Catalog

Material Insight: Faux Leather Suppliers

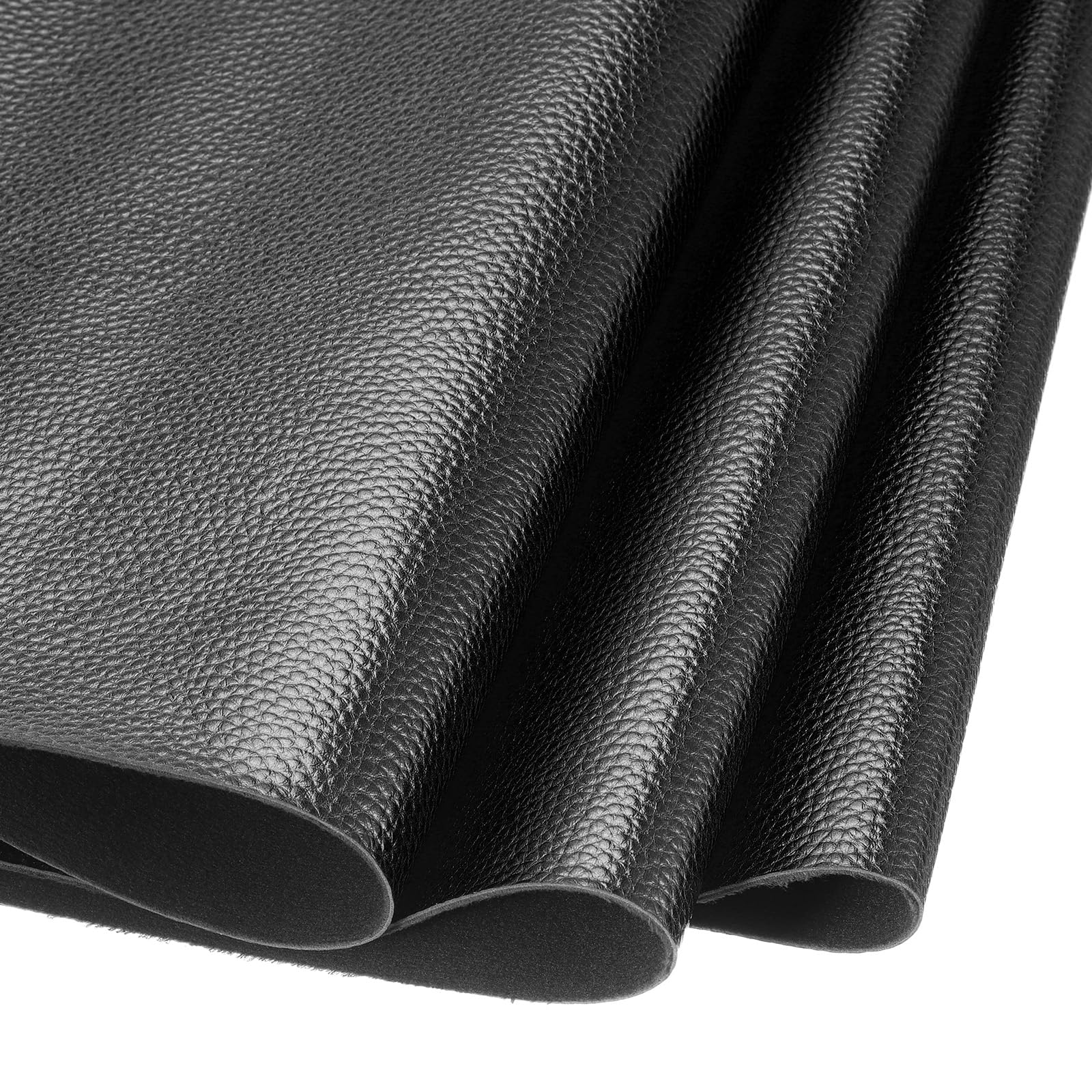

B2B Product Guide: Sourcing Premium Faux Leather Suppliers

Selecting the right faux leather supplier is a strategic decision for manufacturers seeking high-performance, sustainable materials. Faux leather—engineered to replicate the look, feel, and durability of genuine leather—delivers unmatched advantages for modern B2B applications. Unlike traditional leather, it offers consistent quality, reduced lead times, and full traceability, eliminating ethical and ecological concerns tied to animal agriculture. Its versatility supports rigorous design demands across fashion, automotive interiors, furniture, and upholstery, where customization, resilience, and compliance with global sustainability standards are non-negotiable.

Why Faux Leather is the Optimal Choice for Your Application

- Ethical & Eco-Compliant: Eliminates reliance on animal hides, aligning with ESG goals and regulations like REACH and OEKO-TEX®. Reduces water consumption, chemical runoff, and carbon footprint versus traditional tanning.

- Design Flexibility: Available in infinite textures, colors, and weights; easily thermoformed for complex 3D structures (e.g., car seats, ergonomic furniture).

- Performance Consistency: Uniform thickness and defect-free surfaces ensure predictable manufacturing output, minimizing waste and rework.

- Cost Efficiency: Stable pricing unaffected by livestock market volatility; lower total cost of ownership through streamlined processing and durability.

- Regulatory Resilience: Inherently meets fire retardancy (CAL 117, FMVSS 302), abrasion resistance, and phthalate-free requirements for global markets.

Introducing WINIW: Your Trusted Faux Leather Partner for 20+ Years

WINIW has pioneered sustainable synthetic leather solutions since 2003, serving leading brands in automotive, luxury goods, and contract furniture. Our expertise spans R&D, production, and circular innovation—delivering materials that balance uncompromising quality with planetary responsibility. We partner with forward-thinking manufacturers to solve complex material challenges through:

– Proprietary bio-based and recycled content formulations (up to 40% pre-consumer recycled PU).

– Closed-loop water systems and ISO 14001-certified manufacturing.

– Technical support from concept to量产, ensuring seamless integration into your supply chain.

Choose WINIW for materials engineered to elevate performance while advancing your sustainability roadmap—proven by 500+ global clients who trust our science-driven approach.

Technical Performance & Standards

B2B Product Guide: WINIW Faux Leather Solutions

WINIW is a leading innovator in synthetic leather manufacturing, delivering high-performance faux leather solutions tailored for global B2B clients across industries such as furniture, automotive, fashion, and accessories. Our commitment to advanced technology, sustainability, and quality assurance ensures that our products meet the rigorous demands of modern manufacturing while supporting cost-efficiency and environmental responsibility.

Backed by ISO9001-certified production processes and full REACH compliance, WINIW provides a competitive edge through durable, customizable, and ethically produced materials. As a trusted faux leather supplier, we combine technical excellence with flexible manufacturing capabilities to serve large-scale and niche market requirements alike.

Key Technical Advantages

-

Cost-Effective Production: WINIW’s optimized manufacturing processes reduce material waste and energy consumption, translating into lower unit costs without compromising quality. Our economies of scale and vertical integration allow for competitive pricing, especially for bulk orders.

-

Superior Durability: Engineered with high-tensile strength polyurethane (PU) and reinforced backing fabrics, WINIW’s faux leather resists abrasion, tearing, and UV degradation. Ideal for high-traffic applications, it maintains integrity and appearance over extended use.

-

Customizable Colors & Finishes: We offer full color-matching services (Pantone, RAL, or custom references) and a wide range of surface textures—from matte and glossy to embossed and soft-touch. Our digital color management system ensures consistency across production batches.

-

REACH Compliance: All WINIW products are rigorously tested to meet REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) standards, ensuring the absence of harmful substances. This supports safer end-products and facilitates market access in Europe and other regulated regions.

-

ISO9001-Certified Quality Management: Our production facilities are certified under ISO9001, guaranteeing standardized processes, continuous improvement, and traceability from raw material sourcing to finished goods. This ensures consistent product performance and reliability.

Technical Specifications

| Property | Specificatie |

|---|---|

| Material Composition | High-performance PU coating on polyester knit or woven backing |

| Thickness Range | 0.6 mm – 1.8 mm (customizable) |

| Weight | 280 – 450 g/m² (depending on thickness) |

| Tensile Strength | ≥ 80 N/5cm (warp), ≥ 70 N/5cm (weft) |

| Tear Strength | ≥ 30 N (ASTM D2263) |

| Color Fastness to Rubbing | ≥ Grade 4 (dry), ≥ Grade 3 (wet) |

| Light Fastness (UV) | ≥ 30 hours (Blue Wool Scale 5–6) |

| Abrasion Resistance | ≥ 50,000 cycles (Martindale) |

| REACH Compliant | Yes (SVHC-free) |

| ISO9001 Certified | Yes (Production & Quality Control) |

| Customization Options | Color, thickness, texture, roll width (1.37m, 1.45m, 1.50m) |

| Eco-Friendly Certifications | Available (upon request: Oeko-Tex, GRS) |

WINIW’s faux leather is engineered to outperform traditional materials while aligning with sustainable manufacturing goals. Our technical team works closely with B2B partners to deliver tailored solutions that meet exact performance, aesthetic, and regulatory needs—ensuring long-term value and supply chain reliability.

Why Choose Synthetic over Real Leather

Strategic Material Selection Guide: Synthetic Leather vs. Genuine Leather for Commercial Applications

Choosing between synthetic and genuine leather significantly impacts product lifecycle costs, sustainability compliance, and brand alignment with ESG goals. As a B2B partner focused on high-performance materials, WINIW provides engineered solutions that address the evolving demands of furniture, automotive, and consumer goods manufacturers. Below is a comparative analysis to inform strategic procurement decisions.

Core Comparison: Synthetic Leather (e.g., WINIW PU/PVC) vs. Genuine Leather

| Factor | Synthetic Leather (WINIW Standard) | Genuine Leather (Full-Grain, Commercial Grade) |

|---|---|---|

| Cost (USD/sq. yd) | $8.50 – $18.00 (volume-dependent) | $22.00 – $45.00+ (subject to hide variability) |

| Duurzaamheid | – Consistent thickness & performance – Resists fading, cracking, & staining (50,000+ double rubs) – Uniform yield (95%+ material utilization) |

– Natural grain variations affect strength – Prone to water damage & UV degradation – Lower yield (60-70% due to hide defects) |

| Eco-Friendliness | – 40% avg. recycled content (post-industrial) – Zero animal sourcing – 90% lower water usage vs. tanning – OEKO-TEX® certified options |

– High water consumption (15,000+ L/animal) – Chromium/tannin pollution risk – Carbon-intensive (16x higher emissions per kg) – Limited traceability |

Key Strategic Advantages of Premium Synthetic Leather for B2B

- Supply Chain Resilience: Predictable lead times (4-6 weeks) with no seasonal or geographic constraints, unlike hide market volatility.

- Design Flexibility: Custom textures, colors, and performance additives (e.g., antimicrobial, flame-retardant) without minimum order quantity penalties.

- Compliance Assurance: Meets global regulations (REACH, CPSIA) with full material disclosure—critical for EU Ecodesign Directive adherence.

- Waste Reduction: Precision cutting compatibility lowers scrap rates by 25-30% compared to irregular hide shapes.

Addressing Common Misconceptions

- “Synthetic = Low Quality”: Advanced PU formulations (e.g., WINIW’s EcoThane™) exceed genuine leather in abrasion resistance and dimensional stability for high-use applications.

- “Genuine Leather is More Sustainable”: Tannery emissions and land use for livestock represent 14.5% of global GHG—synthetics with recycled inputs offer verifiable carbon reduction.

- “Cost Parity Only at Scale”: WINIW’s vertical integration enables competitive pricing even at 5,000 sq. yd. MOQs, closing the gap with mid-tier leather.

WINIW’s Commitment to Responsible Innovation

We partner with B2B clients to future-proof product lines through:

– Transparent Sourcing: 100% traceable raw materials with blockchain-enabled supply chain mapping.

– Circular Solutions: Take-back programs for end-of-life products to feed mechanical recycling streams.

– Performance Validation: Independent lab testing reports provided with every order for durability and safety metrics.

Selecting engineered leather isn’t a compromise—it’s a strategic investment in scalability, compliance, and environmental stewardship. WINIW delivers the performance specifications your engineering teams require while aligning with corporate sustainability mandates. Request our technical datasheets and sample kits to validate performance for your specific application.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. Our vertically integrated production capabilities and commitment to sustainability position us as a trusted partner across industries including automotive, fashion, furniture, and technical textiles.

Our manufacturing excellence is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive campus integrates advanced production lines with automated systems to ensure efficiency, consistency, and scalability. Designed with sustainability in mind, our factory incorporates energy-efficient machinery and low-emission processes that align with international environmental standards.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and eco-conscious solutions. The team continuously develops new formulations, including water-based PU, recycled content leather, and bio-based polymers.

- In-house laboratories equipped for comprehensive material testing, including wear resistance, color fastness, chemical compliance, and environmental aging.

- Strict quality control protocols implemented at every stage—from raw material inspection to final product packaging. Our QC system adheres to ISO 9001 standards and meets the stringent requirements of European and U.S. markets.

- Annual production capacity exceeding 150 million meters, enabling reliable supply for large-volume global partners.

- Certified compliance with REACH, RoHS, OEKO-TEX® STANDARD 100, and other key regulatory frameworks, ensuring safe and sustainable materials for international customers.

WINIW exports to more than 50 countries, with a strong presence in Europe and the USA. Our logistics network ensures timely delivery through strategic partnerships with global shipping and customs experts. With localized service teams and multilingual support, we provide seamless collaboration for B2B clients worldwide.

| Feature | Specificatie |

|---|---|

| Factory Size | 100,000 sqm |

| R&D Team | 100+ engineers and technicians |

| Quality Standards | ISO 9001, REACH, RoHS, OEKO-TEX® |

| Annual Output | >150 million meters |

| Export Regions | Europe, USA, Asia, Middle East, Australia |

By combining scale, innovation, and uncompromising quality, WINIW delivers synthetic leather solutions that meet the evolving demands of global industries—responsibly and reliably.

Contact Us for Samples

WINIW Premium Synthetic Leather: Sustainable Performance for Modern Manufacturing

WINIW delivers high-performance, eco-conscious synthetic leather solutions engineered for durability and environmental responsibility. Our materials meet rigorous global safety standards while offering exceptional versatility across automotive, furniture, and luxury goods manufacturing. Backed by ISO 14001 certification and OEKO-TEX® STANDARD 100 Class I compliance, we provide B2B partners with traceable, low-impact materials that align with circular economy principles.

Core Product Range & Technical Specifications

| Product Line | Base Material | Thickness (mm) | Tensile Strength (MPa) | Abrasion Resistance (cycles) | Key Applications | Eco-Certifications |

|---|---|---|---|---|---|---|

| WINIW EcoSoft™ | Recycled PET Microfiber | 0.8–1.2 | ≥ 25 | ≥ 50,000 | Upholstery, Bags | GRS 4.0, OEKO-TEX® 100 |

| WINIW ProFlex™ | Water-Based PU | 0.6–1.0 | ≥ 22 | ≥ 35,000 | Automotive Interiors | ISO 14001, REACH Compliant |

| WINIW LuxWeave™ | Plant-Based PU | 1.0–1.5 | ≥ 28 | ≥ 60,000 | High-End Footwear, Fashion | USDA BioPreferred™, OEKO-TEX® 100 |

Why Manufacturers Partner with WINIW

- Sustainability Engineered In: 30%+ recycled content across core collections; 95% reduction in VOC emissions vs. conventional PU

- Performance Guaranteed: Industry-leading tear strength, colorfastness (≥ Grade 4), and hydrolysis resistance for 10+ year lifespans

- Customization Agility: Rapid prototyping for color, texture, and performance tuning (MOQ: 500m)

- Supply Chain Transparency: Full LCA reporting and blockchain-tracked material origins

Applications Driving Industry Innovation

- Automotive: Seamless seat covers meeting FMVSS 302 flammability standards

- Contract Furniture: Heavy-duty upholstery with Martindale ≥ 100,000 cycles

- Luxury Accessories: Premium microfiber with leather-like drape and breathability

- Technical Textiles: Waterproof membranes for outdoor gear (hydrostatic head ≥ 10,000mm)

All WINIW materials undergo third-party testing for safety and durability, ensuring compliance with EU REACH, CPSIA, and California Proposition 65. Our closed-loop water treatment system eliminates hazardous runoff, and 99% of production waste is repurposed into secondary materials.

Request Technical Documentation & Free Samples

Elevate your product line with WINIW’s certified sustainable synthetics. Contact our materials engineering team for:

– Custom performance data sheets

– Physical samples shipped within 48 hours

– Dedicated sourcing consultation

Email MKT88@MicrofiberLeather.com to initiate your project. Free samples available for qualified B2B partners.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.