Introduction: Navigating the Global Market for automotive leather material

Navigating the complexities of the global market for automotive leather material presents a significant challenge for B2B buyers seeking quality and value. As companies look to source premium automotive leather, they must consider factors such as durability, comfort, and aesthetic appeal, which are crucial for enhancing vehicle interiors. This comprehensive guide aims to equip international buyers, particularly those from Africa, South America, the Middle East, and Europe, with the insights necessary to make informed purchasing decisions.

In this guide, we will explore various types of automotive leather, from full-grain to top-grain options, and discuss their specific applications in vehicle interiors, including seats, dashboards, and door panels. We will also provide actionable strategies for vetting suppliers, ensuring that buyers can identify reliable partners who meet their quality and compliance standards. Additionally, we will delve into cost considerations, helping buyers navigate pricing structures and negotiate effectively.

By offering a thorough understanding of the automotive leather landscape, this guide empowers B2B buyers to select the right materials that not only enhance the functionality and style of their vehicles but also align with their budget and operational needs. As you embark on your sourcing journey, let this resource serve as your trusted companion, facilitating successful procurement in the dynamic automotive industry.

Table Of Contents

- Top 6 Automotive Leather Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automotive leather material

- Understanding automotive leather material Types and Variations

- Key Industrial Applications of automotive leather material

- 3 Common User Pain Points for ‘automotive leather material’ & Their Solutions

- Strategic Material Selection Guide for automotive leather material

- In-depth Look: Manufacturing Processes and Quality Assurance for automotive leather material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive leather material’

- Comprehensive Cost and Pricing Analysis for automotive leather material Sourcing

- Alternatives Analysis: Comparing automotive leather material With Other Solutions

- Essential Technical Properties and Trade Terminology for automotive leather material

- Navigating Market Dynamics and Sourcing Trends in the automotive leather material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automotive leather material

- Strategic Sourcing Conclusion and Outlook for automotive leather material

- Important Disclaimer & Terms of Use

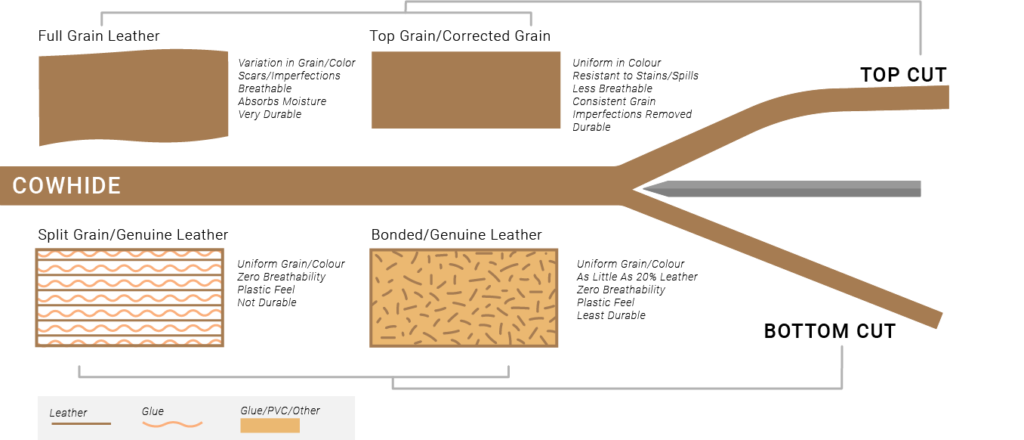

Understanding automotive leather material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather | Retains natural grain; highest durability | Luxury vehicles, high-end interiors | Pros: Exceptional durability, breathability. Cons: Higher cost, requires maintenance. |

| Top-Grain Leather | Sanded surface for a smoother finish; still durable | Mid to high-end vehicles | Pros: Good durability, more affordable than full-grain. Cons: Less natural look and feel. |

| Split Leather | Made from the fibrous part of the hide; less durable | Budget vehicles, commercial fleets | Pros: Cost-effective, lightweight. Cons: Less durable, more susceptible to wear. |

| Perforated Leather | Features holes for breathability; often used in sports cars | Performance vehicles, luxury interiors | Pros: Enhanced comfort, stylish appearance. Cons: Can be harder to clean, may show wear faster. |

| Suede Leather | Soft texture, often dyed in vibrant colors | Custom interiors, specialty vehicles | Pros: Unique aesthetic, soft touch. Cons: Not as durable, can stain easily. |

What Are the Characteristics of Full-Grain Leather for Automotive Use?

Full-grain leather is renowned for its durability and natural beauty, as it retains the hide’s original grain pattern. This type of leather is ideal for luxury vehicles and high-end interiors due to its premium feel and longevity. B2B buyers should consider that while full-grain leather offers superior resistance to wear and tear, it requires regular maintenance to preserve its appearance. The investment is justified for brands looking to convey a message of quality and elegance.

Illustrative image related to automotive leather material

How Does Top-Grain Leather Compare in Quality and Application?

Top-grain leather is a step down from full-grain, featuring a sanded surface that results in a smoother finish. It is commonly used in mid to high-end vehicles, balancing quality and cost-effectiveness. This type of leather is still durable and offers a refined look, making it a popular choice among manufacturers. B2B buyers should weigh the benefits of affordability against the slight reduction in natural aesthetics compared to full-grain options.

Why Choose Split Leather for Budget-Friendly Automotive Solutions?

Split leather, derived from the fibrous layer of the hide, is a more economical alternative for automotive applications. It is typically used in budget vehicles and commercial fleets, where cost is a priority. While split leather is lighter and more affordable, it lacks the durability and luxury appeal of its higher-grade counterparts. B2B buyers should consider the trade-off between cost savings and potential longevity when selecting this option for their projects.

What Advantages Does Perforated Leather Offer for Performance Vehicles?

Perforated leather incorporates small holes that enhance breathability, making it particularly suitable for performance vehicles and luxury interiors. This feature not only improves comfort during long drives but also adds a stylish touch. However, B2B buyers should be aware that while perforated leather enhances the aesthetic and comfort, it may require more care to prevent dirt accumulation in the holes, which could impact its longevity.

How Does Suede Leather Stand Out in Automotive Design?

Suede leather is characterized by its soft texture and vibrant colors, making it a popular choice for custom interiors and specialty vehicles. While it offers a unique aesthetic appeal, suede is less durable and more prone to staining compared to other leather types. B2B buyers looking to create standout interiors should consider the visual impact of suede but also factor in the potential challenges associated with its maintenance and durability.

Key Industrial Applications of automotive leather material

| Industry/Sector | Specific Application of Automotive Leather Material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Car Seat Upholstery | Enhances comfort and luxury, improving customer satisfaction. | Ensure compliance with automotive standards and regulations. |

| Luxury Vehicle Customization | Custom Interiors | Provides a unique, high-end aesthetic, attracting premium buyers. | Source high-quality, customizable options tailored to client specifications. |

| Aftermarket Automotive Services | Seat Repair and Replacement | Increases vehicle resale value and customer loyalty. | Consider leather durability and color matching for seamless repairs. |

| Fleet Management | Durable Upholstery for Commercial Vehicles | Reduces long-term maintenance costs and enhances professional appearance. | Focus on bulk purchasing and long-term supply agreements. |

| Automotive Accessories | Leather Steering Wheel Covers | Improves grip and comfort, enhancing driver experience. | Look for compatibility with various vehicle models and styles. |

How is Automotive Leather Material Used in Car Seat Upholstery?

Automotive leather is prominently used in car seat upholstery, providing a luxurious and comfortable seating experience. This application is crucial for both manufacturers and aftermarket services, as high-quality leather can enhance the overall aesthetic appeal of a vehicle. For international buyers, especially in regions like Africa and Europe, sourcing leather that meets stringent automotive standards is essential. The leather must be durable, resistant to stains, and easy to clean, addressing common issues like wear and tear in high-traffic areas.

Illustrative image related to automotive leather material

What Are the Benefits of Using Automotive Leather in Luxury Vehicle Customization?

In the luxury vehicle sector, automotive leather plays a vital role in creating bespoke interiors that reflect individual customer tastes. This customization can significantly increase the vehicle’s perceived value and marketability. Buyers looking to source leather for luxury vehicles should prioritize options that offer a range of textures and colors while ensuring that the leather is sourced sustainably. Understanding regional preferences for styles can also enhance the appeal of customizations, particularly in diverse markets like South America and the Middle East.

How Does Automotive Leather Contribute to Aftermarket Services?

In the aftermarket automotive sector, leather is widely used for seat repair and replacement. This application is particularly beneficial for businesses focused on enhancing vehicle resale value and customer loyalty. Buyers should consider sourcing leather that matches the original upholstery in terms of color and texture, ensuring a seamless repair that retains the vehicle’s aesthetic integrity. Additionally, high durability is essential to withstand everyday use, making quality sourcing a critical factor.

Why is Automotive Leather Important for Fleet Management?

For fleet management companies, automotive leather is used in the upholstery of commercial vehicles to provide durability and maintain a professional appearance. The use of high-quality leather can reduce long-term maintenance costs, as it is less prone to damage and easier to clean than fabric alternatives. When sourcing leather for fleet applications, businesses should focus on bulk purchasing options and long-term supply agreements to ensure consistent quality and availability across their vehicle fleet.

Illustrative image related to automotive leather material

What Role Does Automotive Leather Play in Accessories?

Automotive leather is also utilized in accessories such as steering wheel covers, enhancing grip and comfort for drivers. This application not only improves the driving experience but also adds a touch of luxury to the vehicle’s interior. Buyers should seek leather that is compatible with various vehicle models to cater to a broad customer base. Additionally, considering factors such as ease of installation and maintenance will help businesses provide added value to their customers.

3 Common User Pain Points for ‘automotive leather material’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather for Diverse Markets

The Problem: B2B buyers often struggle to find high-quality automotive leather that meets the specific demands of various international markets. Factors such as climate, local preferences, and vehicle types can complicate the sourcing process. For instance, leather that works well in the humid environments of South America may not hold up in the dry conditions of the Middle East. Additionally, buyers may face challenges in verifying the authenticity and quality of leather suppliers, leading to concerns about durability and customer satisfaction.

The Solution: To effectively source automotive leather, buyers should focus on building strong relationships with reputable suppliers who understand local market dynamics. Conducting thorough research and due diligence on potential suppliers is essential. Request samples to evaluate quality and durability, specifically looking for full-grain or top-grain leather, as these types offer superior resistance to wear and tear. Additionally, consider collaborating with suppliers who provide detailed product specifications, including information on the tanning process and environmental standards. This transparency will help ensure that the leather not only meets quality expectations but also aligns with sustainability goals.

Scenario 2: Maintaining Leather Interiors in Diverse Environments

The Problem: Once automotive leather is installed, maintaining its appearance and durability can be a significant pain point, especially in regions with extreme weather conditions. For example, leather can crack and fade under intense sunlight, while humidity can lead to mold and mildew. B2B buyers must consider how to educate their customers or teams on proper care and maintenance to prolong the life of leather interiors.

The Solution: Implementing a comprehensive care program is crucial. Provide clients with detailed maintenance guidelines tailored to their specific climate and usage conditions. This can include recommending protective treatments that enhance water and stain resistance, as well as suggesting specific cleaning products that are safe for leather. Additionally, consider offering workshops or training sessions on proper leather care to empower customers with the knowledge needed to maintain their interiors effectively. Establishing a follow-up system to check in with clients can also help address any issues they may encounter, reinforcing the value of the leather and fostering long-term relationships.

Illustrative image related to automotive leather material

Scenario 3: Addressing Allergies and Sensitivities to Leather Materials

The Problem: Some end consumers may have allergies or sensitivities to certain leather treatments or dyes, which can lead to hesitation in purchasing vehicles with leather interiors. This concern is particularly prevalent in markets that prioritize health and wellness. B2B buyers need to navigate these sensitivities while still delivering high-quality products that appeal to a broad audience.

The Solution: To address these concerns, buyers should prioritize sourcing hypoallergenic leather options that utilize natural dyes and treatments. Communicating the benefits of such materials can help alleviate customer fears and position the product as a healthier alternative to synthetic materials. Additionally, establishing partnerships with manufacturers who specialize in eco-friendly and hypoallergenic leather can enhance product offerings. Providing detailed information on the sourcing and treatment processes used can build trust with consumers, ultimately leading to increased sales. Marketing these features prominently in product descriptions and promotional materials will also help attract health-conscious buyers, distinguishing your offerings in a competitive market.

Strategic Material Selection Guide for automotive leather material

What Are the Key Properties of Common Automotive Leather Materials?

When selecting automotive leather materials, it’s crucial to understand the specific properties that influence performance and suitability for various applications. Here, we analyze three common types of automotive leather: full-grain leather, top-grain leather, and synthetic leather.

Full-Grain Leather: The Premium Choice

Full-grain leather is considered the highest quality leather available for automotive applications. It retains the natural grain of the hide, providing durability and a unique aesthetic appeal.

- Key Properties: Full-grain leather has excellent breathability, temperature resistance, and can withstand high-pressure applications. It is also resistant to wear and tear, making it ideal for high-traffic areas in vehicles.

- Pros & Cons: The primary advantage of full-grain leather is its exceptional durability and luxurious look. However, it is also the most expensive option, which may not suit every budget. Additionally, it requires more maintenance than other types, as it can absorb stains if not treated properly.

- Impact on Application: Full-grain leather is particularly well-suited for luxury vehicles where aesthetics and comfort are paramount. Its natural properties ensure that it ages gracefully, enhancing the vehicle’s interior over time.

Top-Grain Leather: A Balance of Quality and Cost

Top-grain leather is the second-highest quality leather and is more affordable than full-grain. It is created by sanding down the top layer of the hide to remove imperfections.

- Key Properties: It offers good durability, resistance to stains, and is easier to clean than full-grain leather. Top-grain leather is also less porous, which makes it suitable for automotive applications where spills are common.

- Pros & Cons: The main advantage is its balance of quality and cost, making it a popular choice for mid-range vehicles. However, it may not provide the same level of durability or natural look as full-grain leather, and its lifespan may be shorter.

- Impact on Application: Top-grain leather is often used in mid-range and luxury vehicles, striking a balance between aesthetics and practicality. It can be used for seats, door panels, and dashboards.

Synthetic Leather: The Cost-Effective Alternative

Synthetic leather, or faux leather, is made from polyurethane or polyvinyl chloride (PVC) and is designed to mimic the look and feel of genuine leather.

- Key Properties: It is resistant to moisture, easy to clean, and can be produced in a variety of colors and textures. Synthetic leather also offers good temperature resistance, making it suitable for automotive applications.

- Pros & Cons: The primary advantage is its affordability and ease of maintenance. However, it lacks the durability and breathability of genuine leather, which may affect long-term comfort and aesthetics.

- Impact on Application: Synthetic leather is commonly used in economy vehicles and for applications where cost is a primary concern. It is ideal for seat covers and interior trim but may not provide the luxury feel associated with genuine leather.

Considerations for International B2B Buyers

When sourcing automotive leather materials, international buyers, particularly from Africa, South America, the Middle East, and Europe, should consider several factors:

- Compliance and Standards: Familiarize yourself with international standards such as ASTM, DIN, and JIS to ensure that the materials meet safety and quality requirements in your region.

- Local Preferences: Different markets may have varying preferences for leather types based on climate, cultural aesthetics, and consumer expectations. For instance, buyers in Europe may prioritize sustainability and eco-friendliness, while those in the Middle East may focus on luxury and durability.

- Supply Chain Logistics: Understand the logistics of sourcing and transporting leather materials, including potential tariffs and trade regulations that could impact costs and delivery timelines.

Summary Table of Automotive Leather Materials

| Materiaal | Typical Use Case for automotive leather material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury vehicle interiors, high-end seating | Exceptional durability and aesthetics | High cost, requires maintenance | Hoog |

| Top-Grain Leather | Mid-range to luxury vehicles, seats, dashboards | Good balance of quality and cost | Less durable than full-grain | Medium |

| Synthetic Leather | Economy vehicles, seat covers, interior trim | Cost-effective, easy to clean | Lacks durability and breathability | Low |

This structured analysis provides B2B buyers with essential insights into the various types of automotive leather materials, helping them make informed purchasing decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for automotive leather material

What Are the Main Stages in the Manufacturing Process of Automotive Leather Material?

The manufacturing process of automotive leather involves several critical stages that ensure the final product meets the high standards required for vehicle interiors. Understanding these stages is essential for B2B buyers seeking quality automotive leather.

-

Material Preparation: The process begins with the selection of raw hides, typically sourced from cattle. The hides undergo a rigorous cleaning and dehairing process to remove any impurities. This step is crucial as it affects the leather’s durability and appearance. After cleaning, the hides are soaked in a chemical solution to soften them, making them easier to process.

-

Tanning: Following preparation, the hides undergo tanning, which is the process of converting raw hides into leather. Common tanning methods include chrome tanning and vegetable tanning. Chrome tanning is favored for automotive leather due to its efficiency and ability to produce soft, durable leather. This stage not only preserves the leather but also enhances its resistance to environmental factors.

-

Forming: Once tanned, the leather is then cut and formed according to the specifications of automotive components such as seats, dashboards, and door panels. This stage may involve the use of advanced cutting technology like computer numerical control (CNC) machines for precision and efficiency.

-

Assembly: After forming, the leather pieces are assembled into their final shapes. This stage often involves stitching, bonding, or other methods of joining the leather components. Quality craftsmanship is essential here to ensure durability and aesthetic appeal.

-

Finishing: The final stage is finishing, where the leather is treated with dyes, coatings, and finishes that enhance its appearance and protect it from wear and tear. This may include applying a protective topcoat that resists scratches and stains. Finishing techniques can vary widely, allowing for customization in color, texture, and sheen to meet specific customer requirements.

What Quality Assurance Measures Are Relevant for Automotive Leather?

Quality assurance (QA) is integral to the manufacturing of automotive leather, ensuring that the products meet international standards and industry expectations. For B2B buyers, understanding these measures can help in selecting reliable suppliers.

-

International Standards: Compliance with international standards such as ISO 9001 is critical. This standard focuses on quality management systems and helps manufacturers ensure consistent quality in their processes. Automotive leather manufacturers may also adhere to specific automotive industry standards, including those set by the International Automotive Task Force (IATF).

-

Industry-Specific Certifications: Certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for certain applications within the automotive sector are important indicators of quality. These certifications assure buyers that the products have undergone rigorous testing and meet safety and performance requirements.

-

Quality Control Checkpoints: Effective quality control (QC) involves multiple checkpoints during the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before processing begins.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages to detect any deviations from quality standards.

– Final Quality Control (FQC): A comprehensive inspection of the finished leather products to ensure they meet all specifications before shipment. -

Common Testing Methods: Various testing methods are employed to assess the quality of automotive leather, including:

– Physical Testing: Evaluating the leather’s tensile strength, tear resistance, and abrasion resistance.

– Chemical Testing: Ensuring the leather is free from harmful substances and meets environmental regulations.

– Aesthetic Testing: Checking for color consistency, texture quality, and overall appearance.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control is crucial to ensure that they receive high-quality automotive leather.

Illustrative image related to automotive leather material

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes and quality control practices. Buyers should look for transparency in operations and adherence to industry standards.

-

Quality Reports: Requesting detailed quality assurance reports can help buyers understand the supplier’s QC protocols. These reports should include information on testing results, compliance with international standards, and any certifications held by the manufacturer.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can be conducted at various stages of production, ensuring that quality is maintained throughout the process.

-

Understanding QC Nuances for International Trade: Different regions may have varying standards and regulations regarding automotive leather. B2B buyers should familiarize themselves with these nuances to ensure compliance and quality. For instance, European buyers might prioritize compliance with REACH regulations concerning chemical safety, while buyers in the Middle East might focus on durability and resistance to high temperatures.

By comprehensively understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions when sourcing automotive leather. These insights not only facilitate the procurement of high-quality materials but also strengthen partnerships with suppliers across different regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive leather material’

Inleiding

This practical sourcing guide provides a comprehensive checklist for B2B buyers looking to procure automotive leather material. Selecting the right leather is crucial for enhancing vehicle interiors, ensuring durability, and meeting aesthetic standards. This checklist will help streamline your sourcing process, allowing you to make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establish clear technical specifications based on the intended application of the leather. Consider factors such as durability, texture, and color, which are vital for the aesthetic appeal and performance of automotive interiors.

– Durability Requirements: Identify the level of wear and tear the leather will encounter.

– Texture Preferences: Decide on the desired finish, such as smooth or textured, which can impact comfort and style.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers that specialize in automotive leather. Look for companies with a strong reputation and experience in the automotive sector, as this can significantly affect product quality.

– Industry Experience: Prioritize suppliers with a proven track record in providing materials for automotive applications.

– Geographical Considerations: Evaluate suppliers based on their location to manage shipping times and costs effectively.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications and compliance with industry standards. This ensures that the leather meets quality and environmental regulations, which is especially important for international transactions.

– Quality Certifications: Check for ISO or other relevant quality certifications.

– Sustainability Practices: Inquire about the supplier’s practices regarding sourcing and processing leather to align with eco-friendly standards.

Step 4: Request Samples

Always request samples of the leather before placing a large order. This allows you to assess the material’s quality, color accuracy, and texture firsthand, ensuring it meets your specifications.

– Color Matching: Ensure that the sample matches your desired color and finish.

– Durability Testing: Consider performing wear tests on samples to evaluate their performance under expected conditions.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers, engage in negotiations regarding pricing and terms of purchase. This is a critical step to ensure you receive the best value while establishing a mutually beneficial relationship.

– Volume Discounts: Discuss pricing structures based on order volumes to maximize savings.

– Payment Terms: Clarify payment terms, including deposits, payment schedules, and any warranties provided.

Illustrative image related to automotive leather material

Step 6: Confirm Delivery and Logistics

Before finalizing your order, confirm delivery timelines and logistics. Efficient logistics are essential for maintaining your production schedules, especially if you are sourcing internationally.

– Shipping Options: Evaluate shipping methods and costs to find the most efficient solutions.

– Lead Times: Confirm lead times to ensure your production timelines align with delivery schedules.

Step 7: Establish a Quality Control Process

Implement a quality control process to ensure that the leather received meets your specifications and quality standards. This is crucial for maintaining consistency in your final products.

– Inspection Protocols: Develop protocols for inspecting leather upon arrival.

– Feedback Mechanism: Create a feedback loop with the supplier to address any quality issues promptly.

By following this checklist, you can navigate the complexities of sourcing automotive leather material effectively, ensuring a successful procurement process that meets your business needs.

Illustrative image related to automotive leather material

Comprehensive Cost and Pricing Analysis for automotive leather material Sourcing

What Are the Key Cost Components in Automotive Leather Material Sourcing?

When sourcing automotive leather materials, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

-

Materials: The cost of raw leather varies significantly based on quality and type, such as full-grain or top-grain leather. Prices can range from $17 to over $384 per square meter, depending on the specific characteristics of the leather.

-

Labor: Labor costs encompass the wages of skilled workers involved in processing and manufacturing leather. This can vary by region, with higher costs typically seen in Europe and lower costs in regions like South America or Africa.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, equipment maintenance, and factory management. Efficient operations can help mitigate these expenses.

-

Tooling: Initial costs for tooling can be significant, especially for custom leather designs. These costs are often amortized over larger production runs, so higher volume orders can reduce the per-unit tooling cost.

-

Quality Control (QC): Ensuring the leather meets industry standards involves additional costs for testing and quality assurance processes. This is critical for maintaining product reliability and compliance with automotive industry regulations.

-

Logistics: Shipping and transportation costs can vary widely based on the distance between suppliers and buyers, as well as the chosen Incoterms. These costs must be factored in, especially for international transactions.

-

Margin: Suppliers will add a profit margin to cover their costs and risks, which can vary based on market conditions and the supplier’s position in the market.

How Do Price Influencers Impact Automotive Leather Material Sourcing?

Several factors influence the final pricing of automotive leather materials, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower prices per unit due to economies of scale. Suppliers may have a MOQ, which can affect overall costs.

-

Specifications and Customization: Customized leather designs or specific requirements can lead to higher costs due to additional processing and material needs. Buyers should clearly communicate their specifications to avoid unexpected charges.

-

Material Quality and Certifications: Higher quality leather that comes with certifications (e.g., eco-friendly, sustainable sourcing) often commands a premium price. Buyers should evaluate the value of certifications relative to their needs.

-

Supplier Factors: The reputation, reliability, and location of the supplier can significantly impact costs. Established suppliers with a proven track record may charge more but offer better quality assurance.

-

Incoterms: The choice of Incoterms affects logistics costs and risk management. For instance, “FOB” (Free On Board) might lead to lower upfront costs but shift more responsibility to the buyer for shipping and insurance.

What Are Effective Buyer Tips for Cost Efficiency in Automotive Leather Sourcing?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, navigating the intricacies of automotive leather sourcing can be challenging. Here are some tips:

-

Negotiate Wisely: Always explore opportunities for negotiation, especially on larger orders. Suppliers may be willing to offer discounts or better terms based on volume.

-

Evaluate Total Cost of Ownership (TCO): Focus on the long-term value of the leather, considering durability, maintenance, and resale value. A higher initial investment in quality leather can lead to lower costs over time.

-

Understand Pricing Nuances: Prices can fluctuate based on market demand, currency exchange rates, and global supply chain dynamics. Staying informed about market trends can help buyers make timely purchasing decisions.

-

Leverage Regional Advantages: Buyers should consider local suppliers to reduce shipping costs and lead times. Understanding regional market conditions can also provide leverage in negotiations.

-

Stay Informed About Regulations: Compliance with local and international regulations can affect sourcing decisions. Buyers should ensure that their suppliers adhere to relevant standards to avoid legal complications.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices for automotive leather materials can serve as a guideline, they are subject to change based on various factors. Buyers should conduct thorough research, communicate clearly with suppliers, and consider all cost components to make informed sourcing decisions. By doing so, they can ensure they receive high-quality materials that meet their specific needs while maintaining cost efficiency.

Alternatives Analysis: Comparing automotive leather material With Other Solutions

Exploring Alternatives to Automotive Leather Material

In the automotive industry, the choice of upholstery material is critical, impacting both aesthetic appeal and functionality. While automotive leather is a popular choice due to its luxurious feel and durability, various alternative materials offer different benefits and drawbacks. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific needs.

Comparison Table

| Comparison Aspect | Automotive Leather Material | Synthetic Leather | Fabric Upholstery |

|---|---|---|---|

| Performance | High durability, luxurious feel | Good durability, less expensive | Moderate durability, comfortable |

| Cost | Higher initial investment | Lower cost | Lowest cost |

| Ease of Implementation | Requires skilled labor for installation | Easier to work with, less skill required | Easy to install, lightweight |

| Maintenance | Requires regular care, resistant to stains | Easy to clean, less maintenance required | Susceptible to stains, needs frequent cleaning |

| Best Use Case | Luxury vehicles, high-end models | Mid-range vehicles, eco-conscious brands | Economy vehicles, budget-conscious consumers |

Detailed Breakdown of Alternatives

Synthetic Leather: Is It a Cost-Effective Solution?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is a popular alternative to automotive leather. Its affordability makes it an attractive option for manufacturers seeking to cut costs without sacrificing too much in aesthetics. Synthetic leather is easier to clean and maintain, making it suitable for family vehicles or commercial fleets where wear and tear is common. However, it may lack the luxurious feel and durability that genuine leather offers, which could be a drawback for high-end applications.

Fabric Upholstery: A Budget-Friendly Option

Fabric upholstery, including materials like polyester or nylon, is the most economical choice among the alternatives. It provides a comfortable seating experience and comes in various colors and patterns, allowing for customization. However, fabric can be more susceptible to stains and wear, requiring more frequent cleaning and maintenance. This option is often favored for economy vehicles or fleet cars where cost is a primary concern, but it may not meet the expectations for luxury or durability in high-end models.

Conclusion: Choosing the Right Upholstery Material for Your Needs

When selecting the right upholstery material for automotive applications, B2B buyers should consider various factors, including performance, cost, ease of implementation, and maintenance requirements. Automotive leather excels in luxury and durability, making it ideal for premium vehicles, while synthetic leather offers a more budget-friendly alternative with easier maintenance. Fabric upholstery is the most economical choice, suitable for budget-conscious consumers but may not deliver the desired luxury. Ultimately, the decision should align with the target market, vehicle type, and branding strategy, ensuring that the chosen material meets both functional and aesthetic requirements.

Essential Technical Properties and Trade Terminology for automotive leather material

What Are the Key Technical Properties of Automotive Leather Material?

Automotive leather is a specialized material designed for durability and aesthetic appeal in vehicle interiors. Understanding its key technical properties is essential for B2B buyers to make informed purchasing decisions.

1. Material Grade

Material grade refers to the quality classification of the leather. The most commonly used grades in automotive applications are full-grain and top-grain leather. Full-grain leather retains the natural grain and is the highest quality, offering superior durability and breathability. Top-grain leather is slightly processed but still maintains a high-quality finish. Selecting the appropriate grade is crucial for ensuring longevity and performance in high-traffic areas of vehicles.

2. Tolerance

Tolerance in automotive leather pertains to the allowable variations in thickness, texture, and color. For instance, automotive leather typically has a thickness tolerance of ±0.5 mm. Understanding these tolerances is important for manufacturers and upholsterers to ensure proper fitting and appearance in vehicle interiors, preventing issues like wrinkling or premature wear.

3. Abrasion Resistance

Abrasion resistance measures the leather’s ability to withstand wear from friction and contact. This property is particularly vital for automotive applications, where seats and interiors are subject to constant use. Leather with high abrasion resistance will maintain its appearance and integrity over time, providing value and reducing replacement costs.

4. Colorfastness

Colorfastness refers to the leather’s ability to retain its color when exposed to light, heat, and moisture. This property is essential for automotive leather as it affects the aesthetic appeal of the vehicle’s interior. High colorfastness ensures that the leather remains vibrant and does not fade, enhancing the overall look and resale value of the vehicle.

5. Fire Resistance

Fire resistance is a critical property that ensures automotive leather meets safety standards. This property prevents the leather from igniting easily and slows down the spread of flames in the event of a fire. Compliance with fire safety regulations is mandatory in many regions, making this property a non-negotiable factor for B2B buyers.

What Are Common Trade Terms Used in the Automotive Leather Industry?

Familiarity with industry jargon can significantly streamline communication and negotiations between suppliers and buyers.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products used in another company’s final product. In the automotive leather industry, OEMs supply leather to automobile manufacturers for use in new vehicles. Understanding OEM relationships can help buyers identify reliable suppliers and ensure quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In automotive leather, MOQs can vary significantly based on the supplier and the type of leather. Knowing the MOQ is crucial for buyers to manage inventory levels and budget effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. In the context of automotive leather, an RFQ helps buyers compare costs and terms from multiple suppliers, facilitating informed decision-making.

4. Incoterms

Incoterms (International Commercial Terms) are a set of international rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms helps buyers clarify shipping, insurance, and delivery responsibilities, which is essential for smooth transactions, especially in cross-border deals.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the automotive leather market, lead times can vary based on the supplier and the complexity of the order. Knowing lead times helps buyers plan production schedules and manage customer expectations effectively.

By grasping these technical properties and trade terms, B2B buyers can navigate the automotive leather market with confidence, ensuring they select the right materials and partners for their business needs.

Illustrative image related to automotive leather material

Navigating Market Dynamics and Sourcing Trends in the automotive leather material Sector

What are the Key Market Dynamics and Trends in the Automotive Leather Material Sector?

The automotive leather material sector is experiencing significant growth driven by a variety of global factors. Increasing consumer demand for premium vehicle interiors, particularly in markets such as Europe and the Middle East, is pushing manufacturers to incorporate high-quality leather into their designs. Moreover, the rise of electric vehicles (EVs) has created opportunities for innovative upholstery solutions, as manufacturers seek to enhance the aesthetic and functional aspects of these vehicles. In regions like Africa and South America, there is a burgeoning middle class eager for luxury goods, including leather interiors, which further fuels market expansion.

Emerging B2B technology trends are reshaping sourcing processes in this sector. Digital platforms and e-commerce solutions are enabling international buyers to access a wider range of suppliers and products, streamlining the procurement process. Additionally, advancements in artificial intelligence and data analytics are helping businesses predict market trends and consumer preferences, allowing for more informed decision-making. Buyers should leverage these technologies to enhance their sourcing strategies and optimize their supply chains.

Furthermore, the industry is witnessing a shift towards customization. Buyers are increasingly looking for unique leather options tailored to specific vehicle models and consumer preferences. This trend emphasizes the importance of establishing strong relationships with suppliers who can provide diverse product offerings, from various leather types and colors to specialized finishes that meet the aesthetic and functional demands of modern vehicles.

How are Sustainability and Ethical Sourcing Impacting the Automotive Leather Material Sector?

Sustainability is becoming a pivotal concern for B2B buyers in the automotive leather sector. The environmental impact of leather production, including water usage and chemical processes, has drawn scrutiny, leading to a demand for more sustainable practices. Buyers are increasingly prioritizing suppliers who adhere to environmentally friendly processes and utilize sustainable raw materials. This shift is particularly relevant for international markets that are instituting stricter regulations around environmental practices.

Ethical sourcing is also gaining prominence, as consumers become more conscious of the origins of the materials used in their vehicles. B2B buyers should seek suppliers who can demonstrate transparency in their supply chains, ensuring that leather is sourced from farms and tanneries that prioritize animal welfare and fair labor practices. Certifications such as the Leather Working Group (LWG) certification can serve as a benchmark for ethical sourcing, giving buyers confidence in their procurement decisions.

In response to these trends, many suppliers are investing in “green” certifications and eco-friendly materials, such as vegetable-tanned leather, which is less harmful to the environment. By choosing suppliers who are committed to sustainability and ethical sourcing, B2B buyers not only enhance their brand reputation but also contribute positively to the environment and society.

What is the Historical Context of Automotive Leather Material?

The use of leather in automotive applications dates back to the early 20th century, when luxury automobiles began incorporating leather upholstery as a symbol of opulence and comfort. Initially, the leather used was predominantly sourced from cattle, and the quality varied significantly based on regional practices in tanning and finishing.

Over the decades, the automotive leather industry has evolved significantly. Advances in tanning technology have improved the durability and aesthetic appeal of leather, making it a staple in modern vehicles. By the late 20th century, the introduction of synthetic alternatives began to challenge traditional leather, but the unique qualities of genuine leather—such as its breathability and luxurious feel—have kept it in demand.

Today, the automotive leather market is characterized by a blend of tradition and innovation, with a focus on sustainability and customization reflecting the changing preferences of consumers and manufacturers alike. For B2B buyers, understanding this historical context is crucial for navigating the current landscape and making informed sourcing decisions.

Illustrative image related to automotive leather material

Frequently Asked Questions (FAQs) for B2B Buyers of automotive leather material

-

How do I choose the right automotive leather supplier?

Selecting the right supplier for automotive leather involves several key steps. First, assess the supplier’s reputation through reviews and industry recommendations. Verify their certifications and quality control processes to ensure they meet international standards. Additionally, request samples to evaluate the leather’s quality, durability, and finish. Consider their ability to meet your specific needs regarding customization, minimum order quantities (MOQ), and delivery timelines. Engaging in direct communication can also help establish a rapport and clarify any concerns regarding pricing and support. -

What types of automotive leather are best for different applications?

For automotive upholstery, full-grain and top-grain leather are the best choices due to their durability and luxurious appearance. Full-grain leather offers the highest quality, retaining the natural texture and breathability, making it ideal for high-end vehicles. Top-grain leather, while slightly less durable, is easier to clean and maintain, suitable for family cars. For specific applications like steering wheels or dashboards, consider perforated leather for breathability or suede for a soft touch. Always match the leather type to your vehicle’s intended use and aesthetic requirements. -

What are typical minimum order quantities (MOQ) for automotive leather?

Minimum order quantities for automotive leather can vary widely among suppliers. Generally, MOQs can range from half a hide (approximately 25 square feet) to several hides depending on the supplier and product type. It’s essential to clarify these details during your initial discussions. Some suppliers may be flexible with smaller orders, especially for new customers or specific projects. Ensure that you understand the implications of MOQs on pricing and shipping costs to make informed purchasing decisions. -

How do I ensure the quality of automotive leather products?

To ensure the quality of automotive leather, request certification documents that guarantee compliance with industry standards, such as ISO or other relevant quality marks. Conduct a thorough inspection of the leather samples for texture, color consistency, and any visible defects. It’s advisable to inquire about the tanning process used, as this can affect durability and maintenance. Establishing a quality assurance process with your supplier can help monitor production quality and address any issues proactively. -

What payment terms should I expect when sourcing automotive leather internationally?

Payment terms can vary significantly depending on the supplier’s policies and your negotiation outcomes. Common practices include advance payments, letters of credit, or net 30/60/90 days. For first-time transactions, suppliers may request a larger upfront payment to mitigate risk. Ensure clarity on payment methods accepted, including wire transfers or online payment platforms. Discussing payment terms upfront can help prevent misunderstandings and facilitate a smoother transaction process. -

What should I consider regarding logistics when importing automotive leather?

Logistics play a critical role in the timely delivery of automotive leather. Consider the shipping methods available (air freight vs. sea freight) and their associated costs and transit times. Verify the supplier’s ability to handle customs clearance and documentation, as this can affect delivery timelines. Additionally, understand the potential for tariffs or import duties based on your country’s regulations. Working with a logistics partner experienced in handling such imports can streamline the process and mitigate delays. -

How can I customize automotive leather for my specific needs?

Customization options for automotive leather can include color, texture, and finishes. Many suppliers offer a range of colors and styles, allowing you to tailor the leather to match your vehicle’s interior design. Discuss your specific needs with the supplier, as they may offer custom dyeing or embossing services. Be prepared to provide design specifications or samples for reference. Understanding the minimum order quantities for customized products is also crucial, as this can affect your overall costs and timelines. -

What are the advantages of using genuine leather over synthetic alternatives?

Genuine leather offers numerous advantages over synthetic alternatives, particularly in terms of durability, comfort, and aesthetic appeal. It is more resistant to wear and tear, making it suitable for high-traffic areas like car interiors. Genuine leather provides better breathability, enhancing comfort during long drives. Additionally, it ages gracefully, developing a unique patina over time, which adds character. While synthetic options may be more economical, they often lack the luxury feel and longevity of genuine leather, making it a worthwhile investment for quality automotive interiors.

Top 6 Automotive Leather Material Manufacturers & Suppliers List

1. Leather Hide Store – Quality Auto Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Quality auto upholstery leather available for aftermarket use. Key product lines include: Essentials Line (durable, soft, and supple), Market Street (smooth, buttery feel, rich color), Urban (heavier weight, extra luxurious), and Dakota (high performance distressed leathers). Noted for color fastness and UV resistance. Options for perforated leather available. Special note: these are aftermarket a…

2. BuyLeatherOnline – Premium Automotive Leather

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: Leather for Car Seats and Automotive: Premium automotive leather designed for car interiors, including seats, dashboards, and door panels. Key features include:

– Exceptional durability and aesthetic appeal

– Enhanced comfort with soft and supple texture

– Resistance to spills, stains, and abrasions

– Easy maintenance for long-lasting beauty

– Available in various types, colors, and textures suita…

3. Relicate – Full Grain Leather Options

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: Full Grain Leather options include Solid Color Leather, Nappa Italia Leather, Napali Leather, and various Black Leather types. OEM Auto Leather Colors are available for brands like BMW®, Ferrari®, Lamborghini®, Porsche®, Rolls Royce®, and American Cars. The collection features Distressed & Heritage Leather types such as Legacy Distressed Leather, Heritage Hide Leather, and various Matte, Vintage, …

4. Hydes Leather – Automotive, Marine & Aviation Leather

Domain: hydesleather.com

Registered: 2006 (19 years)

Introduction: Hydes Leather offers a diverse collection of automotive, marine, and aviation leather, including:

– Automotive Leather: Astro Bomber, Distressed Buffalo, OEM Leather, Pelle Fresco, Prima Nappa, Roser 2 Tone, Royal Steering Wheel Leather, Thema Vintage, Vintage OEM Leather, Vision Woven Leather.

– Alcantara Products: Automotive Alcantara Cover (backed), Panel (unbacked), Multilayer (steering wheel…

5. Midwest Fabrics – Upholstery Leather

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Introduction: Upholstery Leather: Art of Sophistication

6. Apex Leather – Auto Upholstery Supplies

Domain: apexleather.com

Registered: 2005 (20 years)

Introduction: Apex Leather offers a variety of auto upholstery supplies including high performance auto leather, square weave carpet, microsuede, and thread. The leather options include smooth grain leather, distressed leather, natural grain leather, and heavyweight leather. Services provided include CNC panels, CNC perforation, and custom color matching. Apex Leather is known for its quality and service, cater…

Strategic Sourcing Conclusion and Outlook for automotive leather material

In conclusion, the strategic sourcing of automotive leather material presents a unique opportunity for international buyers seeking to enhance their product offerings. By understanding the diverse types of leather available and their specific applications—from seats to dashboards—buyers can make informed decisions that align with both aesthetic and functional requirements. Prioritizing high-quality, durable leather not only elevates the perceived value of vehicles but also ensures longevity and customer satisfaction.

Establishing strong relationships with reputable suppliers and leveraging diverse sourcing strategies will be essential in navigating the complexities of the global leather market. This approach will empower buyers from Africa, South America, the Middle East, and Europe to access premium materials while optimizing costs and maintaining quality.

As the automotive industry continues to evolve, embracing innovative sourcing solutions will be crucial. International B2B buyers are encouraged to stay ahead of market trends, explore sustainable sourcing options, and invest in leather that not only meets current demands but also anticipates future consumer preferences. The time to act is now—position your business for success by strategically sourcing automotive leather that will define the next generation of luxury and comfort in vehicle interiors.

Illustrative image related to automotive leather material

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.