Introduction: Navigating the Global Market for brown leather fabric

In an increasingly competitive global market, sourcing high-quality brown leather fabric can pose significant challenges for B2B buyers. Whether you’re looking to procure materials for upholstery, automotive applications, or fashion design, the need for reliable suppliers who offer consistent quality, competitive pricing, and timely delivery is paramount. This guide serves as your comprehensive resource for navigating the complexities of the brown leather fabric market, addressing critical aspects such as types of leather, application scenarios, supplier vetting processes, and cost considerations.

By delving into the nuances of brown leather fabric, this guide empowers international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including Germany and Vietnam—to make informed purchasing decisions. You’ll discover various types of brown leather, from genuine cowhide to eco-friendly faux options, and learn how to assess their suitability for different projects. Furthermore, we provide insights on how to evaluate potential suppliers to ensure they meet your quality standards and logistical needs.

Ultimately, this guide aims to streamline your sourcing process, mitigate risks, and enhance your competitive edge in the market. Armed with the right knowledge and strategies, you can confidently navigate the global landscape of brown leather fabric, securing the best materials for your business needs.

Table Of Contents

- Top 7 Brown Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for brown leather fabric

- Understanding brown leather fabric Types and Variations

- Key Industrial Applications of brown leather fabric

- 3 Common User Pain Points for ‘brown leather fabric’ & Their Solutions

- Strategic Material Selection Guide for brown leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for brown leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘brown leather fabric’

- Comprehensive Cost and Pricing Analysis for brown leather fabric Sourcing

- Alternatives Analysis: Comparing brown leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for brown leather fabric

- Navigating Market Dynamics and Sourcing Trends in the brown leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of brown leather fabric

- Strategic Sourcing Conclusion and Outlook for brown leather fabric

- Important Disclaimer & Terms of Use

Understanding brown leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Retains natural grain and texture; highly durable | Furniture, automotive upholstery | Pros: Long-lasting, develops a patina; Cons: Expensive, requires maintenance. |

| Top Grain Leather | Sanded and finished surface; more uniform appearance | High-end furniture, bags | Pros: Soft feel, resistant to stains; Cons: Less durable than full grain. |

| Suède | Soft, napped finish; less formal appearance | Apparel, accessories, home decor | Pros: Unique texture, versatile; Cons: Less durable, more prone to staining. |

| Kunstleer | Synthetic material mimicking leather; cost-effective | Budget-friendly upholstery, fashion | Pros: Animal-friendly, easy to clean; Cons: Less breathable, shorter lifespan. |

| Distressed Leather | Aged, worn look; unique character | Vintage-style furniture, accessories | Pros: Unique aesthetics, hides imperfections; Cons: May not appeal to all buyers. |

What Are the Characteristics of Full Grain Leather?

Full grain leather is the highest quality leather available, known for its natural imperfections and robust durability. It retains the original grain pattern, which contributes to its unique character. This type is ideal for high-end applications such as luxury furniture and automotive upholstery, where longevity is paramount. B2B buyers should consider the cost versus the long-term investment, as full grain leather can be pricier but often outlasts alternatives.

How Does Top Grain Leather Compare to Other Types?

Top grain leather is sanded to remove imperfections, providing a more uniform surface while still retaining some natural characteristics. It is softer than full grain leather and is often used in high-end furniture and bags. B2B buyers appreciate its resistance to stains, making it suitable for environments with high traffic or potential spills. However, its durability is slightly less than that of full grain leather, which may influence purchasing decisions based on intended use.

Illustrative image related to brown leather fabric

What Makes Suede a Unique Option for B2B Buyers?

Suede offers a distinct, soft texture with a napped finish that adds a touch of luxury to apparel and home decor. Its casual appearance makes it suitable for accessories and less formal applications. B2B buyers should note that while suede can enhance product appeal, it is less durable and can be more susceptible to stains and damage. This makes it essential to consider the target market and use-case scenarios when selecting suede for products.

Why Choose Faux Leather for Cost-Effective Solutions?

Faux leather is a synthetic alternative that replicates the look and feel of genuine leather at a fraction of the cost. It is often used in budget-friendly upholstery and fashion items, appealing to a broader market. B2B buyers benefit from its easy maintenance and animal-friendly attributes, making it a popular choice. However, its shorter lifespan and reduced breathability compared to genuine leather may deter some buyers looking for long-term durability.

How Does Distressed Leather Enhance Product Aesthetics?

Distressed leather is characterized by its aged, worn appearance, which adds a unique charm to products. It is commonly used in vintage-style furniture and accessories, catering to consumers seeking authenticity and character. For B2B buyers, the appeal lies in the distinctiveness of each piece, as no two hides are alike. However, the aesthetic may not resonate with all customers, making it crucial to understand market preferences before investing in distressed leather products.

Key Industrial Applications of brown leather fabric

| Industry/Sector | Specific Application of brown leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Enhances aesthetic appeal and durability of furniture | Sourcing from certified suppliers for quality assurance |

| Automotive | Interior seating and trim | Provides a luxurious feel and improves vehicle resale value | Compliance with safety and environmental standards |

| Fashion and Accessories | Handbags, belts, and wallets | Offers premium quality and style, appealing to luxury markets | Availability of sustainable leather options and customization |

| Hospitality | Upholstery for restaurant seating | Creates a warm, inviting atmosphere for customers | Need for high-performance materials to withstand heavy usage |

| Marine Industry | Upholstery for boat interiors | Resistance to moisture and UV damage for long-lasting use | Consideration of marine-grade leather options for durability |

How is Brown Leather Fabric Used in Furniture Manufacturing?

In the furniture manufacturing sector, brown leather fabric is primarily used for upholstery on sofas, chairs, and other seating options. The rich color and texture not only enhance the aesthetic appeal but also provide durability, making furniture more appealing to consumers. For international buyers, especially in regions like Africa and South America, sourcing high-quality leather from reputable suppliers is crucial to ensure longevity and customer satisfaction. Additionally, buyers should consider the environmental impact of leather production and seek suppliers who adhere to sustainable practices.

Illustrative image related to brown leather fabric

What Role Does Brown Leather Fabric Play in the Automotive Industry?

In the automotive industry, brown leather fabric is utilized for interior seating, dashboards, and trim. The luxurious appearance of leather elevates the overall feel of a vehicle, thus enhancing its resale value. Buyers from the Middle East and Europe, particularly, should prioritize suppliers who meet stringent safety and environmental regulations. Furthermore, the leather must be treated to withstand wear and tear, as well as climate variations, which is essential for maintaining the vehicle’s interior over time.

How is Brown Leather Fabric Incorporated into Fashion and Accessories?

Fashion and accessories manufacturers leverage brown leather fabric for items like handbags, belts, and wallets. The premium quality of leather appeals to luxury markets, allowing brands to position themselves as high-end. International buyers, particularly from Europe and South America, should focus on sourcing leather that not only meets quality standards but also offers customization options. Additionally, there is a growing demand for sustainable leather alternatives, which should be considered to align with consumer preferences for eco-friendly products.

Why is Brown Leather Fabric Important in the Hospitality Sector?

In the hospitality industry, brown leather fabric is commonly used for upholstery in restaurant seating and hotel lobbies. Its warm tones create a welcoming atmosphere that enhances customer experience. For businesses in Africa and the Middle East, choosing high-performance materials that can withstand heavy usage is vital. Buyers should also consider the ease of cleaning and maintenance, as leather can provide a practical solution in high-traffic areas while still offering a luxurious look.

How Does Brown Leather Fabric Benefit the Marine Industry?

The marine industry employs brown leather fabric for boat interiors, where resistance to moisture and UV damage is critical. This application ensures that the upholstery remains durable and visually appealing despite exposure to harsh marine conditions. Buyers in Europe and South America should seek marine-grade leather options that meet specific durability and safety standards. It’s also essential to verify that the leather is treated for water resistance, ensuring longevity in marine environments.

3 Common User Pain Points for ‘brown leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Brown Leather Fabric for High-End Projects

The Problem: B2B buyers, particularly those in the furniture and automotive industries, often face challenges in sourcing high-quality brown leather fabric that meets their specific project requirements. Many suppliers offer leather that may appear visually appealing but fails to deliver in terms of durability, texture, or color consistency. This can lead to costly delays and dissatisfaction among clients, as the final product does not align with their expectations or standards. Furthermore, navigating the differences between genuine leather and faux options can create confusion, especially when buyers are aiming for authenticity in high-end projects.

Illustrative image related to brown leather fabric

The Solution: To overcome sourcing challenges, B2B buyers should prioritize establishing relationships with reputable suppliers who specialize in brown leather fabrics. Conducting thorough research and asking for samples before committing to a bulk order is critical. Buyers should look for suppliers that provide detailed specifications, including the type of leather, tanning methods, and test results for durability (e.g., double rubs). Additionally, leveraging industry trade shows can help buyers connect directly with manufacturers, allowing them to inspect materials firsthand and negotiate better terms. By prioritizing quality and transparency in sourcing, buyers can ensure that the brown leather fabric meets their project needs and enhances their product offerings.

Scenario 2: Managing Color Variability in Brown Leather Fabric

The Problem: Color consistency is a common pain point for B2B buyers when dealing with brown leather fabrics. As leather is a natural material, there can be significant variations in shade and texture from one hide to another, even within the same batch. This variability can complicate large-scale projects, such as upholstery or automotive interiors, where uniformity is essential for aesthetic appeal. Discrepancies can lead to client dissatisfaction and additional costs if replacements are needed.

The Solution: To mitigate issues related to color variability, buyers should request comprehensive color matching and sample swatches from their suppliers. It’s beneficial to establish a standardized color palette for the project and communicate this with the supplier to ensure all hides are selected from the same dye lot. Additionally, implementing a quality control process during the receiving phase can help catch inconsistencies early. By utilizing digital color matching technologies and maintaining open communication with suppliers about color expectations, buyers can significantly reduce the risk of color discrepancies and improve overall project satisfaction.

Scenario 3: Ensuring Durability and Maintenance of Brown Leather Fabric

The Problem: Another critical concern for B2B buyers is the durability and maintenance of brown leather fabric, especially in high-traffic environments such as commercial spaces or family-oriented settings. Buyers often struggle to find materials that not only look good but can withstand wear and tear while being easy to maintain. This concern is particularly relevant for industries dealing with upholstery, where spills, scratches, and everyday use can rapidly degrade the appearance and longevity of the fabric.

The Solution: Buyers should invest time in understanding the specific properties of different types of brown leather fabrics, including their resistance to stains, ease of cleaning, and overall durability ratings. Choosing leather treated with protective finishes can greatly enhance its resistance to spills and scratches. Additionally, incorporating regular maintenance routines, such as conditioning and cleaning with appropriate products, will help preserve the leather’s appearance and functionality. Educating end-users about proper care can also be beneficial. By selecting durable materials and implementing maintenance best practices, buyers can ensure that the brown leather fabric remains both attractive and functional over time, ultimately leading to higher customer satisfaction and repeat business.

Illustrative image related to brown leather fabric

Strategic Material Selection Guide for brown leather fabric

What Are the Key Materials for Brown Leather Fabric in B2B Applications?

When selecting brown leather fabric for various applications, it is essential to understand the different materials available. Each material has unique properties, advantages, and limitations that can significantly impact the end product’s performance and suitability for specific markets. Below, we analyze four common materials used in brown leather fabric.

Genuine Leather: What Makes It a Preferred Choice?

Genuine leather, derived from animal hides, is renowned for its durability and aesthetic appeal. Key properties include high tensile strength, natural breathability, and a temperature range that allows it to withstand varying environmental conditions. However, genuine leather can be sensitive to moisture and may require regular maintenance to prevent drying or cracking.

Pros:

– Exceptional durability and longevity.

– Aesthetic versatility that enhances the value of end products.

– Natural insulation properties.

Cons:

– Higher cost compared to synthetic alternatives.

– Requires careful handling and maintenance.

– Environmental concerns related to sourcing and tanning processes.

For international B2B buyers, particularly in regions like Europe and the Middle East, compliance with environmental standards (e.g., REACH in Europe) is crucial. Buyers should ensure that their suppliers adhere to sustainable practices in sourcing and processing leather.

Faux Leather: Is It a Viable Alternative?

Faux leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to genuine leather. It is typically more resistant to moisture and easier to clean, making it suitable for high-traffic areas. Key properties include a lightweight design and a wide range of colors and textures.

Pros:

– Lower cost and easier to produce.

– Resistant to stains and moisture.

– No animal cruelty concerns.

Cons:

– Generally less durable than genuine leather.

– Limited breathability can lead to discomfort in certain applications.

– Potential environmental impact from production processes.

For buyers in Africa and South America, faux leather can be particularly appealing due to its affordability and ease of maintenance. However, they should be aware of the varying quality standards and certifications in their regions.

Suede: What Unique Characteristics Does It Offer?

Suede, a type of leather made from the underside of animal hides, is known for its soft texture and luxurious feel. It is often used in upholstery and fashion applications. Key properties include a unique appearance and a comfortable touch, but it is less resistant to stains and moisture than other leather types.

Pros:

– Soft and luxurious feel enhances product appeal.

– Excellent for fashion and high-end applications.

– Good insulation properties.

Illustrative image related to brown leather fabric

Cons:

– Prone to staining and requires special care.

– Less durable compared to other leather types.

– Higher manufacturing complexity due to the need for specialized processes.

International buyers, particularly from Europe, should consider the specific care requirements of suede products. Compliance with EU regulations regarding textile labeling and care instructions is essential.

Vinyl: How Does It Compare to Other Materials?

Vinyl leather, often used in upholstery and automotive applications, is a synthetic alternative that offers a leather-like appearance. Key properties include high durability, easy maintenance, and resistance to fading. Vinyl is also available in various colors and textures, making it versatile for different applications.

Illustrative image related to brown leather fabric

Pros:

– Highly durable and resistant to wear and tear.

– Easy to clean and maintain.

– Cost-effective compared to genuine leather.

Cons:

– Less breathable, which can lead to discomfort.

– May not have the same aesthetic appeal as genuine leather.

– Environmental concerns related to PVC production.

For buyers in regions like Germany and Vietnam, vinyl can be an attractive option due to its affordability and ease of maintenance. However, it is essential to ensure that the vinyl products meet local regulations regarding chemical safety and environmental impact.

Summary Table of Brown Leather Fabric Materials

| Materiaal | Typical Use Case for brown leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end upholstery, luxury goods | Exceptional durability and aesthetics | Higher cost and maintenance needs | Hoog |

| Kunstleer | Budget-friendly upholstery, fashion | Cost-effective and easy to clean | Less durable than genuine leather | Low |

| Suède | Fashion, upscale upholstery | Soft, luxurious feel | Prone to staining and care needed | Medium |

| Vinyl | Automotive, commercial upholstery | Highly durable and easy to maintain | Less breathable and aesthetic appeal | Low |

This guide aims to provide B2B buyers with actionable insights into the strategic selection of materials for brown leather fabric, considering performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for brown leather fabric

What Are the Key Stages in the Manufacturing Process of Brown Leather Fabric?

The manufacturing process of brown leather fabric involves several critical stages that ensure the final product meets quality and aesthetic standards. Understanding these stages can help B2B buyers make informed decisions when sourcing materials.

Material Preparation: Sourcing and Selection

The first step in manufacturing brown leather fabric is the careful selection of raw materials, primarily cowhides. The quality of the leather is determined by the breed, age, and health of the cattle, as well as the tanning process used. Suppliers often source hides from reputable farms, ensuring that they meet specific quality standards.

Once sourced, the hides undergo a rigorous inspection to identify any defects such as scars or blemishes. Only those hides that meet the desired criteria are selected for further processing, ensuring that the raw material is suitable for high-quality leather production.

What Techniques Are Used in the Forming Stage of Leather Manufacturing?

The forming stage involves several key techniques that transform raw hides into usable leather fabric. This process typically includes:

Illustrative image related to brown leather fabric

-

Tanning: The tanning process is crucial as it converts raw animal hides into durable leather. Common methods include chrome tanning, which offers faster processing times and vibrant colors, and vegetable tanning, which uses natural tannins and results in a softer, more environmentally friendly product.

-

Splitting: After tanning, the hides are split into different thicknesses. This step is important for producing leather that meets specific customer requirements, such as upholstery or fashion applications.

-

Dyeing: Brown leather can be achieved through various dyeing processes. Natural dyes are often preferred for their rich colors, while synthetic dyes offer a broader range of shades and consistency. The choice of dye can significantly impact the final appearance and quality of the leather.

-

Finishing: The finishing stage involves applying protective coatings, embossing patterns, or polishing to enhance the leather’s appearance and durability. Techniques may include aniline finishing for a natural look or pigment finishing for uniform color and additional protection.

How Is Quality Assurance Implemented During the Manufacturing Process?

Quality assurance is vital in leather manufacturing to ensure that the end product meets international standards and customer expectations.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt. Suppliers check for defects in the hides and ensure compliance with pre-agreed specifications.

-

In-Process Quality Control (IPQC): During various manufacturing stages, regular checks are conducted to monitor the tanning, splitting, dyeing, and finishing processes. This ensures that any deviations from the standard are detected early.

-

Final Quality Control (FQC): Before the leather is shipped, it undergoes a comprehensive inspection for defects, color consistency, and adherence to specifications. This final check is crucial for maintaining product quality and customer satisfaction.

What International Standards Should B2B Buyers Look for in Brown Leather Fabric?

B2B buyers should be aware of several international quality standards that impact leather manufacturing. The most relevant include:

-

ISO 9001: This quality management standard ensures that organizations consistently provide products that meet customer and regulatory requirements. Companies certified under ISO 9001 demonstrate a commitment to quality and continuous improvement.

-

CE Marking: Particularly relevant for leather products used in consumer goods, CE marking indicates that the product complies with EU safety and health requirements.

-

API Standards: For leather used in automotive applications, API standards ensure that materials meet specific performance criteria essential for safety and functionality.

What Testing Methods Are Commonly Used to Ensure Leather Quality?

Common testing methods for brown leather fabric include:

-

Physical Testing: This includes assessments of strength, durability, and flexibility. Tests such as tensile strength and tear resistance are crucial for determining the leather’s suitability for various applications.

-

Chemical Testing: To ensure that the leather is free from harmful substances, suppliers may conduct chemical analyses to check for compliance with regulations such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals).

-

Environmental Testing: As sustainability becomes increasingly important, testing for environmental impact during the tanning and finishing processes is gaining traction. This may include assessments of water usage and chemical discharge.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of their leather suppliers. Here are some strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed quality reports that outline their testing methods, results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can evaluate the quality of the leather fabric before shipment.

What Are the Unique QC Considerations for International B2B Buyers?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, there are several nuances to consider regarding quality control:

Illustrative image related to brown leather fabric

-

Cultural Differences: Understanding regional manufacturing practices and quality expectations is crucial. What is considered high quality in one region may not meet standards in another.

-

Logistical Challenges: Shipping leather internationally can pose risks such as damage or degradation. Buyers should ensure that suppliers use appropriate packaging and handling procedures.

-

Regulatory Compliance: Different regions may have specific regulations regarding leather products. Buyers should familiarize themselves with these requirements to avoid compliance issues.

By understanding the manufacturing processes and quality assurance protocols for brown leather fabric, B2B buyers can confidently source materials that meet their specific needs while ensuring high standards of quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brown leather fabric’

When sourcing brown leather fabric for your business needs, it’s essential to approach the process systematically. This guide provides a step-by-step checklist designed to help B2B buyers navigate the complexities of procurement, ensuring that they secure high-quality materials that meet their specific requirements.

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the specifications for the brown leather fabric you need. Consider factors such as thickness, texture, and type (genuine or faux leather). This clarity will guide your supplier conversations and ensure you receive samples that align with your project needs.

- Thickness and Weight: Determine the desired weight and thickness based on the intended use, whether for upholstery, accessories, or industrial applications.

- Finish Type: Specify if you need a matte, glossy, or distressed finish to match your design vision.

Step 2: Research Reliable Suppliers

Thorough research on potential suppliers is crucial for ensuring quality and reliability. Look for suppliers that specialize in leather products and have a good reputation in the market.

- Industry Experience: Check how long the supplier has been in business and their expertise in leather sourcing.

- Certifications: Ensure that the suppliers meet international quality standards and have necessary certifications, such as ISO or similar.

Step 3: Request Samples

Always request samples before making a bulk purchase. This step allows you to evaluate the quality, texture, and color accuracy of the brown leather fabric.

- Test Durability: Assess the sample for durability by performing rub tests to understand its wear resistance.

- Color Matching: Ensure the sample matches your project requirements, especially if you are working with existing materials.

Step 4: Verify Supplier Certifications

Confirm that your chosen suppliers hold relevant certifications that validate their practices and product quality. Certifications can indicate compliance with environmental and safety standards.

- Sustainability Practices: Inquire about the environmental impact of their tanning processes and whether they adhere to sustainable practices.

- Quality Assurance Programs: Look for suppliers with robust quality control measures in place.

Step 5: Negotiate Pricing and Terms

Once you’ve shortlisted suppliers, engage in negotiations to secure favorable pricing and terms. Understanding the market price for brown leather fabric will empower your discussions.

- Bulk Discounts: Discuss potential discounts for bulk orders to optimize your procurement costs.

- Payment Terms: Clarify payment terms, delivery timelines, and shipping costs to avoid surprises later.

Step 6: Evaluate Shipping Options

Consider the logistics of getting your leather fabric delivered to your location. Shipping can significantly impact overall costs and delivery timelines.

Illustrative image related to brown leather fabric

- Shipping Providers: Investigate which shipping options the supplier offers and their reliability.

- Lead Times: Confirm lead times for both production and shipping to align with your project schedule.

Step 7: Establish a Relationship

Building a long-term relationship with your chosen supplier can lead to better service and pricing in the future. Maintain open communication and provide feedback on your experiences.

- Regular Updates: Keep suppliers informed about your evolving needs and any changes in your business.

- Feedback Loop: Share feedback about the quality and service to foster a mutually beneficial relationship.

By following this checklist, B2B buyers can confidently source brown leather fabric that meets their requirements, ensuring quality, reliability, and cost-effectiveness in their procurement process.

Comprehensive Cost and Pricing Analysis for brown leather fabric Sourcing

What Are the Key Cost Components for Sourcing Brown Leather Fabric?

When sourcing brown leather fabric, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The type of leather, whether genuine or faux, significantly influences the price. Genuine leather tends to be more expensive due to its durability and luxury appeal, while faux leather often offers a more affordable alternative.

-

Labor: Labor costs vary based on the production location. Regions with lower labor costs can offer competitive pricing, but this may affect quality. Skilled labor is often required for high-quality leather craftsmanship, which can increase costs.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: The costs of molds and specialized equipment for producing custom designs or unique specifications can add to the initial investment.

-

Quality Control (QC): Implementing strict QC measures ensures the fabric meets industry standards. While this adds to costs, it also helps prevent costly returns and defects.

-

Logistics: Transportation costs are influenced by the distance from the supplier to the buyer, shipping methods, and any tariffs or duties involved in international shipping.

-

Margin: Suppliers will include a profit margin, which can vary based on market demand and competition.

How Do Price Influencers Affect Brown Leather Fabric Costs?

Several factors can influence the price of brown leather fabric, including:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower per-unit costs. Suppliers may offer discounts for larger orders, making it financially advantageous for B2B buyers.

-

Specifications and Customization: Custom designs or specific quality requirements can increase costs. Standardized products are typically less expensive than bespoke solutions.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., eco-friendly, sustainable sourcing) often command higher prices. Buyers should assess the value of these certifications against their needs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their reputation for quality and service.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is crucial. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly impacting the total cost.

What Are Some Effective Buyer Tips for Sourcing Brown Leather Fabric?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

Illustrative image related to brown leather fabric

-

Negotiate Effectively: Building a relationship with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate on bulk orders or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the costs associated with shipping, handling, and potential returns. A lower initial price might lead to higher overall costs if quality issues arise.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect the final cost. Engaging with local import-export experts can provide insights into these factors.

-

Request Samples: Before committing to a large order, request samples to assess quality. This can help avoid costly mistakes and ensure the product meets your specifications.

-

Stay Informed on Market Trends: Understanding market demand and trends can help buyers make informed purchasing decisions, potentially leading to better pricing strategies.

Disclaimer on Pricing

Prices for brown leather fabric can fluctuate based on market conditions, supplier location, and the specific characteristics of the material. Always request up-to-date quotes and be aware that the indicative prices provided by suppliers may vary.

Alternatives Analysis: Comparing brown leather fabric With Other Solutions

When considering the best materials for upholstery and other applications, brown leather fabric stands out due to its classic appeal and durability. However, various alternatives are available, each with unique characteristics that may better suit specific project requirements. This analysis compares brown leather fabric with two alternatives: faux leather and brown upholstery fabric, helping B2B buyers make informed decisions.

| Comparison Aspect | Brown Leather Fabric | Kunstleer | Brown Upholstery Fabric |

|---|---|---|---|

| Performance | Highly durable and breathable; ages well with time | Durable but may wear down faster; less breathable | Varies widely; can be durable and stain-resistant, especially in heavy-duty options |

| Cost | Generally higher due to material sourcing and craftsmanship | Typically lower; varies by quality | Wide range; can be cost-effective or premium depending on type and brand |

| Ease of Implementation | Requires specific tools and skills for best results | Easier to work with; often available in pre-cut sizes | Easily available and can be sewn or glued without specialized tools |

| Maintenance | Requires regular conditioning to prevent drying and cracking | Easy to clean but may need replacement sooner | Varies; some types are machine washable, while others require spot cleaning |

| Best Use Case | High-end furniture, automotive interiors, luxury products | Budget-friendly projects, casual settings, and DIY applications | Versatile for residential and commercial upholstery, curtains, and decorative items |

What Are the Advantages and Disadvantages of Faux Leather as an Alternative?

Faux leather, often made from polyurethane or PVC, presents a cost-effective alternative to brown leather fabric. One significant advantage is its affordability, making it an attractive option for budget-conscious projects. Faux leather is also easier to maintain; it can be wiped clean without the need for specialized conditioning. However, it may lack the breathability and long-term durability of genuine leather, leading to potential wear and tear over time. For projects where the aesthetic of leather is desired without the associated costs, faux leather can be a compelling choice.

How Does Brown Upholstery Fabric Compare to Brown Leather Fabric?

Brown upholstery fabric encompasses a range of materials, including cotton blends and synthetic fibers, making it a versatile option for many applications. One of its primary advantages is the wide variety of styles and patterns available, allowing for creative flexibility in design. It is often easier to handle and sew, which can be a significant advantage for DIY projects or those requiring quick turnarounds. However, the performance can vary significantly between different types of upholstery fabric, and some may not offer the same durability or luxury feel as brown leather fabric. For high-traffic areas or settings where aesthetics are paramount, brown leather may still be the preferred choice.

Illustrative image related to brown leather fabric

How Should B2B Buyers Choose the Right Material for Their Needs?

When selecting between brown leather fabric and its alternatives, B2B buyers should consider the specific requirements of their projects. Factors such as budget constraints, the intended use of the product, maintenance capabilities, and desired aesthetics will guide the decision-making process. For high-end applications where longevity and luxury are essential, investing in brown leather fabric may be justified. Conversely, for projects requiring cost efficiency and ease of use, faux leather or brown upholstery fabric may provide suitable solutions. Understanding the unique benefits and limitations of each option will empower buyers to make choices that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for brown leather fabric

What Are the Key Technical Properties of Brown Leather Fabric?

Understanding the technical properties of brown leather fabric is essential for B2B buyers, as these specifications directly influence the quality, durability, and suitability of the material for various applications. Here are some critical properties to consider:

1. Material Grade

Material grade refers to the quality classification of the leather. Common grades include full-grain, top-grain, corrected grain, and bonded leather. Full-grain leather, made from the top layer of the hide, is the highest quality, offering durability and a natural look. Understanding material grade is crucial for buyers because it affects pricing, longevity, and the final product’s aesthetic appeal.

Illustrative image related to brown leather fabric

2. Hide Size

Leather is typically sold by the hide rather than in rolls or sheets. The average size of a cowhide is around 50 square feet, but this can vary depending on the breed and processing method. For B2B buyers, knowing the hide size helps in estimating the quantity needed for projects, which is critical for budgeting and resource management.

3. Tolerance

Tolerance in leather refers to the acceptable variation in thickness and quality across the hide. A standard tolerance is usually between 1.0 to 1.5 mm for upholstery leather. This specification is important for manufacturers who require uniformity in material for consistent production quality. Variations beyond the tolerance can lead to issues in manufacturing and the final product.

4. Durability Rating

Durability rating indicates how well the leather can withstand wear and tear. This is often measured in double rubs, with higher ratings indicating greater resilience. For instance, leather rated at 55,000 double rubs is considered heavy-duty and suitable for high-traffic areas. Understanding durability is essential for B2B buyers, especially when selecting materials for commercial or heavy-use applications.

5. Flammability Classification

Flammability classification indicates how resistant the leather is to catching fire. This is crucial for upholstery used in public spaces or automotive applications, where safety standards must be met. Buyers should look for fabrics that comply with local regulations and standards to ensure safety and liability concerns are addressed.

6. Care and Maintenance Guidelines

Understanding care and maintenance requirements is vital for ensuring the longevity of leather products. Brown leather fabrics may require specific cleaning agents and procedures to maintain their appearance and quality. This knowledge can inform buyers about the total cost of ownership and help them provide better customer service.

Illustrative image related to brown leather fabric

What Are Common Trade Terms Related to Brown Leather Fabric?

Familiarity with industry terminology can significantly streamline the purchasing process. Here are some essential trade terms relevant to brown leather fabric:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, this often pertains to suppliers that provide leather goods for brands that do not manufacture their products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to ensure they meet the supplier’s requirements without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of goods. It allows B2B buyers to compare offers and negotiate better deals, making it an essential tool in procurement.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand shipping costs and liabilities.

Illustrative image related to brown leather fabric

5. Lead Time

Lead time is the amount of time from placing an order to the delivery of the product. Knowing the lead time is crucial for project planning and ensuring materials arrive when needed.

6. Compliance Certification

This refers to documents proving that the leather meets certain industry standards, such as environmental regulations or safety guidelines. Buyers should ensure that their suppliers provide the necessary certifications to avoid legal issues.

In conclusion, understanding the essential technical properties and trade terminology related to brown leather fabric is vital for international B2B buyers. This knowledge enables informed purchasing decisions, effective communication with suppliers, and ultimately, successful project outcomes.

Illustrative image related to brown leather fabric

Navigating Market Dynamics and Sourcing Trends in the brown leather fabric Sector

What Are the Key Trends and Market Dynamics Impacting the Brown Leather Fabric Sector?

The global brown leather fabric market is currently shaped by several pivotal drivers, including the rising demand for premium home furnishings and automotive upholstery. This demand is particularly pronounced in developing regions like Africa and South America, where increasing disposable incomes and a growing middle class are fueling consumption. In Europe and the Middle East, there is a notable trend towards customization and personalization in leather products, allowing buyers to differentiate themselves in competitive markets. Additionally, the integration of B2B technology, such as AI-driven supply chain management and e-commerce platforms, is streamlining procurement processes, making it easier for international buyers to source high-quality materials.

Emerging trends also include the shift towards multifunctional and sustainable fabrics. B2B buyers are increasingly looking for materials that not only meet aesthetic and functional requirements but also align with broader sustainability goals. Innovations such as faux leather alternatives and recycled materials are gaining traction, particularly in markets that prioritize eco-friendly practices. These trends are influencing sourcing strategies, as buyers seek suppliers who can provide both quality and sustainability.

How Are Sustainability and Ethical Sourcing Shaping the Brown Leather Fabric Industry?

The environmental impact of leather production has come under scrutiny, prompting a shift toward more sustainable and ethical sourcing practices. For international B2B buyers, understanding the implications of leather sourcing is critical. The tanning process, traditionally resource-intensive, has led to significant concerns about water use, chemical runoff, and carbon emissions. As a result, there is an increasing demand for ‘green’ certifications, such as the Leather Working Group (LWG) certification, which assesses environmental practices in leather manufacturing.

Illustrative image related to brown leather fabric

Buyers are encouraged to seek partnerships with suppliers who prioritize ethical practices, such as using vegetable-tanned leather, which is less harmful to the environment compared to conventional methods. The focus on transparency in supply chains is also rising, with buyers looking for suppliers who can provide detailed information about sourcing origins and production processes. By prioritizing ethical sourcing, businesses not only mitigate environmental risks but also enhance their brand reputation in a market that increasingly values sustainability.

What Is the Historical Context of Brown Leather Fabric and Its Relevance Today?

Historically, leather has been a symbol of luxury and durability, used in a variety of applications from clothing to upholstery. The evolution of leather craftsmanship can be traced back thousands of years, with traditional techniques still influencing modern production. However, the landscape has transformed significantly with technological advancements, allowing for innovations in both genuine and synthetic leather production.

Today, the brown leather fabric sector benefits from a rich heritage while simultaneously adapting to contemporary demands for sustainability and design versatility. This historical context is essential for B2B buyers, as it underscores the importance of quality and craftsmanship in sourcing decisions. Understanding the evolution of leather not only informs purchasing choices but also assists in identifying suppliers who can provide authentic and high-quality materials that resonate with both tradition and modernity.

Illustrative image related to brown leather fabric

By navigating these market dynamics and sourcing trends, international B2B buyers can make informed decisions that align with their business goals and consumer expectations, ensuring a competitive edge in the evolving brown leather fabric landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of brown leather fabric

-

How do I choose the right brown leather fabric for my project?

Choosing the right brown leather fabric involves considering the intended application, desired aesthetics, and durability requirements. For upholstery, opt for heavier grades that can withstand wear and tear, while fashion applications may benefit from lighter, more supple options. Always request samples to assess the texture, color, and finish before committing to a bulk order. Additionally, evaluate the supplier’s reputation and product specifications to ensure you are getting high-quality material that meets your project needs. -

What are the key quality indicators for brown leather fabric?

Key quality indicators include the leather’s thickness, grain pattern, and finish. Full-grain leather is the highest quality, showcasing natural imperfections, while corrected grain is more uniform but may lack character. Check for the leather’s resistance to wear and its ability to maintain color over time. Additionally, consider certifications such as ISO or environmental standards that indicate responsible sourcing and processing, which can be crucial for B2B partnerships. -

What is the typical minimum order quantity (MOQ) for brown leather fabric?

The MOQ for brown leather fabric varies by supplier and can range from as low as 10 hides to several hundred square meters, depending on the type of leather and the manufacturer’s capacity. Larger orders often yield better pricing, but ensure that your projected demand aligns with the MOQ. Discuss your specific needs with suppliers to negotiate terms that suit both parties, especially if you’re looking for a custom order or particular shades. -

What payment terms should I expect when sourcing brown leather fabric internationally?

Payment terms can differ significantly between suppliers and regions. Common practices include upfront payments, letters of credit, or 30-60 days net payment terms after delivery. When negotiating, consider the total landed cost, including shipping and customs duties, to avoid unexpected expenses. Always clarify payment methods accepted by the supplier and ensure secure transactions, especially for larger orders. -

How can I ensure the authenticity of brown leather fabric?

To ensure authenticity, work with reputable suppliers who provide detailed product descriptions, including the type of leather and its sourcing. Request certifications that verify the material’s origin and processing methods. Additionally, inspect samples for distinctive features of genuine leather, such as natural grain patterns and variations in color. Establishing a relationship with trusted suppliers can also help in verifying the authenticity of the products over time. -

What logistics considerations should I keep in mind when importing brown leather fabric?

Logistics considerations include shipping methods, lead times, and customs regulations in your country. Ensure the supplier provides clear shipping timelines and choose a freight forwarder experienced in handling leather imports. Familiarize yourself with any tariffs or import duties that may apply to leather products in your region, as this can significantly affect your overall costs. Consider using air freight for urgent orders, while sea freight may be more cost-effective for larger shipments. -

How do I vet potential suppliers of brown leather fabric?

Vetting suppliers involves researching their background, reputation, and customer reviews. Request references from previous clients to assess their reliability and quality of service. Analyze their product range and certifications to ensure they meet industry standards. Conducting factory visits or virtual inspections can also provide insights into their manufacturing processes and quality control practices, helping to establish a trustworthy partnership. -

What customization options are available for brown leather fabric?

Customization options for brown leather fabric may include specific colors, finishes, embossing, and cut sizes to fit your project requirements. Many suppliers offer the ability to produce custom hides based on your specifications, which can be beneficial for branding or unique design needs. Discuss your ideas with the supplier and request samples of custom options to evaluate before placing a larger order. This ensures that the final product aligns with your vision and quality expectations.

Top 7 Brown Leather Fabric Manufacturers & Suppliers List

1. Leather Hide Store – Dark Brown Leather Upholstery

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Dark Brown Leather Upholstery from Leather Hide Store. Sold by the hide, not on rolls or sheets. Average size is 50 square feet. Used for furniture, automotive, and general leathercraft. Closeouts available with exceptional quality and greater savings. Various styles available including K1271 OLD LODGE DISTRESS, K1436 MIDNIGHT ORCHID, K1397 ITALIA RICH ESPRESSO, K1413 TENNESSEE WHISKEY, K1416 WHIS…

2. Hobby Lobby – Brown Saddle Faux Leather Fabric

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {‘name’: ‘Brown Saddle Faux Leather Fabric’, ‘sku’: ‘1533801’, ‘discounted_price’: ‘$12.59’, ‘original_price’: ‘$17.99’, ‘discount’: ‘30% Off’, ‘fabric_type’: ‘Fabric By The Yard’, ‘available_increments’: ‘1-yard increments’, ‘average_bolt_size’: ‘approximately 9 yards’, ‘width’: ’55 inches’, ‘vertical_repeat’: ‘29.13 inches’, ‘horizontal_repeat’: ‘8.25 inches’, ‘color’: ‘Brown’, ‘weight’: ‘Extra-…

3. KOVI Fabrics – Brown Upholstery Options

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Brown Upholstery Fabric options available at KOVI Fabrics include various shades such as dark brown, chocolate brown, and leather brown. Fabrics are offered in solid colors and patterns like checkered, stripes, and floral. The fabric is suitable for creating a warm and inviting atmosphere, ideal for high traffic areas due to its ability to hide dirt and stains. However, it may not be recommended f…

4. Naugahyde – Brown Faux Leather Upholstery Vinyl

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Brown Faux Leather Upholstery Vinyl fabric available from various brands including Naugahyde and Boltaflex. Prices range from $8.95 to $33.95 per yard. Multiple colors and patterns available. In stock yardage varies by product, with options for automotive, furniture, and marine use. Free shipping on orders over $199 with coupon code SHIPFREE.

5. OnlineFabricStore – Vinyl & Faux Leather Fabric

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: This company, OnlineFabricStore – Vinyl & Faux Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Tandy Leather – Quality Leather Goods

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Quality Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

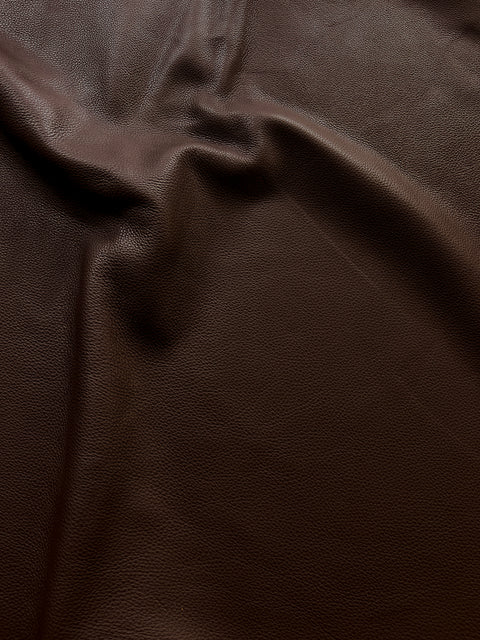

7. Haute House Fabric – HHF Tut Dark Brown Leather Upholstery Fabric

Domain: hautehousefabric.com

Registered: 2013 (12 years)

Introduction: {“name”: “HHF Tut Dark Brown – Leather Upholstery Fabric”, “price”: “$13.30”, “unit_price”: “Per Square Foot”, “sku”: “HHF_TutDarb”, “category”: [“Leather Fabrics”, “Upholstery Fabrics”, “Brown Fabrics”, “Solid Fabrics”, “Haute House Fabric”, “$100 – $200 Per Yard”], “color”: “Dark Brown”, “pattern”: “Solid”, “content”: “Leather”, “upholstery_grade”: “S”, “country_of_origin”: “Italy”, “cleaning_co…

Strategic Sourcing Conclusion and Outlook for brown leather fabric

In summary, the strategic sourcing of brown leather fabric presents significant opportunities for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding the nuances of sourcing quality leather—whether genuine or faux—can enhance product offerings and ensure customer satisfaction. Buyers should prioritize suppliers that provide transparency in sourcing, quality certifications, and a range of options tailored to specific needs, such as upholstery, automotive, or fashion applications.

The value of strategic sourcing lies not only in cost savings but also in building long-term relationships with reliable suppliers. This approach fosters innovation and adaptability, crucial in a rapidly evolving market landscape. As the demand for sustainable and ethically sourced materials continues to rise, buyers must also consider the environmental impact of their sourcing decisions.

Looking ahead, businesses are encouraged to leverage emerging trends in brown leather fabric, such as eco-friendly alternatives and customizable options, to stay competitive. Engage with suppliers who are at the forefront of these developments, and take proactive steps to integrate these materials into your product lines. By doing so, you can enhance your brand’s appeal and ensure a robust market presence in the coming years.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to brown leather fabric

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.