leather scabbard

| Industry/Sector | Specific Application of how to make a leather scabbard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Military & Defense | Customized scabbards for swords and ceremonial weapons | Enhanced protection and durability for valuable assets | Sourcing high-quality leather and durable materials; compliance with military specifications |

| Cultural & Historical Reenactments | Authentic leather scabbards for historical swords | Provides authenticity and enhances the experience of reenactors | Availability of historically accurate designs and materials; skilled artisans for craftsmanship |

| Craftsmanship & Artisanal Goods | Handmade leather scabbards for collectors and enthusiasts | Unique, high-quality products that stand out in the market | Access to skilled leatherworkers; sourcing sustainable leather options |

| Retail & E-commerce | Selling leather scabbards as part of weapon accessories | Expanding product offerings to attract niche markets | Understanding consumer preferences; effective supply chain management for timely delivery |

| Film & Entertainment | Prop scabbards for movie and theater productions | Contributes to set authenticity and enhances visual storytelling | Collaboration with costume designers; sourcing materials that meet production timelines |

How is ‘how to make a leather scabbard’ applied in the Military & Defense sector?

In the Military & Defense sector, leather scabbards are essential for protecting swords and ceremonial weapons. These scabbards not only safeguard the blade from damage but also provide a professional appearance during parades and ceremonies. Buyers from this sector require scabbards that meet specific military standards for durability and functionality, ensuring that the materials used can withstand rigorous conditions. Sourcing high-quality leather and robust hardware is crucial to meet these standards.

What role do leather scabbards play in Cultural & Historical Reenactments?

Cultural and historical reenactment groups often seek authentic leather scabbards for their weapons to enhance the realism of their portrayals. These scabbards are crafted to reflect historical accuracy, which is vital for enthusiasts who value authenticity. Buyers in this sector look for artisans who can replicate historical designs and use traditional methods. Ensuring that the leather used is appropriate for the period being represented is also a key consideration.

How do artisans benefit from making leather scabbards?

In the craftsmanship and artisanal goods sector, handmade leather scabbards serve as unique items for collectors and enthusiasts. These products often highlight the skill and artistry of the maker, allowing businesses to command higher prices for bespoke items. Buyers in this market prioritize quality and craftsmanship, necessitating access to skilled leatherworkers and sustainable materials. This niche also appeals to consumers looking for distinctive gifts or decorative pieces.

Why are leather scabbards important in Retail & E-commerce?

Retailers and e-commerce platforms can expand their offerings by including leather scabbards as part of weapon accessories. This diversification attracts niche markets, particularly among collectors and enthusiasts who appreciate the craftsmanship involved. Businesses must understand consumer preferences and trends to effectively market these products. Efficient supply chain management is essential to ensure timely delivery and maintain customer satisfaction.

How are leather scabbards used in Film & Entertainment?

In the Film & Entertainment industry, leather scabbards are utilized as props to enhance the authenticity of period films and theatrical productions. These scabbards contribute to the overall aesthetic, helping to immerse the audience in the storyline. Collaborating with costume designers is crucial for ensuring that the scabbards meet the artistic vision of the production. Timely sourcing of materials is also vital to align with production schedules and maintain quality standards.

3 Common User Pain Points for ‘how to make a leather scabbard’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Leather for Scabbards

The Problem: B2B buyers often struggle to find high-quality leather that meets the specific requirements for crafting durable and aesthetically pleasing scabbards. This is particularly true for buyers in regions like Africa and South America, where access to premium leather can be limited. Inconsistent quality, varying grades, and lack of transparency in sourcing can lead to increased production costs and dissatisfaction among end-users. The result is either a compromised product or a long, tedious search for suitable materials that can delay production timelines.

The Solution: Establish partnerships with reputable suppliers who specialize in leather goods. Conduct thorough research to identify manufacturers that offer vegetable-tanned leather, which is ideal for scabbard construction due to its durability and ability to mold well. When negotiating with suppliers, request samples to assess the leather’s thickness, texture, and finish. Additionally, consider attending trade shows or leatherworking workshops in your target markets to connect directly with artisans and suppliers. These interactions can not only provide access to quality materials but also allow for the sharing of best practices in leather selection and treatment. Make sure to document the specifications needed for your scabbard projects, as this will help ensure consistency in future orders.

Scenario 2: Inadequate Knowledge of Construction Techniques

The Problem: Many B2B buyers enter the leather crafting market without a solid understanding of the techniques required to make a leather scabbard. This lack of knowledge can lead to inefficient processes, wasted materials, and ultimately, subpar products that fail to meet client expectations. For instance, buyers may struggle with the nuances of shaping the wood core or properly stitching the leather, resulting in scabbards that are not only unattractive but also fail in functionality.

The Solution: Invest in training and resources that enhance your team’s skills in leatherworking. This can be achieved through online courses, instructional videos, or hands-on workshops led by experienced artisans. Focusing on the step-by-step construction of scabbards, from creating the wood core to stitching the leather cover, will empower your team to produce higher-quality products. Additionally, consider developing a comprehensive internal guide that details each construction method, including the tools required and best practices for troubleshooting common issues. By fostering a culture of continuous learning and skill development, your team will be better equipped to meet the demands of the market and create scabbards that are both functional and visually appealing.

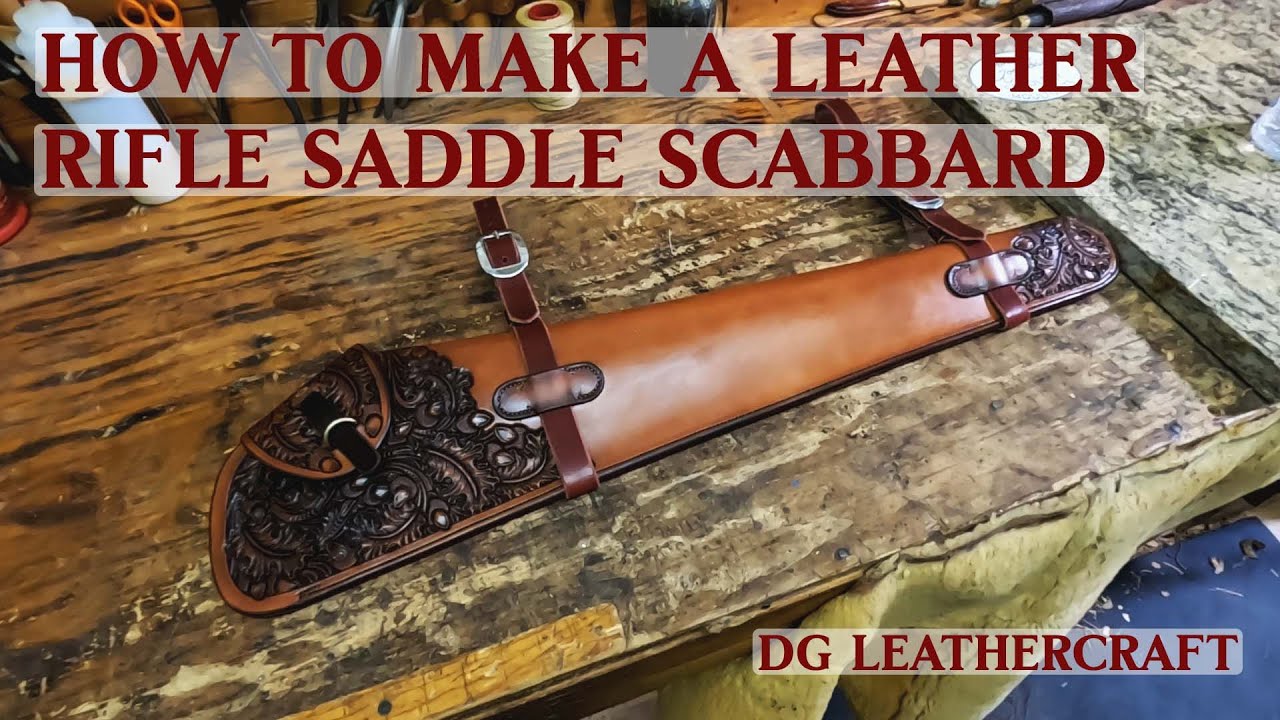

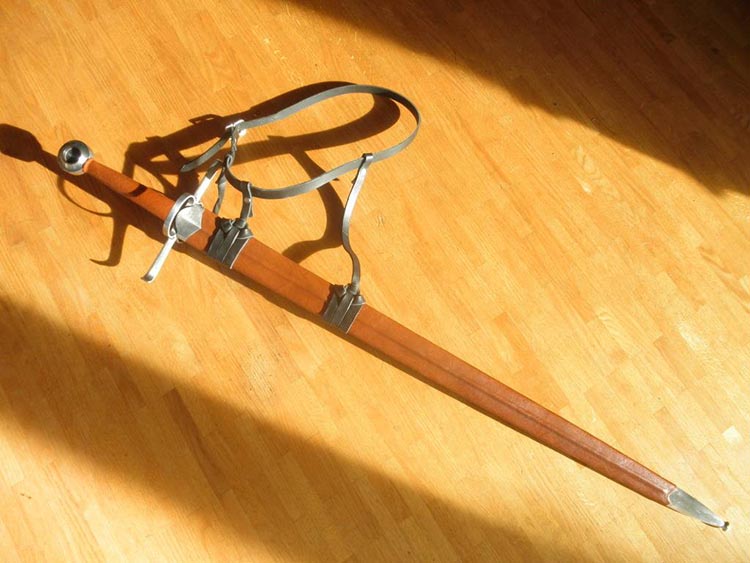

Illustrative image related to how to make a leather scabbard

Scenario 3: Challenges in Customization and Design Variability

The Problem: In a competitive B2B landscape, buyers are often faced with the challenge of meeting diverse customer demands for customized scabbard designs. This includes variations in size, shape, and decorative elements, which can complicate the production process. For example, when clients request unique engravings or specific fit adjustments for different sword types, it can lead to increased lead times and operational inefficiencies, especially if the design process is not streamlined.

The Solution: Implement a flexible design process that accommodates customization while maintaining production efficiency. Utilize CAD software to create digital prototypes of scabbard designs, allowing for easy adjustments based on client specifications. This not only helps in visualizing the final product but also simplifies communication with clients throughout the design phase. Additionally, establish a modular approach to production, where standard components can be combined in various ways to create customized solutions. This strategy reduces waste and ensures that your production team can adapt quickly to changing client needs without compromising on quality. Regularly seek feedback from clients on their preferences and experiences, as this will inform future design iterations and enhance customer satisfaction.

Strategic Material Selection Guide for how to make a leather scabbard

When selecting materials for crafting a leather scabbard, it is crucial to consider various options that align with performance requirements, manufacturing capabilities, and market preferences. Below is an analysis of four common materials used in the production of leather scabbards, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Vegetable-Tanned Leather for Scabbards?

Vegetable-tanned leather is a popular choice for scabbards due to its durability and aesthetic appeal. This type of leather is tanned using natural plant extracts, making it environmentally friendly. It offers excellent abrasion resistance and can withstand varying temperatures, though it is less resistant to moisture compared to synthetic alternatives.

Pros & Cons:

The primary advantage of vegetable-tanned leather is its ability to develop a rich patina over time, enhancing its visual appeal. However, it can be more expensive than chrome-tanned leather and may require more care to maintain its appearance. The manufacturing complexity is moderate, as it involves a longer tanning process.

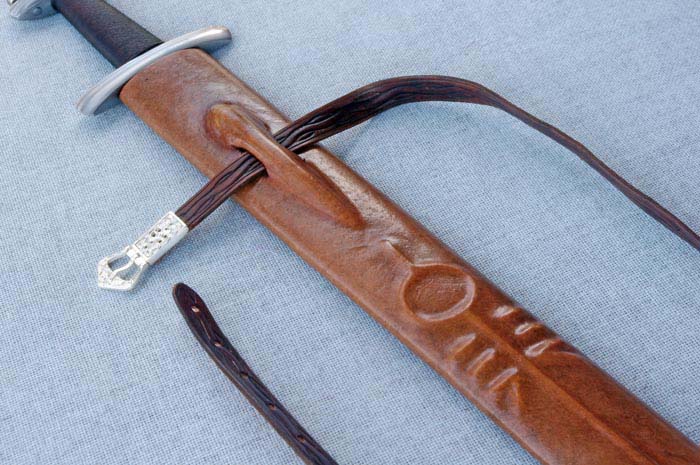

Illustrative image related to how to make a leather scabbard

Impact on Application:

Vegetable-tanned leather is compatible with various media, including swords and knives, as it does not react adversely with metals.

Considerations for International Buyers:

B2B buyers in regions like Europe may prefer vegetable-tanned leather due to stringent environmental regulations. Compliance with standards such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is essential.

How Does Chrome-Tanned Leather Compare for Scabbard Production?

Chrome-tanned leather is another common material used in scabbard production. This leather is tanned using chromium salts, resulting in a product that is more resistant to water and stains compared to vegetable-tanned leather.

Pros & Cons:

The key advantage of chrome-tanned leather is its durability and resistance to environmental factors, making it suitable for outdoor use. However, it may not provide the same aesthetic appeal as vegetable-tanned leather and can be less environmentally friendly. The manufacturing process is generally faster and less labor-intensive.

Impact on Application:

Chrome-tanned leather is ideal for scabbards that may be exposed to moisture, as it offers superior water resistance.

Illustrative image related to how to make a leather scabbard

Considerations for International Buyers:

Buyers in regions with strict environmental regulations, such as Germany, should ensure that suppliers adhere to local standards regarding chromium usage.

What Are the Benefits of Using Synthetic Leather for Scabbards?

Synthetic leather, often made from polyurethane or polyvinyl chloride (PVC), is a cost-effective alternative to traditional leather. It mimics the appearance of leather while offering unique properties.

Pros & Cons:

The primary advantage of synthetic leather is its affordability and ease of maintenance. It is also highly resistant to water and stains. However, it may lack the durability and breathability of genuine leather, which can affect the longevity of the scabbard. The manufacturing complexity is generally lower, making it accessible for mass production.

Impact on Application:

Synthetic leather is suitable for scabbards that require high resistance to moisture and easy cleaning.

Considerations for International Buyers:

B2B buyers from regions like South America may prefer synthetic options due to cost-effectiveness, but should also consider the environmental impact of PVC and its compliance with local regulations.

How Does Wood Core Material Influence Scabbard Durability?

Wood, particularly poplar or birch, is often used as a core material in leather scabbard construction. It provides structural integrity and protection for the blade.

Pros & Cons:

The advantage of using wood is its lightweight nature and ability to absorb shock, which protects the blade. However, wood can be susceptible to moisture damage and may require additional treatment to enhance durability. The manufacturing process involves more complexity, as it requires precise cutting and shaping.

Impact on Application:

Wood cores are particularly suitable for scabbards designed for swords, providing a snug fit and protection.

Considerations for International Buyers:

Buyers should ensure that the wood used complies with international standards for sustainability, such as the Forest Stewardship Council (FSC) certification, especially in regions like Africa where deforestation is a concern.

Summary Table of Material Selection for Leather Scabbards

| Materiaal | Typical Use Case for how to make a leather scabbard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end, aesthetic scabbards | Develops a rich patina | More expensive, requires maintenance | Hoog |

| Chrome-Tanned Leather | Outdoor and moisture-exposed scabbards | Superior water resistance | Less aesthetic appeal, environmental concerns | Medium |

| Synthetic Leather | Cost-effective, easy-maintenance scabbards | Affordable, easy to clean | Less durable, lacks breathability | Low |

| Wood Core (Poplar/Birch) | Structural core for swords | Lightweight, shock-absorbent | Susceptible to moisture, requires treatment | Medium |

This strategic material selection guide provides essential insights for B2B buyers looking to make informed decisions when sourcing materials for leather scabbards. Understanding the properties, advantages, and limitations of each material will facilitate better procurement strategies tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather scabbard

What Are the Main Stages of Manufacturing a Leather Scabbard?

The manufacturing process of a leather scabbard is intricate and requires several stages to ensure both functionality and aesthetic appeal. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Leather Scabbard Production?

Material preparation is the foundational step in scabbard production. The primary materials used are leather (preferably vegetable-tanned for durability and environmental considerations) and wood (often poplar or a similar lightweight wood for the core).

-

Leather Selection: B2B buyers should look for high-quality leather with a thickness of 2-3 oz. This ensures durability and a good fit over the core. The leather is typically sourced from reputable tanneries that adhere to international tanning standards, which can affect the quality and longevity of the finished product.

-

Wood Core Preparation: The wood core is shaped to snugly fit the blade it will house. This involves cutting, chiseling, and sanding the wood to achieve the desired dimensions. Buyers should verify that the supplier uses appropriate wood types to prevent reactions with the blade material, which can lead to corrosion.

-

Quality Checkpoints: Before moving forward, a quality check on the materials is critical. This includes verifying the moisture content of the leather and ensuring the wood is free from knots or imperfections that could compromise the scabbard’s structure.

What Techniques Are Used in Forming the Scabbard?

Once the materials are prepared, the forming stage begins, where the core is shaped and the leather is prepared for wrapping.

-

Core Shaping Techniques: The core can be formed using either a carving method, where the wood is manually shaped to fit the blade, or a slat method, where thin strips are bent and glued together. Each method has its benefits; for instance, the slat method allows for more flexibility in design.

-

Leather Shaping: The leather is soaked to make it pliable and then wrapped around the core. This is a critical point where precision is vital; the leather must fit snugly without wrinkles. Buyers should ensure their suppliers have skilled artisans who can handle leather properly, as improper techniques can lead to defects.

-

Sewing Techniques: The leather is typically sewn using a two-needle method or similar techniques that ensure strength and durability. High-quality thread, such as waxed sinew or heavy-duty thread, should be used to withstand wear and tear.

How Is the Scabbard Assembled and Finished?

The assembly and finishing stages focus on bringing together the components and adding the final touches.

-

Assembly Process: The leather-wrapped core is assembled with any additional components, such as fittings for belt loops or decorative elements. This stage also involves applying adhesives where necessary to ensure structural integrity.

-

Finishing Touches: The final finish can include dyeing, sealing, and polishing the leather to enhance its appearance and protect it from moisture and wear. Buyers should inquire about the types of finishes used, as some may be more eco-friendly or suited for specific climates.

-

Final Quality Check: A thorough inspection is performed to ensure the scabbard meets all design specifications. This includes checking for alignment, stitching quality, and overall aesthetics.

What Are the Key Quality Assurance Standards for Leather Scabbards?

Quality assurance is crucial in the leather scabbard manufacturing process to ensure that products meet international standards and customer expectations.

Illustrative image related to how to make a leather scabbard

Which International Standards Are Relevant for Leather Scabbards?

-

ISO 9001: This international standard outlines requirements for a quality management system. Manufacturers should be certified to ISO 9001, ensuring they have processes in place for consistent quality control and continuous improvement.

-

CE Marking: For products sold in Europe, CE marking may be necessary, indicating compliance with EU safety, health, and environmental requirements. Buyers should confirm that their suppliers understand these regulations.

-

API Standards: If the scabbard is intended for use in industrial applications, adherence to API standards may be relevant, especially regarding material performance and safety.

What Are the Common Quality Control Checkpoints?

Quality control checkpoints are integral to maintaining standards throughout the manufacturing process.

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival. Suppliers should have processes in place to evaluate leather and wood for quality and compliance with specifications.

-

In-Process Quality Control (IPQC): During production, various checkpoints should be established to monitor processes such as cutting, sewing, and finishing. This ensures any deviations from quality standards are addressed immediately.

-

Final Quality Control (FQC): Before shipping, a comprehensive final inspection should occur. This includes testing for durability, fit, and aesthetic quality. Buyers should ask for FQC reports to verify that their orders meet the required standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verification of supplier quality control practices is essential for B2B buyers to ensure they are receiving high-quality products.

-

Conducting Audits: Buyers should perform regular audits of suppliers to assess their manufacturing processes and quality control measures. This can be done through on-site visits or by requesting detailed audit reports.

-

Requesting Quality Control Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC results. This transparency is vital for building trust.

-

Engaging Third-Party Inspectors: For added assurance, buyers can engage third-party inspectors to evaluate the manufacturing processes and finished products. This external validation can help mitigate risks associated with product quality.

What Are the QC Nuances for International B2B Buyers?

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, there are specific nuances to consider.

-

Cultural Differences in Quality Standards: Understanding the local manufacturing culture and quality expectations is crucial. Buyers should ensure their requirements align with the supplier’s capabilities and local standards.

-

Regulatory Compliance: Different regions may have varying regulations regarding materials and manufacturing processes. B2B buyers should be aware of these differences and ensure their suppliers comply with local and international laws.

-

Logistics and Transportation Considerations: Quality can be affected during transportation. Buyers should ensure that suppliers have robust packaging and handling processes to protect the scabbards during shipping.

By understanding these manufacturing processes and quality assurance standards, B2B buyers can make informed decisions, ensuring they source high-quality leather scabbards that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather scabbard’

Inleiding

This guide serves as a comprehensive checklist for B2B buyers aiming to procure the necessary components and expertise for crafting leather scabbards. Whether you’re a manufacturer, supplier, or artisan, understanding the critical steps in sourcing materials and services will enhance the quality and durability of your scabbards, thereby meeting the demands of your clientele in various international markets.

Step 1: Define Your Technical Specifications

Before beginning the procurement process, clearly outline the specifications for the leather scabbard you intend to produce. This includes dimensions, leather type (such as vegetable-tanned), and any additional features like decorative stitching or hardware.

– Ensure that your specifications align with industry standards to facilitate easier communication with suppliers.

Step 2: Research Suitable Materials

Identifying the right materials is crucial for producing high-quality scabbards. Focus on sourcing durable leather and appropriate wood for the core, such as poplar or other lightweight hardwoods.

– Prioritize suppliers that offer sustainable materials, as this can enhance your brand’s reputation and appeal to environmentally conscious buyers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Look for suppliers with a proven track record in leather craftsmanship, as their experience can significantly impact the quality of the final product.

Illustrative image related to how to make a leather scabbard

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers comply with relevant industry standards and certifications. This includes checking for quality certifications such as ISO or compliance with environmental regulations.

– Certifications can indicate a supplier’s commitment to quality and sustainability, which are increasingly important in global markets.

Step 5: Assess Production Capabilities

Investigate the production capabilities of your shortlisted suppliers. Understand their manufacturing processes, lead times, and capacity to handle large orders, especially if you plan to scale your production.

– Engaging with suppliers who can demonstrate flexibility and adaptability in their production methods will help you meet changing market demands.

Step 6: Request Samples for Quality Assurance

Before finalizing any orders, request samples of materials and finished products. This step allows you to assess the quality of the leather, stitching, and overall craftsmanship.

– Use this opportunity to evaluate how well the materials meet your specifications and whether they align with your brand’s quality standards.

Illustrative image related to how to make a leather scabbard

Step 7: Negotiate Terms and Establish Relationships

Once you have selected a supplier, focus on negotiating favorable terms that benefit both parties. Discuss pricing, payment terms, and delivery schedules to ensure clarity and build a long-term partnership.

– Establishing a strong relationship with your suppliers can lead to better pricing, priority service, and collaborative opportunities in future projects.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing materials and expertise for crafting leather scabbards, ensuring high-quality products that meet customer expectations.

Comprehensive Cost and Pricing Analysis for how to make a leather scabbard Sourcing

In the process of sourcing leather scabbards, understanding the cost structure is essential for B2B buyers aiming to optimize their investments. The costs associated with producing a leather scabbard can be broken down into several key components: materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

What Are the Primary Cost Components for Leather Scabbard Production?

-

Materials: The primary raw materials include high-quality leather, typically vegetable-tanned, and wood for the core. Costs for leather can vary significantly based on quality and sourcing location, with prices ranging from $5 to $15 per square foot. Additionally, wood types like poplar or oak may add another $2 to $5 per scabbard, depending on the size and thickness.

-

Labor: Skilled labor is required for both cutting and sewing the leather. Labor costs can fluctuate based on geographical location; for instance, labor in Europe might be more expensive than in parts of Africa or South America. Hourly rates may range from $15 to $50, depending on the skill level required.

-

Manufacturing Overhead: This includes factory utilities, equipment maintenance, and administrative expenses. Overhead typically adds 15-20% to the total manufacturing cost, depending on the production scale and location.

-

Tooling: Initial tooling costs can be significant if specialized tools or machinery are required for production. These costs can be amortized over larger production volumes, making them a less critical factor in high-volume orders.

-

Quality Control (QC): Implementing a QC process ensures that each scabbard meets quality standards, which is crucial for maintaining brand reputation. QC costs can be estimated at around 5-10% of total production costs.

-

Logistics: Shipping and handling costs must be considered, particularly for international shipments. These can vary widely based on Incoterms, shipment size, and distance, often adding 10-15% to the total cost.

-

Margin: Finally, manufacturers typically add a profit margin of 20-30% on top of the total production costs to ensure sustainability and reinvestment in the business.

How Do Price Influencers Affect Leather Scabbard Sourcing?

Several factors can influence the pricing of leather scabbards in the B2B market:

-

Volume/MOQ: Bulk orders often lead to lower per-unit costs due to economies of scale. Minimum order quantities (MOQ) can affect pricing; negotiating favorable terms can be beneficial for large purchasers.

-

Specifications and Customization: Custom designs or specifications can increase costs due to additional labor and material requirements. Buyers should clearly define their needs to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher-quality materials or those with certifications (e.g., eco-friendly) can substantially increase costs. Buyers should assess their target market to determine the acceptable quality threshold.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers might charge a premium for their services, but they often provide better quality assurance and reliability.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They dictate who is responsible for shipping, insurance, and tariffs, affecting the total landed cost of goods.

What Are Some Buyer Tips for Sourcing Leather Scabbards?

-

Negotiation: Always negotiate pricing and terms with suppliers. Highlight potential long-term partnerships to leverage better rates.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also logistics, potential waste, and quality issues.

-

Pricing Nuances for International Buyers: International buyers, especially from regions like Africa and South America, should be aware of currency fluctuations, import duties, and local market conditions that may impact costs.

-

Quality Assessment: Always request samples and conduct thorough assessments of materials and craftsmanship before committing to larger orders. This ensures that the product meets your quality expectations.

-

Market Research: Stay informed about market trends and pricing benchmarks in different regions, particularly in Europe and the Middle East, to ensure competitive sourcing.

Understanding these cost components and price influencers will empower B2B buyers to make informed decisions in sourcing leather scabbards, ensuring that they maximize value while maintaining quality.

Alternatives Analysis: Comparing how to make a leather scabbard With Other Solutions

Introduction: Exploring Alternatives for Crafting Scabbards

When it comes to crafting scabbards for swords, leather remains a popular material due to its durability and aesthetic appeal. However, there are several alternative methods and materials that can achieve similar results, each with its own set of advantages and drawbacks. Understanding these alternatives is essential for B2B buyers looking to make informed decisions based on their specific needs, budget, and operational capabilities.

Comparison Table

| Comparison Aspect | How To Make A Leather Scabbard | Wood Scabbard Construction | Synthetic Material Scabbard |

|---|---|---|---|

| Performance | High durability and aesthetic appeal | Excellent durability; can be heavy | Good durability; lightweight |

| Cost | Moderate; leather and tools required | Low to moderate; wood is generally inexpensive | Variable; costs depend on material quality |

| Ease of Implementation | Requires leatherworking skills; moderate difficulty | Easier for those familiar with woodworking | Simple; often requires minimal tools |

| Maintenance | Requires regular conditioning to prevent drying | Minimal maintenance; wood can warp | Low maintenance; resistant to moisture and wear |

| Best Use Case | Traditional or high-end applications | Historical reenactments, display | Modern or utility applications |

Detailed Breakdown of Alternatives

Wood Scabbard Construction

Creating a wood scabbard involves crafting a core from solid wood, typically poplar or oak, which is then shaped to fit the sword. This method is relatively straightforward for those with woodworking skills, and the materials are generally inexpensive. However, wood scabbards can be heavier and may not provide the same aesthetic appeal as leather. Additionally, they can warp over time if not properly treated. For buyers focused on historical accuracy or functional display, wood scabbards represent a viable alternative, but they may not suit all modern applications.

Synthetic Material Scabbard

Synthetic materials, such as plastics or composites, have gained popularity in recent years for scabbard construction. These materials can be molded into various shapes, providing a lightweight and durable option that is resistant to moisture and wear. The ease of production and minimal maintenance make synthetic scabbards appealing for high-volume manufacturing. However, they may lack the traditional look and feel of leather or wood, which can be a drawback for buyers looking for authenticity. Overall, synthetic materials are best suited for modern applications where functionality and durability are prioritized over aesthetics.

Conclusion: How to Choose the Right Scabbard Solution for Your Needs

Selecting the right scabbard construction method depends on various factors, including the intended use, budget, and desired aesthetics. Leather scabbards offer a classic appeal and durability, making them ideal for high-end or traditional applications. In contrast, wood scabbards can serve well for historical reenactments, while synthetic options excel in modern utility scenarios. B2B buyers should carefully assess their specific requirements, weighing the pros and cons of each alternative, to ensure they choose the most suitable solution for their business needs.

Essential Technical Properties and Trade Terminology for how to make a leather scabbard

When creating a leather scabbard, understanding the essential technical properties and trade terminology is crucial for successful procurement and production. This knowledge not only aids in ensuring quality but also facilitates smoother negotiations and partnerships in the B2B space.

What Are the Key Technical Properties for Leather Scabbard Production?

1. Material Grade

The quality of leather used is paramount. Vegetable-tanned leather, typically ranging from 2 to 3 ounces in thickness, is preferred for scabbards due to its durability and ability to mold well when wet. Understanding the material grade ensures that the scabbard will withstand wear and tear while maintaining its aesthetic appeal.

2. Dimensional Tolerances

Precision in the dimensions of both the leather and wood core is critical. Tolerances should be tight enough to ensure a snug fit for the sword, avoiding excessive movement that could lead to damage. Common tolerances in scabbard construction may range from ±1mm to ±2mm, depending on the specific design and intended use.

3. Finishing Specifications

The finishing process, including dyeing and sealing, impacts both the appearance and longevity of the scabbard. A high-quality finish protects against moisture and wear, making it essential to specify the type of finish (e.g., water-resistant, UV-resistant) required in production.

4. Weight Capacity

Understanding the weight capacity is crucial, particularly for scabbards designed for heavier blades. The materials and construction methods must be capable of supporting the weight without compromising the integrity of the scabbard.

5. Structural Integrity

The scabbard’s design should ensure it can withstand daily use without deforming or breaking. This includes considerations for the wood core’s strength, the stitching quality, and the overall craftsmanship.

6. Customizability

Given the diverse preferences of international clients, the ability to customize dimensions, colors, and features (such as belt systems) is an important property. This flexibility can be a key selling point in B2B transactions.

Illustrative image related to how to make a leather scabbard

What Common Trade Terms Should Buyers Understand When Ordering Leather Scabbards?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are marketed by another company. In the context of leather scabbards, understanding whether a supplier is an OEM can help buyers assess the authenticity and quality of the product.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for buyers, especially when budgeting for initial inventory. Suppliers in the leather goods industry often set MOQs to ensure cost-effectiveness.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to invite suppliers to bid on specific products or services. For leather scabbards, an RFQ should detail specifications, quantities, and delivery timelines to obtain accurate quotes from manufacturers.

Illustrative image related to how to make a leather scabbard

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who is responsible for shipping costs, insurance, and liability during transit, essential for cross-border B2B dealings.

5. Lead Time

This term refers to the time it takes from placing an order until the product is delivered. Understanding lead times is crucial for inventory management and planning, especially in industries with fluctuating demand.

6. Kwaliteit

Quality assurance encompasses the processes that ensure products meet specified requirements. For leather scabbards, this might involve inspections and testing of materials and craftsmanship before delivery, which is vital for maintaining brand reputation.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, foster better supplier relationships, and ultimately enhance their product offerings in the leather goods market.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather scabbard Sector

What Are the Key Market Dynamics and Trends in the Leather Scabbard Sector?

The leather scabbard sector is experiencing notable growth driven by rising demand for handcrafted and customized products across international markets. Buyers in Africa, South America, the Middle East, and Europe are increasingly seeking unique, artisanal scabbards that combine historical craftsmanship with modern design aesthetics. Additionally, the resurgence of interest in historical reenactments, cosplay, and traditional weaponry has created a niche market where high-quality leather goods are prized.

Illustrative image related to how to make a leather scabbard

Emerging B2B technology trends, such as digital marketplaces and online sourcing platforms, are transforming how manufacturers and buyers connect. These platforms enable buyers to access a wider range of suppliers, compare prices, and evaluate product quality from the comfort of their own offices. Moreover, advancements in material science are leading to the development of innovative leather alternatives and eco-friendly tanning processes, making it easier for manufacturers to meet diverse consumer preferences.

Furthermore, the influence of global trade dynamics cannot be overlooked. Tariffs and trade agreements can impact sourcing costs and availability of raw materials. Buyers should remain informed about these factors as they can influence pricing and lead times for leather scabbard production.

How Can Sustainability and Ethical Sourcing Impact Leather Scabbard Production?

Sustainability and ethical sourcing are becoming paramount in the leather industry, particularly as consumers and businesses alike become more environmentally conscious. The production of leather has historically faced scrutiny due to its environmental impact, including deforestation and pollution from tanning processes. Thus, B2B buyers should prioritize suppliers who utilize sustainable practices, such as vegetable tanning methods, which are less harmful to the environment compared to traditional chemical tanning.

Ethical sourcing involves ensuring that raw materials are obtained from suppliers who uphold fair labor practices and animal welfare standards. Buyers can look for certifications such as the Leather Working Group (LWG) certification, which indicates a commitment to responsible sourcing and environmental management. By choosing suppliers with these certifications, buyers can not only mitigate risks but also enhance their brand reputation among increasingly eco-conscious consumers.

Moreover, the integration of recycled materials and innovative leather alternatives, such as plant-based leathers, can further contribute to sustainability efforts. As B2B buyers navigate the leather scabbard market, aligning with suppliers who prioritize sustainability can lead to competitive advantages in an evolving landscape.

What Is the Historical Context of Leather Scabbard Production?

The history of leather scabbard production is rich and intertwined with the development of weaponry and armor throughout various cultures. Traditionally, scabbards were crafted to protect blades from damage and the elements, with early examples dating back to ancient civilizations. Leather, due to its durability and flexibility, became the material of choice for scabbards, often supplemented by wood or metal for structural integrity.

In medieval Europe, the art of leatherworking advanced significantly, leading to ornate designs and embellishments that reflected the status of the sword and its owner. The craftsmanship involved in creating leather scabbards was not only a practical necessity but also a form of artistic expression. Today, this historical craftsmanship continues to inspire modern artisans, who blend traditional techniques with contemporary design, appealing to a global market that values authenticity and heritage in their purchases.

This rich history, combined with modern market dynamics, positions leather scabbards as both functional items and collectible art pieces, making them an attractive product for international B2B buyers seeking to diversify their offerings.

Illustrative image related to how to make a leather scabbard

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather scabbard

-

How do I choose the right leather for making a scabbard?

Choosing the right leather is crucial for durability and aesthetics. Vegetable-tanned leather, typically 2 to 3 ounces in thickness, is preferred for scabbards due to its strength and ability to mold around the core. Ensure the leather is free from defects and has a consistent grain. If you’re sourcing internationally, consider the leather quality standards in your region and request samples to assess the texture and flexibility before making bulk orders. -

What materials do I need to make a leather scabbard?

To create a leather scabbard, you will need a wood core (preferably poplar), vegetable-tanned leather, artificial sinew or heavy-duty waxed thread, glue, and tools for cutting, chiseling, and sewing. Additionally, consider having a chape and belt system for functional and aesthetic purposes. Ensure that your suppliers can provide these materials consistently and in compliance with international quality standards. -

What is the best method for crafting a leather scabbard?

There are several methods for crafting leather scabbards, including the carving method and the slat method. The carving method involves creating a snug wood core shaped to fit the blade, while the slat method uses thin strips of wood that conform to the blade’s shape. For a balance of ease and quality, the basic slot method is recommended, where you create a 1/4” slot for the blade to slide into. Choose a method based on your craftsmanship level and production capabilities. -

How can I ensure a snug fit for the blade in the scabbard?

Achieving a snug fit requires precision during the wood core shaping process. The blade should fit tightly enough to prevent it from falling out but not so tight that it requires force to remove. Test the fit frequently during the construction phase, and consider using thin leather strips to tighten the fit if necessary. Proper soaking and shaping of the leather will also contribute to a snug finish. -

What are the typical minimum order quantities (MOQs) for leather scabbards?

MOQs can vary significantly based on the supplier and the complexity of the design. For custom leather scabbards, MOQs may range from 50 to 200 units, depending on the craftsmanship and materials used. When negotiating with suppliers, inquire about their capacity to handle smaller orders for prototypes or samples, which can help assess quality before committing to larger quantities. -

What payment terms should I consider when sourcing leather scabbards?

Payment terms can vary, but standard practices include a deposit upfront (usually 30-50%) with the balance due upon completion or delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms before finalizing contracts to avoid misunderstandings later. -

How do I vet suppliers for quality and reliability in leather scabbard production?

When vetting suppliers, request references and samples of their previous work to assess quality. Look for suppliers with certifications for quality standards, such as ISO. Additionally, consider their production capacity, lead times, and customer service responsiveness. Establishing clear communication channels will help ensure that your specifications are met throughout the production process. -

What logistics considerations should I keep in mind when importing leather scabbards?

When importing leather scabbards, consider shipping methods, customs regulations, and potential tariffs that may apply to your order. Ensure that your supplier provides all necessary documentation for customs clearance, including invoices and certificates of origin. Working with a logistics partner experienced in international trade can streamline the shipping process and help you navigate any regulatory hurdles efficiently.

Top 5 How To Make A Leather Scabbard Manufacturers & Suppliers List

1. Ye Olde Gaffer – Sword Scabbard Project

Domain: sword-site.com

Registered: 2013 (12 years)

Introduction: How to Make a Sword Scabbard by Ye Olde Gaffer; Project involves creating a wood core covered with leather; Recommended wood: poplar (1/4″ thick); Construction methods: Carving Method, Historic Method (Slat method), Easy Method; Tools needed: chisel, sandpaper, glue, clamps; Leather: 2 to 3 oz vegetable tanned leather; Important considerations: snug fit for the blade, avoid using sandpaper on the …

2. Sword Buyers Guide – Scabbard Materials and Construction

Domain: sword-buyers-guide.com

Registered: 2005 (20 years)

Introduction: Materials used for making a scabbard: 1mm maple slats, lightly oiled goat fur for lining, linen and rabbit skin glue (or PVA adhesive), thin leather sheet for wrapping. Key steps include tracing the shape on maple slats, gluing goat fur for lining, wrapping the core with linen, using heated rabbit skin glue for binding, reinforcing the mouth with leather, and wrapping the core with wet leather. Th…

3. SBG – Leather Scabbard Solutions

Domain: sbg-sword-forum.forums.net

Registered: 1996 (29 years)

Introduction: Solid leather scabbard for a blade of around 26 inches or longer. Concerns about rigidity for re-sheathing the blade. Previous experience with back-seamed sheaths for knives and daggers. Discussion on the challenges of making a pure leather sheath versus a wood scabbard, including wet forming and fit issues. Mention of using 5oz leather for stiffness and a piece measuring over 3.5mm (approximately…

4. Weaver Leather Supply – Traditional Leather Scabbards and Sheaths

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Traditional Leather Scabbard, Wet Forming Leather Sheath, Leather Axe Sheath, Leather Knife Sheath, Leather Tool Sheath, Side-Sewn Leather Sword Scabbard

5. Self Reliance Outfitters – Leather Knife Sheaths

Domain: selfrelianceoutfitters.com

Registered: 2011 (14 years)

Introduction: Leather knife sheaths are the most reliable material for sheaths, combining toughness, stability, and structure. They are quieter than plastic or nylon, making them preferred by the military. However, leather is vulnerable to rain and sunshine, which can wear it down over time. Making a leather knife sheath involves using easy-to-find materials, such as leather, waxed string, and basic tools.

Strategic Sourcing Conclusion and Outlook for how to make a leather scabbard

In the intricate process of crafting a leather scabbard, strategic sourcing plays a pivotal role in ensuring high-quality materials and cost-effective production. By selecting the right leather—preferably vegetable-tanned—and sourcing reliable wood for the core, manufacturers can enhance the durability and aesthetic appeal of their products. Understanding local supply chains, particularly in regions like Africa and South America, can lead to significant cost savings and foster sustainable business relationships.

Furthermore, leveraging advanced leatherworking techniques, such as the two-needle sewing method and proper leather conditioning, can elevate product quality and customer satisfaction. International buyers should prioritize partnerships with suppliers who share a commitment to craftsmanship and ethical sourcing practices.

As the demand for bespoke leather goods continues to grow globally, now is the time for businesses to invest in the art of scabbard making. By aligning with skilled artisans and utilizing sustainable materials, companies can not only meet market expectations but also position themselves as leaders in the leather industry. Embrace this opportunity to innovate and differentiate your offerings in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how to make a leather scabbard

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.