Introduction: Navigating the Global Market for vinyl material for cars

Navigating the global market for vinyl material for cars presents significant challenges for B2B buyers, particularly when it comes to sourcing high-quality materials that meet diverse regional needs. As automotive manufacturers and interior designers increasingly turn to vinyl for its exceptional durability, easy maintenance, and aesthetic versatility, understanding the nuances of this material becomes essential. This guide offers a comprehensive overview of automotive vinyl, exploring various types, applications, and key factors influencing cost.

From the rich textures of luxury-grade vinyl to budget-friendly options that don’t compromise on quality, buyers will find insights into selecting the right materials for their specific projects. Additionally, we delve into the importance of supplier vetting, highlighting best practices for ensuring reliability and sustainability in your procurement process.

For international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—this guide serves as a vital resource. It empowers decision-makers to make informed purchasing choices, enhancing the value of their investments in automotive interiors. With actionable insights and a focus on industry trends, this guide is designed to help you navigate the complexities of the vinyl market, ensuring your projects are both stylish and functional.

Table Of Contents

- Top 8 Vinyl Material For Cars Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for vinyl material for cars

- Understanding vinyl material for cars Types and Variations

- Key Industrial Applications of vinyl material for cars

- 3 Common User Pain Points for ‘vinyl material for cars’ & Their Solutions

- Strategic Material Selection Guide for vinyl material for cars

- In-depth Look: Manufacturing Processes and Quality Assurance for vinyl material for cars

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘vinyl material for cars’

- Comprehensive Cost and Pricing Analysis for vinyl material for cars Sourcing

- Alternatives Analysis: Comparing vinyl material for cars With Other Solutions

- Essential Technical Properties and Trade Terminology for vinyl material for cars

- Navigating Market Dynamics and Sourcing Trends in the vinyl material for cars Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vinyl material for cars

- Strategic Sourcing Conclusion and Outlook for vinyl material for cars

- Important Disclaimer & Terms of Use

Understanding vinyl material for cars Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Vinyl | Made from polyvinyl chloride, excellent durability and UV resistance. | Automotive upholstery, door panels | Pros: Cost-effective, easy to clean. Cons: Less breathable than fabric. |

| Marine Vinyl | Water-resistant and mildew-resistant, designed for high moisture environments. | Boats, outdoor vehicles, marine upholstery | Pros: Ideal for humid conditions, durable against spills. Cons: Limited color options. |

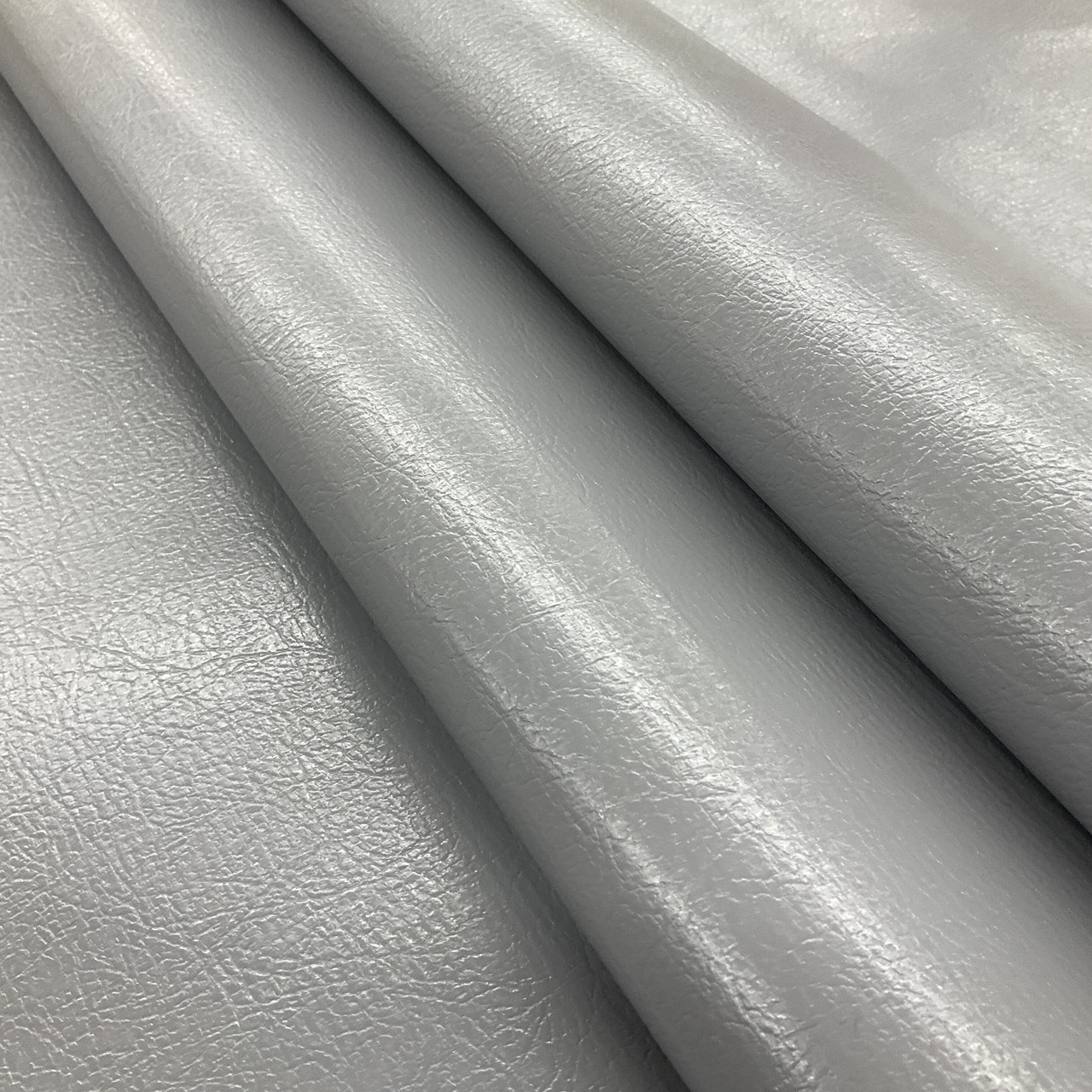

| Leather-like Vinyl | Mimics the appearance of leather but offers greater affordability and ease of maintenance. | High-end automotive interiors | Pros: Luxurious look at a lower price, low maintenance. Cons: May not have the same tactile quality as genuine leather. |

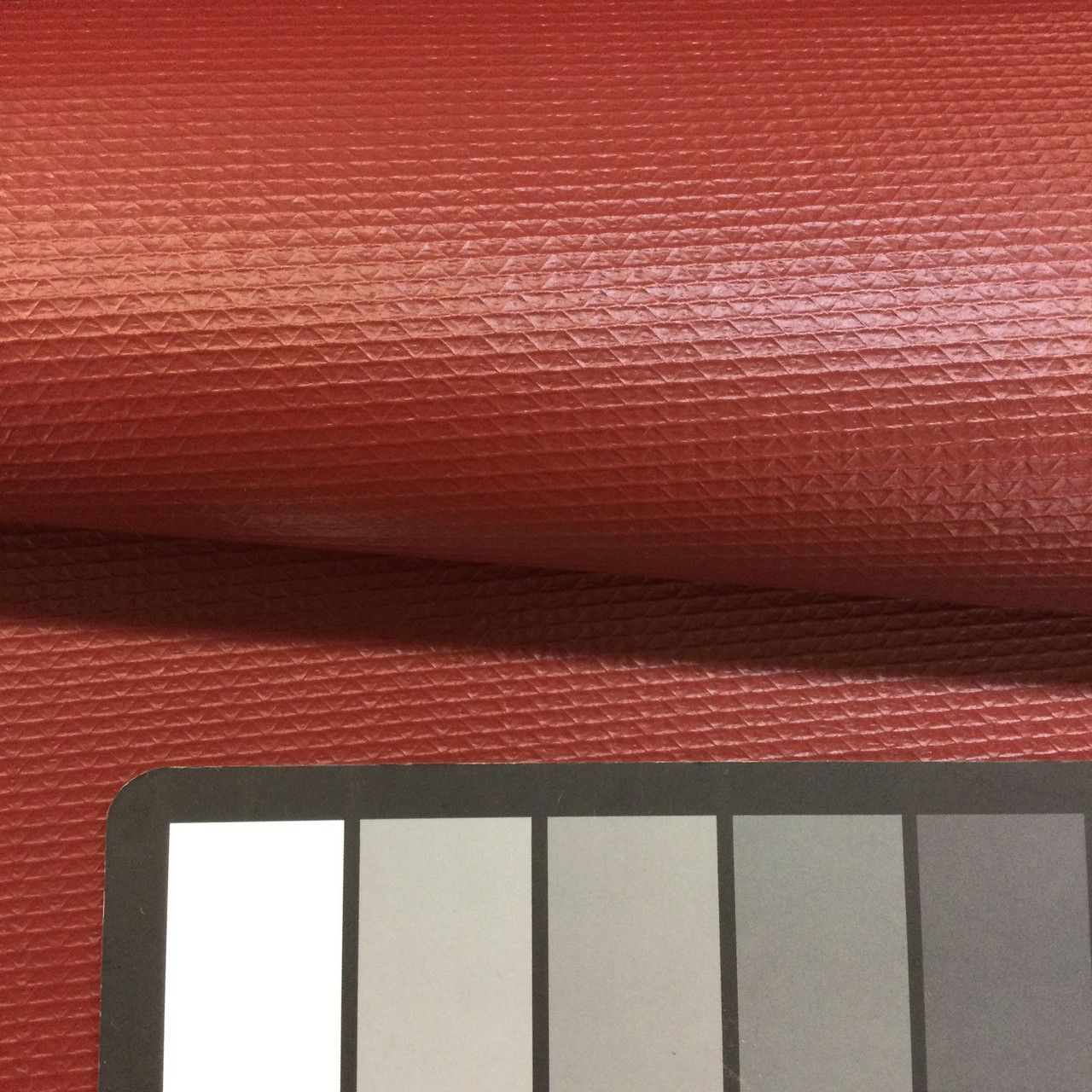

| Textured Vinyl | Features a variety of textures and patterns, providing aesthetic versatility. | Custom automotive interiors, restorations | Pros: Customizable aesthetics, durable. Cons: Some textures may require more care. |

| Anti-Microbial Vinyl | Incorporates additives to resist bacteria and mold, enhancing hygiene. | Medical transport vehicles, family vehicles | Pros: Promotes cleanliness, ideal for high-use areas. Cons: Typically higher cost due to specialized properties. |

What Are the Characteristics and Suitability of PVC Vinyl for Automotive Applications?

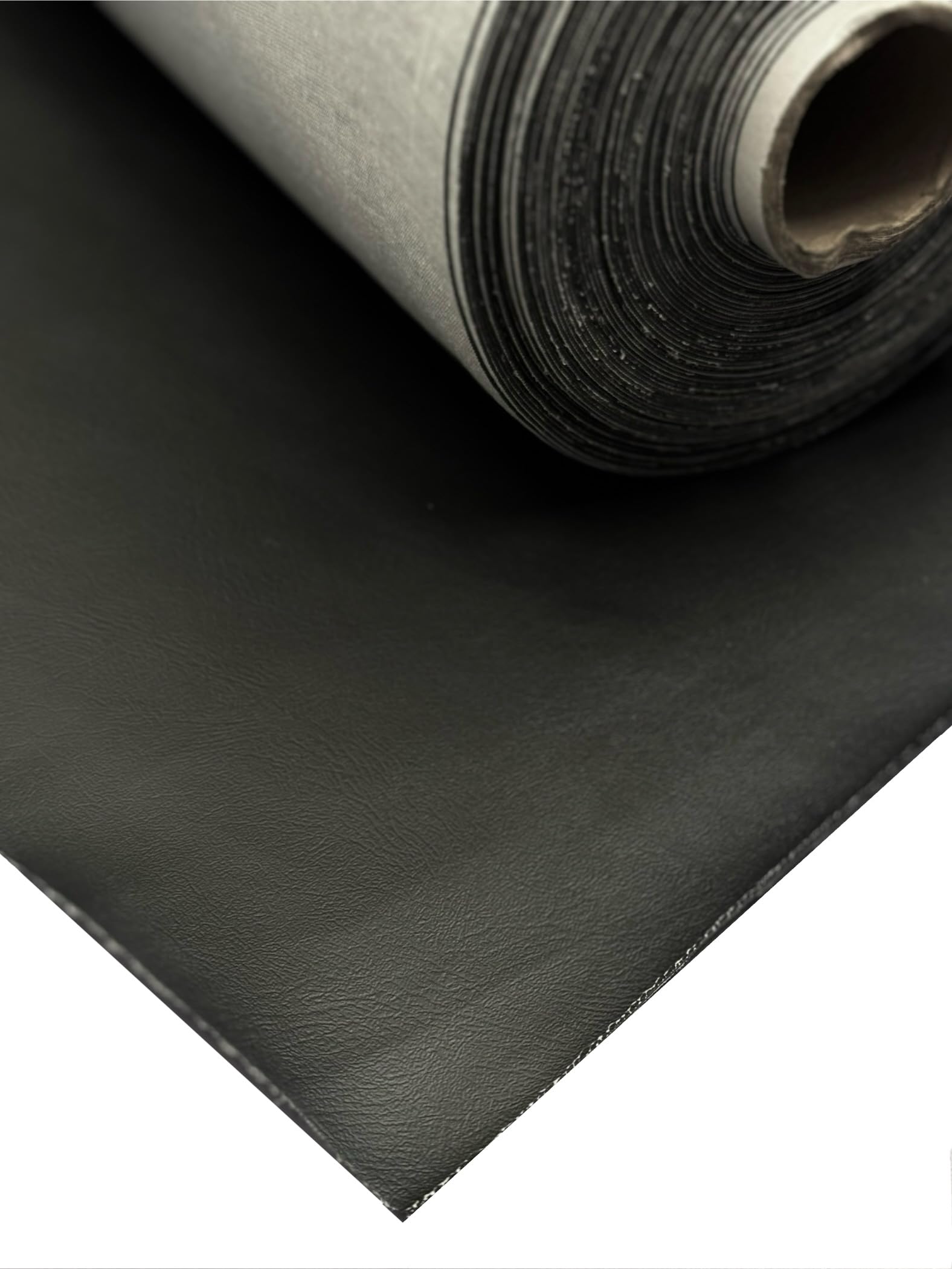

PVC vinyl is a staple in the automotive industry, valued for its exceptional durability and resistance to UV exposure. This material is ideal for upholstery, door panels, and other interior applications where wear and tear are prevalent. B2B buyers should consider PVC vinyl for projects that require a cost-effective solution without sacrificing quality. Its easy maintenance—requiring only mild soap and water for cleaning—makes it a practical choice for busy environments.

How Does Marine Vinyl Differ and When Should It Be Used?

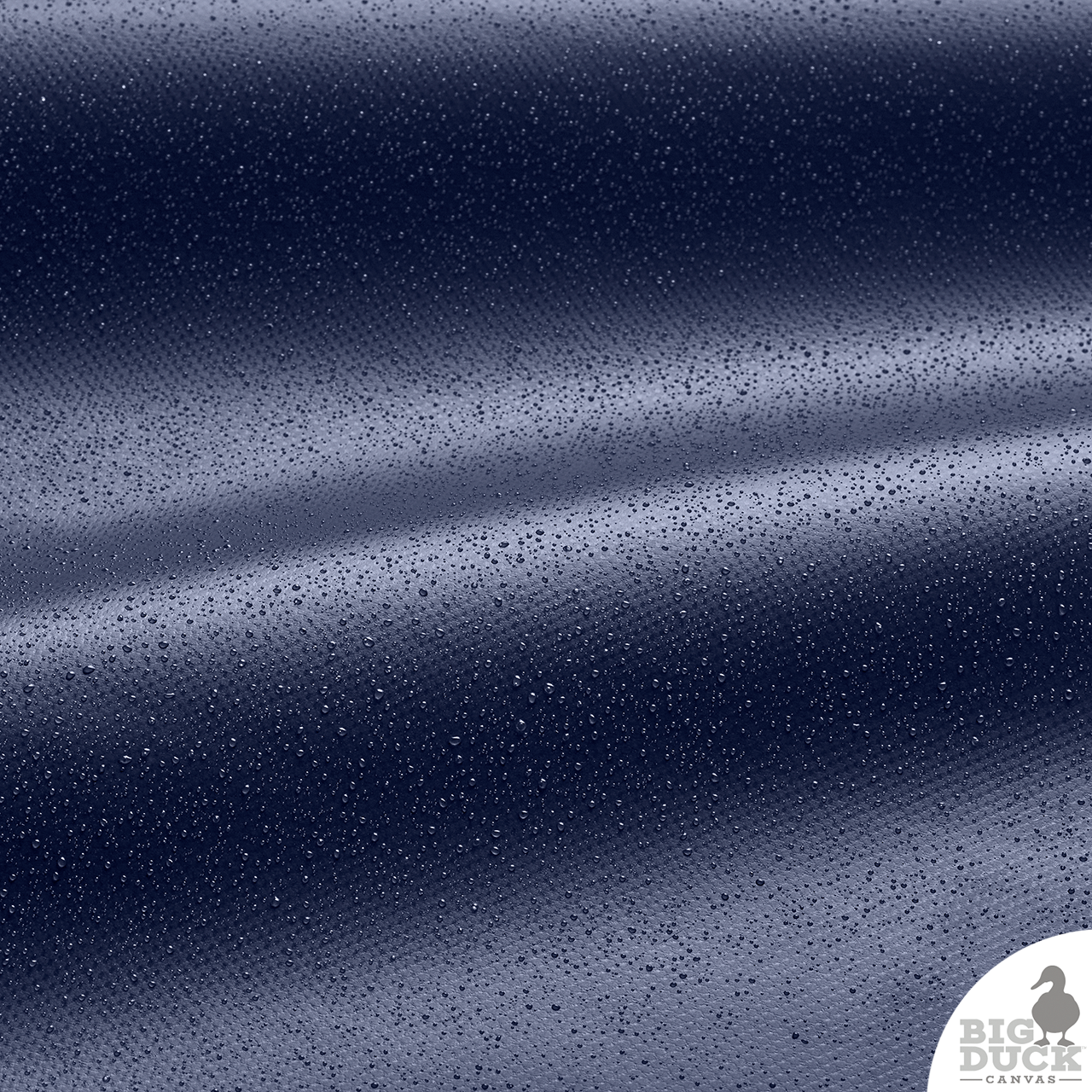

Marine vinyl is specifically designed to withstand moisture, making it suitable for marine and outdoor applications. Its water-resistant and mildew-resistant properties are essential for vehicles exposed to humid conditions, such as boats and outdoor recreational vehicles. B2B buyers in marine industries should prioritize this vinyl type when sourcing materials for upholstery, as it ensures longevity and resilience against spills and moisture. However, the color palette may be more limited compared to other vinyl options.

What Advantages Does Leather-like Vinyl Offer for B2B Buyers?

Leather-like vinyl offers a luxurious aesthetic similar to genuine leather but at a more accessible price point. This material is particularly popular in high-end automotive interiors where appearance is crucial. B2B buyers looking to enhance the visual appeal of their vehicles without the associated costs of real leather will find this option advantageous. Additionally, it requires minimal maintenance, making it suitable for both personal and commercial applications.

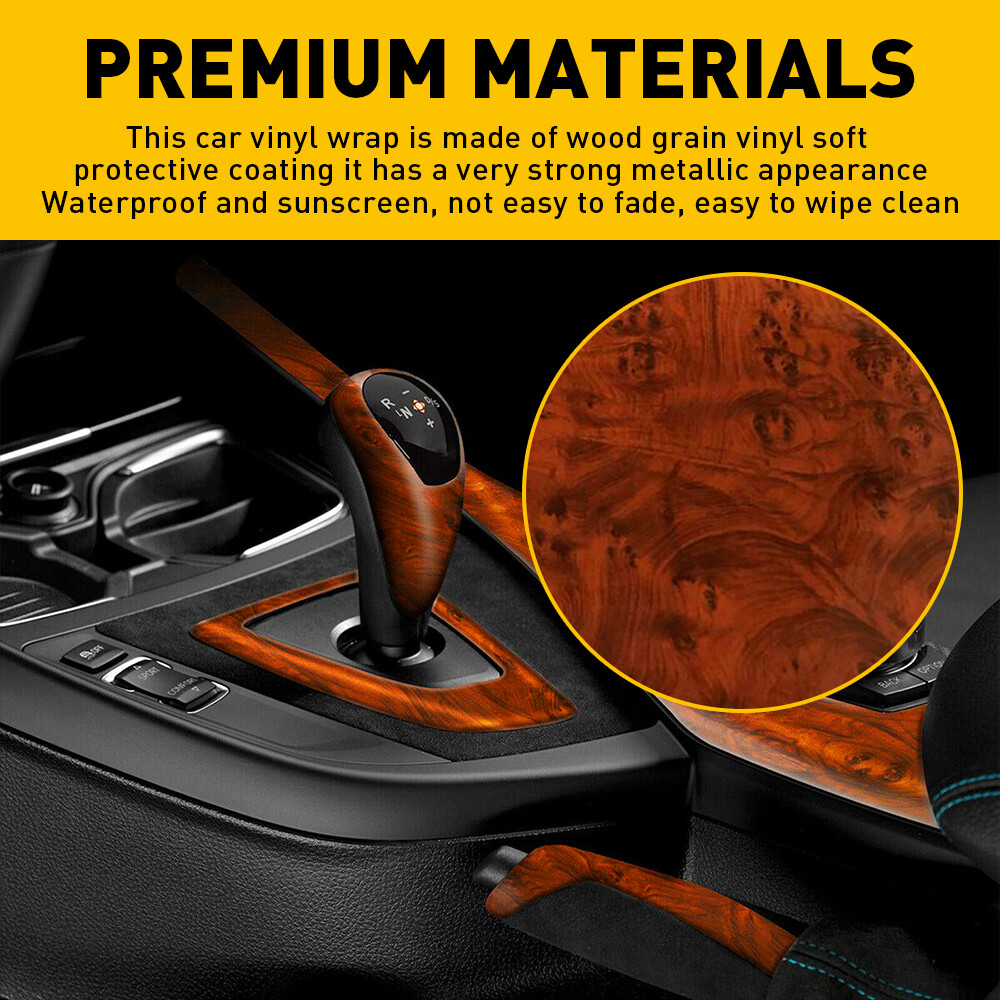

Why Choose Textured Vinyl for Custom Automotive Interiors?

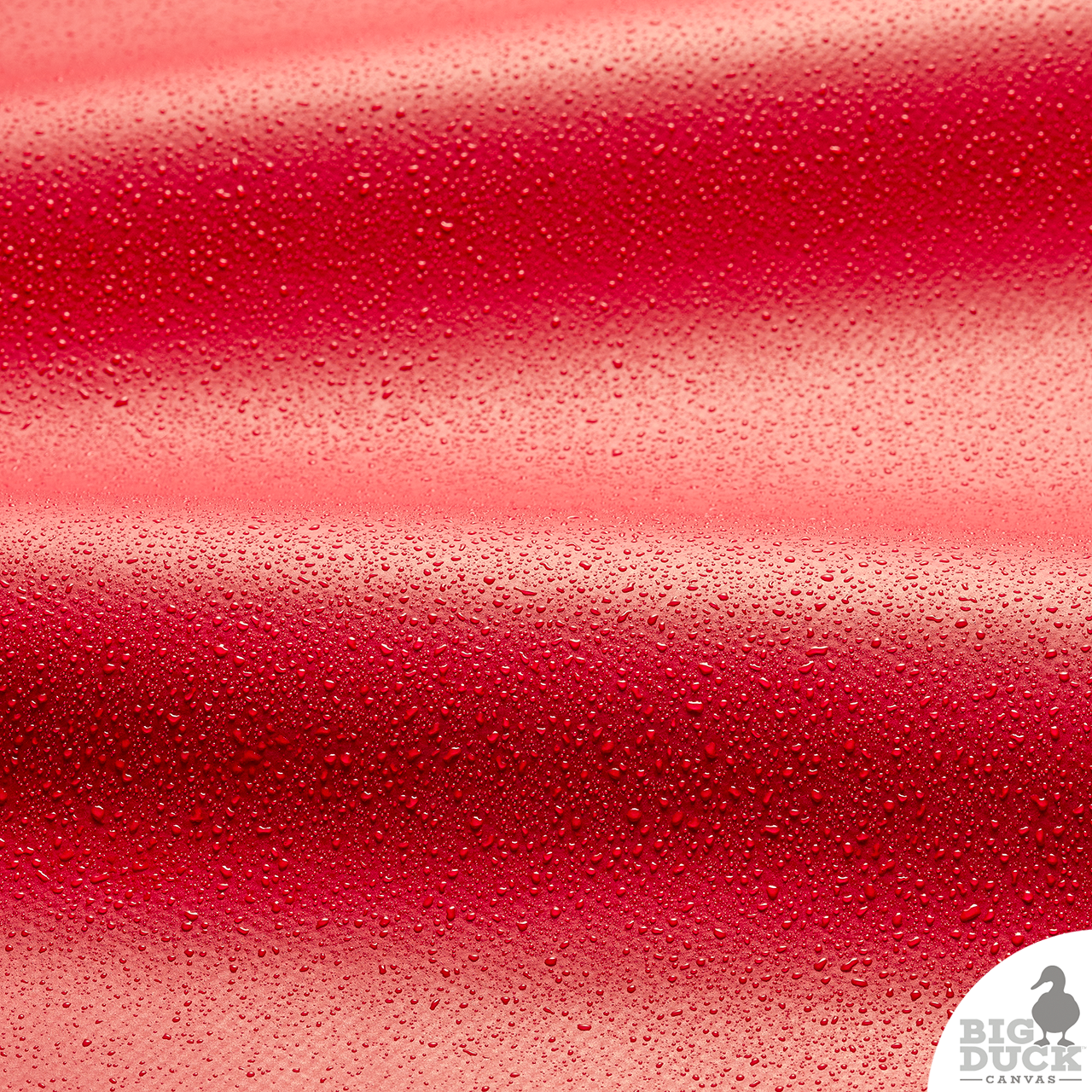

Textured vinyl stands out for its aesthetic versatility, featuring a range of patterns and finishes. This material allows for customization, making it ideal for restoration projects or bespoke automotive designs. B2B buyers should consider textured vinyl when aiming to create unique interiors that reflect specific brand identities or customer preferences. However, it’s important to note that some textures may require additional care to maintain their appearance over time.

What Are the Benefits of Anti-Microbial Vinyl in Automotive Settings?

Anti-microbial vinyl incorporates specialized additives that resist bacteria and mold, making it an excellent choice for vehicles that prioritize hygiene. This type is particularly valuable in medical transport vehicles or family cars where cleanliness is paramount. B2B buyers should evaluate the benefits of anti-microbial properties when sourcing materials for high-use areas, as it can enhance the overall safety and cleanliness of the vehicle’s interior. While this vinyl tends to be more expensive, the added value of hygiene can justify the investment.

Key Industrial Applications of vinyl material for cars

| Industry/Sector | Specific Application of vinyl material for cars | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Interior Upholstery and Trim | Enhances vehicle aesthetics and comfort while ensuring durability and low maintenance. | Ensure high abrasion resistance and UV stability for longevity in various climates. |

| Vehicle Customization | Vinyl Wraps for Exterior Design | Provides a cost-effective way to customize vehicle appearance without permanent changes. | Look for high-quality adhesive properties and easy application techniques. |

| Fleet Management | Seat Covers and Protective Liners | Protects original upholstery, extending the lifespan of fleet vehicles and reducing maintenance costs. | Consider easy-to-clean materials that are also moisture and mildew resistant. |

| Transport and Logistics | Cargo Area Liners and Covers | Protects cargo areas from wear and tear, ensuring cargo safety and integrity. | Source materials that are durable and resistant to chemicals and abrasion. |

| Automotive Repair and Restoration | Replacement Upholstery and Parts | Allows for restoration of vintage vehicles, maintaining aesthetic integrity while providing durability. | Ensure materials match original specifications and are compliant with local regulations. |

How is Vinyl Material Used in Automotive Manufacturing?

In the automotive manufacturing sector, vinyl material is widely used for interior upholstery and trim. Its exceptional durability makes it an ideal choice for car seats, door panels, and dashboards. This application not only enhances the aesthetic appeal of vehicles but also provides a low-maintenance solution that stands up to daily wear and tear. For international buyers, especially in regions like Africa and South America, sourcing high-quality vinyl that offers UV protection and abrasion resistance is crucial, given the varying climate conditions.

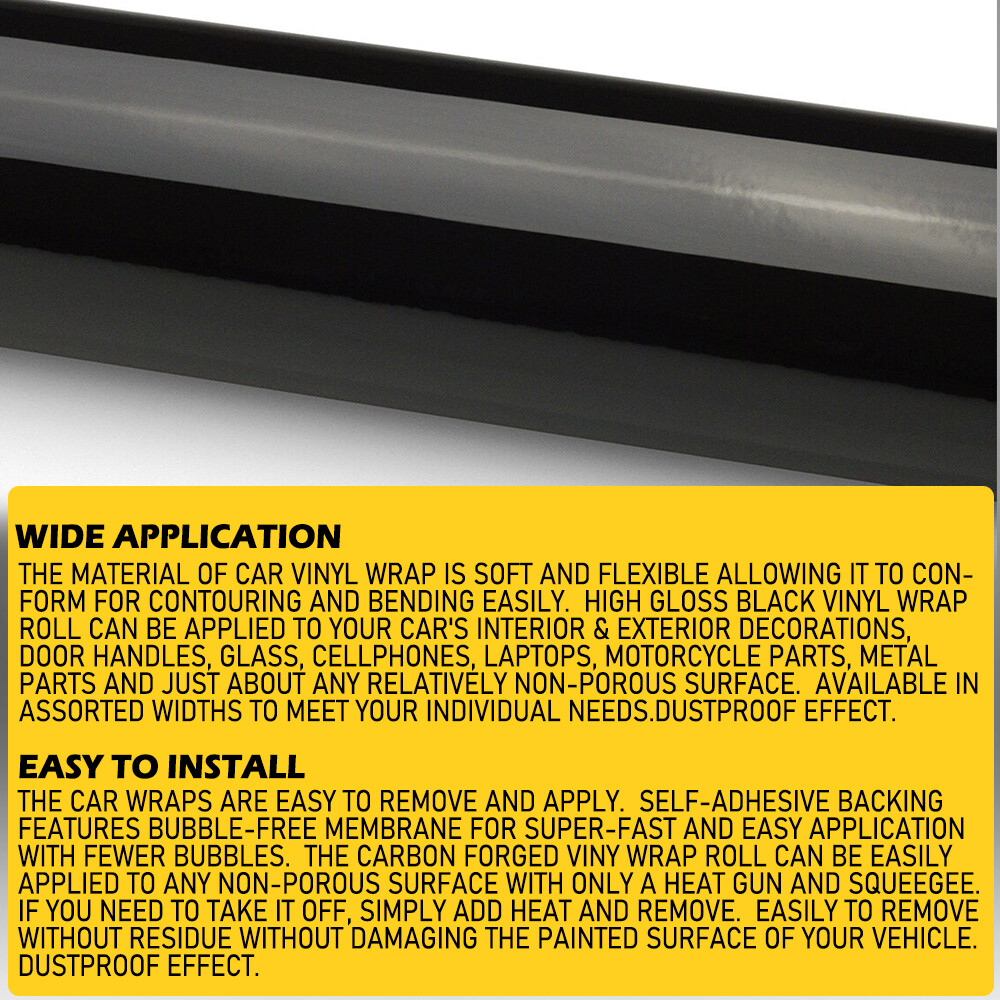

What Role Does Vinyl Play in Vehicle Customization?

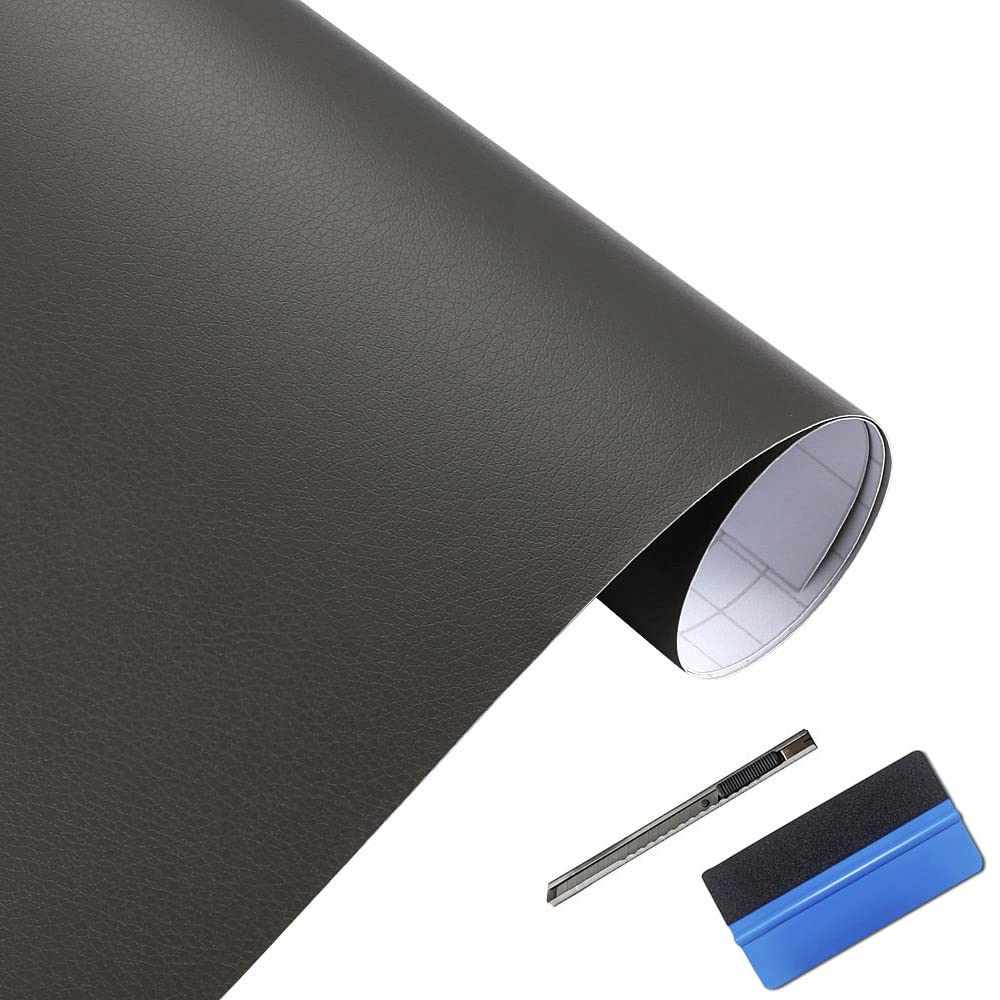

Vinyl wraps are increasingly popular in the vehicle customization industry, allowing businesses to offer clients a cost-effective method of altering a vehicle’s appearance without permanent modifications. These wraps can replicate various textures and finishes, from matte to glossy, providing endless design possibilities. For B2B buyers in Europe and the Middle East, it’s essential to consider the adhesive quality and ease of application, as these factors significantly affect the final outcome and longevity of the wrap.

Illustrative image related to vinyl material for cars

How Does Vinyl Benefit Fleet Management?

In fleet management, vinyl materials are utilized for seat covers and protective liners, which help preserve the original upholstery of vehicles. This not only extends the lifespan of fleet assets but also reduces overall maintenance costs, making it a financially sound investment. Buyers from regions with high humidity, such as parts of Africa and the Middle East, should prioritize sourcing vinyl that is mildew and moisture resistant to ensure long-term performance and cleanliness.

How is Vinyl Material Used in Transport and Logistics?

Vinyl is also employed in the transport and logistics sector, particularly for cargo area liners and covers. These applications protect cargo areas from damage, ensuring the integrity and safety of transported goods. For international buyers, sourcing durable vinyl that is resistant to chemicals and abrasions is vital, especially in harsh working environments. This ensures that the cargo areas remain in good condition, ultimately leading to lower operational costs.

Why is Vinyl Important for Automotive Repair and Restoration?

In the automotive repair and restoration industry, vinyl materials are crucial for replacing upholstery and parts in vintage vehicles. They allow restorers to maintain the aesthetic integrity of classic cars while providing durability that meets modern standards. Buyers should ensure that the vinyl materials sourced match original specifications and comply with local regulations, particularly in European markets, where automotive standards can be stringent. This attention to detail helps preserve the value and authenticity of restored vehicles.

3 Common User Pain Points for ‘vinyl material for cars’ & Their Solutions

Scenario 1: Durability Concerns in Harsh Environments

The Problem: B2B buyers in regions with extreme weather conditions, such as the Middle East or northern Europe, often struggle with the durability of vinyl materials. High temperatures can cause vinyl to warp, crack, or fade, while cold climates may lead to brittleness. This can result in increased replacement costs and customer dissatisfaction, especially for automotive upholstery suppliers who need to ensure long-lasting products.

Illustrative image related to vinyl material for cars

The Solution: To address durability issues, buyers should focus on sourcing high-quality vinyl materials that are specifically engineered for extreme conditions. Look for options that feature UV stabilization to prevent fading and cold-crack ratings that ensure resilience against low temperatures. For example, selecting vinyl with a heavy-duty Wyzenbeek abrasion-resistant layer can enhance longevity. Additionally, establishing relationships with manufacturers who offer warranties on their products can provide peace of mind and safeguard against premature wear.

Scenario 2: Maintenance Challenges for High-Usage Vehicles

The Problem: Companies that manage fleets of vehicles or operate in sectors like transportation often face the challenge of maintaining a clean and professional appearance for their interiors. Vinyl materials, while generally low-maintenance, can become stained or scuffed over time, leading to a need for frequent cleaning and potential reupholstering, which can disrupt operations.

The Solution: B2B buyers should consider investing in vinyl materials that have built-in protective features, such as anti-stain or antimicrobial treatments. These treatments make it easier to wipe down surfaces and minimize the absorption of spills. When purchasing, inquire about the cleaning recommendations and choose materials that can withstand regular cleaning without degrading. Implementing a scheduled maintenance routine that includes cleaning with mild soap and water can help prolong the lifespan of the vinyl and keep the fleet looking sharp.

Illustrative image related to vinyl material for cars

Scenario 3: Limited Customization Options Affecting Brand Identity

The Problem: Businesses looking to maintain a strong brand identity through their vehicle interiors often find that standard vinyl offerings do not align with their brand aesthetics. This can be particularly challenging for companies in competitive markets, such as luxury transport or hospitality, where the visual appeal of the vehicle’s interior is critical.

The Solution: To solve this issue, B2B buyers should prioritize suppliers that offer a wide range of customization options in vinyl materials, including colors, textures, and patterns. Engaging with manufacturers who can provide samples or prototypes allows companies to test how the material complements their brand before making a bulk purchase. Furthermore, exploring vinyl options that mimic premium materials, like leather, at a fraction of the cost can deliver the desired aesthetic without compromising the budget. By ensuring that the selected vinyl matches the overall design and branding strategy, businesses can enhance their image and appeal to their target audience effectively.

Strategic Material Selection Guide for vinyl material for cars

What Are the Key Properties of PVC Vinyl for Automotive Applications?

Polyvinyl Chloride (PVC) is the most common vinyl material used in automotive applications. It is known for its exceptional durability, making it suitable for car interiors that face daily wear and tear. PVC vinyl typically has a temperature rating of -10°F to 150°F, which allows it to perform well in various climates. Its corrosion resistance is notable, especially against oils and moisture, making it an ideal choice for environments prone to spills or humidity.

Pros and Cons: PVC vinyl is relatively low-cost compared to other materials, making it an attractive option for manufacturers. However, its production can involve complex processes that may increase lead times. Additionally, while PVC is durable, it can become brittle over time if not properly maintained, leading to potential cracking.

Impact on Application: PVC is compatible with a range of media, including dyes and finishes, allowing for customization in color and texture. This versatility is essential for car manufacturers looking to differentiate their offerings.

Illustrative image related to vinyl material for cars

How Does PU Vinyl Compare in Terms of Performance?

Polyurethane (PU) vinyl is another popular choice for automotive applications, known for its flexibility and resilience. It performs well under a wider temperature range, typically from -20°F to 180°F, and offers superior abrasion resistance compared to PVC. This makes PU vinyl suitable for high-traffic areas of a vehicle, such as seats and door panels.

Pros and Cons: The primary advantage of PU vinyl is its luxurious feel and aesthetic appeal, which closely mimics leather. However, it comes at a higher cost than PVC, which may be a consideration for budget-conscious buyers. Additionally, while PU vinyl is generally more durable, it may require more careful handling during installation to avoid damage.

Impact on Application: PU vinyl is often used in premium automotive interiors, where aesthetics and comfort are paramount. Its compatibility with various finishes allows manufacturers to create high-end looks without the associated costs of genuine leather.

Illustrative image related to vinyl material for cars

What Are the Benefits of TPO Vinyl in Automotive Interiors?

Thermoplastic Olefin (TPO) vinyl is gaining traction in automotive applications due to its eco-friendly properties and recyclability. TPO has a temperature rating similar to PVC, typically between -20°F and 150°F, and is resistant to UV exposure, making it suitable for sun-exposed areas of a vehicle.

Pros and Cons: One of TPO’s significant advantages is its environmental sustainability, appealing to manufacturers looking to enhance their green credentials. However, TPO can be more challenging to work with during manufacturing due to its unique properties, which may increase production complexity and costs.

Impact on Application: TPO is often used in exterior applications, such as dashboards and trims, where UV resistance is crucial. Its compatibility with other materials allows for innovative designs and finishes.

What Should International Buyers Consider When Selecting Vinyl Materials?

When sourcing vinyl materials for automotive applications, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider compliance with various standards. For instance, ASTM standards in the U.S. and DIN standards in Germany dictate performance criteria that materials must meet. Buyers should also be aware of regional preferences for aesthetics and functionality, as these can vary significantly across markets.

Illustrative image related to vinyl material for cars

Summary Table of Vinyl Materials for Automotive Applications

| Materiaal | Typical Use Case for vinyl material for cars | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC Vinyl | Car seats, door panels, dashboards | Exceptional durability and low cost | Can become brittle over time | Low |

| PU Vinyl | Premium car interiors, high-traffic areas | Luxurious feel and aesthetic appeal | Higher cost and requires careful handling | Hoog |

| TPO Vinyl | Dashboards, trims, eco-friendly applications | Environmentally sustainable and UV resistant | More complex manufacturing process | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions about vinyl materials for automotive applications, ensuring they choose the right product for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for vinyl material for cars

The manufacturing process of vinyl material for cars is a detailed journey that ensures quality and durability, essential for B2B buyers in diverse regions, including Africa, South America, the Middle East, and Europe. Understanding these processes and the associated quality assurance measures can significantly enhance purchasing decisions.

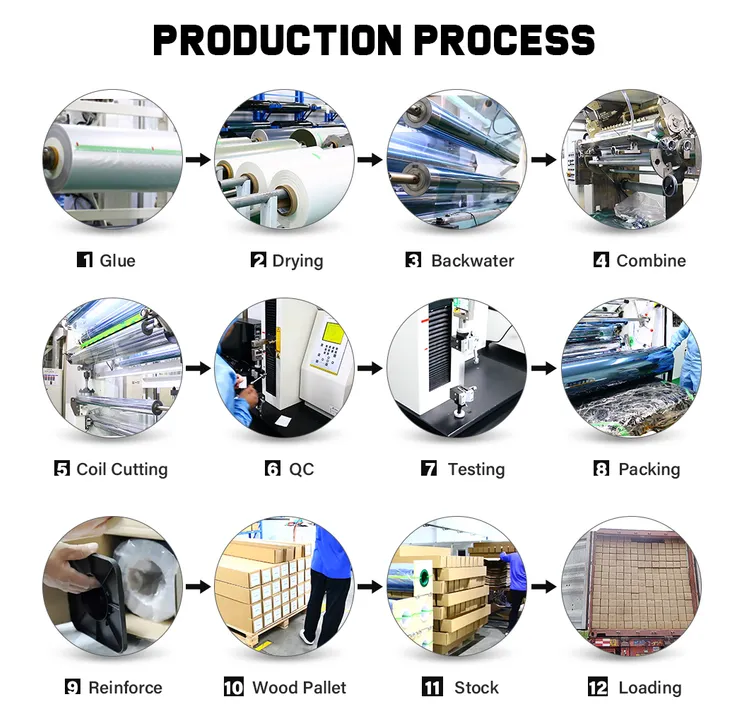

What Are the Main Stages in the Manufacturing Process of Automotive Vinyl?

How Is Material Prepared for Vinyl Production?

The manufacturing of automotive vinyl begins with material preparation, primarily using polyvinyl chloride (PVC) as the base material. This stage involves sourcing high-quality PVC resin, which may undergo blending with plasticizers, stabilizers, and colorants to achieve desired properties such as flexibility, UV resistance, and aesthetic appeal. The mixture is then compounded through heat and mechanical processing to ensure a uniform distribution of materials.

Illustrative image related to vinyl material for cars

What Techniques Are Used for Forming Vinyl?

Once the material is prepared, it undergoes forming, which typically involves calendering or extrusion processes.

-

Calendering: In this method, the compounded PVC is passed through a series of rollers to produce thin sheets of vinyl. This technique allows for precise control over thickness and surface texture, which can be customized to meet specific design requirements.

-

Extrusion: Alternatively, extrusion involves forcing the PVC mixture through a die to create continuous sheets or rolls of vinyl. This method is particularly useful for producing large volumes of vinyl in consistent dimensions.

Both techniques enable manufacturers to create vinyl materials that cater to various automotive applications, including upholstery, door panels, and dashboards.

How Is Vinyl Assembled and Finished?

The assembly stage typically involves cutting, shaping, and sewing the vinyl into specific automotive components. This process is often complemented by the addition of backing materials to enhance durability and comfort. After assembly, the finishing stage applies protective coatings or treatments to improve resistance to UV radiation, moisture, and abrasion. This final step is crucial for ensuring that the vinyl maintains its appearance and functionality over time.

Illustrative image related to vinyl material for cars

What Quality Assurance Measures Are Essential in Vinyl Manufacturing?

Which International Standards Should B2B Buyers Be Aware Of?

Quality assurance in vinyl production is critical to ensuring that the final product meets industry standards. International standards such as ISO 9001 for quality management systems are commonly adopted to guarantee consistent quality and customer satisfaction. Additionally, industry-specific certifications like CE (European Conformity) for safety and compliance can be crucial for products exported to regions such as Europe.

What Are the Key Quality Control Checkpoints in Vinyl Production?

Quality control (QC) is integrated throughout the manufacturing process, with several key checkpoints established:

-

Incoming Quality Control (IQC): This initial inspection ensures that raw materials, such as PVC resin and additives, meet predefined quality specifications before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves regular checks to monitor parameters such as thickness, texture, and color consistency. This proactive approach helps identify potential issues early in the production cycle.

-

Final Quality Control (FQC): After the assembly and finishing processes, FQC evaluates the final products against specifications. This includes visual inspections and physical testing to ensure durability, flexibility, and resistance to environmental factors.

What Testing Methods Are Commonly Used for Vinyl Quality Assurance?

Several testing methods are employed to assess the quality of automotive vinyl, including:

-

Abrasion Resistance Testing: This test evaluates how well the vinyl can withstand wear and tear, simulating everyday use conditions.

-

UV Resistance Testing: Given the exposure of automotive interiors to sunlight, testing for UV resistance ensures that the vinyl does not fade or deteriorate over time.

-

Mildew and Moisture Resistance Testing: This assesses the vinyl’s ability to resist mold and mildew, which is particularly important in humid climates.

These testing methods not only help maintain product integrity but also provide valuable data for B2B buyers regarding the reliability of the materials they are sourcing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control measures of suppliers is essential. Here are effective strategies:

Illustrative image related to vinyl material for cars

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes, quality control checkpoints, and adherence to international standards. This firsthand observation helps establish trust and ensures that the supplier meets required specifications.

-

Quality Reports: Requesting detailed quality reports, including results from testing and inspections, can offer transparency. These documents should outline the methodologies used and the outcomes of various tests.

-

Third-Party Inspections: Engaging third-party inspection services can provide an impartial assessment of the supplier’s quality control processes. This is particularly useful for B2B buyers unfamiliar with local manufacturing practices.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control. Different markets may have varying regulatory requirements and standards. For instance, European buyers might prioritize CE certification, while buyers in other regions may focus more on cost-effectiveness and local compliance standards.

Additionally, understanding cultural differences in business practices can aid in navigating supplier relationships. Establishing clear communication regarding quality expectations and compliance standards is crucial for successful partnerships.

In summary, the manufacturing processes and quality assurance measures for vinyl materials in the automotive sector are complex but essential for ensuring product reliability and customer satisfaction. By understanding these processes and actively engaging in quality verification, B2B buyers can make informed decisions that meet their business needs.

Illustrative image related to vinyl material for cars

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vinyl material for cars’

Inleiding

In the competitive automotive industry, sourcing high-quality vinyl material for cars is essential for manufacturers and upholstery businesses. This guide provides a structured approach to help B2B buyers navigate the sourcing process, ensuring they make informed decisions while procuring durable and aesthetically appealing vinyl materials.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the vinyl material is the foundation of a successful sourcing strategy. Consider factors such as thickness, abrasion resistance, UV stability, and moisture resistance, as these will directly impact the material’s performance in automotive applications.

- Thickness: Determine the required thickness based on the application, whether for seat covers or dashboard overlays.

- Duurzaamheid: Look for materials with high Wyzenbeek abrasion ratings to ensure longevity.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in automotive vinyl. Utilize industry directories, trade shows, and online marketplaces to compile a list of potential partners.

- Supplier Reputation: Check for customer reviews and testimonials to gauge reliability.

- Market Presence: Favor suppliers with a strong presence in your target regions, such as Europe or Africa, to ensure they understand local needs.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications and compliance with industry standards. This step is crucial for ensuring the quality and safety of the vinyl materials you intend to procure.

- Quality Certifications: Look for ISO certifications or industry-specific standards that validate the quality of their products.

- Environmental Compliance: Ensure that the supplier adheres to environmental regulations, particularly if your business prioritizes sustainability.

Step 4: Request Samples for Testing

Always request samples of the vinyl materials before making a bulk order. Testing samples allows you to assess the material’s quality, texture, and performance in real-world conditions.

- Testing Durability: Conduct abrasion and UV exposure tests to evaluate long-term performance.

- Aesthetic Appeal: Ensure the color and texture match your design requirements and customer expectations.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing models and terms of sale. This step is vital for ensuring cost-effectiveness while maintaining quality.

- Cost per Yard: Evaluate the cost per yard and any additional fees, such as shipping or handling.

- Payment Terms: Understand their payment terms, including deposits and credit options, to manage your cash flow effectively.

Step 6: Assess Customer Support and Communication

Good communication and customer support can significantly influence your sourcing experience. Assess how responsive and helpful potential suppliers are during your inquiry process.

- Response Time: Note how quickly they respond to inquiries and provide requested information.

- Support Services: Check if they offer technical support or consultation services to assist with your specific needs.

Step 7: Finalize the Contract

Once you’ve selected a supplier, finalize the contract with clear terms regarding pricing, delivery schedules, and quality guarantees. Ensure that all aspects of your agreement are documented to avoid misunderstandings.

- Review Terms: Carefully review all terms and conditions, including return policies and warranties.

- Legal Compliance: Ensure the contract complies with international trade regulations if sourcing across borders.

By following these steps, B2B buyers can confidently procure high-quality vinyl materials for automotive applications, ensuring they meet both performance and aesthetic standards.

Illustrative image related to vinyl material for cars

Comprehensive Cost and Pricing Analysis for vinyl material for cars Sourcing

What Are the Key Cost Components for Vinyl Material Sourcing in Automotive Applications?

When sourcing vinyl materials for automotive applications, several cost components must be considered to accurately assess the total cost of ownership. The primary components include:

-

Materials: The base cost of polyvinyl chloride (PVC) and any additives for color, texture, and durability significantly impact pricing. High-quality vinyl that offers features like UV resistance or mildew protection typically costs more but provides better longevity.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, cutting, and preparing the vinyl. Regions with higher labor costs will influence overall pricing, especially for specialized tasks like customization.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, thereby lowering the price.

-

Tooling: Tooling costs arise from the equipment needed to produce specific designs or patterns. Custom tooling can be a significant upfront investment but may yield lower costs per unit at higher production volumes.

-

Quality Control (QC): Ensuring that the vinyl meets industry standards involves quality assurance processes that add to the overall cost. Certifications for durability and safety can also influence pricing.

-

Logistics: Shipping and handling costs can vary significantly based on the geographical location of the supplier and the buyer. Factors such as distance, shipping method, and customs duties should be included in the cost analysis.

-

Margin: Suppliers typically add a profit margin on top of their costs, which can vary based on market demand and competitive landscape. Understanding typical margins can help buyers negotiate better prices.

How Do Price Influencers Affect Vinyl Material Costs?

Several factors can influence the price of vinyl materials beyond the basic cost components:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Buyers should assess their needs to determine the most cost-effective minimum order quantity (MOQ).

-

Specifications and Customization: Customized vinyl options, such as specific colors or textures, generally incur higher costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher-quality materials with certifications for performance and safety can command premium pricing. However, they may provide long-term savings by reducing maintenance and replacement costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more for their products but often provide better service and quality assurance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly impact overall costs. Options such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, influencing the final price.

What Are the Best Negotiation Tips for B2B Buyers in the Automotive Vinyl Market?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

-

Research Market Prices: Understanding the market rates for vinyl materials will empower buyers during negotiations. Use price benchmarks to argue for better rates.

-

Leverage Volume Discounts: If possible, consolidate orders to take advantage of bulk purchasing discounts. Suppliers are often willing to negotiate better terms for larger orders.

-

Focus on Total Cost of Ownership (TCO): Instead of just the purchase price, consider the TCO, which includes maintenance, longevity, and replacement costs. Highlighting the potential savings from high-quality materials can justify a higher upfront price.

-

Explore Multiple Suppliers: Engaging multiple suppliers increases competition and may lead to more favorable pricing. Request quotes and compare them to identify the best value.

-

Understand Regional Nuances: Be aware of local market conditions and economic factors that may affect pricing. Different regions may have varying supply chain costs, impacting overall pricing strategies.

Disclaimer on Indicative Prices

Pricing for vinyl materials can fluctuate based on market conditions, supplier capabilities, and regional economic factors. Buyers are encouraged to obtain detailed quotes from suppliers to ensure accurate budgeting and planning.

Alternatives Analysis: Comparing vinyl material for cars With Other Solutions

Exploring Alternatives to Vinyl Material for Car Interiors

When considering materials for automotive interiors, vinyl is a popular choice due to its durability, ease of maintenance, and affordability. However, it’s essential to evaluate alternative materials to determine the best fit for specific applications. This section compares vinyl with two viable alternatives: leather and synthetic fabrics, allowing B2B buyers to make informed decisions based on performance, cost, and other critical factors.

Illustrative image related to vinyl material for cars

| Comparison Aspect | Vinyl Material For Cars | Leather | Synthetic Fabrics |

|---|---|---|---|

| Performance | Durable, moisture-resistant, easy to clean | High-quality, luxurious feel, but can be prone to cracking | Varies by type; can be durable but less resilient than vinyl |

| Cost | Cost-effective, lower than leather | More expensive, requires investment | Generally affordable, but quality can vary significantly |

| Ease of Implementation | Easy to install and work with | Requires skilled labor for installation | Easy to work with; often lighter |

| Maintenance | Low maintenance; easy to wipe clean | Requires regular conditioning and care | Maintenance varies; some are easy to clean while others may stain |

| Best Use Case | Ideal for high-traffic vehicles and families | Best for luxury vehicles or high-end interiors | Suitable for budget-conscious applications or temporary uses |

An In-Depth Look at Alternatives to Vinyl

1. Leather: The Luxurious Option

Leather is often viewed as the premium choice for automotive interiors, providing a sophisticated look and feel. Its natural aesthetic appeals to luxury car manufacturers and buyers seeking a high-end experience. However, while leather offers durability and comfort, it requires regular maintenance to prevent drying, cracking, and staining. Additionally, the cost can be a significant factor, as high-quality leather can dramatically increase the overall price of a vehicle. For B2B buyers focused on luxury markets, leather may be the appropriate choice, provided they can accommodate the associated maintenance and costs.

2. Synthetic Fabrics: The Versatile Alternative

Synthetic fabrics, such as polyester or nylon blends, present a versatile option for automotive interiors. They are generally more affordable than leather and can mimic the look and feel of both leather and vinyl, offering a range of textures and colors. However, the performance of synthetic fabrics varies widely based on the quality of the material used. While some synthetic options can be highly durable and easy to clean, others may not hold up as well against wear and tear compared to vinyl. For buyers targeting budget-conscious consumers or those seeking a variety of design options, synthetic fabrics can provide a valuable alternative.

Making the Right Choice for Automotive Interiors

When selecting the ideal material for automotive interiors, B2B buyers should consider their target market, budget, and the specific use cases for the vehicles. Vinyl stands out for its durability, low maintenance, and cost-effectiveness, making it suitable for a wide range of applications, especially in family vehicles or high-traffic environments. Conversely, leather is an excellent choice for luxury markets where aesthetics and comfort are paramount, while synthetic fabrics can offer flexibility and affordability for varied applications.

Ultimately, the best solution will depend on the specific requirements of the vehicle and the preferences of the end customer. By carefully weighing the pros and cons of each option, buyers can ensure they choose a material that meets both their performance expectations and financial constraints.

Essential Technical Properties and Trade Terminology for vinyl material for cars

What Are the Key Technical Properties of Vinyl Material for Automotive Use?

When considering vinyl materials for automotive applications, several technical properties are vital for ensuring durability, performance, and aesthetic appeal. Understanding these specifications can help B2B buyers make informed decisions.

1. Material Grade

Material grade refers to the quality and composition of the vinyl used in automotive applications, often specified as PVC (Polyvinyl Chloride). Higher-grade vinyls are designed to withstand harsh environmental conditions, including UV exposure, moisture, and temperature fluctuations. For B2B buyers, selecting the appropriate material grade is crucial to ensure longevity and reliability in vehicle interiors.

2. Abrasion Resistance

Abrasion resistance is a measure of how well a vinyl material can withstand wear and tear from friction. This property is often tested using the Wyzenbeek method, which evaluates the number of double rubs a fabric can endure before showing signs of wear. For automotive applications, high abrasion resistance is essential, particularly in high-traffic areas like seats and door panels. This specification directly impacts the lifespan and maintenance costs associated with the material.

3. Cold-Crack Resistance

Cold-crack resistance indicates how well vinyl maintains its integrity under low temperatures. This property is particularly important for regions with extreme weather conditions. A vinyl material with a cold-crack rating of -10°F or lower will ensure that the upholstery does not become brittle or crack in colder climates, making it a reliable choice for B2B buyers operating in diverse geographical areas.

Illustrative image related to vinyl material for cars

4. UV Stabilization

UV stabilization refers to the treatment of vinyl to resist color fading and degradation from sunlight exposure. Vinyl materials with UV-stabilized pigments can maintain their color and finish for extended periods, which is particularly important for vehicles exposed to direct sunlight. For businesses in regions with high sun exposure, this property is critical for ensuring customer satisfaction and minimizing replacement costs.

5. Moisture and Mildew Resistance

Moisture resistance is the ability of vinyl to repel water and prevent mold or mildew growth. This property is particularly beneficial for customers in humid climates or those who frequently deal with spills. Selecting vinyl with mildew-resistant properties can enhance the longevity of the upholstery, thereby increasing customer loyalty and reducing maintenance issues.

What Are Common Trade Terms in the Automotive Vinyl Industry?

Understanding industry-specific jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms related to automotive vinyl materials:

Illustrative image related to vinyl material for cars

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of automotive vinyl, an OEM might supply specific vinyl materials that meet the manufacturer’s standards. B2B buyers often seek OEM products to ensure compatibility and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory levels and budget constraints. Suppliers may set MOQs based on production costs, which can impact pricing and logistics for B2B transactions.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. In the automotive vinyl market, issuing an RFQ helps buyers gather competitive pricing and terms, enabling them to make informed purchasing decisions.

Illustrative image related to vinyl material for cars

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, reducing misunderstandings and disputes. For B2B buyers in different regions, understanding Incoterms is essential for effective logistics and supply chain management.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the automotive industry, understanding lead times is crucial for planning production schedules and inventory management. Buyers should account for lead times when negotiating contracts to ensure timely delivery of vinyl materials.

By grasping these technical properties and trade terms, B2B buyers can navigate the automotive vinyl market more effectively, making informed choices that align with their business needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the vinyl material for cars Sector

What Are the Key Trends Shaping the Vinyl Material for Cars Market?

The vinyl material for cars sector is experiencing significant growth, driven by several global factors. Increasing demand for durable, low-maintenance automotive interiors is prompting manufacturers to invest in high-quality vinyl products. Key trends include the rise of customization, where consumers seek unique textures and colors to personalize their vehicles. This trend is especially pronounced in markets like Germany and Brazil, where aesthetic value is paramount.

Illustrative image related to vinyl material for cars

Emerging B2B technologies, such as advanced textile manufacturing processes and digital printing, are reshaping sourcing strategies. These technologies enable suppliers to offer bespoke solutions quickly, reducing lead times and enhancing product variety. Moreover, the shift towards online procurement platforms is streamlining the purchasing process, allowing international buyers from Africa, South America, and the Middle East to easily access a broader range of vinyl products.

Market dynamics are also influenced by fluctuating raw material costs, particularly polyvinyl chloride (PVC), which remains a staple in vinyl production. Buyers should remain vigilant about supply chain disruptions that could affect pricing and availability. Understanding local market conditions and consumer preferences will be crucial for international B2B buyers to make informed sourcing decisions.

How Is Sustainability and Ethical Sourcing Impacting the Vinyl Material for Cars Sector?

As global awareness of environmental issues rises, the demand for sustainable and ethically sourced materials is increasingly influencing the vinyl material for cars market. Manufacturers are now under pressure to adopt eco-friendly practices and materials to mitigate their environmental impact. This shift is prompting the exploration of alternative vinyl formulations that reduce harmful chemicals and improve recyclability.

Ethical supply chains are becoming essential, with buyers seeking suppliers who demonstrate a commitment to sustainability. Certifications such as ISO 14001 for environmental management and the Global Recycling Standard (GRS) are gaining traction among B2B buyers, as they validate the sustainability claims of suppliers.

Illustrative image related to vinyl material for cars

Investing in ‘green’ vinyl materials not only aligns with corporate social responsibility goals but also appeals to environmentally conscious consumers. B2B buyers should prioritize partnerships with suppliers who are transparent about their sourcing practices and can provide documentation on the sustainability of their products. This approach not only enhances brand reputation but also helps in meeting regulatory requirements in various regions.

What Is the Historical Context of Vinyl Material for Cars?

Vinyl materials have a rich history within the automotive sector, evolving significantly since their introduction in the mid-20th century. Initially favored for their cost-effectiveness and ease of maintenance, vinyl quickly became a staple in car upholstery. Over the decades, advancements in manufacturing techniques have enhanced the durability and aesthetic appeal of vinyl, making it a preferred choice for both manufacturers and consumers.

The shift towards more sophisticated vinyl formulations, designed to mimic leather while offering superior resistance to wear and UV exposure, has further solidified its place in the automotive industry. As consumer preferences have evolved, so too have the applications of vinyl, now extending beyond seating to include door panels, dashboards, and headliners. This evolution underscores the importance of continuous innovation in meeting the changing demands of the automotive market.

In summary, understanding the market dynamics, embracing sustainability, and recognizing the historical context of vinyl materials are crucial for B2B buyers navigating the vinyl material for cars sector. These insights can significantly inform sourcing strategies and enhance competitive advantage in a rapidly evolving market.

Illustrative image related to vinyl material for cars

Frequently Asked Questions (FAQs) for B2B Buyers of vinyl material for cars

-

How do I choose the right vinyl material for automotive applications?

Selecting the right vinyl material for automotive use involves considering durability, ease of cleaning, and design. Look for vinyl that is specifically designed for automotive applications, as it will be engineered to withstand wear, spills, and UV exposure. Evaluate specifications such as abrasion resistance, moisture resistance, and colorfastness. Additionally, assess your target market’s preferences for textures and colors to ensure the material aligns with consumer expectations. -

What is the best vinyl material for car upholstery?

The best vinyl material for car upholstery typically includes high-quality options like PVC with abrasion-resistant coatings. Look for products that offer features such as UV stabilization, mildew resistance, and a non-porous surface for easy cleaning. Popular choices include vinyl with heavy-duty Wyzenbeek ratings and cold-crack resistance for various climates. Ensure the vinyl meets your specific aesthetic and functional needs while providing long-lasting performance. -

How can I verify the quality of vinyl materials from suppliers?

To verify the quality of vinyl materials, request samples from suppliers to assess texture, durability, and overall appearance. Check for certifications that indicate compliance with international quality standards, such as ISO or ASTM. Additionally, read customer reviews and seek references from other businesses that have used the supplier’s products. Conducting a factory audit can also provide insights into manufacturing practices and quality control measures. -

What are the typical minimum order quantities (MOQs) for automotive vinyl?

Minimum order quantities (MOQs) for automotive vinyl can vary significantly by supplier and product type. Generally, MOQs range from 50 to 500 yards, depending on the material’s specialty and the supplier’s production capabilities. It’s essential to discuss your specific needs with potential suppliers to negotiate favorable terms. Some suppliers may offer flexible MOQs for first-time buyers or bulk orders, allowing you to test the market without significant upfront investment. -

What payment terms should I expect when sourcing vinyl materials internationally?

Payment terms for international sourcing of vinyl materials typically include options like upfront deposits, letters of credit, or net payment terms after delivery. Expect to negotiate terms that suit your cash flow needs while protecting the supplier’s interests. Common practices include a 30% deposit upon order confirmation, with the remaining balance due before shipment or upon receipt. Ensure to clarify currency, payment methods, and any applicable taxes or tariffs upfront to avoid surprises. -

How do I handle logistics when importing vinyl materials?

Handling logistics for importing vinyl materials involves coordinating shipping methods, customs clearance, and delivery timelines. Work with reliable freight forwarders who understand the complexities of international shipping and can navigate customs regulations. Consider options such as sea freight for bulk orders or air freight for urgent shipments. Ensure that you have all necessary documentation, including bills of lading and customs declarations, to facilitate smooth delivery and avoid delays. -

What customization options are available for automotive vinyl materials?

Customization options for automotive vinyl materials can include color matching, texture variations, and printed designs. Many suppliers offer a range of textures, from smooth finishes to embossed patterns, to meet specific design requirements. Discuss your vision with potential suppliers, and inquire about their capabilities for custom orders, including lead times and additional costs. Customization allows you to differentiate your offerings and cater to specific market preferences. -

How can I ensure compliance with international trade regulations when sourcing vinyl?

To ensure compliance with international trade regulations when sourcing vinyl, familiarize yourself with import/export laws in both your country and the supplier’s country. This includes understanding tariffs, trade agreements, and product safety standards. Work with a customs broker who can guide you through the regulatory landscape and help with necessary documentation. Additionally, verify that the vinyl meets any relevant environmental regulations, such as REACH in Europe, to avoid penalties and ensure smooth importation.

Top 8 Vinyl Material For Cars Manufacturers & Suppliers List

1. Midwest Fabrics – Automotive Vinyl and Upholstery Fabrics

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Introduction: Automotive Vinyl Fabric, Vinyl Upholstery Fabric, Original OEM Detroit Number Fabrics, GM, FORD, Chrysler, Honda, Toyota, Mazda, Nissan OEM Fabric, Heavy Duty Flock fabric, Soft Impact, Tonneau Cover Material, Carbon Fiber, Brushed Aluminum, Marine Vinyl, Snowmobile Vinyl, 4 way stretch vinyl, various Morbern Vinyl options, Enduratex vinyl options, Nautolex vinyl by the roll, Boltaflex Vinyl by th…

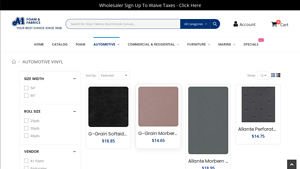

2. A1 Foam and Fabrics – G-Grain Softside Vinyl

Domain: a1foamandfabrics.com

Registered: 2003 (22 years)

Introduction: Automotive Upholstery Vinyl Fabric collections provide superior quality and durability for Automotive, RV, and Truck applications. Key products include: 1. G-Grain Softside Vinyl – Applications: Hospitality, Contract, Residential Interior, Marine Interior, Automotive, RV; Characteristics: Anti Static, Sulfide Stain Resistance, Water Resistant, Formaldehyde Free, No Heavy Metals; Flame Retardancy: …

3. Upholstery Supply USA – Automotive Interior Vinyl

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

Introduction: Automotive Interior Vinyl includes various types of vinyl suitable for car, truck, van, or RV interiors. Key products include Soft Impact Vinyl in multiple styles (G Grain, Longitude, Milled Pebble, Monticello, Valencia, Verona) and Softside Vinyl (Allegro, Anchor). Prices range from $11.75 to $19.40 per yard. Benefits of vinyl include affordability, durability, low maintenance, and a large variet…

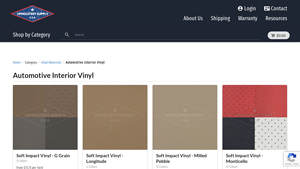

4. Sailrite – Vinyl Automotive Upholstery Fabrics

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Our Favorite Vinyl Automotive Upholstery Fabrics – Sailrite offers durable, waterproof, and easy-to-clean vinyl upholstery fabrics ideal for reupholstering car seats. High-quality vinyl fabrics resemble real leather in texture and appearance, providing a luxurious look at a more economical price. Key features include: easy cleaning, high abrasion resistance, UV resistance, waterproof properties, a…

5. Miami Corp – Automotive Vinyl Upholstery

Domain: miamicorp.com

Registered: 2001 (24 years)

Introduction: Miami Corp offers a wide range of automotive vinyl upholstery options, including OEM matching and aftermarket vinyl in various patterns, textures, and colors. They provide high-end polyurethane options like Ultraleather and vinyl with 4-way stretch. The product categories include OEM Vinyl (3249), Aftermarket Vinyl (735), Ultrafabrics (234), and Closeouts & Specials (36). Customers can filter thei…

6. SMS Auto Fabrics – Classic Auto Interiors

Domain: smsautofabrics.com

Registered: 2000 (25 years)

Introduction: SMS Auto Fabrics offers a wide selection of classic auto interiors, including cloth, vinyl, leather, door panels, headliners, vinyl tops, and carpets for American cars from the 1930s to the 1990s. Featured products include various plaid fabrics for Chevrolet models from 1972 and 1973, as well as door panels for models such as the 1956 Ford Fairlane Sunliner, 1968 Dodge Polara Convertible, and 1970…

7. JJ Auto Fabrics – Automotive and Marine Vinyl Supplies

Domain: jjautofabrics.com

Registered: 2001 (24 years)

Introduction: Automotive and Marine Vinyl and Upholstery Supplies including: Classic Automotive Vinyl, Heavy Weight Vinyl, SoftSide/SoftTouch Automotive Vinyl, Corinthian, Longitude, Sierra, Monticello, Milled Pebble, Soho, Rawhide, Oxen, Heidi, Ex Madrid, G-Grain, Verona, Wallaby, Ezy Vinyls, Knit Back Automotive Vinyl, Enduratex/CGPC, Highland, Perforated Palma, Plain Rosette, Morbern, Volkswagen Woven, Futur…

8. Metro Restyling – Car Wrap Products

Domain: metrorestyling.com

Registered: 2008 (17 years)

Introduction: Metro Restyling is a leading online supplier of car wrap products, offering a wide range of vinyl wrap films, tints, tools, and supplies. Key product categories include: 1. Vinyl Wrap Films: Available brands include 3M, Avery Dennison, PPG STREAM™, Cheetah Wrap, CYS, FlexiShield, Hexis, KPMF, and Metro Wrap. 2. Color Options: A variety of colors such as Black, Blue, Bronze, Brown, Burgundy, Color …

Strategic Sourcing Conclusion and Outlook for vinyl material for cars

In conclusion, strategic sourcing of automotive vinyl materials presents a compelling opportunity for B2B buyers looking to enhance vehicle interiors while balancing cost and quality. The exceptional durability, low maintenance, and customizable options of vinyl make it an ideal choice for various applications, from car seats to dashboards. By prioritizing high-quality vinyl sourced from reputable suppliers, businesses can significantly reduce long-term operational costs and improve customer satisfaction.

Investing in vinyl not only supports a polished aesthetic but also addresses practical concerns such as moisture resistance and ease of cleaning, which are particularly relevant for markets with diverse climates. As the demand for affordable yet luxurious automotive materials grows, staying ahead in sourcing strategies will be crucial for maintaining a competitive edge.

International buyers from Africa, South America, the Middle East, and Europe are encouraged to explore the vast array of vinyl options available. Engaging with trusted suppliers and leveraging insights from this guide will empower you to make informed decisions that enhance your offerings. Embrace the future of automotive interiors by prioritizing strategic sourcing of vinyl materials that align with both quality and market trends.

Illustrative image related to vinyl material for cars

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.