Catalog

Material Insight: Custom Leather Motorcycle Seats

Custom leather motorcycle seats are a key element in both the performance and aesthetic appeal of high-quality motorcycles. Designed to balance comfort, durability, and style, these seats must withstand extreme weather conditions, prolonged use, and frequent exposure to UV light and abrasion. As demand for sustainable, low-maintenance, and customizable seating solutions grows, manufacturers and OEMs are increasingly turning to advanced synthetic materials—particularly high-performance faux leather—to meet these rigorous demands.

Faux leather stands out as the best choice for custom motorcycle seats for several compelling reasons:

– Superior Durability: Modern faux leather resists cracking, fading, and peeling, even under prolonged sun exposure and temperature fluctuations.

– Weather Resistance: Unlike genuine leather, faux leather does not absorb water, making it ideal for all-weather riding conditions.

– Low Maintenance: It requires no conditioning or special treatments, reducing long-term ownership costs.

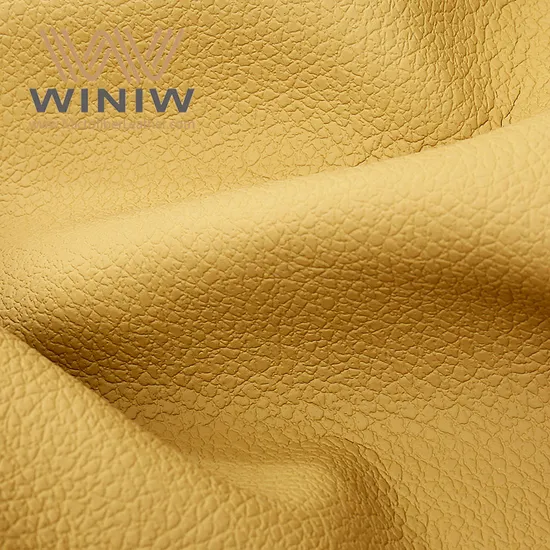

– Design Flexibility: Available in a wide range of colors, textures, and finishes, faux leather allows for full customization to match brand identity or rider preference.

– Eco-Friendly Production: Faux leather eliminates the environmental and ethical concerns associated with animal hide processing, aligning with global sustainability goals.

With over 20 years of specialized experience in synthetic leather innovation, WINIW has established itself as a trusted partner for B2B clients in the automotive, powersports, and luxury goods industries. Our proprietary manufacturing processes deliver faux leather that exceeds industry standards for tensile strength, abrasion resistance, and aesthetic quality. Engineered for performance and designed for longevity, WINIW’s materials are optimized for demanding applications like custom motorcycle seating—where function, comfort, and appearance must perform in harmony.

Technical Performance & Standards

WINIW Custom Leather Motorcycle Seat Solutions: Technical Product Guide

WINIW delivers engineered synthetic leather solutions specifically designed for high-performance motorcycle seating applications. Our proprietary manufacturing process integrates material science with sustainable production to provide OEMs and tier suppliers with a competitively priced, specification-driven alternative to traditional materials. The following technical advantages ensure seamless integration into demanding production environments while meeting global regulatory standards.

Key Technical Advantages

-

Cost-Effective Production Integration

Precision digital cutting compatibility reduces material waste by up to 22% versus conventional leather. Eliminates pre-treatment steps required for natural leather, shortening lead times by 15–30%. Volume-based pricing structures maintain cost stability despite market volatility in raw material markets. -

Enhanced Durability for Riding Conditions

Engineered with multi-layer polymer technology achieving 80,000+ double-rub test results (ISO 12947-2). UV-resistant topcoat prevents color degradation after 500+ hours of xenon arc exposure (ISO 105-B02). Reinforced backing system withstands -30°C to +70°C operational temperatures without delamination. -

Precision Color Customization

Full Pantone® matching capability (up to 1,200+ standard shades) with ΔE < 0.8 color consistency tolerance. Zero minimum order quantity (MOQ) for color variations. Digital color profiling ensures batch-to-batch repeatability within 0.5% tolerance. -

REACH SVHC Compliance

Fully documented absence of Substances of Very High Concern (Annex XIV) including DEHP, BBP, DBP, and DIBP. Certificate of Conformance available for all shipments. Traceable chemical inventory management from raw material sourcing through finished goods. -

ISO 9001-Certified Quality Framework

Real-time in-line thickness monitoring (±0.05mm tolerance) during coating application. Automated defect detection system with 99.2% accuracy rate. Full batch traceability via serialized QR codes linking to raw material certificates and process parameters.

Technical Specifications

| Parameter | Specificatie | Test Standard |

|---|---|---|

| Material Composition | Polyurethane top layer + high-resilience foam backing + non-woven polyester substrate | ASTM D412 |

| Thickness Range | 1.8mm – 2.5mm (customizable) | ISO 2424 |

| Color Fastness (Light) | Grade 7-8 (excellent) | ISO 105-B02 |

| Abrasion Resistance | >80,000 cycles (Martindale) | ISO 12947-2 |

| Tensile Strength | ≥35 N/mm² (warp), ≥30 N/mm² (weft) | ISO 1767 |

| Cold Crack Resistance | Passes at -30°C | ISO 14362-3 |

| VOC Emissions | <10 µg/m³ (chamber test) | ISO 16000-9 |

| Certifications | REACH SVHC Compliant, ISO 9001:2015, OEKO-TEX® STANDARD 100 Class I | Internal Audit No. WI-QA-2023-087 |

WINIW’s motorcycle seat solutions eliminate supply chain vulnerabilities associated with natural leather while delivering measurable performance improvements in real-world riding conditions. Our technical team provides collaborative engineering support from concept validation through production ramp-up, ensuring seamless adoption into existing manufacturing workflows. All materials are produced in solar-powered facilities with closed-loop water treatment systems, aligning with global sustainability initiatives without compromising on technical performance.

Why Choose Synthetic over Real Leather

B2B Product Guide: Custom Leather Motorcycle Seats vs. Real Leather

When manufacturing or sourcing motorcycle seats, material selection plays a critical role in balancing performance, cost, and sustainability. Two popular options in the market are custom leather motorcycle seats—typically made from high-performance synthetic leathers—and genuine (real) leather. Understanding the differences in cost, durability, and environmental impact is essential for B2B decision-making in motorcycle OEMs, aftermarket suppliers, and accessory brands.

Custom leather motorcycle seats, especially those made from premium synthetic materials like WINIW’s eco-leather, are engineered to meet the rigorous demands of motorcycling. These materials offer consistent texture, superior weather resistance, and design flexibility. In contrast, real leather, while traditionally valued for its natural aesthetics, presents certain limitations in performance and sustainability.

Below is a comparative analysis of custom leather motorcycle seats and real leather across key business and operational metrics:

| Feature | Custom Leather Motorcycle Seats | Real Leather |

|---|---|---|

| Cost | – Lower initial and lifecycle cost – No need for extensive conditioning – Reduced waste during production due to precise patterning |

– Higher raw material cost – Requires conditioning and maintenance – Greater material waste due to natural hide inconsistencies |

| Duurzaamheid | – Resistant to UV, moisture, and abrasion – Consistent thickness and performance – Less prone to cracking or fading over time |

– Prone to drying, cracking, and fading with UV exposure – Variable durability due to natural imperfections – Requires protective treatments |

| Eco-Friendliness | – Made from eco-conscious materials (e.g., PU/TPU with low-VOC emissions) – Animal-free production – Often recyclable or bio-based options available – Lower carbon footprint in processing |

– Resource-intensive (land, water, feed for livestock) – Chemical-heavy tanning processes (e.g., chromium) – Higher greenhouse gas emissions – Not aligned with cruelty-free or circular economy goals |

Custom synthetic leather seats offer OEMs and aftermarket brands a scalable, ethical, and high-performance alternative. They support brand differentiation through customizable textures, colors, and embossing—ideal for premium or niche motorcycle models.

In contrast, real leather carries legacy appeal but faces growing scrutiny due to environmental and ethical concerns. For B2B partners focused on innovation, sustainability, and long-term cost efficiency, custom leather solutions present a forward-thinking choice aligned with modern manufacturing standards and consumer expectations.

Key advantages of custom leather for motorcycle seating:

– Design versatility for brand-specific aesthetics

– Enhanced rider comfort with breathable, lightweight structures

– Compliance with global environmental regulations (REACH, RoHS)

– Support for ESG and circular economy initiatives

For motorcycle seat manufacturers seeking performance, consistency, and sustainability, custom leather represents a strategic upgrade over traditional real leather.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global B2B Partners

WINIW stands as a globally trusted manufacturer of premium synthetic leather, engineered for performance, sustainability, and reliability. Our vertically integrated production ecosystem ensures unmatched consistency and innovation, serving leading brands across fashion, automotive, furniture, and technical applications worldwide.

Core Manufacturing Capabilities

Our 100,000 sqm state-of-the-art manufacturing complex integrates end-to-end production under one roof, enabling rigorous quality oversight and agile scalability:

| Capability | Specificatie | B2B Advantage |

|---|---|---|

| Facility Size | 100,000 sqm (Asia & Europe bases) | Supports large-volume orders with 30-day lead times |

| Annual Output | 15 million+ meters | Guarantees supply chain resilience for global clients |

| R&D Team | 40+ material scientists & engineers | Accelerates custom development (6-8 week timelines) |

| QC Laboratories | 5 in-house testing facilities (ISO 17025) | Ensures 100% batch traceability & compliance |

Strategic Strengths Driving Client Success

- Innovation-Driven R&D: Our dedicated team pioneers eco-performance materials, including water-based PU, recycled PET substrates, and bio-based formulations. We hold 28 patents for low-VOC production and circular economy solutions, enabling co-creation of client-specific textures, weights, and functional properties.

- Zero-Compromise Quality Control: Every meter undergoes 12-stage validation, including:

- Colorfastness (AATCC/ISO) and abrasion resistance (Martindale ≥50,000 cycles)

- Eco-toxicity screening (REACH SVHC, OEKO-TEX® STANDARD 100)

- Physical performance testing (tear strength, flex durability, hydrolysis resistance)

- Global Compliance & Sustainability: WINIW materials meet stringent EU/US regulations including REACH, CPSIA, and Prop 65. Our facilities are certified ISO 14001, ISO 9001, and bluesign® approved, with 92% renewable energy usage in production.

- Market-Ready Export Infrastructure: Direct shipments to 40+ countries, with dedicated logistics hubs in Rotterdam and Los Angeles ensuring seamless customs clearance for EU/USA markets. All products include full LCA documentation and GRS-certified recycled content options.

WINIW’s fusion of industrial scale, scientific rigor, and environmental stewardship delivers synthetic leather that exceeds performance expectations while advancing your sustainability goals. Partner with us to transform material specifications into market-leading products.

Contact Us for Samples

WINIW B2B Product Guide: Premium Synthetic Leather for Motorcycle Seats

WINIW specializes in high-performance, eco-friendly synthetic leather engineered specifically for demanding applications in the motorcycle industry. Our advanced microfiber materials deliver exceptional durability, comfort, and aesthetic versatility, making them the preferred choice for OEMs and aftermarket seat manufacturers worldwide.

Designed to withstand UV exposure, abrasion, and extreme weather conditions, WINIW synthetic leather ensures long-lasting performance without compromising on style or sustainability. Our production process eliminates the environmental burden of traditional leather, aligning with global eco-standards and supporting your brand’s green initiatives.

Key Features of WINIW Synthetic Leather for Motorcycle Seats

- Superior abrasion resistance for enhanced rider safety and extended product life

- High tensile and tear strength suitable for dynamic seating structures

- Excellent color fastness and UV resistance to prevent fading

- Breathable, lightweight construction for improved rider comfort

- Water-resistant and easy to clean—ideal for outdoor use

- Customizable textures, finishes, and colors to match brand specifications

- REACH and RoHS compliant; free from harmful substances

- Sustainable alternative to animal leather with lower carbon footprint

Technical Specifications

| Property | Standard Value | Test Method |

|---|---|---|

| Thickness | 0.8 – 1.2 mm | ISO 2417 |

| Tensile Strength | ≥ 200 N/5cm | ISO 13934-1 |

| Tear Strength | ≥ 40 N | ISO 13937-3 |

| Color Fastness (light) | ≥ Grade 4 (100 hrs UV) | ISO 105-B02 |

| Seam Slippage | ≥ 120 N | ISO 13936-1 |

| Cold Crack Resistance | ≤ -20°C | ISO 4649 |

Why Choose WINIW?

- Proven integration with molded foam and composite seat substrates

- Consistent roll-to-roll quality for seamless manufacturing

- Scalable production capacity for global B2B supply chains

- In-house R&D team for material innovation and customization

Custom Leather Motorcycle Seats

WINIW offers end-to-end support for custom motorcycle seat development. From material selection to texture design and performance testing, we collaborate closely with manufacturers to deliver tailored solutions that meet exact functional and aesthetic requirements.

Whether you’re designing cruiser, sport, or touring seats, our synthetic leather adapts to your vision—without sacrificing sustainability or performance.

Call to Action:

Elevate your motorcycle seat production with WINIW’s premium synthetic leather.

Contact us today to request free samples and discuss your custom project.

E-mail: MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.