Introduction: Navigating the Global Market for pu leathe

In today’s competitive landscape, navigating the global market for PU leather presents unique challenges for B2B buyers seeking cost-effective yet stylish solutions. Whether you’re sourcing materials for furniture, fashion, or automotive applications, understanding the nuances of polyurethane leather is crucial. This guide offers a comprehensive exploration of PU leather, including its various types, applications, and the critical considerations for supplier vetting.

With a focus on empowering international buyers, particularly from Africa, South America, the Middle East, and Europe, this resource aims to demystify the complexities associated with PU leather procurement. From assessing product quality and sustainability to analyzing cost-effectiveness, we provide actionable insights tailored to your specific market needs.

Navigating issues such as durability, environmental impact, and potential health concerns associated with PU leather is essential for making informed purchasing decisions. By leveraging the information in this guide, you will be equipped to identify reliable suppliers, evaluate product options, and ultimately choose the best PU leather solutions that align with your business objectives. As you embark on this journey, let us help you make informed choices that not only meet your operational needs but also resonate with your brand values.

Table Of Contents

- Top 5 Pu Leathe Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pu leathe

- Understanding pu leathe Types and Variations

- Key Industrial Applications of pu leathe

- 3 Common User Pain Points for ‘pu leathe’ & Their Solutions

- Strategic Material Selection Guide for pu leathe

- In-depth Look: Manufacturing Processes and Quality Assurance for pu leathe

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu leathe’

- Comprehensive Cost and Pricing Analysis for pu leathe Sourcing

- Alternatives Analysis: Comparing pu leathe With Other Solutions

- Essential Technical Properties and Trade Terminology for pu leathe

- Navigating Market Dynamics and Sourcing Trends in the pu leathe Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pu leathe

- Strategic Sourcing Conclusion and Outlook for pu leathe

- Important Disclaimer & Terms of Use

Understanding pu leathe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 100% PU Leather | Made entirely from synthetic materials, vegan-friendly. | Furniture, automotive upholstery | Pros: Cost-effective, easy to clean. Cons: Less durable, may have a plastic smell. |

| Bicast Leather | Combination of genuine leather and a polyurethane coating. | Fashion accessories, furniture | Pros: More durable than pure PU, retains some leather characteristics. Cons: Can peel, less breathable. |

| Split Leather | Made from lower-quality leather with a PU coating. | Budget furniture, goods for resale | Pros: Affordable, retains some leather look. Cons: Shorter lifespan, less luxurious feel. |

| Bonded Leather | Reconstituted leather fibers bonded with PU. | Affordable luxury items, wallets | Pros: Eco-friendly (uses scraps), versatile. Cons: Less durable, may not age well. |

| Corrected Grain Leather | Real leather treated and coated with PU for uniformity. | High-volume production items | Pros: Cost-effective, consistent appearance. Cons: Lacks the unique character of full-grain leather. |

What Are the Characteristics of 100% PU Leather for B2B Buyers?

100% PU leather is a fully synthetic material that appeals to businesses seeking a vegan alternative. Its affordability and ease of maintenance make it suitable for various applications, particularly in the furniture and automotive industries. However, B2B buyers should consider its limited durability and potential chemical odor, which may affect consumer perception. Selecting high-quality PU leather can mitigate some concerns, but businesses must weigh cost against longevity and customer satisfaction.

How Does Bicast Leather Stand Out in the Market?

Bicast leather combines genuine leather with a polyurethane coating, offering a unique blend of durability and aesthetic appeal. This type is often used in fashion accessories and furniture, providing a more luxurious feel than pure PU leather. B2B buyers should note that while it offers better longevity than 100% PU leather, it is still susceptible to peeling over time. Businesses must assess their target market’s expectations for quality and durability when considering this option.

Why Choose Split Leather for Budget-Friendly Solutions?

Split leather consists of lower-quality leather that is coated with PU, making it an economical choice for businesses targeting budget-conscious consumers. Common applications include budget furniture and resale goods. While it provides a leather-like appearance at a reduced price, B2B buyers should be aware of its shorter lifespan and less luxurious feel. This type may be suitable for high-volume production where cost is a primary concern.

What Are the Advantages of Bonded Leather for Eco-Conscious Brands?

Bonded leather is made from leftover leather scraps that are bonded with a polyurethane layer, presenting a more sustainable option for businesses. It is ideal for affordable luxury items like wallets and accessories. While it can appeal to eco-conscious consumers, B2B buyers should consider its durability and aging characteristics, as bonded leather may not perform as well over time. Brands prioritizing sustainability can leverage this type to enhance their eco-friendly image.

How Does Corrected Grain Leather Fit into High-Volume Production?

Corrected grain leather is real leather that has been treated and coated with PU to ensure a uniform appearance. It is frequently used in high-volume production items where consistency is essential. While this type offers a cost-effective solution, it lacks the unique character of full-grain leather. B2B buyers should evaluate their branding strategy and market expectations when opting for corrected grain leather, as it may not appeal to consumers seeking authenticity.

Key Industrial Applications of pu leathe

| Industry/Sector | Specific Application of PU Leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for Chairs and Sofas | Cost-effective, easy to clean, and versatile design options | Ensure compliance with international safety standards; consider durability and maintenance requirements. |

| Automotive | Interior Trim and Seat Covers | Lightweight, water-resistant, and customizable options | Focus on long-term durability and resistance to wear; verify supplier certifications for automotive-grade materials. |

| Fashion and Apparel | Clothing and Accessories | Affordable alternative to genuine leather with diverse colors | Assess ethical sourcing practices; prioritize suppliers with transparency in material composition. |

| Footwear | Shoes and Boots | Lightweight, easy to mold, and water-resistant | Verify quality to prevent cracking and peeling; consider sourcing from manufacturers with sustainable practices. |

| Home Décor | Wall Coverings and Decorative Items | Aesthetic appeal with lower production costs | Ensure compliance with fire safety regulations; consider the environmental impact of sourcing. |

How is PU Leather Used in Furniture Manufacturing?

In the furniture manufacturing sector, PU leather serves as a popular choice for upholstery on chairs, sofas, and other seating options. Its affordability and ease of maintenance make it attractive for manufacturers looking to offer stylish yet cost-effective products. International buyers, particularly from regions like Africa and South America, should consider the durability of PU leather in high-traffic environments. Additionally, compliance with safety standards is crucial, as buyers seek materials that are not only visually appealing but also safe for consumer use.

What Role Does PU Leather Play in Automotive Applications?

In the automotive industry, PU leather is extensively used for interior trim and seat covers. Its lightweight and water-resistant properties enhance vehicle design while providing comfort. Businesses in this sector must prioritize sourcing PU leather that meets stringent durability standards to withstand wear and tear. International buyers should ensure that suppliers possess automotive-grade certifications, which guarantee that the materials will perform well under various conditions, including temperature fluctuations common in regions like the Middle East and Africa.

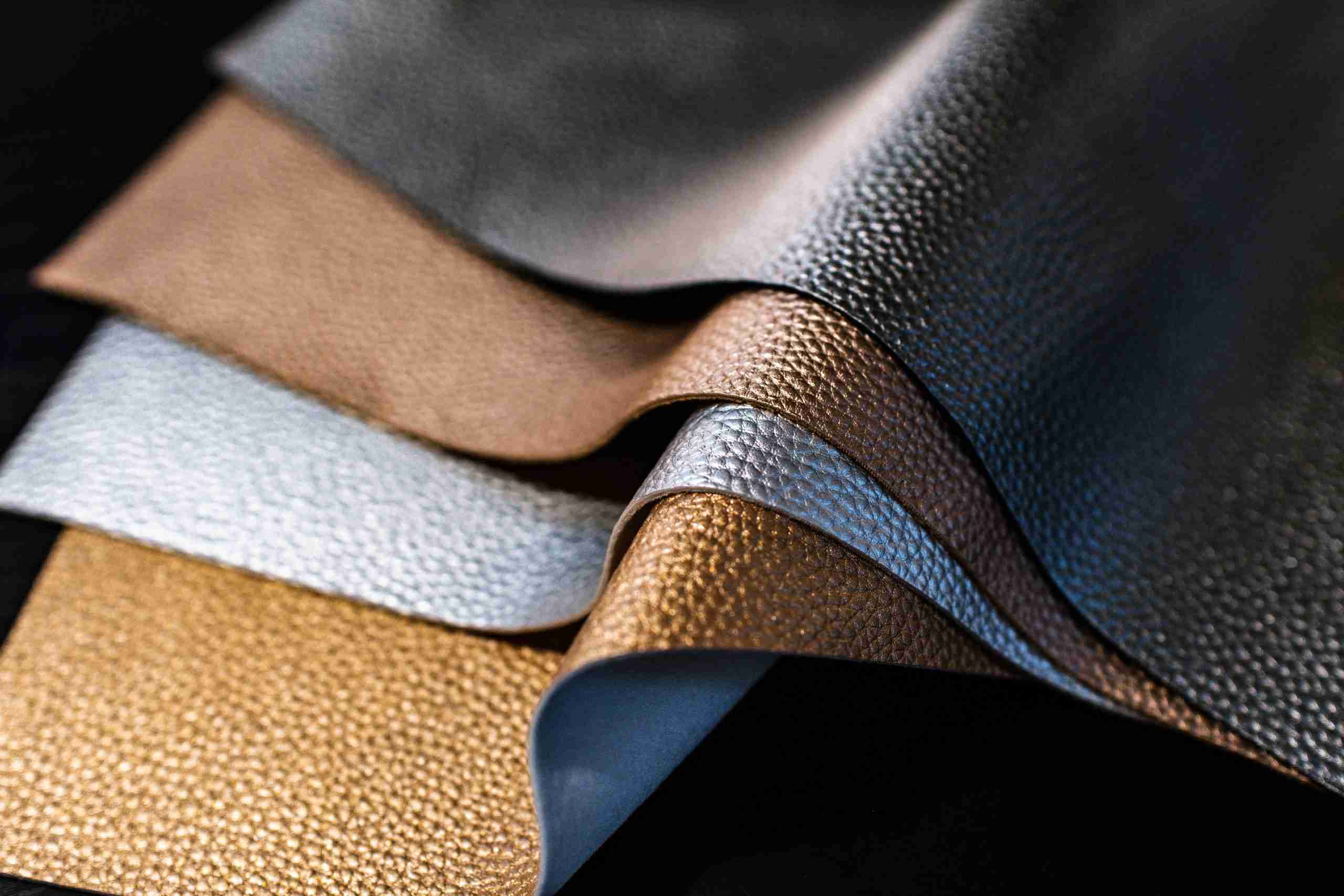

Illustrative image related to pu leathe

Why is PU Leather Popular in Fashion and Apparel?

The fashion and apparel industry utilizes PU leather for a wide range of clothing and accessories, offering an affordable alternative to genuine leather. Its versatility allows for a variety of colors and designs, appealing to a diverse consumer base. For B2B buyers in Europe and South America, ethical sourcing is a significant consideration; they should seek suppliers who provide transparency regarding the production process and material composition. This not only aligns with consumer preferences for sustainability but also mitigates potential reputational risks.

How is PU Leather Beneficial in Footwear Production?

In footwear production, PU leather is favored for its lightweight nature and ability to be molded into various styles, including shoes and boots. Its water-resistant characteristics make it suitable for different climates, particularly in regions with high humidity or rainfall. Buyers should assess the quality of PU leather to prevent issues like cracking or peeling over time, which can affect product longevity. Additionally, sourcing from manufacturers committed to sustainable practices can enhance brand reputation and appeal to environmentally conscious consumers.

What Applications Does PU Leather Have in Home Décor?

PU leather is increasingly used in home décor for wall coverings and decorative items due to its aesthetic appeal and cost-effectiveness. It allows for innovative designs that can transform spaces without the higher costs associated with genuine leather. B2B buyers should ensure that the materials comply with fire safety regulations, especially in residential applications. Furthermore, considering the environmental impact of sourcing PU leather can provide businesses with a competitive edge in markets that value sustainability, such as those in Europe.

Illustrative image related to pu leathe

3 Common User Pain Points for ‘pu leathe’ & Their Solutions

Scenario 1: Durability Concerns with PU Leather Products

The Problem: B2B buyers often face challenges with the durability of PU leather products, particularly in high-use environments such as offices or retail spaces. Many products marketed as PU leather tend to crack, peel, or wear out quickly, leading to frequent replacements and increased costs. This is particularly problematic for businesses looking to maintain a professional appearance without incurring excessive expenses on replacements or repairs.

The Solution: To combat durability issues, B2B buyers should prioritize sourcing PU leather products from reputable manufacturers known for their quality standards. It’s vital to request samples and conduct durability tests, such as abrasion resistance and flexibility tests, before making bulk purchases. Additionally, consider specifying PU leather grades, as higher-quality options may feature enhanced durability features. Implementing a maintenance plan that includes regular cleaning and conditioning can also extend the life of PU leather products, making them more cost-effective in the long run.

Scenario 2: Environmental and Health Concerns Related to PU Leather

The Problem: Another significant concern for B2B buyers is the environmental impact and potential health risks associated with PU leather. Many products contain volatile organic compounds (VOCs) that can emit harmful chemicals into the environment and contribute to indoor air quality issues. This can deter businesses that prioritize sustainability and employee well-being from opting for PU leather products.

The Solution: To address these concerns, buyers should seek out PU leather products that are certified low-VOC or free from harmful chemicals. Collaborating with suppliers who provide transparent information about their manufacturing processes and materials is essential. Additionally, consider investing in alternatives that utilize environmentally friendly production methods, such as vegetable-tanned leather or other sustainable materials. By choosing suppliers committed to eco-friendly practices, businesses can align their purchasing decisions with their sustainability goals while ensuring the safety of their employees and customers.

Scenario 3: Misleading Product Labels and Quality Confusion

The Problem: B2B buyers frequently encounter confusion due to misleading product labels that claim to offer “genuine” or “real” leather when the products are actually PU leather. This lack of clarity can lead to purchasing decisions that do not meet the buyer’s quality expectations, resulting in dissatisfaction and potential damage to the brand’s reputation if subpar products are used in customer-facing applications.

The Solution: To navigate the complexities of product labeling, buyers should invest in training for their procurement teams on how to distinguish between different types of leather products. Implementing a robust supplier vetting process that includes checking certifications and product specifications can help ensure that products meet the desired quality standards. Furthermore, establishing relationships with trusted suppliers who provide clear and accurate labeling can mitigate the risks of misrepresentation. Buyers can also request detailed product information, including composition and manufacturing processes, to make informed purchasing decisions that align with their brand values and quality expectations.

Strategic Material Selection Guide for pu leathe

What Are the Key Materials Used in PU Leather Production?

When selecting PU leather for various applications, understanding the materials involved is crucial for B2B buyers. Here, we analyze common materials used in PU leather production, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Polyurethane in PU Leather?

Polyurethane (PU) is the primary polymer used in the creation of PU leather. It is a thermoplastic polymer that provides a synthetic alternative to genuine leather.

Key Properties:

– Temperature Resistance: PU can withstand a temperature range of -30°C to 80°C, making it suitable for various climates.

– Chemical Resistance: While PU is not highly resistant to strong solvents, it performs well against mild chemicals, making it suitable for furniture and fashion applications.

Pros & Cons:

– Pros: PU leather is less expensive than genuine leather, easy to clean, and available in a wide range of colors and finishes. It is also vegan-friendly and does not dry out over time.

– Cons: However, it lacks the durability of real leather, can crack or peel with frequent use, and may emit a chemical odor initially.

Impact on Application:

The use of PU in furniture, automotive interiors, and fashion accessories is common due to its aesthetic appeal and ease of maintenance. However, it may not be suitable for high-wear applications.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure that the PU leather products comply with local environmental regulations, as some PU products may contain volatile organic compounds (VOCs) that can be harmful.

How Do Bicast Leather and Split Leather Compare in PU Leather Applications?

Bicast leather is created by taking leftover genuine leather and applying a layer of polyurethane, while split leather is made from the fibrous parts of hides that are not suitable for full-grain leather.

Illustrative image related to pu leathe

Key Properties:

– Durability: Bicast leather is generally more durable than PU alone but less so than full-grain leather.

– Appearance: Bicast leather has a more authentic look compared to pure PU, thanks to the genuine leather layer.

Pros & Cons:

– Pros: Bicast leather offers a more luxurious appearance at a lower cost than full-grain leather. It is also easier to maintain than genuine leather.

– Cons: It can still crack and peel over time, especially if subjected to heavy use.

Impact on Application:

Bicast leather is often used in mid-range furniture and fashion items, providing a balance between cost and appearance.

Considerations for International Buyers:

Buyers in Europe, particularly Germany, may prefer products that meet stringent quality standards, such as DIN norms for leather products. Awareness of the sourcing of materials is also critical to ensure ethical practices.

What Are the Environmental Considerations for PU Leather Materials?

The environmental impact of PU leather is a significant concern, particularly in regions with strict environmental regulations.

Illustrative image related to pu leathe

Key Properties:

– Biodegradability: PU leather is not biodegradable, which raises sustainability concerns.

– Toxicity: The manufacturing process may involve toxic chemicals, leading to potential health risks.

Pros & Cons:

– Pros: PU leather is often marketed as an eco-friendlier alternative to genuine leather, as it uses fewer resources in production.

– Cons: The environmental footprint of PU leather is substantial due to its petroleum-based components and the potential for VOC emissions.

Impact on Application:

Sustainability-focused brands may choose PU leather for its lower resource requirements, but they must also consider the long-term environmental implications.

Considerations for International Buyers:

Buyers from the Middle East and Africa should be aware of local environmental regulations and consumer preferences for sustainable products, which may influence purchasing decisions.

Summary Table of PU Leather Materials

| Materiaal | Typical Use Case for PU Leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Furniture, automotive interiors | Affordable, wide color range | Less durable, may emit chemical odors | Low |

| Bicast Leather | Mid-range furniture, fashion | Luxurious appearance at lower cost | Can crack and peel over time | Medium |

| Split Leather | Fashion accessories, upholstery | More authentic look than pure PU | Less durable than full-grain leather | Medium |

| PU Leather (General) | Fashion, upholstery, accessories | Vegan-friendly, easy to clean | Not biodegradable, potential toxicity | Low |

This analysis provides B2B buyers with essential insights into the materials used in PU leather production, helping them make informed decisions based on performance, cost, and environmental considerations.

Illustrative image related to pu leathe

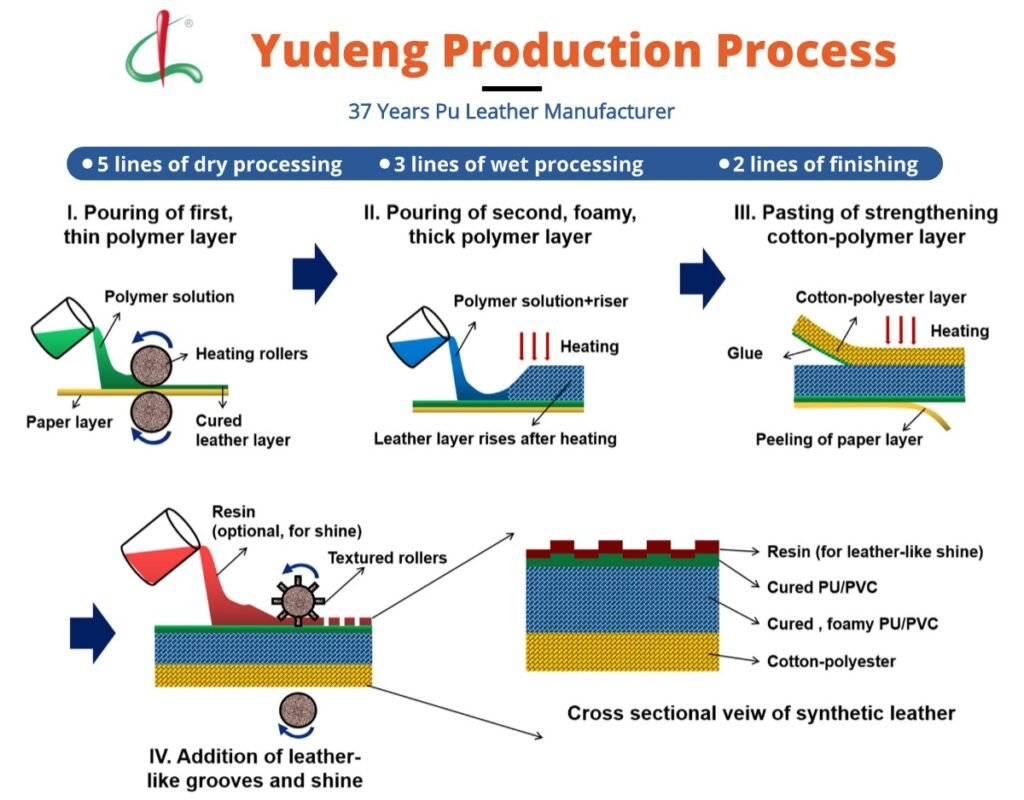

In-depth Look: Manufacturing Processes and Quality Assurance for pu leathe

What Are the Main Stages of PU Leather Manufacturing?

The production of PU leather involves several key stages, each critical to ensuring the quality and performance of the final product. Understanding these stages can help B2B buyers assess the capability of their suppliers.

Material Preparation: What Raw Materials Are Used in PU Leather Production?

The manufacturing process begins with the selection of base materials. PU leather is made from a thermoplastic polymer, typically polyurethane, which is coated onto a fabric backing. The backing material can be polyester or cotton, chosen for its strength and durability. During this stage, suppliers must ensure that the raw materials comply with international safety standards, as this will affect the product’s overall quality and marketability.

Forming: How Is PU Leather Created and Shaped?

Once the materials are prepared, they undergo a forming process. This involves applying a layer of polyurethane onto the chosen fabric. The application can be done through various techniques such as roll coating, spray coating, or laminating. Each technique has its advantages; for instance, roll coating provides a uniform thickness, which is essential for maintaining consistency across batches.

In this stage, the temperature and pressure settings are critical. Precise control ensures that the polyurethane adheres properly and cures effectively, which will influence the durability and texture of the final product.

Assembly: What Are the Key Steps in Assembling PU Leather Products?

After the forming stage, the PU leather is cut and assembled into the desired product shape—be it upholstery, bags, or clothing. This phase often includes sewing and joining different components, which requires skilled labor to ensure that seams are strong and aesthetically pleasing.

Manufacturers may use automated cutting tools and sewing machines to enhance efficiency and precision. Quality assurance during assembly is essential, as any defects can lead to significant issues later in the product lifecycle.

Finishing: How Is PU Leather Treated for Final Presentation?

The finishing stage involves the application of additional coatings or treatments to enhance the appearance and performance of the PU leather. This can include embossing for texture, coloring to achieve specific shades, and protective coatings to improve water resistance and durability.

Finishing techniques are crucial for giving PU leather its final look and feel, and they can also affect the product’s marketability. Buyers should inquire about the types of finishes used and their long-term effects on product performance.

What International Standards Are Relevant for Quality Control in PU Leather Manufacturing?

Quality assurance in PU leather production is vital for meeting both customer expectations and regulatory requirements. Adherence to international standards helps ensure that products are safe, reliable, and of high quality.

ISO 9001: How Does This Standard Apply to PU Leather Production?

ISO 9001 is a widely recognized quality management standard that outlines criteria for establishing a quality management system (QMS). Manufacturers of PU leather should be ISO 9001 certified, demonstrating their commitment to quality at every stage of production. This certification can provide B2B buyers with confidence in their suppliers’ processes and products.

CE Marking and Other Industry-Specific Certifications: What Do They Indicate?

In the European market, CE marking is essential for products to demonstrate compliance with health, safety, and environmental protection standards. Other industry-specific certifications may include those related to environmental impact, such as Oeko-Tex or REACH, which assure buyers that the materials used are free from harmful substances.

What Are the Key Quality Control Checkpoints in PU Leather Manufacturing?

Effective quality control (QC) is integral to producing high-quality PU leather. Manufacturers typically implement several QC checkpoints throughout the production process.

Incoming Quality Control (IQC): What Does This Involve?

IQC is the first checkpoint, where raw materials are inspected upon arrival. This step ensures that only materials meeting predefined quality standards are used in production. B2B buyers should inquire about the criteria used for IQC and the processes in place for handling non-compliant materials.

In-Process Quality Control (IPQC): How Is Quality Monitored During Production?

During the manufacturing process, IPQC measures quality at various stages. This includes monitoring the forming process for consistency and checking the integrity of seams during assembly. It is crucial for identifying defects early, which can save time and costs associated with rework or scrap.

Final Quality Control (FQC): What Tests Are Conducted Before Shipment?

FQC occurs once products are completed. This stage includes comprehensive testing and inspection of finished goods to ensure they meet all specifications. Common tests may involve assessments of durability, colorfastness, and chemical safety. B2B buyers should request FQC reports to verify compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

What Types of Audits and Reports Should Buyers Request?

Buyers should conduct regular audits of their suppliers’ facilities to assess compliance with quality standards. Requesting detailed QC reports, including IQC, IPQC, and FQC findings, can provide insights into a supplier’s commitment to quality.

How Important Are Third-Party Inspections in Ensuring Product Quality?

Third-party inspections can serve as an additional layer of assurance for buyers. Engaging independent inspectors to evaluate the manufacturing process and final products can help identify potential issues that may not be apparent to the buyer.

Illustrative image related to pu leathe

What Nuances Should International Buyers Be Aware Of Regarding QC?

International B2B buyers must be aware of the nuances in quality control practices across different regions. Variability in regulations, cultural standards, and manufacturing capabilities can affect the quality of PU leather products.

How Do Regional Standards Influence Quality?

For instance, European buyers might prioritize compliance with CE marking and other EU standards, while buyers in Africa or South America may focus on local regulations. Understanding these differences can help buyers make informed decisions about their sourcing strategies.

Why Is Transparency in the Manufacturing Process Crucial?

Finally, transparency in the manufacturing process can significantly influence buyer trust. Suppliers should be willing to share their quality control processes, certifications, and test results. This openness can help build long-term partnerships based on mutual trust and reliability.

In conclusion, understanding the manufacturing processes and quality assurance protocols for PU leather is crucial for B2B buyers. By being informed about these elements, buyers can make better decisions, ensuring they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu leathe’

This guide serves as a comprehensive checklist for B2B buyers looking to procure PU leather. By following these steps, you can ensure that you make informed decisions, select reliable suppliers, and understand the implications of your choice of materials.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s critical to establish the specific technical requirements for the PU leather you need. Consider factors such as thickness, finish, color, and intended application (e.g., upholstery, fashion, automotive). Clear specifications help you communicate effectively with suppliers and avoid misunderstandings later.

Step 2: Research Potential Suppliers

Take the time to identify and research potential suppliers who specialize in PU leather. Look for companies with a proven track record in the industry, positive reviews, and substantial experience. Utilize online directories, trade shows, and industry publications to gather a list of candidates that meet your criteria.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your chosen suppliers possess relevant certifications, such as ISO 9001 for quality management or environmental certifications like OEKO-TEX. These certifications indicate that the supplier adheres to industry standards and practices responsible manufacturing. Ask for documentation and conduct due diligence to ensure compliance.

Step 4: Request Samples for Quality Assessment

Always request samples of PU leather from potential suppliers to evaluate the material’s quality. Assess key attributes such as texture, durability, and appearance. Pay attention to how the material feels and smells, as these can be indicators of the production process and quality. This step is vital to ensure that the product meets your expectations before placing a bulk order.

Illustrative image related to pu leathe

Step 5: Understand Pricing Structures and Terms

Discuss pricing structures and payment terms upfront to avoid surprises later. Pricing can vary widely based on quality, customization, and volume. Understand the total cost, including shipping and duties if sourcing internationally, and clarify payment terms such as deposits, credit options, and timelines for payment.

Step 6: Inquire About Production Capabilities and Lead Times

Engage suppliers in discussions about their production capabilities and lead times. This is particularly important if you have a tight deadline for your project. Understanding their capacity to meet your order size and the expected delivery timeline will help you plan accordingly and avoid potential delays.

Step 7: Assess Sustainability Practices

As sustainability becomes increasingly important in material sourcing, inquire about the environmental practices of your suppliers. Understand their manufacturing processes, waste management, and the use of chemicals. Choosing suppliers who prioritize sustainability not only benefits the environment but can also enhance your brand’s reputation in the market.

Illustrative image related to pu leathe

By following this checklist, B2B buyers can navigate the complexities of sourcing PU leather more effectively, ensuring that they make informed decisions that align with their business needs and values.

Comprehensive Cost and Pricing Analysis for pu leathe Sourcing

What Are the Key Cost Components for PU Leather Sourcing?

When analyzing the costs associated with sourcing PU leather, several key components come into play. Materials represent a significant portion of the overall costs. PU leather is primarily made from thermoplastic polymers, which are less expensive compared to genuine leather. The choice of base fabric also affects the cost; higher-quality fabrics will increase the price.

Labor costs are another vital factor, as manufacturing PU leather involves skilled workers who apply coatings and finish the products. In regions with lower labor costs, such as parts of Africa or South America, buyers may find more competitive pricing.

Manufacturing overhead includes the expenses related to factory operations, such as utilities and maintenance. These costs can vary significantly depending on the location of the manufacturer and the efficiency of their operations.

Tooling refers to the equipment and molds needed for production. Custom designs or unique specifications may require additional investment in tooling, which can increase the overall cost.

Quality control (QC) measures are essential to ensure the finished product meets the required standards. Rigorous QC processes can add to costs but are crucial for maintaining product integrity, especially when exporting to markets with strict regulations, like those in Europe.

Logistics also plays a critical role in determining the total cost. International shipping, customs duties, and insurance can significantly impact pricing. Buyers should consider the distance from suppliers and the associated transportation costs.

Illustrative image related to pu leathe

How Do Price Influencers Impact PU Leather Sourcing?

Several factors influence the pricing of PU leather that buyers should consider. Volume and minimum order quantities (MOQ) can lead to substantial price breaks. Suppliers often offer lower per-unit prices for larger orders, making it advantageous for businesses to consolidate purchases.

Specifications and customization also affect pricing. Unique designs or specific performance characteristics may incur additional costs for materials and production processes. Buyers should weigh the importance of customization against budget constraints.

De quality of materials used in production is another critical factor. Higher-grade PU leather, which may have enhanced durability or a more realistic appearance, will come at a premium. Certifications regarding sustainability and safety can also influence costs, particularly in regions where eco-conscious consumerism is on the rise.

Supplier factors such as reputation, reliability, and experience can also affect pricing. Established suppliers may charge more due to their proven track record, while newer companies might offer lower prices to attract business.

Illustrative image related to pu leathe

Lastly, understanding Incoterms is vital for international buyers. These terms dictate the responsibilities of buyers and sellers in shipping arrangements, impacting overall costs. Knowing whether costs include shipping, insurance, and duties can help buyers avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficiency in PU Leather Sourcing?

To maximize cost-efficiency, B2B buyers should engage in thorough negotiation with suppliers. Understanding the cost breakdown can empower buyers to negotiate better terms. Additionally, establishing long-term relationships with suppliers may yield favorable pricing and terms over time.

Considering the Total Cost of Ownership (TCO) is crucial. This includes not only the initial purchase price but also costs related to maintenance, longevity, and potential replacement. Choosing higher-quality PU leather may result in lower long-term costs despite a higher upfront price.

Buyers should be aware of pricing nuances specific to international markets. For instance, tariffs and import duties can significantly affect the final price of PU leather sourced from abroad. Understanding local market conditions and currency fluctuations is essential for accurate budgeting.

Lastly, it is advisable for buyers to remain updated on market trends and fluctuations in raw material costs, which can impact pricing. Keeping abreast of industry news and supplier capabilities will help buyers make informed decisions and secure the best possible deals.

Illustrative image related to pu leathe

Disclaimer on Indicative Prices

Prices for PU leather can vary widely based on the factors discussed above. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing pu leathe With Other Solutions

In today’s marketplace, businesses often seek alternatives to PU leather due to its limitations in durability, environmental impact, and overall performance. Understanding these alternatives is crucial for B2B buyers looking to invest in materials that align with their operational needs and ethical standards. Below, we compare PU leather with two viable alternatives: genuine leather and vegetable-tanned leather.

| Comparison Aspect | PU Leer | Genuine Leather | Vegetable-Tanned Leather |

|---|---|---|---|

| Performance | Moderate; can crack and peel | High; ages well, develops patina | High; durable and eco-friendly |

| Cost | Low; budget-friendly | High; premium investment | Moderate; worth the investment |

| Ease of Implementation | Simple; mass-produced | Complex; requires skilled labor | Moderate; artisan-crafted |

| Maintenance | Low; easy to clean | Moderate; requires conditioning | Moderate; occasional care needed |

| Best Use Case | Fashion items, low-cost furniture | Luxury goods, long-term investment | Eco-conscious products, artisanal goods |

How Does Genuine Leather Compare to PU Leather?

Genuine leather stands as a timeless alternative to PU leather, known for its superior durability and aesthetic appeal. While it is significantly more expensive, its lifespan can range from 10 to 30 years with proper care. Genuine leather develops a unique patina over time, enhancing its character and value. However, it requires more maintenance, such as conditioning, to keep it in prime condition. For B2B buyers in sectors like luxury goods or high-end furniture, genuine leather is often the preferred choice due to its long-term investment value.

What Advantages Does Vegetable-Tanned Leather Offer Over PU Leather?

Vegetable-tanned leather is an eco-friendly alternative that utilizes natural tannins for processing. It is highly durable and does not contain harmful chemicals, making it a safer choice for both consumers and the environment. While the initial cost is moderate, the longevity and ability to age beautifully make it a valuable investment. Like genuine leather, it develops a patina, but it is often favored by businesses focused on sustainability. However, it requires regular care to maintain its quality, which may not be suitable for all B2B buyers.

Conclusion: How to Choose the Right Leather Alternative for Your Business

Selecting the right leather alternative involves assessing your specific business needs, budget constraints, and sustainability goals. PU leather may be suitable for companies prioritizing cost and ease of implementation for short-term use. However, if durability, longevity, and environmental considerations are paramount, genuine or vegetable-tanned leather may provide better long-term value. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their operational objectives and brand values.

Essential Technical Properties and Trade Terminology for pu leathe

What Are the Key Technical Properties of PU Leather for B2B Buyers?

When considering PU leather for commercial applications, understanding its essential technical properties is critical. Here are some of the key specifications that buyers should be aware of:

1. Material Composition

PU leather is primarily made from polyurethane, a thermoplastic polymer that is coated over a base fabric, often polyester or cotton. This composition allows for a variety of textures and colors, making it appealing for diverse applications. For B2B buyers, knowing the material composition can influence product selection based on durability and aesthetic requirements.

2. Durability and Wear Resistance

While PU leather offers an attractive finish, its durability is often less than that of genuine leather. Typically, PU leather has a lifespan of 1 to 3 years under regular use, depending on the quality. For businesses, particularly those in the furniture and fashion industries, understanding wear resistance can impact warranty considerations and customer satisfaction.

3. Ademend vermogen

Breathability refers to the material’s ability to allow air circulation, which affects comfort and moisture management. PU leather is generally less breathable than genuine leather, which can lead to discomfort in products like upholstery. For manufacturers, this is a crucial factor when designing products intended for prolonged use.

4. Chemical Resistance

PU leather is often resistant to water and certain chemicals, which makes it easier to clean and maintain. This property is particularly valuable in commercial environments where hygiene is a priority, such as healthcare or food service industries. Buyers should assess chemical resistance to ensure the longevity of products in specific applications.

5. Colorfastness

Colorfastness indicates the material’s ability to retain its color when exposed to light, washing, or friction. High colorfastness is essential for products that will face frequent handling or exposure to sunlight, making it a significant consideration for fashion and upholstery manufacturers.

6. Environmental Impact

The production of PU leather raises concerns regarding its environmental footprint, as it is not biodegradable and may involve toxic chemicals. B2B buyers increasingly prioritize sustainability, making it important to inquire about the environmental practices of suppliers when sourcing PU leather products.

What Common Trade Terms Should B2B Buyers Know When Sourcing PU Leather?

Navigating the procurement landscape for PU leather requires familiarity with specific trade terminology. Here are some key terms that can facilitate better communication and negotiation:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are sold under another company’s brand name. For B2B buyers, understanding OEM relationships can help in sourcing high-quality PU leather products that meet specific branding requirements.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is vital for buyers to understand as it can impact inventory management and cash flow, especially for smaller businesses or startups.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. B2B buyers should utilize RFQs to ensure they receive competitive pricing and can compare offers effectively, especially when sourcing PU leather from multiple vendors.

4. Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with these terms can help buyers manage logistics and costs effectively when importing PU leather products from international suppliers.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is crucial for B2B buyers to manage inventory and align product launches or campaigns with supply availability.

6. Certification Standards

Certification standards indicate compliance with specific quality, safety, and environmental regulations. B2B buyers should inquire about certifications when sourcing PU leather to ensure products meet industry standards and regulations, especially in sectors like automotive and furniture.

By understanding these essential properties and trade terms, international B2B buyers can make informed decisions when sourcing PU leather, ultimately enhancing their procurement strategies and product offerings.

Illustrative image related to pu leathe

Navigating Market Dynamics and Sourcing Trends in the pu leathe Sector

What Are the Current Market Dynamics Influencing PU Leather Sourcing?

The global PU leather market is experiencing a transformative phase driven by several key factors. First, the increasing demand for affordable, vegan alternatives to genuine leather is propelling growth, particularly in regions like Africa, South America, and parts of Europe, where consumers are becoming more eco-conscious. Countries such as Brazil and Germany are leading the charge in adopting synthetic materials due to their versatility and cost-effectiveness. Additionally, advancements in manufacturing technologies are improving the quality and appearance of PU leather, making it a more attractive option for businesses.

Emerging trends in B2B sourcing include the rise of online marketplaces that facilitate direct connections between manufacturers and international buyers. These platforms provide comprehensive product catalogs, enabling buyers to compare options and make informed decisions based on quality, price, and supplier reliability. Furthermore, the adoption of digital tools for inventory management and supply chain transparency is enhancing procurement processes, allowing businesses to mitigate risks associated with sourcing from various regions.

As the PU leather market evolves, international buyers must stay attuned to shifting consumer preferences and regulatory changes that may impact sourcing decisions. The increasing scrutiny on environmental sustainability and ethical practices will likely influence supplier selection, leading to greater demand for suppliers who can demonstrate compliance with international standards.

How Important Is Sustainability and Ethical Sourcing in the PU Leather Industry?

Sustainability is becoming a critical consideration for B2B buyers in the PU leather sector. The environmental impact of PU leather production is significant, primarily due to the use of petroleum-based polymers and the release of volatile organic compounds (VOCs) during manufacturing. These factors contribute to pollution and health concerns, prompting businesses to seek alternatives that align with sustainable practices.

Ethical sourcing is equally important, as consumers and businesses alike are prioritizing transparency in their supply chains. Buyers are increasingly looking for suppliers who adhere to ethical labor practices and environmental standards. Certifications such as OEKO-TEX, GOTS (Global Organic Textile Standard), and ISO 14001 are becoming essential criteria for evaluating potential suppliers. By choosing PU leather products that come from certified sources, businesses can enhance their brand reputation and appeal to a growing base of environmentally conscious consumers.

Investing in sustainable PU leather not only addresses environmental concerns but can also lead to long-term cost savings. Durable products reduce the need for frequent replacements, ultimately lowering lifecycle costs. As a result, integrating sustainability into sourcing strategies is not just a trend; it is a fundamental shift in how businesses operate within the PU leather market.

What Has Been the Historical Evolution of PU Leather in the B2B Landscape?

The evolution of PU leather dates back to the 1960s when it was first introduced as a synthetic alternative to genuine leather. Initially developed to offer a more affordable option for consumers, PU leather gained popularity in various industries, including fashion, furniture, and automotive. Over the decades, technological advancements have significantly improved the quality of PU leather, making it more durable and aesthetically pleasing.

The growth of the global PU leather market has been marked by increasing consumer awareness regarding animal welfare and environmental sustainability. As a result, PU leather has evolved from merely being a cost-effective alternative to a viable option that aligns with modern ethical standards. Today, it stands as a testament to innovation in materials science, catering to diverse market needs while addressing the pressing challenges of sustainability and ethical sourcing. This historical context is crucial for B2B buyers seeking reliable suppliers who understand the evolving landscape and can offer products that meet contemporary demands.

Frequently Asked Questions (FAQs) for B2B Buyers of pu leathe

-

How do I determine the quality of PU leather when sourcing?

To assess the quality of PU leather, evaluate its thickness, texture, and appearance. High-quality PU leather should have a uniform surface without imperfections, while low-quality versions may appear too shiny or synthetic. Request samples from suppliers to inspect their material firsthand. Additionally, inquire about the manufacturing process and any certifications, such as compliance with environmental and safety standards. Conducting a water test can also help; genuine PU leather will not absorb water, while real leather will. -

What are the key benefits of using PU leather for my business?

PU leather offers several advantages for businesses, including cost-effectiveness and versatility. It is generally less expensive than genuine leather, making it a budget-friendly option for bulk purchases. PU leather is also available in various colors and styles, allowing for greater customization in product offerings. Its ease of maintenance and resistance to water absorption makes it suitable for various applications, from furniture to fashion accessories, especially in markets that prioritize vegan options. -

What should I consider when vetting PU leather suppliers?

When vetting suppliers, focus on their reputation, experience, and production capabilities. Request references from previous clients and check reviews to gauge reliability. Ensure they can provide certifications confirming the quality and safety of their PU leather products. Additionally, inquire about their supply chain transparency, as this can impact product quality and ethical considerations. Understand their production lead times and whether they can accommodate your business’s specific needs, including customization options. -

What are the typical minimum order quantities (MOQs) for PU leather?

MOQs for PU leather can vary widely depending on the supplier and the type of product being ordered. Generally, MOQs can range from 100 to 1,000 meters for fabric, while finished goods may require higher quantities. Discuss your needs with potential suppliers to negotiate MOQs that align with your business model. Smaller businesses may seek suppliers willing to accommodate lower MOQs or offer flexible ordering options to reduce inventory risks. -

What payment terms are common in international PU leather transactions?

Payment terms for international transactions can differ significantly based on supplier policies and your negotiation. Common arrangements include a 30% deposit upfront with the balance due upon shipment, or payment in full before production. Some suppliers may offer letters of credit or escrow services to protect both parties. It’s essential to clarify payment methods, currencies, and potential fees associated with international transactions to avoid misunderstandings and ensure smooth procurement. -

How can I ensure quality assurance (QA) for PU leather products?

To maintain quality assurance, establish clear quality standards and specifications with your supplier before production begins. Request regular updates and samples during the manufacturing process to assess adherence to these standards. Consider implementing third-party inspections prior to shipment, which can help identify any defects or non-compliance with your requirements. Building a strong relationship with your supplier can also enhance communication and lead to better quality control. -

What are the logistics considerations for importing PU leather?

Logistics for importing PU leather involves several factors, including shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder experienced in handling PU leather products to navigate international shipping complexities. Be aware of import tariffs and ensure compliance with regulations in your destination country. Plan for potential delays by allowing adequate lead time in your procurement schedule and maintaining open communication with your supplier throughout the shipping process. -

Is PU leather environmentally friendly, and what should I know about its impact?

While PU leather is often marketed as a vegan alternative, its environmental impact is complex. The production process can involve volatile organic compounds (VOCs) and other chemicals that may be harmful to both health and the environment. It is essential to inquire about the supplier’s manufacturing practices and whether they adhere to sustainable practices, such as using eco-friendly materials or processes. Consider the lifecycle of PU leather products and weigh these factors against your business’s sustainability goals.

Top 5 Pu Leathe Manufacturers & Suppliers List

1. Manuel Dreesmann – PU Leather Explained

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: This company, Manuel Dreesmann – PU Leather Explained, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Reddit – PU Leather vs Real Leather

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the comparison of PU leather and real leather for wallets and handbags. Key points include: 1. PU leather tends to crack and disintegrate with minimal use, leading to reliability issues. 2. Real leather raises ethical concerns regarding its production, often sourced from China, and can be poorly made in mass-market brands. 3. The user is looking for affordable option…

3. Naugahyde – Faux Leather Upholstery Fabric

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: PU Leather & Faux Leather | Vinyl Upholstery Fabric, Free Shipping Coupon Code: SHIPFREE for Most $199 Orders, Available by the yard or full roll, Huge selection of faux leather vinyl upholstery fabric, Brands include Naugahyde, Omnova Boltaflex, Nassimi, Spradling, Suitable for furniture, automotive, marine, and commercial projects, Easy to clean, Durable, Available in various colors: Black, Gray…

4. Carl Friedrik – PU Leather Products

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: PU leather, also known as artificial or imitation leather, is a synthetic material made from polyurethane (PU), a type of plastic. It mimics the look and feel of animal leather and is created by applying a PU resin coating to natural fabrics like nylon, cotton, or vinyl. 100% PU leather is vegan-friendly, while PU coated on split leather (inferior quality animal hide) is not. Benefits include bein…

5. Yorkshire Fabric Shop – PU & Faux Leather

Domain: yorkshirefabricshop.com

Registered: 2014 (11 years)

Introduction: PU leather and faux leather are both alternatives to genuine leather, offering similar aesthetics at a lower price point. PU leather is made from polyurethane, a synthetic material that mimics the feel of leather without using animal products. Faux leather, derived from upholstery fabric like polyester, is designed to resemble real leather and can include finishes such as wax, dye, PVC, or polyure…

Strategic Sourcing Conclusion and Outlook for pu leathe

In today’s competitive landscape, understanding the nuances of PU leather is essential for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. PU leather offers an affordable, versatile alternative to genuine leather, appealing to businesses seeking cost-effective solutions without compromising on aesthetics. However, it is crucial to consider the material’s durability, environmental impact, and potential health concerns linked to its production.

Strategic sourcing of PU leather involves evaluating suppliers based on their manufacturing processes and the quality of materials used. Engaging with manufacturers who prioritize ethical practices and transparency can enhance brand reputation and ensure compliance with emerging sustainability regulations. As global demand for sustainable products grows, sourcing responsibly produced PU leather can position your business favorably in the market.

Looking ahead, it is vital for international B2B buyers to stay informed about evolving trends in synthetic materials and consumer preferences. By leveraging strategic sourcing practices, businesses can not only meet customer demands but also contribute positively to environmental sustainability. Embrace this opportunity to innovate and differentiate your offerings in the competitive landscape of leather alternatives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.