Introduction: Navigating the Global Market for shoe leather lining

In the competitive landscape of the global footwear industry, sourcing high-quality shoe leather lining presents a significant challenge for B2B buyers. Whether you are looking to enhance the comfort and durability of your products or ensure compliance with diverse market standards, understanding the nuances of leather lining options is crucial. This guide delves into the various types of shoe leather linings, their applications, and the best practices for supplier vetting, cost analysis, and quality assurance.

From luxurious full-grain calfskin to economical options like pig suede, the choice of lining can dramatically influence not only the aesthetic appeal but also the functional performance of footwear. As buyers from Africa, South America, the Middle East, and Europe navigate this intricate market, it is essential to be equipped with the right knowledge to make informed purchasing decisions. This comprehensive resource empowers you with insights into the latest trends, sourcing strategies, and critical factors to consider when selecting leather linings.

By the end of this guide, you will be better positioned to identify reputable suppliers and leverage market opportunities, ensuring that your footwear offerings meet the highest standards of quality and comfort. Embrace the potential of superior shoe leather linings to elevate your product line and satisfy the diverse preferences of your clientele across the globe.

Table Of Contents

- Top 8 Shoe Leather Lining Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for shoe leather lining

- Understanding shoe leather lining Types and Variations

- Key Industrial Applications of shoe leather lining

- 3 Common User Pain Points for ‘shoe leather lining’ & Their Solutions

- Strategic Material Selection Guide for shoe leather lining

- In-depth Look: Manufacturing Processes and Quality Assurance for shoe leather lining

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘shoe leather lining’

- Comprehensive Cost and Pricing Analysis for shoe leather lining Sourcing

- Alternatives Analysis: Comparing shoe leather lining With Other Solutions

- Essential Technical Properties and Trade Terminology for shoe leather lining

- Navigating Market Dynamics and Sourcing Trends in the shoe leather lining Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shoe leather lining

- Strategic Sourcing Conclusion and Outlook for shoe leather lining

- Important Disclaimer & Terms of Use

Understanding shoe leather lining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Lining | Breathable, moisture-wicking, and durable | High-end footwear, luxury brands | Pros: Comfortable, long-lasting; Cons: Higher cost. |

| Fleece Lining | Soft, warm, and cozy; mimics natural fibers | Casual footwear, slippers | Pros: Affordable, comfortable; Cons: Not suitable for refined footwear. |

| Polyester Lining | Synthetic, often non-breathable, and less durable | Low-cost shoes, mass production | Pros: Economical; Cons: Can cause odor and discomfort. |

| Cotton Lining | Breathable but moisture-absorbing | Casual and open-back footwear | Pros: Hypoallergenic, natural; Cons: Retains moisture, potential for bacteria growth. |

| Cambrelle Lining | Synthetic, moisture-absorbing, and antibacterial | Sports and heavy-duty footwear | Pros: Breathable, quick-drying; Cons: Limited use in everyday shoes. |

What are the Characteristics of Leather Lining in Shoes?

Leather lining is a premium choice for footwear, known for its breathability and moisture-wicking properties. Typically made from full-grain leather, it provides durability and comfort, making it ideal for high-end shoes. B2B buyers should consider the leather’s quality, ensuring it is not blended with synthetic materials, as this can compromise breathability and lead to foot health issues. Leather linings are particularly suitable for luxury brands and can enhance the overall value of the product.

How Does Fleece Lining Compare for Casual Footwear?

Fleece lining, often made from recycled materials, is soft and warm, making it a popular choice for casual footwear and slippers. Its cozy texture is appealing, but its bulkiness limits its application in refined shoe designs. B2B buyers should evaluate the target market when considering fleece, as it may not align with the aesthetics of high-end footwear. While economical, the use of fleece should be balanced with the desired product positioning.

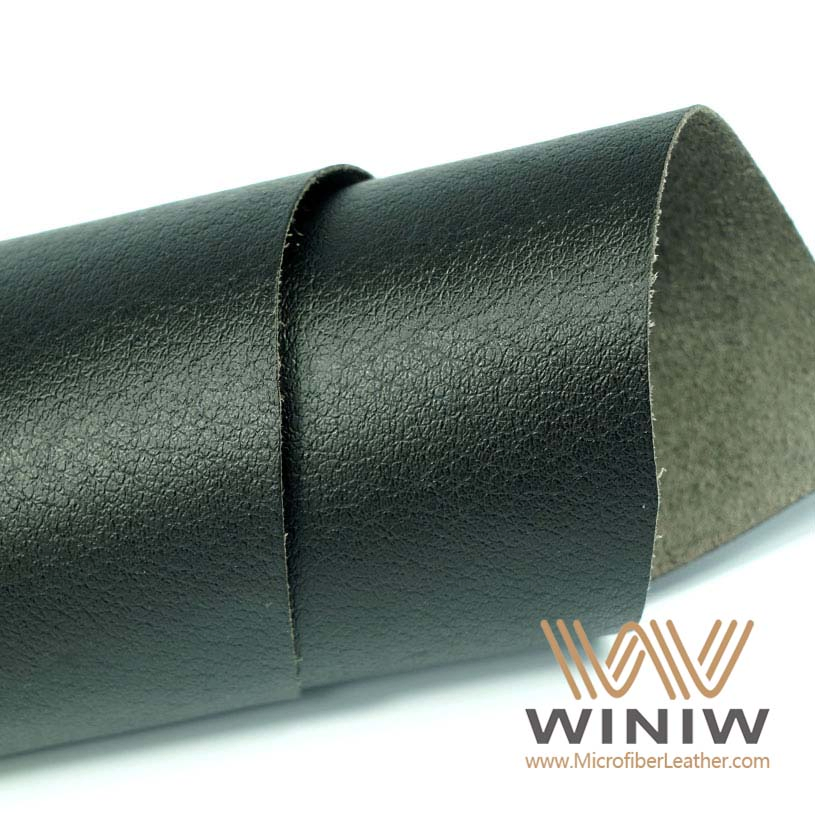

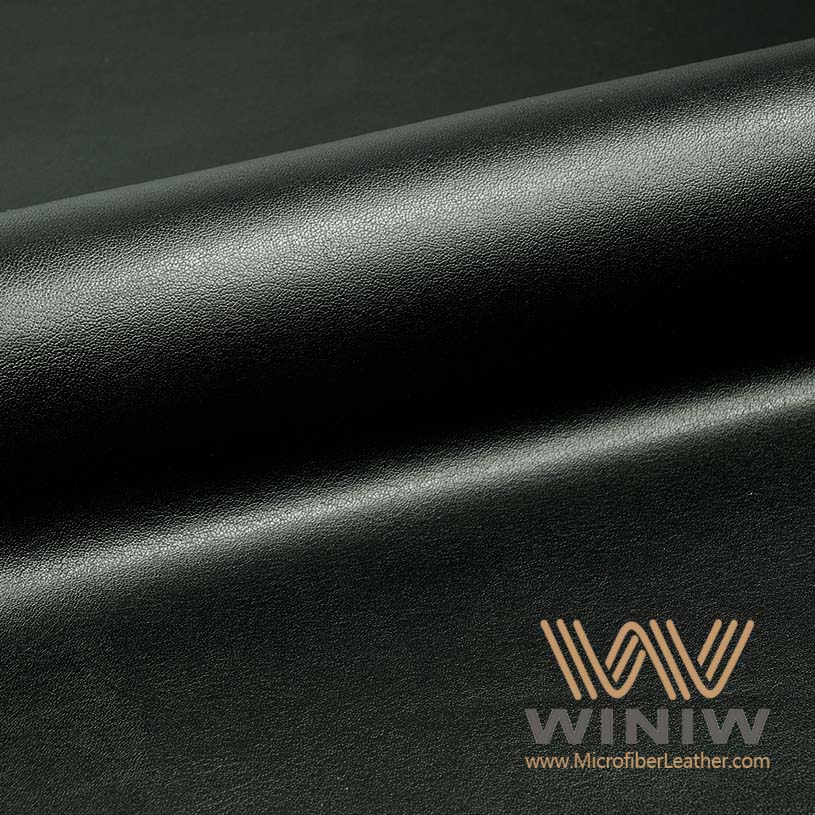

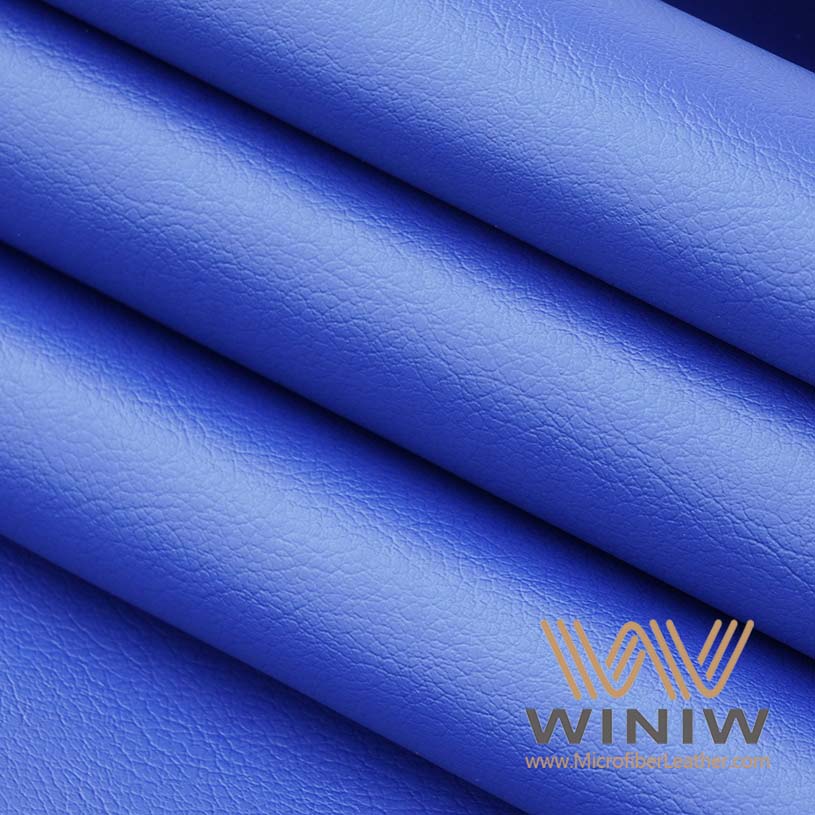

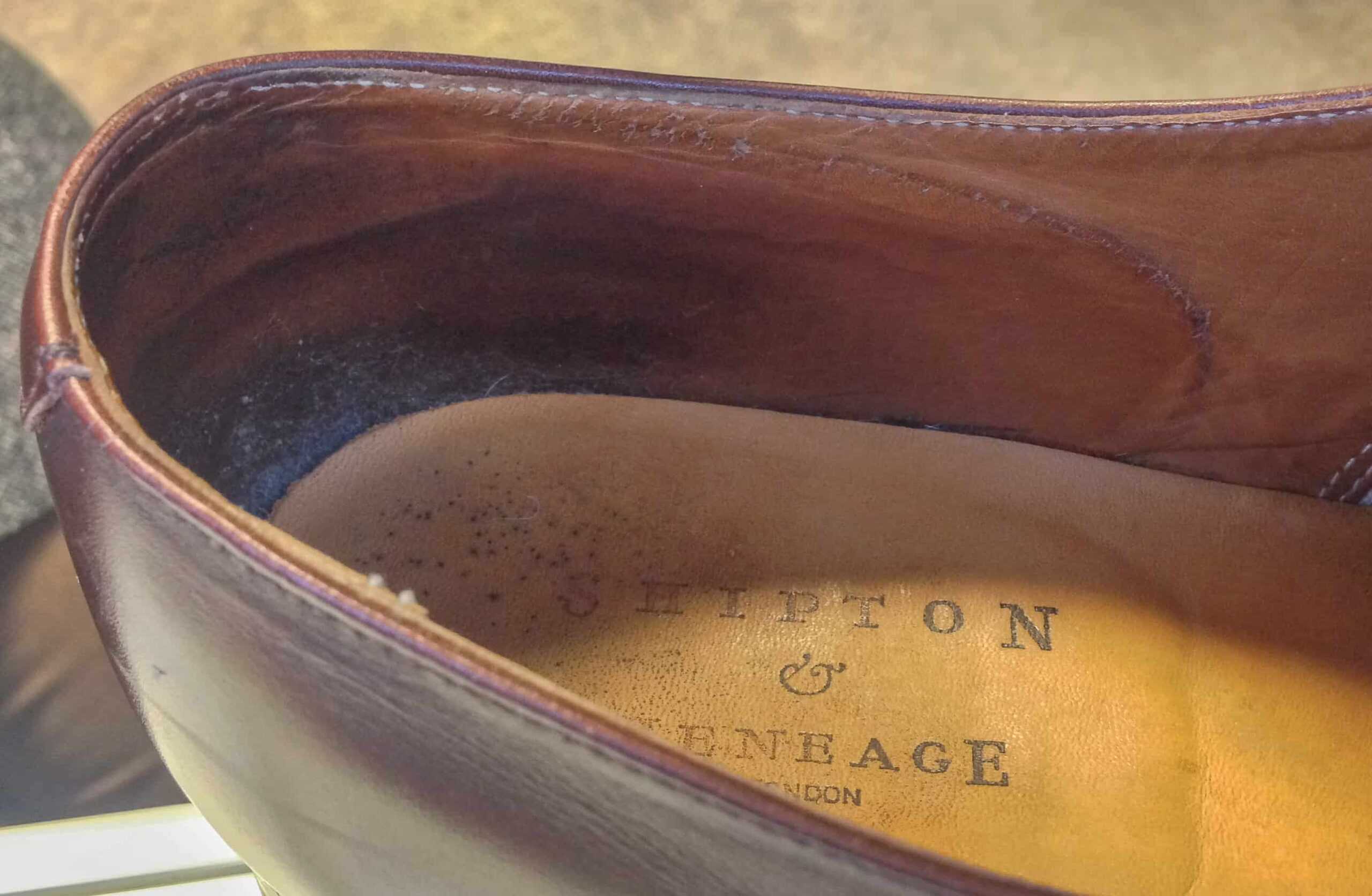

Illustrative image related to shoe leather lining

Why Choose Polyester Lining for Cost-Effective Solutions?

Polyester lining is commonly found in lower-cost shoes due to its affordability. However, it lacks breathability, which can lead to moisture retention and discomfort for the wearer. B2B buyers focusing on mass production may opt for polyester to minimize costs, but they should be aware of the potential negative impact on customer satisfaction. It’s crucial to weigh the benefits of cost savings against the potential for increased returns due to discomfort.

What are the Advantages and Disadvantages of Cotton Lining?

Cotton lining is a natural choice that offers breathability and hypoallergenic properties, making it suitable for casual footwear. However, it tends to absorb moisture, which can chill the feet in cold conditions and promote bacterial growth if not dried properly. B2B buyers should consider cotton for open-back designs or casual footwear where air circulation is enhanced. It’s essential to communicate the care requirements to end-users to maintain product integrity.

When is Cambrelle Lining the Best Option?

Cambrelle lining is a synthetic material known for its moisture-absorbing and antibacterial properties, making it ideal for sports and heavy-duty footwear. Its quick-drying capabilities and breathability are significant advantages for active users. B2B buyers should focus on performance-oriented markets when considering Cambrelle, as its features cater specifically to demanding conditions. However, its limited application in everyday shoes may restrict its broader market appeal.

Key Industrial Applications of shoe leather lining

| Industry/Sector | Specific Application of shoe leather lining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Lining for premium dress shoes | Enhances comfort, breathability, and overall quality | Look for full-grain leather; ensure consistent quality and sourcing sustainability. |

| Sports Equipment | Lining for athletic shoes and boots | Provides moisture-wicking, abrasion resistance, and durability | Consider lightweight yet durable materials; focus on performance characteristics. |

| Fashion Accessories | Lining for handbags and wallets | Adds luxury feel, durability, and aesthetic appeal | Source high-quality, stylish leather options; ensure color and texture consistency. |

| Safety and Workwear | Lining for safety boots | Increases comfort and protection for workers | Prioritize materials that are resistant to wear and tear; check for compliance with safety standards. |

| Leather Goods | Lining for various leather products | Improves product longevity and customer satisfaction | Ensure compatibility with other materials; verify ethical sourcing practices. |

How is Shoe Leather Lining Used in Footwear Manufacturing?

In the footwear manufacturing sector, shoe leather lining is essential for crafting premium dress shoes. It enhances comfort by providing a soft touch against the foot while also ensuring breathability and moisture control. For international buyers, particularly from regions like Africa and South America, sourcing full-grain leather is crucial, as it guarantees durability and quality. Buyers should ensure that their suppliers can consistently deliver high-quality leather that meets aesthetic and functional requirements.

Illustrative image related to shoe leather lining

What Role Does Shoe Leather Lining Play in Sports Equipment?

In the sports equipment industry, shoe leather lining is utilized in athletic shoes and boots to enhance performance. The lining’s moisture-wicking properties help keep the feet dry during intense physical activity, while its abrasion resistance ensures longevity. Buyers from the Middle East and Europe should focus on lightweight materials that do not compromise durability. It’s also important to verify the lining’s performance characteristics to meet specific athletic needs.

How Does Shoe Leather Lining Enhance Fashion Accessories?

For fashion accessories, shoe leather lining is a key component in handbags and wallets, adding a touch of luxury and durability. The high-quality leather lining not only enhances the aesthetic appeal but also contributes to the longevity of the product. B2B buyers from Europe and Africa should consider sourcing leather that offers a variety of colors and textures to meet diverse consumer preferences. Ensuring consistency in quality and style is vital for maintaining brand reputation.

Why is Shoe Leather Lining Important in Safety and Workwear?

In the safety and workwear sector, shoe leather lining plays a critical role in the comfort and protection of safety boots. The right lining improves wearability, ensuring that workers can perform their tasks without discomfort. Buyers should prioritize materials that resist wear and tear, while also confirming compliance with local safety regulations. Sourcing from reputable suppliers who understand safety standards is crucial for maintaining workplace safety.

Illustrative image related to shoe leather lining

How Can Shoe Leather Lining Benefit Various Leather Goods?

Shoe leather lining is also widely used in various leather goods, enhancing product longevity and customer satisfaction. It provides a soft, durable interior that complements the outer material, ensuring a cohesive design. Buyers should ensure that the lining is compatible with other materials used in the product while verifying ethical sourcing practices. This attention to quality can significantly enhance the brand’s reputation and consumer trust.

3 Common User Pain Points for ‘shoe leather lining’ & Their Solutions

Scenario 1: Inconsistent Quality of Leather Linings

The Problem: B2B buyers often face challenges with inconsistent quality in leather linings from different suppliers. This inconsistency can lead to customer dissatisfaction, returns, and ultimately damage to the brand’s reputation. Buyers may receive leather that varies in thickness, texture, or durability, making it difficult to maintain product standards. For instance, a company producing high-end footwear may find that the leather lining provided does not meet the luxury feel their customers expect, leading to a disconnect between product offerings and customer experience.

The Solution: To mitigate this issue, B2B buyers should establish clear quality standards and specifications for leather linings before sourcing. This includes defining parameters such as grain type, weight, and tanning processes. Buyers can request samples from multiple suppliers to evaluate the quality firsthand. Engaging in a dialogue with suppliers about their sourcing and tanning processes can also provide insights into how to ensure consistent quality. Additionally, consider forming long-term partnerships with trusted suppliers who demonstrate reliability and maintain rigorous quality control measures. Implementing a robust inspection process upon receipt of materials can help catch any inconsistencies before they affect production.

Scenario 2: Breathability and Comfort Issues

The Problem: Many buyers encounter issues with breathability and comfort in shoe linings, especially when the materials used do not effectively manage moisture. This can lead to discomfort for the end-users, such as sweaty feet or odor retention, particularly in warmer climates. Buyers from regions like Africa and the Middle East, where temperatures can soar, may find that synthetic linings cause excessive sweating, leading to negative customer feedback and potential loss of sales.

The Solution: To address this challenge, buyers should prioritize the selection of natural leather linings known for their breathability, such as full-grain calfskin or lambskin. These materials are not only comfortable but also have moisture-wicking properties that help regulate temperature. When sourcing, ask suppliers for detailed information on the breathability ratings of their leather products. Additionally, consider integrating moisture-absorbing technologies or lining treatments to enhance comfort further. Collaborating with manufacturers who understand the local climate and consumer expectations can also provide valuable insights into the most suitable lining materials for specific markets.

Scenario 3: Cost Management Without Compromising Quality

The Problem: B2B buyers frequently grapple with the challenge of managing costs while trying to maintain high-quality standards for shoe linings. The pressure to minimize production costs can lead to the temptation of opting for cheaper, lower-quality materials, which can ultimately impact the product’s durability and customer satisfaction. This is particularly relevant for companies looking to expand into competitive markets in South America and Europe, where quality perception is crucial.

The Solution: To balance cost and quality effectively, buyers should conduct a thorough cost-benefit analysis of various lining materials. Investing in higher-quality leather linings upfront may lead to greater customer loyalty and lower return rates, thus saving money in the long run. Buyers can also explore bulk purchasing agreements or long-term contracts with suppliers to negotiate better pricing without sacrificing quality. Additionally, consider alternative lining materials that provide a good balance between cost and performance, such as Cambrelle, which offers moisture management and durability at a competitive price point. Regularly reviewing supplier performance and exploring new suppliers can also reveal cost-saving opportunities while ensuring that quality remains a priority.

Strategic Material Selection Guide for shoe leather lining

When selecting materials for shoe leather lining, B2B buyers must consider various factors that influence product performance, durability, and overall suitability for their specific applications. Here, we analyze four common materials used in shoe leather lining: full-grain leather, suede, synthetic leather, and cotton. Each material offers distinct advantages and disadvantages, making them suitable for different end products.

Illustrative image related to shoe leather lining

What Are the Key Properties of Full-Grain Leather for Shoe Lining?

Full-grain leather is renowned for its durability and breathability, making it an excellent choice for shoe linings. This material retains the natural grain of the hide, providing superior moisture-wicking and temperature-regulating properties. It can withstand high pressure and is resistant to wear and tear, which is crucial for high-quality footwear.

Pros: Full-grain leather offers exceptional durability and comfort, making it ideal for high-end shoes. Its natural breathability helps maintain foot hygiene, reducing odor and moisture buildup.

Cons: The primary drawback is its cost, as full-grain leather is often more expensive than synthetic alternatives. Additionally, it requires careful maintenance to preserve its quality over time.

Impact on Application: Full-grain leather is best suited for premium dress shoes and high-performance footwear where comfort and durability are paramount.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with EU regulations on leather quality and sustainability. Certifications such as the Leather Working Group (LWG) can enhance marketability.

How Does Suede Compare as a Shoe Lining Material?

Suede, a type of leather with a napped finish, offers a soft texture and aesthetic appeal. It is less durable than full-grain leather but provides a unique look and feel.

Pros: Suede is lightweight and comfortable against the skin, making it a popular choice for casual footwear. It is also available in a variety of colors, enhancing design flexibility.

Cons: Suede is more susceptible to staining and water damage, which can limit its usability in certain environments. Its durability is lower compared to full-grain leather.

Impact on Application: Suede is well-suited for casual shoes, loafers, and fashion footwear, where style may take precedence over performance.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for suede in different markets. Ensuring adherence to local regulations regarding animal welfare and environmental impact is essential.

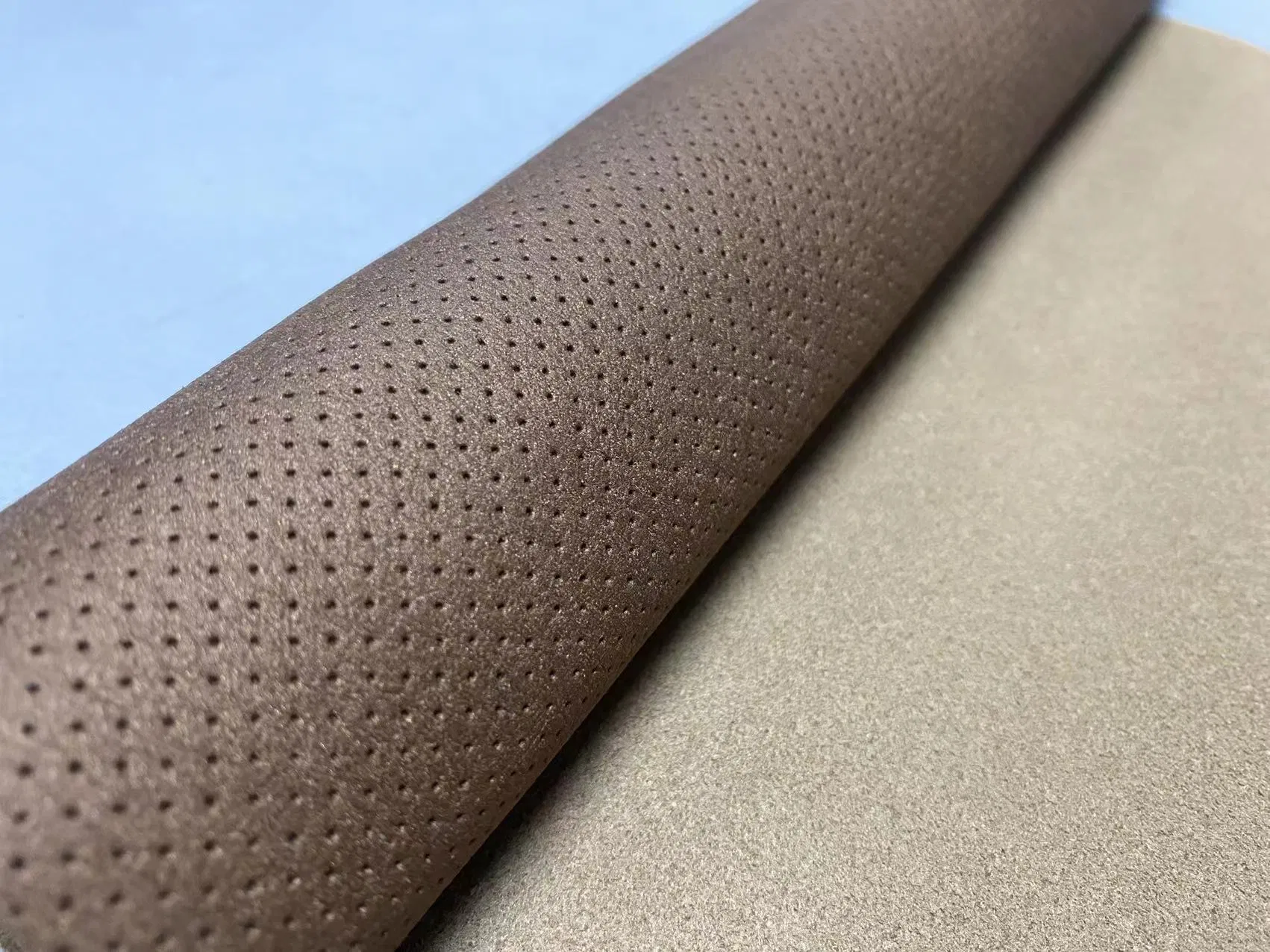

What Are the Benefits of Synthetic Leather for Shoe Linings?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), has gained popularity due to its affordability and versatility.

Pros: Synthetic leather is cost-effective, easy to clean, and resistant to water and stains. It can be produced in various textures and colors, allowing for creative design options.

Illustrative image related to shoe leather lining

Cons: However, synthetic leather lacks the breathability and comfort of natural leather, which can lead to moisture buildup and odor. Its durability is also generally lower than that of high-quality leather.

Impact on Application: This material is commonly used in budget-friendly footwear, sports shoes, and fashion items where cost is a primary concern.

Considerations for International Buyers: Buyers should verify compliance with international standards for synthetic materials, such as REACH in Europe, to avoid regulatory issues.

How Does Cotton Function as a Shoe Lining Material?

Cotton is a natural fiber known for its breathability and softness. While not traditionally used as a primary lining in shoes, it can be effective in specific applications.

Illustrative image related to shoe leather lining

Pros: Cotton is hypoallergenic and comfortable, making it suitable for sensitive skin. It also offers good moisture absorption.

Cons: The main disadvantage is that cotton does not wick moisture away effectively, which can lead to dampness and odor in enclosed footwear.

Impact on Application: Cotton linings are best suited for casual shoes, slippers, and summer footwear where breathability is more critical than durability.

Considerations for International Buyers: Buyers should ensure that cotton materials meet organic certification standards if targeting eco-conscious consumers.

Summary Table of Shoe Leather Lining Materials

| Material | Typical Use Case for shoe leather lining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Premium dress shoes, high-performance footwear | Exceptional durability and breathability | Higher cost, requires maintenance | High |

| Suede | Casual shoes, loafers, fashion footwear | Soft texture, aesthetic appeal | Susceptible to stains and water damage | Medium |

| Synthetic Leather | Budget-friendly footwear, sports shoes | Cost-effective, easy to clean | Lower breathability and durability | Low |

| Cotton | Casual shoes, slippers, summer footwear | Hypoallergenic, comfortable | Poor moisture management | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for shoe leather lining

What Are the Main Stages in the Manufacturing Process of Shoe Leather Lining?

The manufacturing process of shoe leather lining involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages helps B2B buyers appreciate the craftsmanship and technology involved in producing high-quality leather linings.

Material Preparation: How Is Leather Selected and Processed?

The first stage in manufacturing shoe leather lining is material preparation, where raw hides are carefully selected based on quality, weight, and finish. Typically, full-grain leathers, such as calfskin or lambskin, are favored for their durability and breathability.

After selection, the hides undergo a tanning process, which can be either chrome-based or vegetable-based. Chrome tanning is more common due to its efficiency and ability to produce softer leather. In contrast, vegetable tanning is often preferred for its eco-friendliness. The tanning process not only preserves the leather but also enhances its color and texture, making it suitable for lining applications.

Illustrative image related to shoe leather lining

Forming: What Techniques Are Used to Shape Leather Linings?

Once the leather has been tanned and processed, the next stage is forming. This involves cutting the leather into specific shapes and sizes based on the shoe design. Precision cutting techniques, including die-cutting and laser cutting, are employed to ensure accuracy and minimize waste.

Additionally, manufacturers often use computerized pattern-making systems to optimize the layout of cuts. This not only maximizes material usage but also speeds up the production process. The formed leather pieces are then treated to enhance their flexibility and softness, ensuring they can easily conform to the contours of the shoe.

Assembly: How Are Leather Linings Attached to Shoes?

The assembly stage is where the leather lining is attached to the shoe’s upper and insole. This is typically done using high-strength adhesives or stitching, depending on the design requirements.

For premium shoes, linings may be hand-stitched to ensure durability and aesthetic appeal. The assembly process must be carefully monitored to ensure that the linings are securely attached without any gaps or seams that could lead to discomfort. Attention to detail during this stage is crucial, as it directly impacts the shoe’s overall fit and comfort.

Illustrative image related to shoe leather lining

Finishing: What Final Treatments Are Applied to Enhance Quality?

After assembly, the shoe linings undergo a finishing process. This may include applying conditioners or protective coatings to enhance water resistance and durability. Finishing treatments also help maintain the leather’s natural appearance and feel, ensuring it remains comfortable against the skin.

Quality control measures are implemented throughout the finishing stage to ensure that the final product meets industry standards and customer expectations. This could involve additional tests for flexibility, breathability, and moisture-wicking properties.

What Quality Assurance Standards Are Relevant for Shoe Leather Lining?

Quality assurance is a critical aspect of the shoe leather lining manufacturing process, ensuring that the final product meets specific international and industry-specific standards.

What International Standards Should B2B Buyers Look For?

For leather manufacturers, compliance with international quality standards such as ISO 9001 is essential. This standard outlines the requirements for a quality management system, helping organizations consistently provide products that meet customer and regulatory requirements.

In addition to ISO 9001, industry-specific certifications such as CE marking (for European markets) and other compliance standards relevant to specific regions (like API for American buyers) may also be important. These certifications assure buyers that the products have been tested for safety, performance, and environmental impact.

Illustrative image related to shoe leather lining

How Is Quality Control Implemented During Manufacturing?

Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process. Common QC checkpoints include:

- Incoming Quality Control (IQC): This initial phase involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring takes place to identify and rectify any defects or deviations from quality standards.

- Final Quality Control (FQC): Once the shoe linings are completed, a thorough inspection is conducted to ensure they meet all performance and aesthetic criteria.

Common testing methods for leather lining include tensile strength tests, abrasion resistance tests, and moisture absorption tests. These evaluations help confirm that the product will perform well in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is crucial for ensuring the reliability and performance of shoe leather linings. Here are some effective strategies:

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess their quality control processes firsthand. This includes examining documentation, production facilities, and quality assurance protocols.

-

Requesting Reports: Suppliers should provide detailed quality control reports, including results from various testing methods and compliance with international standards. These documents offer insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and product quality. This is especially beneficial for international buyers who may not be able to visit suppliers personally.

What Are the Specific QC Considerations for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must consider additional nuances when it comes to quality control. Variations in local regulations, market demands, and consumer expectations can impact the quality standards required for leather linings.

For example, buyers in Europe may prioritize eco-friendly materials and production methods due to stringent environmental regulations. In contrast, buyers from developing regions may focus on cost-effectiveness and durability.

Illustrative image related to shoe leather lining

Understanding these regional differences can help buyers make informed decisions when selecting suppliers, ensuring that they receive high-quality leather linings that meet their specific needs and expectations.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance practices for shoe leather lining is essential for B2B buyers. By focusing on these critical aspects, buyers can ensure they are sourcing high-quality materials that will enhance their product offerings and satisfy their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shoe leather lining’

The following guide serves as a practical checklist for B2B buyers seeking to procure shoe leather lining. Understanding the nuances of leather lining can lead to better product quality and customer satisfaction. This step-by-step approach will help you navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to outline your specific requirements. Consider factors such as the type of leather (e.g., lambskin, goatskin, or calf lining), weight, thickness, and finish. Each specification impacts the durability, comfort, and overall aesthetic of the final product.

Illustrative image related to shoe leather lining

- Considerations:

- Determine the intended use (e.g., formal shoes, sports footwear).

- Factor in regional preferences, especially if targeting markets in Africa, South America, or Europe.

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is crucial for ensuring quality and reliability. Research potential suppliers through industry directories, trade shows, or referrals from other businesses in your network.

- Key Actions:

- Check supplier credentials and industry experience.

- Look for suppliers that specialize in the specific type of lining you need.

Step 3: Verify Supplier Certifications

Once you’ve shortlisted suppliers, confirm their certifications and compliance with industry standards. Certifications such as ISO or environmental compliance can indicate a commitment to quality and sustainability.

- Importance:

- Certifications ensure that the leather meets safety and environmental regulations.

- They provide assurance regarding the ethical sourcing of materials.

Step 4: Request Samples for Evaluation

Before making a bulk order, request samples of the leather lining to assess quality and performance. Examine the samples for texture, flexibility, breathability, and durability.

- What to Look For:

- Ensure the lining is free from defects and meets your technical specifications.

- Test for moisture-wicking and odor control properties if applicable.

Step 5: Negotiate Pricing and Terms

Engage in discussions regarding pricing, payment terms, and delivery timelines. Effective negotiation can lead to better pricing structures, especially for bulk orders.

- Best Practices:

- Compare pricing across multiple suppliers to ensure competitiveness.

- Consider long-term partnerships for additional discounts or favorable terms.

Step 6: Assess Production Capabilities

Evaluate the supplier’s production capacity to ensure they can meet your demands. Factors such as lead times and the ability to scale production are vital for timely deliveries.

- Considerations:

- Inquire about minimum order quantities and turnaround times.

- Assess their ability to handle custom orders if needed.

Step 7: Establish Quality Control Processes

Finally, set up quality control measures to monitor the consistency and quality of the leather lining throughout the production process. This step is essential for maintaining product standards and customer satisfaction.

- Implementation:

- Develop a checklist or standards that the supplier must meet.

- Consider third-party inspections if necessary to ensure compliance.

By following these steps, B2B buyers can streamline their sourcing process for shoe leather lining, ensuring they select high-quality materials that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for shoe leather lining Sourcing

What Are the Key Cost Components in Shoe Leather Lining Sourcing?

When analyzing the cost structure for sourcing shoe leather lining, several key components come into play:

-

Materials: The primary cost driver, material selection significantly influences price. High-quality leathers like full-grain calfskin may range from $85 to over $200 per hide, depending on size and specifications. Lesser grades, such as pig suede, can be found at much lower prices, starting around $10 per pound. The choice between chrome-tanned and vegetable-tanned leathers can also impact costs.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Skilled labor is essential for quality leather treatment and assembly, particularly for high-end products. In regions like Vietnam, labor costs may be more competitive than in Europe, affecting the overall pricing structure.

-

Manufacturing Overhead: This includes costs related to the operation of machinery, utilities, and facility maintenance. Overhead can be a significant percentage of total costs, particularly in regions with higher operational costs.

-

Tooling: Custom tooling for specific designs can incur additional costs. While standard designs may require minimal tooling expenses, custom specifications can substantially increase the initial investment.

-

Quality Control (QC): Ensuring that the leather lining meets industry standards necessitates rigorous QC processes, which can add to costs. Certifications and compliance with international standards may also be required, depending on the market.

-

Logistics: Shipping and handling costs should be factored in, particularly for international buyers. These can vary widely based on distance, shipping method, and Incoterms. For example, CIF (Cost, Insurance, and Freight) terms may lead to higher costs compared to EXW (Ex Works).

-

Margin: Suppliers will typically add a margin to cover their risks and profit expectations. This can vary based on the supplier’s market positioning and the level of competition.

What Influences Pricing in Shoe Leather Lining Sourcing?

Several factors can influence the pricing of shoe leather linings:

-

Volume and Minimum Order Quantities (MOQs): Higher volumes often lead to reduced per-unit costs. Suppliers may offer better pricing tiers for bulk orders, making it crucial for buyers to assess their needs carefully.

-

Specifications and Customization: Customized orders typically command higher prices due to the additional labor and tooling required. Buyers should evaluate the necessity of custom features against their budget constraints.

-

Material Quality and Certifications: The choice of leather quality—full-grain vs. corrected grain—affects both performance and price. Certifications for eco-friendliness or sustainability can also lead to premium pricing.

-

Supplier Factors: The reputation, reliability, and geographic location of the supplier can significantly influence costs. Established suppliers may charge more for their expertise and quality assurance.

-

Incoterms: The agreed-upon shipping terms can dramatically affect landed costs. Understanding which Incoterm to use can help buyers mitigate unexpected shipping expenses.

What Tips Can Help Buyers Negotiate Better Prices?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiate Terms: Engage in discussions about payment terms and delivery schedules. Flexible payment terms can improve cash flow and enable better pricing negotiations.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial price and consider long-term costs associated with quality, durability, and maintenance. Higher-quality linings may have a higher upfront cost but can result in lower replacement rates and better overall performance.

-

Explore Multiple Suppliers: Request quotes from various suppliers to understand the market better. This approach not only provides leverage in negotiations but also helps identify the best options based on price and quality.

-

Be Informed About Market Trends: Stay updated on global leather prices and trends. Knowledge of market fluctuations can aid in timing purchases and securing better deals.

-

Consider Local Suppliers: When possible, sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall supply chain efficiency.

Disclaimer on Indicative Prices

The prices mentioned are indicative and can fluctuate based on market conditions, supplier agreements, and currency exchange rates. Buyers are encouraged to conduct thorough research and obtain quotes tailored to their specific requirements.

Illustrative image related to shoe leather lining

Alternatives Analysis: Comparing shoe leather lining With Other Solutions

Exploring Alternatives to Shoe Leather Lining for Footwear Manufacturing

In the competitive landscape of footwear manufacturing, selecting the appropriate lining material is crucial for ensuring product quality and customer satisfaction. While shoe leather lining is a traditional choice known for its durability and comfort, alternative materials have emerged that cater to various market demands. This analysis compares shoe leather lining with synthetic options, specifically Cambrelle and polyester linings, to help B2B buyers make informed decisions.

| Comparison Aspect | Shoe Leather Lining | Cambrelle Lining | Polyester Lining |

|---|---|---|---|

| Performance | Excellent breathability, moisture-wicking, and odor control | High moisture absorption and quick drying | Poor breathability; retains moisture |

| Cost | Higher upfront cost due to quality | Moderate cost, competitive for performance | Low cost, affordable for mass production |

| Ease of Implementation | Requires skilled labor for proper installation | Easy to work with, adaptable to various designs | Simple to implement in production lines |

| Maintenance | Needs regular conditioning for longevity | Low maintenance, quick drying properties | Minimal care, but prone to wear and tear |

| Best Use Case | Premium footwear, high-end markets | Sports, work boots, and casual footwear | Budget-friendly shoes, disposable items |

What Are the Advantages and Disadvantages of Cambrelle Lining?

Cambrelle is a synthetic lining composed of two types of nylon, known for its remarkable softness and moisture-absorbing capabilities. It excels in applications requiring breathability, such as sports and outdoor footwear. The quick-drying nature of Cambrelle makes it an excellent choice for active users. However, while it offers good performance, it may not provide the same level of prestige or quality perception as leather lining, which is often preferred in luxury markets.

Why Choose Polyester Lining for Footwear?

Polyester lining is a budget-friendly option commonly found in lower-priced shoes. While it is lightweight and easy to implement in production, its performance is significantly lacking compared to leather and Cambrelle. Polyester does not breathe well, often leading to moisture retention and odor issues. It is best suited for disposable or low-cost footwear where performance is secondary to price. This makes it ideal for manufacturers targeting mass-market segments but can compromise customer satisfaction in the long term.

Illustrative image related to shoe leather lining

Conclusion: How to Choose the Right Lining Solution for Your Footwear Needs

When deciding on a lining material, B2B buyers should consider their target market, the intended use of the footwear, and the overall brand positioning. Shoe leather lining remains a top choice for premium products where quality and comfort are paramount. Cambrelle offers a high-performance alternative for sports and casual footwear, while polyester lining serves as a cost-effective solution for budget-conscious markets. By understanding the unique advantages and limitations of each option, manufacturers can align their product offerings with customer expectations and market trends, ensuring a competitive edge in the footwear industry.

Essential Technical Properties and Trade Terminology for shoe leather lining

What Are the Key Technical Properties of Shoe Leather Lining?

When considering shoe leather lining, several technical properties are critical for ensuring quality, performance, and customer satisfaction. Understanding these specifications can significantly influence purchasing decisions and supply chain efficiency.

1. Material Grade

The material grade refers to the quality of leather used in the lining. Higher grades, such as full-grain leather, provide superior durability, breathability, and comfort. For B2B buyers, opting for high-grade materials can lead to enhanced product longevity, which translates to lower return rates and higher customer satisfaction.

2. Weight

Leather weight is typically measured in ounces per square foot (oz/sq ft). For example, a weight of 1.5 to 2 oz is common for shoe linings. The weight affects the flexibility and comfort of the shoe. Lighter linings are often more comfortable but may sacrifice durability. Thus, understanding weight specifications can guide manufacturers in aligning products with market demands.

Illustrative image related to shoe leather lining

3. Tannage Type

Tannage is the process that converts raw hides into leather. Common types include chrome and vegetable tanning. Chrome-tanned leather is generally more durable and resistant to moisture, while vegetable-tanned leather is more environmentally friendly but less water-resistant. For buyers, knowing the tanning method can help in sourcing leathers that meet specific performance criteria, such as water resistance or eco-friendliness.

4. Cutting Coefficient

The cutting coefficient, often expressed as a percentage, indicates the efficiency of leather usage during production. A coefficient of 70%-73% is common for high-quality leather. This metric is crucial for manufacturers as it directly impacts material costs and waste. A higher cutting coefficient means less waste and better material utilization, which is essential for maintaining profitability.

5. Breathability

Breathability is the leather’s ability to allow moisture vapor to escape. This property is particularly important for shoe linings, as it helps regulate temperature and moisture, enhancing comfort. Buyers should prioritize breathable linings to prevent foot odor and discomfort, especially in warmer climates.

What Are Common Trade Terms in the Shoe Leather Lining Industry?

Familiarity with industry jargon can streamline communication and negotiations between buyers and suppliers. Here are essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. In the context of shoe lining, an OEM might produce linings for a brand that designs shoes. Understanding OEM relationships can help buyers identify reliable sources and negotiate better pricing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For shoe leather lining, MOQs can vary significantly based on material and supplier. Buyers need to be aware of MOQs to manage inventory and cash flow effectively, especially when dealing with multiple suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes detailed specifications and quantities. Understanding how to craft an effective RFQ can lead to more competitive pricing and better supplier options for shoe linings.

4. Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. For B2B buyers, being familiar with Incoterms ensures clarity in shipping logistics and cost management, which is essential for international transactions.

5. Lead Time

Lead time refers to the period from placing an order to receiving it. In the shoe lining industry, lead times can vary based on material availability and production schedules. Understanding lead times is crucial for inventory management and meeting production deadlines.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, optimize their supply chain, and enhance their product offerings in the competitive shoe market.

Navigating Market Dynamics and Sourcing Trends in the shoe leather lining Sector

What Are the Current Market Dynamics and Key Trends in the Shoe Leather Lining Sector?

The global shoe leather lining market is experiencing notable growth driven by several key factors. An increasing demand for high-quality, durable footwear has prompted manufacturers to prioritize premium materials, particularly full-grain and lambskin leather linings. This trend is particularly pronounced in regions such as Europe and the Middle East, where consumers are willing to invest in superior products. Additionally, emerging markets in Africa and South America are witnessing a surge in demand for affordable yet quality footwear, leading to a diversification of sourcing strategies among B2B buyers.

Technological advancements are reshaping sourcing practices, with digital platforms facilitating more efficient procurement processes. B2B buyers are increasingly utilizing e-commerce solutions and online marketplaces to streamline their supply chain operations, allowing for real-time inventory management and enhanced supplier relationships. Furthermore, data analytics is being leveraged to forecast demand trends and optimize inventory levels, ensuring that businesses can respond swiftly to market fluctuations.

Another significant trend is the growing preference for customization in shoe linings, with buyers seeking materials that can be tailored to specific styles and functionalities. This shift is prompting suppliers to innovate and offer a broader range of options, including moisture-wicking and temperature-regulating linings, appealing to the technical demands of modern consumers.

How Is Sustainability and Ethical Sourcing Shaping the Shoe Leather Lining Market?

Sustainability is becoming a critical focus in the shoe leather lining sector, driven by both regulatory pressures and consumer expectations. The environmental impact of leather production—particularly concerning water usage and waste management—has led to increased scrutiny from stakeholders. Consequently, B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using chrome-free tanning methods and sourcing hides from ethically managed farms.

Ethical supply chains are paramount, with businesses increasingly seeking partnerships that align with their corporate social responsibility goals. Certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are gaining traction, as they provide assurance regarding the environmental and social standards upheld in the production process. These certifications not only enhance the credibility of suppliers but also appeal to a growing segment of consumers who prioritize ethical consumption.

In addition to certifications, there is a marked interest in alternative materials that reduce environmental impact. Innovations in synthetic leathers and biodegradable options are emerging, providing B2B buyers with viable alternatives to traditional leather. By embracing these sustainable solutions, companies can enhance their market position and cater to the evolving preferences of eco-conscious consumers.

What Is the Historical Context of Shoe Leather Lining Development?

The evolution of shoe leather lining can be traced back to ancient civilizations, where animal hides were used for footwear due to their availability and durability. Over the centuries, advancements in tanning techniques and leather processing have led to the development of various types of linings, each offering distinct properties and benefits.

Illustrative image related to shoe leather lining

In the 19th century, the industrial revolution brought about significant changes in leather production, making it more accessible and affordable. This era also saw the introduction of synthetic materials, which provided additional options for lining but often lacked the breathability and comfort of natural leathers.

Today, the market reflects a balance between traditional craftsmanship and modern innovations, as manufacturers strive to meet both aesthetic and functional demands. The focus has shifted towards not only the quality of the lining but also its sustainability and ethical sourcing, indicating a significant transformation in consumer values and market expectations. This historical context is crucial for B2B buyers seeking to understand the lineage of materials and the ongoing trends that shape the industry.

In summary, navigating the complexities of the shoe leather lining sector requires an awareness of evolving market dynamics, sustainability imperatives, and a deep understanding of historical trends that influence modern practices. By leveraging this knowledge, international B2B buyers can make informed decisions that align with their business objectives and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of shoe leather lining

-

How do I choose the right type of shoe leather lining for my products?

Selecting the appropriate shoe leather lining involves considering factors such as breathability, durability, and intended use. For high-end footwear, full-grain leather linings offer superior comfort and moisture management. If you’re producing sports or heavy-duty shoes, synthetic options like Cambrelle may be more suitable due to their moisture-wicking properties. Evaluate your target market’s preferences, and consider factors like climate and typical usage to ensure the lining meets customer expectations. -

What are the key characteristics to look for in quality shoe leather lining?

Quality shoe leather lining should be durable, flexible, and breathable. Look for linings that are soft to the touch, resistant to cracking, and able to manage moisture effectively. Ensure that the leather is sourced from reputable suppliers, ideally full-grain or top-grain, as these types provide better longevity and comfort. Additionally, check for resistance to wear and tear, as this impacts the overall quality and lifespan of the finished product. -

What is the minimum order quantity (MOQ) for shoe leather lining?

Minimum order quantities for shoe leather lining can vary significantly by supplier and material type. Typically, MOQs range from 50 to 200 square feet for standard leather products. For custom orders or specialty materials, the MOQ may be higher. It’s essential to discuss your specific needs with suppliers to understand their policies and negotiate terms that align with your production requirements. -

How can I verify the quality of shoe leather lining from suppliers?

To ensure the quality of shoe leather lining, request samples before placing a bulk order. This allows you to assess the material’s characteristics, such as texture, durability, and breathability. Additionally, inquire about the supplier’s quality assurance processes, certifications, and past customer reviews. Establishing a relationship with suppliers who have a proven track record in the industry can further mitigate risks associated with quality. -

What payment terms are typically offered by suppliers of shoe leather lining?

Payment terms can vary widely among suppliers, but common practices include a 30% upfront deposit with the balance due upon delivery or a net 30 days payment after receipt of goods. Some suppliers may offer discounts for early payments or bulk orders. Always clarify payment terms before finalizing contracts, and consider using secure payment methods to protect your financial interests. -

How do I handle logistics and shipping for international orders of shoe leather lining?

When managing logistics for international orders, consider factors such as shipping costs, customs duties, and delivery timelines. Work with suppliers who have experience in international shipping and can assist with documentation and compliance. It’s advisable to use reliable logistics partners to ensure timely delivery. Additionally, factor in potential delays at customs and plan your inventory accordingly to avoid disruptions in your supply chain. -

What customization options are available for shoe leather lining?

Many suppliers offer customization options, including color, thickness, and texture of the leather lining. You can often specify particular finishes or treatments to enhance properties like water resistance or durability. Discuss your specific design needs with suppliers, as they may also provide insights into trending styles and materials that could appeal to your target market. -

How can I effectively vet suppliers for shoe leather lining?

To vet suppliers, research their reputation in the industry through reviews and testimonials. Request references from other clients to gauge their reliability and quality. Evaluate their production capabilities, lead times, and compliance with international standards. Visiting the supplier’s facility, if possible, can provide firsthand insight into their processes and quality control measures, helping you make informed sourcing decisions.

Top 8 Shoe Leather Lining Manufacturers & Suppliers List

1. Avetco – Lining Leather

Domain: avetcoinc.com

Registered: 2005 (20 years)

Introduction: Lining Leather from Avetco is soft, lightweight, and specifically selected for interior use in footwear, handbags, garments, and accessories. It features a smooth finish and breathability, adding comfort, structure, and a refined touch to any finished product. Available in various colors and textures, the lining leather combines function and luxury. Key products include: 2 oz. Lambskin (8–10 sq. f…

2. Beckett Simonon – Types of Shoe Linings

Domain: beckettsimonon.com

Registered: 2012 (13 years)

Introduction: Types of Shoe Linings: 1. Leather Shoe Lining: Breathable, odor-controlling, moisture-wicking, and temperature-regulating; ideal for sweaty feet and wearing without socks; should be 100% full-grain leather. 2. Fleece Shoe Lining: Soft, warm, and cozy; made from recycled plastic or blended with natural fibers; not suited for refined footwear. 3. Polyester Shoe Lining: Common in cheaply made shoes; …

3. The Tannery Row – Calf Lining

Domain: thetanneryrow.com

Registered: 2011 (14 years)

Introduction: {“name”: “Calf Lining”, “price”: “$85.00”, “description”: “Full grain calf lining suitable for lining shoes, bags, or accessories.”, “size”: “12-14 sf”, “hide_type”: “Whole Hides”, “weight”: “1.25-2 oz”, “tannage”: “Chrome”, “cutting_coefficient”: “70%-73%”, “color_options”: [“Black”, “Faggio”, “Ivory”, “Tan”]}

4. Leatherbox – Pigskin Leather Linings

Domain: leatherboxusa.com

Registered: 2023 (2 years)

Introduction: This company, Leatherbox – Pigskin Leather Linings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. American Benchcraft – Leather Lining Essentials

Domain: americanbenchcraft.com

Registered: 2014 (11 years)

Introduction: Leather lining is a thin piece of leather attached to the interior of leather products such as bags, jackets, or shoes. It provides structure, shape, and protects the user’s skin from direct contact with the leather. Types of leather used for lining include: 1. Lambskin – Soft, lightweight, supple, smooth, and delicate. 2. Cowhide – Durable, strong, tough, thick, and resilient. 3. Goatskin – Flexi…

6. Samuel Hubbard – Leather Shoe Linings

Domain: samuelhubbard.com

Registered: 2013 (12 years)

Introduction: Leather shoe linings are crucial for comfort and durability. Types include: 1. Textile Linings: Used in inexpensive shoes, absorb moisture quickly, wear out faster, and can lead to sweaty feet. 2. Leather Linings: More durable, breathable, and comfortable. They conform to feet over time, reducing chafing and blisters. Premium leather becomes softer with age, while inexpensive leather can crack. 3….

7. Wollsdorf – Antibacterial Shoe Lining Leather

Domain: wollsdorf.com

Registered: 2008 (17 years)

Introduction: Shoe lining leather with antibacterial surface protection, designed for comfort and moisture management. Features include: softness and suppleness, moisture absorption and wicking, temperature equalization, antibacterial protection (EVO+), prevention of bacteria spread, and odor reduction.

8. Nagaba – Natural Leather Lining

Domain: nagaba.eu

Introduction: {“types_of_lining”:[{“SKU”:”00″,”type”:”NATURAL LEATHER LINING”,”description”:”Natural pig leather lining from the best Polish tanneries, thickness 0.7 – 0.9 mm, ensures proper moisture drainage.”,”composition”:”Natural leather”},{“SKU”:”01″,”type”:”FELT”,”color”:”black”,”description”:”Black felt made of synthetic fibres, characterized by flexibility, high permeability to water vapor, and moisture…

Strategic Sourcing Conclusion and Outlook for shoe leather lining

In conclusion, strategic sourcing for shoe leather lining is pivotal for B2B buyers seeking quality, durability, and comfort in their products. By understanding the diverse types of lining materials, such as full-grain leather, fleece, and synthetic options, businesses can make informed decisions that enhance their product offerings. Prioritizing high-quality materials not only improves the overall shoe experience for consumers but also supports long-term brand loyalty.

As the global market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, there is a growing demand for sustainable and innovative materials. Buyers should leverage this trend by sourcing from reputable suppliers who prioritize ethical practices and sustainability in their production processes. This commitment not only meets consumer expectations but also positions businesses competitively in the marketplace.

Looking ahead, the future of shoe leather lining is bright, with opportunities for innovation in material technology and design. International B2B buyers are encouraged to explore partnerships that emphasize quality and sustainability, ensuring their products stand out in a crowded market. Take proactive steps today to secure the best materials for tomorrow’s footwear.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.