Introduction: Navigating the Global Market for car upholstery fabric suppliers

In the dynamic landscape of the automotive industry, sourcing high-quality car upholstery fabric suppliers can present significant challenges for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe—such as Germany or Nigeria—finding the right materials that meet both aesthetic and functional requirements is crucial. This guide addresses the complexities of navigating the global market by offering insights into the diverse types of automotive fabrics, their applications, and the essential criteria for selecting reputable suppliers.

Our comprehensive resource covers various fabric options, including durable vinyls, luxurious velvets, and specialty materials designed for specific automotive needs. We delve into critical factors such as supplier vetting processes, cost considerations, and compliance with international safety standards. By equipping buyers with actionable knowledge, this guide empowers you to make informed purchasing decisions that align with your project goals and budget constraints.

As you explore this guide, you will gain a clearer understanding of how to effectively source upholstery materials that not only enhance vehicle interiors but also meet the demands of your target market. From vintage restorations to modern designs, our insights will help you navigate the complexities of the upholstery fabric landscape, ensuring you select the best suppliers for your business needs.

Table Of Contents

- Top 8 Car Upholstery Fabric Suppliers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car upholstery fabric suppliers

- Understanding car upholstery fabric suppliers Types and Variations

- Key Industrial Applications of car upholstery fabric suppliers

- 3 Common User Pain Points for ‘car upholstery fabric suppliers’ & Their Solutions

- Strategic Material Selection Guide for car upholstery fabric suppliers

- In-depth Look: Manufacturing Processes and Quality Assurance for car upholstery fabric suppliers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car upholstery fabric suppliers’

- Comprehensive Cost and Pricing Analysis for car upholstery fabric suppliers Sourcing

- Alternatives Analysis: Comparing car upholstery fabric suppliers With Other Solutions

- Essential Technical Properties and Trade Terminology for car upholstery fabric suppliers

- Navigating Market Dynamics and Sourcing Trends in the car upholstery fabric suppliers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car upholstery fabric suppliers

- Strategic Sourcing Conclusion and Outlook for car upholstery fabric suppliers

- Important Disclaimer & Terms of Use

Understanding car upholstery fabric suppliers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vinyl Upholstery | Durable, waterproof, easy to clean, available in various colors | Automotive interiors, marine, furniture | Pros: Cost-effective, low maintenance. Cons: Can be less breathable, may crack over time. |

| Fabric Upholstery | Soft texture, variety of patterns, available in natural and synthetic fibers | High-end automotive, custom vehicles | Pros: Comfortable, aesthetic appeal. Cons: Higher maintenance, may stain easily. |

| Leather Upholstery | Premium feel, luxurious appearance, durable and age well | Luxury vehicles, classic car restorations | Pros: Long-lasting, easy to clean. Cons: Higher cost, requires regular conditioning. |

| Suede & Velvet | Soft, plush texture, available in a range of colors | High-end automotive, specialty vehicles | Pros: Elegant appearance, comfortable. Cons: Requires careful maintenance, can be more expensive. |

| Nylon & Polyester Blends | Strong, resistant to wear and tear, often treated for stain resistance | Fleet vehicles, commercial automotive | Pros: Durable, versatile. Cons: Can be less comfortable than natural fabrics. |

What are the Characteristics of Vinyl Upholstery for B2B Buyers?

Vinyl upholstery is a practical choice for businesses seeking durable and low-maintenance solutions. Its waterproof nature makes it ideal for automotive interiors and marine applications, where spills and exposure to the elements are common. B2B buyers should consider the variety of colors and textures available, allowing for customization to fit branding or aesthetic needs. However, it’s essential to be aware that while vinyl is cost-effective, it may lack breathability and can crack with prolonged exposure to sunlight.

How Does Fabric Upholstery Stand Out in the Automotive Industry?

Fabric upholstery offers a soft, inviting texture that appeals to consumers looking for comfort and style in automotive interiors. Available in various natural and synthetic fibers, this type of upholstery can be tailored to match the specific needs of high-end vehicles or custom projects. Buyers should note that while fabric provides aesthetic flexibility and comfort, it typically requires more maintenance to keep it looking new, especially in high-traffic areas.

Why Choose Leather Upholstery for Luxury Vehicles?

Leather upholstery is synonymous with luxury and sophistication, making it a preferred choice for high-end automotive applications. Its durability and ability to age gracefully add to its allure, appealing to buyers focused on long-term investment. B2B buyers should consider the higher upfront costs and the need for regular conditioning to maintain the material’s integrity. However, the ease of cleaning and timeless appeal often justify the investment in premium leather.

What Are the Benefits of Suede & Velvet Upholstery in Specialty Vehicles?

Suede and velvet upholstery provide a unique, plush texture that enhances the aesthetic appeal of high-end and specialty vehicles. These fabrics are available in a range of colors and can create a luxurious ambiance. B2B buyers should be aware that while these materials offer comfort and elegance, they require careful maintenance to prevent staining and damage. Their higher price point may also be a consideration when budgeting for projects.

How Do Nylon & Polyester Blends Serve Commercial Automotive Needs?

Nylon and polyester blends are designed for durability and resistance to wear, making them ideal for fleet vehicles and commercial automotive applications. Their stain-resistant properties are particularly beneficial for environments where maintenance resources are limited. B2B buyers will appreciate the versatility and strength of these materials, though they may sacrifice some comfort compared to natural fibers. The affordability and longevity of these blends can provide excellent value for businesses focused on cost-efficiency.

Key Industrial Applications of car upholstery fabric suppliers

| Industry/Sector | Specific Application of car upholstery fabric suppliers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of car interiors and seats | Enhances vehicle aesthetics and comfort | Compliance with safety regulations and durability standards |

| Automotive Restoration | Vintage car upholstery restoration | Preserves historical value and authenticity | Availability of specialty materials and color matching |

| RV and Marine Industry | Upholstery for recreational vehicles and boats | Provides durability against environmental factors | Water resistance and UV stability of fabrics |

| Commercial Vehicle Production | Upholstery for trucks and buses | Improves passenger comfort and vehicle lifespan | Bulk purchasing options and customizability |

| Automotive Aftermarket | Custom upholstery solutions for enthusiasts | Tailored design and improved user experience | Variety of fabrics and patterns to meet diverse needs |

How Are Car Upholstery Fabric Suppliers Used in Automotive Manufacturing?

In the automotive manufacturing sector, car upholstery fabric suppliers play a vital role in producing interiors and seats that not only enhance aesthetics but also ensure passenger comfort. Suppliers provide a range of materials, such as high-quality polyester and vinyl, which meet stringent safety and durability standards. For international buyers, particularly from regions like Europe and Africa, understanding local regulations regarding flame retardancy and environmental impact is crucial. Suppliers must offer fabrics that comply with international safety certifications to facilitate smooth market entry.

What Role Do Car Upholstery Fabric Suppliers Play in Automotive Restoration?

For businesses involved in automotive restoration, particularly those focused on vintage vehicles, car upholstery fabric suppliers are indispensable. These suppliers provide specialty fabrics that match the original materials used in classic cars, preserving their historical value and authenticity. Buyers in South America and the Middle East may seek unique textures or patterns specific to regional tastes, making it essential for suppliers to offer customizable options. The challenge lies in sourcing rare fabrics that align with the original specifications while maintaining quality and durability.

How Are Car Upholstery Fabric Suppliers Essential in the RV and Marine Industry?

In the RV and marine industry, car upholstery fabric suppliers offer materials that withstand harsh environmental conditions, including UV exposure and moisture. Fabrics must be durable and easy to clean, catering to the lifestyle needs of recreational vehicle users and boat owners. For buyers from regions with extreme weather, such as the Middle East, sourcing water-resistant and UV-stabilized fabrics is crucial for ensuring longevity and customer satisfaction. Suppliers need to demonstrate their products’ resilience to potential environmental hazards.

Illustrative image related to car upholstery fabric suppliers

Why Are Car Upholstery Fabric Suppliers Important for Commercial Vehicle Production?

Commercial vehicle manufacturers rely heavily on car upholstery fabric suppliers to enhance passenger comfort in trucks and buses. Upholstery choices can significantly influence the user experience, making it essential for suppliers to provide durable and aesthetically pleasing options. For international buyers, particularly in emerging markets like Nigeria, understanding the balance between cost-effectiveness and quality is vital. Suppliers should offer bulk purchasing options and custom designs to meet the specific needs of commercial vehicle applications.

How Do Car Upholstery Fabric Suppliers Cater to the Automotive Aftermarket?

In the automotive aftermarket, car upholstery fabric suppliers provide custom solutions for enthusiasts looking to personalize their vehicles. This sector values unique designs and high-quality materials that enhance user experience and vehicle aesthetics. For buyers from Europe and Africa, the availability of diverse fabric options and patterns is paramount. Suppliers must be equipped to handle small batch orders while ensuring consistency in quality and color matching to meet the varied demands of individual consumers and small businesses alike.

3 Common User Pain Points for ‘car upholstery fabric suppliers’ & Their Solutions

Scenario 1: Sourcing Quality Materials Across Borders

The Problem:

B2B buyers often struggle with sourcing high-quality car upholstery fabrics from suppliers located in different regions. This challenge is particularly pronounced for international buyers in Africa, South America, the Middle East, and Europe who may face language barriers, differing quality standards, and varying import regulations. Buyers are concerned about the durability, safety certifications, and aesthetic appeal of the materials, making it crucial to ensure that the products meet their specific requirements while also navigating the complexities of international shipping and customs.

The Solution:

To effectively source quality materials, buyers should establish clear communication with suppliers about their specific needs, including fabric specifications, certifications, and sample requests. It is advisable to request samples of the fabrics before committing to large orders, as this allows buyers to assess the quality firsthand. Additionally, utilizing platforms that provide reviews and ratings can help in identifying reputable suppliers. Building a strong relationship with a local representative or agent can also facilitate smoother communication and negotiation, ensuring that all aspects of the transaction are transparent and satisfactory.

Illustrative image related to car upholstery fabric suppliers

Scenario 2: Navigating Compliance and Safety Regulations

The Problem:

Another significant pain point for B2B buyers is the challenge of ensuring compliance with local and international safety regulations for automotive fabrics. Different regions have specific requirements regarding flame retardancy, UV resistance, and environmental impact. For example, buyers in Europe may need to adhere to stringent EU regulations, while those in the Middle East might have different standards. Failure to meet these regulations can lead to costly fines, product recalls, and damage to the brand’s reputation.

The Solution:

Buyers should proactively educate themselves about the relevant regulations in their target markets. This includes understanding the specific safety standards required for automotive fabrics, such as the FMVSS 302 in the U.S. or the EN 1021 in Europe. Collaborating with suppliers who are knowledgeable about these regulations and can provide the necessary certifications is crucial. Additionally, buyers should consider integrating compliance checks into their procurement process, requiring suppliers to submit documentation verifying that their products meet the applicable standards. Regular audits and product testing can further ensure ongoing compliance.

Scenario 3: Managing Inventory and Supply Chain Disruptions

The Problem:

Supply chain disruptions are a common concern for B2B buyers, particularly in the context of global events like pandemics or geopolitical tensions. Buyers may face delays in receiving their upholstery materials, leading to project setbacks and increased costs. Additionally, managing inventory levels can be challenging when suppliers have inconsistent lead times or limited stock availability, making it difficult to fulfill customer orders promptly.

The Solution:

To mitigate these risks, buyers should diversify their supplier base and avoid reliance on a single source. Establishing relationships with multiple suppliers can create a buffer against disruptions. Implementing a just-in-time inventory system can also help manage stock levels more efficiently, ensuring that materials arrive as needed without overstocking. It is beneficial to maintain open lines of communication with suppliers to stay informed about potential delays and stock availability. Furthermore, investing in inventory management software can provide real-time insights into stock levels and help forecast future needs, enabling buyers to make informed purchasing decisions.

Strategic Material Selection Guide for car upholstery fabric suppliers

What Are the Key Properties of Common Upholstery Materials for Car Interiors?

When selecting upholstery materials for automotive applications, several factors come into play, including durability, comfort, and compliance with industry standards. Here, we analyze four common materials used in car upholstery: Polyester, Vinyl, Leather, and Nylon.

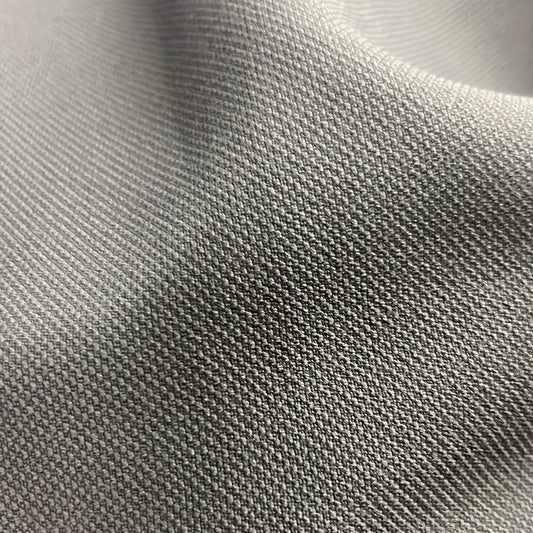

How Does Polyester Perform as an Upholstery Material?

Polyester is a synthetic fabric known for its durability and resistance to abrasion. It typically has a high temperature tolerance and is resistant to shrinking and stretching. Polyester fabrics are often treated to enhance their flame retardancy, making them suitable for automotive applications.

Pros: Polyester is relatively inexpensive and offers a wide range of colors and patterns, making it versatile for various designs. Its durability ensures that it can withstand the wear and tear of daily use.

Cons: While polyester is durable, it may not offer the same level of luxury or comfort as natural fibers like leather. Additionally, it can be less breathable, which may affect comfort in hotter climates.

International Considerations: Buyers from regions like Africa and the Middle East should ensure that the polyester fabrics meet local flame retardancy standards, such as those set by ASTM or DIN.

What Advantages Does Vinyl Offer for Automotive Upholstery?

Vinyl is a popular choice for car interiors due to its water resistance and ease of cleaning. It is a synthetic material that mimics leather but is typically more affordable. Vinyl upholstery can also be treated for UV resistance, making it suitable for vehicles exposed to direct sunlight.

Pros: Its low maintenance and resistance to stains make vinyl an attractive option for families and commercial vehicles. Additionally, it is available in various textures and colors.

Cons: Vinyl can be less breathable than other materials, leading to discomfort in hot weather. Over time, it may crack or fade if not properly maintained.

International Considerations: In regions like South America, where humidity can be high, it’s crucial to choose vinyl that has been treated for moisture resistance to ensure longevity.

Illustrative image related to car upholstery fabric suppliers

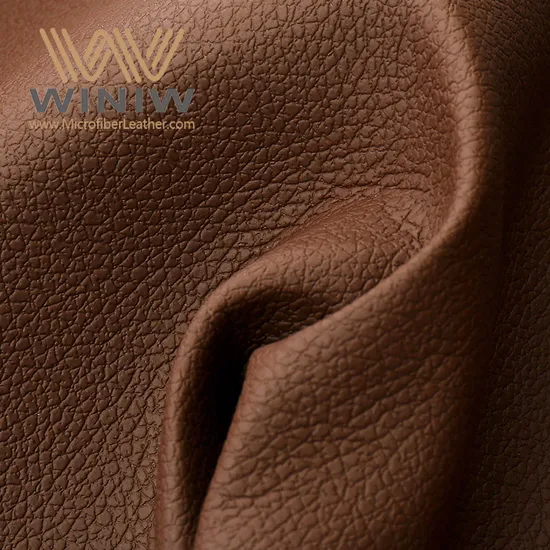

Why Is Leather Considered a Premium Upholstery Material?

Leather is often regarded as the luxury choice for car interiors. It provides a high-end appearance and is generally more breathable than synthetic options. Leather can withstand significant wear and tear and can be treated for additional protection against stains and spills.

Pros: The aesthetic appeal and comfort of leather make it a preferred choice for high-end vehicles. It also ages well, developing a unique patina over time.

Cons: Leather is more expensive than synthetic materials and requires regular maintenance to keep it looking its best. It can also be sensitive to temperature changes, potentially leading to cracking if not cared for properly.

International Considerations: Buyers in Europe, particularly in countries like Germany, should ensure that leather products comply with EU regulations concerning animal welfare and chemical treatments.

How Does Nylon Compare as an Upholstery Material?

Nylon is another synthetic option that offers excellent durability and resistance to abrasion. It is often used in automotive applications where strength and resilience are paramount. Nylon can also be treated for stain resistance, making it suitable for various environments.

Pros: Its strength and elasticity make nylon a great choice for high-traffic areas in vehicles. It is also lightweight and can be dyed easily, allowing for a wide range of design options.

Cons: Nylon can be more expensive than polyester and may not provide the same level of comfort or luxury as leather. Additionally, it can be prone to fading if exposed to direct sunlight for extended periods.

International Considerations: Buyers from Africa and the Middle East should verify that nylon upholstery meets local standards for UV resistance, particularly in regions with high sun exposure.

Summary of Material Selection for Car Upholstery

| Material | Typical Use Case for car upholstery fabric suppliers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General automotive upholstery | Durable and cost-effective | Less breathable than natural fibers | Low |

| Vinyl | Budget-friendly automotive interiors | Easy to clean and maintain | Can crack and fade over time | Low |

| Leather | Luxury automotive interiors | High-end appearance and comfort | Expensive and requires maintenance | High |

| Nylon | High-traffic automotive areas | Excellent durability | Can fade and is more costly | Medium |

This guide aims to provide B2B buyers with a comprehensive understanding of the materials available for automotive upholstery, enabling informed purchasing decisions tailored to their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for car upholstery fabric suppliers

What Are the Main Stages in the Manufacturing Process of Car Upholstery Fabrics?

The manufacturing process of car upholstery fabrics is a multi-step operation that involves careful planning and execution to ensure high-quality outcomes. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting the appropriate raw materials, such as polyester, nylon, or vinyl, based on the desired properties of the final product. Suppliers often source high-grade fibers that meet specific criteria for durability, flame resistance, and aesthetic appeal. This stage may also involve dyeing and treating the materials to enhance colorfastness and other characteristics.

-

Forming: In this stage, the prepared materials are cut into the required shapes and sizes, often using advanced cutting technology such as laser or die cutting. This process is critical to ensure precision and consistency in the fabric pieces that will be used in automotive interiors.

-

Assembly: After the materials are cut, they are sewn or bonded together to form larger pieces that will fit into the car’s interior. This stage may involve various techniques such as stitching, welding, or gluing, depending on the fabric type and design specifications. Quality control at this stage is crucial to ensure that seams are strong and that the fabric meets aesthetic standards.

-

Finishing: The final stage includes treatments that enhance the fabric’s properties, such as applying protective coatings for UV resistance, stain resistance, or anti-microbial properties. This process may also involve additional dyeing or printing to achieve the desired look and feel.

How Is Quality Assurance Implemented in Car Upholstery Fabric Manufacturing?

Quality assurance is vital in the automotive industry, where safety and durability are paramount. Suppliers adhere to international standards and industry-specific regulations to ensure their products meet the highest quality benchmarks.

-

International Standards: Suppliers often comply with ISO 9001, which outlines the requirements for a quality management system. This certification ensures that the manufacturer has processes in place for consistent product quality, which is crucial for B2B buyers looking for reliable suppliers.

-

Industry-Specific Standards: In addition to ISO certifications, upholstery fabrics may need to meet specific industry standards such as CE marking for safety or API specifications for materials used in automotive applications. These standards ensure that the fabrics can withstand the rigors of automotive use, including exposure to sunlight, heat, and moisture.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and rectify defects early. Common checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival at the manufacturing facility. Suppliers check for compliance with specifications, including material properties and certifications. This ensures that only high-quality materials enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process. This may involve checking dimensions, seam strength, and adherence to design specifications. IPQC helps catch defects early, reducing waste and ensuring that products meet quality standards.

-

Final Quality Control (FQC): Once the manufacturing process is complete, a comprehensive inspection is conducted on the finished products. This includes testing for durability, colorfastness, flame retardancy, and other relevant characteristics. Only products that pass this final inspection are approved for shipment.

What Testing Methods Are Commonly Used for Car Upholstery Fabrics?

Testing is a critical aspect of quality assurance, particularly for automotive applications. Common testing methods include:

-

Abrasion Resistance Testing: This assesses how well the fabric can withstand wear and tear over time, often measured using the Martindale or Taber abrasion tests.

-

Flame Retardancy Testing: Fabrics are subjected to specific flame tests to ensure they meet safety standards, such as MVSS302 or California T.B. 117.

-

Colorfastness Testing: This evaluates how well the fabric retains its color when exposed to light, washing, or rubbing. Tests like the AATCC 16 are commonly used.

-

Tensile Strength Testing: This measures the fabric’s strength and durability, crucial for ensuring that upholstery can withstand everyday use without tearing.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are some actionable steps:

-

Supplier Audits: Conducting regular audits of the supplier’s manufacturing facilities can provide insights into their quality control practices. This includes reviewing their documentation, inspection processes, and compliance with international standards.

-

Quality Reports: Request detailed quality reports from suppliers that outline their testing methods, results, and adherence to industry standards. This documentation can help buyers assess the reliability of the fabrics.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspections can verify compliance with relevant standards and identify potential issues before products are shipped.

-

Certifications and Accreditations: Buyers should look for suppliers with recognized certifications, such as ISO 9001, to ensure adherence to quality management practices. Additionally, industry-specific certifications can provide further assurance of product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances when dealing with quality control in different markets. Some considerations include:

Illustrative image related to car upholstery fabric suppliers

-

Regional Standards: Different regions may have specific regulations regarding textile quality and safety. Buyers should familiarize themselves with local standards in their target markets to ensure compliance.

-

Cultural Expectations: Understanding cultural expectations regarding quality and durability can influence purchasing decisions. For instance, buyers from Germany may prioritize stringent quality standards, while those from Nigeria may focus on cost-effectiveness.

-

Logistical Challenges: International shipping can complicate quality assurance. Buyers should establish clear communication channels with suppliers to address any quality concerns promptly, especially if discrepancies arise post-shipment.

By understanding the manufacturing processes and quality assurance measures employed by car upholstery fabric suppliers, B2B buyers can make informed decisions that ensure the success of their projects and maintain high standards in automotive interiors.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car upholstery fabric suppliers’

In the competitive landscape of car upholstery fabric procurement, having a structured approach is essential for B2B buyers aiming to source quality materials. This guide serves as a comprehensive checklist to streamline the sourcing process, ensuring that you engage with reputable suppliers who can meet your specific needs.

Step 1: Define Your Technical Specifications

Understanding the requirements of your project is the foundation of effective sourcing. Clearly outline the types of fabrics you need, including characteristics such as durability, flame retardancy, and UV resistance. For instance, automotive fabrics should meet specific standards like MVSS302 for flame retardancy and possess high abrasion resistance to withstand wear and tear.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in automotive upholstery fabrics. Use industry directories, trade shows, and online platforms to compile a list of candidates. Pay attention to their market reputation, history, and the variety of materials they offer, ensuring they align with your technical specifications.

Step 3: Evaluate Supplier Certifications

Verify that the suppliers hold necessary certifications relevant to the automotive industry. Look for compliance with international standards and local regulations, as this indicates their commitment to quality and safety. Certifications such as ISO 9001 or specific automotive standards can serve as a benchmark for reliability.

Step 4: Request Samples

Before making a bulk purchase, request fabric samples to assess quality firsthand. Evaluate the textures, colors, and patterns to ensure they meet your aesthetic and functional requirements. This step is crucial as it allows you to perform tests for durability, colorfastness, and ease of maintenance.

Step 5: Check References and Reviews

Engage with previous clients or seek out reviews to gain insights into the supplier’s reliability and customer service. Ask for case studies or testimonials from companies in similar industries or regions, which can provide a clearer picture of their operational capabilities and responsiveness.

Step 6: Discuss Pricing and Payment Terms

Once you have shortlisted suppliers, initiate discussions on pricing structures and payment terms. Ensure that you understand the total costs, including shipping and any potential tariffs, especially when dealing with international suppliers. Negotiate terms that align with your budget while maintaining a focus on quality.

Step 7: Finalize the Contract

After selecting a supplier, carefully review and finalize the contract. Ensure that all terms, including delivery timelines, quality assurances, and after-sales support, are clearly documented. This step protects both parties and establishes a solid framework for your business relationship.

By following these steps, you will be better equipped to navigate the complexities of sourcing car upholstery fabrics, ensuring that you partner with suppliers who can deliver quality products that meet your specific needs.

Comprehensive Cost and Pricing Analysis for car upholstery fabric suppliers Sourcing

What Are the Key Cost Components in Sourcing Car Upholstery Fabrics?

When sourcing car upholstery fabrics, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of fabric significantly impacts pricing. Common materials such as polyester, vinyl, and nylon vary in cost based on quality and durability. Fabrics with enhanced properties, such as flame retardancy and UV resistance, typically command higher prices.

-

Labor: Labor costs are influenced by the complexity of the fabric’s manufacturing process. Customizations such as unique patterns or specific thread counts can increase labor requirements, affecting overall costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Suppliers with advanced manufacturing technologies may offer higher quality at a premium price due to lower overhead costs.

-

Tooling: Custom tooling for specific fabric designs or patterns can add to initial costs. However, suppliers might amortize these costs over large production runs, which can lower the price per unit in bulk orders.

-

Quality Control (QC): Rigorous quality control processes ensure product reliability and compliance with industry standards. Suppliers investing in robust QC measures may charge higher prices but provide better assurance of product performance.

-

Logistics: Transportation and warehousing costs are significant, especially for international shipments. The choice of shipping methods and routes can affect lead times and costs. Understanding the logistics involved can help buyers optimize their supply chain.

-

Margin: Suppliers typically incorporate a margin that reflects their business model, market positioning, and risk factors. Buyers should consider this margin when evaluating supplier quotes.

How Do Price Influencers Affect Car Upholstery Fabric Sourcing?

Several factors can influence the pricing of car upholstery fabrics, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to significant discounts. Suppliers are more willing to negotiate prices when buyers commit to larger quantities, reducing the per-unit cost.

-

Specifications and Customization: Custom fabric specifications, such as unique colors, patterns, or technical requirements, can increase costs. Buyers should assess whether customization aligns with their needs and budget.

-

Material Quality and Certifications: Fabrics that meet specific industry certifications, such as flame retardancy or eco-friendliness, may carry higher price tags. Buyers should weigh the benefits of these certifications against their project requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings can influence pricing. Established suppliers with a proven track record may charge a premium, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of trade (Incoterms) is crucial for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall costs.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing?

To optimize costs and ensure a successful procurement process, consider the following tips:

-

Negotiation: Engage in open discussions with suppliers to explore pricing flexibility. Highlighting potential for long-term partnerships can encourage suppliers to offer better terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, shipping, tariffs, and potential downtime due to quality issues. A lower upfront cost may lead to higher long-term costs if the fabric does not perform as expected.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local market conditions that can affect final prices. Establishing relationships with local agents can provide valuable insights and help navigate these complexities.

-

Research and Comparison: Conduct thorough research on multiple suppliers to compare prices, quality, and service levels. This can help in identifying the best value for your specific needs.

Conclusion

Sourcing car upholstery fabrics requires a comprehensive understanding of cost components and pricing influencers. By being informed and strategic, international B2B buyers can make decisions that enhance their supply chain efficiency while ensuring product quality. Always remember that indicative prices can vary based on multiple factors, so thorough due diligence is essential for successful procurement.

Alternatives Analysis: Comparing car upholstery fabric suppliers With Other Solutions

Exploring Alternative Solutions for Car Upholstery Needs

In the competitive landscape of car upholstery, buyers often seek various solutions that can meet their specific project requirements. While traditional car upholstery fabric suppliers offer a wide range of materials, exploring alternative solutions can provide additional options tailored to unique needs. This analysis compares car upholstery fabric suppliers with two viable alternatives: custom upholstery services and synthetic leather technologies.

| Comparison Aspect | Car Upholstery Fabric Suppliers | Custom Upholstery Services | Synthetic Leather Technologies |

|---|---|---|---|

| Performance | High durability and variety of textures | Tailored fit and design, high quality | Water-resistant, easy to clean |

| Cost | Moderate to high, depending on material | Generally higher due to labor and customization | Often lower than premium fabrics but varies |

| Ease of Implementation | Requires sourcing and inventory management | Requires lead time for design and production | Simple installation, often DIY-friendly |

| Maintenance | Regular cleaning needed; varies by fabric | Depends on material choice; generally easy | Low maintenance; resistant to stains |

| Best Use Case | Bulk purchases for manufacturers or restorers | Unique projects requiring specific design | Cost-effective solution for mass production |

What Are the Advantages and Disadvantages of Custom Upholstery Services?

Custom upholstery services allow buyers to create bespoke designs that perfectly fit their vehicle’s interior. The primary advantage is the ability to match specific aesthetic preferences and functional needs, ensuring a tailored experience. However, this option often comes at a premium price due to the labor involved and longer lead times for production. Custom upholstery is ideal for high-end restorations or unique projects where standard fabric offerings fall short.

How Does Synthetic Leather Compare to Traditional Upholstery Fabrics?

Synthetic leather, or faux leather, presents a modern alternative to traditional upholstery fabrics. Its primary advantages include lower costs and easier maintenance, making it an attractive option for budget-conscious buyers. Synthetic leather is water-resistant and generally more durable against wear and tear, which can be beneficial for high-traffic automotive environments. However, it may lack the luxurious feel and breathability of natural fabrics, which could be a drawback for premium applications. This option is best suited for mass production and projects where cost efficiency is a priority.

Conclusion: How Should B2B Buyers Choose the Right Upholstery Solution?

When selecting the right upholstery solution, B2B buyers should consider their specific project requirements, including budget constraints, desired aesthetics, and performance needs. Traditional car upholstery fabric suppliers provide a robust selection of materials ideal for various applications, while custom upholstery services offer unique, tailored solutions. Synthetic leather technologies serve as a cost-effective alternative, particularly for high-volume production. By weighing these options carefully, buyers can make informed decisions that align with their operational goals and customer expectations.

Illustrative image related to car upholstery fabric suppliers

Essential Technical Properties and Trade Terminology for car upholstery fabric suppliers

What Are the Essential Technical Properties of Car Upholstery Fabrics?

In the automotive upholstery industry, understanding the technical properties of fabrics is crucial for ensuring quality, durability, and compliance with industry standards. Here are some key specifications that B2B buyers should consider:

-

Material Composition

The fabric’s composition—whether it is polyester, nylon, or a blend—affects its performance, durability, and aesthetic appeal. For instance, polyester is often favored for its resistance to wear and fading, making it suitable for high-traffic areas in vehicles. Understanding material composition helps buyers select fabrics that align with their specific application needs, such as luxury interiors or rugged utility vehicles. -

Abrasion Resistance

Measured in double rubs (DR), abrasion resistance quantifies how well a fabric can withstand friction. Fabrics with a rating of 50,000 DR or higher are typically recommended for automotive use, as they can endure frequent use without significant wear. This property is vital for B2B buyers seeking longevity in upholstery, reducing the need for frequent replacements and maintenance. -

Flame Retardancy

Compliance with flame retardancy standards (e.g., MVSS302, California T.B. 117) is essential for automotive fabrics. Fabrics that meet these standards minimize fire risks, thus ensuring safety for passengers. Buyers should verify the flame retardancy certifications of upholstery materials, especially when sourcing for markets with stringent safety regulations. -

Lightfastness

This property measures a fabric’s ability to resist fading when exposed to sunlight. Fabrics with a high lightfastness rating (e.g., 300 hours) are ideal for automotive applications, where sunlight exposure can lead to rapid degradation of color and quality. For B2B buyers, selecting fabrics with strong lightfastness ensures that the aesthetics of the vehicle’s interior remain intact over time. -

Width and Roll Size

Understanding the fabric width (typically ranging from 54″ to 60″) and roll size (commonly 50 yards) is crucial for calculating material requirements for upholstery projects. Accurate measurements help buyers avoid excess waste and manage inventory effectively, ensuring cost-efficiency in production.

What Are the Common Trade Terms in Automotive Upholstery Supply?

Familiarity with industry jargon is essential for navigating the B2B landscape of automotive upholstery. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that may be marketed by another manufacturer. In the context of automotive upholstery, it signifies fabrics produced specifically for car manufacturers. Understanding OEM specifications ensures that buyers source materials compatible with original vehicle designs. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Knowing the MOQ helps buyers assess whether they can meet purchase requirements without overcommitting financially. This is particularly important for smaller companies or startups looking to manage cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers should utilize RFQs to gather competitive pricing and evaluate supplier capabilities, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. These terms clarify who is responsible for shipping, insurance, and tariffs, helping buyers manage logistics and costs effectively when sourcing materials globally. -

Lead Time

This term refers to the time taken from placing an order to the delivery of goods. Understanding lead times is crucial for B2B buyers to plan their production schedules and manage customer expectations effectively.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions that enhance their procurement processes and ensure high-quality outcomes in automotive upholstery projects.

Navigating Market Dynamics and Sourcing Trends in the car upholstery fabric suppliers Sector

What Are the Current Market Dynamics and Key Trends in Car Upholstery Fabric Sourcing?

The global car upholstery fabric market is experiencing significant shifts driven by various factors, including evolving consumer preferences, technological advancements, and sustainability concerns. Notably, the demand for high-quality, durable materials is growing, particularly in regions like Africa, South America, the Middle East, and Europe. Buyers from these regions are increasingly prioritizing fabrics that not only meet aesthetic and functional requirements but also comply with international safety standards, such as flame retardancy and UV stability.

Emerging B2B technologies are reshaping the sourcing landscape. Innovations such as digital fabric sampling and AI-driven inventory management systems are streamlining procurement processes, allowing buyers to efficiently assess material options and manage stock levels. Moreover, the rise of e-commerce platforms enables international buyers to access a broader range of suppliers and materials, enhancing competitive pricing and availability.

Another notable trend is the increasing integration of smart textiles in automotive upholstery, offering features like temperature control and enhanced durability. As vehicle manufacturers seek to differentiate their products, the demand for innovative materials that combine functionality with design is on the rise. Buyers should keep abreast of these developments to leverage opportunities in sourcing high-performance fabrics that cater to modern automotive applications.

How Is Sustainability and Ethical Sourcing Impacting the Car Upholstery Fabric Sector?

Sustainability has become a cornerstone of the automotive industry, with buyers increasingly aware of the environmental impacts of their sourcing decisions. For car upholstery fabric suppliers, this means adopting eco-friendly practices and materials that minimize waste and reduce carbon footprints. Key environmental concerns include the use of non-toxic dyes, recyclable materials, and the reduction of water usage in production processes.

Ethical sourcing is also gaining traction, as consumers demand transparency in supply chains. Suppliers that can demonstrate responsible sourcing practices—such as fair labor conditions and sustainable farming methods—are likely to gain a competitive edge. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming essential for suppliers seeking to establish credibility and trust with international buyers.

Additionally, the push for circular economy practices is prompting suppliers to explore options like upcycled fabrics and biodegradable materials. Buyers from regions like Germany and Nigeria, where environmental regulations are becoming stricter, should prioritize suppliers that offer green certifications and sustainable alternatives to conventional upholstery materials. This not only aligns with global sustainability goals but also enhances brand reputation in increasingly eco-conscious markets.

What Is the Historical Context of the Car Upholstery Fabric Industry?

The car upholstery fabric industry has evolved significantly over the past century. Initially dominated by natural fibers like cotton and wool, the market saw a shift towards synthetic materials in the mid-20th century, driven by advancements in technology and the demand for more durable and versatile fabrics. Innovations such as polyester and nylon became popular due to their resilience and ease of maintenance.

As consumer preferences shifted towards customization and aesthetics, the industry adapted by offering a wider variety of colors, patterns, and textures. In recent years, the focus has expanded to include sustainability and ethical sourcing, reflecting broader societal trends. This evolution highlights the industry’s responsiveness to changing market dynamics and consumer expectations, making it crucial for B2B buyers to stay informed about historical trends to better understand current and future sourcing opportunities.

Illustrative image related to car upholstery fabric suppliers

In summary, the car upholstery fabric sector is navigating a complex landscape shaped by technological advancements, sustainability imperatives, and evolving consumer preferences. By understanding these dynamics, international B2B buyers can make informed decisions that align with both market demands and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of car upholstery fabric suppliers

-

1. How do I choose the right upholstery fabric for automotive applications?

Selecting the right upholstery fabric involves considering factors such as durability, aesthetic appeal, and compliance with safety standards. Look for materials with high abrasion resistance and flame retardancy ratings, particularly those that meet MVSS302 or equivalent standards. Additionally, assess the fabric’s lightfastness to ensure it can withstand exposure to sunlight without fading. Engaging with suppliers that offer a variety of samples can help you make an informed choice tailored to your specific needs. -

2. What are the most common types of upholstery fabrics used in vehicles?

The most common upholstery fabrics for vehicles include polyester, vinyl, and blends that incorporate nylon or polypropylene. Polyester is favored for its durability and ease of maintenance, while vinyl offers excellent waterproofing and is often used for seats. For a touch of luxury, fabrics like suede and velvet are also popular. Ultimately, the best choice will depend on the vehicle type and the intended use, whether it’s for luxury cars, commercial vehicles, or classic restorations. -

3. What minimum order quantities (MOQ) should I expect from upholstery fabric suppliers?

MOQs can vary significantly based on the supplier and the type of fabric. Typically, for upholstery fabrics, you may encounter MOQs ranging from 10 to 50 yards for standard materials. For custom or specialized fabrics, MOQs can increase to 100 yards or more. It’s advisable to discuss your specific needs with suppliers to negotiate favorable terms, especially if you’re looking to make smaller initial purchases for testing or prototyping. -

4. How can I verify the quality of upholstery fabric before purchasing?

To ensure fabric quality, request physical samples from suppliers. This allows you to evaluate the texture, durability, and overall appearance. Additionally, inquire about certifications that indicate compliance with industry standards for flame retardancy and abrasion resistance. Reviews and testimonials from other B2B buyers can also provide insights into the supplier’s reliability and the quality of their products. -

5. What payment terms are typically offered by upholstery fabric suppliers?

Payment terms can vary widely among suppliers, but common options include upfront payment, net 30, or net 60 terms, depending on your relationship with the supplier and order size. Some suppliers may offer discounts for early payment or bulk purchases. It’s crucial to clarify payment methods accepted (e.g., bank transfer, credit card) and any potential fees associated with international transactions, especially when dealing with suppliers from different continents. -

6. How do I handle customs and logistics when importing upholstery fabrics?

When importing upholstery fabrics, familiarize yourself with the customs regulations in your country, including import duties and taxes. Collaborate with a freight forwarder to streamline logistics and ensure compliance with shipping regulations. Additionally, ensure that your supplier provides all necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance. Planning for potential delays in transit can also help avoid disruptions in your supply chain. -

7. Can I customize upholstery fabric designs, and what is the process?

Yes, many suppliers offer customization options, including colors, patterns, and materials. The process typically involves submitting your design specifications or samples to the supplier, who will then create a prototype for your approval. Be prepared for minimum order quantities and potential lead times for custom orders. Clear communication regarding your expectations and timeline is essential to ensure the final product meets your needs. -

8. What should I consider when vetting upholstery fabric suppliers?

When vetting suppliers, assess their experience in the industry and their ability to meet your specific requirements. Check for certifications that demonstrate compliance with safety and quality standards. Evaluate their customer service responsiveness, as effective communication is crucial for successful partnerships. Additionally, seek references or reviews from other B2B clients to gauge their reliability and reputation in the market.

Top 8 Car Upholstery Fabric Suppliers Manufacturers & Suppliers List

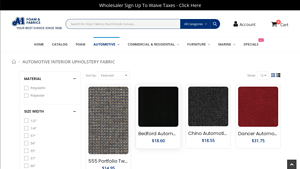

1. A1 Foam and Fabrics – 555 Portfolio Tweed Collection

Domain: a1foamandfabrics.com

Registered: 2003 (22 years)

Introduction: {“products”:[{“name”:”555 Portfolio Tweed Collection”,”market_applications”:”Automotive, RV, Furniture”,”characteristics”:{“abrasion_resistance”:”50,000+ DR #10 Cotton Duck”,”flame_retardancy”:”California T.B. 117 Section E-Class 1(Pass), NFPA 260-Class 1 (Pass), UFAC Class 1 (Pass)”,”lightfastness”:”UV Stable”},”price”:”$14.95″},{“name”:”Bedford Automotive Velvet”,”market_applications”:”Automotiv…

2. Original Auto Fabric – Vintage & New Upholstery Materials

Domain: oemautofabric.com

Registered: 2018 (7 years)

Introduction: Original Auto Fabric offers a wide selection of vintage and new auto upholstery materials, including specialty car cloths, marine and automotive vinyls, custom carpets, floor mats, and vinyl tops. They provide over 230 licensed logos for floor mats, molded carpet to OEM specifications, and specialize in high-end imported luxury carpets. Their product categories include Auto Cloths (691 options), L…

3. Midwest Fabrics – Upholstery Supplies & Fabrics

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Introduction: Upholstery Supplies & Fabrics, Indoor Furniture Upholstery Fabric, Outdoor Furniture Fabric, Automotive Upholstery Fabric, Heavy Duty Flock Fabric, Contract Fabrics (Culp Contract Classic, Culp Ribby, Culp Ground Control, etc.), Marine Vinyl, Vinyl Automotive, Upholstery Tools, Upholstery Thread & Bobbins, Industrial Staples, Zippers, Upholstery Adhesives, Upholstery Foam, Automotive Carpets, Trun…

4. Miami Corp – Car Upholstery Fabrics

Domain: miamicorp.com

Registered: 2001 (24 years)

Introduction: This company, Miami Corp – Car Upholstery Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

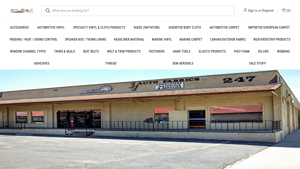

5. JJ Auto Fabrics – Automotive and Marine Vinyl Supplies

Domain: jjautofabrics.com

Registered: 2001 (24 years)

Introduction: Automotive-Marine Vinyl and Upholstery Supplies include a variety of products such as Classic Automotive Vinyl, Heavy Weight Vinyl, SoftSide/SoftTouch Automotive Vinyl, Corinthian, Longitude, Sierra, Monticello, Milled Pebble, Soho, Rawhide, Oxen, Heidi, Ex Madrid, G-Grain, Verona, Wallaby, Ezy Vinyls, Knit Back Automotive Vinyl, Enduratex/CGPC, Highland, Perforated Palma, Plain Rosette, Morbern, …

6. Fabric Warehouse – Automotive Upholstery Fabrics

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Automotive Fabric: Seat Vinyl Upholstery Sew Foam and Headliners Fabric. Ships free over $100. Various colors available including Beige, Black, Blue, Bronze, Brown, Gold, Gray, Green, Ivory, and more. Available by the yard with options for remnants. Fabric weights include Extra Heavy, Heavy, Lightweight, Medium, and Very Heavyweight. Patterns include Solid, Geometric, and more. Popular products in…

7. DLT Upholstery Supply – Vinyl & Foam Products

Domain: dltcorporation.com

Registered: 2009 (16 years)

Introduction: DLT Upholstery Supply offers a wide range of products including:

– Vinyl & Faux Leather: Automotive Vinyls, Marine Vinyls, Commercial & Home Vinyls, Economy/Value-Priced Vinyls, Specified Restaurant Vinyls, Specialty Vinyls, Contract Polyurethanes, Ultrafabrics Collections.

– Foam: Foam Sheets/Cushioning Foam, Sew Foam/Roll Foam.

– Performance Fabrics: Alcantara, Byrne High-Performance Tweed, Con…

8. Sailrite – Vinyl Automotive Upholstery Fabrics

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Our Favorite Vinyl Automotive Upholstery Fabrics – Sailrite offers durable, waterproof, and easy-to-clean vinyl fabrics ideal for reupholstering car seats. Vinyl is a cost-effective alternative to leather, providing a luxurious look and feel with beautiful texture and graining. Key benefits include: easy cleaning, high abrasion resistance, UV resistance, waterproof properties, economical pricing, …

Strategic Sourcing Conclusion and Outlook for car upholstery fabric suppliers

As the automotive industry continues to evolve, the importance of strategic sourcing in procuring high-quality car upholstery fabrics cannot be overstated. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, selecting the right suppliers is crucial for ensuring durability, aesthetics, and compliance with safety standards. Key takeaways include the need for suppliers who offer a diverse range of materials, such as velvets, suedes, and specialty vinyls, while also adhering to regulations regarding flame retardancy and UV stability.

Building long-term partnerships with reputable fabric suppliers not only enhances product quality but also fosters innovation in design and functionality. By leveraging a supplier’s expertise and market knowledge, businesses can gain a competitive edge, optimize their supply chain, and respond effectively to market demands.

Looking ahead, the landscape for car upholstery fabric suppliers is ripe with opportunities for collaboration and growth. As you explore potential partnerships, consider the evolving preferences of consumers and the increasing demand for sustainable materials. Engage with suppliers who can meet these expectations and drive your projects toward success. Embrace strategic sourcing today to position your business for a prosperous tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to car upholstery fabric suppliers

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.