Introduction: Navigating the Global Market for tandy leather factory stamps

In the competitive landscape of leathercraft, sourcing Tandy leather factory stamps presents a unique challenge for international B2B buyers. With the rising demand for high-quality, durable stamping tools that enhance product aesthetics, understanding the nuances of these tools is essential for making informed purchasing decisions. This guide delves into the diverse types of Tandy leather factory stamps, including design, border, and geometric stamps, each tailored for specific applications in leather crafting.

We will explore key considerations such as supplier vetting processes, cost analysis, and the importance of selecting the right materials, whether brass or stainless steel, to meet your production needs. Additionally, we will provide insights into how these stamps can elevate your leather products, catering to various market preferences across Africa, South America, the Middle East, and Europe, including countries like Brazil and Germany.

By leveraging the information within this comprehensive guide, B2B buyers will be empowered to navigate the global market with confidence, ensuring that their investments in Tandy leather factory stamps yield the desired quality and performance for their creative projects. With the right tools, businesses can differentiate themselves in a crowded marketplace, ultimately leading to increased customer satisfaction and loyalty.

Table Of Contents

- Top 2 Tandy Leather Factory Stamps Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for tandy leather factory stamps

- Understanding tandy leather factory stamps Types and Variations

- Key Industrial Applications of tandy leather factory stamps

- 3 Common User Pain Points for ‘tandy leather factory stamps’ & Their Solutions

- Strategic Material Selection Guide for tandy leather factory stamps

- In-depth Look: Manufacturing Processes and Quality Assurance for tandy leather factory stamps

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘tandy leather factory stamps’

- Comprehensive Cost and Pricing Analysis for tandy leather factory stamps Sourcing

- Alternatives Analysis: Comparing tandy leather factory stamps With Other Solutions

- Essential Technical Properties and Trade Terminology for tandy leather factory stamps

- Navigating Market Dynamics and Sourcing Trends in the tandy leather factory stamps Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tandy leather factory stamps

- Strategic Sourcing Conclusion and Outlook for tandy leather factory stamps

- Important Disclaimer & Terms of Use

Understanding tandy leather factory stamps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Design Stamps | Intricate patterns and motifs, including floral and geometric designs | Custom leather goods, fashion accessories, and art | Pros: High-quality impressions, versatile designs. Cons: Higher initial investment. |

| Border Stamps | Create decorative edges and frames with various styles | Crafting bags, wallets, and belts | Pros: Enhances aesthetic appeal, easy to use. Cons: Limited to border applications. |

| Beveler Stamps | Tools for adding depth and dimension to leather designs | High-end leathercraft, custom furniture, and art | Pros: Creates professional-looking depth, durable. Cons: Requires skill for optimal results. |

| Background Stamps | Used to texture backgrounds, providing a finished look | Leather goods production, upholstery, and crafts | Pros: Adds texture easily, consistent results. Cons: May not suit all design styles. |

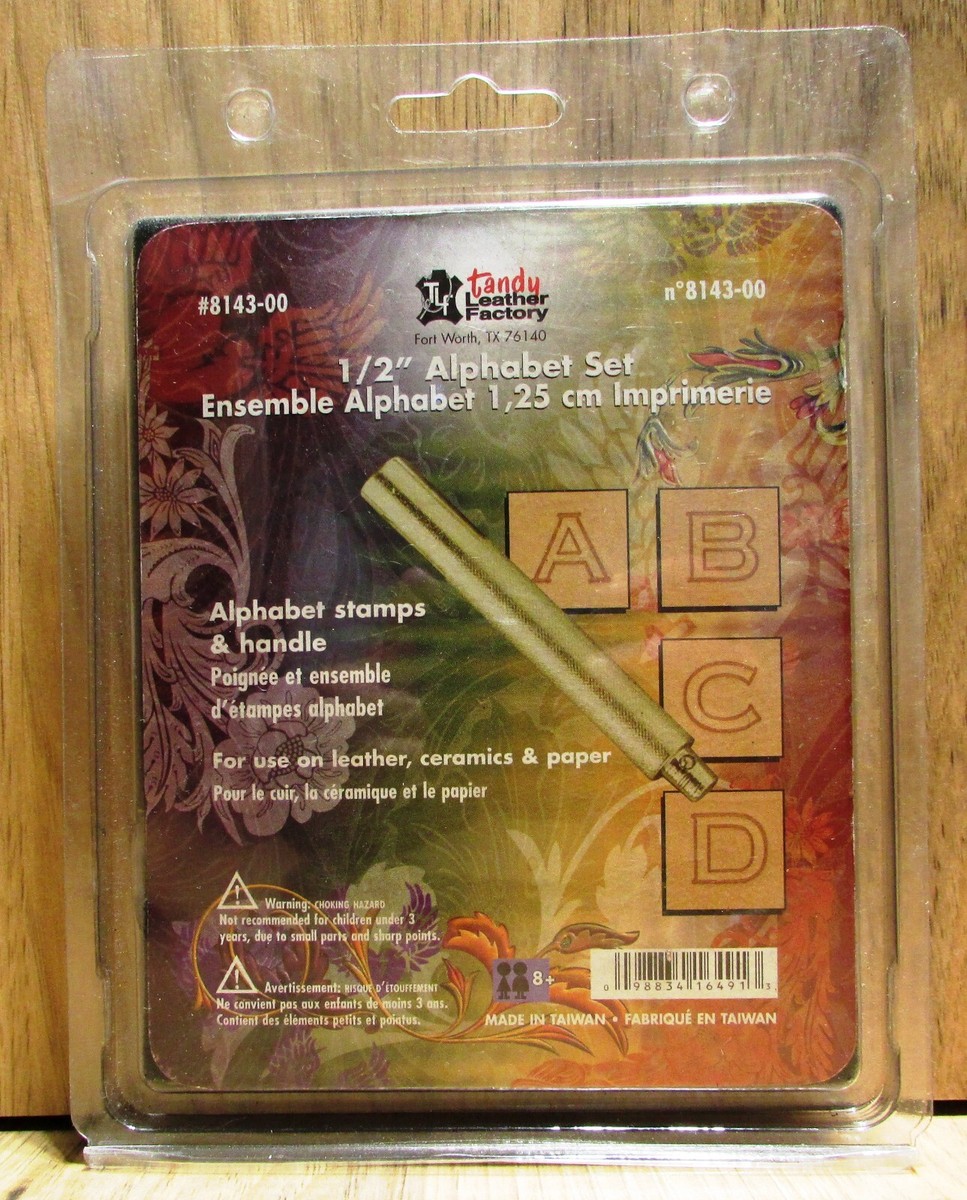

| Alphabet Stamps | Lettering options for personalization, including various fonts | Branding, custom gifts, and personalization | Pros: Customizable options, enhances branding. Cons: Limited to text applications. |

What Are Design Stamps and Their B2B Significance?

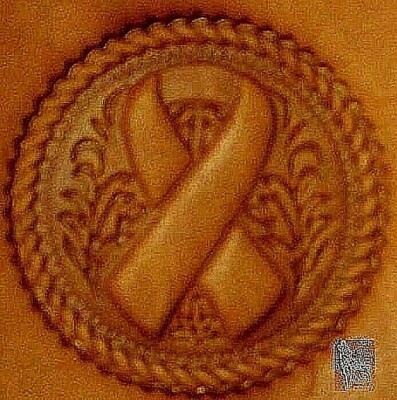

Design stamps are essential tools in the leathercraft industry, known for their intricate patterns and motifs. They allow artisans to transform ordinary leather into unique works of art, making them particularly suitable for custom leather goods, fashion accessories, and artistic projects. B2B buyers should consider the quality of materials and the variety of designs available, as these factors influence the final product’s appeal and marketability.

How Do Border Stamps Enhance Leather Projects?

Border stamps are designed to create decorative edges and frames, adding a professional touch to leather products such as bags, wallets, and belts. These stamps come in various styles, allowing for customization and creativity. For businesses, investing in high-quality border stamps can enhance product aesthetics, thereby increasing customer satisfaction and sales potential. However, buyers should note that these stamps are primarily limited to border applications.

Why Choose Beveler Stamps for Leathercraft?

Beveler stamps are critical for adding depth and dimension to leather designs, making them popular in high-end leathercraft and custom furniture production. They create a professional look by enhancing the visual appeal of the leather. While these stamps are durable and produce high-quality results, they require a certain level of skill to use effectively. B2B buyers should consider training for their teams to maximize the benefits of these tools.

What Role Do Background Stamps Play in Leathercraft?

Background stamps are used to add texture to leather, providing a finished look to various products. They are essential for mass production in leather goods, upholstery, and crafts. Their ability to create consistent results makes them invaluable for businesses looking to maintain quality across large orders. However, buyers should be aware that background stamps may not suit every design style, so selecting the right stamp for the intended application is crucial.

How Can Alphabet Stamps Benefit Branding and Customization?

Alphabet stamps offer a unique way to personalize leather products, making them ideal for branding and custom gifts. These stamps come in various fonts and styles, allowing businesses to tailor their offerings to customer preferences. While they enhance the uniqueness of products and can significantly boost branding efforts, buyers should consider their specific needs and the types of projects they frequently undertake to ensure they select the right alphabet stamps for their operations.

Key Industrial Applications of tandy leather factory stamps

| Industry/Sector | Specific Application of Tandy Leather Factory Stamps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom branding on leather goods | Enhances brand identity and customer loyalty | Quality of stamps, durability, and design customization options |

| Furniture and Interior Design | Decorative leather accents on furniture | Adds value and uniqueness to products | Compatibility with materials, design flexibility, and cost |

| Automotive | Leather interiors and custom upholstery | Improves aesthetic appeal and perceived luxury | Material compatibility, resistance to wear, and design options |

| Craft and Hobby | Personalized leather goods for DIY enthusiasts | Attracts niche markets and increases sales opportunities | Variety of designs, ease of use, and price point |

| Leather Goods Manufacturing | Mass production of customized leather products | Streamlines production processes and reduces lead times | Consistency in quality, bulk purchasing options, and support |

How Can Tandy Leather Factory Stamps Enhance Branding in the Fashion Industry?

In the fashion and apparel sector, Tandy leather factory stamps are used to imprint logos and unique designs on leather goods such as handbags, wallets, and belts. This application not only enhances brand recognition but also adds a personal touch that resonates with consumers. For international buyers, especially in regions like Africa and South America, sourcing stamps that offer high durability and customization options is crucial, as they must withstand varying environmental conditions while maintaining quality.

What Role Do Tandy Leather Factory Stamps Play in Furniture and Interior Design?

In the furniture and interior design industry, Tandy leather factory stamps are utilized to create decorative accents on leather upholstery. This application allows manufacturers to differentiate their products, adding aesthetic value and uniqueness. Buyers from Europe and the Middle East should consider the compatibility of stamps with various leather types and ensure they can achieve intricate designs that align with current design trends, thereby increasing the product’s marketability.

How Are Tandy Leather Factory Stamps Used in Automotive Customization?

The automotive industry employs Tandy leather factory stamps for creating custom leather interiors and upholstery designs. This application enhances the aesthetic appeal of vehicles, contributing to a sense of luxury and personalization. For B2B buyers in this sector, particularly in Brazil and Germany, it is essential to source stamps that offer resistance to wear and tear, ensuring longevity and quality in high-traffic areas of vehicles.

What Benefits Do Tandy Leather Factory Stamps Offer to Craft and Hobby Markets?

In the craft and hobby sector, Tandy leather factory stamps are popular among DIY enthusiasts for creating personalized leather goods. This application allows crafters to express their creativity and cater to niche markets with unique, custom-made items. Buyers should focus on the variety of designs available and the ease of use of the stamps, as this can significantly influence their purchasing decisions and ultimately enhance their product offerings.

How Do Tandy Leather Factory Stamps Streamline Production in Leather Goods Manufacturing?

For leather goods manufacturers, Tandy leather factory stamps facilitate the mass production of customized leather products, improving efficiency and reducing lead times. This application is vital for businesses looking to scale operations while maintaining high-quality standards. International buyers should prioritize sourcing stamps that ensure consistency in quality and explore bulk purchasing options to optimize their supply chain and production processes.

3 Common User Pain Points for ‘tandy leather factory stamps’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Impressions with Tandy Leather Stamps

The Problem: Many B2B buyers, particularly those in manufacturing or artisanal leatherwork, face the challenge of achieving consistent impressions when using Tandy leather factory stamps. This inconsistency can stem from various factors such as uneven pressure application, insufficient material preparation, or the quality of the stamping tools themselves. Inconsistent results can lead to customer dissatisfaction, wasted materials, and increased production costs, ultimately affecting the bottom line.

The Solution: To ensure consistent impressions, it is crucial to invest in high-quality Tandy leather factory stamps and to standardize the stamping process. Buyers should carefully select stamps that are suited for their specific project requirements, considering factors such as size, design intricacy, and material compatibility. Additionally, it is recommended to establish a uniform stamping technique, which includes using a quality mallet to apply even pressure across the stamp. Properly preparing the leather surface by conditioning it can also enhance the quality of the impression. Regular maintenance of the stamps, including cleaning and inspecting for wear, can further ensure longevity and performance, thus minimizing inconsistencies.

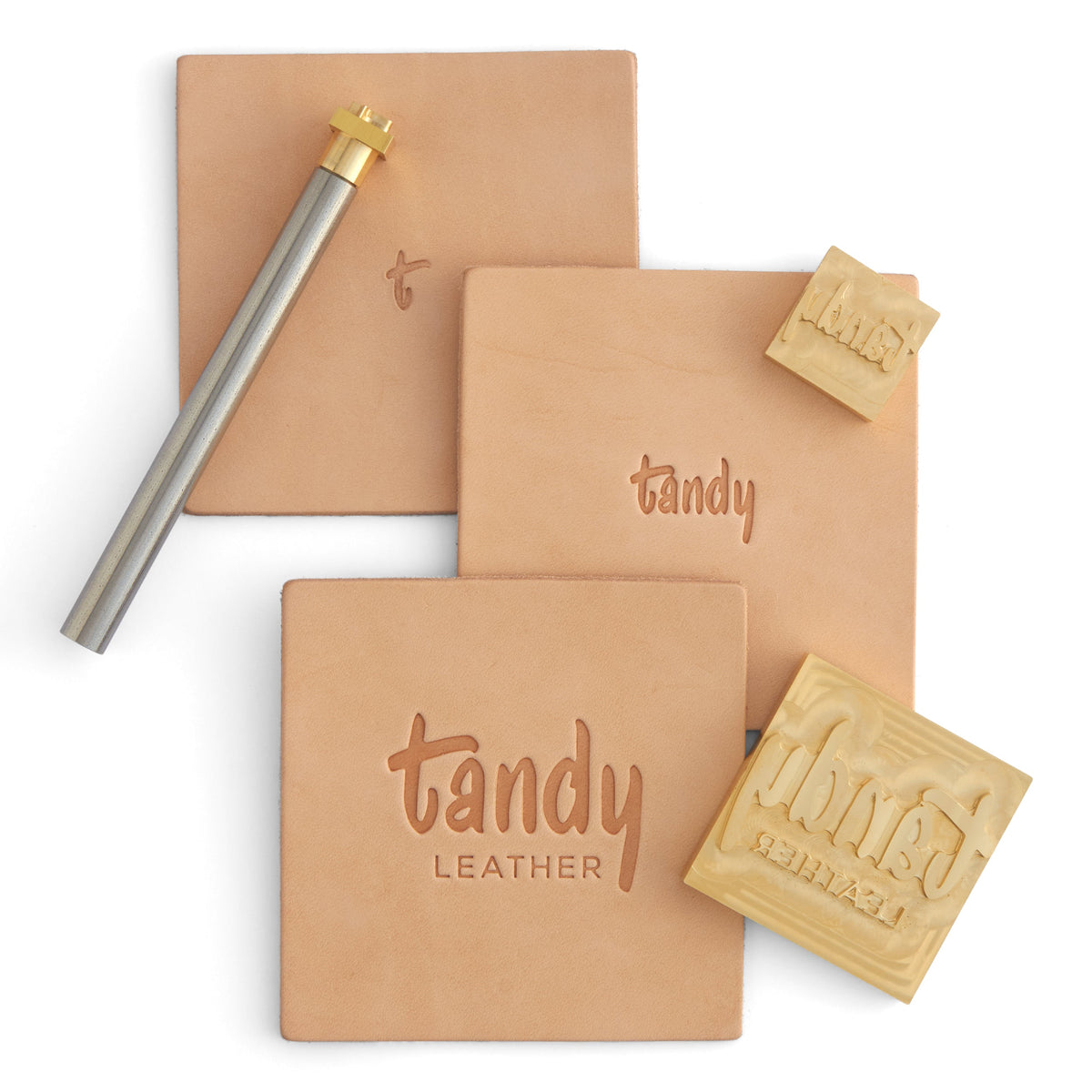

Illustrative image related to tandy leather factory stamps

Scenario 2: Navigating the Extensive Range of Tandy Leather Stamps

The Problem: B2B buyers often feel overwhelmed by the extensive range of Tandy leather stamps available, including various designs, sizes, and materials. This abundance can lead to confusion about which products best meet their specific needs, resulting in potential purchasing errors or missed opportunities to enhance product offerings. For international buyers, particularly those in regions like Africa and South America, shipping costs and lead times can exacerbate the impact of making the wrong choice.

The Solution: To navigate the vast selection effectively, buyers should begin by clearly defining their project requirements and desired outcomes. Creating a checklist of essential features—such as stamp type (e.g., decorative, functional), material (brass vs. stainless steel), and size—can help streamline the decision-making process. Utilizing Tandy’s online resources, including product guides and customer reviews, can provide additional insights into the practical applications of various stamps. Furthermore, engaging directly with Tandy’s customer service or sales representatives can offer personalized recommendations based on specific industry applications, ensuring that purchases align with business goals and avoid costly mistakes.

Scenario 3: Maintaining the Quality and Longevity of Stamps

The Problem: Over time, many users encounter wear and tear on their Tandy leather stamps, which can significantly diminish the quality of impressions. Factors such as improper cleaning, storage, and usage can lead to stamps becoming less effective. For B2B buyers relying on these tools for consistent output, the degradation of stamping quality can result in increased operational costs and negatively impact brand reputation.

The Solution: To maintain the quality and longevity of Tandy leather factory stamps, it is essential to implement a regular maintenance routine. Buyers should clean stamps after each use to remove any residual leather or dyes, using a soft brush or cloth. Additionally, storing stamps in a dry environment, ideally in a padded case or dedicated storage solution, will protect them from physical damage and rust. Periodically inspecting stamps for signs of wear and replacing them as necessary will help maintain the integrity of the stamping process. Educating staff on proper usage techniques can also minimize wear and prolong the lifespan of the tools, ensuring that the business continues to deliver high-quality leather products consistently.

Strategic Material Selection Guide for tandy leather factory stamps

When selecting materials for Tandy leather factory stamps, understanding the properties, advantages, and limitations of each material is crucial for B2B buyers. This analysis focuses on four common materials used in the production of leather stamps: brass, stainless steel, aluminum, and carbon steel. Each material offers unique characteristics that can influence the performance and suitability of the stamps for various applications.

What Are the Key Properties of Brass for Leather Stamps?

Brass is a popular choice for leather stamps due to its excellent machinability and corrosion resistance. It typically withstands moderate temperatures and pressures, making it suitable for various stamping applications. Brass stamps are known for their durability and can produce intricate designs with consistent impressions.

Pros and Cons of Brass Stamps

The primary advantage of brass is its resistance to rust and corrosion, which extends the lifespan of the stamps. Additionally, brass can be easily engraved, allowing for detailed designs. However, brass is generally more expensive than other materials and may require more complex manufacturing processes, which can increase lead times.

Impact on Application

Brass stamps are compatible with various leather types, including vegetable-tanned and chrome-tanned leathers. They are particularly effective for detailed designs due to their ability to hold fine lines and intricate patterns.

How Does Stainless Steel Compare for Tandy Leather Stamps?

Stainless steel is another commonly used material for leather stamps, known for its high strength and resistance to corrosion. It can withstand high temperatures and pressures, making it ideal for heavy-duty applications.

Pros and Cons of Stainless Steel Stamps

The key advantage of stainless steel is its exceptional durability and resistance to wear, ensuring long-term performance. However, stainless steel is typically more expensive than brass and may be harder to engrave, which can limit design complexity.

Impact on Application

Stainless steel stamps are highly versatile and can be used on various leather types, including those that require higher pressure during stamping. They are particularly well-suited for industrial applications where durability is paramount.

What Are the Benefits of Using Aluminum for Leather Stamps?

Aluminum is a lightweight and cost-effective option for leather stamps. It has good machinability and can be anodized for additional corrosion resistance.

Illustrative image related to tandy leather factory stamps

Pros and Cons of Aluminum Stamps

The main advantage of aluminum is its low cost and ease of manufacturing, making it an attractive option for businesses looking to minimize expenses. However, aluminum is less durable than brass or stainless steel, which can result in a shorter lifespan for the stamps.

Impact on Application

Aluminum stamps are best suited for lighter stamping applications and may not perform well on thicker or tougher leather types. They are ideal for projects that require frequent design changes due to their lower cost.

Why Choose Carbon Steel for Tandy Leather Stamps?

Carbon steel is known for its hardness and ability to maintain a sharp edge, making it suitable for detailed stamping work. It generally has a high strength-to-weight ratio and can withstand significant pressure.

Pros and Cons of Carbon Steel Stamps

The primary advantage of carbon steel is its ability to produce sharp, clean impressions. However, it is prone to rust and corrosion if not properly maintained, which can limit its lifespan compared to stainless steel and brass.

Illustrative image related to tandy leather factory stamps

Impact on Application

Carbon steel stamps are particularly effective for intricate designs and are compatible with various leather types. However, they require careful handling and maintenance to prevent rusting.

Summary Table of Material Selection for Tandy Leather Factory Stamps

| Materiaal | Typical Use Case for tandy leather factory stamps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Detailed designs on vegetable-tanned leather | Excellent corrosion resistance | Higher manufacturing complexity | Hoog |

| Stainless Steel | Heavy-duty industrial applications | Exceptional durability | More expensive and harder to engrave | Hoog |

| Aluminum | Lightweight, cost-effective designs | Low cost and easy to manufacture | Less durable than other materials | Low |

| Carbon Steel | Intricate designs requiring sharp impressions | Maintains a sharp edge | Prone to rust without maintenance | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, allowing them to make informed decisions based on their specific needs and applications. Understanding the properties and implications of each material will enhance the effectiveness of leather stamping projects across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for tandy leather factory stamps

What Are the Main Stages of Manufacturing Tandy Leather Factory Stamps?

The manufacturing process for Tandy Leather factory stamps involves several critical stages, each essential for producing high-quality, durable stamping tools. Understanding these stages can help B2B buyers assess the reliability and quality of the products they are considering.

Illustrative image related to tandy leather factory stamps

Material Preparation: What Materials Are Used for Tandy Leather Stamps?

The first step in manufacturing Tandy Leather stamps is material preparation. The primary materials used include high-grade brass and stainless steel, known for their durability and resistance to corrosion. Suppliers often select these materials based on their ability to withstand repeated use while maintaining the integrity of the design. The raw materials undergo rigorous inspection to ensure they meet specified standards before proceeding to the next stage.

How Are Tandy Leather Stamps Formed?

Once the materials are prepared, the forming process begins. This typically involves precision machining techniques such as CNC (Computer Numerical Control) routing. CNC machining allows for the creation of intricate designs with high accuracy, ensuring that each stamp produces a consistent impression. This technique is particularly important for design stamps, where detailed patterns are essential for the final product’s aesthetic appeal.

What Is Involved in the Assembly Stage?

After the forming process, the assembly stage takes place. This stage may involve attaching the stamp heads to the handles. High-quality adhesives and mechanical fixtures are utilized to ensure a secure bond, which is critical for maintaining performance during use. The assembly process is closely monitored to minimize any potential defects that could affect the functionality of the stamps.

How Are Tandy Leather Stamps Finished?

Finishing is the final stage in the manufacturing process. This involves polishing and applying protective coatings to enhance durability and aesthetic quality. The finishing process can include treatments to improve rust resistance, ensuring that the stamps maintain their appearance and functionality over time. Quality checks during this stage are essential to ensure that the final products meet the expected standards.

What Quality Assurance Standards Are Relevant to Tandy Leather Stamps?

Quality assurance is a crucial aspect of the manufacturing process for Tandy Leather stamps. Various international standards and industry-specific regulations guide the quality assurance practices employed during production.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is one of the most recognized international standards for quality management systems. It provides a framework for improving product quality and customer satisfaction. B2B buyers should look for suppliers who are ISO 9001 certified, as this indicates a commitment to quality management processes.

In addition to ISO standards, other industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be relevant, depending on the intended use of the stamps. These certifications demonstrate compliance with safety and performance standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established to ensure product quality. These checkpoints can be categorized into three main areas: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

How Is Incoming Quality Control (IQC) Conducted?

IQC involves inspecting raw materials upon receipt to ensure they meet predefined specifications. This initial inspection helps prevent defective materials from entering the production process, thereby reducing the likelihood of quality issues in the final product.

What Is In-Process Quality Control (IPQC)?

During the manufacturing process, IPQC is employed to monitor production activities and ensure compliance with quality standards. This can include regular checks on machining accuracy, assembly integrity, and finishing quality. By identifying and addressing any issues in real-time, manufacturers can minimize defects and maintain consistent quality.

How Is Final Quality Control (FQC) Implemented?

FQC is conducted once the stamps are fully assembled and finished. This stage typically involves a comprehensive inspection of the final product, including functionality tests and aesthetic evaluations. Products that do not meet quality standards are either reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying the quality control practices of suppliers is essential for ensuring the reliability of the products purchased. There are several methods buyers can utilize to conduct this verification.

What Audit Practices Should Buyers Implement?

Regular audits of suppliers can help assess their adherence to quality management standards. Buyers should request access to audit reports and certifications to verify compliance with ISO 9001 and other relevant standards. This transparency can foster trust and ensure that suppliers are committed to maintaining high-quality production processes.

How Can Third-Party Inspections Enhance Assurance?

Engaging third-party inspection services can provide an objective assessment of a supplier’s quality control practices. These inspections can occur at various stages of the manufacturing process, offering insights into material quality, production accuracy, and final product compliance.

Illustrative image related to tandy leather factory stamps

What Nuances Should International B2B Buyers Be Aware Of?

International buyers, especially from diverse markets such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality assurance and compliance.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have varying regulations regarding product safety and quality. B2B buyers should familiarize themselves with these regulations to ensure that the products they import comply with local laws. This is particularly important for stamps used in industries with strict compliance requirements.

What Are the Benefits of Understanding Local Market Expectations?

Understanding the expectations of local markets can aid in selecting the right suppliers and products. Buyers should consider factors such as cultural preferences, design trends, and specific applications when evaluating Tandy Leather stamps. This knowledge can help optimize purchasing decisions and improve customer satisfaction.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices associated with Tandy Leather factory stamps is essential for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and quality control, buyers can make informed decisions and ensure they are sourcing high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tandy leather factory stamps’

Inleiding

This sourcing guide aims to assist international B2B buyers in procuring Tandy Leather factory stamps effectively. Given the diverse range of stamps available, from design stamps to specialized tools, understanding the procurement process is essential for ensuring quality and consistency in leathercraft projects. This checklist will provide actionable steps to streamline your sourcing journey.

Step 1: Identify Your Project Requirements

Begin by clearly defining the specific needs of your leathercraft projects. Consider factors such as the types of designs you wish to create, the scale of production, and the materials you will be working with. This step is vital to ensure that you select the right stamps that will meet your artistic and functional requirements.

- Types of Stamps: Determine if you need decorative, geometric, or alphabet stamps based on your design goals.

- Volume Needs: Assess whether you require individual stamps or complete sets for larger projects.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of Tandy Leather stamps. Look for companies that specialize in leathercraft tools and have a strong track record in the industry. A well-established supplier can provide a wider selection and better customer service.

- Online Reviews: Check customer feedback on platforms like Trustpilot or Google Reviews to gauge supplier reliability.

- Industry Recommendations: Seek referrals from other leathercraft professionals or forums to find trusted sources.

Step 3: Evaluate Product Quality

Once you have a shortlist of suppliers, evaluate the quality of their products. Request samples if possible to assess the durability and precision of the stamps. High-quality tools are essential for achieving consistent results in your leatherwork.

- Material Assessment: Look for stamps made from rust-resistant materials like brass or stainless steel for longevity.

- Design Precision: Ensure the stamps produce clear, detailed impressions that match your design needs.

Step 4: Verify Supplier Certifications

It’s crucial to verify any certifications or standards that the supplier adheres to, especially if you’re importing goods internationally. Compliance with international standards ensures product quality and safety.

- Certifications: Check for ISO certifications or other relevant industry standards that demonstrate the supplier’s commitment to quality.

- Sustainability Practices: Inquire about the supplier’s environmental policies, particularly if sustainability is a priority for your business.

Step 5: Compare Pricing and Terms

Gather pricing information from multiple suppliers to ensure you are getting competitive rates. However, remember that the lowest price doesn’t always equate to the best value. Consider shipping costs, payment terms, and return policies as part of your evaluation.

- Bulk Discounts: Ask about discounts for larger orders, which can significantly reduce costs.

- Transparent Terms: Ensure that the terms of sale are clear, particularly regarding warranties and after-sales support.

Step 6: Place a Test Order

Before committing to a large purchase, consider placing a test order with your selected supplier. This allows you to evaluate their order fulfillment process, product quality, and customer service firsthand.

Illustrative image related to tandy leather factory stamps

- Order Size: Start with a small batch to minimize risk while assessing the supplier’s reliability.

- Feedback Loop: Use this opportunity to provide feedback to the supplier and gauge their responsiveness.

Step 7: Establish a Long-Term Relationship

Once you have found a reliable supplier, focus on building a long-term partnership. Consistent communication and feedback can help optimize your sourcing process and ensure that you receive quality products for your future projects.

- Regular Check-Ins: Schedule periodic reviews to discuss product updates or new offerings.

- Loyalty Benefits: Inquire about loyalty programs or benefits for repeat customers to enhance your procurement strategy.

By following this checklist, you can streamline the sourcing process for Tandy Leather factory stamps, ensuring you select the best tools for your leathercraft endeavors.

Comprehensive Cost and Pricing Analysis for tandy leather factory stamps Sourcing

What Are the Key Cost Components for Tandy Leather Factory Stamps?

When evaluating the cost structure for sourcing Tandy leather factory stamps, several critical components come into play.

-

Materials: The primary materials include high-quality brass or stainless steel for stamp heads and durable plastics or metals for handles. The choice of material significantly impacts both durability and cost, with brass generally being more expensive due to its corrosion resistance and longevity.

-

Labor: Labor costs encompass the wages of skilled craftsmen who design, produce, and finish the stamps. As Tandy leather products are often crafted with precision, skilled labor is essential, which can lead to higher costs, especially in regions with elevated wage standards.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility, such as utilities, equipment maintenance, and administrative expenses. Overhead can vary widely based on geographic location and facility size.

-

Tooling: The initial investment in specialized tools for crafting stamps can be substantial. This cost is amortized over the production run, affecting the unit price. Custom tooling for unique designs can further escalate these costs.

-

Quality Control (QC): Ensuring that every stamp meets quality standards requires a dedicated QC process, adding to overall costs. Quality certifications may also be necessary for international buyers, impacting pricing.

-

Logistics: Transportation costs for shipping products from the manufacturing facility to buyers can fluctuate based on distance, shipping method, and fuel prices. International shipping may involve additional tariffs and duties, influencing total costs.

-

Margin: Suppliers typically add a markup to cover their costs and generate profit. This margin can vary based on competition, demand, and exclusivity of the product.

How Do Price Influencers Affect Sourcing Tandy Leather Factory Stamps?

Several factors influence the pricing of Tandy leather factory stamps, which B2B buyers must consider:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to achieve cost efficiency, especially for high-demand items.

-

Specifications/Customization: Custom designs or specific features can drive up costs. It’s essential to weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Premium materials and certifications such as ISO can enhance product value but also increase costs. Buyers should assess the necessity of these factors based on market needs.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers may offer higher prices due to perceived quality, while new entrants might provide competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears costs and risks during shipping. This can significantly impact the total landed cost of the products.

What Tips Can Help Buyers Optimize Their Costs?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to optimize their costs when sourcing Tandy leather factory stamps:

-

Negotiation: Leverage relationships with suppliers to negotiate better pricing, especially for larger orders. Establishing long-term partnerships can also lead to discounts.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the purchase price. Consider factors like longevity, maintenance, and potential resale value of the stamps.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and their impact on pricing. Additionally, understanding local taxes and import duties can help in calculating the final cost.

-

Research and Comparison: Always compare multiple suppliers and products. This not only helps in finding the best price but also in assessing the overall quality and reliability of the stamps.

Disclaimer

The prices mentioned in reference sources are indicative and may vary based on market conditions, supplier changes, and negotiation outcomes. Always confirm current pricing directly with the supplier for accurate budgeting.

Alternatives Analysis: Comparing tandy leather factory stamps With Other Solutions

Introduction to Alternative Solutions for Leather Stamping

When it comes to leather crafting, selecting the right stamping tools is essential for achieving high-quality results. While Tandy Leather Factory stamps are well-regarded for their durability and precision, various alternatives can also meet the needs of B2B buyers in diverse markets, including Africa, South America, the Middle East, and Europe. This section will compare Tandy stamps against other viable solutions, helping buyers make informed decisions based on performance, cost, and ease of use.

Comparison Table

| Comparison Aspect | Tandy Leather Factory Stamps | Craftool® Stamps | Custom CNC Stamps |

|---|---|---|---|

| Performance | High-quality impressions, versatile designs | Reliable but less intricate | Extremely detailed, customizable designs |

| Cost | $2.99 – $44.99 per stamp | $2.99 – $19.99 per stamp | $100+ per unit |

| Ease of Implementation | Easy to use with basic tools | User-friendly for beginners | Requires technical knowledge for setup |

| Maintenance | Minimal; occasional cleaning needed | Low; durable materials | Moderate; may need recalibration |

| Best Use Case | General leather crafting, small to medium projects | Hobbyists, small businesses | Large-scale production, specialized designs |

Detailed Breakdown of Alternatives

Craftool® Stamps

Craftool® stamps offer a range of affordable options for leather crafters, making them an appealing alternative for small businesses and hobbyists. These stamps are known for their reliability and ease of use, which is beneficial for beginners who are still mastering their techniques. However, while they provide good quality impressions, they may lack the intricate detail found in Tandy’s offerings. This makes Craftool® stamps suitable for general leather crafting but less ideal for projects requiring complex designs.

Custom CNC Stamps

For businesses looking for highly detailed and unique designs, custom CNC (Computer Numerical Control) stamps present a compelling option. These stamps are manufactured using advanced technology, allowing for intricate patterns and designs that can be tailored to specific client needs. However, the cost of custom CNC stamps can be significantly higher, starting at $100 or more per unit, which may not be feasible for smaller operations. Additionally, the setup process requires technical expertise, making it less accessible for casual crafters. Nevertheless, for large-scale production and specialized designs, custom CNC stamps can yield exceptional results.

Illustrative image related to tandy leather factory stamps

Conclusion: Choosing the Right Leather Stamping Solution

B2B buyers should carefully consider their specific needs when selecting leather stamping solutions. Tandy Leather Factory stamps offer a balance of quality and affordability, making them ideal for a wide range of projects. Craftool® stamps serve as an excellent choice for those on a budget or just starting out in leather crafting. In contrast, custom CNC stamps are best suited for businesses that require intricate designs and have the budget to support higher costs. Ultimately, understanding the unique demands of your projects and budget constraints will guide you in choosing the most appropriate stamping solution for your leather crafting endeavors.

Essential Technical Properties and Trade Terminology for tandy leather factory stamps

What Are the Essential Technical Properties of Tandy Leather Factory Stamps?

When considering the procurement of Tandy leather factory stamps, understanding their technical properties is crucial for ensuring quality and performance. Here are some key specifications to keep in mind:

-

Material Grade:

Tandy leather stamps are typically made from high-quality materials such as brass and stainless steel. Brass stamps are known for their durability and resistance to corrosion, making them suitable for long-term use. Stainless steel offers similar longevity and is less prone to rust, which is vital for maintaining clean impressions over time. For B2B buyers, selecting the right material ensures that the stamps will withstand the rigors of production and deliver consistent results. -

Stamp Size and Design:

Stamps come in various sizes and designs, which can affect the impression size and detail. Standard sizes may range from 1/4 inch to several inches in diameter. The design intricacies, such as the depth and detail of the impression, are essential for achieving the desired aesthetic in leather products. For manufacturers, understanding these specifications helps in selecting the right stamps to match their product designs. -

Tolerance Levels:

Tolerance refers to the allowable deviation in the dimensions of the stamp and the impression it creates. High-quality stamps typically have tighter tolerances, ensuring that each impression is consistent and meets the required specifications. For B2B buyers, this is critical in maintaining quality control across large production runs, reducing waste and rework costs. -

Durability and Wear Resistance:

The durability of a stamp directly impacts its lifespan and effectiveness. Stamps designed for heavy-duty use will exhibit higher wear resistance, allowing for thousands of impressions without degradation in quality. For businesses, investing in durable tools minimizes replacement costs and downtime, contributing to overall efficiency. -

Compatibility with Handles:

Tandy stamps often come with specific handles designed for optimal performance. Compatibility ensures that the stamp can be securely attached, facilitating better control and precision during use. Understanding this property allows buyers to make informed decisions about the tools they need for their stamping processes.

What Are Common Trade Terms Relevant to Tandy Leather Factory Stamps?

Understanding trade terminology is essential for B2B buyers to navigate the procurement process effectively. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer):

This term refers to companies that manufacture products that may be marketed under another company’s brand. In the context of leather stamps, buyers may source OEM stamps to offer unique branding options for their products. -

MOQ (Minimum Order Quantity):

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding the MOQ is crucial for buyers to plan their inventory effectively and avoid overcommitting resources. A lower MOQ can be beneficial for smaller businesses or those testing new products. -

RFQ (Request for Quotation):

An RFQ is a formal process where buyers request pricing information from suppliers. This document typically outlines the specifications and quantities required. Submitting an RFQ can help businesses compare offers from different suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms):

These are standardized terms used in international shipping to clarify the responsibilities of buyers and sellers. Understanding Incoterms helps B2B buyers manage logistics, insurance, and transportation costs more effectively, which is vital for international transactions. -

Lead Time:

Lead time is the period between placing an order and receiving the goods. This term is crucial for supply chain management, as it affects inventory levels and production schedules. Buyers must consider lead times when planning their manufacturing processes to ensure timely delivery of finished products. -

Customization Options:

Many suppliers offer customization for stamps, allowing businesses to create unique designs or branding. Understanding the available customization options helps buyers differentiate their products in the market, adding value to their offerings.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when sourcing Tandy leather factory stamps, ultimately enhancing your production capabilities and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the tandy leather factory stamps Sector

What Are the Key Market Dynamics and Trends Influencing Tandy Leather Factory Stamps?

The market for Tandy leather factory stamps is shaped by various global drivers, including the increasing demand for custom leather goods and the rise of artisanal craftsmanship. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in interest for high-quality leatherworking tools. This is largely driven by a resurgence in DIY culture and the growing popularity of leathercraft as a hobby and profession. Additionally, technological advancements in manufacturing processes, such as CNC routing for precision stamping, are enhancing product quality and consistency, making these tools more appealing to buyers.

Emerging trends in sourcing include a focus on local supply chains to reduce lead times and shipping costs. Buyers are increasingly looking for suppliers who can provide not only quality products but also quick turnaround times. This is particularly relevant for international buyers who may face longer shipping durations. Furthermore, the incorporation of e-commerce platforms is transforming the way B2B transactions occur, allowing buyers from diverse regions to easily access a wider range of products, compare prices, and evaluate suppliers based on customer reviews and ratings.

Illustrative image related to tandy leather factory stamps

How Are Sustainability and Ethical Sourcing Shaping the Tandy Leather Stamps Market?

Sustainability is becoming a critical factor for B2B buyers in the leathercraft industry. The environmental impact of leather production, including water usage and chemical treatments, has led many buyers to prioritize ethical sourcing practices. Suppliers that demonstrate commitment to sustainable practices—such as using vegetable-tanned leather or sourcing materials from certified eco-friendly suppliers—are increasingly favored.

The importance of ethical supply chains cannot be overstated, as buyers are not only looking for quality products but also seeking suppliers who align with their values. Certifications such as the Leather Working Group (LWG) certification can serve as a benchmark for buyers to assess the sustainability of their suppliers. Additionally, adopting “green” materials in the manufacturing of stamping tools, such as biodegradable or recycled components, is becoming a key differentiator in the market.

What Is the Brief Evolution and History of Tandy Leather Factory Stamps?

Tandy Leather has a storied history that dates back to its founding in the early 20th century. Initially established as a small leather supply company, Tandy quickly evolved into a leader in the leathercraft industry, recognized for its high-quality materials and tools. Over the decades, Tandy has expanded its product offerings to include a wide variety of stamping tools, including an extensive range of stamps designed for both novice and professional leatherworkers.

The evolution of Tandy leather factory stamps reflects broader trends in craftsmanship and customization. As consumer preferences shifted towards personalized goods, Tandy adapted its product lines to cater to this demand, introducing innovative designs and durable materials. Today, Tandy leather factory stamps are synonymous with quality and precision, making them a staple for both hobbyists and professional artisans around the world.

Illustrative image related to tandy leather factory stamps

In summary, understanding the market dynamics, sustainability concerns, and historical context of Tandy leather factory stamps equips international B2B buyers with the insights necessary to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of tandy leather factory stamps

-

How do I choose the right Tandy leather factory stamp for my project?

Selecting the appropriate Tandy leather stamp requires understanding the design you wish to create. Consider the type of leather you’re working with, as some stamps perform better on specific materials. For intricate designs, opt for detailed design stamps, while border stamps are ideal for framing projects. Additionally, evaluate the size and depth of the impression you want; larger stamps work well for bold statements, while smaller stamps are suited for fine detail. It’s also helpful to view samples of each stamp’s output to ensure it aligns with your project vision. -

What are the benefits of using Tandy leather factory stamps for bulk orders?

Bulk orders of Tandy leather factory stamps can significantly reduce costs per unit, making them a smart investment for businesses. Additionally, buying in larger quantities ensures you have a consistent supply of stamps for your production needs, minimizing downtime. This is particularly advantageous for manufacturers who require specific designs regularly. Furthermore, bulk purchases often qualify for discounts or promotional offers, enhancing your overall profit margins. Establishing a relationship with the supplier can also yield benefits like priority shipping or customization options. -

What is the minimum order quantity (MOQ) for Tandy leather factory stamps?

The minimum order quantity (MOQ) for Tandy leather factory stamps varies based on the specific product and supplier agreements. Generally, MOQs can range from a few pieces for standard items to larger quantities for custom designs. It’s essential to communicate directly with the supplier to understand their MOQ policies, as they can accommodate different order sizes. If you’re starting a new venture, inquire about sample orders to test the products before committing to larger purchases. -

What payment terms can I expect when purchasing Tandy leather factory stamps internationally?

When engaging in international transactions for Tandy leather factory stamps, payment terms can differ based on the supplier’s policies and your negotiation. Common payment methods include bank transfers, credit cards, and, in some cases, PayPal. Terms may include full payment upfront, a deposit with the balance due upon shipment, or net payment terms (e.g., Net 30 or Net 60). Establishing clear payment terms upfront helps prevent misunderstandings and ensures a smooth transaction process. -

How can I ensure the quality of Tandy leather factory stamps before purchase?

To ensure the quality of Tandy leather factory stamps, request product samples or detailed images of the stamps in use. Look for reviews or testimonials from other buyers, especially those in your region or industry. It’s also beneficial to inquire about the manufacturing process, materials used, and any quality assurance measures in place. If possible, visit the supplier’s facility to see the production and stamping results firsthand, which can provide peace of mind regarding your investment. -

What are the logistics involved in importing Tandy leather factory stamps?

Importing Tandy leather factory stamps involves several logistical considerations, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder who understands international trade regulations, especially for your specific destination. Ensure you have all necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs processing. Be aware of potential import duties and taxes that may apply, and factor these into your overall cost structure to avoid unexpected expenses. -

Can I customize Tandy leather factory stamps for my brand?

Yes, many suppliers of Tandy leather factory stamps offer customization options to align with your brand identity. Customization can include unique designs, logos, or specific dimensions tailored to your needs. Discuss your requirements with the supplier and ask about their capabilities regarding custom orders, including lead times and costs. Keep in mind that minimum order quantities may apply for customized stamps, so it’s advisable to plan your order accordingly. -

What should I consider when vetting suppliers for Tandy leather factory stamps?

When vetting suppliers for Tandy leather factory stamps, consider their industry reputation, years of experience, and customer reviews. Evaluate their product range and manufacturing capabilities to ensure they can meet your specific needs. Communication is key; assess their responsiveness and willingness to provide information. Additionally, check for certifications or standards that demonstrate quality and safety compliance. If possible, request references from previous clients to gain insights into their reliability and service quality.

Top 2 Tandy Leather Factory Stamps Manufacturers & Suppliers List

1. Tandy Leather – Leather Stamping Tools

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Leather Stamping Tools, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Tandy Leather Factory – Stamp

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Brand”:”Tandy Leather Factory”,”Type”:”Stamp”,”Condition”:”New”,”Shipping Cost”:”US $11.30 USPS Priority Mail”,”Returns”:”30 days returns, buyer pays for return shipping”,”Item Number”:”286047159446″,”Seller”:”Cole’s Classic Collectibles”,”Seller Feedback”:”100% positive”,”Location”:”Cleveland, Oklahoma, United States”,”Delivery Estimate”:”Between Fri, Oct 31 and Tue, Nov 4 to 60602″}

Strategic Sourcing Conclusion and Outlook for tandy leather factory stamps

In the evolving landscape of leathercraft, Tandy Leather Factory stamps present an exceptional opportunity for international B2B buyers seeking quality and versatility. By strategically sourcing these premium stamping tools, businesses can enhance their product offerings, ensuring consistent quality and intricate designs that meet diverse market demands. The extensive range, from geometric and floral motifs to customizable alphabet sets, empowers artisans to express creativity while maintaining professional standards.

Investing in Tandy’s durable, rust-resistant materials not only elevates craftsmanship but also positions businesses favorably within competitive markets, particularly in regions like Africa, South America, the Middle East, and Europe. This strategic sourcing approach fosters long-term partnerships and sustainable growth, as companies can depend on reliable tools that stand the test of time.

Illustrative image related to tandy leather factory stamps

Looking ahead, the future of leathercraft is bright. As consumer preferences shift toward personalized and unique products, now is the time to integrate Tandy Leather Factory stamps into your offerings. By doing so, you not only meet current market trends but also set the stage for innovation and expansion. Engage with Tandy Leather today to explore how these tools can transform your business and inspire creativity among your clients.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.