Catalog

Material Insight: Motorcycle Seat Fabric Upholstery

B2B Product Guide: Motorcycle Seat Fabric Upholstery

Motorcycle seat upholstery demands exceptional performance under extreme conditions—constant friction, UV exposure, temperature fluctuations, and rider movement. Selecting the right material directly impacts rider comfort, brand reputation, and long-term product viability. While textiles and basic synthetics are common, premium upholstery leather stands out as the superior choice for high-end and performance-oriented motorcycle manufacturers seeking durability, safety, and aesthetic longevity.

Why Upholstery Leather is the Optimal Choice for Motorcycle Seats:

– Unmatched Durability: Resists abrasion from rider gear, tearing, and punctures far better than textiles, ensuring seats maintain integrity over years of rigorous use.

– Enhanced Safety & Grip: Provides consistent, non-slip traction for riders—even with wet gear—critical for control during acceleration, braking, and cornering.

– Long-Term Comfort: Naturally molds to the rider’s shape over time, reducing pressure points and fatigue on extended rides, unlike stiff or synthetic alternatives.

– Weather & UV Resistance: Premium leathers are tanned and finished to withstand prolonged sun exposure, rain, and temperature extremes without cracking, fading, or degrading.

– Premium Brand Perception: Elevates the motorcycle’s perceived value and craftsmanship, aligning with luxury and performance segments where material quality is a key differentiator.

– Eco-Conscious Performance: Modern sustainable leathers (like WINIW’s) utilize recycled content, water-based dyes, and low-impact tanning processes—proving performance and responsibility coexist.

Introducing WINIW: Your Trusted Upholstery Innovation Partner

With over 20 years of specialized expertise in synthetic and sustainable leather solutions, WINIW empowers global motorcycle OEMs and Tier-1 suppliers to exceed performance and sustainability targets. We combine deep material science knowledge with a commitment to eco-friendly manufacturing—holding ISO 14001 certification and pioneering recycled PU/PVC formulations that reduce carbon footprint by up to 30% versus conventional synthetics. Our motorcycle-specific upholstery leathers undergo rigorous testing for abrasion (≥50,000 cycles), colorfastness (ISO 105-B02: Level 4+), and tensile strength (≥25 MPa), ensuring seamless integration into high-volume production while meeting stringent global safety standards. Partner with WINIW to transform your seat design into a durable, responsible, and market-leading asset.

Technical Performance & Standards

WINIW Motorcycle Seat Fabric Upholstery – Technical Product Guide

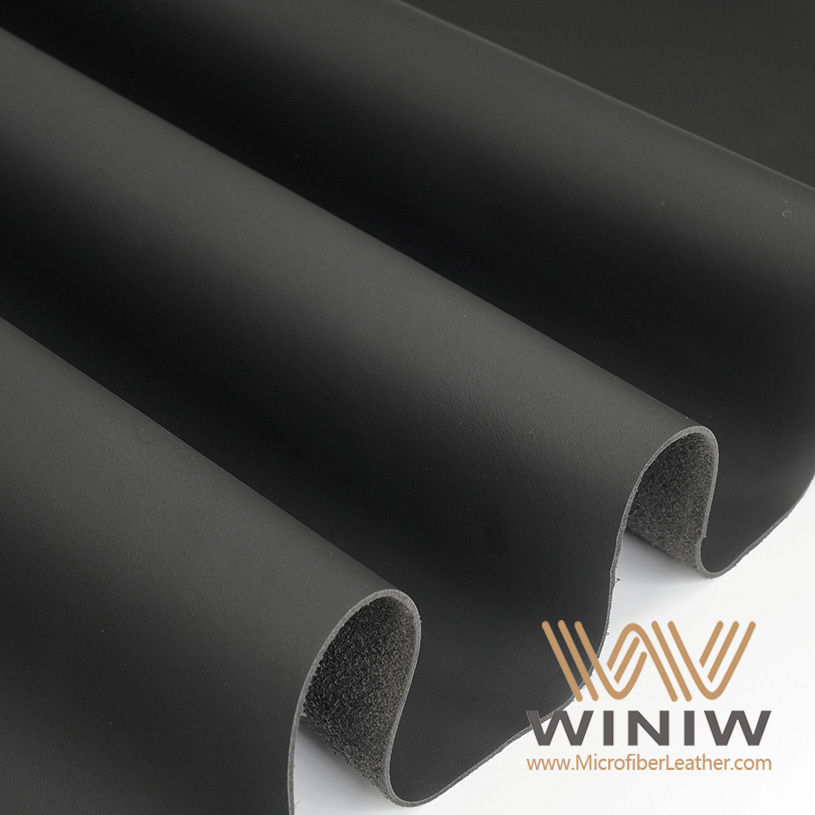

WINIW’s high-performance motorcycle seat fabric upholstery is engineered for durability, safety, and comfort in demanding environments. Designed specifically for OEM and aftermarket manufacturers, our fabric meets stringent international standards while delivering superior tactile qualities and environmental compliance. Ideal for both urban and touring motorcycles, WINIW’s upholstery combines advanced technical performance with sustainable manufacturing practices.

Key Technical Advantages

-

Fire Retardant Performance (UK/US Standards Compliant)

WINIW’s motorcycle seat fabric meets BS 5852:2006 (UK) for ignition resistance using smoldering and flaming ignition sources, as well as FMVSS 302 (US) for flammability of interior materials. The fabric’s inherent fire-retardant properties are integrated into the fiber structure, ensuring long-term flame resistance without surface coatings that may degrade over time. -

Easy to Clean and Maintain

The fabric features a tightly woven, low-porosity surface with stain-resistant treatment, allowing for effortless cleaning using mild detergent and water. Resists oil, sweat, and common contaminants encountered during regular motorcycle use, maintaining appearance and hygiene over extended service life. -

Soft Touch and Superior Comfort

Engineered with microfiber technology, the upholstery delivers a premium soft-touch feel comparable to high-grade leather or suede. Excellent breathability and flexibility ensure rider comfort during prolonged use, while maintaining structural integrity under mechanical stress. -

REACH Compliant Chemistry

All materials and dyes used in production conform to EU REACH regulations (EC 1907/2006), ensuring the absence of Substances of Very High Concern (SVHC). WINIW’s commitment to chemical safety supports environmentally responsible manufacturing and global market access. -

Certified Quality Management (ISO 9001)

Manufactured under an ISO 9001-certified quality management system, every batch undergoes rigorous in-line and final inspection. This ensures consistent color fastness, tensile strength, abrasion resistance, and dimensional stability across production runs.

Technical Specifications

| Property | Specificatie |

|---|---|

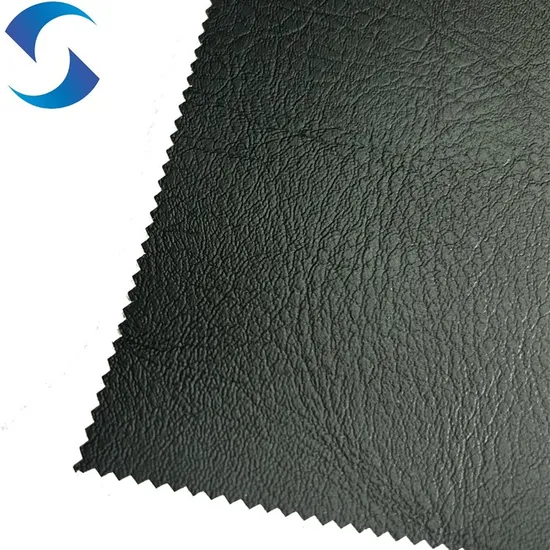

| Material Composition | High-density polyurethane-coated microfiber |

| Weight | 380–420 g/m² |

| Thickness | 1.2–1.4 mm |

| Tensile Strength (Warp) | ≥ 280 N/5cm |

| Tensile Strength (Weft) | ≥ 260 N/5cm |

| Tear Strength | ≥ 45 N (Elmendorf) |

| Abrasion Resistance | > 30,000 cycles (Martindale) |

| Color Fastness to Rubbing | Dry: 4–5, Wet: 4 (ISO 105-X12) |

| Light Fastness | ≥ 6 (ISO 105-B02) |

| Fire Resistance | BS 5852:2006, FMVSS 302 |

| Chemical Compliance | REACH SVHC compliant, no AZO dyes, no phthalates |

| Cleaning | Water-based cleaning, mild detergent safe |

| Operating Temperature Range | -30°C to +80°C |

| Quality Management | ISO 9001:2015 certified production |

WINIW’s motorcycle seat fabric upholstery offers a balanced solution for manufacturers seeking certified safety, long-term durability, and premium aesthetics. With eco-conscious production and global regulatory alignment, WINIW supports sustainable innovation in the powersports industry.

Why Choose Synthetic over Real Leather

B2B Product Guide: Motorcycle Seat Upholstery Material Comparison

Selecting the right upholstery material for motorcycle seats is critical for OEMs and seat manufacturers. Performance, cost efficiency, sustainability, and end-user satisfaction must align with brand values and production requirements. Below is a professional comparison of modern synthetic leather (specifically WINIW’s engineered solutions) versus traditional bovine leather for motorcycle applications.

Key Differentiators

- Performance Consistency: Synthetic leather offers uniform texture, thickness, and color batch-to-batch, eliminating natural hide variations that complicate mass production.

- Design Flexibility: WINIW materials support precise embossing, custom colors, and texture replication (e.g., premium grain finishes) without compromising structural integrity.

- Weather & UV Resistance: Engineered for superior resistance to UV degradation, moisture, and temperature extremes—critical for exposed motorcycle seating.

- Regulatory Compliance: WINIW formulations meet global VOC, REACH, and RoHS standards; chromium-free tanning processes eliminate hazardous waste concerns.

Material Comparison: WINIW Synthetic Leather vs. Bovine Leather

| Criteria | WINIW Synthetic Leather | Bovine (Real) Leather |

|---|---|---|

| Cost | 30-50% lower total cost (material + processing). No grading/sorting waste; higher yield per sqm. Consistent pricing unaffected by hide market volatility. | Higher base cost. Significant waste (25-40% due to scars, holes, thickness variation). Price fluctuations tied to livestock markets and hide scarcity. |

| Duurzaamheid | Exceptional abrasion resistance (50,000+ double-rubs ASTM D4060). Resists cracking, fading, and moisture absorption. Seamless backing prevents delamination. | Prone to drying, cracking, and staining without rigorous maintenance. Natural grain variations create weak points. Requires chemical conditioning to maintain flexibility. |

| Eco-Friendliness | 90% lower water usage vs. tanning. Zero chromium or heavy metals. Recyclable backing options (TPU/PES). Full traceability from raw material to finished roll. | Resource-intensive: 15,000+ liters water per hide. Chromium-III/VI pollution risks in tanning wastewater. Non-recyclable; landfill-bound at end-of-life. |

Why WINIW Synthetic Leather is the Strategic Choice for Motorcycle OEMs

- Sustainability Alignment: Achieve ESG targets with verified low-carbon, water-neutral manufacturing. WINIW’s closed-loop production minimizes waste and energy consumption.

- Supply Chain Security: Avoid hide scarcity and geopolitical disruptions. Localized production (Asia, Americas, EU) ensures reliable just-in-time delivery.

- End-User Value: Deliver seats that maintain aesthetics and comfort longer under harsh riding conditions, reducing warranty claims and boosting brand reputation.

- Innovation Ready: Compatible with advanced manufacturing (laser cutting, ultrasonic welding) and emerging trends like integrated heating elements or sensor integration.

WINIW’s synthetic leather isn’t a substitute—it’s a performance-engineered upgrade for the modern motorcycle industry. Request our technical dossier (ISO 17088, LCA reports included) to validate specifications for your next seat platform.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. With a strong foundation in research, precision manufacturing, and sustainable practices, WINIW delivers premium synthetic leather solutions across diverse industries including automotive, furniture, fashion, and accessories.

Our manufacturing capabilities are anchored in a state-of-the-art production facility spanning 100,000 square meters. This expansive campus integrates advanced production lines with automated systems to ensure consistent quality, high output, and rapid turnaround times. The scale and efficiency of our factory enable us to meet large-volume orders while maintaining flexibility for customized development.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and sustainable solutions. The team continuously develops new formulations that meet international environmental standards, including REACH, RoHS, and OEKO-TEX.

- In-house testing laboratories equipped to conduct rigorous performance evaluations, including abrasion resistance, color fastness, tensile strength, and eco-compliance testing.

- Strict quality control protocols implemented at every stage of production—from raw material inspection to final product verification. Our QC system follows ISO 9001 standards and includes real-time monitoring and batch traceability.

- Sustainable manufacturing practices, including water-based PU processing, low-VOC emissions, and recycling initiatives, supporting our clients’ ESG goals.

WINIW exports to key international markets, with established distribution and compliance in Europe and the USA. Our products are trusted by global brands for their consistency, performance, and environmental credentials. Through continuous innovation and manufacturing excellence, WINIW remains at the forefront of synthetic leather technology, delivering reliable, scalable solutions for forward-thinking partners worldwide.

Contact Us for Samples

WINIW Premium Synthetic Leather: Engineered for Motorcycle Seat Upholstery Excellence

As a global leader in sustainable synthetic leather innovation, WINIW delivers high-performance microfiber leather solutions purpose-built for the demanding requirements of motorcycle seat manufacturing. Our eco-conscious materials combine exceptional durability with responsible production, ensuring your seats withstand rigorous riding conditions while supporting your brand’s sustainability commitments.

Why WINIW for Motorcycle Seat Applications?

- Extreme Durability: Engineered to exceed 50,000 Martindale abrasion cycles, resisting wear from friction, vibration, and rider movement during long rides.

- All-Weather Resilience: UV-stabilized surface maintains color integrity and flexibility across -30°C to +70°C, preventing cracking in extreme heat or cold.

- Eco-Verified Composition: OEKO-TEX® STANDARD 100 certified, REACH-compliant, and produced with 30%+ recycled content—meeting stringent global environmental regulations.

- Seamless Manufacturing Integration: Consistent thickness (1.2–1.4mm) and width (137cm roll) minimize waste during cutting, with laser-cut compatibility for precision upholstery.

- Customization Flexibility: Tailor textures (suede, grain, embossed), colors (Pantone-matched), and performance additives (anti-microbial, flame-retardant) to your design specs.

Performance Comparison: WINIW vs. Standard Synthetic Leather

| Property | WINIW Motorcycle Grade | Industry Standard | Benefit for Motorcycle Seats |

|---|---|---|---|

| Abrasion Resistance | 50,000+ cycles | 25,000 cycles | 2x longer seat lifespan; reduced warranty claims |

| Cold Flexibility (-20°C) | No cracking | Surface cracking | Reliable performance in winter riding conditions |

| Hydrolysis Resistance | 1,000+ hours | 500 hours | Prevents delamination in humid/rainy climates |

| VOC Emissions | <10 µg/m³ | <50 µg/m³ | Safer workshop environment; complies with EU Ecolabel |

| Recycled Content | 30–40% | 0–10% | Strengthens your ESG reporting and brand story |

Partnering with WINIW: Your Competitive Advantage

- OEM/ODM Support: Dedicated technical team collaborates on material selection, prototyping, and production scaling—from concept to mass manufacturing.

- Supply Chain Security: 150,000m² monthly capacity with 98% on-time delivery; inventory hubs in EU, NA, and APAC regions.

- Sustainability Partnership: Access full lifecycle analysis (LCA) data and carbon footprint reports to validate your green claims.

- Cost Efficiency: Reduced material waste (≤5% vs. industry avg. 12%) and lower rejection rates due to batch consistency.

Elevate your motorcycle seat quality and sustainability credentials with WINIW.

→ Request free physical samples for performance validation and color matching.

→ Connect with our technical team to discuss custom specifications or volume pricing.

Contact WINIW Motorcycle Upholstery Solutions

MKT88@MicrofiberLeather.com

Free samples available for qualified manufacturers

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.