Introduction: Navigating the Global Market for leather patch company

Navigating the global market for leather patch companies presents unique challenges, particularly for international B2B buyers seeking high-quality, customizable products. The growing demand for personalized leather patches—used in apparel, accessories, and promotional items—has created a competitive landscape where sourcing reliable suppliers can be daunting. This comprehensive guide aims to equip buyers with the knowledge necessary to make informed purchasing decisions, covering essential topics such as types of leather patches, their diverse applications, effective supplier vetting processes, and cost considerations.

As businesses in regions like Africa, South America, the Middle East, and Europe (including Nigeria and Brazil) seek to enhance their brand identity, understanding the intricacies of the leather patch market becomes crucial. Buyers will learn how to identify high-quality materials, evaluate production methods, and leverage customization options that resonate with their target audience. Additionally, the guide will address the importance of customer service and communication in establishing long-term partnerships with suppliers.

Armed with actionable insights, international B2B buyers can navigate the complexities of sourcing leather patches, ensuring their products not only meet quality standards but also reflect their brand’s unique identity. This guide is designed to streamline the purchasing process, ultimately leading to successful collaborations and impactful branding.

Table Of Contents

- Top 4 Leather Patch Company Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather patch company

- Understanding leather patch company Types and Variations

- Key Industrial Applications of leather patch company

- 3 Common User Pain Points for ‘leather patch company’ & Their Solutions

- Strategic Material Selection Guide for leather patch company

- In-depth Look: Manufacturing Processes and Quality Assurance for leather patch company

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather patch company’

- Comprehensive Cost and Pricing Analysis for leather patch company Sourcing

- Alternatives Analysis: Comparing leather patch company With Other Solutions

- Essential Technical Properties and Trade Terminology for leather patch company

- Navigating Market Dynamics and Sourcing Trends in the leather patch company Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather patch company

- Strategic Sourcing Conclusion and Outlook for leather patch company

- Important Disclaimer & Terms of Use

Understanding leather patch company Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Leather Patch Hats | Personalized designs, various hat styles, low minimums | Promotional events, corporate branding | Pros: Unique branding, low minimums. Cons: Higher costs for small orders. |

| DIY Leather Patch Kits | Kits for self-assembly, customizable patch shapes | Crafting, team-building activities | Pros: Cost-effective, hands-on engagement. Cons: Requires time and skill. |

| Bulk Leather Patch Suppliers | Focus on large orders, competitive pricing, variety of styles | Retail, corporate gifts | Pros: Economical for large purchases, wide selection. Cons: Less flexibility in design. |

| Specialty Leather Patch Companies | Unique materials (e.g., eco-friendly), niche markets | Fashion, outdoor gear | Pros: Differentiation through unique products. Cons: Limited availability and higher prices. |

| Full-Service Leather Patch Manufacturers | In-house production, extensive customization options | Branding agencies, event organizers | Pros: Comprehensive service from design to delivery. Cons: Longer lead times. |

What Are the Key Characteristics of Custom Leather Patch Hats?

Custom leather patch hats are highly sought after in the B2B landscape due to their ability to showcase a company’s brand identity. These companies typically offer a range of styles, including trucker hats and snapbacks, with options for personalized designs. The flexibility of low minimum orders makes them appealing for promotional events and corporate branding initiatives. Buyers should consider the balance between quality and cost, especially for smaller orders, as customization can lead to higher prices.

How Do DIY Leather Patch Kits Benefit Businesses?

DIY leather patch kits are designed for businesses that value creativity and engagement. These kits allow teams to create their own patches, fostering collaboration and a sense of ownership among employees. They are particularly useful for crafting events or team-building exercises. However, while they can be cost-effective, businesses must weigh the time and skill required for assembly against the potential savings.

Illustrative image related to leather patch company

What Advantages Do Bulk Leather Patch Suppliers Offer?

Bulk leather patch suppliers cater to businesses looking for large quantities of customized products at competitive prices. They often provide a wide selection of hat styles and customization options, making them ideal for retail and corporate gifting. The primary consideration for buyers is the cost-effectiveness of larger orders, though this often comes with reduced flexibility in design changes.

Why Choose Specialty Leather Patch Companies?

Specialty leather patch companies focus on unique materials and designs, often targeting niche markets such as fashion or outdoor gear. By offering eco-friendly or innovative options, these companies help brands differentiate themselves in a crowded market. However, buyers should be aware that these unique offerings may come at a premium price and might have limited availability.

What Should Buyers Expect from Full-Service Leather Patch Manufacturers?

Full-service leather patch manufacturers provide a comprehensive solution, from initial design to final production and delivery. This can be particularly beneficial for branding agencies and event organizers seeking a seamless process. While the extensive customization options are a significant advantage, buyers should consider the potential for longer lead times and ensure they plan accordingly to meet their project deadlines.

Key Industrial Applications of leather patch company

| Industry/Sector | Specific Application of leather patch company | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom leather patch hats for branding | Enhances brand visibility and creates a unique identity | Quality of leather, customization options, and lead time |

| Outdoor & Sports | Durable hats for outdoor activities and sports teams | Provides functional benefits and promotes team spirit | Material durability, weather resistance, and bulk pricing |

| Promotional Products | Leather patches for corporate giveaways and events | Strengthens brand recognition and customer loyalty | Minimum order quantities, design flexibility, and shipping options |

| Hospitality & Events | Custom hats for staff uniforms in restaurants and events | Enhances professional appearance and customer experience | Customization options, comfort, and style selection |

| Agricultural & Rural | Leather patch hats for farming and outdoor work | Protects from sun exposure while promoting a brand | Breathability, fit, and bulk order discounts |

How Are Leather Patch Companies Serving the Fashion & Apparel Sector?

In the fashion and apparel industry, leather patch companies provide custom patches for hats that serve as a powerful branding tool. These patches not only enhance the aesthetic appeal of the hats but also help in creating a unique identity for brands in a crowded market. B2B buyers from regions like Africa and South America often seek high-quality leather that stands out, ensuring durability and style. Key considerations include the quality of leather used, the variety of customization options available, and efficient lead times to meet seasonal demands.

Illustrative image related to leather patch company

What Role Do Leather Patch Companies Play in Outdoor & Sports Industries?

In outdoor and sports industries, leather patch hats are tailored for functionality and style. These hats are often used by sports teams and outdoor enthusiasts, providing protection from the elements while promoting team spirit. B2B buyers, particularly from the Middle East and Europe, prioritize materials that are durable and weather-resistant. Sourcing considerations include the hat’s breathability, fit, and the availability of bulk pricing, which is crucial for team orders.

How Can Leather Patch Companies Enhance Promotional Products?

Leather patch companies significantly contribute to the promotional products sector by offering custom patches for corporate giveaways and events. These patches help in reinforcing brand recognition and fostering customer loyalty. International buyers from diverse markets, including Nigeria and Brazil, look for flexibility in design and reasonable minimum order quantities to suit various promotional strategies. Shipping options and timely delivery are also critical factors that influence purchasing decisions.

Why Are Leather Patch Hats Important for Hospitality & Events?

In the hospitality industry, custom hats with leather patches are integral to staff uniforms in restaurants and events. These hats not only enhance the professional appearance of staff but also improve the overall customer experience by creating a cohesive brand image. B2B buyers in this sector should consider customization options that reflect their brand identity, as well as the comfort and style of the hats to ensure staff satisfaction and performance.

Illustrative image related to leather patch company

What Benefits Do Leather Patch Hats Offer to Agricultural & Rural Businesses?

For agricultural and rural businesses, leather patch hats serve a dual purpose: they protect workers from sun exposure while promoting the brand. These hats are essential for outdoor work environments, where functionality is paramount. Buyers in these sectors should focus on the breathability of the materials, the fit for long hours of wear, and the potential for bulk order discounts to accommodate larger teams or events.

3 Common User Pain Points for ‘leather patch company’ & Their Solutions

Scenario 1: Difficulty in Meeting Unique Branding Needs

The Problem: B2B buyers often struggle to find a leather patch company that can accommodate their unique branding requirements. Many companies offer generic designs and limited customization options, making it challenging for brands to stand out in a competitive marketplace. This is particularly problematic for businesses looking to create a strong identity through custom leather patches that reflect their brand ethos.

The Solution: To overcome this challenge, buyers should seek out leather patch companies that specialize in custom designs and offer a variety of materials and styles. Start by clearly outlining your brand identity and the specific elements you want to incorporate into your design. Look for manufacturers that provide a mock-up service, allowing you to visualize how your branding will appear on the final product. Companies that can produce patches in various shapes, sizes, and colors will give you the flexibility needed to create a distinctive look. Additionally, ensure that the company has a robust customer service team to assist you throughout the design process, helping you refine your ideas and make adjustments as necessary.

Scenario 2: Uncertainty Around Quality and Material Sourcing

The Problem: Many B2B buyers are concerned about the quality of leather used in patches, as well as the ethical sourcing of materials. Given the variety of suppliers and materials available, it can be difficult to ascertain whether the leather is genuine, sustainably sourced, or of high quality. This uncertainty can lead to dissatisfaction with the final product and potential damage to the buyer’s brand reputation.

The Solution: Buyers should conduct thorough research on potential leather patch suppliers, focusing on their sourcing practices and material quality. Look for companies that provide detailed information about their leather, including its origin, treatment, and any certifications related to sustainability. Request samples before placing large orders to evaluate the quality firsthand. Additionally, consider working with suppliers who are transparent about their manufacturing processes and can provide testimonials or case studies from previous clients. This will help ensure that you receive high-quality products that align with your brand values.

Scenario 3: Challenges with Minimum Order Quantities and Pricing

The Problem: For smaller businesses or startups, high minimum order quantities can be a significant barrier when trying to source custom leather patches. Many suppliers set minimums that exceed the budget or inventory needs of smaller enterprises, making it difficult for them to enter the market or test new products without incurring substantial costs.

The Solution: To navigate this issue, buyers should seek out leather patch companies that offer flexible ordering options. Look for suppliers that have low minimum order requirements, allowing you to order as few as one or a small batch of patches. This flexibility enables you to test designs and gauge customer response without overcommitting financially. Additionally, inquire about bulk pricing discounts for larger orders as your business grows. It can be advantageous to establish a relationship with a supplier who is willing to work with your business model, which may include negotiating terms that accommodate your unique needs as a smaller buyer. By prioritizing suppliers with adaptable policies, you can better manage your inventory and budget while still obtaining high-quality products.

Strategic Material Selection Guide for leather patch company

What Are the Key Materials Used in Leather Patches for B2B Applications?

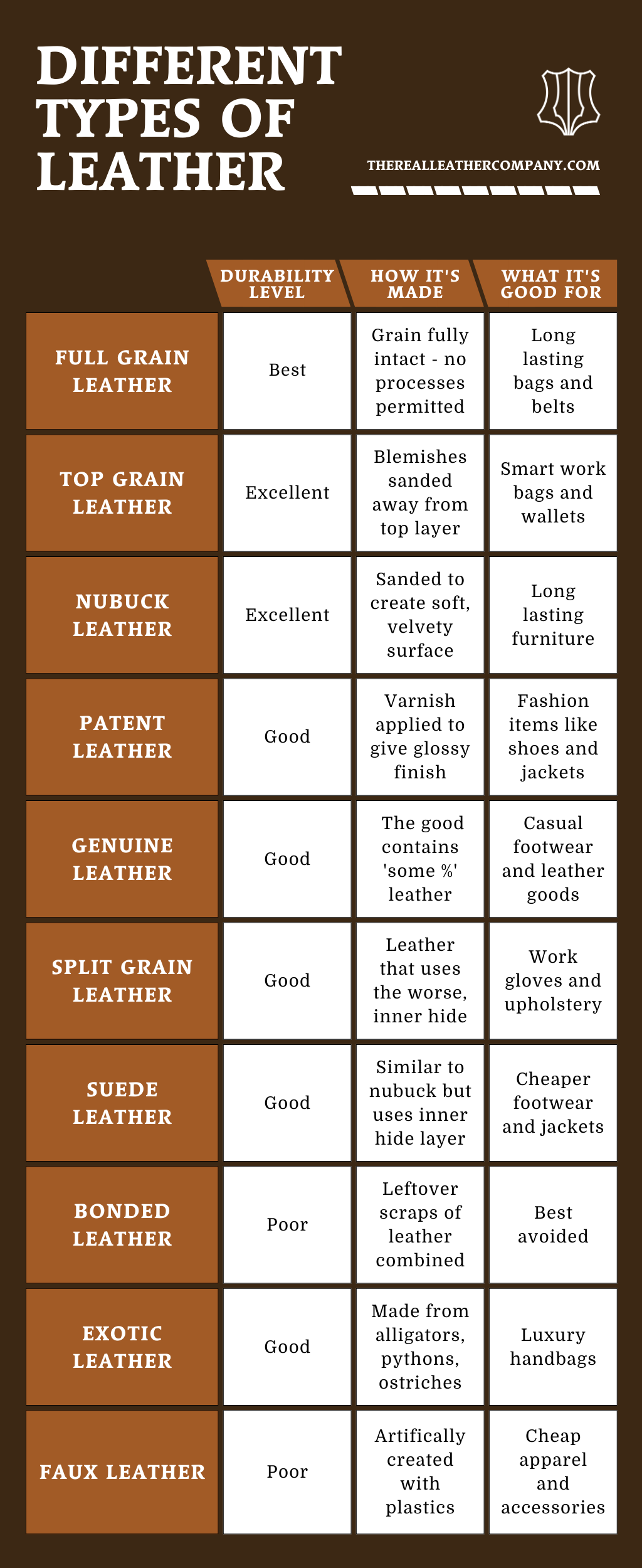

When selecting materials for leather patches, it’s essential to consider the properties, advantages, and limitations of each option. This analysis focuses on four common materials used in the leather patch industry: genuine leather, synthetic leather, twill fabric, and eco-friendly materials. Each material offers unique characteristics that can influence product performance and market appeal.

Illustrative image related to leather patch company

How Does Genuine Leather Perform in Leather Patch Applications?

Genuine leather is a traditional choice for leather patches, known for its durability and aesthetic appeal. It can withstand various environmental conditions, making it suitable for outdoor applications. Genuine leather typically has a temperature rating that allows it to maintain its integrity in both hot and cold climates, which is crucial for international buyers in diverse regions.

Pros: The primary advantage of genuine leather is its durability and natural look, which can enhance brand perception. It also ages well, developing a unique patina over time.

Cons: However, genuine leather can be costly and may require specific care to maintain its appearance. It can also be less resistant to moisture compared to synthetic alternatives.

Impact on Application: Genuine leather is compatible with various media, including embroidery and printing, making it versatile for branding purposes.

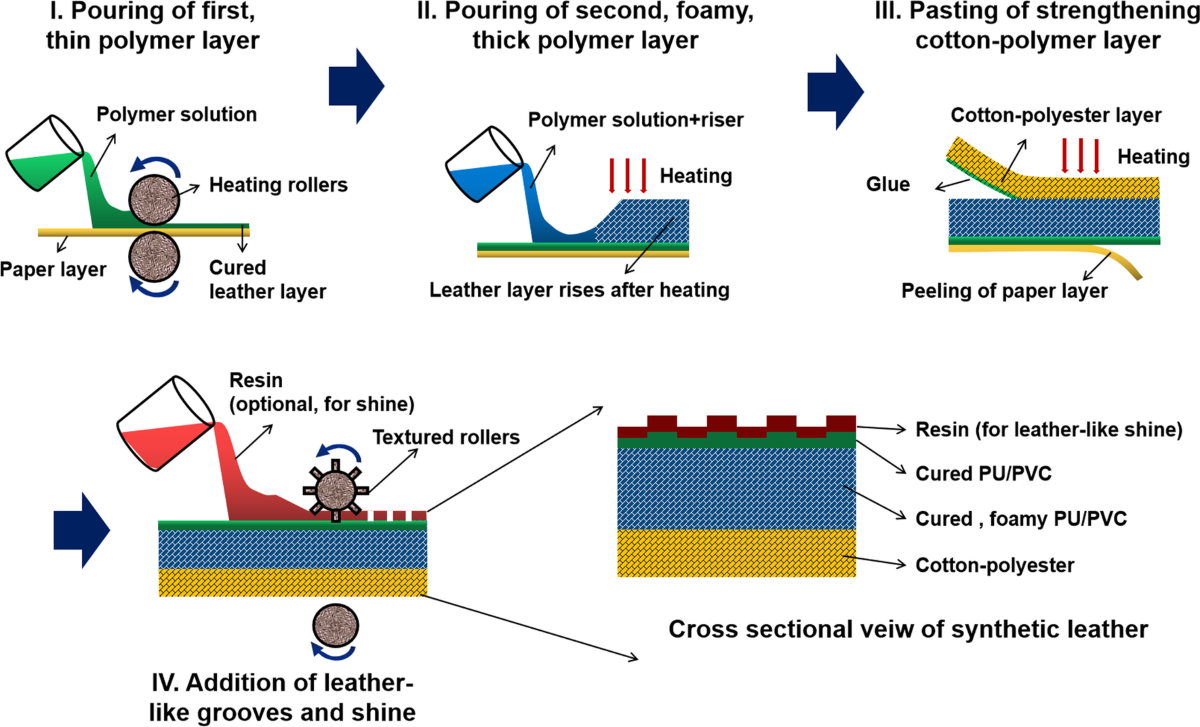

What Are the Benefits of Synthetic Leather in Leather Patch Production?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is a popular alternative to genuine leather. It offers a similar aesthetic but with enhanced resistance to moisture and UV light, making it suitable for outdoor use.

Illustrative image related to leather patch company

Pros: One of the key advantages of synthetic leather is its lower cost and easier maintenance compared to genuine leather. It is also more consistent in quality and can be produced in a variety of colors and finishes.

Cons: On the downside, synthetic leather may not offer the same level of breathability or durability as genuine leather, which could affect its longevity in demanding applications.

Impact on Application: Synthetic leather is compatible with various printing techniques, making it an excellent choice for high-volume production runs.

How Does Twill Fabric Compare as a Material for Leather Patches?

Twill fabric, often made from cotton or a cotton blend, is another option for leather patches. It is known for its diagonal weave, which provides durability and a unique texture.

Illustrative image related to leather patch company

Pros: The primary advantage of twill fabric is its cost-effectiveness and versatility. It can be easily dyed and printed, allowing for vibrant designs and branding opportunities.

Cons: However, twill fabric may not provide the same level of durability as leather, particularly in outdoor settings. It is also less resistant to wear and tear over time.

Impact on Application: Twill fabric is suitable for applications where a softer touch is desired, and it can be effectively combined with leather patches for a layered look.

What Are Eco-Friendly Materials and Their Role in Leather Patch Production?

Eco-friendly materials, such as recycled leather or organic cotton, are gaining popularity among consumers and businesses focused on sustainability. These materials often align with global trends toward environmentally responsible manufacturing practices.

Pros: The key advantage of eco-friendly materials is their reduced environmental impact, appealing to a growing segment of environmentally conscious consumers. They can also enhance brand reputation.

Cons: However, eco-friendly materials may come with a higher price tag and can be less readily available than traditional materials.

Impact on Application: These materials are often compatible with various printing and embroidery techniques, allowing for creative branding solutions.

Summary of Material Selection for Leather Patches

| Material | Typical Use Case for leather patch company | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end fashion and outdoor gear patches | Durability and aesthetic appeal | Higher cost and moisture sensitivity | High |

| Synthetic Leather | Promotional items and mass-produced patches | Cost-effective and easy to maintain | Less breathable and durable | Medium |

| Twill Fabric | Casual wear and soft-touch patches | Versatile and vibrant designs | Less durable in harsh conditions | Low |

| Eco-Friendly Materials | Sustainable fashion and brand-conscious items | Reduced environmental impact | Higher cost and limited availability | Medium to High |

This guide provides a comprehensive overview of the materials commonly used in leather patch production, equipping B2B buyers with the insights needed to make informed decisions based on their specific market needs and regional considerations.

Illustrative image related to leather patch company

In-depth Look: Manufacturing Processes and Quality Assurance for leather patch company

What Are the Key Stages in the Manufacturing Process for Leather Patch Products?

The manufacturing process for leather patch products involves several critical stages that ensure high-quality outcomes and meet the specific needs of B2B buyers. Understanding these stages can help businesses in Africa, South America, the Middle East, and Europe to make informed purchasing decisions.

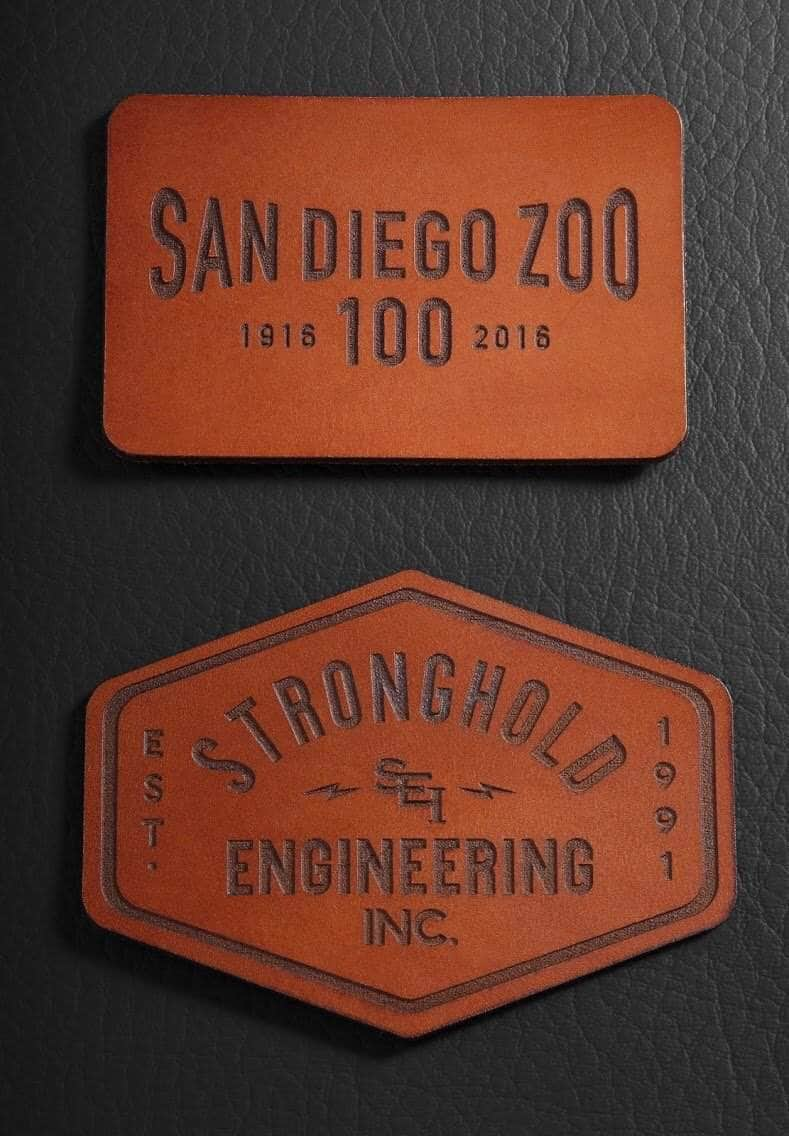

Material Preparation: What Goes into High-Quality Leather Patches?

The first step in the manufacturing process is material preparation, which involves sourcing and selecting the right type of leather. High-quality leather is typically sourced from reputable tanneries, ensuring it meets specific standards for durability and aesthetics. Common types of leather used include full-grain, top-grain, and suede, each offering unique characteristics suitable for different applications.

Once sourced, the leather undergoes a thorough inspection for defects such as scarring or discoloration. This is crucial, as even minor imperfections can affect the final product’s quality. Additionally, the leather may be treated with dyes or finishes to enhance its appearance and longevity.

Forming: How Are Leather Patches Shaped?

After preparing the leather, the next stage is forming. This involves cutting the leather into the desired shapes and sizes for patches. Precision cutting is essential to ensure uniformity across products, especially for custom orders. Techniques like die-cutting are commonly used, allowing for intricate designs and patterns that can cater to a variety of brand identities.

In some cases, leather patches may be embossed or debossed with logos or designs, adding an extra layer of customization. This process not only enhances the aesthetic appeal but also creates a tactile experience that can elevate the brand’s presence in the market.

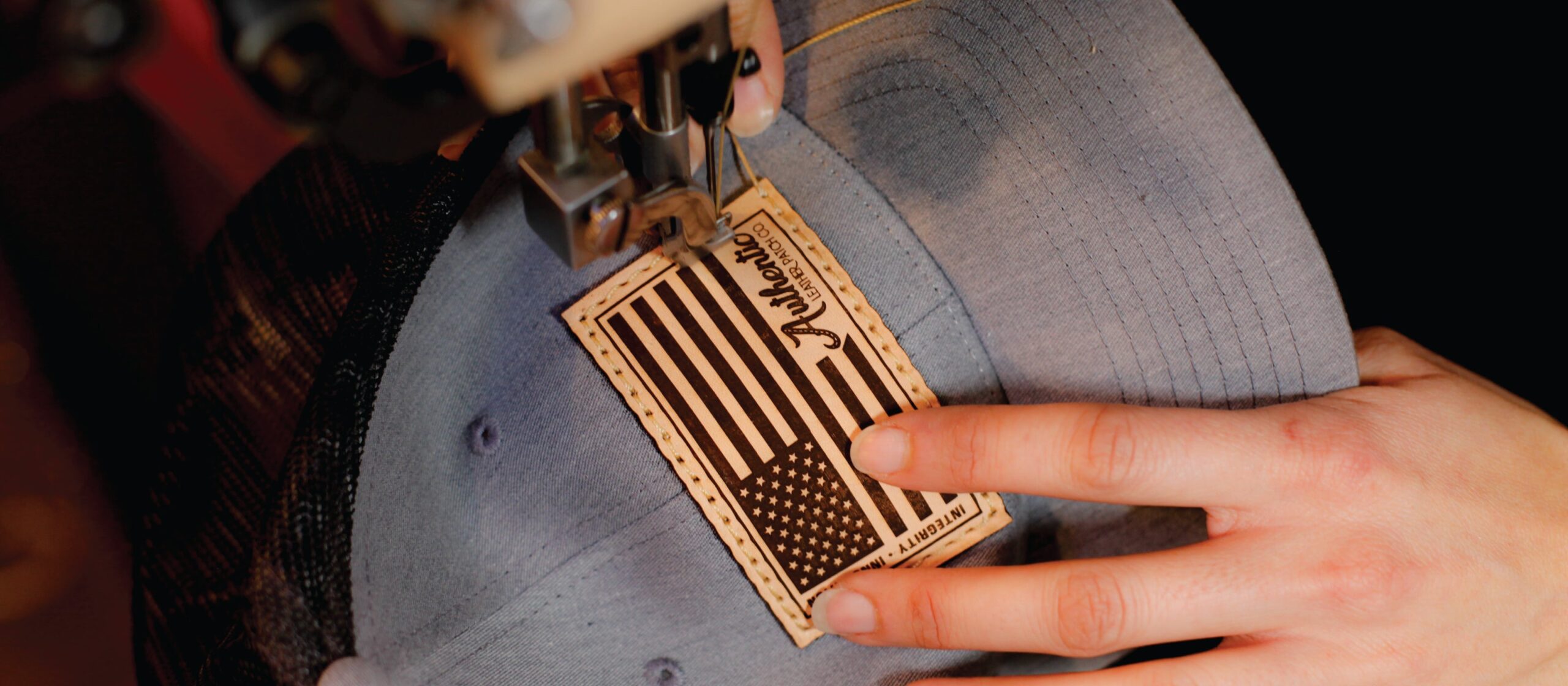

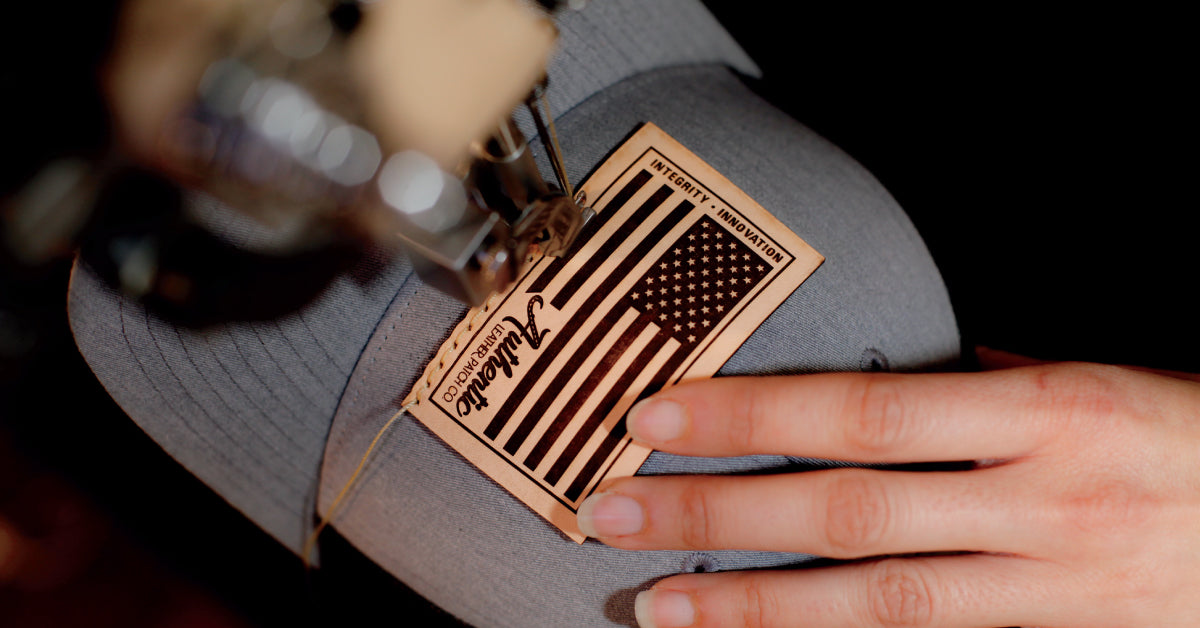

Assembly: What Techniques Are Used to Attach Patches?

Assembly is a critical phase where the leather patches are attached to the chosen products, such as hats or bags. The two primary methods of attachment include hand stitching and machine stitching. Hand stitching is often preferred for its craftsmanship and durability, while machine stitching can be used for mass production, ensuring efficiency.

Adhesive backing is another option, but it is generally less favored among quality-conscious buyers due to concerns about longevity and performance. Companies that prioritize quality often emphasize the importance of stitching over adhesive methods, ensuring a more reliable product.

Finishing: What Enhancements Are Made to the Final Product?

The finishing stage involves several processes that enhance the overall quality and appearance of the leather patches. This may include applying protective coatings, polishing, or conditioning the leather to improve its feel and longevity. Quality manufacturers also conduct a final inspection to ensure that all products meet the established standards before they are packaged and shipped.

What Quality Assurance Measures Are Essential for Leather Patch Manufacturing?

Quality assurance is paramount in the leather patch manufacturing industry, ensuring that products meet international standards and buyer expectations. Implementing robust quality control measures helps maintain consistency and reliability, crucial factors for B2B buyers.

Which International Standards Should B2B Buyers Look For?

Several international standards are relevant in the leather manufacturing sector. The ISO 9001 standard, which focuses on quality management systems, is particularly significant as it demonstrates a commitment to continuous improvement and customer satisfaction. Buyers should seek suppliers who are ISO certified, as this indicates a systematic approach to quality assurance.

Additionally, industry-specific certifications like CE marking for consumer goods ensure compliance with health, safety, and environmental requirements, which can be particularly relevant for buyers in regions such as Europe.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to maintaining product integrity throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials, including leather hides, are inspected for quality and compliance with specifications before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that the production processes adhere to quality standards. This can include checking stitching consistency and material integrity.

-

Final Quality Control (FQC): Before products are packaged, a comprehensive review is performed to ensure that all items meet design specifications and quality requirements. This includes checking for defects, ensuring proper attachment of patches, and verifying that all products are free from flaws.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. This can be achieved through several means:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their quality management systems and practices. Audits can reveal whether suppliers adhere to international standards and their internal quality control processes.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the testing methods and results used by the supplier. These reports often include data on defect rates and compliance with industry standards.

-

Third-Party Inspections: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can be especially beneficial for international buyers who may not have the resources for on-site audits.

What Nuances Should International Buyers Consider Regarding Quality Control?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, several nuances must be considered:

-

Cultural Differences: Understanding cultural attitudes towards quality can impact negotiations and expectations. Buyers should communicate their quality requirements clearly and ensure mutual understanding.

-

Regulatory Compliance: Different regions have varying regulations regarding materials and manufacturing processes. Buyers should familiarize themselves with local regulations in their target markets to ensure that products comply.

-

Logistical Considerations: Quality assurance processes may vary based on logistical challenges. Buyers should assess how these factors might affect the quality of the products being delivered.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing leather patch products, ensuring they align with their brand values and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather patch company’

In today’s competitive market, sourcing leather patches for hats and other apparel requires a systematic approach to ensure quality, customization, and supplier reliability. This guide serves as a practical checklist to help B2B buyers streamline their procurement process, particularly for those in regions like Africa, South America, the Middle East, and Europe.

Illustrative image related to leather patch company

1. Identify Your Customization Needs

Before reaching out to suppliers, clarify the specific customization requirements for your leather patches. Consider the type of leather, patch shape, size, and color options. Understanding your needs helps suppliers provide accurate quotes and design mock-ups, ensuring you get a product that aligns with your brand identity.

2. Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in leather patches. Look for companies with a strong reputation in your industry and positive customer reviews. Pay attention to their portfolio and product offerings to ensure they can meet your specific requirements.

- Key Considerations:

- Years of experience in the industry.

- Range of customization options available.

- Previous clients and case studies.

3. Request Samples

Once you have shortlisted potential suppliers, request samples of their leather patches. This step is crucial to evaluate the quality of materials, stitching, and overall craftsmanship. Samples will give you a tangible sense of what to expect and help you make an informed decision.

4. Evaluate Production Capabilities

Assess the supplier’s production capabilities to ensure they can meet your order volume and timeline. Inquire about their manufacturing processes, lead times, and whether they can handle rush orders if necessary. A reliable supplier should be able to scale production according to your business needs.

Illustrative image related to leather patch company

5. Understand Pricing Structures

Discuss pricing structures with potential suppliers, including minimum order quantities and bulk pricing options. Understanding the cost breakdown is essential for budget planning, especially if you’re looking to order in larger volumes. Don’t hesitate to negotiate to get the best value.

- Considerations:

- Are there any hidden fees (e.g., setup, shipping)?

- What are the discounts for bulk orders?

- Are there financing options available for larger purchases?

6. Verify Certifications and Compliance

Ensure that the supplier adheres to relevant industry standards and certifications, especially if you are sourcing from international suppliers. Compliance with environmental and labor regulations is critical to avoid potential risks to your brand’s reputation.

7. Establish Communication Channels

Effective communication is key to a successful partnership. Confirm that the supplier has clear communication protocols and is responsive to inquiries. A supplier that prioritizes customer service can significantly impact your procurement experience and overall satisfaction.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing leather patches, ensuring they partner with reliable suppliers who can deliver quality products that enhance their brand.

Comprehensive Cost and Pricing Analysis for leather patch company Sourcing

Understanding the cost structure and pricing dynamics of sourcing leather patches is crucial for B2B buyers looking to make informed decisions. Here, we analyze the various components that contribute to the overall cost and pricing of leather patch products, alongside actionable insights for international buyers.

What Are the Key Cost Components in Leather Patch Production?

-

Materials: The choice of leather significantly impacts the overall cost. Authentic leather tends to be more expensive than synthetic alternatives. Premium hides, such as oil-tanned or vegetable-tanned leather, can also increase costs. Additionally, the sourcing of eco-friendly materials may appeal to buyers focused on sustainability but can add to the price.

-

Labor: Hand-stitching and other artisanal techniques add labor costs, which can vary based on the region. Countries with higher labor costs may reflect this in pricing, while those with lower labor costs can offer more competitive rates. Understanding local labor market conditions is essential for buyers.

-

Manufacturing Overhead: This includes costs related to facility maintenance, equipment, and utilities. Companies with efficient production processes can offer more favorable pricing, so evaluating a supplier’s manufacturing capabilities is vital.

-

Tooling and Setup Costs: Custom patches often require specific tools and setups. These costs can be amortized over larger orders, making bulk purchases more economical. Buyers should inquire about any setup fees that may apply to smaller orders.

-

Quality Control (QC): Rigorous QC processes ensure that the final product meets the buyer’s specifications. However, extensive QC measures can add to production costs. Buyers should assess the supplier’s QC standards and how they impact pricing.

-

Logistics: Shipping costs can vary widely based on the origin and destination. International buyers must consider freight costs, customs duties, and potential delays. Understanding Incoterms is crucial for clarifying responsibilities and costs associated with shipping.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Buyers should expect to negotiate margins, especially for larger orders.

What Influences Pricing for Leather Patches?

Several factors can affect the pricing of leather patches:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize pricing.

-

Specifications and Customization: Custom shapes, sizes, and designs can significantly impact pricing. Buyers should be clear about their requirements to avoid unexpected costs.

-

Material Quality and Certifications: High-quality materials or certified sustainable options may come at a premium. Buyers should weigh the benefits of higher-quality materials against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer companies might offer competitive rates to build their client base.

What Are Some Buyer Tips for Cost-Efficiency?

-

Negotiate Effectively: Establishing a good relationship with suppliers can lead to better pricing. Be open about your budget and explore options for discounts on bulk orders.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate factors like shipping, potential tariffs, and the longevity of the product. A lower upfront cost may not always equate to a better deal.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local market conditions. These factors can significantly influence the total cost of sourcing leather patches from suppliers in different regions.

-

Seek Local Suppliers: Whenever possible, consider sourcing from local manufacturers. This approach can reduce logistics costs and lead to faster turnaround times.

In summary, understanding the cost components and pricing influences in the leather patch industry is essential for B2B buyers. By leveraging these insights, buyers can make informed decisions that align with their budget and business goals.

Illustrative image related to leather patch company

Alternatives Analysis: Comparing leather patch company With Other Solutions

Understanding Alternatives for Leather Patch Solutions

When considering leather patch solutions, it’s essential to evaluate alternatives that can deliver similar branding benefits while potentially offering different advantages. This analysis will compare the offerings from a leather patch company against two viable alternatives: embroidered patches and printed fabric patches. Each alternative has unique characteristics that can influence a B2B buyer’s decision based on their specific needs.

| Comparison Aspect | Leather Patch Company | Embroidered Patches | Printed Fabric Patches |

|---|---|---|---|

| Performance | Durable and premium look | Highly durable, vibrant colors | Less durable, can fade over time |

| Cost | Moderate to high pricing | Generally lower cost | Lowest cost option |

| Ease of Implementation | Requires custom design work | Quick turnaround, simple setup | Fast production, easy design |

| Maintenance | Low maintenance | Low maintenance | Medium maintenance |

| Best Use Case | Premium branding, outdoor apparel | Corporate events, uniforms | Promotional items, giveaways |

Pros and Cons of Each Alternative

Embroidered Patches

Embroidered patches are a popular choice for many businesses due to their vibrant colors and durability. They can be easily sewn onto a variety of fabrics, making them versatile for uniforms or promotional apparel. The cost is generally lower than leather patches, which can be appealing for bulk orders. However, they may lack the premium feel of leather and can sometimes be less impactful in terms of brand representation. Additionally, while they are durable, they may not withstand extreme outdoor conditions as well as leather patches.

Printed Fabric Patches

Printed fabric patches represent the most cost-effective solution for branding. They can be produced quickly and are ideal for giveaways or promotional events. The design process is straightforward, allowing for fast turnaround times. However, the longevity of printed patches can be a drawback; they are prone to fading and wear over time, which may not align with brands seeking a premium image. They are best suited for temporary uses rather than long-term branding efforts.

How to Choose the Right Solution for Your Business

Selecting the appropriate leather patch solution depends on various factors, including your brand image, budget, and intended use. For companies looking to establish a premium presence, leather patches are likely the best option despite their higher cost. If budget constraints are a priority, embroidered patches can provide a balance of quality and affordability. For short-term promotions or giveaways, printed fabric patches offer a low-cost solution but may not convey the same level of professionalism or durability.

B2B buyers should carefully assess their branding goals and the specific contexts in which their products will be used to make the best decision. Understanding the strengths and weaknesses of each option will empower businesses to select a solution that aligns with their strategic objectives.

Essential Technical Properties and Trade Terminology for leather patch company

What Are the Key Technical Properties of Leather Patches for B2B Buyers?

When sourcing leather patches for products such as hats or apparel, understanding the technical properties is crucial. Here are some critical specifications that impact quality, durability, and branding.

Illustrative image related to leather patch company

1. Material Grade

The material grade of leather refers to its quality and durability, which can vary significantly. Common grades include full-grain, top-grain, and corrected-grain leather. Full-grain leather is the highest quality, retaining the natural texture and durability. For B2B buyers, selecting the right material grade is essential for ensuring the longevity of the product and aligning with brand values.

2. Stitching Technique

The method of stitching used in leather patches is vital for both aesthetics and durability. Hand-stitched patches often offer superior quality compared to machine-stitched options, as they provide a unique, artisanal look. B2B buyers should consider the stitching technique to ensure the final product meets their quality standards and enhances brand perception.

3. Patch Shape and Size

Custom shapes and sizes of leather patches can significantly impact branding effectiveness. B2B companies can opt for unique shapes that align with their brand identity, enhancing visibility and recognition. Understanding the available options allows buyers to tailor products to specific market needs.

Illustrative image related to leather patch company

4. Color and Finish

Leather patches come in various colors and finishes, such as matte, glossy, or distressed. The choice of color and finish can affect branding and customer appeal. B2B buyers should consider how these factors will resonate with their target audience and how they align with their overall branding strategy.

5. Adhesive Backing

While some leather patches are sewn onto garments, others may use adhesive backing for easier application. Understanding the quality and type of adhesive used is crucial for ensuring that patches remain securely attached over time. This factor can influence the durability and overall customer satisfaction with the product.

What Are Common Trade Terms in the Leather Patch Industry?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms that buyers should know.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather patch industry, buyers often collaborate with OEMs to create custom patches that fit their branding needs. Understanding this term helps buyers identify suitable manufacturing partners.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. In the leather patch market, MOQs can vary significantly between suppliers. B2B buyers should be aware of MOQs to align their purchasing strategies with their production needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. In the context of leather patches, submitting an RFQ can help buyers gather competitive pricing and options from different manufacturers, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. For B2B transactions involving leather patches, understanding Incoterms is crucial for clarifying shipping costs, risk, and delivery obligations. This knowledge can help buyers avoid misunderstandings and ensure smooth logistics.

5. Customization Options

Customization options refer to the various ways a product can be tailored to meet specific requirements, such as design, size, color, and material. Understanding the range of customization options available for leather patches allows buyers to create unique products that resonate with their target markets.

Illustrative image related to leather patch company

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring that their leather patch products meet both quality standards and market expectations.

Navigating Market Dynamics and Sourcing Trends in the leather patch company Sector

What Are the Current Market Dynamics and Sourcing Trends in the Leather Patch Company Sector?

The leather patch company sector is witnessing robust growth driven by increasing demand for personalized and branded merchandise across various industries, including fashion, outdoor gear, and promotional products. Key trends shaping the market include the rise of customizations, where buyers increasingly seek unique designs tailored to their brand identity. This demand is particularly pronounced among international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, where cultural nuances and local aesthetics play a significant role in product design.

Technological advancements are also redefining sourcing strategies. Online platforms and digital design tools enable buyers to create mock-ups and visualize their products before committing to orders, enhancing the customer experience. Furthermore, the trend towards low minimum order quantities allows businesses, regardless of size, to enter the market without substantial upfront investment. This flexibility is appealing to startups and small businesses in emerging markets like Nigeria and Brazil, where brand differentiation is crucial for competitive advantage.

Emerging sourcing trends also highlight a shift towards local and regional suppliers. B2B buyers are increasingly looking for partners who can provide faster turnaround times and reduced shipping costs, as well as those who understand local market dynamics. As global supply chains become more intricate, fostering relationships with suppliers who can adapt to changing market needs is vital for maintaining a competitive edge.

How Is Sustainability and Ethical Sourcing Impacting the Leather Patch Company Sector?

Sustainability has become a crucial factor in the leather patch company sector, with growing awareness of environmental impacts driving B2B buyers to prioritize ethical sourcing. Buyers are increasingly concerned about the lifecycle of the materials used in their products, opting for suppliers who can demonstrate responsible sourcing practices. This includes the use of eco-friendly leather and non-toxic dyes, which not only minimize environmental harm but also appeal to consumers’ preferences for sustainable products.

Illustrative image related to leather patch company

Ethical supply chains are gaining importance, as businesses strive to ensure transparency and fairness in their sourcing practices. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) provide assurance to buyers that their materials are sourced responsibly and sustainably. As demand for sustainable products continues to rise, companies that integrate these principles into their operations are likely to gain a competitive advantage in the marketplace.

Moreover, the trend towards recycling and upcycling is on the rise, with businesses exploring innovative ways to repurpose leather waste into new products. This not only reduces waste but also creates unique offerings that can attract environmentally conscious consumers. For B2B buyers, aligning with suppliers who prioritize sustainability can enhance brand reputation and appeal to an increasingly eco-aware customer base.

What Is the Brief Evolution of the Leather Patch Company Sector?

The leather patch company sector has evolved significantly over the past few decades. Originally focused on traditional uses in rugged apparel and outdoor gear, the sector has expanded to embrace a wider range of applications, including fashion accessories and promotional merchandise. The advent of digital printing technologies and customization tools has transformed the industry, allowing for greater creativity and personalization in product offerings.

Historically, leather was primarily sourced from large-scale tanneries, but recent shifts have seen a rise in small, artisan producers who emphasize quality and craftsmanship. This evolution reflects a broader consumer trend towards authenticity and artisanal products, with buyers valuing the story behind the materials and the craftsmanship involved. As the sector continues to grow, the integration of technology, sustainability, and customization will likely shape its future, providing exciting opportunities for B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of leather patch company

-

How do I select the right leather patch supplier for my business?

When choosing a leather patch supplier, consider factors such as product quality, customization options, and reputation in the industry. Look for suppliers that provide samples or mock-ups to assess their craftsmanship. Check customer reviews and request references to gauge reliability. Additionally, ensure they can accommodate your specific needs, such as minimum order quantities (MOQs) and lead times. It’s essential to communicate your brand vision clearly to find a partner that aligns with your business goals. -

What are the typical minimum order quantities (MOQs) for leather patches?

MOQs for leather patches can vary significantly among suppliers, ranging from as few as one piece to several hundred. Some companies cater to smaller businesses by offering low or no minimums, while others may require larger orders for bulk pricing. It’s advisable to clarify these details upfront when negotiating with potential suppliers. Understanding your needs and the supplier’s capabilities will help you determine the best fit for your order size and budget. -

What customization options are available for leather patches?

Most leather patch suppliers offer a variety of customization options, including different shapes, sizes, colors, and stitching styles. You can often choose from various leather types, such as natural, black, or chestnut, to match your branding. Many companies also allow for unique designs or logos, enabling you to create a distinct look for your products. Be sure to discuss your design ideas and requirements with the supplier to explore all available options. -

What payment terms should I expect when ordering leather patches?

Payment terms can differ widely among suppliers. Common arrangements include upfront payments, deposits, or payment upon delivery. Some suppliers may offer flexible terms based on your order size or established relationship. It’s crucial to discuss and agree on payment conditions before finalizing your order to avoid any misunderstandings. Always ensure that the payment methods offered are secure and convenient for your business operations. -

How can I ensure quality assurance for my leather patches?

To ensure quality assurance, request samples before placing a bulk order. This allows you to assess the material, craftsmanship, and overall design. Establish clear quality standards and guidelines with your supplier, including acceptable defect rates and inspection processes. Regular communication throughout the production process is vital, so consider scheduling updates or visits if feasible. Some suppliers may offer guarantees or warranties, providing additional peace of mind regarding the quality of their products. -

What logistics considerations should I keep in mind when sourcing leather patches internationally?

When sourcing leather patches internationally, consider shipping times, costs, and customs regulations. Research potential tariffs or import duties that may apply to your products. It’s also essential to discuss logistics with your supplier, including packaging methods and shipping options. Ensure that the supplier can provide tracking information and reliable shipping partners. Establishing a clear timeline for delivery will help you manage your inventory and meet customer expectations. -

How do I handle communication barriers with international suppliers?

Effective communication is crucial when working with international suppliers. To overcome potential language barriers, use clear and concise language in your correspondence. Utilize visual aids, such as sketches or mock-ups, to clarify your design ideas. Consider scheduling video calls for more complex discussions, allowing for real-time feedback. It’s also beneficial to establish a single point of contact to streamline communication and ensure consistency throughout the project. -

What factors should I consider when evaluating the supplier’s reliability?

To assess a supplier’s reliability, examine their track record, including years in business, customer reviews, and case studies. Look for suppliers with a history of meeting deadlines and maintaining quality standards. Ask for references from other B2B clients, particularly those in your industry, to gain insights into their experiences. Additionally, consider their responsiveness to inquiries and willingness to accommodate your specific needs as indicators of their reliability.

Top 4 Leather Patch Company Manufacturers & Suppliers List

1. Leather Patch Company – Authentic Leather Patch Hats

Domain: leatherpatchcompany.com

Registered: 2017 (8 years)

Introduction: Authentic Leather Patch Hats, 100% Authentic Leather, Hand Stitched, Huge Hat Selection, Custom Patch Shapes, No Minimum Orders, Various Patch Shapes, Four Hide Colors (Natural Leather, Dark Brown Leather, Chestnut Leather, Black Leather), Customer Service Focused, Design-It-Yourself Option, Mock-Up Request Available.

2. The Leather Patch – Custom Hats & Patches

Domain: theleatherpatch.com

Registered: 2022 (3 years)

Introduction: The Leather Patch Custom Hat Company offers a variety of custom hats including mid-profile hats, low-profile hats, unstructured hats, Flexfit® hats, custom beanies, ponytail hats, and flat bill hats. They also provide wedding hats and DIY patches such as acrylic and leather patches. Additionally, the company features promotional gifts including beverage holders, bottle openers, Christmas ornaments…

3. SoCal Leather Patches – Hand-Stitched Custom Designs

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, SoCal Leather Patches – Hand-Stitched Custom Designs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. KC Laser Co – Custom Leather Patch Hats

Domain: kclaserco.com

Registered: 2019 (6 years)

Introduction: Custom Leather Patch Hats, Handmade Gifts, Family Owned in Kansas City. Key products include: 1. KC Inset – Richardson 112 Leather Patch Hat – $24.00 (was $35.00) 2. Hook N’ Loop Richardson 112 Hat with Velcro – Various Colors – $19.50 (was $26.00) 3. Custom Bible & Book Rebinding with Hand Bound Premium Leather – $37.50 (was $50.00) 4. Build Your Own Lake Hat – Pick Your Hat Pick Your Patch – $24…

Strategic Sourcing Conclusion and Outlook for leather patch company

In navigating the competitive landscape of the leather patch industry, strategic sourcing is paramount for businesses aiming to enhance brand visibility and customer loyalty. Key takeaways from this guide highlight the importance of selecting suppliers that offer high-quality, customizable products with flexible ordering options. Businesses can capitalize on low minimum order quantities and bulk pricing to optimize their inventory and reduce costs. Authenticity in materials, particularly 100% genuine leather, significantly elevates the perceived value of branded merchandise, making it crucial for companies to partner with reputable manufacturers.

Looking forward, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe have a unique opportunity to leverage the growing demand for customized leather products. By aligning with manufacturers that prioritize craftsmanship and customer service, businesses can differentiate themselves in crowded markets. As you explore partnerships in this space, consider how tailored leather patch solutions can not only enhance your product offerings but also strengthen your brand identity. Embrace this opportunity to invest in quality and innovation, ensuring your business stands out in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to leather patch company

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.