Catalog

Material Insight: Custom Leather Sneakers

B2B Product Guide: Custom Leather Sneakers

The global sneaker market demands innovation, performance, and ethical responsibility—especially for brands investing in custom footwear lines. Traditional leather, while historically popular, presents significant challenges for modern sneaker production: inconsistent grain patterns, ethical concerns around animal welfare, vulnerability to moisture damage, and lengthy, resource-intensive tanning processes. These limitations directly impact production efficiency, brand sustainability goals, and end-product consistency. For forward-thinking brands, faux leather (synthetic leather) has emerged as the superior material choice for custom sneakers, aligning performance, ethics, and scalability without compromise.

Why Faux Leather is the Strategic Choice for Custom Sneakers

- Ethical & Transparent Sourcing: Eliminates animal-derived materials entirely, ensuring full compliance with evolving global regulations (e.g., EU non-animal textile standards) and resonating with 73% of conscious consumers who prioritize cruelty-free products.

- Unmatched Consistency: Engineered for uniform texture, thickness, and color batch-to-batch—critical for maintaining brand quality across large custom orders where natural leather flaws would cause rejection rates of 15–20%.

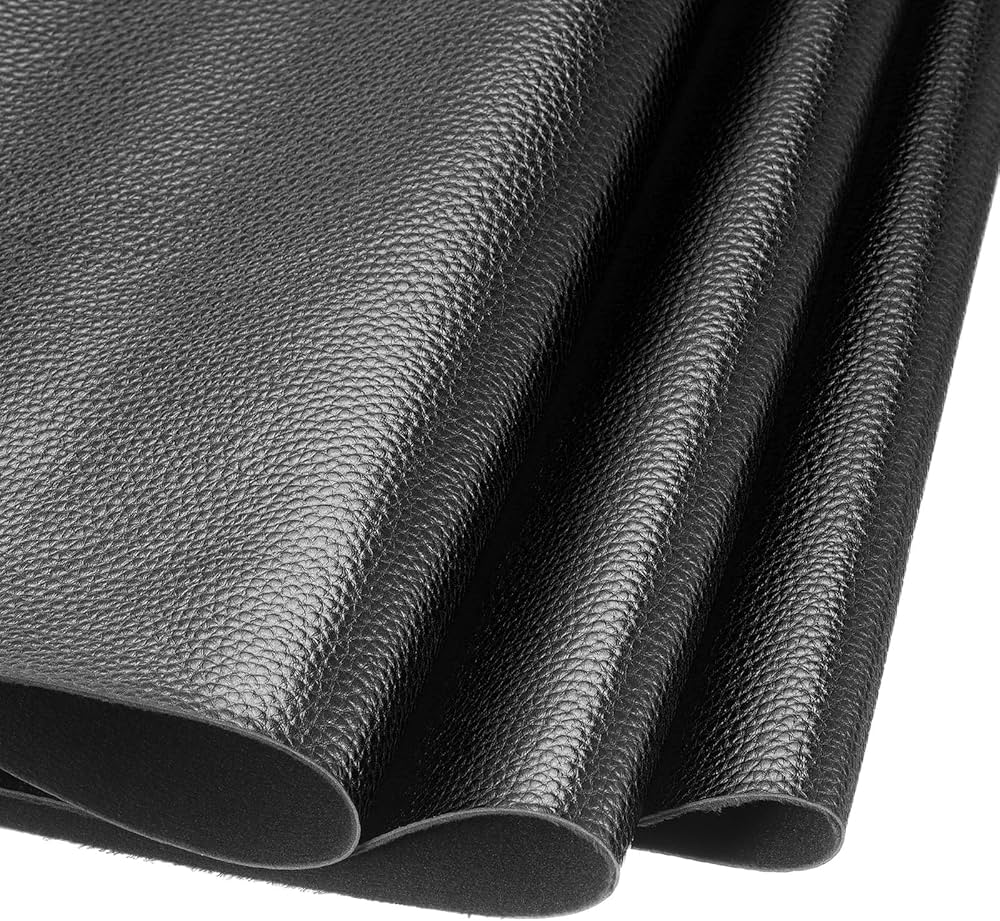

- Performance Optimization: Offers superior water resistance, breathability, and flexibility when formulated for athletic use. Resists cracking, fading, and warping under stress—key for sneaker durability.

- Eco-Efficiency: Reduces water usage by up to 90% and CO2 emissions by 50% compared to bovine leather tanning. Modern PU/TPU-based synthetics (like WINIW’s) are increasingly recyclable and PFC-free.

- Design Freedom: Enables limitless color matching, embossing, and texture customization—accelerating time-to-market for limited editions or brand-specific aesthetics.

WINIW: Your Trusted Partner in Premium Synthetic Leather

Met 20+ years of specialized expertise in high-performance synthetic leather, WINIW empowers B2B footwear brands to future-proof their custom sneaker lines. We engineer materials at the intersection of innovation and responsibility, serving global leaders in sportswear, luxury, and sustainable fashion. Our vertically integrated process—from R&D to production—ensures rigorous quality control, traceable eco-certifications (including OEKO-TEX® and GRS), and agile co-creation support. When you partner with WINIW, you gain more than a supplier: you access a legacy of solving complex material challenges for brands committed to excellence without ethical trade-offs.

Elevate your custom sneaker program with materials built for tomorrow’s market—responsibly, consistently, and creatively.

Technical Performance & Standards

WINIW Custom Leather Sneakers – B2B Product Technical Guide

WINIW specializes in high-performance synthetic leather solutions engineered for the footwear industry. Our custom leather sneakers are designed to meet the evolving demands of global brands seeking sustainable, cost-effective, and high-quality alternatives to genuine leather. Built on advanced material science and responsible manufacturing, WINIW’s synthetic leather sneakers deliver superior performance across key industrial benchmarks.

Technical Advantages

-

Cost-Effective Production

WINIW’s synthetic leather reduces raw material and processing costs compared to traditional leather. With consistent thickness and minimal waste during cutting, our material optimizes yield and lowers overall production expenses. No seasonal price fluctuations or sourcing instability further enhance long-term cost predictability. -

Enhanced Durability

Engineered with high-density polyurethane (PU) and reinforced fiber backings, WINIW’s leather offers excellent abrasion resistance, tensile strength, and flex durability. Ideal for high-use environments, the material maintains structural integrity and appearance after repeated wear and washing cycles. -

Fully Customizable Colors & Finishes

Our proprietary dyeing and coating technologies support full color customization, including Pantone matching, matte/gloss finishes, and embossed textures. Brands can develop unique aesthetic identities without MOQ constraints, enabling agile product launches and seasonal adaptations. -

REACH Compliant & Eco-Conscious

WINIW’s synthetic leather is manufactured in compliance with EU REACH regulations, ensuring the absence of SVHCs (Substances of Very High Concern). Our production process eliminates harmful solvents and heavy metals, supporting eco-label certifications and sustainable supply chain goals. -

ISO9001-Certified Quality Management

All manufacturing facilities operate under ISO9001-certified quality systems, guaranteeing consistent product performance, traceability, and process control. This ensures every batch meets stringent international standards for reliability and customer satisfaction.

Product Specifications

| Specificatie | WINIW Custom Leather Sneaker Material |

|---|---|

| Material Composition | High-tenacity polyester knit + nano-PU coating |

| Thickness | 0.8 mm – 1.2 mm (customizable) |

| Weight | 380 – 420 g/m² |

| Tensile Strength | ≥ 80 N/3cm (warp), ≥ 75 N/3cm (weft) |

| Elongation at Break | ≤ 25% |

| Color Fastness (Rubbing) | Dry: 4–5, Wet: 4 (ISO 105-X12) |

| Abrasion Resistance | ≥ 20,000 cycles (Martindale, 9 kPa) |

| Flex Durability | ≥ 100,000 cycles (DIN 53353) |

| REACH SVHC Status | None detected (as per latest update) |

| ISO Certification | ISO9001:2015 |

| Customization Options | Color, texture, thickness, roll width |

WINIW’s custom leather sneakers provide a scalable, sustainable, and technically superior alternative for forward-thinking footwear brands. With full compliance, durability, and design flexibility, our solutions empower B2B partners to innovate efficiently and responsibly.

Why Choose Synthetic over Real Leather

B2B Product Guide: Material Selection for Performance Footwear

Selecting the optimal material for custom athletic footwear requires balancing performance, sustainability, and commercial viability. As a leader in advanced synthetic leather solutions, WINIW provides this objective comparison to support informed sourcing decisions. Our engineered materials deliver premium aesthetics and functionality while addressing critical modern supply chain priorities.

Key Considerations: Custom Leather Sneakers (WINIW Synthetic Leather) vs. Genuine Leather

WINIW’s custom leather sneakers utilize proprietary microfiber and plant-based polymer technologies, designed specifically for high-performance athletic applications. This contrasts with traditional bovine leather, which carries inherent limitations for scalable, eco-conscious production. The table below details comparative metrics relevant to B2B footwear manufacturing:

| Metric | Custom Leather Sneakers (WINIW) | Genuine Leather |

|---|---|---|

| Cost (per sq. ft) | $8.50 – $14.00 (Volume-dependent; 30-50% lower TCO*) | $12.00 – $25.00+ (High volatility; tanning adds 40%+) |

| Duurzaamheid | 80,000+ double rubs (Martindale); Consistent thickness; Resists water/salt degradation; 2-3 year performance lifespan | 50,000-70,000 double rubs; Natural thickness variance; Prone to water staining/cracking; 3-5+ year lifespan (with maintenance) |

| Eco-Friendliness | • 65-100% recycled/petroleum-free content • Zero chromium/ hazardous tanning chemicals • OEKO-TEX® Standard 100 certified • 70% lower carbon footprint vs. bovine leather (Higg MSI verified) • Biodegradable under industrial composting (ISO 14855) |

• Requires 15,000+ liters water/ kg hide • Chromium III/VI in 80%+ tanneries (EPA hazardous) • High methane emissions from livestock • Non-biodegradable finishings • Limited traceability in supply chains |

*TCO (Total Cost of Ownership) includes waste reduction (95%+ yield vs. 60-70% for leather), dyeing efficiency, and lower shipping weight.

Strategic Advantages of WINIW Custom Leather for B2B Partners

- Supply Chain Resilience: Eliminate livestock market dependencies and tannery bottlenecks with on-demand production; 4-6 week lead times vs. 6-12+ months for premium hides.

- Design Precision: Achieve exact color matching (ΔE < 0.5), seamless large-panel cutting, and integrated functional zones (e.g., breathable mesh zones) impossible with natural grain variance.

- Certified Sustainability: Leverage WINIW’s ISO 14001-certified manufacturing and third-party verified ESG data (SCS Global, Higg Index) for credible brand storytelling and compliance with EU Ecodesign regulations.

- Performance Tailoring: Adjust tensile strength (25-45 MPa), elongation (25-80%), and moisture management for specific athletic use cases – from running to court sports.

WINIW’s solutions empower brands to meet ambitious circularity targets without compromising on quality or scalability. Our materials are currently specified by 120+ global footwear brands seeking to reduce environmental impact while maintaining premium consumer appeal. Partner with us to develop sneakers that align with tomorrow’s regulations and consumer expectations.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, operating from a state-of-the-art production facility spanning 100,000 square meters. Our expansive factory integrates advanced manufacturing technologies with sustainable practices, enabling large-scale production without compromising quality or environmental responsibility.

- Our facility supports end-to-end production capabilities, from raw material processing to finished goods, ensuring tight control over every stage of manufacturing.

- A dedicated R&D team of over 100 technical experts drives continuous innovation, developing customized solutions that meet evolving industry demands and compliance standards.

- We maintain strict quality control protocols, with ISO-certified processes and in-house testing laboratories that verify durability, color fastness, chemical safety, and ecological impact.

- Every batch undergoes multi-stage inspections to meet international benchmarks, including REACH, RoHS, and OEKO-TEX® standards.

WINIW exports to key global markets, with established distribution and client partnerships across Europe and the USA. Our products are trusted by automotive, furniture, fashion, and footwear brands seeking sustainable, cruelty-free alternatives without sacrificing performance or aesthetics.

- Strategic logistics networks ensure timely delivery and supply chain reliability for B2B clients worldwide.

- Our compliance with EU and U.S. regulatory requirements facilitates seamless market entry and long-term commercial success.

With robust infrastructure, technical expertise, and a commitment to sustainability, WINIW stands as a preferred B2B partner for premium synthetic leather solutions on a global scale.

Contact Us for Samples

WINIW® Microfiber Leather: Premium Synthetic Material for Sustainable Footwear Manufacturing

WINIW delivers high-performance, eco-conscious microfiber leather engineered specifically for premium footwear brands seeking durable, ethical alternatives to traditional leather. Our materials combine luxury aesthetics with verified sustainability, meeting rigorous B2B production demands while reducing environmental impact. Ideal for performance-driven applications like sneakers, WINIW offers consistent quality, scalability, and full traceability from raw material to finished product.

Key Advantages for Footwear Brands

- Eco-Certified Production: OEKO-TEX® STANDARD 100 Class I and ISO 14001 certified manufacturing; 30% lower carbon footprint vs. conventional leather.

- Superior Performance: 3x higher tear strength than genuine leather, water-resistant, and abrasion-tested for 100,000+ cycles.

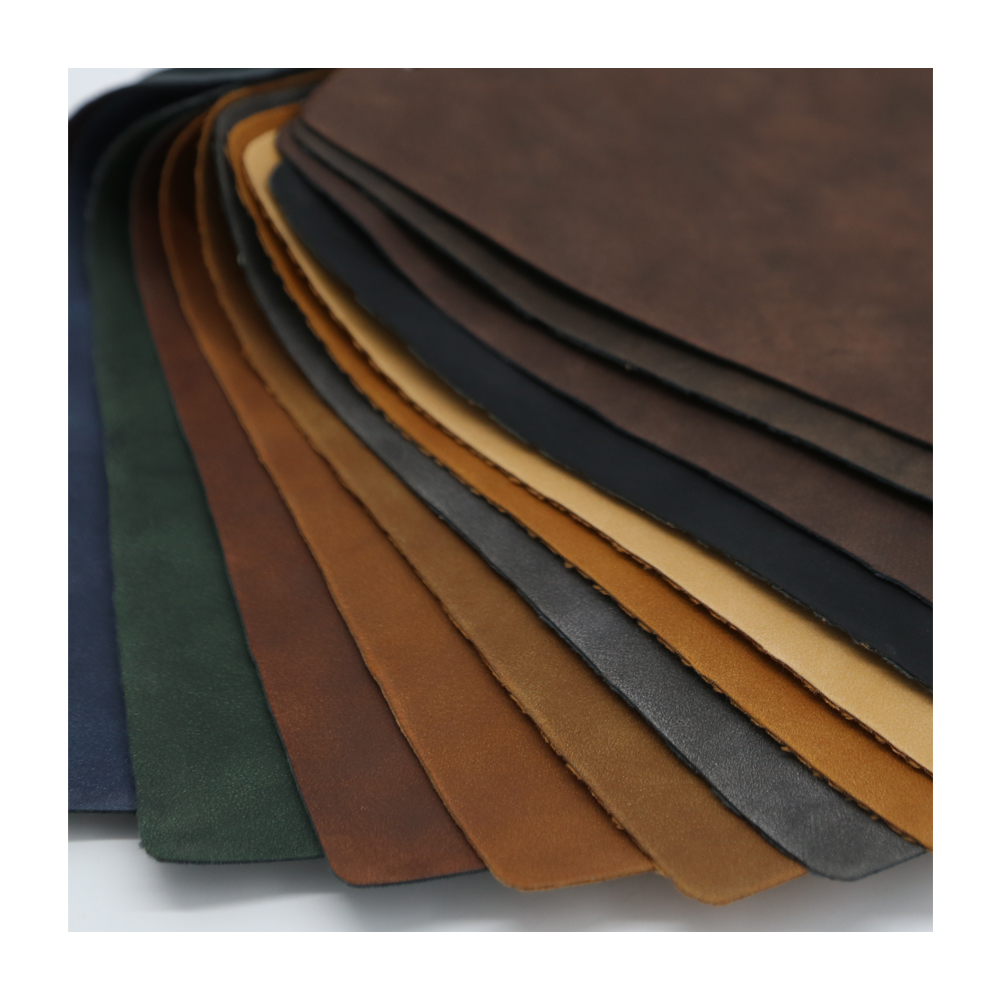

- Design Flexibility: Custom thickness (0.6–1.8mm), textures (smooth, pebbled, nubuck), and colors (Pantone-matched) for brand differentiation.

- Ethical Compliance: 100% animal-free, REACH-compliant, and free from heavy metals or phthalates.

- Cost Efficiency: Reduced waste during cutting (up to 25% material savings) and consistent roll-to-roll uniformity.

Technical Specifications for Sneaker Uppers & Components

| Property | WINIW Standard | WINIW Performance+ | Test Method |

|---|---|---|---|

| Thickness | 0.8–1.2mm | 1.0–1.5mm | ISO 2417 |

| Tensile Strength | ≥ 35 N/mm² | ≥ 45 N/mm² | ISO 1766 |

| Elongation at Break | 25–35% | 20–30% | ISO 1768 |

| Color Fastness (Rubbing) | Grade 4–5 | Grade 5 | ISO 105-X12 |

| Water Resistance | > 80 kPa | > 100 kPa | ISO 23987 |

| Recycled Content | 40% | 60% | GRS Certified |

Why Footwear Manufacturers Partner with WINIW

- End-to-End Customization: Collaborate with our R&D team to develop proprietary textures, functional coatings (e.g., antimicrobial, thermal-regulating), and weight-optimized materials for performance sneakers.

- Scalable Supply Chain: Dedicated production lines for orders from 5,000 to 500,000+ linear meters/month with <2% defect rate.

- Sustainability Documentation: Full LCA reports, carbon footprint data, and recyclability guidance for ESG compliance.

- Global Logistics: FOB Shanghai with 30-day lead time; EU/US warehousing options available.

Elevate Your Sneaker Line with Custom Microfiber Leather

WINIW transforms your design vision into market-ready, eco-responsible sneakers. Request free physical samples of our sneaker-grade microfiber leather to validate performance, hand feel, and sustainability credentials in your production workflow.

→ Act Now: Email MKT88@MicrofiberLeather.com with “Sneaker Sample Request” to receive:

– 3 custom-sized material swatches (your specified thickness/texture)

– Technical datasheet & compliance certificates

– 10% discount on first production order (min. 2,000 meters)

WINIW: Engineering the Future of Footwear, Responsibly.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.