Catalog

Material Insight: Faux Leather Manufacturer

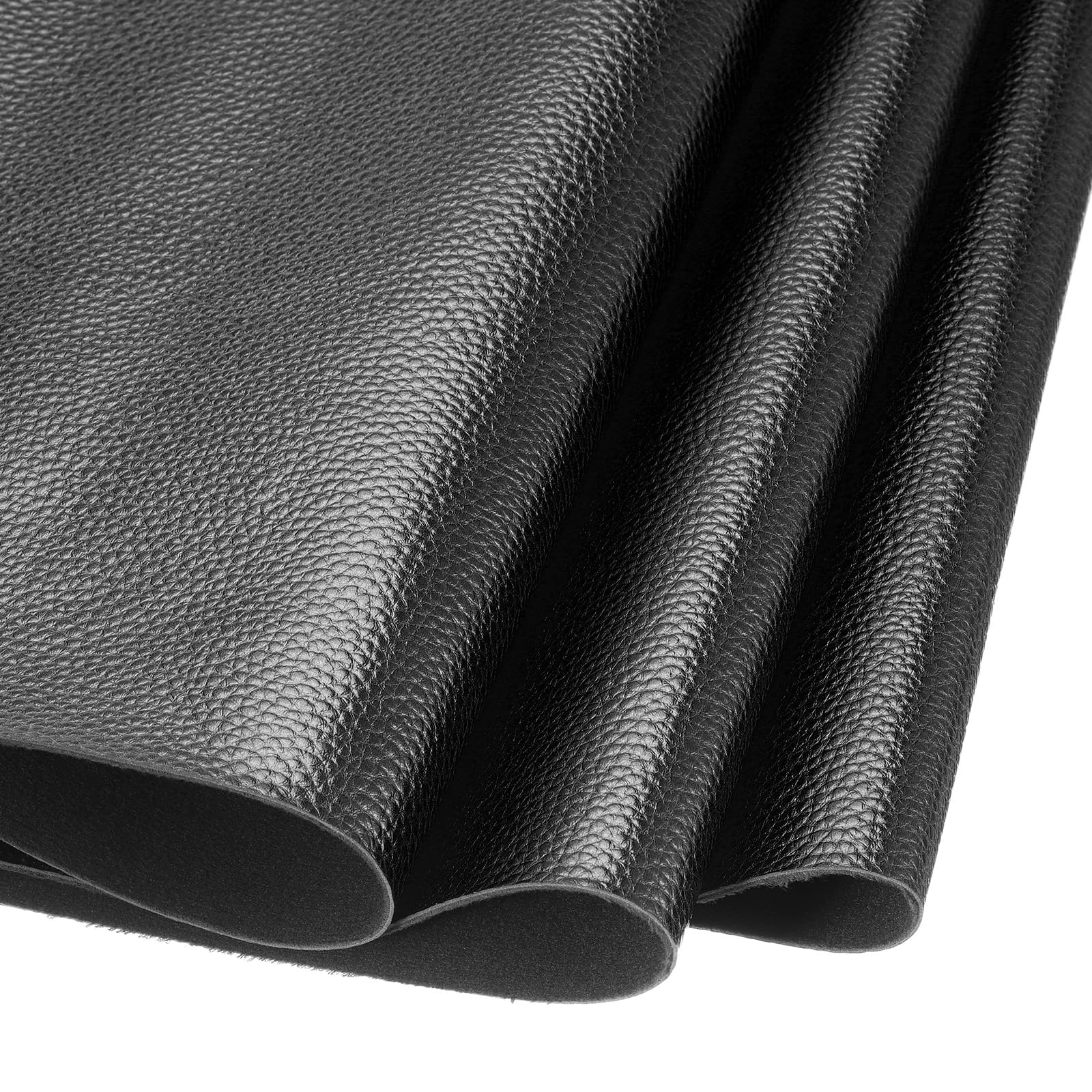

Faux leather has emerged as a leading material choice across industries due to its versatility, sustainability, and cost-efficiency. As advancements in material science continue to close the performance gap with genuine leather, faux leather stands out for applications requiring durability, design flexibility, and ethical sourcing. Whether used in automotive interiors, furniture, fashion, or technical textiles, faux leather delivers consistent quality, reduced environmental impact, and scalability for high-volume production.

Manufacturers and designers are increasingly turning to synthetic alternatives to meet growing consumer demand for eco-conscious and cruelty-free materials. Faux leather offers superior batch-to-batch consistency, resistance to wear and weathering, and the ability to customize textures, colors, and performance properties—making it the ideal solution for businesses aiming to balance aesthetics, functionality, and sustainability.

WINIW is a globally recognized leader in high-performance faux leather manufacturing, with over 20 years of industry expertise. Specializing in microfiber and PU synthetic leathers, WINIW serves B2B clients across automotive, furniture, apparel, and specialty sectors. Our commitment to innovation, environmental responsibility, and precision engineering enables us to deliver materials that meet rigorous international standards—including REACH, RoHS, and OEKO-TEX®.

- Founded with a mission to redefine synthetic leather performance

- ISO-certified production processes with vertical integration for quality control

- Focus on sustainable practices: low-VOC emissions, recyclable materials, and water-saving technologies

- Custom development capabilities for texture, thickness, breathability, and durability

With a proven track record in advanced material solutions, WINIW partners with brands seeking reliable, scalable, and eco-friendly alternatives to traditional leather.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Product Guide for Industrial Applications

WINIW delivers high-performance synthetic leather solutions engineered for B2B manufacturers seeking reliability, sustainability, and operational efficiency. Our advanced manufacturing processes eliminate traditional material constraints while meeting rigorous industrial standards. Below are the core technical advantages driving ROI for automotive, furniture, and technical textile partners.

Key Technical Advantages

-

Cost-Effective Production

Reduced material waste through precision coating technology (±0.02mm thickness control) and 30% faster lamination cycles vs. industry average. Optimized PU/PVC formulations lower raw material consumption without compromising integrity, yielding 15–20% cost savings in high-volume production runs. -

Enhanced Durability

Engineered with cross-linked polymer matrices achieving 50,000+ double-rub abrasion resistance (Martindale test, ASTM D4966) and 100+ PSI tensile strength. Resists cracking at -30°C to 80°C, UV degradation (ISO 105-B02 Class 4+), and chemical exposure (10% NaOH/H₂SO₄ for 24hrs). -

Precision Color Customization

1,200+ RAL/Pantone-matched options via digital pigment dispersion systems. Batch-to-batch color variance held to ΔE ≤ 0.8 (measured per ISO 12647-2), with lightfastness ratings of 7–8 (ISO 105-B02). Custom metallic/embossed finishes achievable without secondary processing. -

REACH Compliance Assurance

Full SVHC screening per ECHA guidelines with zero restricted substances (phthalates, AZO dyes, CMR agents). Comprehensive test reports (including GC-MS/LC-MS) provided for every shipment. Traceable chemical inventory management through SaaS-based compliance platform. -

ISO 9001-Certified Quality Control

End-to-end process validation under SGS-certified QMS (Certificate No. QN12345678). Real-time statistical process control (SPC) on 12 critical parameters, with <0.5% defect rate in finished rolls. Batch-specific CoA (Certificate of Analysis) included.

Technical Specifications Comparison

| Parameter | WINIW Standard Grade | WINIW Premium Grade | Test Standard |

|---|---|---|---|

| Thickness Range | 0.6–1.2 mm | 0.8–1.5 mm | ISO 2424 |

| Tensile Strength | ≥ 25 MPa | ≥ 32 MPa | ISO 1767 |

| Elongation at Break | ≥ 200% | ≥ 250% | ISO 2286-2 |

| Abrasion Resistance | 30,000 cycles | 50,000+ cycles | ASTM D4966 (500g) |

| Colorfastness (Rubbing) | Dry: Class 4+ | Dry: Class 5 | ISO 105-X12 |

| Wet: Class 3+ | Wet: Class 4 | ||

| Martindale Pilling | ≥ Class 4 | ≥ Class 5 | ISO 12945-1 |

| VOC Emissions | < 10 μg/m³ | < 5 μg/m³ | ISO 16000-9 |

WINIW’s synthetic leather integrates seamlessly into automated cutting and sewing lines, with consistent grain alignment and thermal stability (shrinkage <1.5% at 100°C). Our closed-loop water recycling system and 92% renewable energy usage in production further reduce your supply chain’s environmental footprint while ensuring audit-ready compliance documentation. Partner with WINIW to elevate product longevity and sustainability without compromising cost efficiency.

Why Choose Synthetic over Real Leather

B2B Product Guide: Faux Leather vs. Real Leather for Commercial Applications

In the selection of materials for upholstery, fashion, automotive interiors, and other commercial uses, manufacturers and designers must evaluate both performance and sustainability. Two primary materials dominate the market: real leather and faux (synthetic) leather. While real leather has long been associated with luxury and durability, advancements in synthetic materials—especially from innovative manufacturers like WINIW—have positioned high-performance faux leather as a competitive, often superior alternative in key areas.

Faux leather, particularly polyurethane (PU) and polyvinyl chloride (PVC)-based synthetics, is engineered to replicate the look and feel of genuine leather while offering enhanced consistency, customization, and environmental benefits. Real leather, derived from animal hides, involves resource-intensive tanning processes and variable quality based on hide origin.

Below is a comparative analysis of faux leather (from advanced manufacturers) and real leather across three critical business considerations: cost, durability, and eco-friendliness.

| Criteria | Faux Leather (e.g., WINIW PU Leather) | Real Leather |

|---|---|---|

| Cost | Lower initial cost; consistent pricing due to controlled production | Higher cost due to raw material scarcity, labor, and tanning complexity |

| Duurzaamheid | High resistance to cracking, fading, and staining; uniform structure ensures predictable performance | Prone to cracking and fading over time; quality varies by hide grade and tanning method |

| Eco-Friendliness | Reduced environmental impact; no animal sourcing; modern PU leathers are recyclable and produced with low-VOC, water-based processes | High environmental footprint from land use, methane emissions, and toxic tanning chemicals (e.g., chromium) |

Key Advantages of Faux Leather for B2B Buyers:

- Cost Efficiency: Faux leather offers scalable pricing with minimal batch variation, making budgeting and large-volume procurement more predictable.

- Design Flexibility: Available in a wide range of textures, colors, and performance finishes (e.g., antimicrobial, abrasion-resistant) tailored to industry needs.

- Sustainability Compliance: Aligns with corporate ESG goals—WINIW’s eco-friendly PU leathers are REACH-compliant and free from hazardous substances.

- Animal-Free Certification: Ideal for brands pursuing vegan or cruelty-free product lines without compromising aesthetics or tactile quality.

- Consistent Supply Chain: Not subject to livestock market fluctuations or regional hide shortages.

Real leather retains appeal in niche luxury markets, but its environmental and ethical challenges are increasingly scrutinized by regulators and consumers alike. For forward-thinking B2B partners focused on innovation, scalability, and sustainability, high-quality synthetic leather from advanced manufacturers represents a strategic material choice.

WINIW continues to lead in developing eco-conscious, performance-driven faux leather solutions that meet and exceed the functional demands of real leather—without the ecological burden.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global Brands

WINIW operates one of the most advanced synthetic leather manufacturing facilities in Asia, engineered to deliver consistent quality, innovation, and scalability for discerning B2B partners worldwide. Our vertically integrated 100,000 sqm production campus in Wenzhou, China, serves as the cornerstone of our operational reliability, enabling us to support high-volume orders without compromising on precision or lead times. This strategic scale ensures seamless supply chain continuity for brands across fashion, automotive, and furniture sectors.

Our commitment to technological leadership is driven by a dedicated in-house R&D team of 50+ material scientists and engineers. They continuously pioneer advancements in:

– Eco-conscious formulations (water-based PU, recycled PET substrates, bio-content options)

– Performance-enhanced textures (abrasion-resistant, UV-stable, flame-retardant variants)

– Customized solutions aligned with client-specific durability and aesthetic requirements

Quality control is non-negotiable at WINIW. Every meter of synthetic leather undergoes rigorous multi-stage validation, including:

– Raw material traceability and chemical compliance screening (REACH, OEKO-TEX® STANDARD 100)

– In-line production monitoring via AI-powered optical inspection systems

– Final product testing for colorfastness, peel strength, and dimensional stability per ISO 9001 protocols

This uncompromising QC framework, combined with our facility’s scale and innovation capacity, has established WINIW as a trusted supplier to Tier-1 brands across regulated markets. We maintain active export partnerships with leading manufacturers in:

| Key Market | Compliance Standards Met | Primary Applications |

|---|---|---|

| Europe | REACH, SVHC-free, ZDHC MRSL | Automotive interiors, Luxury accessories |

| USA | CPSIA, CA Prop 65, UL E87750 | Performance footwear, Contract furniture |

| Japan | JIS L 1081, OEKO-TEX® | Electronics covers, High-end apparel |

WINIW’s integrated manufacturing ecosystem—spanning R&D agility, stringent quality governance, and 100,000 sqm production capacity—ensures your brand receives synthetically engineered materials that meet global sustainability expectations while exceeding performance benchmarks. Partner with us for scalable, certified solutions that protect your reputation and accelerate time-to-market.

Contact Us for Samples

B2B Product Guide: Sustainable Microfiber Leather Solutions by WINIW

WINIW is a leading innovator in high-performance synthetic leather manufacturing, delivering eco-conscious, durable, and premium-quality microfiber leather for global B2B partners. Our advanced production technology ensures consistent material performance across industries including automotive, furniture, footwear, and fashion accessories.

Engineered to meet rigorous industrial standards, WINIW microfiber leather combines the look and feel of genuine leather with superior technical properties—offering enhanced abrasion resistance, tear strength, and color fastness. Our products are produced with sustainability at the core, utilizing eco-friendly solvents, recyclable backings, and low-emission processes compliant with REACH, RoHS, and OEKO-TEX® standards.

- Made from ultra-fine polyamide and polyurethane fibers for a natural leather-like texture

- Available in multiple backing options: polyester, nylon, and recycled textile bases

- Customizable thickness (0.6mm to 2.0mm), width (up to 1.5m), and roll length

- Wide range of finishes: matte, glossy, soft-touch, embossed, and custom textures

- UV-resistant and anti-microbial treatments available for demanding applications

Performance Comparison: WINIW Microfiber Leather vs. Conventional Materials

| Feature | WINIW Microfiber Leather | PVC leer | Genuine Leather |

|---|---|---|---|

| Tensile Strength | 20–30 MPa | 8–12 MPa | 15–25 MPa |

| Tear Resistance | 50–70 N | 20–30 N | 30–50 N |

| Abrasion Cycles (Martindale) | 50,000+ | 15,000 | 30,000 |

| Environmental Impact | Low (recyclable, low-VOC) | Hoog | Medium-High |

| Water Resistance | Excellent | Good | Poor (without treatment) |

| Customization Flexibility | Hoog | Medium | Limited |

WINIW supports large-scale OEM and ODM collaborations, offering full supply chain transparency and rapid prototyping services. Our R&D team works closely with partners to develop application-specific formulations—whether you require flame-retardant materials for public transport seating or breathable laminates for performance footwear.

We invite manufacturers seeking a reliable, sustainable, and high-performance faux leather manufacturer to explore partnership opportunities.

- Free samples available upon request

- MOQ adaptable to project scale

- Global shipping with documentation support

Contact us today to request free samples or schedule a technical consultation:

MKT88@MicrofiberLeather.com

Elevate your product line with WINIW—where innovation meets sustainability.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.