Introduction: Navigating the Global Market for custom leather sectional

In the ever-evolving global market, sourcing custom leather sectionals presents a unique challenge for B2B buyers. With an increasing demand for high-quality, durable seating solutions that cater to diverse consumer preferences, businesses must navigate a complex landscape of suppliers and options. This guide is designed to equip international buyers, particularly from Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—with the insights necessary for making informed purchasing decisions.

The scope of this comprehensive guide includes an exploration of various types of custom leather sectionals, such as modular, L-shaped, and U-shaped designs, tailored to meet specific spatial and aesthetic requirements. We will delve into applications across different sectors, from hospitality to residential markets, highlighting how these versatile pieces can enhance environments. Additionally, we will provide practical strategies for vetting suppliers, ensuring quality and reliability, while also discussing cost considerations that can impact your procurement strategy.

By addressing these critical aspects, this guide empowers B2B buyers to confidently select the right custom leather sectionals that not only align with their business needs but also resonate with their customers’ expectations for style and comfort. As you navigate this dynamic market, let this resource be your trusted companion in achieving successful sourcing outcomes.

Table Of Contents

- Top 6 Custom Leather Sectional Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather sectional

- Understanding custom leather sectional Types and Variations

- Key Industrial Applications of custom leather sectional

- 3 Common User Pain Points for ‘custom leather sectional’ & Their Solutions

- Strategic Material Selection Guide for custom leather sectional

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather sectional

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather sectional’

- Comprehensive Cost and Pricing Analysis for custom leather sectional Sourcing

- Alternatives Analysis: Comparing custom leather sectional With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather sectional

- Navigating Market Dynamics and Sourcing Trends in the custom leather sectional Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather sectional

- Strategic Sourcing Conclusion and Outlook for custom leather sectional

- Important Disclaimer & Terms of Use

Understanding custom leather sectional Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| U-Shaped Sectional | Provides ample seating; wraps around a corner | Large family homes, open spaces | Pros: Maximizes seating; ideal for gatherings. Cons: Requires significant space. |

| L-Shaped Sectional | Fits snugly in corners; versatile design | Apartments, smaller living areas | Pros: Space-efficient; flexible layout. Cons: Limited seating compared to larger types. |

| Modular Sectional | Composed of separate sections; customizable layout | Offices, co-working spaces, modern homes | Pros: Highly adaptable; can be reconfigured. Cons: May require more investment upfront. |

| Chaise Sectional | Includes an extended seat for lounging | Residential, hospitality settings | Pros: Offers comfort; stylish. Cons: Less seating capacity for larger groups. |

| Reclining Sectional | Features reclining seats for enhanced comfort | Home theaters, luxury lounges | Pros: Adds comfort and relaxation. Cons: More mechanical parts may require maintenance. |

What are the Characteristics of U-Shaped Sectionals?

U-shaped sectionals are designed to provide maximum seating capacity, making them ideal for larger spaces such as family homes and open layouts. Their unique shape allows for conversation and interaction among multiple users, fostering a communal atmosphere. When purchasing for B2B applications, consider the overall space dimensions and the potential for multi-functional use, as these sectionals can serve both seating and aesthetic purposes in living areas or reception spaces.

How Do L-Shaped Sectionals Fit into Smaller Spaces?

L-shaped sectionals are particularly well-suited for corners and smaller rooms, offering flexibility without compromising on comfort. They can seamlessly integrate into various layouts, making them a popular choice for urban apartments and smaller family homes. When sourcing L-shaped sectionals, B2B buyers should evaluate the fabric options and customization capabilities to align with branding or interior design themes, ensuring they meet both aesthetic and functional requirements.

Why Choose Modular Sectionals for Your Business?

Modular sectionals consist of independent pieces that can be rearranged to create different configurations, making them an excellent choice for dynamic environments like offices or co-working spaces. Their adaptability allows businesses to easily modify seating arrangements based on the occasion or space requirements. Buyers should consider the range of modular options available and how they can enhance collaborative working environments while also reflecting the company’s brand identity.

What are the Benefits of Chaise Sectionals?

Chaise sectionals include an extended seating area that invites relaxation and comfort, making them a popular choice for both residential and hospitality settings. Their stylish design can elevate the aesthetic of a room while providing a cozy spot for lounging. For B2B buyers, it’s essential to assess the durability of materials, especially in high-traffic areas, to ensure longevity and return on investment.

How Do Reclining Sectionals Enhance Comfort?

Reclining sectionals are designed with integrated reclining mechanisms, providing a luxurious seating experience that enhances relaxation. They are commonly found in home theaters and upscale lounges where comfort is a priority. When purchasing for commercial use, B2B buyers should focus on the reliability of the reclining mechanism and ease of maintenance, as these factors will influence customer satisfaction and the overall usability of the furniture.

Key Industrial Applications of custom leather sectional

| Industry/Sector | Specific Application of custom leather sectional | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Lounge areas in hotels and resorts | Enhances guest comfort and aesthetic appeal | Durability, maintenance requirements, customization options |

| Corporate Offices | Employee lounges and reception areas | Promotes a welcoming atmosphere and employee well-being | Size, modularity, and ergonomic design |

| Retail | Waiting areas in showrooms and boutiques | Creates an inviting environment that encourages customer engagement | Style alignment with brand identity, comfort, and durability |

| Event Management | Seating for conference rooms and event spaces | Provides flexible seating arrangements for various events | Flexibility in design, ease of transport, and setup |

| Educational Institutions | Common areas in universities and colleges | Offers comfortable seating for students and faculty | Customization for specific space requirements and durability |

How Are Custom Leather Sectionals Utilized in the Hospitality Sector?

In the hospitality industry, custom leather sectionals are frequently used in lounge areas of hotels and resorts. These spaces are designed to provide guests with comfort and relaxation, enhancing their overall experience. The durability of leather is particularly advantageous in high-traffic environments, as it withstands wear and tear while maintaining an upscale appearance. For international buyers, sourcing options should consider local climate conditions and maintenance practices to ensure longevity.

What Role Do Custom Leather Sectionals Play in Corporate Offices?

Corporate offices leverage custom leather sectionals in employee lounges and reception areas to create a welcoming atmosphere. These sectionals not only promote comfort but also contribute to a positive corporate culture, enhancing employee satisfaction and productivity. When sourcing for corporate settings, buyers should prioritize ergonomic designs and modular options that can adapt to different office layouts, ensuring optimal use of space.

Illustrative image related to custom leather sectional

How Do Retail Environments Benefit from Custom Leather Sectionals?

In retail environments, custom leather sectionals are strategically placed in waiting areas of showrooms and boutiques to create inviting spaces that encourage customer interaction. A well-designed seating area can significantly enhance the shopping experience, leading to increased dwell time and sales. Buyers in this sector should focus on customization options that align with their brand identity and customer demographics while ensuring the furniture is durable enough to withstand frequent use.

Why Are Custom Leather Sectionals Important for Event Management?

Event management companies often utilize custom leather sectionals for seating in conference rooms and event spaces. These sectionals provide flexibility in seating arrangements, accommodating various event sizes and formats. When sourcing for this application, considerations should include ease of transport and setup, as well as the ability to customize designs for different themes or branding requirements.

How Do Educational Institutions Use Custom Leather Sectionals?

Educational institutions incorporate custom leather sectionals in common areas to offer comfortable seating for students and faculty. These spaces serve as social hubs, promoting interaction and collaboration among students. Buyers from this sector should consider the sectional’s durability and ease of maintenance, as well as customization options that fit the specific aesthetic and functional needs of their campuses.

3 Common User Pain Points for ‘custom leather sectional’ & Their Solutions

Scenario 1: Sizing and Fit Challenges for Custom Leather Sectionals

The Problem: B2B buyers often face difficulties when it comes to ensuring that a custom leather sectional fits perfectly in the intended space. This issue can stem from inaccurate measurements or miscommunication regarding the dimensions of the sectional. Buyers may find themselves with a product that is either too large, overwhelming the space, or too small, failing to meet their functional needs. This not only affects aesthetics but can also disrupt the overall design vision for a commercial or hospitality setting.

The Solution: To avoid sizing issues, buyers should prioritize precise measurements and consider the layout of the room before placing an order. A detailed measurement plan should include not only the dimensions of the sectional but also the surrounding furniture and any architectural features like windows or doors. Additionally, utilizing 3D modeling tools or design software can help visualize how the sectional will fit within the space. Engaging with manufacturers who offer virtual consultations or in-home assessments can also ensure that buyers receive tailored advice based on their specific environments.

Scenario 2: Quality Concerns with Custom Leather Materials

The Problem: Another common pain point for buyers is the concern over the quality of leather used in custom sectionals. With numerous grades and types of leather available, determining the right material that balances durability, aesthetics, and budget can be overwhelming. Buyers might worry about issues such as wear and tear, color fading, and maintenance requirements, especially in high-traffic areas like lounges or conference rooms.

The Solution: To mitigate quality concerns, buyers should conduct thorough research on the different types of leather available, such as full-grain, top-grain, or bonded leather. Understanding the properties of each type will enable buyers to make informed decisions based on their specific use case. It is advisable to request leather samples from suppliers to assess texture, color, and durability firsthand. Additionally, establishing clear communication with manufacturers regarding warranties and maintenance recommendations can help buyers ensure they are making a sound investment in high-quality materials that will withstand the test of time.

Illustrative image related to custom leather sectional

Scenario 3: Customization Limitations Leading to Buyer Frustration

The Problem: Many B2B buyers experience frustration when they realize that their customization options for a custom leather sectional are limited. This can occur if manufacturers do not offer a wide range of styles, colors, or configurations, leaving buyers feeling constrained in their design choices. Such limitations can hinder the ability to create a cohesive brand identity, especially in environments like hotels, restaurants, or corporate offices, where aesthetics play a crucial role in customer perception.

The Solution: To overcome customization limitations, buyers should proactively seek out manufacturers known for their extensive customization capabilities. This includes options for modular designs, a variety of leather finishes, and the ability to create bespoke shapes that cater to unique spatial requirements. Engaging in discussions with manufacturers about their design processes and flexibility can reveal hidden possibilities that may not be immediately apparent. It may also be beneficial to collaborate with interior designers who specialize in commercial spaces to ensure that the chosen sectional not only meets functional needs but also aligns with the overall branding and design ethos of the business.

Strategic Material Selection Guide for custom leather sectional

What Are the Key Properties of Common Materials Used in Custom Leather Sectionals?

When selecting materials for custom leather sectionals, it is essential to consider the properties that affect performance, durability, and suitability for specific applications. Here, we analyze four common materials used in the construction of leather sectionals: genuine leather, bonded leather, faux leather, and fabric.

Genuine Leather: What Makes It a Preferred Choice?

Genuine leather is a natural product derived from animal hides, known for its durability and luxurious appearance. It boasts high resistance to wear and tear, making it suitable for high-traffic areas. Genuine leather can withstand temperature fluctuations and is relatively easy to clean, provided it is treated appropriately.

Illustrative image related to custom leather sectional

Pros: Genuine leather offers superior durability, a classic aesthetic, and develops a unique patina over time, enhancing its appeal. It is also breathable, which adds to comfort.

Cons: The primary drawbacks include a higher cost compared to synthetic alternatives and potential ethical concerns related to animal sourcing. Additionally, it requires regular maintenance to prevent drying and cracking.

For international buyers, particularly in regions like Europe and the Middle East, compliance with environmental and ethical sourcing standards is crucial. Buyers should look for certifications that ensure the leather is sourced responsibly.

Bonded Leather: Is It a Cost-Effective Alternative?

Bonded leather is composed of leather scraps and fibers bonded together with a polyurethane coating. This material mimics the look of genuine leather at a fraction of the cost.

Illustrative image related to custom leather sectional

Pros: It is more affordable, lightweight, and easier to maintain than genuine leather. Bonded leather is also available in various colors and finishes, appealing to diverse aesthetic preferences.

Cons: The durability is significantly lower than that of genuine leather, and it may not age as gracefully. Over time, bonded leather can peel or crack, reducing its lifespan.

For B2B buyers in regions like South America, where cost sensitivity is higher, bonded leather can be an attractive option. However, buyers should be aware of the potential need for more frequent replacements due to its limited durability.

Illustrative image related to custom leather sectional

Faux Leather: How Does It Compare to Natural Options?

Faux leather, or synthetic leather, is made from materials like polyurethane or polyvinyl chloride (PVC). It is designed to replicate the look and feel of genuine leather while offering various advantages.

Pros: Faux leather is typically more affordable, easier to clean, and available in a wide range of colors and textures. It is also a cruelty-free option, appealing to ethically-conscious consumers.

Cons: While it is resistant to stains and spills, faux leather can be less durable and may not withstand heavy use as effectively as genuine leather. It can also be less breathable, leading to discomfort in warmer climates.

International buyers from Africa and Europe may find faux leather appealing due to its cost-effectiveness and ethical considerations. However, they should consider the climate in which the sectional will be used, as this can impact the material’s performance.

Illustrative image related to custom leather sectional

Fabric: When Is It the Right Choice for Custom Sectionals?

Fabric upholstery encompasses a wide range of materials, including cotton, polyester, and blends. It is often chosen for its comfort and versatility.

Pros: Fabric is available in countless colors and patterns, allowing for extensive customization. It is generally more affordable than leather and offers a softer feel.

Cons: Fabric can be less durable than leather and may stain more easily. It also requires regular cleaning to maintain its appearance.

For B2B buyers, particularly those in regions with varying climates, fabric can be a suitable option for custom sectionals. However, it is essential to choose high-quality, stain-resistant fabrics to ensure longevity.

Illustrative image related to custom leather sectional

Summary Table of Material Selection for Custom Leather Sectionals

| Material | Typical Use Case for custom leather sectional | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end residential or commercial settings | Superior durability and luxury feel | High cost and maintenance required | High |

| Bonded Leather | Budget-friendly residential applications | Cost-effective and lightweight | Less durable, may peel over time | Medium |

| Faux Leather | Family-friendly or casual settings | Easy to clean and cruelty-free | Less durable and breathable | Low |

| Fabric | Versatile residential applications | Extensive customization options | Can stain easily and less durable | Medium |

This analysis provides a comprehensive overview of the materials commonly used in custom leather sectionals, helping B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather sectional

What Are the Main Stages in the Manufacturing Process of Custom Leather Sectionals?

The manufacturing process for custom leather sectionals involves several key stages that ensure both quality and craftsmanship. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Materials Selected and Processed?

The first step in manufacturing custom leather sectionals is the careful selection of materials. High-quality leather is sourced from reputable tanneries, ensuring durability and aesthetics. The leather is then treated and dyed using environmentally friendly processes, which is particularly relevant for buyers from regions with stringent environmental regulations.

Once the leather is prepared, the next step is to cut the material into specific patterns. This is done using precision cutting tools or automated machines that ensure accuracy. The wood used for the frame is usually laminated hardwood, chosen for its strength and stability, and is cut to size before being treated to enhance its longevity.

Illustrative image related to custom leather sectional

How Is the Forming Process Executed for Optimal Comfort?

Forming the sectional involves shaping the frame and cushioning to ensure comfort and support. The wood frame is typically constructed using interlocking joints, which provide durability and stability. Techniques such as steam bending may be employed to create curves in the frame, enhancing the sectional’s design and comfort.

Cushions are filled with high-density foam, often encased in a fabric shell for added comfort. Quality manufacturers will also incorporate features like channeled back cushions to maintain their shape and support.

What Assembly Techniques Are Commonly Used?

The assembly stage combines all components into a finished product. Skilled craftsmen meticulously join the frame, attach the cushions, and cover the entire structure with leather. Quality manufacturers employ techniques such as double stitching to reinforce seams and prevent wear over time.

During this stage, attention to detail is paramount. Assemblers check for alignment and structural integrity, ensuring that every piece meets the brand’s quality standards before moving on to the finishing stage.

How Is the Finishing Process Handled to Ensure Aesthetic Appeal?

The finishing stage is crucial for both aesthetics and protection. After the sectional is assembled, it undergoes a thorough cleaning and treatment process. Leather conditioners and protectants are applied to enhance the appearance and durability of the leather, making it resistant to stains and wear.

Finally, the sectional is inspected for any cosmetic imperfections such as scratches or uneven dyeing. This ensures that the final product meets the high expectations of international buyers.

What Quality Assurance Standards Are Relevant for Custom Leather Sectionals?

Quality assurance is an integral part of the manufacturing process for custom leather sectionals. Adherence to international standards like ISO 9001 guarantees that manufacturers follow a systematic approach to quality management. This standard emphasizes continuous improvement and customer satisfaction, making it particularly relevant for B2B buyers.

Which International and Industry-Specific Standards Should Buyers Be Aware Of?

In addition to ISO 9001, various industry-specific certifications are essential for custom leather sectionals. For instance, the CE mark indicates compliance with European health, safety, and environmental protection standards, while the API certification may be relevant for specific materials and processes used in certain regions.

Understanding these certifications helps B2B buyers assess the credibility of suppliers. Buyers from regions like Africa, South America, the Middle East, and Europe should particularly ensure that their suppliers adhere to relevant local standards as well.

What Are the Key QC Checkpoints During the Manufacturing Process?

Quality control (QC) checkpoints are vital throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This is conducted when raw materials arrive at the factory. It involves inspecting leather and wood for defects or inconsistencies.

-

In-Process Quality Control (IPQC): During assembly, regular inspections are conducted to ensure that all components are being fitted correctly and that workmanship meets the specified standards.

-

Final Quality Control (FQC): Once the sectional is completed, it undergoes a final inspection that includes functionality tests and aesthetic checks.

Each checkpoint is designed to catch any potential issues early in the process, reducing the risk of defective products reaching the market.

What Testing Methods Are Commonly Used in Quality Assurance?

Testing methods for custom leather sectionals may include:

-

Durability Testing: This assesses how well the leather holds up under various conditions, including abrasion, tearing, and stretching.

-

Comfort Testing: Evaluates the sectional’s support and comfort levels, ensuring it meets ergonomic standards.

-

Environmental Testing: This can include checking for VOC emissions and ensuring compliance with environmental regulations, which is particularly important for markets in Europe and North America.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should conduct thorough due diligence to verify a supplier’s quality control practices. This can include:

-

Supplier Audits: Regular audits help assess the supplier’s adherence to quality standards and manufacturing processes. Buyers should look for suppliers who are open to audits and provide access to their facilities.

-

Quality Control Reports: Requesting detailed QC reports can provide insights into the supplier’s processes and any issues that have been encountered and resolved.

-

Third-Party Inspections: Engaging independent inspectors can offer an unbiased assessment of the supplier’s quality control processes and product quality.

What Are the Nuances of QC for International B2B Buyers?

For international B2B buyers, understanding local regulations and standards is crucial. Buyers from different regions may face varying requirements regarding materials, safety, and environmental impact. This is particularly relevant when importing custom leather sectionals into markets with stringent regulations, such as those in Europe.

Illustrative image related to custom leather sectional

Additionally, cultural differences may affect expectations regarding quality and service. Thus, effective communication and clarity about specifications are essential to ensure that the final product meets the buyer’s expectations.

By understanding the manufacturing processes and quality assurance measures associated with custom leather sectionals, B2B buyers can make informed decisions, ensuring they partner with reputable suppliers who prioritize quality and sustainability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather sectional’

In today’s competitive market, sourcing custom leather sectionals requires careful consideration and strategic planning. This guide serves as a practical checklist for B2B buyers, particularly those in diverse international markets such as Africa, South America, the Middle East, and Europe. By following these steps, you can ensure a successful procurement process that meets your unique requirements.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical specifications for the custom leather sectional. This includes dimensions, design style (e.g., L-shaped, modular), and specific features like reclining options or built-in storage. Detailed specifications help suppliers provide accurate quotes and reduce the risk of miscommunication.

- Consider ergonomics: Ensure the sectional meets comfort standards for your target market.

- Material quality: Specify the type of leather (e.g., full-grain, top-grain) to align with your brand’s quality expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom leather sectionals. Look for manufacturers with a strong reputation and experience in international shipping to your region.

- Check online reviews and ratings: Use platforms like Trustpilot or industry-specific forums to gauge supplier reliability.

- Examine their portfolio: Assess their previous work to ensure they can meet your design expectations.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that potential suppliers hold necessary certifications and comply with international quality standards. This ensures that the products you receive are safe and reliable.

Illustrative image related to custom leather sectional

- ISO certifications: Look for suppliers with ISO 9001 certification, indicating quality management standards.

- Sustainability certifications: Consider suppliers with eco-friendly practices, which can be a selling point in your market.

Step 4: Request Samples

Always request samples of the materials and finishes used in the sectionals before making a bulk order. This step is crucial for assessing the quality and aesthetics of the leather.

- Evaluate texture and durability: Ensure the leather meets your quality standards and feels appropriate for your target audience.

- Confirm color accuracy: Verify that the color samples match your specifications to avoid discrepancies in the final product.

Step 5: Negotiate Terms and Pricing

Once you’ve identified suitable suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. Having clear terms in place is vital to avoid misunderstandings later.

- Bulk order discounts: Discuss potential discounts for larger orders, which can improve your profit margins.

- Payment flexibility: Explore options like staggered payments or letters of credit for better cash flow management.

Step 6: Establish a Communication Plan

Effective communication is key to a successful procurement process. Establish a clear communication plan to ensure that all parties are aligned throughout the project.

- Designate points of contact: Assign specific individuals responsible for communication on both sides to streamline the process.

- Set regular check-ins: Schedule periodic updates to discuss progress, address concerns, and make adjustments as necessary.

Step 7: Plan for Logistics and Delivery

Finally, develop a logistics plan that accounts for shipping, customs clearance, and delivery timelines. Proper logistics management can prevent delays and additional costs.

Illustrative image related to custom leather sectional

- Understand import regulations: Familiarize yourself with the customs requirements in your region to avoid unexpected hurdles.

- Choose reliable logistics partners: Collaborate with experienced freight forwarders to ensure smooth transportation of your custom leather sectionals.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing custom leather sectionals effectively, ensuring high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for custom leather sectional Sourcing

What Are the Key Cost Components in Custom Leather Sectional Sourcing?

When sourcing custom leather sectionals, several cost components play a critical role in determining the final pricing. These include:

-

Materials: The choice of leather (genuine, bonded, or synthetic), frame materials (hardwood, plywood), and cushioning impact costs significantly. Quality leather can command a higher price, but it also offers durability and aesthetic appeal.

-

Labor: Skilled labor is essential for crafting high-quality furniture. The labor costs can vary based on the region and the complexity of the design. Customization requires more skilled labor, which can increase expenses.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including factory utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help keep these costs in check.

-

Tooling: Custom designs often require specialized tools or molds, which can increase initial costs. However, these costs are typically amortized over larger production runs.

-

Quality Control (QC): Implementing stringent QC measures ensures the final product meets quality standards. While this adds to the cost, it can prevent expensive returns and dissatisfaction in the long run.

-

Logistics: Shipping costs, especially for international buyers, can vary widely based on distance, volume, and shipping methods. Understanding these costs is crucial for accurate pricing.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can fluctuate based on demand and competition.

How Do Price Influencers Affect Custom Leather Sectional Costs?

Several factors influence the pricing of custom leather sectionals, which B2B buyers should be aware of:

Illustrative image related to custom leather sectional

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers negotiate better terms.

-

Specifications and Customization: Custom features such as specific dimensions, colors, or additional functionalities can significantly impact pricing. Buyers should clearly communicate their needs to avoid unexpected costs.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., eco-friendly, fire-retardant) may increase costs but can enhance the product’s marketability.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers may offer better quality assurance but at a premium.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is vital for determining responsibility and costs associated with logistics. This can affect the overall cost structure significantly.

What Are the Best Negotiation Tips for B2B Buyers in Custom Leather Sectionals?

To achieve cost efficiency when sourcing custom leather sectionals, buyers should consider the following strategies:

-

Negotiate Volume Discounts: Leverage order size to negotiate better pricing. Suppliers are often willing to reduce prices for larger quantities.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also maintenance, durability, and potential resale value. A higher initial investment may yield better long-term savings.

-

Research and Compare Suppliers: Conduct thorough research on multiple suppliers to understand market rates and identify the best options for quality and cost.

-

Clarify Specifications Early: Providing clear and detailed specifications from the outset can minimize misunderstandings and unexpected costs later in the process.

-

Be Mindful of Pricing Nuances for International Transactions: Consider currency fluctuations, import duties, and local taxes when budgeting for international purchases. These factors can significantly impact the total cost.

Disclaimer on Pricing

Prices for custom leather sectionals can vary widely based on design, materials, and supplier negotiations. The figures mentioned are indicative and subject to change based on market conditions and specific buyer requirements. Always consult with suppliers for accurate and up-to-date pricing.

Alternatives Analysis: Comparing custom leather sectional With Other Solutions

Introduction to Alternative Solutions for Custom Leather Sectionals

When considering furniture solutions for commercial or residential spaces, the custom leather sectional stands out for its luxury and versatility. However, it’s essential for B2B buyers to explore alternative options that might offer distinct advantages in terms of functionality, cost, and maintenance. This analysis compares custom leather sectionals with two viable alternatives: modular fabric sectionals and traditional upholstered sofas, helping buyers make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Custom Leather Sectional | Modular Fabric Sectional | Traditional Upholstered Sofa |

|---|---|---|---|

| Performance | High durability; upscale aesthetic | Flexible configurations; comfortable for gatherings | Classic design; good for smaller spaces |

| Cost | Higher upfront investment | Moderate to low cost; budget-friendly options | Variable; can be affordable or premium |

| Ease of Implementation | Requires custom order; longer delivery times | Quick assembly; available in various configurations | Generally ready-to-use; immediate availability |

| Maintenance | Requires special care; cleaning products needed | Easy to clean; machine washable options available | Easy maintenance; fabric can be treated for stains |

| Best Use Case | Luxury environments; high-traffic areas | Versatile spaces; informal settings | Traditional settings; smaller rooms |

Detailed Breakdown of Alternatives

Modular Fabric Sectionals

Modular fabric sectionals offer the flexibility to adapt to various room layouts and can be easily reconfigured as needs change. Their moderate to low cost makes them an attractive option for budget-conscious buyers. Additionally, many models come with removable and machine-washable covers, simplifying maintenance. However, they may lack the upscale appeal of leather and might not provide the same level of durability under heavy use, especially in high-traffic areas.

Traditional Upholstered Sofas

Traditional upholstered sofas are a classic choice that can fit into a variety of décor styles. They are often readily available, making them an ideal solution for buyers who need immediate furnishing. The price range can be wide, allowing options for both budget and luxury markets. Maintenance is generally straightforward, with many fabrics treated for stains. However, they may not offer the same level of comfort for larger gatherings as sectional options, and their design might not be as adaptable as modular or leather sectionals.

Illustrative image related to custom leather sectional

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right furniture solution requires a clear understanding of the unique demands of your space. Custom leather sectionals offer a luxurious and durable option suitable for high-end environments, while modular fabric sectionals provide flexibility and affordability, making them ideal for dynamic spaces. Traditional upholstered sofas can serve as a reliable and immediate choice for more conventional settings. By carefully assessing the performance, cost, ease of implementation, maintenance, and best use cases of each option, B2B buyers can make informed decisions that align with their specific requirements and budget constraints.

Essential Technical Properties and Trade Terminology for custom leather sectional

What Are the Key Technical Properties of Custom Leather Sectionals?

When sourcing custom leather sectionals, understanding the technical properties is essential for ensuring product quality and meeting client expectations. Here are some critical specifications that B2B buyers should consider:

Material Grade

Material grade refers to the quality of leather used in the sectional. Common grades include full-grain, top-grain, and bonded leather. Full-grain leather is the highest quality, retaining the natural grain and durability, while top-grain is sanded and treated for a more uniform appearance. Bonded leather is made from scraps and offers a lower-cost option but is less durable. Selecting the appropriate material grade is crucial for aligning with the target market’s expectations regarding luxury and longevity.

Frame Construction

The frame construction of a sectional significantly impacts its durability and stability. Quality sectionals often use kiln-dried hardwood frames, which resist warping and provide a solid foundation. A well-constructed frame reduces the risk of sagging and increases the lifespan of the furniture. B2B buyers should ensure that the manufacturer provides specifications on the materials and methods used in frame construction to guarantee product longevity.

Illustrative image related to custom leather sectional

Cushion Density

Cushion density, measured in pounds per cubic foot (PCF), affects comfort and support. Higher density foams (typically 1.8 PCF or above) offer better durability and resistance to flattening over time. For seating areas that experience heavy use, specifying high-density cushions can enhance customer satisfaction and decrease return rates due to wear and tear.

Stitching Quality

The stitching quality is another vital property that influences both aesthetics and durability. Double-stitched seams are preferred as they provide added strength and help prevent fraying. B2B buyers should inquire about the type of thread used and the stitching techniques applied, as these factors can significantly affect the sectional’s longevity and overall appearance.

Tolerance Levels

Tolerance levels refer to the permissible variations in dimensions and specifications during manufacturing. Establishing clear tolerance levels ensures that the final product meets design expectations and fits seamlessly within the intended space. For instance, if a sectional is designed to fit a specific area, strict adherence to tolerance levels is essential for ensuring customer satisfaction and reducing costly returns.

What Common Trade Terms Should B2B Buyers Understand?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some common trade terms related to custom leather sectionals:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or products that are then marketed under another company’s brand name. In the context of furniture, an OEM might manufacture custom leather sectionals for a retailer. Understanding OEM relationships can help buyers identify the quality and origin of their products.

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell. This term is essential for B2B buyers as it affects inventory management and pricing. Knowing the MOQ helps in planning purchases and negotiating better terms.

RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. By issuing an RFQ for custom leather sectionals, buyers can obtain competitive pricing and ensure they are getting the best value for their investment.

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers navigate global trade logistics effectively.

Illustrative image related to custom leather sectional

Lead Time

Lead time refers to the duration between placing an order and receiving the product. Understanding lead times is crucial for inventory planning and customer fulfillment, especially in markets with high demand. Buyers should discuss lead times with suppliers to ensure timely delivery.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom leather sectionals, enhancing their product offerings and ensuring customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the custom leather sectional Sector

What Are the Key Market Dynamics Influencing Custom Leather Sectionals?

The custom leather sectional market is experiencing significant growth due to several global drivers. Increasing disposable income, particularly in emerging markets across Africa and South America, has led to a surge in demand for premium furniture. Moreover, a growing trend towards personalized home decor has prompted buyers to seek customizable options that align with their unique tastes. Technological advancements in manufacturing processes, such as 3D modeling and automated cutting, are streamlining production and allowing for more intricate designs. Additionally, the rise of e-commerce platforms has made it easier for international B2B buyers to source custom leather sectionals from diverse suppliers, enhancing competition and product variety.

As international buyers, particularly from regions like Brazil and Germany, navigate these market dynamics, they should also be aware of evolving sourcing trends. Increasingly, suppliers are leveraging digital tools for inventory management and customer engagement, improving efficiency and responsiveness. Blockchain technology is also emerging as a means to ensure transparency in supply chains, allowing buyers to track product origins and manufacturing practices. Understanding these trends will be crucial for buyers looking to make informed decisions in a rapidly changing landscape.

How Is Sustainability Shaping the Custom Leather Sectional Market?

Sustainability is becoming a cornerstone of the custom leather sectional sector, driven by growing consumer awareness and regulatory pressures. The environmental impact of leather production is substantial, often involving deforestation and high water usage. Therefore, buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing practices. This includes using leather from tanneries that adhere to strict environmental regulations and utilize sustainable practices in their operations.

Illustrative image related to custom leather sectional

Furthermore, certification programs such as the Leather Working Group (LWG) offer buyers a way to identify and partner with manufacturers that meet high environmental standards. Additionally, the use of eco-friendly materials, such as vegetable-tanned leather or recycled components, is gaining traction. This not only appeals to environmentally conscious consumers but also enhances brand reputation. For B2B buyers, aligning with sustainable suppliers can open new market opportunities and foster long-term relationships based on shared values.

How Has the Custom Leather Sectional Market Evolved Over Time?

The custom leather sectional market has undergone a significant transformation over the past few decades. Initially, leather furniture was primarily associated with luxury and high-end markets, often perceived as exclusive and expensive. However, advancements in manufacturing techniques and material sourcing have democratized access to quality leather products, making them more affordable for a wider audience.

The rise of modular designs has also revolutionized the sector, allowing consumers to create versatile living spaces tailored to their specific needs. Customization options have expanded, enabling buyers to select from various styles, colors, and configurations. This evolution reflects changing consumer preferences towards personalization and adaptability in home furnishings. As a result, the custom leather sectional market is now characterized by a blend of luxury, functionality, and sustainability, appealing to a diverse range of B2B buyers globally.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather sectional

1. How can I ensure the quality of custom leather sectionals from suppliers?

To guarantee the quality of custom leather sectionals, conduct thorough supplier vetting. Request samples of materials and finished products, and check for certifications that indicate adherence to industry standards. Additionally, inquire about the manufacturing processes, quality control measures, and warranty policies. Engaging in site visits can provide further insights into the supplier’s operations. Establishing clear communication regarding quality expectations and specifications is crucial to ensuring the final product meets your standards.

2. What are the typical lead times for custom leather sectional orders?

Lead times for custom leather sectionals can vary significantly based on the supplier and the complexity of the order. Generally, you can expect a timeframe of 4 to 8 weeks for production, depending on the level of customization and material availability. It’s essential to discuss lead times upfront with your supplier to align your purchasing schedule with your business needs. Additionally, consider potential delays due to logistics or international shipping, particularly when sourcing from overseas.

3. What customization options should I consider for leather sectionals?

When sourcing custom leather sectionals, consider options such as size, shape (L-shaped, U-shaped, modular), leather type (genuine, bonded, or synthetic), color, and additional features like reclining capabilities or built-in storage. Discussing these options with your supplier will help you create a product that aligns with your branding and customer preferences. Additionally, inquire about the possibility of bespoke designs to meet specific aesthetic or functional requirements.

4. What is the minimum order quantity (MOQ) for custom leather sectionals?

Minimum order quantities (MOQs) for custom leather sectionals typically depend on the supplier and the specifics of your order. Some suppliers may require a MOQ of 5 to 10 units for custom orders, while others may have more flexible terms. When sourcing, clarify the MOQ upfront to ensure it aligns with your business’s purchasing capabilities. Consider negotiating terms, especially if you’re looking to establish a long-term partnership with the supplier.

5. What payment terms should I expect when ordering custom leather sectionals?

Payment terms for custom leather sectional orders can vary widely among suppliers. Common practices include a deposit of 30-50% at the time of order placement, with the balance due upon completion or prior to shipment. Some suppliers may offer flexible payment options or credit terms for established customers. It’s important to discuss and agree on payment terms upfront to avoid any misunderstandings later in the transaction process.

6. How can I assess the reliability of a supplier for custom leather sectionals?

To assess a supplier’s reliability, research their reputation through reviews, testimonials, and industry references. Request a list of past clients and case studies to understand their experience with the supplier. Additionally, evaluate their responsiveness to inquiries, adherence to timelines, and willingness to provide documentation such as quality certifications. Engaging in direct communication can also help establish trust and gauge their professionalism.

7. What logistics considerations should I keep in mind when importing custom leather sectionals?

When importing custom leather sectionals, consider factors such as shipping methods, costs, and customs regulations. Work with logistics partners experienced in international shipping to navigate tariffs and import duties. Ensure that the supplier provides accurate documentation for customs clearance. Planning for potential delays and having a contingency plan can help mitigate risks associated with international logistics.

Illustrative image related to custom leather sectional

8. How can I handle quality assurance for custom leather sectionals upon receipt?

Implement a comprehensive quality assurance process upon receiving your custom leather sectionals. Inspect each unit for defects, including stitching, leather quality, and structural integrity. Compare the received products against the agreed specifications and quantities. Document any discrepancies and address them promptly with the supplier to facilitate returns or exchanges. Establishing a clear process for quality checks will help maintain customer satisfaction and uphold your brand’s reputation.

Top 6 Custom Leather Sectional Manufacturers & Suppliers List

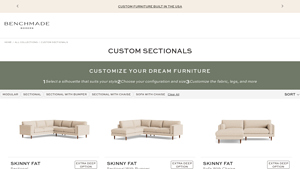

1. BenchMade Modern – Custom Sectionals

Domain: benchmademodern.com

Registered: 2014 (11 years)

Introduction: Custom Sectionals available in various styles including Modular Sectional, Sectional with Bumper, Sectional with Chaise, and Sofa with Chaise. Products feature a lifetime warranty, crafted in the USA, and a 100-day trial. Options include extra deep seating and bench cushions. Prices range from approximately $5,681 to $11,381 depending on the model and configuration. Ratings for products are genera…

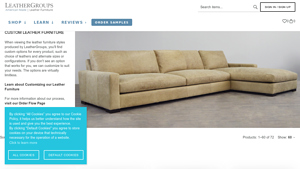

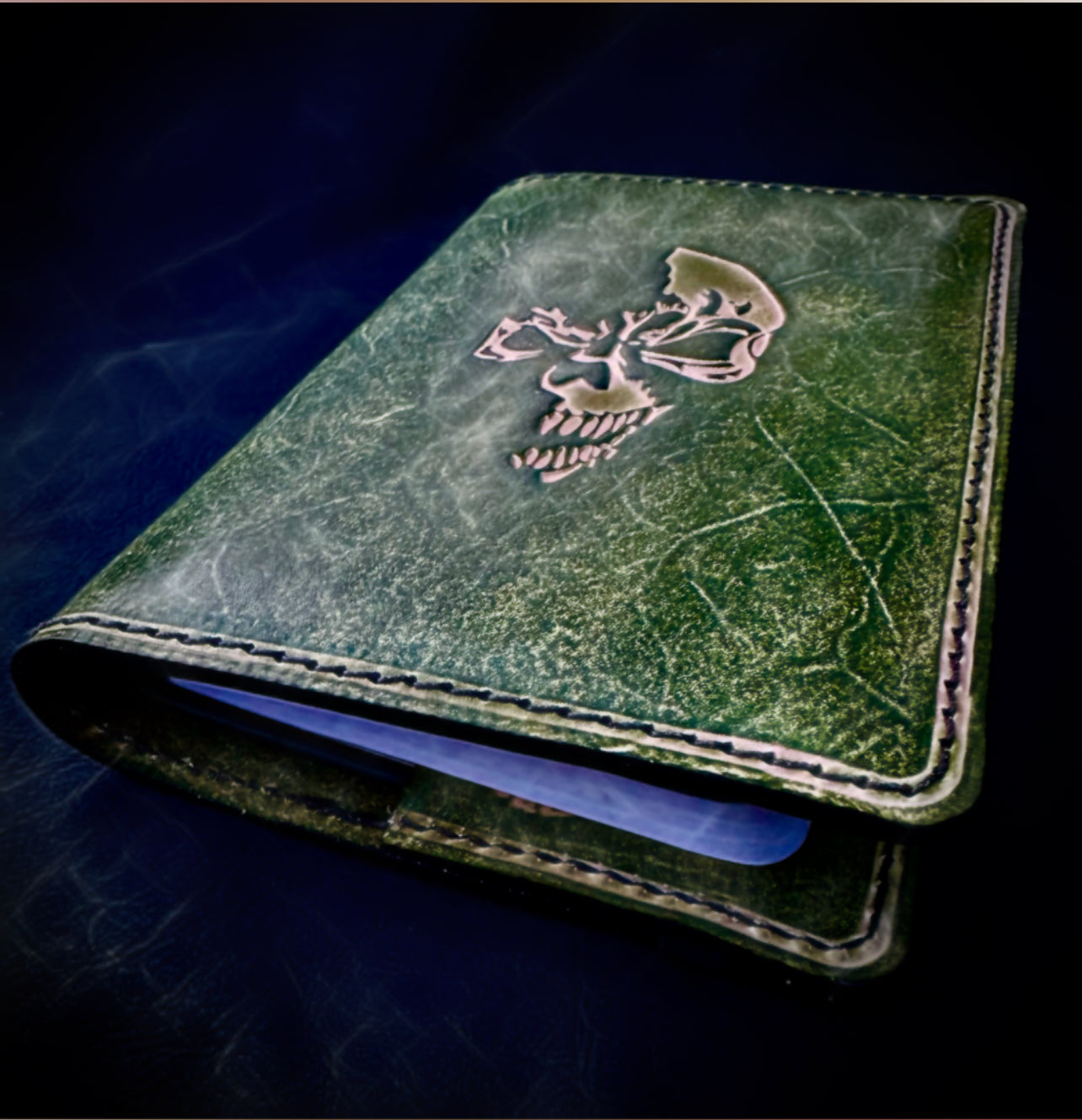

2. Leather Groups – Custom Leather Furniture

Domain: leathergroups.com

Registered: 2002 (23 years)

Introduction: American Made Custom Leather Furniture; Categories: Sofas, Sectionals, Chairs, Ottomans; Customization options: custom length, custom arm size, custom height, nail head trim, custom shaping; Leather types: Full Grain, Aniline Full Grain, Pigmented; Collections: Arizona, Bonham, Braxton, Bruno, Dexter, Julien, Langston, Muir, Midtown, Oscar, Reno; Financing options available; Free white glove deliv…

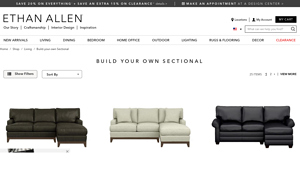

3. Ethan Allen – Build-Your-Own Sectional

Domain: ethanallen.com

Registered: 1995 (30 years)

Introduction: Build-Your-Own Sectional from Ethan Allen allows customers to customize their sectional sofas. The product features a variety of fabric and leather options, enabling personalization in style and comfort. Customers can choose from different configurations and sizes to fit their living space. The sectional is part of a broader collection that includes sofas, loveseats, accent chairs, and other livin…

4. Leather Sofa Co – Alexandria Sectional

Domain: leathersofaco.com

Registered: 2004 (21 years)

Introduction: [{‘name’: ‘Alexandria Sectional (Left Arm Loveseat + Left Arm Right Chaise Sofa)’, ‘base_leather’: ‘Sooner Golden Tan’, ‘price’: ‘$9,200.00’, ‘description’: ‘Few designs offer a more perfect balance of style and comfort than the Alexandria. This contemporary off the floor silhouette features a beautifully sculpted frame and soft.’}, {‘name’: ‘Roma – Sofa with Power RA/LA Incliners & Power Headrest…

5. American Leather – Custom Sofas & Sectionals

Domain: americanleather.com

Registered: 1997 (28 years)

Introduction: Custom sofas and sectionals featuring modern styles, hundreds of configurations, and over 400 upholstery options. Contract approved products include various sectional and sofa models such as Alessandro, Athlea, Barcelona, Brooke, Carmet, Chelsea, Cooks, Copenhagen, Curved Matteo, Daley, Danford, Doran, Dorian, Emery, Espen, Estero, Giselle, Henley, and Kaden.

6. Room & Board – Custom Leather Sectionals

Domain: roomandboard.com

Registered: 1996 (29 years)

Introduction: Custom leather sectionals from Room & Board, offering personalized design options, high-quality materials, and a variety of styles to fit any living space.

Strategic Sourcing Conclusion and Outlook for custom leather sectional

What Are the Key Takeaways for Sourcing Custom Leather Sectionals?

In the competitive landscape of custom leather sectionals, strategic sourcing remains pivotal for B2B buyers. Understanding the diverse options, from modular designs to reclining capabilities, allows businesses to meet varied consumer preferences while ensuring flexibility in their offerings. Quality assurance through reliable manufacturers is paramount, as it directly impacts customer satisfaction and brand reputation. With the increasing demand for customization, leveraging data analytics to identify market trends can enhance sourcing strategies, ensuring that products align with consumer desires.

How Can B2B Buyers Position Themselves for Future Success?

As you navigate the sourcing landscape, consider the importance of building strong partnerships with suppliers who prioritize quality and sustainability. This not only enhances your product portfolio but also positions your brand as a leader in responsible sourcing practices. Looking ahead, the integration of innovative designs and materials will be essential to staying competitive in the global market.

What Steps Should You Take Next?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, now is the time to capitalize on emerging trends in the custom leather sectional market. Engage with manufacturers, explore customization options, and invest in quality to meet the evolving demands of your clientele. By prioritizing strategic sourcing, you can drive growth and establish a strong foothold in this dynamic industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.