Catalog

Material Insight: Leather Manufacturers

B2B Product Guide: Faux Leather for Leather Manufacturers

As global demand for sustainable, high-performance materials continues to rise, leather manufacturers are increasingly turning to faux leather as a strategic solution that aligns with environmental goals, cost-efficiency, and evolving customer expectations. Faux leather offers a compelling alternative to traditional animal hides, combining consistent quality, design flexibility, and reduced environmental impact—making it an ideal choice for modern manufacturing processes.

Faux leather is the best choice for leather manufacturers for several key reasons:

- Consistent Supply and Quality: Unlike natural leather, which can vary in texture, thickness, and grain due to biological factors, faux leather provides uniform performance and appearance across batches, streamlining production and reducing waste.

- Sustainability and Compliance: With growing regulatory and consumer pressure to reduce environmental impact, faux leather—especially when produced using eco-conscious methods—supports compliance with sustainability standards and ESG goals.

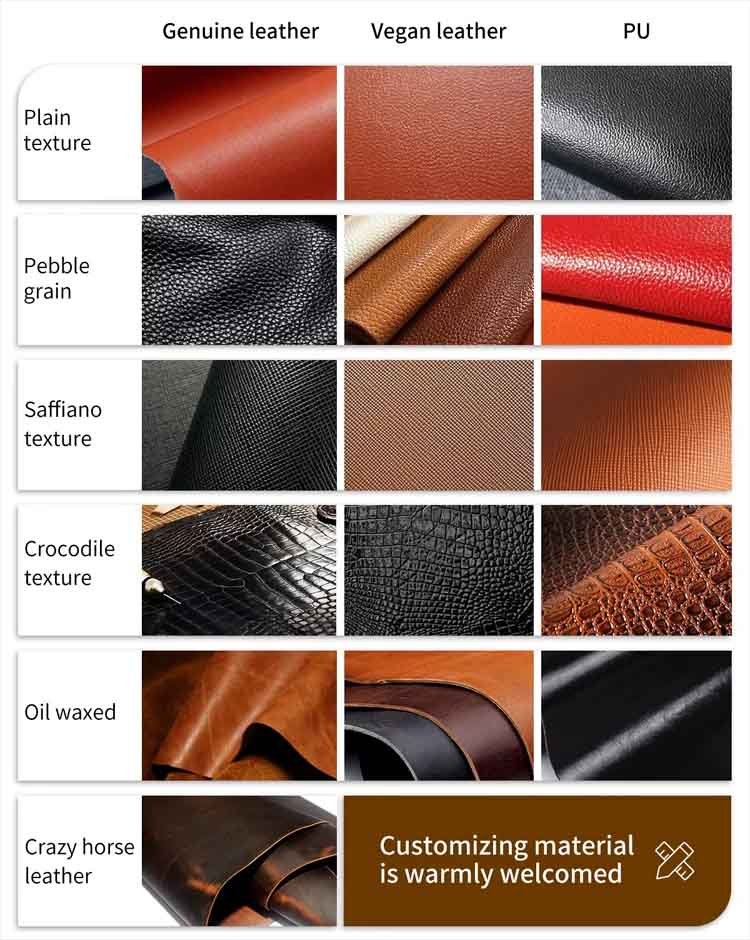

- Design Versatility: Faux leather can be engineered to mimic a wide range of textures, finishes, and performance characteristics, allowing manufacturers to offer diverse product lines without sourcing multiple raw materials.

- Cost-Effective Scaling: Lower processing costs, reduced dependency on volatile hide markets, and longer material yields contribute to improved profit margins over time.

For over 20 years, WINIW has been a trusted partner to leather manufacturers worldwide, specializing in high-performance synthetic leather solutions. Our deep industry expertise, commitment to innovation, and focus on eco-friendly production methods have positioned us as a leader in the faux leather sector. From advanced microfiber technologies to water-based, low-VOC manufacturing processes, WINIW delivers materials that meet rigorous industrial standards while supporting a more sustainable future.Partnering with WINIW means access to reliable supply chains, technical support, and customizable solutions designed to meet the exact needs of modern leather manufacturing operations.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Advantages for Manufacturing Partners

WINIW delivers high-performance synthetic leather engineered specifically for industrial manufacturers seeking sustainable, reliable, and compliant materials. Our solutions optimize production costs while meeting stringent global regulatory standards, ensuring seamless integration into your supply chain without compromising environmental responsibility.

Key technical advantages for your production lines:

- Cost-Effective Production: Reduced material waste through consistent roll-to-roll thickness tolerance (±0.05mm) and optimized cutting yields. Lower lifecycle costs via extended product lifespan and minimal maintenance requirements compared to traditional leather.

- Exceptional Durability: Engineered with high-density PU/polyester composite structures achieving 50,000+ Martindale abrasion cycles (ISO 12947-2). Resists tearing (≥50N), UV degradation (ISO 105-B02), and hydrolysis for long-term structural integrity in demanding applications.

- Precision Color Customization: Pantone®-matched color consistency (ΔE <1.5) across batches via in-line digital dyeing systems. Supports complex multi-tone designs and proprietary color libraries with zero water discharge in the coloring process.

- REACH SVHC Compliance: Fully documented absence of Substances of Very High Concern (as per ECHA updates). Traceable chemical inventory with <10ppm residual DMF and zero azo dyes (EN 14362-1:2012).

- ISO 9001-Certified Quality Control: Statistical process control (SPC) monitoring at all production stages. Batch-specific certificates of conformance with real-time access to test data via our B2B portal.

Technical Specifications Comparison

| Parameter | WINIW Standard Grade | WINIW Premium Grade | Test Standard |

|---|---|---|---|

| Thickness Tolerance | ±0.05mm | ±0.03mm | ISO 2417:2010 |

| Abrasion Resistance | 50,000 cycles | 100,000 cycles | ISO 12947-2 |

| Tensile Strength | ≥35 MPa | ≥45 MPa | ISO 1798:2014 |

| Color Fastness (Light) | Grade 7 | Grade 8 | ISO 105-B02 |

| Hydrolysis Resistance | 1,000 hrs @ 70°C | 2,000 hrs @ 70°C | ISO 1419:2018 |

| VOC Emissions | <10 µg/m³ | <5 µg/m³ | ISO 16000-9:2006 |

| REACH Declaration | Full SVHC compliance | Full SVHC compliance | EC 1907/2006 |

| Production Lead Time | 15-20 dagen | 20-25 days | — |

WINIW’s closed-loop manufacturing process eliminates wastewater discharge and reduces carbon footprint by 40% versus conventional leather production. All materials are certified by independent labs (SGS, TÜV) with full documentation for global market access. Partner with us to enhance your product value while meeting evolving sustainability mandates.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather in Modern Manufacturing

In today’s evolving market, businesses across fashion, automotive, and furniture industries are reevaluating material choices to balance performance, sustainability, and cost-efficiency. One of the most significant decisions involves selecting between real leather and synthetic leather—particularly advanced solutions from leading manufacturers such as WINIW. Understanding the differences in sourcing, performance, and environmental impact is critical for informed procurement.

Real Leather: Traditional Attributes and Limitations

Real leather is derived from animal hides, primarily bovine, and undergoes extensive tanning and finishing processes. It has long been valued for its natural texture, breathability, and premium aesthetic. However, it comes with notable drawbacks:

- High variability in quality due to natural imperfections in hides

- Significant environmental footprint from livestock farming and chemical tanning

- Longer lead times and supply chain vulnerabilities

- Higher cost per square meter, especially for consistent, top-grade material

Synthetic Leather Manufacturers: The Modern Alternative

Leading synthetic leather manufacturers utilize advanced polyurethane (PU) and polyvinyl chloride (PVC) technologies—along with emerging bio-based polymers—to produce materials that replicate the look and feel of real leather while offering greater consistency and control.

Key advantages include:

- Uniform thickness and appearance across production batches

- Customizable textures, colors, and performance features (e.g., water resistance, UV stability)

- Reduced lead times and scalable production for large-volume orders

- Compliance with animal-free and cruelty-free standards

Manufacturers like WINIW prioritize eco-conscious innovation, integrating water-based PU systems, recycled content, and low-VOC emissions into their production lines, aligning with global sustainability standards.

Comparative Analysis: Synthetic Leather vs. Real Leather

| Categorie | Synthetic Leather (High-Grade, e.g., WINIW) | Real Leather |

|---|---|---|

| Cost | Lower to moderate; stable pricing | High; fluctuates with hide supply and grade |

| Duurzaamheid | High resistance to cracking, fading, and abrasion; consistent performance | Prone to drying, cracking, and staining over time; varies by hide quality |

| Eco-Friendliness | Improved with water-based PU, recyclability, and reduced CO₂ emissions; no animal sourcing | High environmental cost from land use, methane emissions, and toxic tanning chemicals (e.g., chromium) |

Strategic Considerations for B2B Buyers

When evaluating suppliers, businesses should consider:

- Long-term total cost of ownership, including maintenance and waste reduction

- Brand alignment with sustainability goals and ESG reporting

- Need for design flexibility and material consistency in mass production

- Regulatory compliance in regions restricting animal products or hazardous chemicals

Synthetic leather from advanced manufacturers represents a forward-thinking choice for brands seeking high-performance, ethical, and scalable materials without compromising on quality. As technology progresses, the performance gap continues to narrow—while the sustainability and economic advantages of synthetic solutions grow stronger.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered Excellence for Global B2B Partners

WINIW stands at the forefront of sustainable synthetic leather manufacturing, delivering precision-engineered solutions trusted by leading brands across industries. Our vertically integrated capabilities ensure uncompromising quality, traceability, and innovation from raw material to finished product – all aligned with stringent global environmental standards.

Core Manufacturing Strengths

- Scale & Sustainability: Operate a state-of-the-art 100,000 sqm (over 1 million sq ft) manufacturing complex powered by renewable energy initiatives and certified eco-processes (ISO 14001, OEKO-TEX® STANDARD 100). This scale enables consistent large-volume production while minimizing environmental impact through closed-loop water systems and 95%+ waste recycling.

- Advanced R&D Leadership: Deploy a dedicated 80+ member technical team focused on material science innovation, holding 47+ patents in eco-friendly PU/PVC formulations, microfiber technology, and bio-based polymers. We co-develop custom solutions meeting specific performance, aesthetic, and sustainability targets (e.g., 30%+ plant-derived content, PFAS-free finishes).

- Military-Grade Quality Control: Implement a 7-stage QC protocol exceeding ISO 9001 standards, including raw material spectroscopy, real-time production monitoring, and final product testing for abrasion resistance (Martindale >50,000 cycles), colorfastness (ISO 105-B02: Grade 4-5), and eco-compliance (REACH, CPSIA). Every batch includes full traceability documentation.

Global Market Validation

Our commitment to excellence drives consistent export success to regulated markets, with 65% of annual production shipped to North America and Europe. WINIW materials are currently specified by:

– Top 3 European automotive interior suppliers

– Leading U.S. athletic footwear brands

– Premium Italian furniture manufacturers

This global adoption underscores our ability to meet the most demanding technical, ethical, and regulatory requirements – ensuring your supply chain resilience and brand integrity. Partner with WINIW for synthetic leather that performs, protects, and progresses.

Contact Us for Samples

WINIW B2B Product Guide: Sustainable Microfiber Leather Solutions

WINIW is a leading innovator in high-performance, eco-friendly microfiber leather for global industries including automotive, furniture, footwear, and fashion accessories. Our advanced manufacturing processes deliver synthetic leather that matches or exceeds the look, feel, and durability of genuine leather—without the environmental impact.

Engineered for performance and sustainability, WINIW microfiber leather offers consistent quality, superior strength, and customizable finishes for discerning B2B partners. As a trusted supplier to leading manufacturers, we support scalable production with reliable lead times and global logistics.

Key Advantages of WINIW Microfiber Leather

- Eco-Friendly Composition: Made from ultra-fine polyamide and polyurethane fibers, our materials are free from harmful solvents and heavy metals. Fully REACH and OEKO-TEX® STANDARD 100 compliant.

- Superior Performance: High tensile strength, excellent abrasion resistance, and superior color fastness ensure long-lasting product integrity.

- Customization Flexibility: Available in a wide range of textures (suede, grain, embossed), colors, thicknesses (0.6mm to 2.0mm), and backings (PU-coated, fabric, non-woven).

- Consistent Quality: Uniform thickness and surface finish reduce waste during cutting and production—ideal for automated manufacturing lines.

- Animal-Friendly & Sustainable: 100% animal-free, cruelty-free, and designed for circularity. Recyclable at end-of-life in certified facilities.

Industry Applications

- Automotive Interiors: Seats, door panels, steering wheels, armrests – meets stringent fogging, wear, and VOC emission standards.

- Furniture & Upholstery: Ideal for sofas, chairs, and office seating with high durability and easy maintenance.

- Footwear: Lightweight, breathable, and flexible—perfect for athletic, casual, and safety footwear.

- Fashion Accessories: Used in handbags, wallets, belts, and watch straps with premium aesthetics and long-term performance.

- Electronics & Luggage: Scratch-resistant and elegant finish for premium cases, bags, and protective covers.

Technical Specifications Overview

| Property | WINIW Standard Range | Testing Standard |

|---|---|---|

| Thickness | 0.6 mm – 2.0 mm | ISO 2589 |

| Tensile Strength | ≥ 200 N/5cm | ISO 1765 |

| Elongation at Break | ≤ 30% | ISO 1765 |

| Martindale Abrasion | 30,000 – 100,000 cycles | ISO 12947 |

| Color Fastness (Rubbing) | Grade 4–5 (dry/wet) | ISO 105-X12 |

| VOC Emissions | Compliant with ISO 12219-2 | Automotive Grade |

Why Partner with WINIW?

- ISO 9001 & ISO 14001 Certified Manufacturing

- In-house R&D team for custom development

- MOQs tailored to B2B production scales

- Fast prototyping and sample turnaround

- Global shipping with full documentation

Call to Action for Leather Manufacturers

Elevate your production with sustainable, high-performance microfiber leather. WINIW offers free samples to qualified leather manufacturers seeking to innovate and meet growing market demand for eco-conscious materials.

Contact our marketing team today to request your complimentary sample kit and technical datasheet.

E-mail: MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.