Introduction: Navigating the Global Market for polyurethane leather material

In the fast-evolving landscape of synthetic materials, navigating the global market for polyurethane leather (PU leather) presents unique challenges for B2B buyers, especially when sourcing quality products that meet both cost and sustainability criteria. With its increasing demand across industries such as fashion, furniture, and automotive, understanding the nuances of PU leather is essential for making informed purchasing decisions. This guide delves into the various types of polyurethane leather, their applications, and critical factors such as supplier vetting, pricing strategies, and environmental considerations.

Our comprehensive resource empowers international buyers from regions including Africa, South America, the Middle East, and Europe—such as Saudi Arabia and Vietnam—by providing actionable insights into the PU leather market. By exploring the strengths and weaknesses of PU leather compared to natural alternatives, buyers can evaluate options that align with their brand values and target demographics. Furthermore, this guide offers practical tips on assessing product quality and supplier reliability, ensuring that you can confidently invest in materials that fulfill your business needs while adhering to ethical and sustainability standards.

As you embark on this journey through the world of polyurethane leather, let this guide serve as your trusted companion, equipping you with the knowledge necessary to navigate the complexities of sourcing and procurement in this dynamic market.

Table Of Contents

- Top 5 Polyurethane Leather Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for polyurethane leather material

- Understanding polyurethane leather material Types and Variations

- Key Industrial Applications of polyurethane leather material

- 3 Common User Pain Points for ‘polyurethane leather material’ & Their Solutions

- Strategic Material Selection Guide for polyurethane leather material

- In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane leather material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane leather material’

- Comprehensive Cost and Pricing Analysis for polyurethane leather material Sourcing

- Alternatives Analysis: Comparing polyurethane leather material With Other Solutions

- Essential Technical Properties and Trade Terminology for polyurethane leather material

- Navigating Market Dynamics and Sourcing Trends in the polyurethane leather material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane leather material

- Strategic Sourcing Conclusion and Outlook for polyurethane leather material

- Important Disclaimer & Terms of Use

Understanding polyurethane leather material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Leer | 100% synthetic, vegan, available in various colors | Furniture, fashion accessories, automotive | Pros: Affordable, easy to clean, water-resistant. Cons: Less durable, can crack or peel. |

| Bicast Leather | Genuine leather backing with a PU coating | Upholstery, handbags, footwear | Pros: Combines real leather feel with cost-effectiveness. Cons: Limited durability compared to full-grain leather. |

| Split Leather | Made from leftover leather scraps, coated with PU | Furniture, wallets, belts | Pros: More affordable than full-grain leather. Cons: Less attractive, prone to wear and tear. |

| Bonded Leather | Shredded leather fibers bonded with PU | Office furniture, bookbinding | Pros: Eco-friendly, reduces waste from leather production. Cons: Short lifespan, often looks synthetic. |

| Corrected Grain Leather | Real leather with a polyurethane finish for uniformity | High-end furniture, luxury accessories | Pros: Durable, maintains a leather-like appearance. Cons: May lack the natural feel of full-grain leather. |

What Are the Key Characteristics of PU Leather?

PU leather, or polyurethane leather, is an entirely synthetic material that mimics the appearance and texture of real leather. It is often used in furniture, fashion accessories, and automotive interiors due to its affordability and water-resistant properties. However, B2B buyers should be aware of its limitations, including lower durability and the potential for cracking or peeling over time. When sourcing PU leather, consider the expected lifespan and usage frequency to ensure it meets your business’s needs.

How Does Bicast Leather Differ from Other Types?

Bicast leather features a genuine leather backing coated with a layer of PU, providing a balance between the authenticity of leather and the cost-effectiveness of synthetic materials. This type is particularly suitable for upholstery, handbags, and footwear. While it offers a more appealing aesthetic compared to pure synthetic options, it may not withstand heavy wear as well as full-grain leather. B2B buyers should evaluate the intended application and customer expectations regarding quality and longevity.

What Is the Value of Split Leather in B2B Markets?

Split leather is produced from the fibrous parts of cowhide that remain after the top grain has been removed. Coated with PU, it offers a more economical alternative for various applications, including furniture and accessories. Although it is more affordable than full-grain leather, its appearance may not be as attractive, and it is prone to wear and tear. Businesses should consider the trade-off between cost and aesthetic appeal when choosing split leather for their products.

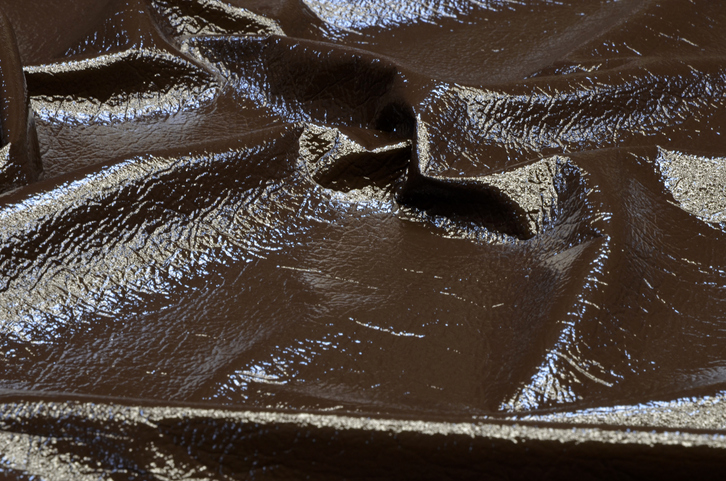

Illustrative image related to polyurethane leather material

How Is Bonded Leather an Eco-Friendly Option?

Bonded leather is created from shredded leather fibers mixed with PU, making it a sustainable choice that utilizes waste from leather production. It is commonly used in office furniture and bookbinding. While it is an eco-friendly option, bonded leather typically has a shorter lifespan and may exhibit a synthetic appearance. B2B buyers focused on sustainability should weigh the benefits of reduced waste against the potential need for more frequent replacements.

What Are the Benefits of Corrected Grain Leather?

Corrected grain leather is real leather that has undergone a finishing process with a polyurethane layer to achieve a uniform appearance. This type is often used in high-end furniture and luxury accessories, providing durability while maintaining a leather-like look. However, it may lack the natural feel and unique characteristics of full-grain leather. Businesses should assess customer preferences for authenticity and tactile experience when considering corrected grain leather for their offerings.

Key Industrial Applications of polyurethane leather material

| Industry/Sector | Specific Application of polyurethane leather material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture | Upholstery for sofas and chairs | Cost-effective, easy to clean, and available in various colors | Ensure compliance with fire safety and environmental regulations |

| Automotive | Interior seating and trim | Durable, lightweight, and resistant to wear and tear | Check for VOC emissions and long-term durability |

| Fashion & Accessories | Handbags and wallets | Versatile design options and lower production costs | Focus on quality assurance and ethical sourcing practices |

| Footwear | Shoes and boots | Affordable alternative to leather with diverse styles | Evaluate breathability and comfort for end-users |

| Sports Equipment | Protective gear and apparel | Lightweight and easy to maintain | Prioritize abrasion resistance and compliance with safety standards |

How is polyurethane leather material used in the furniture industry?

In the furniture industry, polyurethane leather is extensively utilized for upholstery on sofas, chairs, and other seating options. Its appeal lies in its affordability and ease of maintenance, making it an attractive choice for manufacturers looking to reduce costs without sacrificing aesthetics. For international buyers, especially from regions like Africa and the Middle East, it is crucial to consider local fire safety regulations and environmental standards when sourcing PU leather upholstery to ensure compliance and marketability.

What are the applications of polyurethane leather in the automotive sector?

In the automotive sector, polyurethane leather is commonly used for interior seating and trim. It offers a lightweight yet durable alternative to genuine leather, providing excellent resistance to wear and tear, which is vital for vehicles subjected to heavy use. B2B buyers should assess the material for volatile organic compound (VOC) emissions, as these can affect air quality within vehicles. Additionally, sourcing PU leather that meets automotive industry standards for durability and aesthetics is essential for maintaining a competitive edge.

How does polyurethane leather serve the fashion and accessories market?

Polyurethane leather has found a significant role in the fashion and accessories market, particularly in the production of handbags and wallets. Its versatility allows designers to create a wide range of styles and colors while keeping production costs low. For international buyers, it is important to focus on quality assurance processes to ensure that the PU leather used meets consumer expectations for durability and feel. Ethical sourcing practices are also increasingly important, as consumers demand transparency in the materials used.

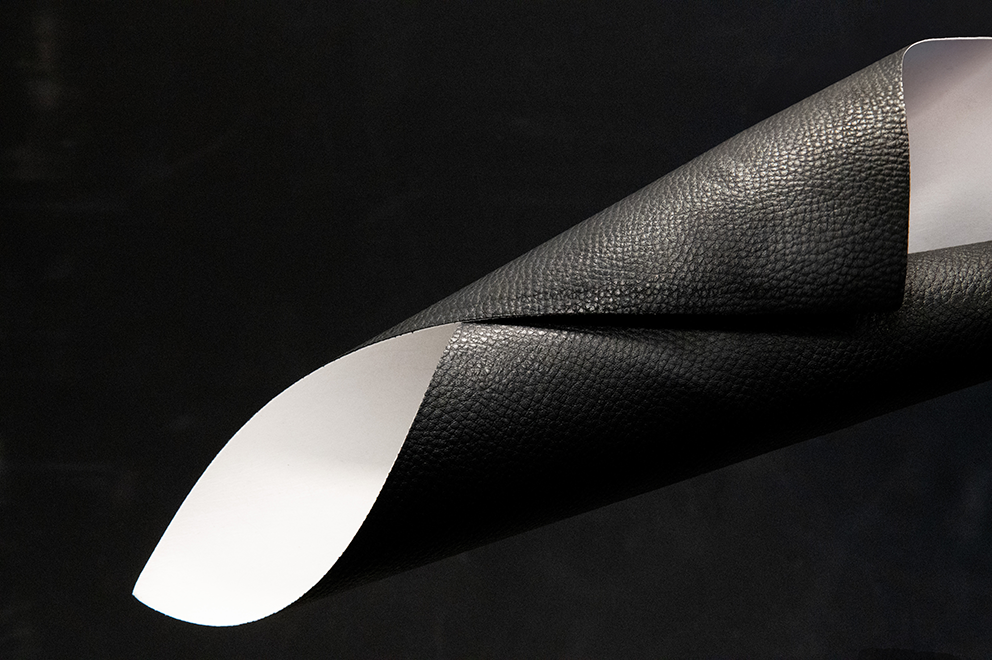

Illustrative image related to polyurethane leather material

What is the role of polyurethane leather in footwear manufacturing?

In footwear manufacturing, polyurethane leather is utilized for a variety of shoe types, including casual and formal footwear. Its affordability and the ability to mimic the appearance of genuine leather make it a popular choice among manufacturers. Buyers should evaluate the breathability and comfort of PU leather shoes, as these factors directly impact customer satisfaction. Additionally, ensuring that the material meets quality standards for durability will help in reducing returns and enhancing brand reputation.

How is polyurethane leather applied in sports equipment?

Polyurethane leather is increasingly used in the production of protective gear and apparel in the sports industry. Its lightweight nature and ease of maintenance make it ideal for items such as gloves, pads, and uniforms. B2B buyers should prioritize sourcing PU leather that offers abrasion resistance and compliance with safety standards, as these characteristics are crucial for ensuring athlete safety and performance. Understanding regional preferences for sports equipment can also aid in tailoring products to specific markets.

3 Common User Pain Points for ‘polyurethane leather material’ & Their Solutions

Scenario 1: Durability Concerns with Polyurethane Leather Products

The Problem: One of the most pressing challenges B2B buyers face when sourcing polyurethane leather is its durability. Many companies invest in products made from PU leather expecting them to last, only to find that they crack, peel, or fade after a short period of use. This can lead to significant financial losses and damage to brand reputation, especially in sectors like furniture and fashion where quality is paramount.

The Solution: To mitigate durability issues, buyers should focus on sourcing high-quality polyurethane leather that meets specific industry standards. Conduct thorough research on suppliers, looking for those who provide detailed product specifications and durability testing results. Consider requesting samples to evaluate the material’s performance in real-world conditions. Additionally, implementing a rigorous quality control process upon receipt of products can ensure that only the best materials are used in production. By prioritizing quality over cost, companies can enhance the lifespan of their PU leather products, leading to better customer satisfaction and reduced replacement costs.

Scenario 2: Environmental and Health Concerns Related to PU Leather

The Problem: As awareness of environmental issues grows, B2B buyers are increasingly concerned about the sustainability and safety of the materials they use. Polyurethane leather is often criticized for its non-biodegradable nature and potential toxic chemical emissions during production. This can complicate sourcing decisions for companies that aim to align with eco-friendly practices and ensure the health and safety of their employees and customers.

The Solution: Buyers should prioritize suppliers who are transparent about their manufacturing processes and materials. Look for polyurethane leather products that are certified as free from harmful chemicals and have undergone eco-friendly production methods. Additionally, consider engaging with suppliers who provide options for recycled or sustainable PU leather. This not only reduces the environmental impact but also positions your brand as a responsible choice in the market. Furthermore, maintaining an open dialogue with suppliers about their environmental practices can lead to mutually beneficial partnerships that enhance your company’s sustainability goals.

Scenario 3: Misleading Labels and Product Quality Confusion

The Problem: B2B buyers often encounter confusion regarding product labels, as many items marketed as “leather” may actually be various forms of polyurethane leather. Terms like “genuine leather” or “leather-like” can mislead buyers into purchasing inferior products that do not meet their quality standards. This can result in dissatisfaction, returns, and increased costs associated with re-sourcing materials.

The Solution: To avoid the pitfalls of misleading labeling, buyers should educate themselves about the different types of synthetic leathers available in the market. Establish clear criteria for what constitutes acceptable materials for your products and communicate these standards to your suppliers. It may also be beneficial to develop a checklist or a set of questions to ask potential suppliers regarding their products’ composition and certifications. Engaging with suppliers who provide clear, honest labeling and detailed product descriptions can help ensure that you receive the quality you expect. Regular training for procurement teams on identifying high-quality PU leather can also minimize confusion and improve sourcing decisions, ultimately leading to a more robust and reliable product line.

Strategic Material Selection Guide for polyurethane leather material

What Are the Common Materials Used in Polyurethane Leather?

When selecting polyurethane leather (PU leather) for various applications, understanding the underlying materials is crucial for international B2B buyers. The following analysis delves into three common materials that constitute PU leather, highlighting their properties, advantages, disadvantages, and considerations specific to regions such as Africa, South America, the Middle East, and Europe.

1. Polyurethane Coated Fabric

Key Properties:

Polyurethane coated fabric typically consists of a textile base (like polyester or nylon) coated with a layer of polyurethane. This material offers good flexibility and can be engineered to provide varying levels of thickness and texture. It generally has a temperature tolerance of up to 80°C and is resistant to water and stains.

Pros & Cons:

The primary advantage of this material is its affordability and ease of production, making it suitable for mass manufacturing. However, it is less durable than genuine leather, often lasting only 1-2 years with regular use. Additionally, it may not withstand high-pressure applications well, leading to potential wear and tear.

Illustrative image related to polyurethane leather material

Impact on Application:

This material is commonly used in upholstery for furniture and automotive interiors, where aesthetic appeal and cost-effectiveness are priorities. However, it may not be suitable for high-traffic areas due to its limited durability.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding chemical emissions, particularly VOCs, which can be a concern in the manufacturing process. Standards such as ASTM for textiles may be applicable, depending on the end-use.

2. Bicast Leather

Key Properties:

Bicast leather combines real leather scraps with a polyurethane coating, offering a unique blend of materials. This type often has a temperature rating similar to that of coated fabric, but its breathability is significantly improved due to the leather content.

Illustrative image related to polyurethane leather material

Pros & Cons:

The key advantage of bicast leather is its appearance; it can mimic genuine leather’s look while being more affordable. However, it is still less durable than full-grain leather and can crack or peel over time, particularly in humid conditions.

Impact on Application:

Bicast leather is typically used in fashion accessories and furniture, where a leather-like appearance is desired without the associated costs. Its suitability for high-end applications may be limited due to its lower longevity.

Considerations for International Buyers:

Buyers should be aware of the labeling practices in their regions, as bicast leather may be marketed under various names. Compliance with local quality standards, such as those from DIN or JIS, should also be verified.

3. Reconstituted Leather

Key Properties:

Reconstituted leather is made from leftover leather fibers bonded with polyurethane. This material can provide a more sustainable option compared to traditional leather, with temperature resistance similar to other PU leathers.

Pros & Cons:

One of the main advantages of reconstituted leather is its eco-friendliness, as it utilizes waste materials. However, it may not offer the same durability as full-grain leather, and its lifespan can vary widely based on manufacturing quality.

Impact on Application:

This material is often used in products where sustainability is a selling point, such as eco-friendly fashion items and furniture. However, its performance in high-stress applications may be limited.

Considerations for International Buyers:

International buyers should consider the environmental certifications of reconstituted leather. Compliance with sustainability standards is becoming increasingly important, especially in European markets.

Summary Table

| Materiaal | Typical Use Case for polyurethane leather material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Coated Fabric | Upholstery, automotive interiors | Cost-effective and easy to produce | Limited durability, not suitable for high-traffic | Low |

| Bicast Leather | Fashion accessories, furniture | Mimics genuine leather appearance | Less durable, prone to cracking in humidity | Medium |

| Reconstituted Leather | Eco-friendly fashion items, furniture | Utilizes waste materials, eco-friendly | Variable durability, may not perform well under stress | Medium |

This guide aims to equip B2B buyers with the insights needed to make informed decisions about polyurethane leather materials, considering performance, application suitability, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane leather material

What Are the Main Stages in the Manufacturing Process of Polyurethane Leather Material?

The manufacturing of polyurethane (PU) leather involves several critical stages, each requiring specific techniques to ensure that the final product meets industry standards. Understanding these stages is essential for B2B buyers to assess the quality and reliability of PU leather products.

Material Preparation: What Goes Into PU Leather?

The initial stage of PU leather manufacturing begins with material preparation. This involves selecting the right base fabric, typically polyester or cotton, which is coated with a layer of polyurethane. The quality of the base fabric significantly impacts the overall durability and feel of the final product. Buyers should look for suppliers who prioritize high-grade fabrics to ensure longevity.

Illustrative image related to polyurethane leather material

In addition to fabric selection, the chemical formulation of the polyurethane is crucial. Manufacturers often customize the polymer blend to achieve specific properties such as softness, flexibility, and water resistance. It’s advisable for B2B buyers to inquire about the chemical sourcing and formulation processes to ensure that they are environmentally friendly and compliant with international regulations.

Forming: How Is PU Leather Created?

The forming stage involves coating the prepared fabric with polyurethane. This is typically accomplished using techniques such as:

- Direct Coating: A liquid polyurethane is applied directly to the fabric, creating a seamless bond. This method allows for greater control over thickness and texture.

- Foaming: In this technique, the polyurethane is foamed before application, creating a softer, more padded feel. This is particularly popular in furniture upholstery.

- Lamination: This involves layering multiple materials, including a breathable membrane, to enhance durability and comfort.

Each method has its advantages, and B2B buyers should consider the intended use of the PU leather when evaluating these techniques. For example, furniture applications may benefit from foaming, while fashion accessories might require direct coating for a sleek finish.

Assembly: What Are the Key Steps in Assembling PU Leather Products?

Once the PU leather has been formed, the next step is assembly. This stage typically includes cutting, stitching, and finishing processes. The cutting stage is critical, as precision here ensures that the final product fits together seamlessly. Automated cutting machines are often used to enhance accuracy and reduce waste.

Stitching is another vital component, as it affects both aesthetics and durability. High-quality threads and specialized stitching techniques, such as double-stitching, can significantly improve the lifespan of the product. B2B buyers should verify that suppliers employ skilled labor and use industrial-grade sewing machines to ensure robust assembly.

Finishing: How Is Quality Enhanced in PU Leather?

The finishing stage involves applying additional treatments to enhance the product’s appearance and functionality. Common finishing processes include:

- Surface Treatments: These may include applying a protective coating to improve resistance to wear and tear.

- Texturing: Techniques like embossing can be used to create a more realistic leather-like finish, appealing to consumers seeking aesthetics.

- Coloring: PU leather can be dyed in various colors, allowing for customization. Eco-friendly dyes should be prioritized to minimize environmental impact.

B2B buyers should ensure that suppliers have robust finishing processes that meet their specific requirements for durability and aesthetics.

What Are the Quality Control Measures for PU Leather?

Quality control (QC) is paramount in the manufacturing of PU leather, ensuring that products meet both customer expectations and regulatory standards. Different checkpoints throughout the manufacturing process help maintain quality.

What International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Additionally, certifications like CE (Conformité Européenne) indicate compliance with European health, safety, and environmental protection standards.

For buyers from regions like Africa, South America, the Middle East, and Europe, understanding these standards can help in selecting reputable suppliers. It is essential to request documentation proving compliance with relevant standards.

What Are the Common Quality Control Checkpoints?

Quality control in PU leather manufacturing typically involves several checkpoints:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. It ensures that only high-quality fabrics and chemicals are used.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the application of polyurethane and stitching quality. This step helps identify defects early, reducing waste.

- Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to ensure that all items meet established quality standards. This includes checking for visual defects, consistency in thickness, and adherence to specifications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Audits: Conducting on-site audits allows buyers to assess the manufacturing environment and QC measures firsthand.

- Reports: Requesting detailed QC reports can provide insights into the supplier’s adherence to standards and any corrective actions taken for past issues.

- Third-Party Inspections: Engaging independent inspection services can offer an unbiased evaluation of product quality before shipment.

What Nuances Should International Buyers Consider in QC and Certification?

International buyers should be aware of potential nuances in quality control and certification processes. For instance, different regions may have varying standards for materials and manufacturing processes. Buyers should ensure that suppliers can demonstrate compliance with both local and international regulations.

Additionally, language barriers may complicate understanding quality documents. It is beneficial to work with suppliers who can provide documentation in the buyer’s preferred language to avoid misinterpretations.

By understanding the manufacturing processes and quality assurance measures for PU leather, B2B buyers can make informed decisions that align with their product needs and sustainability goals. Prioritizing suppliers who adhere to stringent quality standards will not only ensure product satisfaction but also foster long-term partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane leather material’

In the competitive landscape of material sourcing, polyurethane leather (PU leather) offers a viable alternative for businesses looking for cost-effective, versatile materials. This step-by-step checklist will guide B2B buyers through the critical stages of sourcing PU leather, ensuring that you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications required for your PU leather. This includes considerations such as thickness, texture, color, and finish. Understanding your specific needs will help you communicate effectively with suppliers and ensure that the material meets the intended application, whether for furniture, apparel, or automotive use.

Illustrative image related to polyurethane leather material

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers of PU leather. Look for companies that specialize in synthetic materials and have experience in your industry. Utilize online directories, industry trade shows, and networking events to gather a list of potential suppliers who can meet your requirements.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Pay attention to their manufacturing processes, quality control measures, and any certifications they hold, such as ISO or environmental certifications, which can indicate their commitment to quality and sustainability.

Step 4: Request Samples for Quality Assessment

Once you have narrowed down your list of potential suppliers, request samples of their PU leather products. Assess the samples for quality, including durability, color consistency, and texture. This hands-on evaluation will give you a better understanding of the material’s performance and help you determine if it meets your specifications.

Illustrative image related to polyurethane leather material

Step 5: Verify Certifications and Compliance

It’s essential to verify that the PU leather complies with relevant industry standards and regulations. Check for certifications that indicate the absence of harmful chemicals, such as VOCs, which can pose health risks. Ensuring compliance not only protects your business but also aligns with growing consumer demand for safer, eco-friendly products.

Step 6: Discuss Pricing and Payment Terms

Engage in negotiations regarding pricing and payment terms before finalizing your order. Understand the cost structure, including any additional fees for customization or shipping. Be clear about your budget and seek transparency from suppliers to avoid unexpected costs later in the procurement process.

Step 7: Establish Clear Communication Channels

Maintain open lines of communication with your chosen supplier throughout the sourcing process. Discuss timelines, delivery schedules, and any potential issues that may arise. Effective communication helps foster a strong relationship and ensures that both parties are aligned on expectations, leading to a smoother procurement experience.

Illustrative image related to polyurethane leather material

By following these steps, B2B buyers can effectively navigate the sourcing process for polyurethane leather, ensuring that they select high-quality materials that meet their specific needs while also aligning with industry standards and sustainability goals.

Comprehensive Cost and Pricing Analysis for polyurethane leather material Sourcing

What Are the Key Cost Components in Sourcing Polyurethane Leather Material?

When sourcing polyurethane leather (PU leather), understanding the cost structure is crucial for effective budgeting and negotiation. The cost breakdown typically includes:

-

Materials: The primary component is the thermoplastic polymer, which varies in quality and type. Higher-grade materials often come at a premium, influencing the overall cost.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process and the region in which production occurs. Regions with lower labor costs may offer competitive pricing but could compromise on quality.

-

Manufacturing Overhead: This includes factory operations, utilities, and maintenance costs. Efficient manufacturing processes can help minimize overhead, thereby reducing the overall cost.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. The complexity of the tooling required will affect pricing, making it essential to factor these costs into the total budget.

-

Quality Control (QC): Implementing rigorous quality control measures is vital to ensure product consistency. However, this adds to the overall cost. Buyers should consider the balance between cost and quality assurance.

-

Logistics: Shipping and handling costs can vary widely based on the distance, mode of transport, and the volume of the order. International buyers should be particularly mindful of potential tariffs and customs duties.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can vary based on market demand and supplier competition.

How Do Price Influencers Affect the Cost of PU Leather?

Several factors can significantly influence the pricing of PU leather:

-

Volume/MOQ: Bulk orders often attract discounts, as suppliers are more willing to negotiate on price for larger volumes. Establishing a minimum order quantity (MOQ) can be beneficial for both parties.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should clearly define their specifications to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., eco-friendly or hypoallergenic) can lead to higher prices. Buyers should assess the importance of these factors in relation to their target market.

-

Supplier Factors: Supplier reliability, experience, and market reputation can impact pricing. Established suppliers may charge more due to perceived value, while emerging suppliers might offer competitive rates to build their customer base.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is essential. Different Incoterms can affect the total cost, as they determine who is responsible for shipping, insurance, and tariffs.

What Are the Best Negotiation Tips for B2B Buyers Sourcing PU Leather?

To enhance cost-efficiency and overall value, buyers should consider the following negotiation strategies:

-

Conduct Market Research: Understanding market prices and trends can provide leverage during negotiations. Having comparative data can help justify your pricing expectations.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the long-term costs associated with PU leather, such as maintenance, durability, and replacement frequency. This holistic view can justify a higher upfront investment for better quality.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. A trusted relationship may encourage suppliers to offer discounts or better payment terms.

-

Leverage Volume Discounts: If feasible, consolidate orders to meet higher MOQs, which can lead to reduced prices. Regularly placing large orders can also enhance negotiation power.

-

Consider Regional Variations: Different regions have varying production costs and supplier capabilities. Buyers should explore multiple sources globally, particularly in regions known for lower manufacturing costs.

Conclusion: What Should International Buyers Keep in Mind?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should remain mindful of local market conditions, currency fluctuations, and import regulations when sourcing PU leather. It’s crucial to maintain flexibility in negotiations and to have a clear understanding of the total cost implications to ensure a successful procurement strategy.

Disclaimer: Prices for PU leather can vary widely based on numerous factors, including market conditions, supplier pricing strategies, and material quality. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing polyurethane leather material With Other Solutions

Exploring Alternatives to Polyurethane Leather Material

In the quest for sustainable and cost-effective materials, polyurethane leather (PU leather) has gained traction in various industries. However, it is essential for B2B buyers to explore viable alternatives that may offer enhanced durability, environmental benefits, and overall value. Below, we compare PU leather with two notable alternatives: vegetable-tanned leather and recycled PET fabric.

| Comparison Aspect | Polyurethane Leather Material | Vegetable-Tanned Leather | Recycled PET Fabric |

|---|---|---|---|

| Performance | Moderate; prone to cracking and peeling | High; ages well and develops a unique patina | Moderate; good for casual use but less durable than leather |

| Cost | Low; affordable option | Higher; premium pricing due to craftsmanship | Low to moderate; cost-effective depending on sourcing |

| Ease of Implementation | Easy; mass-produced | Moderate; requires skilled artisans for production | Easy; widely available and produced at scale |

| Maintenance | Low; easy to clean but not durable | Moderate; requires regular conditioning | Low; machine washable but can wear out |

| Best Use Case | Fashion items, inexpensive furniture | Luxury goods, high-end furniture | Casual wear, bags, and eco-friendly products |

In-Depth Analysis of Alternatives

What are the Benefits of Vegetable-Tanned Leather Over PU Leather?

Vegetable-tanned leather is a natural alternative that offers superior durability and a unique aesthetic. Unlike PU leather, which is made from synthetic materials, vegetable-tanned leather is derived from natural sources, resulting in a product that not only lasts longer but also develops character over time. While the initial cost is higher, the longevity and the potential for a unique patina can make it a more economical choice in the long run. However, it requires regular maintenance to keep it in optimal condition and is not as water-resistant as PU leather.

How Does Recycled PET Fabric Compare to Polyurethane Leather?

Recycled PET fabric, made from repurposed plastic bottles, presents a sustainable solution for businesses focused on eco-friendliness. This material is lightweight and easy to clean, making it suitable for casual applications such as bags and apparel. The cost can be comparable to PU leather, depending on sourcing and production methods. However, it may not match the durability of genuine leather or vegetable-tanned leather, which can limit its use in high-wear environments.

Making the Right Choice for Your Business Needs

When selecting a material, B2B buyers must consider various factors, including performance, cost, and the intended application. Polyurethane leather serves as an affordable and versatile option, particularly for fast fashion and low-cost furniture. However, for businesses aiming for sustainability and long-term investment, vegetable-tanned leather or recycled PET fabric may provide better durability and environmental benefits. Ultimately, the choice should align with the company’s values, target market, and product longevity requirements. By carefully evaluating these alternatives, buyers can make informed decisions that cater to their specific needs while enhancing their brand’s reputation.

Essential Technical Properties and Trade Terminology for polyurethane leather material

What Are the Key Technical Properties of Polyurethane Leather Material?

When evaluating polyurethane (PU) leather for B2B applications, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the quality classification of PU leather, which can vary based on the manufacturing process and materials used. High-grade PU leather typically offers better durability and aesthetic appeal, making it suitable for premium applications such as high-end furniture or fashion accessories. For buyers, selecting the right material grade can significantly impact product longevity and customer satisfaction.

2. Thickness

The thickness of PU leather, usually measured in millimeters (mm), plays a vital role in its durability and application. Thicker materials tend to be more robust and resistant to wear, making them ideal for heavy-use environments like automotive interiors or commercial upholstery. A precise thickness specification ensures that buyers receive products that meet their durability needs.

Illustrative image related to polyurethane leather material

3. Abrasion Resistance

Abrasion resistance measures the material’s ability to withstand wear and tear from friction. This property is particularly important for products that will be subject to frequent use, such as chairs and bags. A higher abrasion resistance rating indicates that the PU leather will maintain its appearance and performance over time, thereby reducing replacement costs for businesses.

4. Water Resistance

Water resistance is a crucial property for PU leather, especially in regions with high humidity or for products exposed to moisture. While PU leather generally does not absorb water like genuine leather, varying degrees of water resistance can be specified. Buyers should assess their specific environmental conditions to ensure the chosen material meets their requirements.

5. VOC Emissions

Volatile Organic Compounds (VOCs) are chemicals released during the manufacturing of PU leather that can affect air quality and human health. Understanding the VOC emissions of a specific PU leather product is essential for compliance with health and environmental regulations. Buyers should seek certifications that indicate low VOC emissions to ensure product safety.

What Are Common Trade Terminology and Jargon Related to Polyurethane Leather?

Familiarity with trade terminology can enhance communication between B2B buyers and suppliers, ensuring smoother transactions. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are used in another company’s end products. In the context of PU leather, an OEM might produce leather upholstery for furniture manufacturers. Understanding OEM relationships can help buyers identify potential suppliers and ensure quality standards.

Illustrative image related to polyurethane leather material

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory management and cost efficiency. Knowing the MOQ helps businesses assess their purchasing power and negotiate better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products or services. When dealing with PU leather, providing detailed specifications in an RFQ can lead to more accurate quotes and better supplier responses. It is a vital step in the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs, which is particularly important for B2B transactions involving PU leather across borders. Familiarity with Incoterms helps mitigate risks and reduces misunderstandings in logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the PU leather industry, lead times can vary based on factors like production capacity and shipping methods. Understanding lead times is critical for inventory planning and ensuring that businesses meet their operational deadlines.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding polyurethane leather materials, leading to successful procurement outcomes.

Illustrative image related to polyurethane leather material

Navigating Market Dynamics and Sourcing Trends in the polyurethane leather material Sector

What Are the Key Market Dynamics Impacting Polyurethane Leather Material?

The polyurethane (PU) leather market is experiencing significant growth driven by several global factors. The rising demand for affordable, vegan-friendly alternatives to genuine leather is a primary catalyst, particularly among fashion and furniture industries. Additionally, increasing consumer awareness regarding animal welfare and sustainability is pushing brands toward synthetic materials. Emerging markets in Africa, South America, the Middle East, and Europe are witnessing a surge in PU leather applications, notably in automotive interiors and upholstery, driven by urbanization and rising disposable incomes.

Furthermore, technological advancements in manufacturing processes are enhancing the quality and aesthetic appeal of PU leather, making it a viable option for high-end markets. Innovations in coating techniques, for instance, are improving durability and resistance to wear and tear, addressing one of the main criticisms of traditional PU leather. As these technologies evolve, international B2B buyers can leverage these advancements to meet consumer demands for both cost-effectiveness and quality.

How Is Sustainability and Ethical Sourcing Influencing the Polyurethane Leather Market?

Sustainability is becoming a cornerstone of the polyurethane leather industry, with increasing pressure on manufacturers to adopt eco-friendly practices. The environmental impact of PU leather production, particularly concerning volatile organic compounds (VOCs) and non-biodegradable materials, is prompting businesses to seek sustainable alternatives. For B2B buyers, understanding the environmental implications of their sourcing decisions is crucial. Certifications such as OEKO-TEX® and Global Organic Textile Standard (GOTS) can help identify suppliers committed to reducing their ecological footprint.

Ethical sourcing is also gaining traction, as consumers and corporations alike demand transparency in supply chains. B2B buyers should prioritize partnerships with manufacturers who practice ethical labor standards and sustainable sourcing. This not only mitigates reputational risks but also aligns with the growing consumer preference for brands that demonstrate corporate social responsibility. By emphasizing sustainability and ethical sourcing, businesses can enhance their market positioning and appeal to increasingly conscious consumers.

What Is the Brief Evolution of Polyurethane Leather?

The evolution of polyurethane leather dates back to the mid-20th century when synthetic alternatives to genuine leather were first developed. Initially, PU leather was primarily used in lower-end products due to its perceived inferiority compared to natural leather. However, advancements in polymer technology and manufacturing processes have transformed PU leather into a competitive material suitable for various applications, including high-end fashion, automotive interiors, and furniture.

Today, PU leather is recognized for its versatility and adaptability, offering a wide range of colors and textures that mimic the aesthetics of genuine leather. Its evolution reflects broader trends in consumer preferences towards sustainable and cruelty-free materials, making it a relevant choice for modern businesses. As the market continues to mature, ongoing innovations will likely further enhance its appeal among B2B buyers seeking quality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane leather material

-

How do I identify quality polyurethane leather for my business needs?

To identify quality polyurethane leather, examine its texture, smell, and durability. High-quality PU leather should have a uniform texture without visible imperfections. It should not emit strong chemical odors, which can indicate low-quality production processes. Perform a water test; genuine PU leather will repel water while lower quality may absorb it. Additionally, request samples from suppliers to assess the material’s feel and flexibility. Look for certifications that guarantee the absence of harmful substances and compliance with international standards. -

What are the main advantages of using polyurethane leather in my products?

Polyurethane leather offers several advantages for B2B buyers. It is generally more cost-effective than genuine leather, making it an attractive option for manufacturers looking to reduce production costs. PU leather is easy to clean, water-resistant, and available in various colors and styles. It also aligns with vegan and sustainability trends, as it can be made without animal products. However, it is essential to weigh these benefits against its lower durability compared to genuine leather. -

What should I consider when vetting suppliers of polyurethane leather?

When vetting suppliers, consider their production capabilities, material quality, and compliance with international standards. Request samples to assess the texture and durability of their PU leather. Verify their certifications for environmental sustainability and health safety, especially regarding VOC emissions. Additionally, check their reputation through customer reviews and industry references. It’s also beneficial to inquire about their manufacturing processes to ensure ethical practices and transparency. -

What are the typical minimum order quantities (MOQ) for polyurethane leather?

Minimum order quantities for polyurethane leather can vary significantly depending on the supplier and production capabilities. Generally, MOQs may range from 500 to 1,000 square meters for bulk orders. However, some suppliers may offer smaller quantities for initial orders or samples. It’s advisable to communicate your specific needs to potential suppliers to negotiate favorable terms that align with your business requirements. -

What payment terms are common when purchasing polyurethane leather?

Common payment terms for purchasing polyurethane leather include a deposit upfront (typically 30%) with the balance paid before shipment. Some suppliers may offer net 30 or net 60 terms, allowing buyers time to pay after receiving goods. Always clarify payment methods accepted, such as wire transfers, letters of credit, or online payment platforms. Ensure the terms are documented in a purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance (QA) for my polyurethane leather orders?

To ensure quality assurance, establish clear specifications and standards with your supplier before placing an order. Request detailed documentation of their QA processes, including testing methods for durability, color fastness, and chemical safety. Consider implementing a third-party inspection service to assess the quality of the leather before shipment. Regular communication with the supplier during production can also help address any issues that arise. -

What are the logistics considerations when importing polyurethane leather?

When importing polyurethane leather, consider shipping methods, customs duties, and local regulations. Choose a reliable freight forwarder experienced in handling textile imports to navigate logistics efficiently. Understand the customs clearance process in your country to avoid delays. Also, factor in lead times for production and shipping when planning your inventory. Having a clear logistics strategy will help ensure timely delivery and minimize costs. -

Is polyurethane leather recyclable or environmentally friendly?

Polyurethane leather is not biodegradable, which raises environmental concerns. However, some manufacturers are now producing eco-friendly versions using recycled materials or sustainable practices. Before sourcing PU leather, inquire about the supplier’s recycling policies and the environmental impact of their production processes. Although it may not be entirely recyclable, choosing suppliers committed to sustainable practices can mitigate some environmental concerns associated with PU leather.

Top 5 Polyurethane Leather Material Manufacturers & Suppliers List

1. Manuel Dreesmann – PU Leather Solutions

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: This company, Manuel Dreesmann – PU Leather Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. HowStuffWorks – PU Leather Guide

Domain: home.howstuffworks.com

Registered: 1998 (27 years)

Introduction: PU (Polyurethane) leather is an artificial leather made of polyurethane, which is a type of plastic. It is 100% vegan, with no animal skin involved. There are two types of PU leather: full-synthetic (totally vegan) and semi-synthetic (contains a natural leather base). PU leather is water-resistant, easy to clean, and available in a wide variety of colors. However, it lacks the authentic appearance…

3. Decorative Fabrics Direct – PU Leather & Faux Leather

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: PU Leather & Faux Leather | Vinyl Upholstery Fabric

– Terms: Free Shipping Coupon Code: SHIPFREE for Most $199 Orders

– Shop By Use: Interior Upholstery, Outdoor Upholstery, Drapery, Curtain Lining

– Shop By Color: Black, Gray, Blue, Turquoise, Aqua, Brown, Beige, Green, Orange, Coral, Purple, Red, Pink, White, Yellow, Gold

– Shop By Pattern: Animal, Birds, Fish, Beach, Nautical, Tropical, Buffalo…

4. Carl Friedrik – PU Leather Accessories

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: PU leather, also known as artificial or imitation leather, is made from polyurethane, a synthetic plastic. It mimics the look and feel of animal leather and can be produced from various backing materials, including nylon, cotton, or split leather. PU leather is vegan-friendly when made entirely from synthetic materials. It is mass-produced, affordable, and can be dyed in various colors. Benefits i…

5. Rahui – PU Leather Solutions

Domain: rahui.com

Registered: 2015 (10 years)

Introduction: This company, Rahui – PU Leather Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for polyurethane leather material

In navigating the complexities of polyurethane leather sourcing, it is essential for international B2B buyers to weigh the pros and cons meticulously. Polyurethane leather offers significant cost advantages, versatility in design, and a vegan-friendly alternative to genuine leather. However, its drawbacks—such as limited durability and potential environmental concerns—demand careful consideration. Buyers must prioritize quality and supplier transparency, ensuring that the products align with both market demands and sustainability goals.

Strategic sourcing remains a pivotal approach in securing high-quality materials while fostering supplier relationships that can adapt to evolving market conditions. By focusing on transparency and ethical sourcing, businesses can not only enhance their product offerings but also build trust with their customer base.

Looking ahead, the demand for alternative materials like PU leather is likely to grow, particularly in regions such as Africa, South America, the Middle East, and Europe. As global consumers become increasingly eco-conscious, suppliers who prioritize sustainable practices will stand out in the marketplace. Therefore, it is imperative for buyers to engage with forward-thinking manufacturers who are committed to innovation and sustainability in polyurethane leather production. Embrace the opportunity to lead in this burgeoning market by sourcing responsibly today.

Illustrative image related to polyurethane leather material

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.