Introduction: Navigating the Global Market for how to make a leather knife sheath

Navigating the intricate world of leather craftsmanship can be a daunting task, especially when seeking to create a high-quality leather knife sheath. For B2B buyers across diverse markets in Africa, South America, the Middle East, and Europe—such as Germany and Brazil—understanding the nuances of sourcing materials and skilled artisans is crucial. This guide provides a comprehensive overview of the leather knife sheath-making process, addressing essential aspects such as types of leather, tools required, and effective techniques to ensure durability and functionality.

By delving into the various applications of leather sheaths, from custom knife production to outdoor equipment, this guide equips international buyers with the knowledge needed to make informed purchasing decisions. It also emphasizes the importance of vetting suppliers, ensuring that they meet quality standards while considering cost-effectiveness. With insights into material sourcing and craftsmanship, B2B buyers can confidently navigate the global market, reducing risks associated with poor-quality products.

Ultimately, this guide serves as a valuable resource for businesses aiming to enhance their product offerings with expertly crafted leather knife sheaths, fostering partnerships that prioritize quality, sustainability, and innovation. As the demand for bespoke leather goods continues to grow, equipping your business with the right knowledge can set you apart in a competitive landscape.

Table Of Contents

- Top 4 How To Make A Leather Knife Sheath Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather knife sheath

- Understanding how to make a leather knife sheath Types and Variations

- Key Industrial Applications of how to make a leather knife sheath

- 3 Common User Pain Points for ‘how to make a leather knife sheath’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather knife sheath

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather knife sheath

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather knife sheath’

- Comprehensive Cost and Pricing Analysis for how to make a leather knife sheath Sourcing

- Alternatives Analysis: Comparing how to make a leather knife sheath With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather knife sheath

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather knife sheath Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather knife sheath

- Strategic Sourcing Conclusion and Outlook for how to make a leather knife sheath

- Important Disclaimer & Terms of Use

Understanding how to make a leather knife sheath Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Folded Sheath | Simple design, typically made from a single piece of leather folded over. | Artisan knife makers, custom knife shops | Pros: Cost-effective, easy to produce. Cons: Less durable than multi-layer designs. |

| Stitched Sheath | Features multiple pieces stitched together for added strength and design flexibility. | Leather goods manufacturers, outdoor retailers | Pros: Highly customizable, durable. Cons: More labor-intensive, requires skilled labor. |

| Molded Sheath | Form-fitted to the knife shape, often using heat or moisture to shape the leather. | High-end knife manufacturers, bespoke artisans | Pros: Perfect fit, enhanced protection. Cons: Requires more time and specialized equipment. |

| Dye-Enhanced Sheath | Utilizes various dyes for aesthetic appeal, often combined with unique patterns. | Fashion-oriented knife brands, custom leather shops | Pros: Attractive appearance, brand differentiation. Cons: Dyeing process can add to production time. |

| Multi-Layer Sheath | Composed of several layers of leather for added protection and design complexity. | Tactical gear manufacturers, outdoor survival brands | Pros: Extremely durable, offers customization. Cons: Higher material costs, more complex assembly. |

What Are the Key Characteristics of a Folded Sheath?

The folded sheath is one of the simplest designs, typically made from a single piece of leather that is folded over to accommodate the knife. This type is cost-effective and straightforward to produce, making it suitable for artisan knife makers and custom knife shops looking to minimize production costs. However, while it is easy to manufacture, it may lack the durability and protection offered by more complex designs.

How Does a Stitched Sheath Stand Out?

Stitched sheaths are crafted from multiple pieces of leather stitched together, allowing for greater design flexibility and strength. This type is popular among leather goods manufacturers and outdoor retailers, as it provides a robust solution for knife storage. The customization options are vast, but this method is more labor-intensive and requires skilled craftsmanship, which can increase production costs.

What Makes a Molded Sheath Ideal for High-End Products?

Molded sheaths are specifically designed to fit the knife’s shape, often utilizing heat or moisture to achieve a perfect fit. This type is favored by high-end knife manufacturers and bespoke artisans who prioritize protection and aesthetics. While molded sheaths offer superior fit and protection, they require more time and specialized equipment for production, making them a more significant investment.

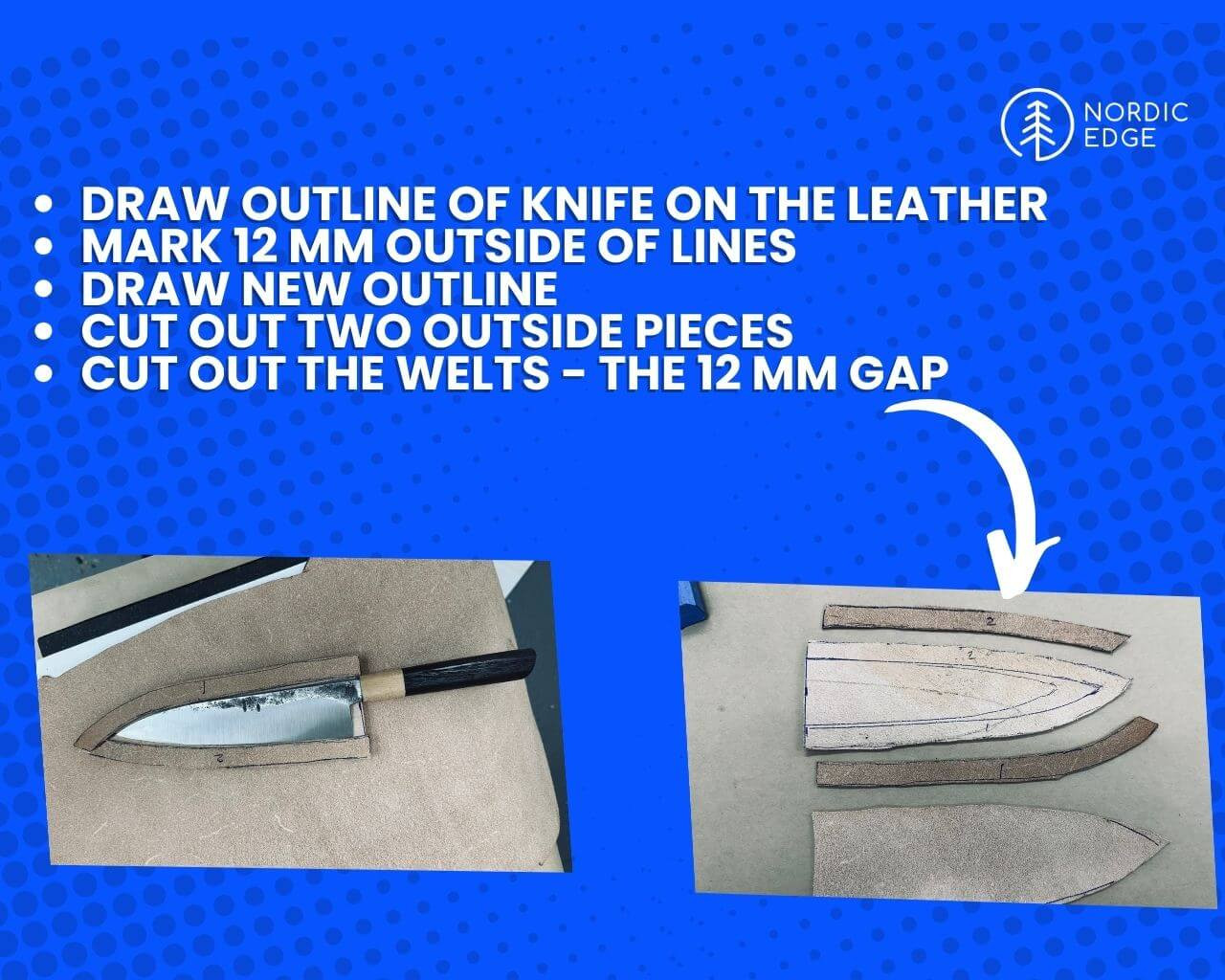

Illustrative image related to how to make a leather knife sheath

Why Consider Dye-Enhanced Sheaths for Fashion-Oriented Brands?

Dye-enhanced sheaths utilize various dyes to create visually appealing designs, often incorporating unique patterns. This type is particularly suitable for fashion-oriented knife brands and custom leather shops aiming to differentiate their products. While they enhance aesthetic appeal, the dyeing process can add to production time and complexity, which buyers should consider when planning their inventory.

What Are the Benefits of Multi-Layer Sheaths?

Multi-layer sheaths consist of several layers of leather, providing exceptional durability and the potential for intricate designs. They are commonly used by tactical gear manufacturers and outdoor survival brands, offering robust protection for knives in demanding environments. However, the increased material costs and complexity of assembly can be a drawback for some buyers, necessitating careful consideration of production capabilities and pricing strategies.

Key Industrial Applications of how to make a leather knife sheath

| Industry/Sector | Specific Application of how to make a leather knife sheath | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Custom knife sheaths for hunting and camping knives | Enhances customer satisfaction with personalized products | Quality of leather, durability, and weather resistance |

| Culinary Equipment | Sheaths for chef knives and culinary tools | Improves safety and extends the life of expensive knives | Sourcing high-quality leather and craftsmanship |

| Artisan Craftsmanship | Handmade leather sheaths for artisanal knives | Supports local craftsmanship and unique product offerings | Availability of skilled artisans and leather types |

| Military and Tactical Gear | Sheaths for tactical knives used by military and law enforcement | Increases operational efficiency and safety for personnel | Compliance with regulations and durability standards |

| Retail and E-commerce | Selling leather knife sheaths as accessories | Expands product line and enhances brand image | Cost-effectiveness and market trends |

How is ‘how to make a leather knife sheath’ utilized in the outdoor recreation industry?

In the outdoor recreation sector, crafting custom knife sheaths is essential for enhancing the functionality and safety of hunting and camping knives. Businesses can offer personalized options, appealing to consumers looking for unique, durable solutions. The ability to source high-quality leather that withstands various weather conditions is critical, especially in regions like Africa and South America, where outdoor activities are prevalent. Buyers must consider the leather’s durability and resistance to elements to ensure longevity and customer satisfaction.

Illustrative image related to how to make a leather knife sheath

What role does a leather knife sheath play in culinary equipment?

In the culinary equipment industry, leather knife sheaths are vital for protecting chef knives and other culinary tools. These sheaths not only enhance safety by preventing accidental cuts but also prolong the lifespan of high-value knives. For B2B buyers, sourcing high-quality leather that meets hygiene and safety standards is essential. Additionally, buyers should seek suppliers who can offer craftsmanship that aligns with culinary professionals’ expectations, particularly in markets like Europe, where culinary standards are high.

How does artisan craftsmanship benefit from leather knife sheath production?

Artisan craftsmanship thrives on the production of handmade leather sheaths for artisanal knives, allowing businesses to create unique and high-quality products. This approach supports local artisans and promotes sustainable practices, appealing to eco-conscious consumers. For international buyers, especially in the Middle East and Europe, it is crucial to ensure that the artisans possess the necessary skills and that the leather used is ethically sourced. This not only enhances the product’s value but also aligns with the growing trend towards sustainability in craftsmanship.

Why are leather knife sheaths critical for military and tactical gear?

In the military and tactical gear sector, leather knife sheaths serve as essential accessories for tactical knives used by personnel. These sheaths improve operational efficiency and ensure safety during missions. For businesses in this field, compliance with military regulations and durability standards is paramount. Buyers must source materials that can withstand rigorous conditions, ensuring that the sheaths are reliable and functional in high-stress environments, particularly in regions with challenging climates.

Illustrative image related to how to make a leather knife sheath

How can retail and e-commerce benefit from selling leather knife sheaths?

Retail and e-commerce platforms can significantly benefit from incorporating leather knife sheaths into their product lines as accessories. This not only expands their offerings but also enhances their brand image by providing quality, handcrafted items. For B2B buyers, understanding market trends and consumer preferences is vital to ensure that the products meet demand. Cost-effectiveness in sourcing and the ability to market unique features can differentiate their offerings in competitive markets across various regions, including South America and Europe.

3 Common User Pain Points for ‘how to make a leather knife sheath’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Knife Sheaths

The Problem: B2B buyers often struggle with sourcing high-quality leather that meets specific requirements for durability, aesthetic appeal, and cost-effectiveness. This challenge can be particularly pronounced for businesses operating in diverse markets such as Africa or South America, where local availability may vary widely. Poor quality leather can lead to sheaths that wear quickly, resulting in customer dissatisfaction and increased warranty claims.

The Solution: To address this issue, buyers should establish relationships with reliable suppliers who specialize in leather goods. Attend trade shows or industry expos to connect with reputable vendors and assess their offerings firsthand. Additionally, consider sourcing leather scraps from local artisans or manufacturing units to reduce costs while supporting local economies. Always request samples to evaluate the leather’s quality before committing to larger orders. Emphasizing sustainability in sourcing can also enhance brand reputation and attract environmentally conscious customers.

Scenario 2: Mastering the Craft of Leather Sheath Construction

The Problem: Many buyers, especially those new to leather crafting, find it daunting to construct a knife sheath that meets both functional and aesthetic standards. This lack of expertise can lead to wasted materials, increased labor costs, and ultimately, unsatisfactory products that fail to resonate with end-users. The fear of producing subpar work can deter businesses from expanding their product lines to include custom knife sheaths.

Illustrative image related to how to make a leather knife sheath

The Solution: Investing in training and resources is crucial for overcoming this learning curve. Buyers should seek out workshops or online courses that focus on leather crafting techniques specific to sheath construction. Collaborating with experienced leather workers can also provide invaluable insights and mentorship. Additionally, leveraging video tutorials and instructional content can offer step-by-step guidance. To further mitigate the risk of material waste, create paper prototypes to test designs before cutting into leather. This approach not only saves resources but also helps refine the final product.

Scenario 3: Ensuring Durability and Functionality in Knife Sheath Design

The Problem: A common issue faced by manufacturers is ensuring that the knife sheath design is both durable and functional. Sheaths that do not securely hold the knife can lead to accidents and damage, while those that are too tight may cause wear on the blade. This delicate balance is critical for maintaining product integrity and safety, especially in industries where knives are essential tools, such as culinary or outdoor sectors.

The Solution: To achieve a well-balanced design, it is essential to conduct thorough testing and prototyping. Start by designing the sheath with adjustable components, such as snap fasteners or belt loops, to accommodate various knife sizes and user preferences. Utilize feedback from actual users in the target market to refine the design and functionality. Incorporating features like reinforced stitching and burnished edges can enhance durability. Additionally, consider using computer-aided design (CAD) software to simulate the sheath’s performance under various conditions, allowing for modifications before production begins. This proactive approach not only ensures safety but also builds a reputation for quality craftsmanship.

Illustrative image related to how to make a leather knife sheath

Strategic Material Selection Guide for how to make a leather knife sheath

When selecting materials for crafting a leather knife sheath, it’s essential to consider various factors that affect performance, durability, and cost. Below, we analyze several common materials used in the production of leather knife sheaths, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Different Leather Types for Knife Sheaths?

-

Vegetable-Tanned Leather

– Key Properties: Vegetable-tanned leather is treated with natural tannins from plant sources, making it biodegradable and environmentally friendly. It exhibits excellent durability and can withstand moderate abrasion and moisture.

– Pros & Cons: This type of leather is known for its rigidity, which provides good protection for the knife. However, it can be more expensive than chrome-tanned leather and may require more time to break in. Its natural finish allows for dyeing and tooling, enhancing aesthetic appeal.

– Impact on Application: Ideal for sheaths that require a sturdy structure, vegetable-tanned leather can accommodate various knife shapes and sizes. It is also compatible with various dyes and finishes.

– Considerations for International Buyers: Buyers from regions like Europe may prefer vegetable-tanned leather due to its compliance with environmental regulations. Standards such as the REACH regulation in the EU can influence material sourcing. -

Chrome-Tanned Leather

– Key Properties: Chrome-tanned leather is processed using chromium salts, resulting in a softer and more flexible material. It has good resistance to water and is less prone to mold and mildew.

– Pros & Cons: This leather is typically less expensive and easier to work with than vegetable-tanned leather. However, it may not provide the same level of rigidity and protection, making it less suitable for heavy-duty applications.

– Impact on Application: Chrome-tanned leather is suitable for sheaths that require flexibility and comfort, such as those used in outdoor or tactical environments. However, it may not accept dyes as well as vegetable-tanned leather.

– Considerations for International Buyers: Buyers in regions like South America and Africa may find chrome-tanned leather more accessible due to lower costs and availability. However, they should ensure compliance with local environmental standards regarding chemical treatments. -

Nylon or Synthetic Leather

– Key Properties: Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers high durability and resistance to water and stains. It is lightweight and can mimic the appearance of real leather.

– Pros & Cons: Synthetic options are generally more affordable and easier to maintain than natural leather. However, they may lack the aesthetic appeal and traditional craftsmanship associated with genuine leather.

– Impact on Application: Ideal for budget-friendly knife sheaths, synthetic leather can be used in various applications, including casual and outdoor use. However, it may not provide the same level of protection against sharp blades as thicker leather options.

– Considerations for International Buyers: Buyers in the Middle East may prefer synthetic materials due to their affordability and ease of care. Compliance with local regulations regarding synthetic materials should be verified. -

Full-Grain Leather

– Key Properties: Full-grain leather retains the natural grain of the hide, providing exceptional durability and breathability. It ages beautifully, developing a unique patina over time.

– Pros & Cons: This leather type is considered the highest quality, offering superior strength and aesthetics. However, it can be the most expensive option and may require more care to maintain its appearance.

– Impact on Application: Full-grain leather is perfect for high-end knife sheaths that prioritize both functionality and style. Its durability makes it suitable for heavy-duty applications.

– Considerations for International Buyers: Buyers in Europe, particularly in Germany, may favor full-grain leather for its quality and craftsmanship. Compliance with EU quality standards can enhance marketability.

Summary Table of Material Selection for Leather Knife Sheaths

| Materiaal | Typical Use Case for how to make a leather knife sheath | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Sturdy, traditional knife sheaths requiring durability | Environmentally friendly, customizable | Higher cost, longer break-in period | Hoog |

| Chrome-Tanned Leather | Flexible, comfortable sheaths for tactical use | Lower cost, easy to work with | Less rigidity, limited dye acceptance | Medium |

| Nylon or Synthetic Leather | Budget-friendly sheaths for casual use | Affordable, lightweight | Lacks aesthetic appeal, less durable | Low |

| Full-Grain Leather | High-end sheaths prioritizing quality and style | Exceptional durability, ages well | Most expensive, requires maintenance | Hoog |

This analysis provides a comprehensive overview of material options for leather knife sheaths, helping B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather knife sheath

What Are the Key Stages in the Manufacturing Process of Leather Knife Sheaths?

The production of leather knife sheaths involves several critical stages, each requiring specific techniques to ensure a high-quality final product. These stages can be categorized as material preparation, forming, assembly, and finishing.

How Is Material Prepared for Leather Knife Sheaths?

The first step in the manufacturing process is material preparation. High-quality leather is sourced, often from reputable suppliers that provide full-grain or top-grain leather known for its durability and aesthetic appeal. The leather is then inspected for defects, and any unsuitable pieces are removed.

Illustrative image related to how to make a leather knife sheath

Once the leather is selected, it undergoes conditioning to enhance its suppleness, ensuring it can be easily worked with during later stages. Additional materials, such as thread, rivets, and snaps, are also gathered, with a focus on corrosion-resistant metals for hardware to enhance durability.

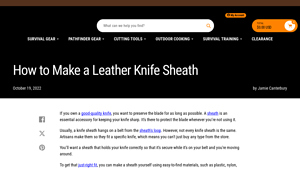

What Techniques Are Used in the Forming Stage?

The forming stage involves cutting the leather into the necessary shapes and sizes. Manufacturers typically use precision cutting tools or die-cutting machines to ensure consistent dimensions across all sheaths. Templates made from thick paper or cardboard may be used to guide the cutting process, allowing for the creation of prototypes before final production.

After cutting, the edges of the leather pieces are burnished. This process smooths the edges and prevents fraying, contributing to the sheath’s overall durability. Various burnishing techniques can be employed, including manual rubbing with wax or using specialized burnishing machines to ensure uniformity.

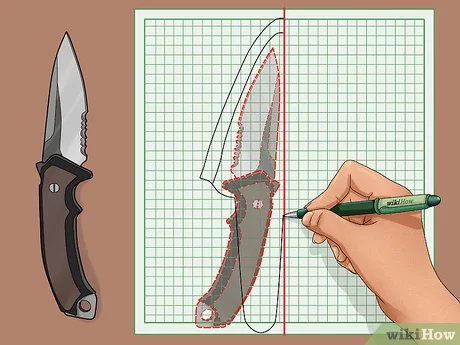

How Is Assembly Completed for Leather Knife Sheaths?

Assembly begins with the gluing of the leather pieces together. Manufacturers often use contact cement, ensuring that the glue is evenly applied and allowed to set before applying pressure to bond the materials. This step is crucial for maintaining the integrity of the sheath, as improper adhesion can lead to functional failures.

Following the initial assembly, fasteners are attached. Snap fasteners are commonly used, requiring precise hole punching and securing to ensure they function correctly. The assembly process may also include sewing, which requires skilled labor to ensure straight, tight seams. Dual-needle stitching is often employed for added strength, particularly on stress points.

What Finishing Processes Are Essential for Quality Leather Knife Sheaths?

Finishing is the final stage of production and involves several steps to enhance the appearance and functionality of the sheath. This includes dyeing, edge sealing, and applying protective coatings. Manufacturers might use natural dyes for an eco-friendly approach, or synthetic dyes for vibrant colors, depending on market demand.

Additionally, edge finishing techniques, such as sealing or waxing, are applied to prevent moisture absorption and enhance durability. Quality inspection is paramount during this stage to ensure each sheath meets the specified aesthetic and functional standards before reaching the consumer.

Illustrative image related to how to make a leather knife sheath

What Quality Assurance Practices Are Critical in Leather Knife Sheath Manufacturing?

Quality assurance (QA) is integral to leather sheath production, ensuring that the final product meets international standards and customer expectations. Implementing a robust QA framework can significantly reduce defects and enhance customer satisfaction.

Which International Standards Should Be Followed?

Manufacturers must adhere to internationally recognized standards such as ISO 9001, which provides a framework for quality management systems. This standard emphasizes continuous improvement, customer focus, and process-based approaches, which are essential for maintaining high-quality production.

In addition to ISO standards, specific industry standards may apply, such as CE marking for products sold within the European Union, indicating compliance with health, safety, and environmental protection standards. For B2B buyers in regions like Africa and South America, understanding these certifications can provide a competitive advantage and ensure product reliability.

Illustrative image related to how to make a leather knife sheath

What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): During production, periodic checks are conducted to monitor processes and identify defects early, minimizing waste and rework.

- Final Quality Control (FQC): Before shipping, finished products are thoroughly inspected against predefined criteria, including dimensions, stitching quality, and overall aesthetics.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of their suppliers. Conducting regular audits can help assess compliance with quality standards and identify potential areas for improvement.

Additionally, requesting quality assurance reports, including statistical process control (SPC) data, can provide insights into the consistency of the manufacturing process. Third-party inspections can also be beneficial, offering an impartial evaluation of the supplier’s production capabilities and adherence to quality standards.

What Nuances Should International Buyers Consider for Quality Control?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding regional differences in quality standards and regulations is crucial. Buyers should be aware of the varying requirements for imports, which may include specific certifications or documentation for leather goods.

Illustrative image related to how to make a leather knife sheath

Furthermore, establishing clear communication with suppliers about quality expectations can help mitigate misunderstandings and ensure that the final products align with market demands. Building strong relationships with manufacturers who prioritize quality assurance can lead to long-term partnerships and improved supply chain reliability.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices in leather knife sheath production equips B2B buyers with the knowledge necessary to make informed purchasing decisions. By focusing on quality at every stage, from material preparation to final inspection, buyers can ensure they receive products that meet their needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather knife sheath’

Inleiding

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring the necessary materials and tools to create leather knife sheaths. Understanding the process and sourcing the right supplies is essential for ensuring quality, durability, and functionality in your leather products. This guide outlines the key steps to consider when embarking on this project.

Step 1: Define Your Technical Specifications

Before you begin sourcing materials, outline the specific requirements for your leather knife sheath. Consider factors such as the type of knife, desired sheath style, and any additional features like fasteners or decorative elements. This clarity will help you communicate effectively with suppliers and ensure you procure the right materials.

Illustrative image related to how to make a leather knife sheath

- Key considerations: Knife dimensions, thickness of leather, and design preferences.

Step 2: Source Quality Leather

The quality of leather is paramount in creating a durable knife sheath. Look for suppliers that offer high-grade leather, preferably vegetable-tanned or top-grain options, known for their strength and aesthetic appeal.

- What to check: Supplier certifications, types of leather available, and sourcing practices to ensure sustainability.

Step 3: Identify Essential Tools and Materials

Creating a leather knife sheath requires specific tools and materials. Compile a list that includes leather punches, needles, thread, glue, and fasteners. Ensure that the tools are compatible with the leather types you choose.

- Recommended tools: Leather needles, contact cement, and burnishing tools for finishing edges.

Step 4: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request company profiles, product samples, and references from other B2B buyers in your region or industry. Assess their ability to meet your specifications and timelines.

- Important aspects: Supplier reputation, delivery capabilities, and product quality consistency.

Step 5: Request Samples and Test Materials

Once you’ve shortlisted suppliers, request samples of the leather and tools. Testing these materials will help you evaluate their quality and suitability for your project. Pay attention to factors like texture, flexibility, and durability.

- Testing criteria: Comfort in handling, ease of stitching, and edge finishing capabilities.

Step 6: Negotiate Pricing and Terms

After selecting your suppliers, negotiate pricing, minimum order quantities, and payment terms. Building a good relationship with your suppliers can lead to better deals and more favorable terms in the long run.

Illustrative image related to how to make a leather knife sheath

- Considerations for negotiation: Bulk order discounts, shipping costs, and payment flexibility.

Step 7: Place Your Order and Confirm Delivery

Once terms are agreed upon, place your order and confirm delivery timelines. Ensure that you have clear communication regarding shipping methods and tracking information to avoid any delays.

- Final checks: Review order details for accuracy and establish a follow-up schedule to track the delivery process.

By following these steps, B2B buyers can effectively source the materials and tools needed to produce high-quality leather knife sheaths, ensuring a successful project outcome.

Comprehensive Cost and Pricing Analysis for how to make a leather knife sheath Sourcing

What Are the Key Cost Components in Making a Leather Knife Sheath?

When analyzing the cost structure for producing a leather knife sheath, several key components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margin.

-

Materials: The choice of leather is crucial, as prices can vary significantly based on quality, thickness, and source. For example, high-quality vegetable-tanned leather can cost between $8 to $15 per square foot, while lower-grade options may be available for $3 to $5. Additional materials such as leather punches, needles, glue, and fasteners will add to the total material cost, which can range from $10 to $30 per sheath, depending on specifications.

-

Labor: Labor costs will depend on the skill level required for the sheath-making process. In regions with lower wage rates, such as parts of Africa and South America, labor costs can be significantly reduced. On average, skilled artisans may charge between $15 to $30 per hour. Given that a single sheath might take 2 to 4 hours to produce, labor costs could range from $30 to $120 per sheath.

-

Manufacturing Overhead: This includes expenses related to facility operation, utilities, and indirect labor costs. Typically, overhead can account for 15-30% of the total production cost. It’s essential for businesses to factor this into their pricing strategy.

-

Tooling: Initial investments in tools and machinery can be substantial, especially for manufacturers aiming for high precision. Tooling costs might range from a few hundred to several thousand dollars, depending on the scale of operations. These costs are often amortized over a larger production volume.

-

Quality Control (QC): Implementing robust QC processes ensures the final product meets industry standards and buyer expectations. QC costs can add approximately 5-10% to the overall production costs.

-

Logistics: Shipping and handling costs are significant, especially for international orders. Depending on the Incoterms used, logistics costs may vary widely. For example, DAP (Delivered At Place) terms might include all shipping costs, while FOB (Free On Board) terms may require buyers to handle their own shipping.

-

Margin: The profit margin for B2B transactions can typically range from 10% to 30%, depending on market conditions, competition, and perceived value.

How Do Price Influencers Affect the Cost of Leather Knife Sheaths?

Several factors influence pricing in the leather knife sheath market, particularly for B2B buyers. Understanding these influences can help businesses negotiate better deals.

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Higher volumes often lead to discounts, making it essential for buyers to consider bulk purchases when feasible.

-

Specifications and Customization: Custom designs or specific requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Materials: As previously mentioned, the type and quality of leather used can greatly influence pricing. Buyers should weigh the benefits of high-quality materials against budget constraints.

-

Quality and Certifications: Certifications, such as eco-friendly or organic leather, can also affect pricing. Suppliers offering certified materials may charge a premium.

-

Supplier Factors: The reliability and reputation of suppliers can affect costs. Established suppliers may charge more but can provide assurances regarding quality and delivery timelines.

-

Incoterms: The chosen Incoterms will influence total costs, including potential tariffs and insurance, which are vital considerations for international transactions.

What Buyer Tips Can Help Ensure Cost-Efficiency in Leather Knife Sheath Procurement?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Terms: Engage in discussions with suppliers to negotiate better pricing, especially if you’re considering larger orders. Suppliers may be willing to offer discounts or flexible payment terms to secure larger contracts.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term factors such as durability, maintenance, and resale value, which can affect overall costs.

-

Evaluate Multiple Suppliers: Conduct thorough research and compare various suppliers. This can provide leverage during negotiations and help identify the best value for money.

-

Stay Informed on Pricing Trends: Keep abreast of market trends and material prices to make informed purchasing decisions. This knowledge can aid in timing your orders to coincide with favorable pricing conditions.

-

Understand Regional Regulations: Be aware of any trade regulations or tariffs that may apply to your purchases, as these can significantly impact costs.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on current market conditions, supplier negotiations, and specific requirements. Buyers should conduct due diligence to obtain accurate and updated pricing information.

Alternatives Analysis: Comparing how to make a leather knife sheath With Other Solutions

Exploring Alternatives to Making a Leather Knife Sheath

In the world of knife sheath production, there are various methods available beyond traditional leather crafting. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational needs, budget constraints, and production capabilities. Below, we compare the traditional method of making a leather knife sheath with two viable alternatives: synthetic sheaths and wooden sheaths.

| Comparison Aspect | How To Make A Leather Knife Sheath | Synthetic Knife Sheath | Wooden Knife Sheath |

|---|---|---|---|

| Performance | High durability and aesthetics; offers a classic look. | Generally durable; waterproof options available. | Sturdy but can be heavy; prone to wear and damage. |

| Cost | Medium to high, depending on leather quality and tools needed. | Generally lower; costs can vary based on material quality. | Medium; wood type and craftsmanship affect pricing. |

| Ease of Implementation | Requires skill and tools; can be time-consuming for beginners. | Easy to produce; often mass-produced with minimal effort. | Requires woodworking skills; more complex than synthetic options. |

| Maintenance | Needs regular conditioning to avoid drying and cracking. | Low maintenance; often waterproof and easy to clean. | Requires periodic sealing and care to prevent damage. |

| Best Use Case | Ideal for custom, high-end knives; appeals to artisans and enthusiasts. | Suitable for mass production and budget-friendly options. | Best for aesthetic appeal or as a collectible; not ideal for heavy use. |

Detailed Breakdown of Alternatives

Synthetic Knife Sheath

Synthetic sheaths, often made from materials like nylon or molded plastics, present a modern alternative to leather. They are typically lighter and can be designed to be waterproof, making them ideal for outdoor or tactical use. The production process is generally more straightforward, allowing for mass manufacturing. However, while synthetic materials can provide durability, they may lack the aesthetic appeal and craftsmanship that leather offers. For B2B buyers, synthetic sheaths are cost-effective and suitable for high-volume orders, but they may not resonate with customers seeking premium products.

Wooden Knife Sheath

Wooden sheaths offer a unique blend of aesthetics and functionality. They can provide a rustic or vintage look that appeals to collectors and enthusiasts. However, crafting wooden sheaths requires a higher level of skill and woodworking expertise. Additionally, wooden sheaths can be heavier and may require more maintenance to prevent damage from moisture or wear. B2B buyers should consider wooden sheaths for niche markets focused on craftsmanship and style, but they may not be practical for high-volume production due to the complexity of the crafting process.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right sheath-making method, B2B buyers should assess their target market, production capabilities, and budget. Leather sheaths are ideal for high-end, custom products that appeal to discerning customers, while synthetic options offer cost-effective solutions for mass production. Wooden sheaths can cater to niche markets but may require specialized skills. Ultimately, aligning the chosen method with the specific needs of your business and customer preferences will lead to the most effective and profitable outcomes.

Essential Technical Properties and Trade Terminology for how to make a leather knife sheath

What Are the Essential Technical Properties for Making a Leather Knife Sheath?

When creating leather knife sheaths, understanding the technical properties of the materials and construction methods is crucial for ensuring durability and functionality. Here are some key specifications that B2B buyers should consider:

-

Material Grade

The grade of leather used is fundamental to the quality of the sheath. Full-grain leather is the highest quality, retaining the natural grain and providing superior durability and resistance to wear. For B2B buyers, selecting the appropriate material grade can enhance product longevity and customer satisfaction, impacting brand reputation. -

Thickness

Leather thickness is typically measured in ounces (1 ounce = 1/64 inch). For knife sheaths, a thickness of 8-10 ounces is commonly recommended, providing adequate protection without sacrificing flexibility. Understanding the required thickness helps manufacturers create products that meet safety and usability standards, ultimately reducing returns and increasing customer trust. -

Edge Finish

The edge of a leather sheath can be left raw, burnished, or dyed. A burnished edge is smoothened to prevent fraying and enhance aesthetic appeal. For B2B buyers, specifying edge finish can reduce the likelihood of product defects and improve the overall presentation of the sheath, making it more marketable. -

Tolerance Levels

Tolerance refers to the acceptable variation in dimensions during production. For knife sheaths, maintaining tight tolerances is critical to ensure that the knife fits securely and the sheath functions properly. B2B buyers should prioritize manufacturers who implement rigorous quality control processes to minimize discrepancies and ensure product reliability. -

Fastener Type

The choice of fasteners (e.g., snap fasteners, rivets) impacts both the functionality and aesthetics of the sheath. Different fasteners offer varying degrees of security and ease of use. Buyers should assess the fastener quality and installation methods to ensure they align with their product specifications and customer expectations.

What Are Common Trade Terms Relevant to Leather Knife Sheath Production?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms that may arise:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end products. For leather knife sheath makers, partnering with an OEM can help in sourcing quality materials or components while maintaining brand integrity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding the MOQ is crucial for budgeting and inventory management, especially when launching new products or entering new markets. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers asking for pricing and terms for specific products or services. For buyers, issuing an RFQ can help gauge market prices and negotiate better terms, ensuring they get the best value for their investments. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms helps B2B buyers understand their obligations regarding shipping costs, risks, and insurance, facilitating smoother transactions across borders. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For B2B operations, managing lead times is critical for inventory planning and meeting customer demand, ultimately affecting service levels and satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they partner with manufacturers that align with their quality standards and business goals.

Illustrative image related to how to make a leather knife sheath

Navigating Market Dynamics and Sourcing Trends in the how to make a leather knife sheath Sector

What are the Current Market Dynamics and Key Trends in the Leather Knife Sheath Sector?

The global market for leather knife sheaths is witnessing a dynamic transformation driven by several factors. First, the rise in outdoor activities and DIY crafts has fueled demand among hobbyists and professionals alike, particularly in regions like Africa and South America, where traditional craftsmanship is being revived. Additionally, the trend towards personalization and custom-made products is gaining traction. International B2B buyers are increasingly seeking unique, high-quality leather goods that reflect individual tastes and local craftsmanship.

Emerging technologies, such as laser cutting and automated stitching, are reshaping the production landscape, making it easier for manufacturers to meet diverse customer needs efficiently. This shift toward tech-driven processes is particularly relevant for buyers from Europe and the Middle East, where precision and quality control are paramount. Furthermore, e-commerce platforms are facilitating direct connections between artisans and international buyers, reducing traditional barriers to entry in the global market.

How is Sustainability and Ethical Sourcing Addressed in the Leather Knife Sheath Industry?

Sustainability is becoming a non-negotiable aspect for B2B buyers in the leather knife sheath sector. The environmental impact of leather production, including water consumption and chemical runoff, necessitates a shift towards sustainable practices. Buyers are increasingly prioritizing suppliers who implement ethical sourcing strategies, such as utilizing vegetable-tanned leather or recycled materials, which align with eco-friendly standards.

Certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are gaining importance among B2B buyers. These certifications assure that the leather has been produced following stringent environmental and ethical guidelines. Additionally, the demand for transparency in supply chains is rising, as buyers seek to understand the origins of materials and the practices employed in their production. Suppliers who can demonstrate a commitment to sustainability and ethical sourcing are likely to gain a competitive advantage in this evolving market.

What is the Brief Evolution and History of Leather Knife Sheaths?

The history of leather knife sheaths dates back centuries, rooted in various cultural practices across the globe. Traditionally, sheaths were crafted by artisans using locally sourced materials, often passed down through generations, reflecting the craftsmanship and heritage of a region. In Africa, for instance, traditional leatherworking techniques are deeply embedded in local cultures, while in Europe, the craft has evolved with modern techniques and materials.

In recent decades, the leather knife sheath industry has evolved significantly, driven by advancements in technology and changing consumer preferences. The rise of DIY culture has led to a resurgence in interest in handmade products, prompting a blend of traditional craftsmanship with modern design sensibilities. Today, international B2B buyers are not only looking for functional products but also for items that tell a story and connect with cultural heritage, making this a vibrant and evolving sector in the global market.

Illustrative image related to how to make a leather knife sheath

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather knife sheath

-

How do I select the right leather for making a knife sheath?

Choosing the right leather is crucial for durability and aesthetics. Full-grain leather is often recommended due to its strength and natural finish, making it ideal for knife sheaths. Additionally, consider the thickness; a 4-6 oz. leather is typically suitable for sheaths, as it provides enough protection without being overly bulky. Always verify the leather’s source and quality to ensure it meets your specific needs. Suppliers from regions like South America or Europe often provide high-quality options, so establishing connections with reputable tanners is beneficial. -

What tools are essential for crafting a leather knife sheath?

Key tools for making a leather knife sheath include a sharp utility knife or scalpel for cutting, leather punches for creating holes, and a leather needle set for stitching. Additionally, leather glue (contact cement) is necessary for bonding pieces, while a burnishing tool is important for finishing edges. Depending on your production scale, investing in a drill press for burnishing can enhance efficiency. When sourcing tools, consider suppliers that specialize in leatherworking equipment, as they can offer specialized products tailored to your needs. -

What are the minimum order quantities (MOQs) for leather sheaths from suppliers?

MOQs for leather sheaths can vary widely based on the supplier and the complexity of the design. Many manufacturers may require a minimum of 50-100 units for custom orders, while smaller quantities may be available for standard designs. It’s essential to discuss your specific requirements with potential suppliers to understand their MOQ policies. For international buyers, negotiating MOQs can sometimes be possible, especially if you can provide future order forecasts. -

How can I customize my leather knife sheath design?

Customization can include various aspects, such as size, color, stitching patterns, and additional features like snap fasteners or embossed logos. When working with a supplier, provide detailed specifications and visual references to ensure your vision is accurately represented. Many manufacturers offer design services or templates to assist in this process. Additionally, ensure that any customization aligns with your target market’s preferences, particularly if you are catering to regions with distinct cultural aesthetics. -

What payment terms should I expect when sourcing leather knife sheaths internationally?

Payment terms can vary significantly based on the supplier’s policies and the buyer’s location. Common terms include a 30% deposit upfront with the balance due upon completion or before shipment. Some suppliers may offer net 30 or net 60 terms for established relationships. It’s crucial to establish clear payment terms before placing orders to avoid misunderstandings. Additionally, consider using secure payment methods such as letters of credit or escrow services to protect your transactions, especially in international trade. -

How do I ensure quality assurance (QA) when purchasing leather knife sheaths?

To ensure quality, request samples before placing bulk orders. This allows you to assess the leather quality, craftsmanship, and overall design. Establishing quality control standards in advance is essential; communicate these to your supplier. Additionally, consider third-party inspections, especially for larger orders, to verify that the products meet your specifications. Building a good relationship with suppliers can also foster accountability, encouraging them to maintain high standards throughout the production process. -

What logistics considerations should I keep in mind when importing knife sheaths?

Logistics for importing knife sheaths include understanding shipping costs, delivery times, and customs regulations in your country. It’s advisable to work with a logistics partner experienced in international trade to navigate these complexities. Ensure that all necessary documentation, such as invoices and shipping labels, is prepared to avoid delays at customs. Additionally, consider the shipping method (air vs. sea) based on urgency and cost-effectiveness, as these factors will significantly impact your overall procurement strategy. -

How can I build long-term relationships with leather sheath suppliers?

Building long-term relationships with suppliers involves consistent communication, transparency, and reliability. Regularly provide feedback on products and services, and be open to discussing potential improvements. Establishing a partnership based on mutual respect can lead to better pricing, priority in production schedules, and tailored services. Consider visiting suppliers’ facilities when feasible to strengthen the relationship and gain insights into their production processes, which can also enhance your understanding of quality control.

Top 4 How To Make A Leather Knife Sheath Manufacturers & Suppliers List

1. Instructables – Leather Craft Essentials

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Leather Punches, Leather Glue, Leather Needle Set, Snap Fasteners, Utility Knife or Scalpel, Candle Wax, Thick Paper for Template, Optional Pulleys (cost about $4), Razor Blade, Sanding Tools (disk sander or orbital sander), Black Marker for Dyeing Edges.

2. Reddit – Leather Knife Sheath Tutorial

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Knife sheath made from leather, featuring contrast on the edge. The video tutorial demonstrates the process of creating the sheath, including techniques for stitching and pattern making.

3. Self Reliance Outfitters – Leather Knife Sheaths

Domain: selfrelianceoutfitters.com

Registered: 2011 (14 years)

Introduction: Leather knife sheaths are the most reliable material for protecting and carrying knives, combining toughness, stability, and structure. They are quieter than plastic or nylon sheaths and are preferred by the military. However, leather is vulnerable to rain and sunshine, which can wear it down over time. Making a leather knife sheath involves using easy-to-find materials such as leather, waxed stri…

4. Bladesmiths Forum – Leather Pouch Sheath Tutorial

Domain: bladesmithsforum.com

Registered: 2011 (14 years)

Introduction: Leather Pouch Sheath Tutorial

– Leather Type: Vegetable tanned cowhide

– Leather Weight: 7-8 oz.

– Materials Required:

– Glue: PVA (Polyvinyl Acetate, Elmer’s)

– Candle

– Thread: Waxed linen

– Dye

– Dye Applicators

– Eco-Flow: Gloss, Satin

– Saran Wrap

– Latex Gloves

– Tools Required:

– Knife

– Gouge (Adjustable V Gauge)

– Foam Pieces or Folded Towels or a Box of Sand

– Coa…

Strategic Sourcing Conclusion and Outlook for how to make a leather knife sheath

As you embark on the journey of crafting leather knife sheaths, the significance of strategic sourcing cannot be overstated. By leveraging local resources and upcycling leather scraps, businesses can not only reduce costs but also enhance sustainability—a key value proposition in today’s market. Engaging with local artisans and suppliers can foster beneficial partnerships, ensuring a steady supply of quality materials while promoting community development.

Moreover, understanding the nuances of leather crafting techniques, such as precise cutting, effective gluing, and meticulous stitching, can elevate the quality of your products, appealing to a broader customer base. This is especially relevant for international buyers from Africa, South America, the Middle East, and Europe, where craftsmanship and durability are highly valued.

Looking ahead, the demand for personalized and handcrafted items is on the rise, creating an excellent opportunity for businesses willing to invest in quality production methods. Embrace this chance to innovate and diversify your offerings in the leather goods market. Take the first step today by exploring local suppliers and honing your craftsmanship skills, ensuring that your products stand out in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to how to make a leather knife sheath

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.