Introduction: Navigating the Global Market for embossed leather fabric

In the competitive landscape of global sourcing, navigating the market for embossed leather fabric presents unique challenges for B2B buyers. With a myriad of options available, from rustic and Southwestern styles to modern and exotic patterns, the task of identifying quality suppliers while ensuring cost-effectiveness can be daunting. This guide addresses these challenges head-on by offering insights into the diverse types of embossed leather fabrics, their applications across industries, and crucial supplier vetting processes tailored for international markets, particularly in Africa, South America, the Middle East, and Europe, including countries like Brazil and Vietnam.

Through a comprehensive exploration of the embossed leather fabric market, this guide empowers B2B buyers to make informed purchasing decisions. It delves into the intricacies of various embossing techniques and the unique characteristics of each type of leather, enabling buyers to select materials that align with their specific project requirements. Additionally, we provide actionable insights into pricing structures, shipping considerations, and best practices for establishing long-term partnerships with reputable suppliers. By equipping buyers with this knowledge, we aim to streamline the sourcing process, reduce risks associated with procurement, and ultimately enhance the quality and aesthetic appeal of their final products.

Table Of Contents

- Top 7 Embossed Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for embossed leather fabric

- Understanding embossed leather fabric Types and Variations

- Key Industrial Applications of embossed leather fabric

- 3 Common User Pain Points for ’embossed leather fabric’ & Their Solutions

- Strategic Material Selection Guide for embossed leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for embossed leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ’embossed leather fabric’

- Comprehensive Cost and Pricing Analysis for embossed leather fabric Sourcing

- Alternatives Analysis: Comparing embossed leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for embossed leather fabric

- Navigating Market Dynamics and Sourcing Trends in the embossed leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of embossed leather fabric

- Strategic Sourcing Conclusion and Outlook for embossed leather fabric

- Important Disclaimer & Terms of Use

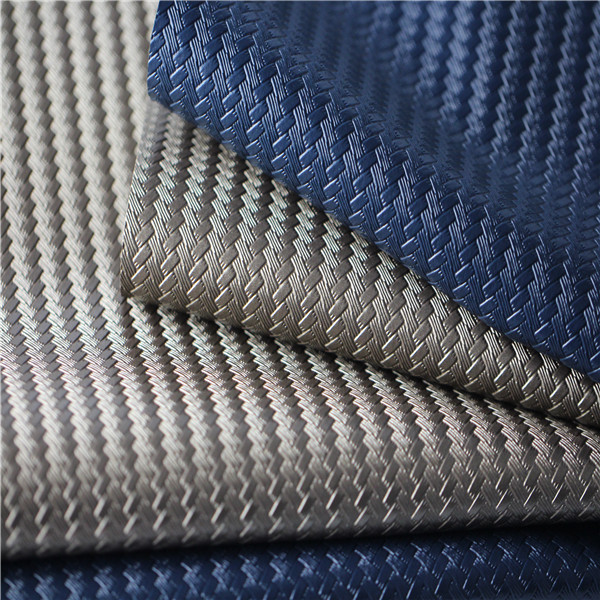

Understanding embossed leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

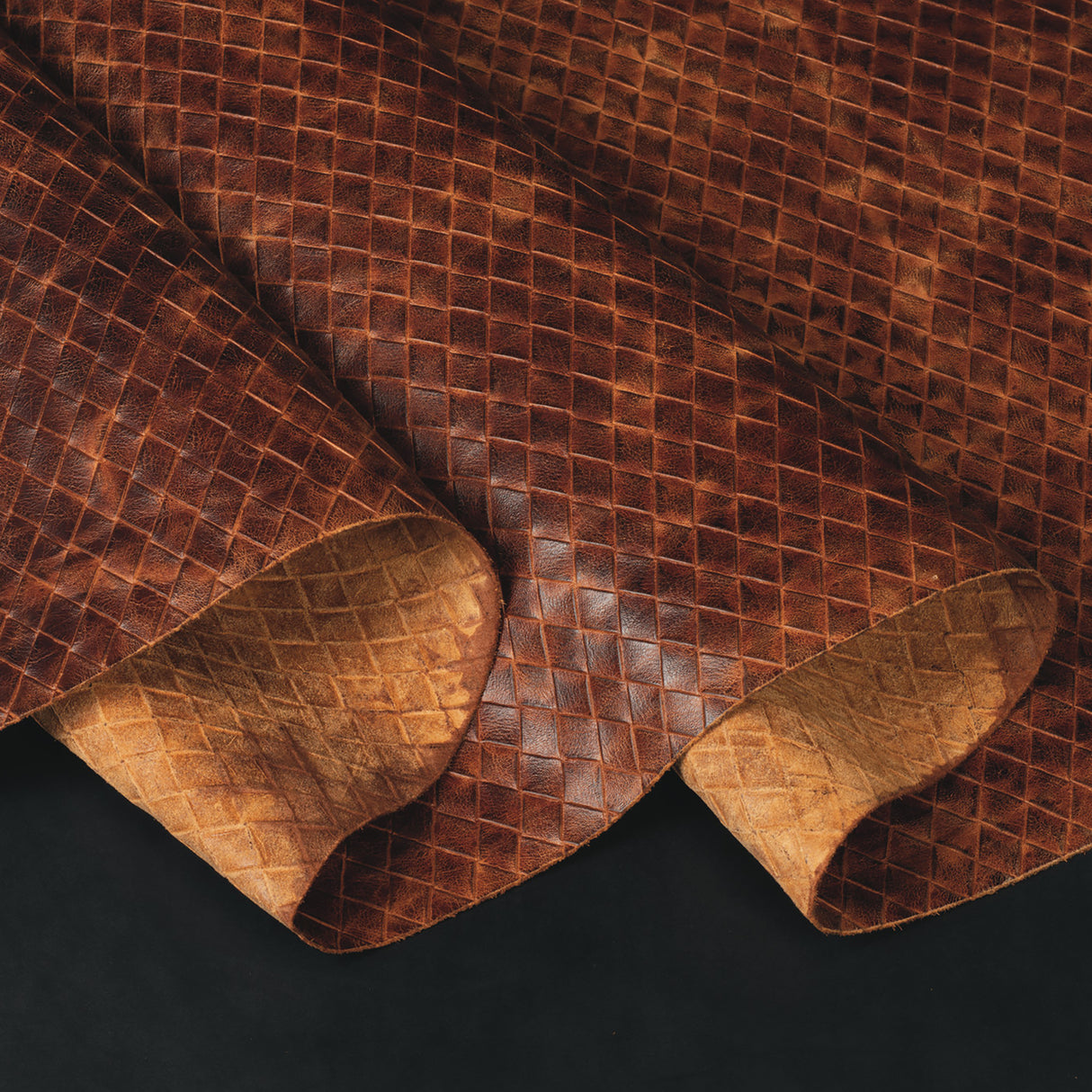

| Western Embossed Leather | Characterized by rustic designs, often inspired by Western motifs like floral and animal prints. | Upholstery for furniture, fashion accessories, and home decor. | Pros: Unique aesthetic appeal; Cons: Limited color options. |

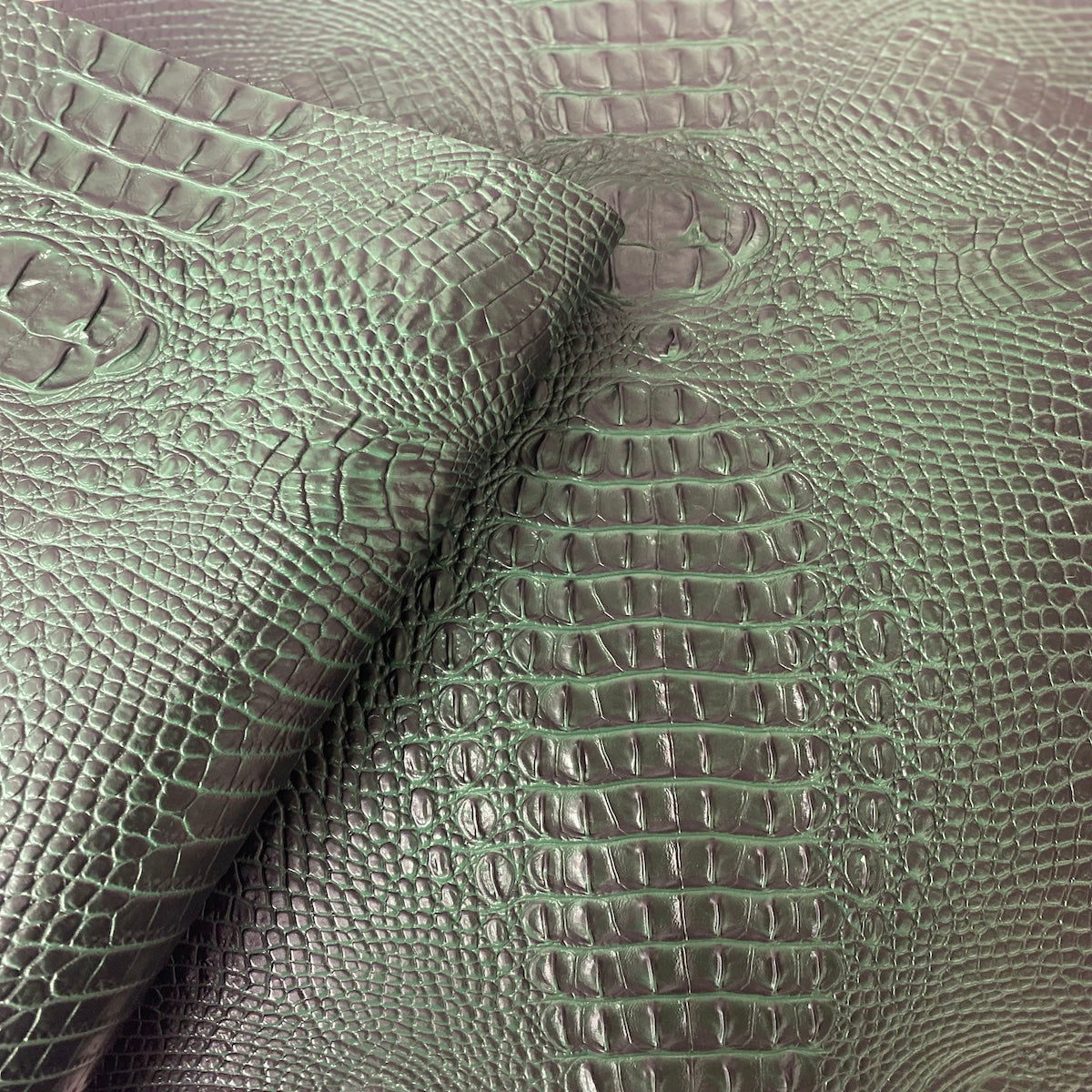

| Croc Embossed Leather | Features a distinct crocodile skin pattern, offering a luxurious look. Available in various colors. | High-end fashion, luxury upholstery, and bespoke leather goods. | Pros: Premium appearance; Cons: Higher price point. |

| Custom Embossed Leather | Allows for personalized designs and patterns tailored to client specifications. | Custom projects in luxury markets, promotional items, and corporate gifts. | Pros: Tailored to specific needs; Cons: Longer lead times. |

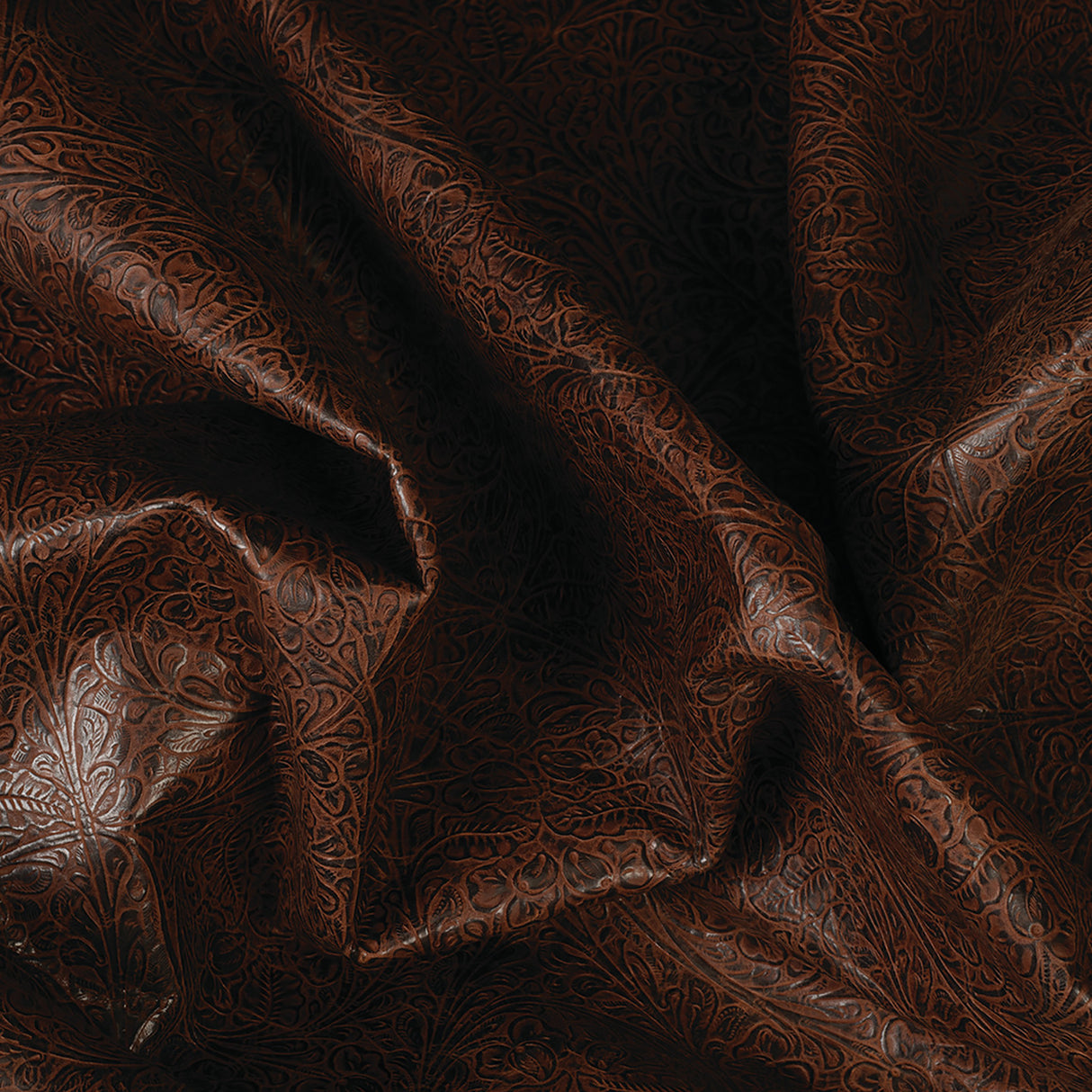

| Floral Embossed Leather | Showcases intricate floral designs, adding elegance and sophistication. | Home decor, apparel, and accessories targeting feminine markets. | Pros: Attractive for specific demographics; Cons: Niche appeal may limit market. |

| Lizard Embossed Leather | Mimics the texture of lizard skin, offering a trendy and exotic look. | Fashion accessories, handbags, and upscale furniture. | Pros: Unique texture; Cons: May not appeal to all buyers. |

What are the Key Characteristics of Western Embossed Leather?

Western embossed leather is known for its rustic and bold designs, often featuring motifs inspired by Western culture, such as floral patterns and animal prints. This type of leather is typically used in upholstery for furniture, fashion accessories, and home decor projects. For B2B buyers, the unique aesthetic appeal can enhance product offerings, especially in markets that appreciate Western themes. However, buyers should consider that the variety of color options may be limited compared to other types.

How Does Croc Embossed Leather Stand Out?

Croc embossed leather is distinguished by its luxurious crocodile skin pattern, which is often available in a range of vibrant colors. This type is primarily used in high-end fashion, luxury upholstery, and bespoke leather goods. B2B buyers looking to target upscale markets will find croc embossed leather appealing for its premium appearance. However, the higher price point may be a consideration for budget-conscious buyers.

Why Choose Custom Embossed Leather for Specific Projects?

Custom embossed leather offers the flexibility of personalized designs and patterns tailored to the client’s specifications. This type is ideal for custom projects in luxury markets, promotional items, and corporate gifts. B2B buyers can leverage this option to create unique products that stand out in a competitive market. However, potential drawbacks include longer lead times and the need for clear communication to ensure design accuracy.

Illustrative image related to embossed leather fabric

What Advantages Does Floral Embossed Leather Provide?

Floral embossed leather features intricate designs that add elegance and sophistication to various products. It is often used in home decor, apparel, and accessories aimed at feminine markets. For B2B buyers, this type can attract specific demographics looking for stylish and unique options. However, its niche appeal may limit its market reach, making it essential to assess target customer preferences.

How Does Lizard Embossed Leather Appeal to Trendy Markets?

Lizard embossed leather mimics the texture of lizard skin, offering an exotic and trendy appearance. This type is popular in fashion accessories, handbags, and upscale furniture. B2B buyers can capitalize on the unique texture to attract customers seeking distinctive products. However, it may not appeal to all buyers, so understanding market trends and customer preferences is crucial for successful sales.

Key Industrial Applications of embossed leather fabric

| Industry/Sector | Specific Application of embossed leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture & Upholstery | Custom upholstered furniture pieces | Enhances aesthetic appeal and durability of products | Quality of leather, embossing options, and shipping times |

| Automotive | Interior leather accents and upholstery | Provides luxury feel and improves resale value | Sourcing full hides, customization options, and compliance with local regulations |

| Fashion & Accessories | Designer handbags, wallets, and belts | Adds unique texture and exclusivity to products | Availability of trendy patterns, color matching, and lead times |

| Home Decor | Decorative wall coverings and home accents | Elevates interior design and adds value to properties | Weight, thickness, and compatibility with adhesives |

| Footwear | Stylish shoe designs and components | Enhances comfort and style, appealing to fashion-forward consumers | Flexibility, breathability, and durability of the material |

How is Embossed Leather Fabric Used in the Furniture and Upholstery Industry?

In the furniture and upholstery sector, embossed leather fabric is utilized to create custom upholstered pieces that offer both aesthetic appeal and durability. Buyers often look for unique patterns and textures that can enhance the overall design of their products. This material addresses the need for high-quality, long-lasting upholstery that can withstand everyday use. Key considerations for international buyers include the quality of the leather, available embossing options, and efficient shipping times to ensure timely delivery.

What Role Does Embossed Leather Fabric Play in the Automotive Industry?

Embossed leather fabric is a popular choice for automotive interiors, particularly for seats, dashboards, and other accents. It provides a luxurious feel that can significantly enhance the vehicle’s resale value. Buyers in this industry must focus on sourcing full hides that meet specific quality standards and customization options to match vehicle designs. Compliance with local regulations regarding materials is also crucial, especially for international buyers from regions such as Africa and South America.

Why is Embossed Leather Fabric Important for Fashion and Accessories?

In the fashion industry, embossed leather fabric is frequently used for designer handbags, wallets, and belts, offering unique textures that set products apart. This exclusivity can attract discerning consumers willing to pay a premium for distinctive items. When sourcing for fashion applications, buyers should prioritize trendy patterns, ensure color matching with existing designs, and consider lead times to meet market demands.

How is Embossed Leather Fabric Used in Home Decor?

Embossed leather fabric serves as an elegant choice for decorative wall coverings and home accents. Its ability to elevate interior design makes it a valuable addition for businesses focused on enhancing property value. Buyers need to consider the weight and thickness of the material, as well as its compatibility with adhesives for installation. International buyers should also be aware of any specific design trends prevalent in their markets.

Illustrative image related to embossed leather fabric

What Benefits Does Embossed Leather Fabric Provide in Footwear?

In the footwear industry, embossed leather fabric is utilized to create stylish shoe designs that combine comfort and aesthetics. This material appeals to fashion-forward consumers looking for unique styles. When sourcing for footwear applications, buyers should focus on the flexibility, breathability, and durability of the leather to ensure it meets consumer expectations. Additionally, understanding regional fashion trends can help in selecting the most appealing designs.

3 Common User Pain Points for ’embossed leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Embossed Leather Fabric

The Problem:

B2B buyers often struggle to find high-quality embossed leather fabric that meets their specific design and durability requirements. Many suppliers offer subpar materials that do not stand up to rigorous use or fail to maintain their aesthetic appeal over time. This challenge is compounded when buyers are not familiar with the characteristics of genuine leather versus synthetic alternatives, leading to costly mistakes in procurement. For instance, a furniture manufacturer may order a bulk supply of embossed leather intended for upholstery, only to discover that it wears poorly or loses its embossed pattern after minimal use.

The Solution:

To overcome this sourcing challenge, buyers should prioritize working with reputable suppliers known for their quality assurance processes. Request samples before making large orders to evaluate the texture, durability, and overall appearance of the embossed leather. Inquire about the tanning process and the type of leather used—full-grain leather generally offers better quality and longevity compared to corrected grain or synthetic options. Additionally, consider establishing a long-term relationship with a supplier who can provide consistent quality and custom options tailored to your needs. Collaborating with suppliers who offer transparent information about their sourcing and manufacturing processes can significantly enhance your procurement experience.

Illustrative image related to embossed leather fabric

Scenario 2: Understanding Customization Options for Embossed Leather

The Problem:

Many B2B buyers are unaware of the extent of customization available with embossed leather fabric, leading to missed opportunities for unique branding or specific design needs. For example, a company looking to create a bespoke line of luxury handbags might order standard embossed leather without realizing they could have requested a custom pattern that aligns with their brand identity. This lack of awareness can result in products that do not resonate with their target market or fail to differentiate from competitors.

The Solution:

Buyers should actively engage with suppliers to explore customization possibilities. When discussing embossed leather options, ask about the ability to create custom patterns, colors, and finishes. Some suppliers offer programs where you can specify the design, ensuring that it reflects your brand’s ethos. Before committing, request prototypes to assess how the customizations translate into the final product. This proactive approach not only enhances brand visibility but also fosters innovation in product development, setting your offerings apart in a competitive marketplace.

Scenario 3: Managing Lead Times and Inventory Levels for Embossed Leather Fabric

The Problem:

Timely delivery of embossed leather fabric can be a critical issue for B2B buyers, especially when working on tight production schedules. Delays in shipment can halt manufacturing processes, leading to missed deadlines and dissatisfied clients. Additionally, managing inventory levels is crucial; excess stock can tie up capital, while insufficient inventory can lead to rushed orders that compromise quality.

The Solution:

To effectively manage lead times, establish clear communication with your suppliers regarding production schedules and shipping timelines. Implement a just-in-time inventory system to align orders with production needs, reducing excess stock while ensuring timely availability. Consider using technology, such as inventory management software, to track usage rates and anticipate demand. Building a buffer stock of essential embossed leather varieties can also mitigate the risk of supply chain disruptions. Regularly reviewing and adjusting your inventory strategy based on market trends and historical data will help maintain a balance between supply and demand, ensuring your operations run smoothly.

Strategic Material Selection Guide for embossed leather fabric

What Are the Key Materials Used in Embossed Leather Fabric?

When selecting embossed leather fabric for various applications, understanding the properties and implications of different materials is crucial for B2B buyers. Below, we analyze four common materials used in embossed leather fabric, focusing on their key properties, advantages, disadvantages, and specific considerations for international buyers.

1. Cowhide Leather

Key Properties: Cowhide is known for its durability and flexibility, making it suitable for a wide range of applications. It typically has a temperature rating of up to 70°C and can withstand moderate pressure. Its natural grain provides a unique aesthetic.

Pros & Cons: The primary advantage of cowhide leather is its resilience; it is resistant to wear and tear, making it ideal for upholstery and fashion accessories. However, it can be relatively expensive compared to synthetic alternatives, and the manufacturing process can be complex, involving tanning and embossing.

Illustrative image related to embossed leather fabric

Impact on Application: Cowhide is compatible with various media, including upholstery, automotive interiors, and fashion items. Its natural properties allow for excellent dye retention, enhancing the embossed patterns.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, especially in markets like Europe and the Middle East. Buyers should also be aware of the ethical sourcing of cowhide, which can influence purchasing decisions in regions sensitive to animal welfare.

2. Synthetic Leather (PU and PVC)

Key Properties: Synthetic leather, made from polyurethane (PU) or polyvinyl chloride (PVC), offers good resistance to moisture and UV light. It typically maintains its integrity at temperatures ranging from -30°C to 60°C.

Pros & Cons: The major advantage of synthetic leather is its cost-effectiveness and ease of manufacturing. It can be produced in various colors and textures, providing versatility. However, it may not offer the same level of durability and breathability as natural leather, which can limit its use in high-wear applications.

Impact on Application: Synthetic leather is widely used in furniture, automotive interiors, and fashion. Its water-resistant properties make it suitable for outdoor applications, but it may not perform well in extreme temperatures.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the environmental impact of synthetic materials, as regulations around plastics are tightening globally. Understanding local compliance standards is crucial when sourcing synthetic leather.

3. Exotic Leathers (e.g., Crocodile, Lizard)

Key Properties: Exotic leathers are prized for their unique textures and patterns. They typically have high tensile strength and can withstand significant wear. However, they require careful handling and maintenance.

Pros & Cons: The main advantage of exotic leathers is their luxury appeal and exclusivity, making them ideal for high-end fashion and luxury goods. The downside is their high cost and the complexity of sourcing, as they are often subject to strict regulations.

Illustrative image related to embossed leather fabric

Impact on Application: Exotic leathers are commonly used in premium products such as handbags, wallets, and upholstery for luxury vehicles. Their distinct appearance can significantly enhance the aesthetic value of a product.

Considerations for International Buyers: Buyers must navigate complex regulations regarding the trade of exotic leathers, particularly in Europe and the U.S. Compliance with CITES (Convention on International Trade in Endangered Species) is essential for legal sourcing.

4. Recycled Leather

Key Properties: Recycled leather is made from scraps and offcuts, bonded together to create a new material. It generally offers moderate durability and can be produced in various textures and finishes.

Illustrative image related to embossed leather fabric

Pros & Cons: The primary advantage of recycled leather is its sustainability, appealing to environmentally conscious buyers. It is often less expensive than new leather. However, its durability may not match that of full-grain leather, which could limit its application in high-stress environments.

Impact on Application: Recycled leather is suitable for a range of products, including bags, wallets, and upholstery. Its eco-friendly nature can enhance brand reputation among consumers who prioritize sustainability.

Considerations for International Buyers: Buyers should ensure that recycled leather meets local environmental standards and certifications. The growing trend towards sustainable materials is particularly relevant in European markets, where eco-labels can influence purchasing decisions.

Illustrative image related to embossed leather fabric

Summary Table

| Materiaal | Typical Use Case for embossed leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide Leather | Upholstery, fashion accessories | High durability | Higher cost, complex manufacturing | Hoog |

| Synthetic Leather | Furniture, automotive interiors | Cost-effective, versatile | Less durable, not breathable | Low |

| Exotic Leathers | Luxury handbags, high-end upholstery | Unique aesthetic, luxury appeal | Very high cost, sourcing complexity | Hoog |

| Recycled Leather | Bags, wallets, eco-friendly products | Sustainable, lower cost | Moderate durability | Medium |

This guide serves as a strategic resource for international B2B buyers, helping them navigate the complexities of selecting embossed leather fabric materials that align with their specific needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for embossed leather fabric

What Are the Key Stages in the Manufacturing Process of Embossed Leather Fabric?

The manufacturing of embossed leather fabric involves several critical stages, each crucial for producing high-quality products that meet the diverse needs of international B2B buyers. Understanding these stages is vital for making informed purchasing decisions.

Material Preparation: How Is Leather Processed for Embossing?

The journey begins with the selection of high-quality raw hides, typically full-grain leather, which is the highest grade available. The hides undergo a tanning process to preserve them and enhance their durability. This stage can involve either vegetable tanning, which is environmentally friendly, or chrome tanning, which offers a quicker turnaround.

After tanning, the leather is conditioned to ensure optimal moisture levels. This conditioning prepares the leather for the embossing process. Once conditioned, the hides are cut into manageable sizes, often referred to as “hides” or “sides,” which can be sold in halves (approximately 20-23 square feet) or full sizes (40-50 square feet).

What Techniques Are Used in the Embossing Process?

Embossing leather involves applying a design or pattern to the surface, enhancing its aesthetic appeal and texture. This is typically achieved using heat and pressure applied through specialized embossing plates or rollers. The process can involve various techniques:

- Heat Embossing: Utilizes heated plates to imprint designs onto the leather.

- Cold Embossing: Involves applying pressure without heat, often used for more delicate patterns.

- Digital Embossing: A newer technique that uses digital printing technology to create intricate designs.

Once embossed, the leather is inspected for quality, ensuring that the design has been accurately transferred without any defects.

Finishing: How Is Embossed Leather Prepared for Market?

The finishing stage is crucial in determining the final look and feel of the embossed leather. This involves several processes:

- Dyeing: Leather is dyed to achieve the desired color, enhancing the embossed patterns.

- Sealing: A protective coating is applied to improve durability and resistance to wear and tear.

- Polishing: This process gives the leather a smooth finish and enhances its luster.

After finishing, the embossed leather is ready for cutting and assembling into products such as upholstery, handbags, or other leather goods.

What Quality Assurance Measures Are Essential for Embossed Leather Fabric?

Quality assurance (QA) is vital in ensuring that the embossed leather fabric meets international standards and customer expectations. Various measures are put in place throughout the manufacturing process.

Which International Standards Should B2B Buyers Consider?

B2B buyers should be aware of several international standards that govern the quality of leather products:

Illustrative image related to embossed leather fabric

- ISO 9001: Focuses on quality management systems, ensuring consistent quality across production.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Relevant for specific applications, particularly in automotive or industrial uses.

These standards provide a framework for ensuring that products are safe, reliable, and of high quality.

What Are the Key QC Checkpoints in the Production Process?

Quality control (QC) involves systematic checks at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Initial inspection of raw materials upon arrival at the facility to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to identify and rectify defects early.

- Final Quality Control (FQC): A comprehensive examination of finished products to ensure they meet quality standards before shipment.

These checkpoints help mitigate the risk of defects and ensure that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is crucial to ensuring product reliability.

Illustrative image related to embossed leather fabric

What Are Effective Methods for Supplier Audits?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and QC measures firsthand. This provides insights into the supplier’s commitment to quality.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s QC protocols and their adherence to international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. This is particularly important for buyers in regions like Africa and South America, where local regulations may differ.

What Are the Unique QC Considerations for Different Regions?

When sourcing embossed leather fabric from various regions, B2B buyers should be mindful of specific QC nuances:

-

Africa and South America: Buyers should be aware of the local regulatory frameworks and ensure that suppliers comply with both local and international standards. This may involve additional certifications or documentation.

-

Middle East and Europe: In these regions, buyers often prioritize environmental sustainability and ethical sourcing practices. Suppliers must demonstrate compliance with regulations such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) to ensure that their products are free from harmful substances.

Conclusion: Ensuring Quality in Embossed Leather Fabric Manufacturing

In conclusion, understanding the manufacturing processes and quality assurance measures for embossed leather fabric is essential for B2B buyers. By being informed about each stage of production, relevant standards, and effective verification methods, buyers can confidently source high-quality embossed leather products that meet their specific needs. Prioritizing these factors will ultimately lead to better business outcomes and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ’embossed leather fabric’

To assist B2B buyers in sourcing embossed leather fabric effectively, this guide outlines a step-by-step checklist. Each step is designed to ensure that buyers make informed decisions, securing high-quality materials while fostering strong supplier relationships.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. This includes determining the type of embossed leather you need—such as cowhide, goat, or synthetic—and the desired finish and texture. Additionally, consider factors like thickness, weight, and color options, which can significantly affect both aesthetics and functionality.

Illustrative image related to embossed leather fabric

- Key Considerations:

- Thickness (e.g., 1.0 mm vs. 2.0 mm)

- Specific embossing patterns (e.g., croc, floral, custom designs)

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in embossed leather. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers and distributors.

- What to Look For:

- Supplier experience and reputation in the industry

- Geographic location and shipping capabilities, especially relevant for international sourcing

Step 3: Evaluate Supplier Certifications and Compliance

Before proceeding with any supplier, verify their certifications and compliance with industry standards. This is crucial for ensuring product quality and ethical sourcing practices.

- Check For:

- ISO certifications or compliance with environmental standards

- Evidence of sustainable practices and ethical labor conditions

Step 4: Request Samples for Quality Assessment

Always request samples of the embossed leather before placing a bulk order. This allows you to evaluate the quality, texture, and appearance of the material firsthand.

- Considerations When Evaluating Samples:

- Color accuracy and consistency with your specifications

- Durability and feel of the leather, especially for upholstery or fashion applications

Step 5: Negotiate Terms and Pricing

Once you’ve identified a supplier that meets your criteria, it’s time to negotiate terms and pricing. Be clear about your budget while also considering the total cost of ownership, including shipping and potential tariffs for international purchases.

- Key Points to Discuss:

- Minimum order quantities and pricing tiers

- Delivery timelines and payment terms

Step 6: Establish a Communication Plan

Effective communication is vital for a successful partnership. Establish a clear communication plan that outlines points of contact, preferred methods of communication, and regular check-ins throughout the ordering process.

Illustrative image related to embossed leather fabric

- Plan Elements:

- Designate a primary contact for both parties

- Schedule regular updates during production and shipping

Step 7: Review and Finalize the Purchase Agreement

Before finalizing your order, review all terms and conditions laid out in the purchase agreement. Ensure that all aspects, including warranties, return policies, and liability clauses, are clearly defined and acceptable.

- Key Aspects to Confirm:

- Warranty coverage for defects

- Procedures for handling disputes or returns

By following this checklist, B2B buyers can streamline their procurement process for embossed leather fabric, ensuring they secure quality materials that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for embossed leather fabric Sourcing

What Are the Key Cost Components in Sourcing Embossed Leather Fabric?

When sourcing embossed leather fabric, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to embossed leather fabric

-

Materials: The type of leather used significantly impacts the cost. Full-grain cowhide is often preferred for its durability and quality, while synthetic options may lower costs but could compromise quality. Specialty embossed patterns like croc or floral designs may also incur higher material costs due to their intricate manufacturing processes.

-

Labor: Skilled labor is required for both the embossing process and the overall crafting of leather products. Regions with a higher cost of living may see elevated labor costs, which can influence the final pricing of embossed leather.

-

Manufacturing Overhead: This includes factory rent, utilities, and equipment maintenance. Efficient production facilities may lower these costs, allowing suppliers to offer competitive pricing.

-

Tooling: The creation of embossing plates and other tooling involves a significant upfront investment, particularly for custom designs. This cost is often amortized over large production runs, making it crucial for buyers to consider minimum order quantities (MOQs).

-

Quality Control (QC): Ensuring that products meet specific standards incurs additional costs. Buyers should look for suppliers with robust QC processes, as this can prevent costly returns and ensure product reliability.

-

Logistics: Shipping costs can vary widely based on the supplier’s location and the shipping method used. International buyers must factor in import duties and taxes, which can further impact the total cost.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. Understanding this margin can provide insight into pricing flexibility during negotiations.

How Do Price Influencers Affect the Cost of Embossed Leather Fabric?

Several factors influence the pricing of embossed leather fabric:

-

Volume and Minimum Order Quantities (MOQ): Suppliers often provide discounts for larger orders. Understanding MOQ can help buyers secure better pricing.

-

Specifications and Customization: Custom designs or specific embossing patterns can lead to increased costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like eco-friendly or sustainable practices) can increase costs. Buyers should assess the importance of these factors relative to their target market.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Established suppliers may charge more but provide greater reliability and quality assurance.

-

Incoterms: The terms of shipping can significantly impact costs. Buyers should be clear about who bears the responsibility for shipping, insurance, and import duties to avoid unexpected expenses.

What Are Effective Buyer Tips for Negotiating Prices on Embossed Leather Fabric?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-effectiveness:

-

Negotiate Terms: Always negotiate payment terms and pricing based on volume. Suppliers may offer better rates for larger orders or favorable payment terms for repeat business.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in shipping, potential returns, and long-term durability to understand the true cost of your investment.

-

Understand Pricing Nuances: Different regions may have varying pricing standards based on local demand, production costs, and market conditions. Familiarize yourself with these dynamics to make informed decisions.

-

Explore Multiple Suppliers: Don’t settle for the first quote. By comparing several suppliers, you can better understand the market rate and leverage this information in negotiations.

Disclaimer

Prices for embossed leather fabric can vary significantly based on the factors discussed above. The indicative prices provided in this analysis are subject to change based on market conditions, supplier pricing strategies, and specific order requirements. Always request formal quotes from suppliers to ensure accurate pricing.

Alternatives Analysis: Comparing embossed leather fabric With Other Solutions

Understanding Alternative Solutions to Embossed Leather Fabric

In the competitive landscape of upholstery and fashion, embossed leather fabric stands out for its unique texture and aesthetic appeal. However, various alternatives offer different advantages and can be more suitable depending on specific project requirements. This analysis compares embossed leather fabric with synthetic leather and textile options, enabling international B2B buyers to make informed decisions.

| Comparison Aspect | Embossed Leather Fabric | Synthetic Leather | Upholstery Fabric |

|---|---|---|---|

| Performance | High durability, natural feel | Good durability, varies by quality | Moderate durability, often less resilient |

| Cost | Higher price point, premium quality | Generally lower cost, varies widely | Lower cost, budget-friendly options |

| Ease of Implementation | Requires skilled labor for upholstery | Easier to cut and sew; less skill needed | Straightforward to work with, versatile |

| Maintenance | Requires regular conditioning | Easy to clean, less upkeep | Variable maintenance based on material type |

| Best Use Case | Luxury items, high-end furniture | Mass-produced goods, budget applications | Everyday furniture, casual settings |

What Are the Pros and Cons of Synthetic Leather as an Alternative?

Synthetic leather, often made from polyurethane or PVC, mimics the appearance of real leather while offering several benefits. One of its main advantages is cost-effectiveness, making it accessible for mass production. It is also easier to clean and maintain than natural leather, which can be appealing for high-traffic areas. However, synthetic leather typically lacks the durability and luxurious feel of genuine embossed leather, making it less suitable for high-end applications. Additionally, the environmental impact of producing synthetic materials can be a concern for eco-conscious buyers.

Illustrative image related to embossed leather fabric

How Does Upholstery Fabric Compare to Embossed Leather Fabric?

Upholstery fabric encompasses a broad range of textiles, from cotton blends to polyester and beyond. These fabrics can provide a softer, more casual look, making them ideal for everyday furniture and decor. They often come at a lower price point compared to embossed leather, appealing to budget-conscious buyers. However, upholstery fabrics may not offer the same durability or upscale appearance as embossed leather, especially in high-use settings. This option is best for projects where comfort and cost are prioritized over luxury and longevity.

Conclusion: How to Choose the Right Solution for Your Business Needs

When evaluating the best solution for your business needs, consider the specific applications and target audience for your products. If your focus is on luxury and durability, embossed leather fabric remains a top choice despite its higher cost. For mass production or budget-sensitive projects, synthetic leather or upholstery fabric may present viable alternatives. Ultimately, understanding your project requirements and customer expectations will guide you in selecting the most appropriate material for your endeavors, ensuring both satisfaction and profitability.

Essential Technical Properties and Trade Terminology for embossed leather fabric

What Are the Key Technical Properties of Embossed Leather Fabric?

When sourcing embossed leather fabric, understanding its technical properties is vital for ensuring quality and suitability for your specific applications. Here are several critical specifications to consider:

1. Material Grade

Material grade refers to the quality classification of leather, which can range from full-grain to corrected grain. Full-grain leather is the highest quality, preserving the natural texture and durability. For B2B buyers, selecting a higher grade ensures longevity and a premium feel, essential for products like luxury upholstery or high-end fashion accessories.

Illustrative image related to embossed leather fabric

2. Thickness

The thickness of embossed leather, typically measured in millimeters (mm), impacts its application versatility. Standard thickness ranges from 1.0 mm to 2.5 mm. Thicker leather offers increased durability, making it ideal for items that undergo wear and tear, such as bags and footwear. B2B buyers should assess their specific product requirements to select the appropriate thickness that balances durability and flexibility.

3. Tolerance

Tolerance indicates the allowable variation in thickness and dimensions of the leather. For embossed leather, a typical tolerance might be ±0.5 mm. Tight tolerances are crucial for applications requiring precise cuts and consistent quality, such as automotive interiors or tailored garments. Understanding tolerance helps buyers ensure that their production processes run smoothly without unexpected adjustments.

4. Finish Type

The finish of embossed leather affects its appearance and performance. Common finish types include aniline, semi-aniline, and pigmented. Aniline finishes showcase the natural grain and maintain breathability, while pigmented finishes offer greater resistance to stains and fading. For B2B buyers, understanding finish types is essential for aligning with customer preferences and product requirements.

5. Embossing Patterns

Embossing patterns can vary widely, from simple textures to intricate designs like crocodile or floral motifs. The choice of pattern can affect both aesthetics and marketability. Buyers should consider the target market and the intended use of the embossed leather to select patterns that resonate with their customer base.

What Are Common Trade Terms Related to Embossed Leather Fabric?

Navigating the world of embossed leather requires familiarity with specific trade terminology. Here are several essential terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the leather industry, OEMs may provide embossed leather components for brands in fashion or automotive sectors. Understanding OEM relationships can enhance sourcing strategies and optimize supply chain management.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For embossed leather, MOQs can vary significantly based on the supplier and the specifics of the embossing process. Buyers must assess their production needs against MOQs to avoid excess inventory or missed opportunities.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. For embossed leather procurement, an RFQ can include specifications such as material grade, thickness, and desired embossing patterns. Utilizing RFQs helps buyers ensure competitive pricing and aligns supplier capabilities with their project requirements.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify costs, risks, and logistics, essential for B2B buyers importing embossed leather. Familiarity with Incoterms can facilitate smoother negotiations and shipping arrangements.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the leather industry, lead times can be influenced by factors such as embossing processes and shipping logistics. Buyers should consider lead times when planning production schedules to ensure timely delivery to their customers.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their business objectives and customer needs in the embossed leather market.

Navigating Market Dynamics and Sourcing Trends in the embossed leather fabric Sector

What Are the Key Market Dynamics and Trends Influencing the Embossed Leather Fabric Sector?

The embossed leather fabric market is witnessing robust growth driven by several global factors. The increasing demand for unique, aesthetically appealing materials in sectors such as automotive, furniture, and fashion is a significant driver. Buyers from Africa, South America, the Middle East, and Europe are particularly interested in high-quality, customizable embossed leather options that can cater to local tastes and preferences. Emerging technologies, such as digital printing and advanced embossing techniques, are enabling manufacturers to produce intricate designs and patterns, enhancing the appeal of embossed leather products. Additionally, the rise of e-commerce platforms has made sourcing more accessible for international buyers, allowing them to connect with suppliers worldwide.

Moreover, trends such as personalization and customization are reshaping the market. B2B buyers are increasingly looking for suppliers who can offer tailored solutions, including unique embossing patterns and colors. Sustainability is also becoming a focal point, as companies seek to align their sourcing practices with environmentally friendly standards. This shift is particularly relevant in regions like Europe, where regulatory frameworks often prioritize sustainable materials.

Illustrative image related to embossed leather fabric

How Is Sustainability Influencing the Sourcing of Embossed Leather Fabric?

Sustainability and ethical sourcing are becoming paramount in the embossed leather fabric sector. The environmental impact of leather production has prompted buyers to seek suppliers who prioritize eco-friendly practices. This includes the use of vegetable-tanned leather, which minimizes harmful chemicals, and the sourcing of hides from sustainable farms. Buyers are also increasingly interested in suppliers who have obtained green certifications, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification, which signify adherence to environmental standards.

Furthermore, ethical supply chains are critical for B2B buyers looking to build brand integrity and consumer trust. By choosing suppliers committed to ethical practices, companies can enhance their brand image and appeal to environmentally conscious consumers. This trend is especially pronounced in markets like Europe, where consumers are more likely to support brands that demonstrate a commitment to sustainability. As a result, international buyers should prioritize partnerships with suppliers who can provide transparency in their sourcing processes and offer eco-friendly embossed leather options.

What Is the Historical Context of Embossed Leather Fabric in the B2B Market?

The evolution of embossed leather fabric can be traced back to ancient practices where artisans would use manual techniques to create intricate patterns on leather hides. Historically, embossed leather was used primarily in luxury goods and high-end fashion due to its unique aesthetic appeal and durability. Over time, technological advancements have transformed the production methods, allowing for mass customization and a wider variety of designs.

In the modern B2B context, embossed leather has found applications across various industries, from automotive interiors to upscale furniture. The growing demand for unique design elements has propelled embossed leather into the spotlight, making it a sought-after material for businesses aiming to differentiate their products. As the market continues to evolve, the interplay of tradition and innovation will likely shape the future of embossed leather fabric, providing ample opportunities for international buyers to explore diverse sourcing options.

Frequently Asked Questions (FAQs) for B2B Buyers of embossed leather fabric

-

How do I choose the right embossed leather fabric for my project?

Choosing the right embossed leather fabric involves understanding your project’s specific requirements, including durability, texture, and aesthetic appeal. Consider the intended use—whether for upholstery, accessories, or custom designs. Research various embossing patterns and finishes to find one that aligns with your brand identity. It’s also vital to assess the weight and thickness of the leather, as this affects both the feel and performance. Collaborating with suppliers who offer samples can help you make an informed decision before placing a bulk order. -

What are the typical minimum order quantities (MOQs) for embossed leather fabric?

Minimum order quantities for embossed leather fabric can vary significantly by supplier and product type. Generally, MOQs range from 10 to 50 hides, depending on the supplier’s production capabilities and the specific embossing pattern. For custom orders, higher MOQs may apply due to the additional costs associated with setting up embossing plates. Always inquire directly with suppliers for their specific MOQ policies and consider negotiating terms, especially if you are a repeat customer or plan for larger orders in the future. -

What are the payment terms commonly offered by suppliers of embossed leather fabric?

Payment terms can differ widely among suppliers, but most B2B transactions involve options like net 30, net 60, or even payment upon delivery. Some suppliers may offer discounts for early payment or bulk orders. It’s advisable to clarify payment methods accepted (e.g., bank transfers, credit cards) and whether a deposit is required for custom orders. Establishing clear payment terms upfront can help foster a reliable relationship and avoid misunderstandings later in the transaction process. -

How can I ensure the quality of embossed leather fabric before purchasing?

To ensure quality, request samples before committing to a large order. Evaluate the texture, finish, and durability of the leather through physical examination and testing. Additionally, inquire about the supplier’s quality assurance processes, including any certifications they hold. Look for reviews and testimonials from previous buyers to gauge the supplier’s reputation. Establishing a direct line of communication with the supplier can also facilitate discussions about quality standards and expectations. -

What logistics considerations should I keep in mind when importing embossed leather fabric?

Logistics considerations include understanding shipping costs, customs duties, and lead times associated with importing embossed leather fabric. Ensure that the supplier provides detailed shipping information, including the estimated delivery timeline. Familiarize yourself with local import regulations and any applicable tariffs to avoid unexpected costs. It may also be beneficial to work with a freight forwarder experienced in handling leather goods to streamline the shipping process. -

Can I customize the embossing design on leather fabric?

Yes, many suppliers offer customization options for embossing designs. Typically, this process involves selecting the leather color and the desired embossing pattern. After finalizing your choices, you will need to work closely with the supplier to create or modify embossing plates. Custom orders may require a higher MOQ and longer lead times, so it’s essential to discuss these aspects upfront to align your production schedule with your business needs. -

What types of embossed leather patterns are available for purchase?

Embossed leather comes in a variety of patterns, including classic designs like crocodile and lizard prints, as well as floral and geometric motifs. Specialty patterns may also be available for niche markets, such as western or rustic themes. When sourcing, consider not only the aesthetics but also the texture and how it will complement your end products. Suppliers often provide catalogs or online galleries showcasing their available patterns, which can assist you in making an informed choice. -

How do I vet suppliers of embossed leather fabric for reliability?

Vetting suppliers involves several steps, including checking their business credentials, industry reputation, and customer feedback. Look for suppliers with a solid track record in the leather industry and those who provide transparent communication regarding their processes. Request references from previous clients and examine their response times to inquiries. Additionally, consider visiting the supplier’s facility if feasible, or utilizing third-party verification services to assess their operational standards. This due diligence can help ensure you partner with a reliable supplier.

Top 7 Embossed Leather Fabric Manufacturers & Suppliers List

1. Western Embossed Leather – Key Patterns

Domain: barbarossaleather.com

Registered: 2005 (20 years)

Introduction: Western Embossed Leather features designs inspired by the American West, including Big Sky, Southwest, and Texas styles. The patterns include cattle skulls, paisley motifs, and tribal designs. Key patterns available are Aztec, Birchbark, Bits, Brandito, Brands, Cheyenne, Corona, Derby, Driftwood, Indiano, Loredo, Navajo, Odyssey, Paisley, Plumas, Roses, Secoya, Skulls, Sugar Skulls, Sundance Croc,…

2. Your Western Decorating – Embossed Leathers

Domain: yourwesterndecorating.com

Registered: 2019 (6 years)

Introduction: Embossed Leathers for upholstery needs and home decor projects. Sold by 1/2 hide (20-23 sq ft) and full hide (40-50 sq ft). In stock orders ship in 2-3 business days. Products include: Autumn Turquoise Embossed Leather ($260.00), Soft Blossom Amber Forest Embossed Leather ($295.00), Longhorn Metallic Coffee Embossed Leather ($260.00), CUSTOM Paisley Golden Dove Embossed Leather ($1,322.00), Floral…

3. A Leather Store – Embossed Leather Collection

Domain: aleatherstore.com

Registered: 2021 (4 years)

Introduction: Embossed Leather collection includes various types of embossed leather products such as:

1. CASHMERE – embossed vegetable tanned natural Double Shoulder from $18.51

2. AMBER – embossed glossy double shoulders, hand dyed and embossed from $18.51

3. LACE – embossed vegetable tanned natural Double Shoulder from $16.09

4. FONTANELLAS & MARTÍ BULL SIDES – TORRO – 2.0/2.2mm from $15.93 (Sold Out)

5…

4. Spoonflower – Embossed Leather Look Fabrics & Home Decor

Domain: spoonflower.com

Registered: 2005 (20 years)

Introduction: Embossed-leather-look designs available in fabric by the yard, fabric by the meter, wallpaper, and home decor items such as curtains, bedding, pillows, and dining products. Supports Spoonflower’s community of artists. Custom design upload option available.

5. Leather Hide Store – Premium Embossed Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Premium Embossed Leather from Leather Hide Store, made from 100% full grain cowhide. Features a variety of embossed prints including croc, gator, florals, lizard, and stingray. Ideal for upholstery, custom auto, and general leathercraft use. Hand finished by leather artisans. Closeouts available at discounted prices. Popular items include Smooth Smoky Black Croc, Mojave Lizard, Savannah Tortoise S…

6. Etsy – Embossed Leather Fabric

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Embossed Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Avetco Inc – Embossed Leather

Domain: avetcoinc.com

Registered: 2005 (20 years)

Introduction: Embossed Leather features intricate patterns and textures pressed into high-quality hides, offering the look of exotic skins or custom designs with added durability. Suitable for handbags, footwear, upholstery, and fashion accessories, it adds visual depth and sophistication to any project. Available in a wide range of patterns, finishes, and colors. Key products include: 1. Bernard Oily Pull-Up C…

Strategic Sourcing Conclusion and Outlook for embossed leather fabric

The strategic sourcing of embossed leather fabric presents a wealth of opportunities for international buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. As the demand for unique and high-quality materials continues to rise, suppliers are diversifying their offerings to include an array of patterns and finishes—from rustic to modern styles. This variety not only enhances the aesthetic appeal of products but also allows businesses to cater to specific consumer preferences, thereby driving sales.

Understanding the nuances of sourcing embossed leather is crucial. Buyers should prioritize suppliers who offer customization options, ensuring that the material aligns with their brand identity and market needs. Additionally, considering factors such as lead times, shipping logistics, and pricing strategies can significantly impact procurement efficiency and overall profitability.

Looking forward, the embossed leather market is poised for growth, driven by trends in interior design, fashion, and automotive applications. Buyers are encouraged to leverage this momentum by establishing strong partnerships with reliable suppliers and staying abreast of emerging trends. By adopting a proactive approach to strategic sourcing, businesses can not only enhance their product offerings but also secure a competitive edge in their respective markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to embossed leather fabric