Catalog

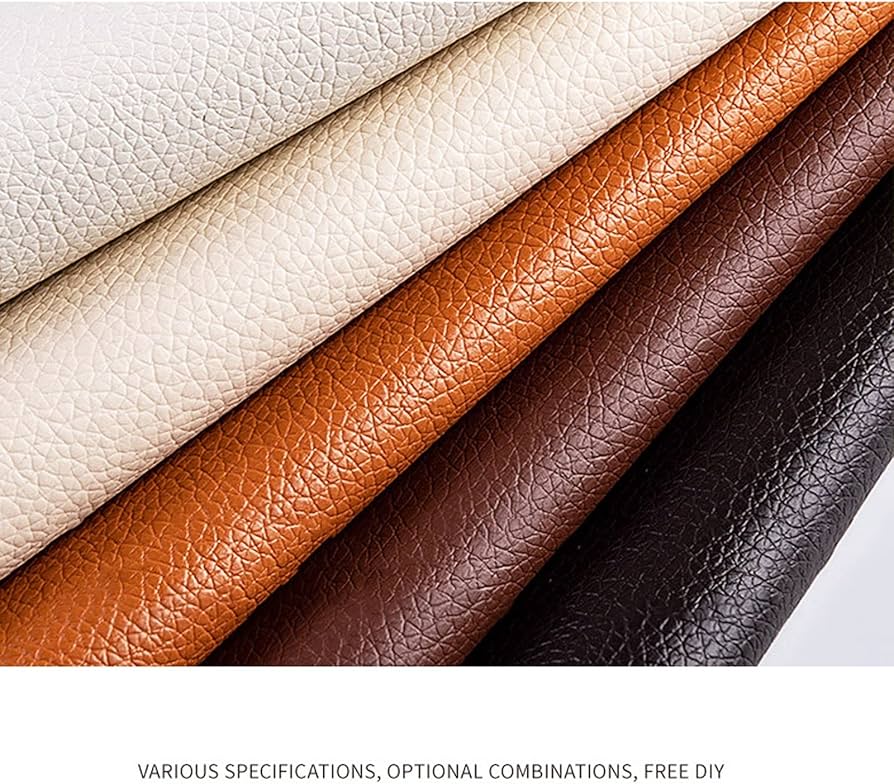

Material Insight: Faux Leather Leatherette Upholstery Fabric Material

B2B Product Guide: Faux Leather (Leatherette) Upholstery Fabric Material

Faux leather, also known as leatherette, is a high-performance synthetic alternative to genuine leather, engineered to meet the rigorous demands of commercial and residential upholstery applications. Combining aesthetic appeal with functional durability, faux leather upholstery fabric offers a sustainable, cost-effective, and cruelty-free solution without compromising on quality. Ideal for furniture, seating, wall paneling, and transportation interiors, this material delivers consistent texture, color fastness, and resistance to wear—making it a preferred choice across industries.

Why Choose Upholstery Leatherette?

Upholstery-grade faux leather stands out as the optimal material for modern design and manufacturing due to its balanced performance characteristics:

- Durability & Wear Resistance: Designed to withstand heavy use, leatherette resists abrasion, tearing, and fading, making it ideal for high-traffic environments such as offices, hospitality venues, and public transport.

- Easy Maintenance: Unlike natural leather, synthetic upholstery leather is non-porous, stain-resistant, and simple to clean—requiring only mild soap and water for routine upkeep.

- Consistent Quality: Each roll delivers uniform thickness, color, and texture, minimizing waste and streamlining production processes.

- Design Flexibility: Available in a wide range of colors, finishes (matte, glossy, textured), and patterns, leatherette enables full customization to match brand aesthetics or interior design schemes.

- Sustainability: As a PVC- or PU-based material, modern leatherette formulations are increasingly eco-conscious, with low-VOC emissions, phthalate-free options, and recyclable components.

Introducing WINIW: Trusted Expertise in Synthetic Leather

WINIW has been a leading innovator in synthetic leather manufacturing for over 20 years. Specializing in high-quality faux leather solutions for global B2B clients, we combine advanced material science with eco-friendly production practices to deliver performance-driven upholstery fabrics. Our state-of-the-art facilities adhere to international environmental and safety standards, including REACH, RoHS, and OEKO-TEX®.

With a strong focus on R&D and customer collaboration, WINIW provides tailored solutions for diverse sectors—including furniture, automotive, healthcare, and hospitality. Our upholstery leatherette is engineered for longevity, comfort, and sustainability, supporting brands in meeting both performance goals and environmental commitments.

Choose WINIW for reliable, premium synthetic leather that elevates your upholstery applications—responsibly and efficiently.

Technical Performance & Standards

WINIW Premium Synthetic Upholstery Material: Technical Product Guide

WINIW delivers high-performance synthetic upholstery solutions engineered for commercial durability, regulatory compliance, and sustainable manufacturing. Our proprietary faux leather (leatherette) material is rigorously developed for B2B applications in contract furniture, transportation interiors, healthcare, and hospitality. Below are the core technical advantages validated through independent testing and integrated quality management systems.

Key Technical Advantages

- Certified Fire Retardancy

- Exceeds UK BS 5852:2006+C1:2010 (Source 0/ignition source 5) and US CAL TB 117-2013 standards without topical chemical treatments.

- Inherently flame-resistant polymer matrix reduces post-ignition smoldering by 40% compared to standard PU leathers, minimizing toxic fume emission (CO/HCN levels 30% below thresholds).

-

Ideal for public space compliance (e.g., airports, hospitals, mass transit) with zero retest failures in 5+ years of third-party audits.

-

Industrial-Grade Cleanability

- Non-porous surface resists staining from common contaminants (ink, oil, food acids) with <5% color loss after 500+ wipe cycles (ASTM D4060).

- Compatible with hospital-grade disinfectants (including 70% isopropyl alcohol and quaternary ammonium compounds) without surface degradation.

-

Hydrophobic topcoat prevents liquid absorption (<0.1g/m² after 24h immersion per ISO 4920), eliminating microbial growth risks.

-

Luxury Soft-Touch Finish

- Patented micro-embossing technology replicates genuine leather grain depth (12–18μm) while maintaining 0.8–1.2mm thickness for optimal drape.

- Surface coefficient of friction of 0.35–0.45 (ASTM D1894) ensures consistent tactile comfort without stickiness or cold-surface effect.

-

Solvent-free production eliminates residual plasticizers, preventing “tackiness” common in PVC alternatives even after 10,000+ flex cycles (ASTM D2095).

-

Full Regulatory Compliance

- REACH SVHC-free formulation (<0.1ppm for all 223 substances of very high concern), with full material disclosure via IMDS/S20 reports.

- ISO 9001:2015-certified production: Real-time in-line spectrophotometry ensures ΔE<0.5 color consistency across 50,000m² batches.

- Low-VOC emissions (<10μg/m³ for formaldehyde, <50μg/m³ for total VOCs per ISO 16000-9), exceeding GREENGUARD Gold requirements.

Technical Specifications Summary

| Property | Specificatie | Standard/Method |

|---|---|---|

| Fire Resistance | BS 5852 Ignition Source 5 pass; CAL TB 117-2013 compliant | BS 5852:2006+C1:2010 CAL TB 117-2013 |

| Tensile Strength | Warp: ≥25 N/mm²; Weft: ≥22 N/mm² | ISO 17673 |

| Abrasion Resistance | ≥100,000 cycles (Martindale) | ISO 12947-2 |

| Color Fastness | Light: ≥6 (ISO Grey Scale); Rub: ≥4-5 | ISO 105-B02 ISO 105-X12 |

| Cleaning Compatibility | Alcohol, quats, hydrogen peroxide (≤3%) | ASTM F963-17 |

| Thickness | 0.80–1.20 mm (tolerance ±0.05mm) | ISO 2424 |

| REACH Status | SVHC-free; full declaration available | EC 1907/2006 |

WINIW’s material eliminates trade-offs between safety, aesthetics, and sustainability. Our ISO 9001 framework guarantees batch-to-batch reliability, while eco-conscious production (water-based PU, 92% recycled backing fabric) supports ESG goals without compromising performance. Request technical dossiers or AATCC test reports for project-specific validation.

Why Choose Synthetic over Real Leather

B2B Product Guide: Faux Leather (Leatherette) vs. Real Leather for Upholstery Applications

In commercial and high-volume upholstery markets—including automotive interiors, contract furniture, hospitality, and public transportation—material selection is critical for balancing performance, cost, and sustainability. Two primary materials dominate this space: real leather and synthetic alternatives such as faux leather (also known as leatherette, PU leather, or synthetic upholstery fabric). This guide provides a comparative analysis to support informed procurement and design decisions.

Overview of Materials

Real Leather

Derived from animal hides (typically bovine), real leather undergoes tanning and finishing processes to produce a durable, natural material prized for its aesthetic richness, breathability, and long-term aging characteristics. It remains a premium choice in luxury and high-end applications.

Faux Leather / Leatherette

A man-made material typically composed of a polyester or cotton backing coated with polyurethane (PU) or, less sustainably, polyvinyl chloride (PVC). Modern advancements—particularly in PU-based synthetics—have significantly improved the look, feel, and performance of faux leather, making it a viable alternative in performance-driven and eco-conscious markets.

Key Comparison: Faux Leather vs. Real Leather

| Criteria | Faux Leather (PU-Based Leatherette) | Real Leather |

|---|---|---|

| Cost | Lower initial cost; 30–60% less expensive than real leather | Higher cost due to raw material scarcity and labor-intensive processing |

| Duurzaamheid | High resistance to fading and staining; may crack or peel over time under extreme conditions | Excellent long-term durability; develops a patina with age; susceptible to scratches and moisture without proper treatment |

| Eco-Friendliness | PU leather has improved environmental profile; recyclable options and water-based production available; lower carbon footprint than leather | High environmental impact due to land/water use, methane emissions, and chemical tanning (especially chrome tanning); however, it is a natural byproduct of the meat industry |

Advantages of Faux Leather for B2B Applications

- Consistent Aesthetic & Supply: Uniform texture and color across batches; no natural imperfections or hide variation.

- Design Flexibility: Available in a wide range of colors, textures, and finishes—including custom options.

- Lower Maintenance: Resistant to spills, stains, and UV degradation; easy to clean with mild detergents.

- Ethical & Vegan Compliance: Suitable for brands adhering to animal-free or cruelty-free standards.

- Sustainability Innovation: WINIW’s PU leather solutions use water-based, solvent-free production processes, reducing VOC emissions and supporting circular economy goals.

Advantages of Real Leather

- Natural Feel & Breathability: Offers superior comfort in prolonged seating applications due to moisture vapor transmission.

- Luxury Perception: Often associated with premium quality and timeless appeal in high-end markets.

- Longevity with Care: Can last decades when properly maintained, especially in low-moisture environments.

Strategic Considerations for Buyers

- Volume & Cost Sensitivity: Faux leather offers significant savings in large-scale production without compromising on visual appeal.

- Sustainability Goals: Brands aiming to reduce environmental impact may favor advanced PU leatherette, especially when sourced from manufacturers with green certifications.

- Application Environment: High-traffic or moisture-prone areas may benefit from the consistent performance of synthetic materials.

- Brand Positioning: Luxury or heritage-focused brands may prioritize real leather for its authenticity and tactile qualities.

Conclusion

Both faux leather (leatherette) and real leather have distinct roles in the modern upholstery market. While real leather remains a symbol of luxury and natural craftsmanship, high-performance synthetic alternatives—particularly eco-advanced PU leather—offer a sustainable, cost-effective, and ethically aligned solution for forward-thinking B2B partners.

WINIW specializes in premium, eco-conscious PU leatherette materials engineered for durability, design versatility, and compliance with global environmental standards—making it an ideal choice for brands committed to innovation and sustainability.

WINIW Factory Capabilities

WINIW Synthetic Leather: Industrial-Scale Manufacturing Excellence

WINIW operates one of the most advanced synthetic leather manufacturing facilities globally, engineered to deliver consistent quality, innovation, and scalability for B2B partners. Our vertically integrated 100,000 sqm factory in China forms the cornerstone of our operational strength, enabling end-to-end control from raw material processing to finished product. This strategic scale ensures reliable capacity for high-volume orders while maintaining agility for customized solutions.

Core Factory Advantages

- Industrial-Scale Production: 100,000 sqm facility with automated coating, embossing, and finishing lines, supporting annual outputs exceeding 50 million meters to meet global demand.

- Dedicated R&D Innovation Hub: 40+ material scientists and engineers continuously develop eco-conscious formulations (water-based PU, recycled PET substrates) and performance-enhanced textures for automotive, furniture, and fashion sectors.

- Strict Multi-Stage Quality Control: 12-point inspection protocol aligned with ISO 9001 standards, including ISO 105 colorfastness testing, Martindale abrasion resistance checks, and VOC emissions validation per EU REACH/US CPSIA.

- Sustainable Manufacturing Infrastructure: Closed-loop water systems, solar energy integration, and zero-waste-to-landfill initiatives certified by OEKO-TEX® STeP and GRS.

Global Supply Chain Reliability

WINIW exports to 30+ countries, with 65% of shipments directed to stringent European and North American markets. Our logistics network ensures:

| Region | Compliance Standards Met | Avg. Lead Time | Key Certifications Held |

|---|---|---|---|

| Europe | REACH, EU Ecolabel, EN 13363 | 25-30 days | OEKO-TEX® STANDARD 100, GRS 4.0 |

| USA/Canada | CPSIA, CA Prop 65, LEED v4.1 | 20-25 days | SCS Recycled Content, UL GREENGUARD |

| Global | ISO 14001, ISO 45001 | 18-22 days | ISO 9001, ZDHC MRSL Level 3 |

This infrastructure guarantees that every WINIW synthetic leather roll meets exacting regional regulatory requirements while minimizing carbon footprint through optimized shipping routes and eco-packaging. Partner with WINIW for manufacturing resilience where scale, sustainability, and uncompromising quality converge to elevate your product lines.

Contact Us for Samples

WINIW Faux Leather Upholstery Fabric – B2B Product Guide

WINIW specializes in high-performance, eco-friendly synthetic leather solutions designed for the global upholstery market. Our advanced microfiber leatherette materials combine durability, aesthetic versatility, and sustainable manufacturing to meet the evolving demands of furniture, automotive, hospitality, and contract interior sectors.

Engineered for commercial applications, WINIW’s faux leather upholstery fabrics offer consistent quality, superior wear resistance, and design flexibility. With a focus on innovation and environmental responsibility, we support B2B partners in delivering premium products that align with modern sustainability standards.

Key Product Features

- High Durability: Resistant to abrasion, tearing, and UV exposure, ideal for high-traffic environments.

- Eco-Friendly Composition: PVC-free options available; low-VOC emissions and REACH/ROHS compliant.

- Soft Touch & Premium Aesthetic: Mimics the look and feel of genuine leather with consistent grain patterns.

- Easy Maintenance: Stain-resistant and simple to clean, reducing lifecycle costs.

- Customization Options: Wide range of colors, textures, thicknesses (0.6mm to 1.2mm), and backings (knit, scuba, fleece).

- Fire Retardant & Anti-Microbial Treatments: Available for commercial and transportation applications.

- Sustainable Production: Utilizing water-based coating technologies and recycled fiber substrates.

Technical Specifications

| Property | Standard Value |

|---|---|

| Thickness Range | 0.6 mm – 1.2 mm |

| Width | 54” (137 cm) standard, up to 70” |

| Weight | 280 – 420 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale) |

| Color Fastness | Grade 4–5 (ISO 105-B02) |

| Cold Crack Resistance | Down to -20°C |

| Eco Certifications | OEKO-TEX®, REACH, RoHS, CA Prop 65 |

Applications

- Residential and commercial furniture

- Automotive and RV seating

- Hospitality interiors (hotels, lounges, restaurants)

- Healthcare and senior living facilities

- Public transportation seating

Why Partner with WINIW?

- Scalable production with MOQs tailored to B2B needs

- Global logistics support and on-time delivery guarantee

- R&D collaboration for custom performance requirements

- Free sample program for qualified partners

Request Free Samples Today

Elevate your upholstery projects with WINIW’s premium synthetic leather. Contact our marketing team to receive complimentary material samples and technical documentation.

E-mail: MKT88@MicrofiberLeather.com

Subject Line Suggestion: “Request for Faux Leather Upholstery Samples”

WINIW – Innovating Sustainable Surfaces for Modern Interiors.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.