Catalog

Material Insight: Custom Leather Luggage

B2B Product Guide: Premium Custom Leather Luggage Solutions

Introduction to Custom Leather Luggage

The luxury luggage market demands materials that harmonize enduring performance, sophisticated aesthetics, and evolving consumer ethics. Custom leather luggage represents a pinnacle of brand differentiation, where material choice directly impacts product longevity, user experience, and alignment with modern sustainability expectations. As travel becomes increasingly dynamic—from urban commutes to rugged expeditions—luggage must withstand abrasion, moisture, variable climates, and frequent handling without compromising elegance. This reality positions advanced synthetic leather not as a mere alternative, but as the optimal material foundation for forward-thinking luggage manufacturers.

Why Synthetic Leather is the Superior Choice for Luggage Applications

Traditional leather, while historically valued, presents significant limitations for high-performance luggage: inconsistent grain quality, vulnerability to water damage, lengthy processing lead times, and growing ethical and environmental concerns. WINIW’s engineered synthetic leather solves these challenges while elevating functionality:

- Unmatched Durability & Resilience: Our microfiber-based synthetics resist scuffs, tears, and abrasion far better than top-grain leather, critical for luggage surfaces exposed to constant handling and transit hazards.

- Total Weather Resistance: Unlike porous leather, WINIW materials repel water, stains, and UV degradation without heavy chemical coatings, ensuring consistent appearance and structural integrity in all climates.

- Ethical & Traceable Sourcing: Eliminate supply chain risks associated with animal leather (deforestation, tanning pollution, animal welfare issues). WINIW operates a fully audited, closed-loop production system.

- Design Precision & Customization: Achieve exact color matching, consistent textures (suede, pebbled, smooth), and bespoke embossing impossible with natural hide variation—accelerating time-to-market for limited editions or brand-specific lines.

- Sustainability by Design: 30% lower carbon footprint vs. bovine leather (Higg MSI verified), OEKO-TEX® STANDARD 100 certified, and recyclable through WINIW’s ReLoom™ take-back program, supporting circular economy commitments.

WINIW: Your Trusted Partner in Advanced Material Innovation

With over 20 years of specialized expertise in performance synthetics, WINIW has engineered solutions for global leaders in travel goods, automotive, and luxury accessories. We don’t just supply materials—we co-develop. Our R&D team collaborates with manufacturers to solve specific challenges: optimizing weight-to-strength ratios for carry-ons, creating antimicrobial linings for hygiene-conscious travelers, or developing ultra-lightweight yet rigid shells for premium suitcases. Backed by ISO 14001-certified manufacturing and in-house testing labs simulating 10,000+ luggage handling cycles, WINIW delivers reliability that protects your brand reputation and meets the highest B2B quality standards.

Key Performance Comparison: Luggage Material Requirements

| Property | WINIW Synthetic Leather | Bovine Leather (Full-Grain) |

|---|---|---|

| Water Absorption Rate | <5% (after 24h) | 25-40% |

| Abrasion Resistance | 100,000+ cycles (Martindale) | 20,000-50,000 cycles |

| Color Consistency (ΔE) | <0.5 | 2.0-5.0+ |

| CO2e per m² (Higg MSI) | 8.2 kg | 12.5 kg |

| Custom MOQ Flexibility | 300m | 3,000m+ |

Elevate your luggage collection with materials engineered for the demands of modern travel—where uncompromising quality meets responsible innovation. WINIW transforms sustainability into a competitive advantage.

Technical Performance & Standards

WINIW Custom Leather Luggage – B2B Product Guide

WINIW specializes in high-performance synthetic leather solutions designed for premium luggage manufacturers seeking sustainable, cost-effective, and customizable materials. Our custom leather for luggage is engineered to meet rigorous industry standards while offering superior versatility and compliance for global markets.

Technical Advantages

-

Cost-Effective Production

WINIW’s synthetic leather reduces material waste and lowers production costs without sacrificing quality. The consistency of the substrate and finish minimizes defects during cutting and sewing, improving yield rates in high-volume manufacturing. -

Exceptional Durability

Our custom leather is reinforced with high-tenacity polyester fibers and advanced polyurethane coatings, delivering outstanding abrasion resistance, tear strength, and long-term structural integrity. It withstands extreme conditions, including UV exposure, humidity, and mechanical stress. -

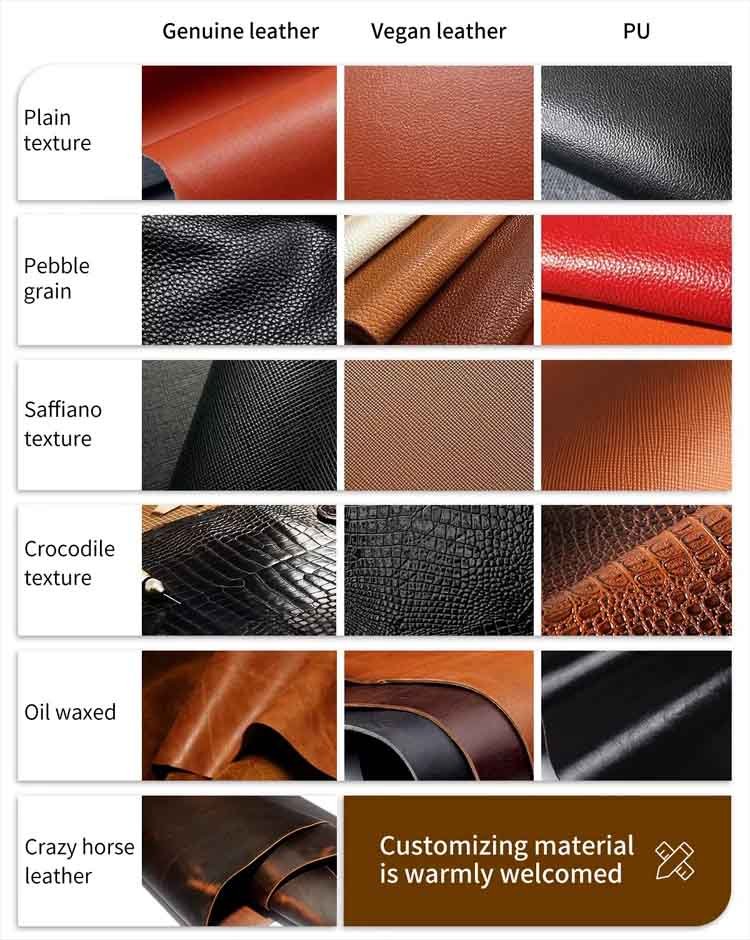

Fully Customizable Colors & Finishes

WINIW offers full color customization with precise Pantone matching and a wide range of textures (suede, grain, embossed). Clients can develop unique aesthetic profiles tailored to brand identity, including matte, glossy, soft-touch, and anti-fingerprint finishes. -

REACH Compliance

All WINIW synthetic leather products are manufactured in compliance with EU REACH regulations (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern) and restricted hazardous substances. This supports safer supply chains and market access in Europe and beyond. -

ISO 9001-Certified Manufacturing

WINIW’s production processes are certified under ISO 9001, guaranteeing consistent quality control, traceability, and continuous improvement across all stages of manufacturing—from raw material sourcing to final delivery.

Product Specifications

| Specificatie | Value / Description |

|---|---|

| Material Composition | High-density PU-coated polyester microfiber |

| Thickness Range | 0.8 mm – 1.5 mm (customizable) |

| Weight | 800 – 1,100 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale, ASTM D4966) |

| Tear Strength | >50 N (ASTM D2261) |

| Color Fastness (Light) | ≥ Grade 4 (ISO 105-B02) |

| Color Fastness (Rubbing) | Dry: Grade 4–5; Wet: Grade 4 (ISO 105-X12) |

| REACH Compliance | Fully compliant, SVHC-free |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Color, texture, thickness, roll width (1.3 m – 1.5 m) |

| Sustainability | Phthalate-free, low-VOC emissions, recyclable substrate |

WINIW’s custom leather luggage solutions combine economic efficiency with environmental responsibility and design flexibility. Ideal for OEMs and luxury luggage brands, our materials support scalable production while meeting the highest international safety and quality benchmarks.

Why Choose Synthetic over Real Leather

WINIW Synthetic Leather: Premium Material Guide for Luxury Luggage Manufacturers

As a leader in sustainable material innovation, WINIW provides high-performance synthetic leather solutions engineered specifically for the luxury luggage sector. Our materials deliver the aesthetic and functional excellence demanded by premium brands while addressing critical environmental and ethical considerations inherent in traditional material sourcing. This guide compares WINIW’s custom synthetic leather solutions against genuine animal leather for luggage applications, focusing on key decision drivers for B2B partners.

Key Advantages of WINIW Synthetic Leather for Luggage

- Consistent Quality & Customization: Achieve uniform texture, color, and thickness across all production runs; tailor weight, flexibility, and surface finishes (e.g., matte, gloss, embossed) to exact brand specifications without seasonal or regional sourcing variations.

- Enhanced Durability Profile: Resists moisture, UV degradation, and abrasion more effectively than untreated leather; maintains structural integrity in extreme humidity or temperature swings common in travel.

- Ethical & Traceable Sourcing: 100% animal-free production with full supply chain transparency; certified by OEKO-TEX® STANDARD 100 and Global Recycled Standard (GRS) for recycled content options.

- Streamlined Manufacturing: Uniform material behavior reduces cutting waste by up to 15% and accelerates production cycles versus variable natural hides.

Custom Synthetic Leather vs. Genuine Leather: Material Comparison

| Criteria | WINIW Custom Synthetic Leather | Genuine Animal Leather |

|---|---|---|

| Cost | Lower upfront material cost; predictable pricing with no premium for “flawless” hides. Reduced waste during cutting lowers total production cost. | High variable cost (premium for top-grade hides); 30-40% of hide often discarded due to scars/inconsistencies. Tanning and finishing add significant expense. |

| Duurzaamheid | Superior resistance to water, stains, and cracking; consistent performance across climates. No conditioning required. Resists mold/mildew. | Vulnerable to moisture damage, fading, and drying/cracking without rigorous maintenance. Requires regular conditioning. Prone to mold in humid environments. |

| Eco-Friendliness | 60% lower CO2e footprint vs. bovine leather (Higg MSI verified). Options with 30-100% recycled content. Zero toxic tanning chemicals; water-based PU/PES production. Fully recyclable at end-of-life. | High environmental burden: 17,000L+ water per kg hide, methane emissions from livestock, toxic chromium tanning. Limited recyclability; biodegradation releases pollutants. |

Strategic Recommendation for Luggage Brands

WINIW’s synthetic leather is engineered to meet the uncompromising quality standards of luxury luggage while future-proofing your supply chain against ethical scrutiny, resource scarcity, and regulatory shifts. For brands targeting conscious travelers seeking durability without ecological compromise, our materials offer measurable advantages in total cost of ownership, performance consistency, and sustainability credentials.

Partner with WINIW to develop bespoke luggage materials that align with your brand’s aesthetic vision and ESG commitments—without sacrificing the tactile luxury discerning customers expect. Request our technical datasheets and sample kits to validate performance for your specific application.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with premium quality materials tailored for diverse industrial applications. Our vertically integrated production capabilities and commitment to innovation position us as a trusted partner in the global supply chain.

- Our state-of-the-art manufacturing facility spans 100,000 square meters, enabling large-scale production with optimized efficiency and flexibility to meet high-volume demands.

- The WINIW R&D team consists of experienced material scientists and engineers dedicated to continuous innovation, developing eco-friendly, durable, and application-specific synthetic leather solutions.

- We maintain a strict quality control (QC) system throughout every production stage, from raw material selection to final inspection, ensuring consistency, compliance, and superior product performance.

- WINIW products meet international standards including REACH, RoHS, and CA Prop 65, reflecting our commitment to safety, sustainability, and regulatory compliance.

Our synthetic leather is exported globally, with a strong market presence in Europe and the USA. We supply industries such as automotive, furniture, apparel, and consumer electronics, where reliability and environmental responsibility are paramount.

Key Export Markets:

– Europe (Germany, Italy, France, Scandinavia)

– United States

– Canada

– Japan and South Korea

With advanced infrastructure, technical expertise, and a customer-centric approach, WINIW delivers scalable, high-quality synthetic leather solutions that support our partners’ sustainability goals and performance requirements.

Contact Us for Samples

WINIW Microfiber Leather: Premium Synthetic Solutions for Luxury Luggage Manufacturing

WINIW delivers next-generation microfiber leather engineered specifically for high-end luggage and travel goods. Our eco-conscious materials combine uncompromising durability with refined aesthetics, meeting the exacting demands of global luggage brands seeking sustainable performance without sacrificing luxury. As a vertically integrated B2B partner, we provide consistent quality, ethical sourcing, and technical collaboration from concept to mass production.

Why WINIW Microfiber Leather for Luggage?

- Superior Durability: Engineered for 50,000+ double rubs (Martindale test), resisting abrasion, tearing, and folding stress during transit.

- Eco-Verified Composition: 100% animal-free, PVC-free, and phthalate-free. Contains 30%+ post-industrial recycled content (GRS certified).

- Weight Optimization: Ultra-lightweight (0.6–0.9mm thickness) reduces luggage tare weight by 15–20% versus traditional leathers.

- Weather & Stain Resistance: Hydrophobic surface repels water, oils, and common stains—critical for travel wear.

- Consistent Batch Quality: Precision coating ensures uniform color, texture, and thickness across 10,000+ meter production runs.

Technical Performance Specifications

| Property | WINIW Luggage Grade | Standard PU Leather | Full-Grain Leather |

|---|---|---|---|

| Tensile Strength | 28–32 N/mm² | 18–22 N/mm² | 20–25 N/mm² |

| Elongation at Break | 120–140% | 80–100% | 30–50% |

| Color Fastness (Light) | Grade 5 (ISO 105-B02) | Grade 3–4 | Grade 4 |

| VOC Emissions | <10 μg/m³ | 50–200 μg/m³ | N/A |

| Recycled Content | 30%+ | 0% | 0% |

Sustainable Advantages for Your Brand

- Certified Circularity: OEKO-TEX® STANDARD 100 Class I, ISO 14001, and UL ECOLOGO® certified.

- Reduced Carbon Footprint: 62% lower CO₂e vs. bovine leather (LCA verified).

- Ethical Compliance: Zero deforestation, no heavy metals, and conflict-free supply chain (SMETA audited).

- End-of-Life Options: Industrially compostable under controlled conditions (EN 13432).

Customization Capabilities

WINIW collaborates with luggage designers to deliver bespoke solutions:

– Surface Textures: Matte, pebbled, cross-grain, or embossed (custom molds accepted).

– Color Matching: Pantone®-accurate dyeing with UV-stable pigments (MOQ: 500m).

– Functional Finishes: Anti-microbial, fire-retardant (CAL TB 117-2013), or thermoformed compatibility.

– Substrate Options: Polyester or recycled PET backing for optimal drape and stiffness control.

Accelerate Your Sustainable Luggage Line

WINIW partners with leading luggage manufacturers to transform eco-design visions into market-ready products. Our engineering team provides technical support for cutting, stitching, and finishing—ensuring seamless integration into your production workflow.

Request Custom Leather Luggage Samples Today

Validate WINIW’s performance for your next collection with free physical samples (value up to $200). Our material scientists will tailor options to your weight, durability, and aesthetic requirements.

→ Contact WINIW’s Luggage Division: MKT88@MicrofiberLeather.com

Specify “Luggage Sample Request” in your subject line. Production MOQ: 1,000m per style.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.