Introduction: Navigating the Global Market for how to make a leather holster

In the competitive landscape of leather goods, sourcing high-quality leather holsters can present a significant challenge for B2B buyers. Understanding how to make a leather holster not only enhances product offerings but also empowers businesses to meet the diverse needs of their clientele. This comprehensive guide delves into the intricacies of holster creation, covering various types such as fitted and western-style designs, along with essential applications across different sectors, including law enforcement, outdoor recreation, and fashion.

International buyers from regions like Africa, South America, the Middle East, and Europe will find this guide particularly invaluable. It addresses critical aspects such as supplier vetting processes, material sourcing, cost analysis, and production techniques. By equipping buyers with the knowledge to navigate the complexities of leather holster manufacturing, this guide fosters informed purchasing decisions that enhance product quality and market competitiveness.

Whether you are a seasoned leather artisan or a newcomer seeking to expand your product line, understanding the nuances of leather holster production is essential. With actionable insights and expert tips, this guide aims to streamline the procurement process, ensuring that your business can confidently offer durable, stylish, and functional leather holsters that meet the expectations of your global clientele.

Table Of Contents

- Top 3 How To Make A Leather Holster Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather holster

- Understanding how to make a leather holster Types and Variations

- Key Industrial Applications of how to make a leather holster

- 3 Common User Pain Points for ‘how to make a leather holster’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather holster

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather holster

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather holster’

- Comprehensive Cost and Pricing Analysis for how to make a leather holster Sourcing

- Alternatives Analysis: Comparing how to make a leather holster With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather holster

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather holster Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather holster

- Strategic Sourcing Conclusion and Outlook for how to make a leather holster

- Important Disclaimer & Terms of Use

Understanding how to make a leather holster Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fitted Leather Holster | Custom-fit to specific firearm, vacuum-formed design | Custom firearm accessories, Law enforcement | Pros: Excellent fit and retention; Cons: Time-consuming to produce. |

| Western Leather Holster | Open-top design, often decorative, typically for revolvers | Cowboy action shooting, reenactments | Pros: Stylish and traditional; Cons: Less secure than fitted holsters. |

| OWB (Outside Waistband) Holster | Holster worn outside the waistband, versatile attachment options | Concealed carry, tactical applications | Pros: Easy access and draw; Cons: Can be less discreet. |

| IWB (Inside Waistband) Holster | Sits inside the waistband, offers concealment | Personal defense, law enforcement | Pros: Excellent concealment; Cons: Can be uncomfortable for prolonged wear. |

| Cross-Draw Holster | Positioned for drawing across the body, often angled | Tactical situations, horseback riding | Pros: Quick access for right- or left-handed users; Cons: Less common, may require custom designs. |

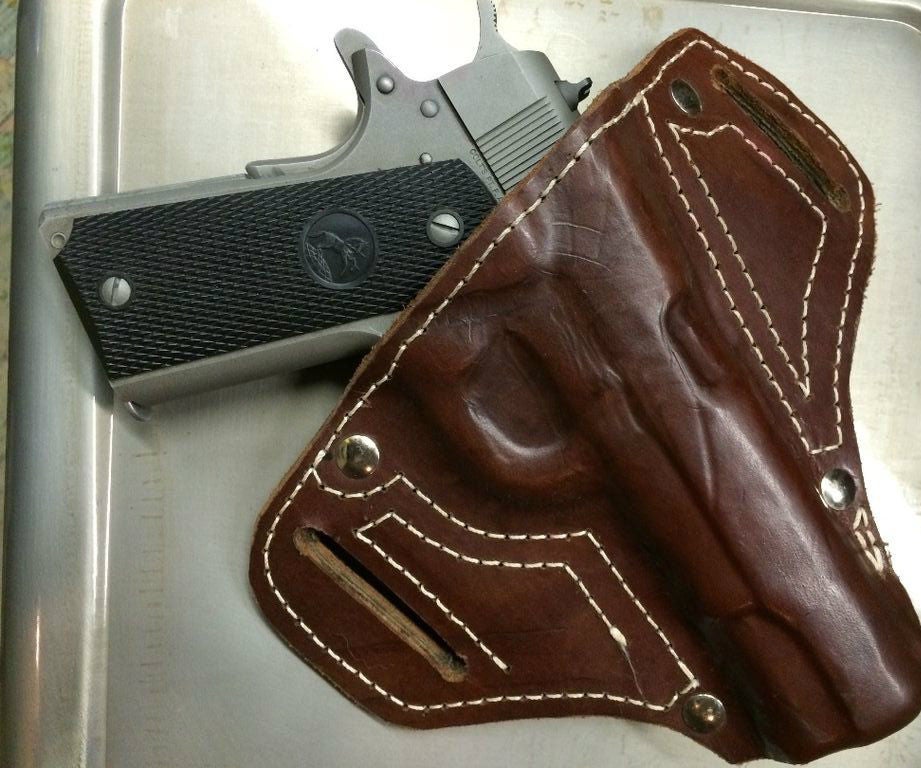

What Are the Characteristics of Fitted Leather Holsters?

Fitted leather holsters are designed specifically for individual firearms, providing a snug fit that enhances retention and accessibility. These holsters are typically vacuum-formed, ensuring that the leather contours precisely to the shape of the firearm. This type is particularly suitable for B2B buyers in law enforcement or custom firearm accessory sectors, where functionality and security are paramount. Buyers should consider the time and labor involved in producing these holsters, as the custom fitting process can extend lead times.

How Do Western Leather Holsters Stand Out?

Western leather holsters are characterized by their open-top design and often decorative elements, making them ideal for revolvers used in cowboy action shooting or reenactments. They prioritize style and ease of access, appealing to B2B buyers looking for unique, themed products. However, while they offer a classic aesthetic, their less secure fit may not be suitable for all applications, particularly in high-stakes environments.

Illustrative image related to how to make a leather holster

Why Choose OWB Holsters for Tactical Applications?

Outside Waistband (OWB) holsters are worn externally, allowing for quick and easy access to the firearm. They are versatile and can accommodate various attachment methods, which is advantageous for tactical applications. B2B buyers focusing on personal defense or tactical gear may find OWB holsters appealing due to their accessibility. However, they may sacrifice some concealment, making them less suitable for discreet carry situations.

What Makes IWB Holsters Ideal for Concealed Carry?

Inside Waistband (IWB) holsters are designed for concealed carry, sitting within the waistband for maximum discretion. This type is favored by personal defense professionals and law enforcement due to its ability to conceal the firearm effectively. B2B buyers should consider the comfort factor, as IWB holsters can be less comfortable for extended wear, necessitating the selection of high-quality materials and ergonomic designs.

How Do Cross-Draw Holsters Enhance Accessibility?

Cross-draw holsters are positioned to allow the user to draw the firearm across their body, often angled for quick access. This design is particularly useful in tactical situations or for individuals who may be seated, such as horseback riders. B2B buyers looking for unique holster solutions may find cross-draw holsters beneficial, although they may require custom designs to meet specific needs.

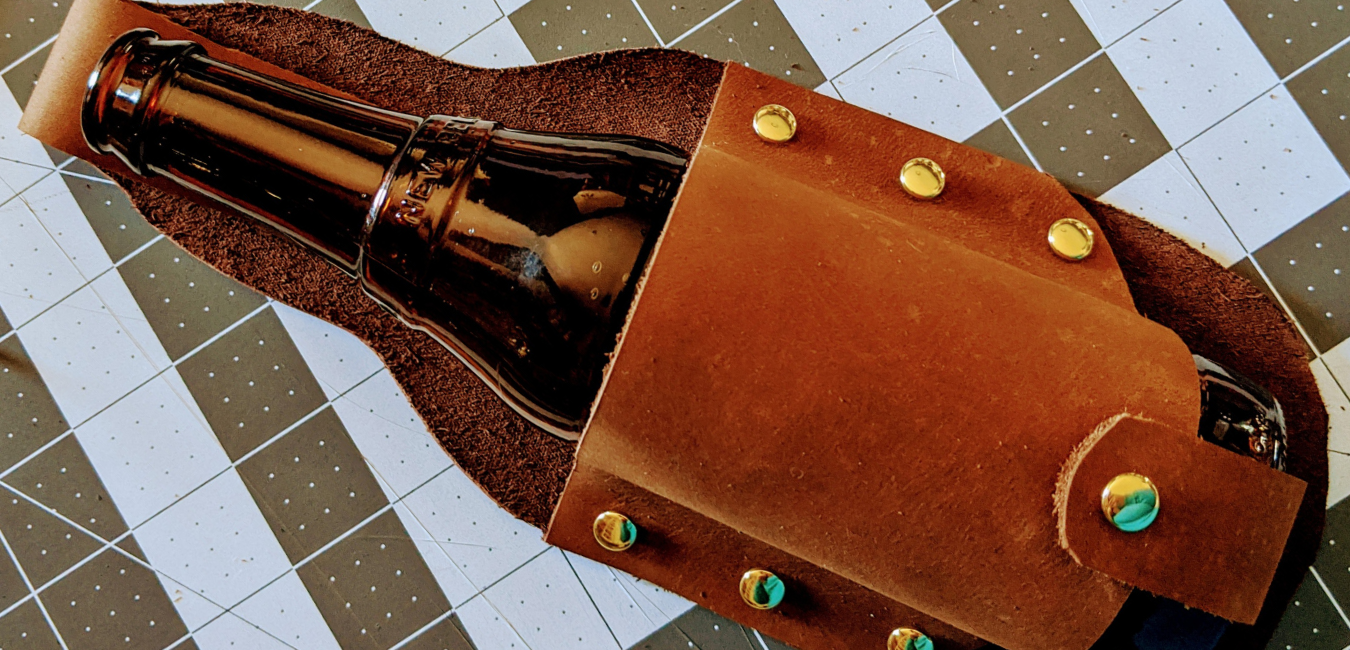

Illustrative image related to how to make a leather holster

Key Industrial Applications of how to make a leather holster

| Industry/Sector | Specific Application of how to make a leather holster | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Custom holsters for firearms used by officers | Enhanced officer safety and accessibility of equipment | Quality leather, local regulations, customization options |

| Outdoor Recreation | Holsters for hunting and outdoor activities | Durable, weather-resistant gear for outdoor enthusiasts | Material sourcing, weight considerations, design variations |

| Military | Tactical holsters for soldiers | Reliability in combat situations and ease of access | Compliance with military standards, durability requirements |

| Retail (Leather Goods) | Production of leather holsters for sale | Expanding product range and attracting niche markets | Sourcing sustainable leather, craftsmanship quality |

| Security Services | Holsters for personal protection and security personnel | Improved accessibility and security for personnel | Customization needs, local regulations, material quality |

How is ‘how to make a leather holster’ applied in law enforcement?

In law enforcement, custom leather holsters are essential for carrying firearms securely and comfortably. Officers require holsters that allow for quick access while ensuring the weapon is safely stored. These holsters must be made from high-quality leather to withstand daily wear and tear, and they often require specific designs to accommodate various firearms. For international buyers, understanding local regulations regarding firearm carrying and holster specifications is crucial to ensure compliance and functionality.

What are the applications for leather holsters in outdoor recreation?

In the outdoor recreation sector, leather holsters are crafted for hunting and adventure activities, providing a robust solution for carrying firearms or tools. These holsters must be weather-resistant and durable, as they are often exposed to harsh conditions. Buyers from regions like Africa and South America may seek holsters that blend functionality with aesthetic appeal, ensuring that the product meets both practical and cultural expectations. Sourcing materials that can withstand environmental challenges is a key consideration.

How do military applications utilize leather holsters?

Military personnel rely on tactical leather holsters for their firearms, which are designed for both reliability and rapid accessibility in high-pressure situations. These holsters must meet stringent military standards, emphasizing durability and performance under stress. International B2B buyers in this sector should prioritize suppliers who understand the specific military requirements and can provide products that can withstand combat conditions while offering customization to fit various weapon types.

In what ways do retail businesses benefit from leather holster production?

Retailers specializing in leather goods can expand their product offerings by including high-quality leather holsters. This not only attracts a niche market interested in firearms accessories but also enhances the overall brand reputation for craftsmanship and quality. Buyers should consider sourcing sustainable materials and skilled artisans to ensure that the holsters meet customer expectations for both functionality and aesthetic appeal. Understanding market trends and consumer preferences in different regions can significantly impact sales.

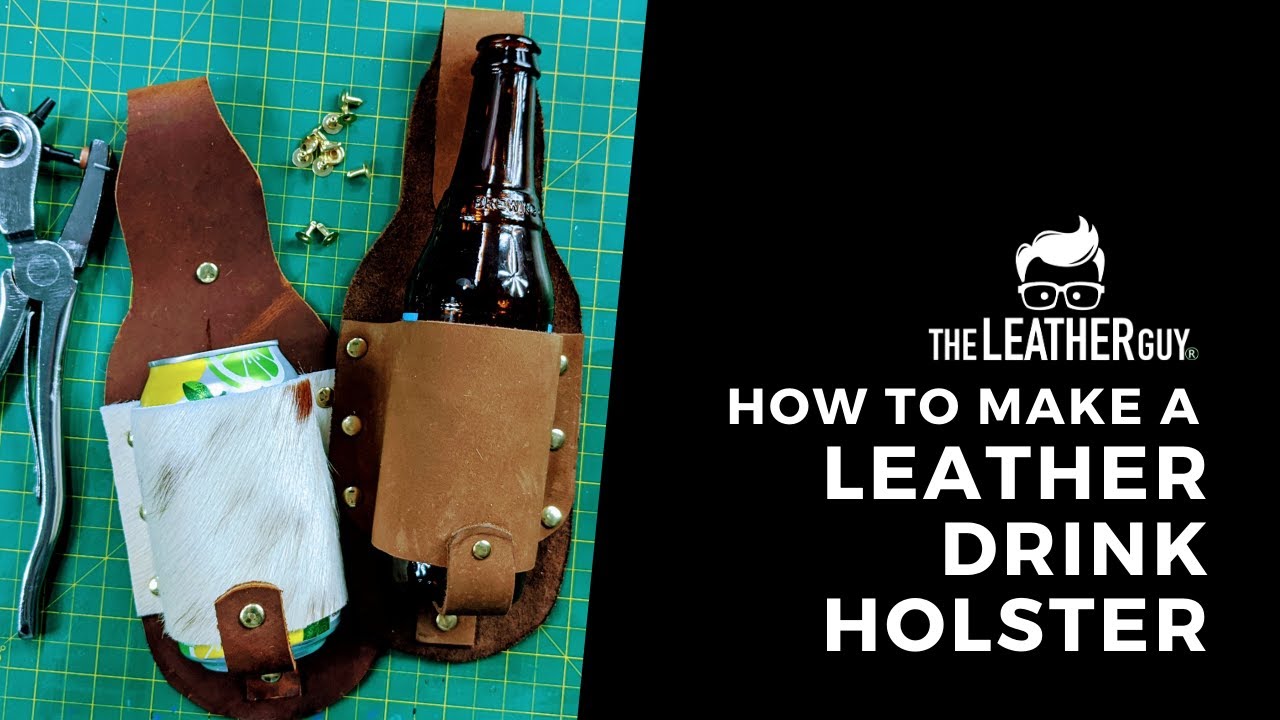

Illustrative image related to how to make a leather holster

What role do leather holsters play in security services?

In the security sector, leather holsters are crucial for personnel who require immediate access to their firearms or tools while maintaining a professional appearance. These holsters enhance both security and accessibility, allowing security personnel to perform their duties effectively. Buyers need to consider customization options that align with their operational needs, as well as compliance with local regulations governing the use of such equipment. Quality and comfort are paramount to ensure that personnel can operate efficiently in various environments.

3 Common User Pain Points for ‘how to make a leather holster’ & Their Solutions

Scenario 1: Misalignment in Holster Design and User Needs

The Problem: B2B buyers, especially those in the law enforcement or security sectors, often face the challenge of creating leather holsters that cater to specific firearm models and user preferences. A poorly designed holster can lead to discomfort, lack of accessibility, and even safety issues. This is particularly critical in regions where individuals may require specialized holsters for non-standard firearm sizes or shapes, leading to a mismatch between the holster and the weapon it is intended to carry.

The Solution: To address this issue, buyers should invest in a comprehensive needs assessment before commencing the holster-making process. This includes gathering detailed specifications of the firearms intended for use, such as dimensions, weight, and any additional accessories. Engaging directly with end-users through surveys or interviews can provide insights into their preferences regarding holster features, such as retention methods or draw angles. Once the requirements are clear, leveraging advanced CAD (Computer-Aided Design) software can aid in creating precise templates. This approach ensures that the final product is tailored to the user’s needs, enhancing both comfort and usability. Additionally, prototyping with less expensive materials can allow for testing and adjustments before committing to the final leather product.

Scenario 2: Inconsistent Leather Quality Affecting Durability

The Problem: For B2B buyers sourcing leather for holsters, inconsistency in leather quality can lead to products that wear out quickly or fail to provide adequate protection for the firearm. This is particularly pertinent in international markets where the quality of leather can vary significantly based on local suppliers. Buyers might find themselves dealing with a high return rate or dissatisfied customers due to the leather degrading faster than expected, which can harm their business reputation and profitability.

Illustrative image related to how to make a leather holster

The Solution: Establishing strong relationships with reputable leather suppliers is essential. Buyers should prioritize sourcing leather from well-known manufacturers who provide transparency regarding their tanning processes and material specifications. It’s advisable to request samples from multiple suppliers and perform physical tests, such as abrasion resistance and flexibility assessments, to ensure durability. Additionally, opting for full-grain vegetable-tanned leather, known for its strength and aging characteristics, can provide a reliable option. Buyers should also consider implementing a quality assurance process that includes regular inspections of incoming leather shipments to ensure they meet established standards. This proactive approach can mitigate the risk of quality issues, fostering customer trust and satisfaction.

Scenario 3: Skill Gaps in Leather Crafting Techniques

The Problem: Many B2B buyers may encounter difficulties in finding skilled artisans who can execute the intricate techniques required to create high-quality leather holsters. As the demand for custom leather goods increases, there may be a shortage of craftsmen who are proficient in advanced leatherworking skills, such as stitching, edge finishing, and molding. This skill gap can lead to inconsistent product quality and longer lead times, ultimately affecting customer satisfaction and business operations.

The Solution: To bridge the skill gap, buyers should consider investing in training programs for their workforce. This can involve partnering with local leatherworking schools or offering workshops led by experienced artisans. Additionally, documenting standard operating procedures (SOPs) for each step of the holster-making process can serve as a valuable training resource for new employees. Encouraging a culture of continuous learning and craftsmanship can also motivate existing staff to refine their skills. Furthermore, utilizing online resources, such as video tutorials and leatherworking forums, can provide ongoing education and inspiration for artisans. By prioritizing skill development, businesses can enhance the quality of their products and foster a strong, competent workforce capable of meeting market demands.

Strategic Material Selection Guide for how to make a leather holster

What Are the Key Properties of Common Leather Materials for Holster Manufacturing?

When selecting materials for leather holster production, several options are commonly considered. Each material has distinct properties and implications for performance, durability, and cost. Here’s a detailed analysis of four prevalent leather types used in holster manufacturing.

How Does Full-Grain Leather Perform in Holster Applications?

Full-grain leather is the highest quality leather available, characterized by its natural surface and durability. It is resistant to wear and tear, making it an ideal choice for holsters that require longevity and strength. The material can withstand significant pressure and provides excellent abrasion resistance.

Pros: The primary advantage of full-grain leather is its durability and ability to develop a unique patina over time, enhancing its aesthetic appeal. It also offers superior breathability, which is crucial for comfort when worn against the skin.

Cons: The cost of full-grain leather is relatively high, which may impact production budgets. Additionally, it requires skilled craftsmanship to work with, increasing manufacturing complexity.

Impact on Application: Full-grain leather is compatible with various climates, maintaining its integrity in both humid and dry environments.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, especially regarding leather sourcing and tanning processes. Buyers in regions like Africa and South America may also face challenges related to import tariffs and local regulations.

Illustrative image related to how to make a leather holster

What Are the Benefits of Top-Grain Leather for Holster Production?

Top-grain leather, while slightly less durable than full-grain, is still a popular choice for holsters. It has been sanded and finished to remove imperfections, resulting in a smoother surface.

Pros: Top-grain leather is more affordable than full-grain, making it accessible for mass production. It also offers a good balance of durability and aesthetics, appealing to a broad market.

Cons: The sanding process can reduce its natural strength, making it less resistant to wear over time compared to full-grain leather.

Impact on Application: This type of leather is suitable for everyday use but may not withstand extreme conditions as effectively as full-grain leather.

Considerations for International Buyers: Buyers should ensure that top-grain leather meets local quality standards, as preferences for leather quality can vary significantly across regions, particularly in Europe and the Middle East.

How Does Vegetable-Tanned Leather Compare to Other Options?

Vegetable-tanned leather is made using natural tannins from plant sources, resulting in a more environmentally friendly option. This leather is known for its rigidity and ability to hold shape, making it suitable for holsters.

Pros: One of the significant advantages of vegetable-tanned leather is its eco-friendliness and the ability to be dyed easily, allowing for customization. It also develops a rich character over time.

Cons: The rigidity can be a drawback for comfort, especially in hot climates. Additionally, it may require more maintenance to prevent drying out.

Illustrative image related to how to make a leather holster

Impact on Application: Vegetable-tanned leather performs well in moderate climates but may not be suitable for extreme conditions without proper care.

Considerations for International Buyers: Compliance with environmental regulations is crucial, especially in regions with stringent laws regarding chemical use. Buyers should also consider the availability of vegetable-tanned leather in their local markets.

Why Choose Suede Leather for Holster Manufacturing?

Suede leather, made from the underside of the hide, offers a soft texture and unique appearance. While not as durable as other leather types, it can be used for specific holster designs.

Pros: Suede provides a comfortable fit against the skin and can be more affordable than other leather types. It also allows for creative designs due to its versatility.

Cons: The primary disadvantage is its susceptibility to staining and wear, which may limit its longevity in holster applications.

Illustrative image related to how to make a leather holster

Impact on Application: Suede is best suited for lighter use and may not hold up under heavy-duty conditions.

Considerations for International Buyers: Buyers should be aware of the maintenance requirements for suede, especially in humid regions, and ensure that their suppliers can provide high-quality materials.

Summary of Material Selection for Leather Holsters

| Material | Typical Use Case for how to make a leather holster | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end, durable holsters for everyday use | Exceptional durability and aesthetics | Higher cost and manufacturing complexity | High |

| Top-Grain Leather | Versatile holsters for mass production | Affordable with good aesthetics | Less durable than full-grain | Medium |

| Vegetable-Tanned Leather | Eco-friendly holsters with customization options | Environmentally friendly and dyeable | Rigid and requires maintenance | Medium |

| Suede Leather | Lightweight, casual holsters | Comfortable and versatile | Susceptible to stains and wear | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions in leather holster manufacturing. By understanding the properties, advantages, and limitations of each material, businesses can better align their production processes with market demands and regional preferences.

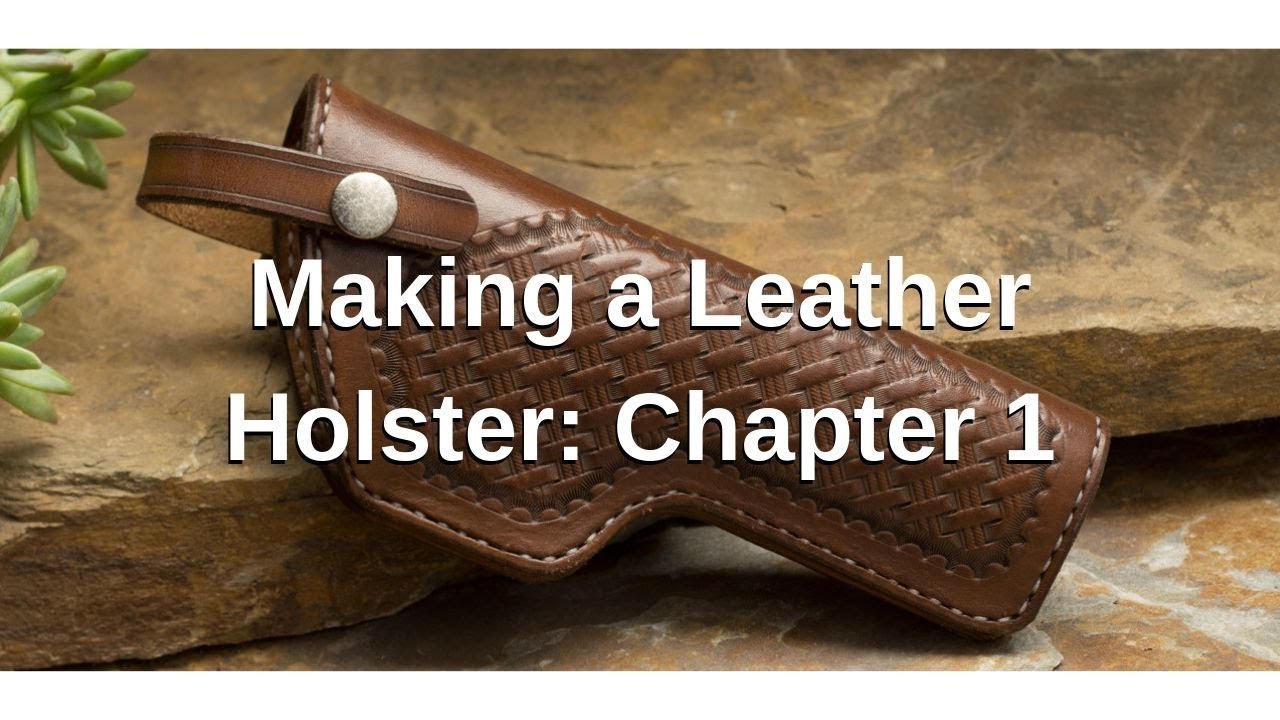

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather holster

What are the Main Stages of Manufacturing a Leather Holster?

Manufacturing a leather holster involves several critical stages, each contributing to the final product’s quality and functionality. Understanding these stages can help B2B buyers assess suppliers’ capabilities and ensure they receive high-quality products.

Material Preparation: What Materials Are Essential for Leather Holster Production?

The first step in the manufacturing process is the careful selection and preparation of materials. High-quality leather, typically full-grain vegetable-tanned leather, is preferred for its durability and aesthetic appeal. The thickness of the leather is crucial; a range of 8 to 10 ounces is common, providing enough rigidity while still allowing for some flexibility.

Once the leather is selected, it undergoes several preparatory steps. This includes cutting the leather into appropriate shapes and sizes, which can be done using sharp scissors or specialized leather shears. Additionally, any necessary treatments, such as soaking the leather to facilitate forming, are applied. For instance, soaking with water is recommended over alcohol to avoid drying out the leather.

How is Leather Forming Achieved in Holster Manufacturing?

Forming is a pivotal stage in creating a fitted leather holster. After cutting the leather pieces, they are soaked (preferably in water) and then shaped around the firearm using a vacuum bag or mold. This process requires careful attention to detail to ensure that the holster fits snugly around the specific gun model.

To achieve a precise fit, manufacturers often utilize a deer antler or similar tool to press the leather around the firearm, ensuring all contours and details are accurately captured. Once the leather has dried and set in the desired shape, it is ready for assembly.

What Techniques Are Used During the Assembly of Leather Holsters?

The assembly stage involves joining the formed leather pieces together. This is typically done using a strong adhesive, such as Barge Cement, ensuring that the two halves align perfectly. Clamps may be employed during the curing process to maintain alignment and integrity.

After the adhesive has set, the next step is to outline the holster’s final shape, including belt loops and stitching lines. Precision is key; manufacturers often use a leather stitching groover to create channels for stitching, ensuring a neat and durable finish. The stitching process itself may involve using a sewing machine or hand-stitching techniques, with waxed thread for added strength.

What Finishing Techniques Enhance the Quality of Leather Holsters?

Finishing is the final stage in holster manufacturing, where the product is prepared for sale. This includes sanding the edges for a smooth finish and applying conditioners like Neatsfoot oil to enhance the leather’s appearance and longevity. Dyes may also be applied to achieve the desired color, although natural aging will affect the leather’s hue over time.

Illustrative image related to how to make a leather holster

Quality finishing not only improves the aesthetic appeal of the holster but also contributes to its durability. Properly finished leather is more resistant to wear and environmental factors, making it a preferable choice for end-users.

What Quality Assurance Practices Should B2B Buyers Expect in Leather Holster Manufacturing?

Quality assurance (QA) is an essential component of leather holster manufacturing, ensuring that the final product meets international standards and customer expectations. For B2B buyers, understanding these practices is crucial for supplier evaluation.

Which International Standards Are Relevant for Leather Holster Manufacturing?

International standards such as ISO 9001 provide a framework for quality management systems, ensuring consistent product quality and customer satisfaction. Adherence to such standards indicates that a manufacturer has established processes for continuous improvement and quality control.

Additionally, industry-specific certifications may be relevant, such as CE marking for products sold in the European market or API standards for certain firearm accessories. Buyers should inquire about these certifications to ensure compliance with regional regulations and market requirements.

Illustrative image related to how to make a leather holster

What Are the Key Quality Control Checkpoints in Leather Holster Production?

Quality control (QC) involves several checkpoints throughout the manufacturing process. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards for quality and consistency.

-

In-Process Quality Control (IPQC): During production, random samples may be tested to monitor adherence to manufacturing specifications. This could include checking the dimensions of cut leather pieces or the strength of adhesive bonds.

-

Final Quality Control (FQC): Before shipping, finished holsters undergo a final inspection to verify overall quality, including stitching integrity, finish quality, and fit.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take a proactive approach in verifying supplier quality control practices. This can include:

-

Audits: Conducting on-site audits can provide insight into a manufacturer’s processes and adherence to quality standards.

-

Quality Reports: Requesting documentation of quality control measures, including test results and compliance certifications, can help assess a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes and product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in leather holster manufacturing is vital. Variations in local regulations, market expectations, and material availability can impact product quality.

Buyers should be aware of regional certifications and standards that may differ from international norms. Additionally, establishing strong communication with suppliers regarding quality expectations and any specific regional requirements can facilitate smoother transactions and ensure product quality.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for leather holsters is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control measures, buyers can make informed decisions and ensure they partner with reputable manufacturers.

Illustrative image related to how to make a leather holster

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather holster’

In the competitive landscape of leather goods manufacturing, creating high-quality leather holsters requires meticulous planning and sourcing. This guide aims to provide B2B buyers with a practical checklist to effectively procure the necessary materials and tools for making leather holsters. By following these steps, you can ensure that your production meets industry standards while maximizing quality and efficiency.

Step 1: Identify Your Target Market

Understanding your target market is crucial for tailoring your holster designs and materials. Research the specific needs of customers in regions like Africa, South America, the Middle East, and Europe, considering factors such as local regulations, preferences, and climate conditions. This knowledge will help you select the right leather types and designs that resonate with your audience.

Step 2: Determine Leather Specifications

Choosing the right leather is fundamental to the quality of your holsters. Look for full-grain vegetable-tanned leather, typically in the range of 8-10 oz thickness, as it offers durability and a premium feel. Ensure that the leather is sourced from reputable suppliers who can provide details about tanning processes and environmental compliance.

Step 3: Source Quality Tools and Equipment

Investing in high-quality tools is essential for precision in leatherwork. Compile a list of necessary tools such as leather shears, stitching needles, and mallets, ensuring they meet industry standards for durability and performance. Consider suppliers who offer tool kits tailored for leather crafting, which can streamline your procurement process.

Illustrative image related to how to make a leather holster

Step 4: Evaluate Supplier Certifications

Before finalizing suppliers, verify their certifications and compliance with international standards. Look for ISO certifications or other relevant quality assurance measures that demonstrate their commitment to quality and sustainability. This step mitigates risks associated with subpar materials and ensures reliable supply chains.

Step 5: Request Samples for Quality Assessment

Always request samples before placing bulk orders. This allows you to evaluate the leather’s texture, weight, and finish, ensuring it meets your specifications. Assess the samples against your criteria for durability and aesthetic appeal, as these factors significantly impact customer satisfaction.

Step 6: Negotiate Pricing and Terms

Once you identify potential suppliers, engage in negotiations to secure favorable pricing and terms. Discuss bulk purchase discounts, payment terms, and delivery schedules to optimize your supply chain logistics. Establishing clear agreements can lead to long-term partnerships and cost savings.

Illustrative image related to how to make a leather holster

Step 7: Plan for Sustainable Practices

In today’s market, sustainability is a key consideration. When sourcing leather and materials, inquire about eco-friendly practices and ethical sourcing from suppliers. Implementing sustainable practices can enhance your brand’s reputation and appeal to environmentally conscious consumers.

By following this step-by-step checklist, B2B buyers can effectively procure the necessary resources for producing high-quality leather holsters, ensuring that they meet market demands while maintaining excellence in craftsmanship.

Comprehensive Cost and Pricing Analysis for how to make a leather holster Sourcing

What Are the Key Cost Components in Sourcing Leather Holsters?

When analyzing the cost structure for sourcing leather holsters, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Illustrative image related to how to make a leather holster

Materials represent a significant portion of the total cost. High-quality leather, such as full-grain vegetable-tanned leather, typically weighs between 8-10 oz and can vary in price based on thickness and treatment. Additional materials like thread, adhesives, and finishing products also contribute to the overall expense.

Labor costs will depend on the complexity of the holster design and the skill level required for assembly. Skilled artisans will command higher wages, especially in regions where craftsmanship is valued, affecting the pricing structure.

Manufacturing overhead includes expenses related to the facility, utilities, and general administrative costs associated with production. This can vary significantly depending on the location of the manufacturing plant, impacting both labor and overhead costs.

Tooling costs are incurred for the equipment needed to produce the holsters, such as cutting tools, sewing machines, and stamping dies. Investing in durable and efficient machinery can optimize production but may require a higher upfront cost.

Quality control (QC) is essential in ensuring that the final product meets industry standards. This process might involve inspections, testing, and certification, which can add to the overall cost.

Illustrative image related to how to make a leather holster

Logistics also play a crucial role, particularly for international transactions. Transportation, customs duties, and insurance must be factored into the total cost, especially for buyers in Africa, South America, the Middle East, and Europe.

Margin is the profit that manufacturers add to the cost of production. This can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Leather Holster Sourcing?

Several factors can influence pricing in the leather holster market. Volume and minimum order quantity (MOQ) are critical; bulk orders often result in lower per-unit costs. Buyers should negotiate MOQs that align with their purchasing capabilities to optimize costs.

Specifications and customization also affect pricing. Customized holsters with specific designs or features may incur additional costs due to increased labor and material requirements. Therefore, understanding the balance between customization and cost is essential.

Material quality and certifications can significantly impact pricing. Premium materials and certified sustainable practices may command higher prices but offer better durability and consumer appeal. Buyers should evaluate the long-term benefits of investing in quality materials against upfront costs.

Supplier factors such as location, reputation, and reliability can also influence pricing. Suppliers in regions with established leather industries may provide better pricing due to economies of scale. Establishing strong relationships with suppliers can lead to favorable terms and reduced costs.

Incoterms can complicate pricing further, as they define the responsibilities of buyers and sellers in international shipping. Buyers should be familiar with Incoterms to avoid unexpected costs related to shipping, customs, and insurance.

Illustrative image related to how to make a leather holster

What Tips Can Help Buyers Negotiate Better Prices for Leather Holsters?

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes.

Negotiation is key; establishing a rapport with suppliers can lead to better pricing and terms. Buyers should articulate their needs clearly and be willing to discuss potential bulk orders or long-term partnerships to leverage better pricing.

Cost-efficiency can be achieved by analyzing the Total Cost of Ownership (TCO). This includes not only the purchase price but also factors like maintenance, durability, and potential resale value. Understanding TCO can guide buyers in selecting suppliers that provide the best overall value.

Pricing nuances specific to international buyers should also be considered. Factors like currency fluctuations, import duties, and local market conditions can affect final costs. Buyers should conduct thorough market research and consider hedging against currency risk when sourcing internationally.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct thorough due diligence and seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing how to make a leather holster With Other Solutions

Exploring Alternatives to Making a Leather Holster

When considering the creation of a leather holster, it is essential to evaluate various alternatives that can provide similar functionality or aesthetic appeal. This analysis will compare traditional leather holster making with two other viable methods: Kydex holster production and the use of fabric holsters. Each alternative presents unique advantages and challenges, making it important for B2B buyers to carefully assess their specific needs.

| Comparison Aspect | How To Make A Leather Holster | Kydex Holster Production | Fabric Holster Production |

|---|---|---|---|

| Performance | High durability and aesthetic appeal | Excellent retention and water resistance | Moderate durability, lightweight |

| Cost | Moderate (materials and tools) | Moderate to high (specialized materials) | Low (inexpensive fabrics) |

| Ease of Implementation | Requires craftsmanship and tools | Requires specialized equipment | Easy, minimal tools needed |

| Maintenance | Requires conditioning and care | Low maintenance, durable | Moderate; prone to wear and tear |

| Best Use Case | Fashionable, custom-fit holsters for collectors | Tactical and competitive shooting | Casual use or light-duty applications |

Detailed Breakdown of Alternatives

Kydex Holster Production

Kydex holsters are made from a thermoplastic material known for its durability and excellent retention. They are particularly favored in tactical and competitive shooting contexts due to their ability to securely hold firearms while remaining lightweight. The production process involves heating Kydex sheets, forming them around a mold, and then cooling them to create a rigid structure. While Kydex holsters require less maintenance than leather, they can be more expensive due to the need for specialized equipment. Additionally, they lack the traditional aesthetic appeal of leather, making them less desirable for collectors or those seeking a classic look.

Fabric Holster Production

Fabric holsters, often made from materials like nylon or canvas, provide a lightweight and cost-effective solution for carrying firearms. They are generally easier to produce, requiring minimal tools and sewing skills, making them accessible for beginners or those seeking quick solutions. However, fabric holsters typically offer moderate durability and may not provide the same level of firearm retention as leather or Kydex options. They are best suited for casual use, such as everyday carry or light-duty applications, but may not withstand rigorous environments as well as their leather or Kydex counterparts.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate method for holster production, B2B buyers should consider factors such as the intended use, budget constraints, and desired aesthetic. Leather holsters are ideal for those prioritizing craftsmanship and traditional appeal, while Kydex is better suited for tactical applications requiring durability and retention. Fabric holsters can serve well for lightweight, casual use at a lower cost. Ultimately, understanding the specific needs of your target market will guide you in choosing the most effective solution for holster production.

Illustrative image related to how to make a leather holster

Essential Technical Properties and Trade Terminology for how to make a leather holster

What Are the Essential Technical Properties for Making a Leather Holster?

When creating a leather holster, understanding the essential technical properties is crucial for ensuring product quality and meeting customer expectations. Here are several key specifications that should be considered:

-

Material Grade

The grade of leather used significantly impacts the durability and appearance of the holster. Full-grain vegetable-tanned leather, typically ranging from 8 to 10 oz in thickness, is preferred for its strength and natural aesthetic. This type of leather ages well and develops a unique patina, making it highly desirable for both functional and aesthetic purposes. -

Tolerance

Tolerance refers to the allowable deviation in measurements during the cutting and assembling processes. For holsters, maintaining tight tolerances (±1/16 inch) ensures a snug fit for the firearm, enhancing safety and usability. Poor tolerances can lead to ill-fitting holsters that may compromise the weapon’s retention and accessibility. -

Stitching Strength

The stitching used in the assembly of the holster must withstand significant stress. A minimum of 5 stitches per inch is recommended, using waxed thread for durability. The stitching technique—such as saddle stitching—provides additional strength compared to machine sewing, making it essential for high-quality production. -

Finish Type

The finish applied to the leather affects both its appearance and longevity. Common finishes include oil-based treatments like Neatsfoot oil, which moisturizes and darkens the leather, and waxes that add water resistance. Selecting the appropriate finish is critical for meeting customer preferences and ensuring the holster withstands environmental factors. -

Edge Treatment

Proper edge treatment techniques, such as burnishing and beveling, are essential for aesthetics and durability. Smooth edges reduce wear over time and enhance the overall look of the holster. In B2B contexts, attention to edge quality can differentiate a supplier’s products in a competitive market. -

Weight Capacity

The holster must be designed to accommodate the specific weight of the firearm it is intended for. Understanding the weight capacity helps manufacturers ensure that the holster provides adequate support without sagging or losing shape over time. This is particularly important for B2B buyers who cater to law enforcement or military clients with specific gear requirements.

What Are Common Trade Terms in Leather Holster Manufacturing?

Familiarity with industry terminology is essential for effective communication and transaction management in the leather holster manufacturing sector. Here are several common trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For holster production, an OEM may provide leather components or tools essential for the assembly of holsters. -

MOQ (Minimum Order Quantity)

MOQ specifies the lowest number of units that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to ensure they meet supplier requirements while aligning with their inventory needs. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing and other information from suppliers for specific products. For holster manufacturers, submitting an RFQ can help in comparing costs and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risk transfer, and insurance obligations. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. It is a critical factor for businesses that rely on timely delivery to meet customer demands and maintain inventory levels. -

Customs Duties

These are tariffs imposed on goods when they are transported across international borders. Understanding customs duties is important for B2B buyers to accurately calculate total costs when importing leather holsters from other countries.

In summary, grasping the technical properties and trade terminology associated with leather holster manufacturing is essential for B2B buyers. This knowledge not only aids in selecting high-quality products but also facilitates smoother transactions and partnerships in the global marketplace.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather holster Sector

What Are the Current Market Dynamics and Key Trends in the Leather Holster Sector?

The leather holster market is experiencing a notable transformation, influenced by global drivers such as increasing firearm ownership and rising interest in outdoor activities. This sector is expanding rapidly, particularly in regions like Africa, South America, the Middle East, and Europe, where cultural and legal factors are encouraging the purchase of both firearms and their accessories. Additionally, the rise of e-commerce platforms is facilitating access to diverse leather holster designs and materials, allowing international B2B buyers to source products more efficiently.

Illustrative image related to how to make a leather holster

Emerging technologies are reshaping the leather crafting process, including the adoption of laser cutting and 3D modeling, which enable manufacturers to achieve higher precision and customization in their products. Furthermore, digital supply chain management tools are streamlining sourcing and inventory processes, enhancing the overall efficiency for B2B buyers. As the market matures, buyers are increasingly looking for suppliers that offer innovative designs, durability, and a variety of customization options to cater to specific needs.

Another significant trend is the growing consumer preference for handmade and artisanal products, which reflects a desire for quality and craftsmanship. This trend is particularly pronounced in Europe and the Middle East, where traditional leatherworking techniques are highly valued. B2B buyers are encouraged to stay abreast of these trends to align their sourcing strategies with evolving consumer preferences.

How Is Sustainability and Ethical Sourcing Impacting the Leather Holster Industry?

Sustainability and ethical sourcing have become paramount concerns in the leather industry, including the leather holster sector. The environmental impact of leather production, particularly from conventional tanning processes, has led to increased scrutiny and demand for more sustainable practices. International B2B buyers are increasingly seeking suppliers who prioritize eco-friendly methods, such as vegetable tanning, which uses natural materials and reduces harmful chemicals in the production process.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are now more aware of labor practices and the conditions under which leather products are made. Certifications such as the Leather Working Group (LWG) and Fair Trade can serve as indicators of responsible sourcing. By partnering with suppliers who uphold these standards, businesses not only meet regulatory requirements but also enhance their brand image and appeal to ethically conscious consumers.

Illustrative image related to how to make a leather holster

In addition to ethical sourcing, the use of ‘green’ materials, such as recycled leather and biodegradable alternatives, is gaining traction. B2B buyers should explore these options to not only satisfy regulatory compliance but also to cater to a growing market segment that values sustainability. Adopting sustainable practices can lead to long-term cost savings and improved customer loyalty, providing a competitive edge in the marketplace.

What Is the Evolution and History of Leather Holster Making?

The craft of leather holster making has deep historical roots, tracing back to the early days of firearms. Initially, holsters were simple leather pouches designed for functionality rather than aesthetics. Over time, as firearms became more advanced and varied, so did the designs and techniques used in holster making. The introduction of various leather types and tanning processes allowed artisans to create more durable and aesthetically pleasing products.

In the 19th century, the rise of Western culture popularized decorative leather holsters, which showcased both craftsmanship and individuality. This period marked a shift towards customization, with consumers seeking unique designs that reflected personal style. As the 20th century progressed, the industrialization of leather production led to mass manufacturing, but the demand for handmade, artisanal products has seen a resurgence in recent years.

Today, leather holster making is a blend of traditional techniques and modern innovations, appealing to a diverse global market. B2B buyers can leverage this rich history and evolving craftsmanship to enhance their product offerings and connect with consumers who appreciate both quality and heritage. Understanding this evolution is crucial for buyers aiming to source products that resonate with contemporary values while honoring the craft’s storied past.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather holster

-

How do I choose the right leather for making a holster?

Selecting the right leather is crucial for durability and functionality. Full-grain vegetable-tanned leather is recommended, typically in the 8-10 oz thickness range. This type of leather offers excellent strength and forms well around the firearm. When sourcing leather, ensure it is sourced ethically and sustainably, considering local suppliers from regions like Africa or South America for unique textures and colors. Always request samples to assess quality before placing larger orders. -

What tools are essential for making a leather holster?

Basic tools include a cutting mat, sharp scissors or leather shears, a metal ruler, a cutting blade, and stitching supplies like waxed thread and needles. For more refined results, consider investing in a hole punch set, edge beveler, and burnishing tools. You can source these tools from local suppliers or international wholesalers specializing in leatherworking. Ensure that the tools you choose are compatible with the thickness and type of leather you plan to use. -

What is the minimum order quantity (MOQ) for leather holster materials?

Minimum order quantities can vary significantly among suppliers. For leather, MOQs may range from 10 to 100 square feet, depending on the supplier’s policies and the type of leather. When sourcing other materials, like hardware or tools, inquire about bulk purchasing options, as suppliers may offer better pricing for larger orders. Always clarify MOQs before proceeding with an order to ensure it aligns with your production needs. -

How can I ensure quality assurance when sourcing leather holster materials?

Quality assurance is vital in leather production. Always request detailed specifications and certifications from suppliers, including information on leather grades and tanning processes. Conduct audits or site visits when possible, especially for international suppliers. Additionally, consider establishing a quality control checklist for incoming materials to ensure they meet your standards before use in production. -

What customization options are available for leather holsters?

Customization options can include leather color, texture, stitching patterns, and hardware choices. Many suppliers offer personalized branding solutions, such as embossing or stamping logos on the holster. When discussing customization, ensure that the supplier can accommodate your specific requests and timelines. It’s beneficial to provide a clear design brief to avoid misunderstandings and ensure the final product meets your expectations. -

What payment terms should I expect when sourcing holster materials internationally?

Payment terms vary by supplier and region but typically include options like advance payment, partial payment before shipping, or payment upon delivery. It’s essential to negotiate terms that protect your investment and ensure a smooth transaction. Consider using secure payment methods like letters of credit or escrow services, particularly for larger orders or new suppliers. Always review the terms thoroughly to avoid any unexpected charges or conditions. -

How do I handle logistics and shipping for international orders of holster materials?

Logistics can be complex when sourcing internationally. Engage with suppliers that offer reliable shipping options and have experience with customs regulations in your country. Discuss lead times, shipping methods, and costs upfront to avoid surprises. Utilize freight forwarders or third-party logistics providers if needed, as they can streamline the shipping process and handle customs clearance efficiently. -

What are the common challenges faced when sourcing leather holster materials internationally?

Challenges may include language barriers, differing quality standards, and shipping delays. Additionally, navigating customs regulations can complicate the import process. To mitigate these challenges, establish clear communication with suppliers, ensure you understand their processes, and consider working with local agents who can assist with logistics and compliance. Building strong relationships with your suppliers can also help in addressing issues proactively.

Top 3 How To Make A Leather Holster Manufacturers & Suppliers List

1. Instructables – Fitted Leather Holster for Colt 1911

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Fitted Leather Holster for Colt Model 1911 .45 Caliber pistol; made from heavy weight leather (approximately 8 oz); formed using isopropyl alcohol (recommended to use water instead); assembly involves Barge Cement or E6000 glue; features belt loops for proper angle; stitched with a technique of over and under passes; finished with Chicago screws and chamfered edges; moisturized with Neatsfoot oil …

2. Leatherworker.net – Hand Stitching & Sewing Machines

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: 1) Hand stitching – relatively inexpensive method for leather holster making. 2) Machine sewing – relatively expensive method, with prices starting from $1000 USD for a basic hand-operated sewing machine and $2800 USD for a motorized sewing machine. Recommended sewing machines include: Juki DNU – 1541S, Juki DU – 1181N, Singer 29K – 71 (1949), Chinese Patcher (Tinkers Delight), Warlock TSC-441, Te…

3. Tandy Leather – Holster Design Video

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Holster Design Video, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how to make a leather holster

The process of crafting a leather holster is not only an art but also a strategic opportunity for B2B buyers looking to enhance their product offerings. Understanding the intricacies of leather selection, tooling, and assembly can significantly improve product quality and customer satisfaction. By sourcing high-grade materials, such as full-grain vegetable-tanned leather, businesses can ensure durability and aesthetic appeal, thereby increasing the perceived value of their products.

Moreover, leveraging local craftsmanship and establishing partnerships with skilled artisans can create unique selling propositions, especially in regions like Africa, South America, and the Middle East. This strategic sourcing approach fosters community engagement and supports sustainable practices, which resonate well with today’s conscious consumers.

As we look to the future, B2B buyers should embrace innovation in leatherworking techniques and sustainability practices. Investing in advanced tools and training can enhance production efficiency and product quality. We encourage international buyers to explore these opportunities and consider collaborations that not only elevate their product lines but also contribute positively to their communities. The journey of creating exceptional leather holsters begins with informed sourcing—take the next step today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.