Catalog

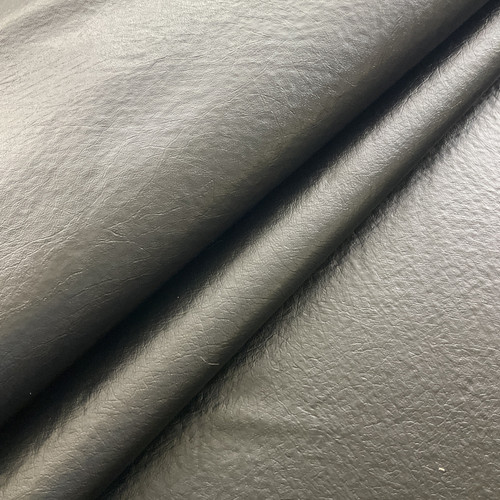

Material Insight: Buffalo Leather Company

B2B Product Guide: Premium Synthetic Leather Solutions for the Modern Leather Goods Market

For manufacturers historically reliant on exotic hides like buffalo leather, evolving market demands—stricter sustainability regulations, ethical sourcing complexities, and volatile raw material costs—present significant operational challenges. Genuine buffalo leather, while possessing unique aesthetic qualities, introduces critical limitations for scalable, responsible production: inconsistent grain patterns, lengthy tanning cycles, and substantial environmental impact from land/water use and chemical processing. These factors often conflict with global brand commitments to circularity and carbon neutrality.

Faux leather emerges as the strategically superior choice for this application due to:

– Consistent Quality & Scalability: Engineered to eliminate natural hide imperfections, ensuring uniform color, texture, and thickness across unlimited production runs.

– Ethical & Traceable Sourcing: Fully animal-free composition aligns with cruelty-free certifications (e.g., PETA-Approved Vegan) and simplifies supply chain transparency.

– Enhanced Performance: Superior resistance to abrasion, UV degradation, and moisture compared to untreated exotic leathers—critical for high-end bags, footwear, and upholstery.

– Reduced Environmental Footprint: Eliminates deforestation, methane emissions, and toxic tannery effluents; WINIW’s processes use 90% less water than conventional leather tanning.

Introducing WINIW: Your Partner in Premium Synthetic Innovation

With over 20 years of specialized expertise in high-performance synthetic leathers, WINIW delivers material science solutions tailored for discerning B2B clients in luxury goods, automotive, and furniture sectors. We pioneer eco-engineered materials that replicate the tactile richness of exotic hides—without their ethical or ecological burdens. Our vertically integrated R&D, certified production (ISO 14001, OEKO-TEX® STANDARD 100), and collaborative design approach empower brands to future-proof collections while exceeding sustainability KPIs. Partner with WINIW to transform material limitations into market differentiation.

Next Section: WINIW’s Buffalo-Style Synthetic Range – Technical Specifications & Application Benefits

Technical Performance & Standards

WINIW Buffalo Leather: B2B Product Guide

WINIW is a leading synthetic leather manufacturer specializing in high-performance, eco-friendly materials designed for industrial and commercial applications. Our proprietary “buffalo leather” product line replicates the robust texture and premium appearance of genuine buffalo hide while offering superior consistency, sustainability, and cost-efficiency. Engineered for durability and versatility, WINIW’s synthetic buffalo leather is ideal for furniture, automotive interiors, luggage, footwear, and industrial upholstery.

-

Cost-Effective Production: WINIW’s synthetic buffalo leather reduces raw material waste and eliminates the variability associated with natural hides, resulting in predictable supply chains and lower total production costs. Unlike genuine leather, it requires no complex tanning processes involving heavy metals, reducing processing time and overhead.

-

Exceptional Durability: Our material is engineered with high-density polyurethane and reinforced backings to deliver outstanding abrasion resistance, tensile strength, and tear resistance. It maintains structural integrity under prolonged mechanical stress and adverse environmental conditions.

-

Customizable Colors & Finishes: WINIW offers full color customization with batch-to-batch consistency. Clients can specify Pantone-matched hues, matte or glossy finishes, embossed textures (including natural grain replication), and special effects such as anti-scratch or anti-fungal coatings.

-

REACH Compliant: WINIW’s buffalo leather is fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). It is free from SVHCs (Substances of Very High Concern), phthalates, AZO dyes, and other hazardous substances, ensuring safe use across consumer and industrial markets.

-

ISO 9001 Certified Manufacturing: Our production processes are certified to ISO 9001 standards, guaranteeing consistent quality control, process efficiency, and continuous improvement. This certification underscores our commitment to reliability and customer satisfaction in every batch.

Technical Specifications

| Property | Specificatie |

|---|---|

| Base Material | High-density polyurethane (PU) |

| Backing Fabric | Polyester knit (various weights available) |

| Thickness Range | 0.8 mm – 2.0 mm (customizable) |

| Width | 137 cm (54 inches) standard, up to 150 cm |

| Weight | 280 – 450 g/m² (based on thickness) |

| Abrasion Resistance | >50,000 cycles (Martindale, dry) |

| Color Fastness to Rubbing | Grade 4–5 (wet & dry) |

| Light Fastness | ≥4 (ISO 105-B02) |

| Tensile Strength | ≥80 N/5cm (warp and weft) |

| Tear Resistance | ≥15 N (Elmendorf) |

| Cold Crack Resistance | Down to -20°C |

| Environmental Compliance | REACH, RoHS, OEKO-TEX® STANDARD 100 (Class II) |

| Certifications | ISO 9001:2015, SGS tested |

WINIW’s synthetic buffalo leather delivers a sustainable, high-performance alternative to natural leather without compromising on aesthetics or function. With a focus on B2B partnerships, we support bulk orders, OEM customization, and technical collaboration to meet evolving market demands.

Why Choose Synthetic over Real Leather

B2B Material Comparison Guide: Buffalo Leather vs. Real Leather (Bovine Focus)

As a leading innovator in sustainable synthetic alternatives, WINIW provides this objective analysis to support informed material selection for premium goods manufacturing. This guide compares traditional buffalo leather (a specific type of real leather) against standard bovine leather (the most prevalent “real leather” in global supply chains), focusing on core procurement metrics. Note: “Real Leather” here refers to animal-derived hides, distinct from WINIW’s advanced synthetic leathers.

Key Comparison: Buffalo Leather vs. Standard Bovine Leather

| Metric | Buffalo Leather | Standard Bovine Leather |

|---|---|---|

| Cost | Premium (2-3x bovine) due to rarity, thicker hides, and complex processing. Sourcing volatility impacts pricing stability. | Moderate. Economies of scale from mass cattle farming ensure consistent supply and lower base costs. Price fluctuations tied to meat industry cycles. |

| Duurzaamheid | Exceptional tensile strength & abrasion resistance. Thicker grain (1.8-2.4mm+) suits heavy-use applications. Prone to inconsistent thickness and natural markings affecting yield. | High durability with predictable thickness (1.0-1.6mm). Consistent grain structure enables efficient pattern cutting. Susceptible to scratches in lighter finishes. |

| Eco-Friendliness | Lower environmental burden per hide (byproduct of meat industry), but resource-intensive tanning (high water/chemical use). Limited traceability in supply chains. | Significant land/water use in cattle farming (17kg CO2e per kg hide). Chrome tanning dominates (toxic sludge risk); <15% is vegetable-tanned. Certifications (e.g., LWG) improving traceability. |

Critical Considerations for B2B Buyers

- Supply Chain Vulnerability:

- Buffalo leather relies on niche, region-specific farming (India, Southeast Asia). Geopolitical or climate disruptions cause severe shortages.

-

Bovine leather faces ethical scrutiny (deforestation for pasture) and regulatory pressure (EU deforestation rules).

-

Performance Limitations:

- Both materials exhibit natural inconsistencies (scars, insect bites), increasing waste during cutting (up to 25% vs. <5% for engineered synthetics).

-

Moisture sensitivity requires chemical treatments, compromising biodegradability.

-

Sustainability Reality Check:

- Neither option aligns with circular economy goals. Tanned leather cannot be infinitely recycled; end-of-life often means landfill.

- Chemical residues (PCP, azo dyes) in low-compliance tanneries pose brand compliance risks (REACH, ZDHC).

WINIW’s Sustainable Alternative: Engineered Performance Leather

For brands prioritizing consistent quality, supply security, and verifiable eco-credentials, WINIW’s synthetic leathers deliver:

- Cost Predictability: Fixed pricing with no agricultural volatility; 30-50% lower total cost of ownership via near-zero waste cutting.

- Engineered Durability: UV/stain resistance, uniform thickness (±0.05mm), and 50,000+ double-rub abrasion ratings for luxury upholstery.

- Proven Eco-Advantage:

- 60% lower carbon footprint vs. bovine leather (ISO 14044 LCA verified).

- 100% chrome-free, water-based PU/PVC options (OEKO-TEX® STANDARD 100).

- Recyclable through WINIW’s closed-loop programs (up to 95% material recovery).

WINIW enables responsible innovation without compromising on luxury aesthetics or performance. Request our full technical dossier and ISO-certified LCA reports to validate your sustainability claims.

WINIW: Where Engineering Meets Environmental Stewardship.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global markets with innovation, quality, and sustainability at the core of its operations. With a state-of-the-art production facility spanning 100,000 square meters, WINIW integrates advanced manufacturing capabilities with deep technical expertise to deliver premium synthetic leather solutions for diverse industrial and consumer applications.

The company’s large-scale factory is equipped with automated production lines and eco-conscious processing units, enabling high-volume output without compromising environmental standards. This extensive manufacturing footprint supports efficient production cycles and ensures reliable delivery for large B2B orders across international supply chains.

Key strengths of WINIW’s manufacturing and operational capabilities include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, performance enhancement, and sustainable development. The team continuously develops new formulations to meet evolving industry demands, including low-VOC, recyclable, and bio-based synthetic leather options.

- Strict quality control (QC) protocols implemented at every stage of production. From raw material inspection to finished product testing, WINIW adheres to international standards such as ISO 9001, REACH, and OEKO-TEX® to guarantee consistency, durability, and safety.

- In-house testing laboratories equipped to perform wear resistance, color fastness, tensile strength, and environmental compliance assessments, ensuring all products meet or exceed client specifications.

- A proven track record of exporting to highly regulated markets, including Europe and the USA, where WINIW’s products are trusted by leading brands in automotive, furniture, apparel, and accessories industries.

- Strong logistical partnerships enabling seamless global distribution and on-time delivery to clients across North America, Western Europe, and Asia.

WINIW’s combination of scale, technical excellence, and quality assurance makes it a preferred B2B partner for brands seeking reliable, sustainable, and high-performance synthetic leather solutions.

Contact Us for Samples

WINIW Premium Synthetic Leather Solutions: Sustainable Alternative for Premium Goods Manufacturers

As a leader in advanced microfiber leather innovation, WINIW delivers high-performance synthetic alternatives engineered specifically for discerning B2B partners in the luxury goods, footwear, and upholstery sectors. Our materials address critical industry challenges—including supply chain volatility, environmental compliance, and evolving consumer sustainability demands—without compromising on aesthetics, durability, or tactile quality. For manufacturers like your esteemed buffalo leather company, WINIW provides a consistent, traceable, and eco-responsible material source to future-proof production.

Core Advantages for Premium Product Manufacturers

- Unmatched Consistency: Eliminate natural hide variation with uniform texture, thickness, and color batch-to-batch, reducing waste and streamlining cutting efficiency.

- Eco-Performance Leadership: Achieve 65% lower water consumption and 50% reduced CO₂ emissions versus conventional leather tanning processes.

- Regulatory Ready: Compliant with REACH, OEKO-TEX® STANDARD 100 Class I, and Prop 65—ensuring market access across EU, US, and Asia.

- Customization Flexibility: Tailor weight (0.6–1.2mm), finish (suede, pebble, exotic embossing), and color to match specific design requirements.

- Enhanced Durability: Superior abrasion resistance (>50,000 cycles Martindale) and UV stability for extended product lifecycles.

Technical Specifications Comparison

| Property | WINIW Premium Microfiber | Conventional Buffalo Leather | Advantage |

|---|---|---|---|

| Tensile Strength | 35–45 N/mm² | 20–30 N/mm² | +50% |

| Tear Strength | 80–100 N | 40–60 N | +65% |

| Water Absorption | <5% | 15–25% | -70% |

| Recycled Content | 30% (certified PCR) | 0% | Sustainable sourcing |

| Lead Time | 2–3 weeks | 8–12 weeks | 70% faster |

Target Applications for Your Product Lines

- Luxury Footwear: Replace exotic hides with abrasion-resistant microfiber for uppers and linings (reducing weight by 20%).

- High-End Upholstery: Achieve consistent grain structure for automotive interiors and furniture, with fire-retardant options (CAL 117 compliant).

- Accessories: Craft durable wallets, belts, and bags with water-repellent finishes that resist staining and cracking.

- Sustainability-Driven Collections: Leverage our traceable supply chain for certified eco-lines meeting GRS (Global Recycled Standard) requirements.

Why Partner with WINIW?

We operate ISO 14001-certified facilities and prioritize circularity through closed-loop water systems and 95% solvent recovery. Unlike inconsistent natural hides, WINIW ensures batch reliability while offering full transparency—from raw material sourcing to finished roll. Our R&D team collaborates directly with manufacturers to solve specific engineering challenges, such as optimizing breathability for footwear or enhancing softness for handbags.

Request Your Complimentary Sample Kit Today

Experience WINIW’s premium hand feel, color depth, and performance firsthand. Contact our B2B solutions team to receive free 30cm x 30cm samples tailored to your application:

MKT88@MicrofiberLeather.com

Specify: “Buffalo Leather Company Sample Request” for priority processing. All samples include full technical datasheets and sustainability documentation.

Elevate your product integrity while advancing environmental stewardship—without sacrificing the luxury standard your clients expect. WINIW: Engineered Responsibility.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.