Introduction: Navigating the Global Market for how to treat nubuck leather

In the competitive landscape of international trade, sourcing high-quality nubuck leather products presents unique challenges for B2B buyers. With its luxurious texture and durability, nubuck leather is increasingly favored for a variety of applications, from fashion accessories to furniture. However, understanding how to effectively treat nubuck leather to maintain its pristine condition is crucial for preserving product value and ensuring customer satisfaction. This comprehensive guide delves into the intricacies of nubuck leather care, covering essential topics such as types of nubuck, appropriate treatment methods, and best practices for supplier vetting.

By navigating through the complexities of nubuck leather treatment, this guide empowers B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including regions like Brazil and Nigeria—to make informed purchasing decisions. Whether you are looking to enhance the longevity of your products or establish partnerships with reliable suppliers, our insights will help you identify quality care solutions that align with your business needs. From understanding the cost implications to exploring innovative treatment techniques, this resource serves as a vital tool in optimizing your supply chain and elevating your product offerings in the global market.

Table Of Contents

- Top 5 How To Treat Nubuck Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to treat nubuck leather

- Understanding how to treat nubuck leather Types and Variations

- Key Industrial Applications of how to treat nubuck leather

- 3 Common User Pain Points for ‘how to treat nubuck leather’ & Their Solutions

- Strategic Material Selection Guide for how to treat nubuck leather

- In-depth Look: Manufacturing Processes and Quality Assurance for how to treat nubuck leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to treat nubuck leather’

- Comprehensive Cost and Pricing Analysis for how to treat nubuck leather Sourcing

- Alternatives Analysis: Comparing how to treat nubuck leather With Other Solutions

- Essential Technical Properties and Trade Terminology for how to treat nubuck leather

- Navigating Market Dynamics and Sourcing Trends in the how to treat nubuck leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to treat nubuck leather

- Strategic Sourcing Conclusion and Outlook for how to treat nubuck leather

- Important Disclaimer & Terms of Use

Understanding how to treat nubuck leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nubuck Brush Treatment | Uses a soft-bristled brush to clean and rejuvenate the nap | Footwear, bags, and upholstery | Pros: Maintains texture; easy to apply. Cons: Requires regular maintenance. |

| Nubuck Waterproofing Spray | Creates a protective barrier against moisture and stains | Outdoor apparel and accessories | Pros: Enhances durability; prevents water damage. Cons: Needs reapplication every few months. |

| Nubuck Conditioner | Nourishes and maintains flexibility of the leather fibers | Fashion goods and leather furniture | Pros: Restores softness; prevents cracking. Cons: May darken the leather; requires testing. |

| Nubuck Cleaner | Specialized cleaner for removing tough stains and dirt | High-end fashion and luxury items | Pros: Effective stain removal; enhances appearance. Cons: Must follow specific instructions; potential for discoloration. |

| Nubuck Eraser | Rubber tool for spot cleaning and removing scuffs | Apparel, bags, and accessories | Pros: Convenient for quick fixes; easy to use. Cons: May alter texture if used improperly. |

What are the key characteristics of Nubuck Brush Treatment?

Nubuck Brush Treatment is essential for maintaining the luxurious texture of nubuck leather. This method employs a soft-bristled brush to gently clean and revitalize the nap, ensuring that the leather retains its signature velvety feel. Regular brushing not only removes surface dirt but also lifts the fibers, making the product look fresh and well-cared-for. This treatment is particularly suitable for businesses dealing in footwear, bags, and upholstery, where the aesthetic appeal is paramount. Buyers should consider the frequency of maintenance required to keep the products looking their best.

How does Nubuck Waterproofing Spray enhance product longevity?

Nubuck Waterproofing Spray is designed to create a protective layer over nubuck leather, making it less susceptible to moisture and stains. This treatment is particularly beneficial for outdoor apparel and accessories that are exposed to various environmental conditions. By applying this spray, businesses can enhance the durability of their products and appeal to customers seeking longevity and resilience. However, it is crucial for buyers to note that the spray needs to be reapplied every few months to maintain its effectiveness.

Why is Nubuck Conditioner important for leather products?

Nubuck Conditioner plays a vital role in preserving the flexibility and softness of nubuck leather. This treatment nourishes the fibers, preventing them from becoming brittle or cracked over time. It is particularly relevant for businesses involved in the production of fashion goods and leather furniture, where maintaining a luxurious feel is essential. Buyers should be aware that while conditioners enhance the leather’s appearance, they may darken the material, necessitating a patch test before full application.

What advantages does Nubuck Cleaner offer for tough stains?

Nubuck Cleaner is a specialized product formulated to tackle tough stains and dirt without damaging the leather. This treatment is ideal for high-end fashion and luxury items that require meticulous care to maintain their pristine condition. By effectively removing stains, Nubuck Cleaner can significantly enhance the appearance of products, making them more appealing to consumers. However, buyers must follow the specific instructions provided with the cleaner to avoid potential discoloration or damage to the leather.

Illustrative image related to how to treat nubuck leather

How can Nubuck Eraser be used for quick maintenance?

The Nubuck Eraser is a practical tool designed for quick spot cleaning and removing scuffs from nubuck leather. Its convenience makes it suitable for apparel, bags, and accessories, allowing businesses to offer customers a simple solution for maintaining their products. While the eraser is easy to use, it is important for buyers to apply it gently to avoid altering the texture of the leather. This quick maintenance option can be a selling point for businesses looking to provide value-added services to their clients.

Key Industrial Applications of how to treat nubuck leather

| Industry/Sector | Specific Application of how to treat nubuck leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Regular cleaning and conditioning of nubuck jackets | Extends product lifespan and maintains aesthetic appeal | Quality of cleaning products and conditioners, availability of nubuck-specific tools |

| Footwear | Application of waterproofing sprays | Reduces returns due to damage from water exposure | Compatibility with nubuck material, eco-friendly options for sustainability |

| Furniture & Upholstery | Maintaining nubuck upholstery in high-traffic areas | Enhances durability and cleanliness of furniture | Availability of bulk cleaning solutions and protective sprays, supplier reliability |

| Automotive | Care for nubuck leather interiors | Preserves luxury feel and resale value of vehicles | Suppliers offering specialized automotive leather care products, compliance with safety standards |

| Sporting Goods | Treatment of nubuck in sports equipment | Improves performance and longevity of products | Sourcing durable treatments that withstand extreme conditions, local regulations on chemical use |

How is Nubuck Leather Treated in the Fashion & Apparel Industry?

In the fashion and apparel sector, nubuck leather is frequently used for jackets, bags, and shoes. Regular cleaning and conditioning are essential to maintain the luxurious appearance and texture of these items. By implementing a consistent care routine, businesses can significantly extend the lifespan of their products, reducing the frequency of replacements and enhancing customer satisfaction. International buyers, especially in regions like Africa and South America, should prioritize sourcing high-quality cleaning and conditioning products that are tailored for nubuck to ensure effective maintenance.

What Role Does Waterproofing Play in the Footwear Sector?

Footwear manufacturers often face challenges related to water damage, particularly in regions with high humidity or rainfall. Applying nubuck-specific waterproofing sprays can mitigate these issues, protecting shoes from stains and prolonging their usability. This is crucial for businesses aiming to minimize return rates and maintain customer loyalty. Buyers in the Middle East and Europe should consider sourcing waterproofing solutions that are compatible with nubuck and are environmentally friendly, aligning with global sustainability trends.

How is Nubuck Leather Maintained in Furniture & Upholstery?

In the furniture and upholstery industry, nubuck is valued for its soft, tactile quality. Regular maintenance, including cleaning and conditioning, is vital, especially in high-traffic areas where wear and tear are more pronounced. This not only enhances the durability of the furniture but also keeps it looking pristine, which is essential for customer retention. B2B buyers should look for bulk cleaning solutions and protective sprays from reliable suppliers to ensure consistent product quality and performance.

Illustrative image related to how to treat nubuck leather

Why is Nubuck Care Important for Automotive Interiors?

Automotive manufacturers and dealerships utilize nubuck leather for its luxurious feel in vehicle interiors. Proper care, including the use of specialized cleaning products, is necessary to preserve the leather’s quality and appearance, which directly impacts the vehicle’s resale value. Buyers in this sector should seek suppliers that provide comprehensive automotive leather care solutions, ensuring compliance with safety and quality standards to meet consumer expectations.

How Can Nubuck Treatment Enhance Sporting Goods?

In the sporting goods industry, nubuck leather is often used in equipment such as bags and apparel. Effective treatment and maintenance of nubuck help improve the performance and longevity of these products, addressing the wear and tear from rigorous use. B2B buyers should focus on sourcing durable treatments that can withstand extreme conditions while adhering to local regulations regarding chemical use, ensuring safe and effective care for their nubuck products.

3 Common User Pain Points for ‘how to treat nubuck leather’ & Their Solutions

Scenario 1: Struggling with Stain Removal on Nubuck Leather Products

The Problem: B2B buyers often face significant challenges when it comes to dealing with stains on nubuck leather items, such as shoes or bags. The porous nature of nubuck makes it particularly susceptible to oil, grease, and water stains. Clients frequently report frustration over persistent marks that not only detract from the aesthetic appeal of the product but also diminish its perceived value. For businesses that rely on high-quality leather goods, this can lead to customer dissatisfaction and potential loss of sales.

Illustrative image related to how to treat nubuck leather

The Solution: To effectively address stains on nubuck leather, it is crucial to implement a dual approach of preventive care and immediate action. First, educate your clients on the importance of using a nubuck-specific cleaner and brush. A soft-bristled brush can gently lift dirt and restore the leather’s nap without damaging it. Additionally, advise clients to invest in a high-quality nubuck eraser for light stains and a specialized nubuck cleaner for tougher marks. Always emphasize the need to conduct a patch test before applying any cleaner to ensure compatibility. This proactive approach helps maintain the product’s quality and extends its lifespan, ultimately enhancing customer satisfaction.

Scenario 2: Maintaining the Luxurious Appearance of Nubuck Leather

The Problem: One of the primary concerns for B2B buyers is maintaining the luxurious appearance of nubuck leather over time. Without proper care, the soft texture can become flat and shiny, which detracts from its premium appeal. Businesses that manufacture or sell nubuck products are particularly concerned about keeping their inventory looking pristine, as first impressions are critical in the competitive leather market.

The Solution: Implementing a regular maintenance routine is key to preserving the elegant look of nubuck leather. Recommend that businesses incorporate a cleaning schedule that includes brushing the leather weekly with a nubuck brush to refresh the nap and remove dust. Additionally, suggest using a nubuck conditioner every few months to nourish the fibers and restore their softness. For enhanced protection, advise clients to apply a nubuck-friendly waterproofing spray, particularly in regions prone to wet weather. This comprehensive care regimen not only helps maintain the appearance of the leather but also reinforces the brand’s commitment to quality, encouraging repeat business.

Scenario 3: Navigating the Risks of Water Damage on Nubuck Leather

The Problem: Nubuck leather’s susceptibility to water damage is a significant concern for B2B buyers, especially in regions where humidity and rain are common. Water can cause unsightly water stains, and if not treated promptly, it can lead to irreversible damage. This is particularly problematic for businesses that operate in sectors like fashion or outdoor gear, where the durability and appearance of leather products directly impact their reputation and bottom line.

The Solution: To mitigate the risks associated with water damage, businesses should emphasize the importance of preventive measures. Educate clients about the benefits of applying a water-repellent spray specifically designed for nubuck leather, which can help create a protective barrier against moisture. In addition, advise them to store nubuck items in a cool, dry place and to avoid exposing them to wet conditions whenever possible. In the event of water exposure, instruct clients to blot the area with a clean, absorbent cloth and allow the product to air dry naturally, away from heat sources. This proactive strategy not only protects their investment but also enhances customer confidence in the durability of their nubuck leather products.

Strategic Material Selection Guide for how to treat nubuck leather

What Materials Are Essential for Treating Nubuck Leather?

When it comes to treating nubuck leather, selecting the right materials is crucial for maintaining its appearance and longevity. Below, we analyze four common materials used in the care and treatment of nubuck leather, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Nubuck Brush: What Are Its Key Properties and Benefits?

Nubuck brushes typically feature soft bristles designed to lift dirt and restore the nap of the leather without causing damage. These brushes are essential for regular maintenance, allowing users to keep the leather looking fresh and vibrant.

Pros: They are durable, easy to use, and relatively inexpensive. Regular brushing can significantly extend the life of nubuck products by preventing dirt buildup.

Cons: While effective for light cleaning, they may not be sufficient for deep stains or heavy grime, necessitating additional cleaning products.

Illustrative image related to how to treat nubuck leather

Impact on Application: Regular use of a nubuck brush can enhance the leather’s appearance and maintain its texture, making it suitable for high-end fashion items.

Considerations for International Buyers: Buyers in regions like Africa and South America may need to consider local availability and shipping costs. Compliance with regional standards for cleaning products may also be necessary.

Nubuck Cleaner: How Does It Perform in Various Conditions?

Nubuck cleaners are specially formulated to remove stains without damaging the leather. They often come in spray or liquid form and are designed to be gentle yet effective.

Pros: These cleaners can effectively treat a wide range of stains, including oil and water marks, while preserving the leather’s texture.

Illustrative image related to how to treat nubuck leather

Cons: Some formulations may contain chemicals that could darken the nubuck or alter its texture if not tested properly. Additionally, the cost can vary significantly based on brand and quality.

Impact on Application: Effective cleaning can restore the original color and texture of nubuck leather, making it suitable for luxury goods and high-traffic items.

Considerations for International Buyers: Buyers should ensure that the cleaner complies with local regulations and standards, such as ASTM or JIS, especially when importing products. Understanding local preferences for eco-friendly or hypoallergenic products may also influence purchasing decisions.

Nubuck Conditioner: What Are the Key Advantages and Limitations?

Nubuck conditioners are designed to nourish the leather, preventing it from drying out and cracking. They help maintain flexibility and enhance the leather’s natural appearance.

Pros: Regular conditioning can significantly extend the life of nubuck products, making them more resistant to wear and tear. They are generally easy to apply.

Cons: Some conditioners may leave a residue or darken the leather, which can be a concern for buyers looking to maintain a specific aesthetic.

Impact on Application: Conditioning is vital for items exposed to varying climates, as it helps the leather adapt to environmental changes.

Considerations for International Buyers: Buyers should be aware of the specific conditioning products available in their region and any import restrictions on chemical products. It’s also important to consider the climate of their market, as different regions may require different conditioning frequencies.

Waterproofing Spray: How Does It Enhance Nubuck Leather Care?

Waterproofing sprays are designed to create a barrier against moisture and stains, making them an essential part of nubuck leather care.

Pros: These sprays can significantly enhance the durability of nubuck leather by protecting it from water damage and stains, especially in humid climates.

Illustrative image related to how to treat nubuck leather

Cons: The effectiveness of these sprays can vary, and improper application may lead to uneven protection or discoloration.

Impact on Application: Waterproofing is particularly important for outdoor products, such as footwear and bags, where exposure to the elements is common.

Considerations for International Buyers: Buyers should ensure that the waterproofing sprays they choose are compliant with local environmental regulations. Additionally, understanding the preferences for product performance in different climates can guide purchasing decisions.

Summary Table of Material Selection for Nubuck Leather Treatment

| Materiaal | Typical Use Case for how to treat nubuck leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nubuck Brush | Regular maintenance and cleaning | Durable and easy to use | Not effective for deep stains | Low |

| Nubuck Cleaner | Stain removal and deep cleaning | Effective on various stains | May alter texture if not tested | Medium |

| Nubuck Conditioner | Nourishing and maintaining flexibility | Extends product life | Can darken leather | Medium |

| Waterproofing Spray | Protection against moisture and stains | Enhances durability in humid climates | Effectiveness varies; improper application risks | Medium to High |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that enhance the care and longevity of nubuck leather products in their markets.

Illustrative image related to how to treat nubuck leather

In-depth Look: Manufacturing Processes and Quality Assurance for how to treat nubuck leather

What Are the Key Stages in the Manufacturing Process of Nubuck Leather?

The manufacturing of nubuck leather involves several critical stages, each integral to ensuring the quality and durability of the final product. Understanding these stages can help B2B buyers make informed decisions when sourcing nubuck leather goods.

Material Preparation: What Does It Entail?

The first stage in the manufacturing process is material preparation, which involves selecting high-quality raw hides, typically from cattle. The hides must be free from defects and of sufficient thickness to allow for sanding. Once selected, the hides undergo a thorough cleaning process to remove any dirt, blood, or hair. This step is essential, as impurities can affect the quality of the nubuck leather produced.

After cleaning, the hides are soaked in a tanning solution, often chromium-based or vegetable-based, to preserve the leather and enhance its durability. The tanning process can take several weeks and is crucial for ensuring that the leather maintains its structure and flexibility over time.

How Is Nubuck Leather Formed?

The next stage is forming, which includes sanding down the outer layer of the hide to create the nubuck finish. This process is what distinguishes nubuck from other types of leather. Sanding must be done meticulously to achieve a fine, velvety texture without compromising the integrity of the leather. This step requires skilled labor and specialized equipment, which can vary depending on the manufacturer.

Once the desired nap is achieved, the leather is cut into patterns for various products, such as bags, shoes, or jackets. Precision in cutting is vital to minimize waste and ensure that each piece meets quality specifications.

What Finishing Techniques Are Commonly Used?

Finishing is the final stage of manufacturing nubuck leather and involves several techniques to enhance the appearance and functionality of the leather. Common finishing processes include dyeing, waterproofing, and applying protective coatings. Each of these processes contributes to the leather’s aesthetic appeal and its resistance to stains and moisture.

Dyeing can be done using various methods, including drum dyeing or spray dyeing, depending on the desired outcome. The protective coatings applied at this stage can significantly increase the leather’s lifespan by providing resistance against water and stains.

How Is Quality Assurance Implemented in Nubuck Leather Manufacturing?

Quality assurance (QA) is critical in the manufacturing of nubuck leather, ensuring that products meet international standards and customer expectations. QA processes typically involve several checkpoints throughout the manufacturing cycle.

Which International Standards Are Relevant for Nubuck Leather?

B2B buyers should be aware of several international quality standards, with ISO 9001 being the most recognized for general quality management systems. This standard ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for certain industrial applications may also be relevant. These certifications can indicate that a manufacturer adheres to specific safety and quality protocols.

What Are the Common QC Checkpoints in Nubuck Leather Production?

Quality control checkpoints are strategically placed throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials as they arrive to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): This checkpoint occurs during the manufacturing process, where samples are tested for adherence to quality standards.

- Final Quality Control (FQC): Once products are completed, they undergo final inspections to verify that they meet both aesthetic and functional quality criteria.

These checkpoints help identify and rectify any defects before the final product reaches the market, reducing returns and enhancing customer satisfaction.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying the quality control practices of suppliers is crucial for ensuring product reliability. Here are some effective strategies:

Illustrative image related to how to treat nubuck leather

What Steps Should B2B Buyers Take for Supplier Audits?

Conducting thorough supplier audits can provide insights into a manufacturer’s quality control processes. Buyers should look for:

- Documentation of Quality Standards: Suppliers should be able to provide evidence of compliance with international standards like ISO 9001.

- Inspection Reports: Regular reports on quality inspections, including data on defect rates and corrective actions taken, can offer transparency.

- Certifications: Verification of any industry-specific certifications can further assure buyers of the supplier’s commitment to quality.

How Important Are Third-Party Inspections in Quality Assurance?

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. Independent inspectors can evaluate raw materials, production processes, and finished goods, offering an additional layer of assurance. This practice is particularly beneficial for international B2B buyers who may face challenges in conducting on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific nuances when dealing with international suppliers. Variations in quality standards, cultural practices, and logistical challenges can affect quality assurance processes.

Illustrative image related to how to treat nubuck leather

How Do Cultural Differences Impact Quality Control?

Cultural attitudes toward quality and craftsmanship can vary significantly across regions. Buyers should engage in clear communication with suppliers to establish mutual expectations for quality standards. Understanding local manufacturing practices and norms can also help buyers anticipate potential challenges.

What Logistical Considerations Should Buyers Keep in Mind?

Logistics play a crucial role in the quality assurance process. Buyers should consider:

- Shipping Methods: The mode of transportation can impact product condition upon arrival. For example, extreme temperatures during shipping can affect leather quality.

- Lead Times: Longer lead times may increase the risk of quality degradation. Buyers should negotiate terms that allow for adequate time for quality checks before shipping.

By understanding the manufacturing processes and quality assurance measures in nubuck leather production, B2B buyers can make informed decisions and ensure that they source high-quality products that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to treat nubuck leather’

To effectively treat nubuck leather, a systematic approach is essential for ensuring long-lasting quality and appearance. This guide outlines a comprehensive checklist for B2B buyers to procure the necessary tools and products for maintaining nubuck leather, whether for manufacturing, retail, or maintenance purposes.

Step 1: Identify Your Specific Nubuck Leather Needs

Understanding the type of nubuck leather you are working with is crucial. Different finishes and qualities may require specific care products. Determine the intended use—be it for footwear, bags, or upholstery—to tailor your sourcing strategy accordingly.

- Consider the texture and color: Different nubuck types may react differently to cleaning and conditioning agents.

- Assess the environmental conditions: Products used in humid climates may need different properties compared to those used in dry regions.

Step 2: Research Quality Care Products

Investing in high-quality care products is vital for maintaining nubuck leather. Look for reputable brands that specialize in leather care, as they often provide better formulations that are specifically designed for nubuck.

- Check for product ingredients: Ensure that the products are free from harsh chemicals that could damage the leather.

- Seek eco-friendly options: With increasing demand for sustainable products, consider sourcing biodegradable or non-toxic cleaners and conditioners.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. This ensures that you partner with companies that have a proven track record in supplying high-quality nubuck care products.

- Request documentation: Ask for certifications and quality assurance processes that demonstrate their commitment to product quality.

- Seek testimonials: Look for reviews or case studies from other businesses in your industry to gauge reliability.

Step 4: Assess Product Availability and Lead Times

Understanding the availability of products and the supplier’s ability to meet your timelines is essential for maintaining your operations without interruption.

- Inquire about stock levels: Regularly check the inventory status to avoid delays in your supply chain.

- Clarify lead times: Establish clear timelines for product delivery to ensure timely maintenance of your nubuck leather products.

Step 5: Determine Pricing and Payment Terms

Establishing a clear understanding of pricing structures is crucial for budgeting and cost management.

Illustrative image related to how to treat nubuck leather

- Request detailed quotes: Ensure that all potential costs are included, such as shipping and taxes.

- Negotiate payment terms: Flexible payment options can help manage cash flow, especially for bulk purchases.

Step 6: Implement a Quality Control Process

Once products are sourced, implement a quality control process to monitor their effectiveness. Regular assessment ensures that the materials used are performing as expected and allows for adjustments if necessary.

- Conduct periodic evaluations: Regularly test the products on sample nubuck items to ensure they meet your quality standards.

- Collect feedback: Gather insights from your team on the performance of the care products to inform future sourcing decisions.

Step 7: Train Your Team on Nubuck Care Best Practices

Lastly, educating your staff on the proper techniques for treating nubuck leather is critical.

- Develop training materials: Create guides that outline best practices for cleaning, conditioning, and protecting nubuck leather.

- Host workshops: Organize sessions to demonstrate the proper use of care products and tools, ensuring consistent care across your operations.

By following this structured checklist, B2B buyers can effectively source and implement the necessary care for nubuck leather, ensuring its longevity and maintaining its luxurious appearance.

Comprehensive Cost and Pricing Analysis for how to treat nubuck leather Sourcing

What Are the Key Cost Components for Treating Nubuck Leather?

Understanding the cost structure involved in treating nubuck leather is crucial for B2B buyers. The primary cost components include:

-

Materials: The main materials required are nubuck leather itself, specialized cleaners, conditioners, waterproofing sprays, and brushes. High-quality materials often come at a premium, but they ensure better durability and effectiveness in maintenance.

-

Labor: Skilled labor is required for the proper treatment of nubuck leather. This includes the application of cleaning and conditioning products, as well as the intricate brushing techniques needed to maintain the leather’s unique nap. Labor costs can vary significantly based on geographic location and expertise.

-

Manufacturing Overhead: This includes costs associated with the production environment, utilities, and equipment used in the treatment process. Efficient manufacturing processes can help to minimize these overheads, affecting the overall pricing.

-

Tooling: Initial investment in tools such as brushes, erasers, and specialized cleaning equipment is necessary. While these costs are often one-time, they can add to the overall expense if high-quality tools are chosen.

-

Quality Control (QC): Ensuring the quality of treated nubuck leather is vital. Costs here involve testing products and processes to ensure they meet required standards, which can influence the pricing structure.

-

Logistics: Shipping and handling costs can vary based on the origin of the materials and the destination. International logistics can add significant costs, particularly if customs duties and tariffs are involved.

-

Margin: Suppliers typically build in a profit margin based on the costs mentioned above. Understanding the margin can help buyers negotiate better terms.

How Do Price Influencers Affect Nubuck Leather Treatment Costs?

Several factors influence the pricing of nubuck leather treatment services:

-

Volume/MOQ: Bulk purchases often yield better pricing. Suppliers are more likely to offer discounts for larger orders, which can significantly lower the cost per unit.

-

Specifications/Customization: Customized treatments or specific requirements can increase costs. Buyers should communicate their needs clearly to avoid unexpected expenses.

-

Materials: The choice of cleaning and conditioning products can greatly influence the final price. Higher quality or branded products may come at a premium but can offer better results.

-

Quality/Certifications: Suppliers with recognized quality certifications may charge higher prices due to their commitment to quality standards. Buyers should weigh the benefits of certified products against their costs.

-

Supplier Factors: The supplier’s location, reputation, and operational efficiencies can affect pricing. Buyers should conduct thorough research to select suppliers that offer competitive pricing without compromising quality.

-

Incoterms: Understanding Incoterms is essential for international buyers. These terms dictate who bears the costs and risks during shipping, which can influence total costs significantly.

What Tips Can Help B2B Buyers Negotiate Better Pricing for Nubuck Leather Treatment?

B2B buyers can adopt various strategies to ensure cost-efficiency and favorable pricing:

-

Negotiation: Engage suppliers in discussions about pricing flexibility. Highlighting long-term relationships or potential bulk orders can lead to better terms.

-

Total Cost of Ownership: Consider not just the initial purchase price but also the long-term costs associated with maintenance, durability, and potential replacements. A higher upfront cost may be justified if the product lasts longer.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should be aware of currency fluctuations, import duties, and local market conditions. Building relationships with local suppliers can mitigate some of these challenges.

-

Benchmarking Prices: Conducting market research to understand average pricing can provide leverage during negotiations. Knowing what competitors pay for similar services can inform your strategy.

-

Long-Term Partnerships: Establishing long-term relationships with suppliers can yield benefits such as loyalty discounts and priority service, which can lower overall costs.

Disclaimer on Indicative Prices

Prices for treating nubuck leather can vary widely based on the factors discussed above. The information provided serves as a guideline, and actual costs may differ based on specific circumstances and supplier negotiations. Always conduct thorough due diligence and obtain multiple quotes before making purchasing decisions.

Alternatives Analysis: Comparing how to treat nubuck leather With Other Solutions

Exploring Treatment Alternatives for Nubuck Leather

When it comes to treating nubuck leather, various solutions exist beyond traditional care methods. Businesses must evaluate these alternatives based on performance, cost, ease of implementation, maintenance, and suitability for specific use cases. The following analysis compares the standard treatment of nubuck leather with two viable alternatives: synthetic leather treatment and traditional leather care products.

Illustrative image related to how to treat nubuck leather

| Comparison Aspect | How To Treat Nubuck Leather | Synthetic Leather Treatment | Traditional Leather Care Products |

|---|---|---|---|

| Performance | High durability and aesthetic appeal; maintains soft texture | Good durability but lacks the natural feel of nubuck | Effective for various leather types; may not preserve nubuck’s unique texture |

| Cost | Moderate; requires specific brushes and conditioners | Generally lower; often sold in bulk | Varies widely; premium products can be expensive |

| Ease of Implementation | Straightforward; requires basic tools and techniques | Simple; usually involves application of a spray or wipe | Requires more expertise; different products for different leather types |

| Maintenance | Regular brushing and conditioning needed; low long-term upkeep | Minimal; occasional cleaning and reapplication of treatment | Requires consistent care; often involves multiple products |

| Best Use Case | Ideal for high-end fashion items and luxury accessories | Suitable for mass-market products needing low maintenance | Best for traditional leather goods requiring thorough treatment |

What Are the Pros and Cons of Synthetic Leather Treatment?

Synthetic leather treatment represents an alternative that appeals to manufacturers focused on cost efficiency. The primary advantage is its lower cost and ease of application, making it a popular choice for mass-produced goods. However, while synthetic treatments can offer decent durability, they often lack the luxurious feel and aesthetic of nubuck leather. This method may also not adequately address the unique characteristics of nubuck, such as its breathability and softness, which are crucial for high-end products.

How Do Traditional Leather Care Products Compare?

Traditional leather care products are versatile and can be used on various leather types, including nubuck. They often include cleaners, conditioners, and protectants that can rejuvenate and maintain the leather’s integrity. However, they may require more expertise to use effectively, as different products must be selected based on the leather type. Additionally, some traditional products might not be suitable for nubuck, risking damage to its unique texture. While they can be effective, the need for multiple products and a more involved maintenance routine can deter some buyers.

Conclusion: Choosing the Right Nubuck Leather Treatment Solution

For B2B buyers, the decision on how to treat nubuck leather should be driven by the specific needs of their products and target markets. If the goal is to maintain high-end, luxurious items, investing in specialized nubuck care products is advisable. Conversely, for businesses focused on cost and ease of maintenance in mass production, synthetic leather treatments may be more suitable. Traditional leather care products can also be effective but require careful consideration to ensure compatibility with nubuck. Ultimately, understanding the unique properties of nubuck leather and the intended use case will guide buyers to the right treatment solution that balances quality, cost, and maintenance.

Essential Technical Properties and Trade Terminology for how to treat nubuck leather

What Are the Key Technical Properties of Nubuck Leather?

When it comes to treating nubuck leather, understanding its essential properties is crucial for maintaining quality and durability. Here are the critical specifications:

-

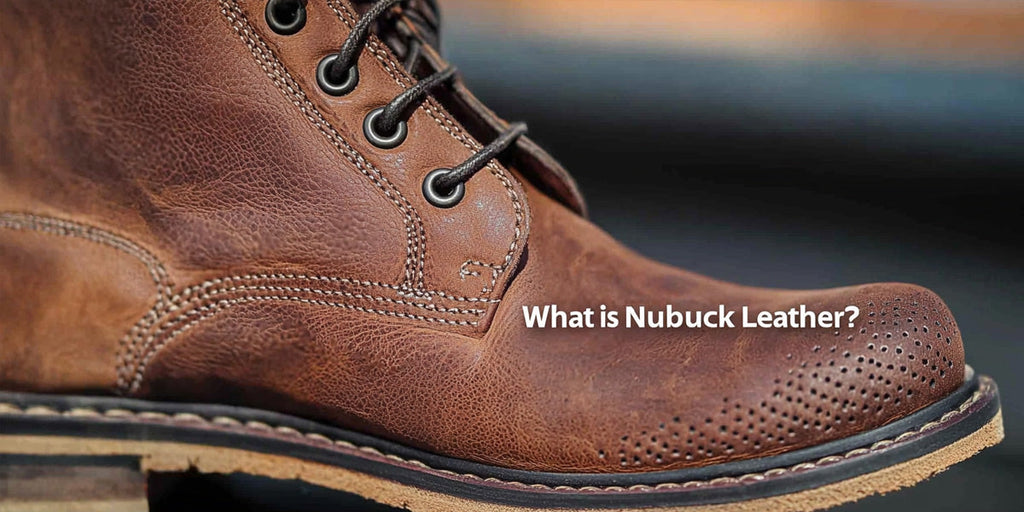

Material Grade: Nubuck is typically categorized as a top-grain leather, derived from the outer layer of the hide. This grade indicates a higher quality compared to lower grades, which can affect the longevity and aesthetic appeal of the product. For B2B buyers, choosing high-grade nubuck ensures that their products will withstand wear and maintain a luxurious finish.

-

Water Resistance: While nubuck has inherent water resistance due to its full-grain nature, it is still susceptible to moisture damage. The degree of water resistance can vary significantly based on the treatment used. For businesses, understanding the water resistance level helps in determining the appropriate care products and protective sprays to offer customers.

-

Nap Texture: The characteristic soft, velvety surface of nubuck, known as the nap, is created by sanding the leather. This texture is essential for aesthetic appeal but can be easily damaged. Businesses must educate customers on the importance of regular brushing and proper care to preserve this unique feature, which directly impacts customer satisfaction and product longevity.

-

Durability and Flexibility: Nubuck leather is celebrated for its durability, but it also requires conditioning to maintain its flexibility. B2B companies should prioritize offering conditioning products that nourish the leather fibers, preventing cracking and ensuring the leather retains its supple nature over time.

-

Scratch Resistance: Although nubuck is robust, its fine nap is prone to scratches. Understanding this property allows businesses to educate their customers on how to handle and maintain their nubuck products properly, thus reducing returns and increasing customer loyalty.

Which Common Trade Terms Should B2B Buyers Know When Dealing with Nubuck Leather?

Navigating the terminology associated with nubuck leather treatment is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or products that are used in another company’s end product. In the context of nubuck leather, OEMs may be responsible for supplying leather goods manufacturers with high-quality nubuck materials tailored to specific requirements.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. For nubuck leather suppliers, understanding MOQ is vital for inventory management and production planning, ensuring that they can meet client demands without overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a formal process where a buyer requests pricing and terms from suppliers. For B2B buyers of nubuck leather, issuing an RFQ helps in comparing prices and quality across different suppliers, ensuring they make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping responsibilities, risk management, and cost allocation when procuring nubuck leather from different regions.

-

PPE (Personal Protective Equipment): In the context of working with nubuck leather, PPE may refer to gear that protects workers during the treatment and maintenance processes. Businesses should prioritize safety standards and training, ensuring that their employees are equipped to handle materials safely.

By understanding these properties and terminology, B2B buyers can make informed decisions, ensuring that their investments in nubuck leather products yield high-quality, durable results. This knowledge not only enhances product care but also fosters stronger supplier relationships and improves overall business operations.

Navigating Market Dynamics and Sourcing Trends in the how to treat nubuck leather Sector

What Are the Key Market Dynamics and Trends in the Nubuck Leather Sector?

The global market for nubuck leather treatment is experiencing significant growth, driven by increasing consumer demand for high-quality, durable leather goods across various sectors, including fashion, automotive, and furniture. Key trends influencing this market include the rise of e-commerce platforms facilitating international trade, which allows B2B buyers from regions like Africa, South America, the Middle East, and Europe to access a wider range of nubuck leather products and treatments. Additionally, advancements in cleaning and conditioning technologies, such as eco-friendly sprays and brushes, are emerging as essential tools for maintaining the quality of nubuck leather, ensuring it remains a preferred choice for luxury items.

Furthermore, as more businesses recognize the importance of customer education in maintaining nubuck leather products, the demand for comprehensive care guides and instructional content is rising. This trend is particularly notable in markets like Brazil and Nigeria, where the appreciation for premium leather goods is growing, and businesses are investing in training their workforce to handle nubuck leather appropriately. The interplay of these factors is creating a dynamic environment for B2B buyers, who must stay informed on best practices and sourcing strategies to remain competitive.

Illustrative image related to how to treat nubuck leather

How Are Sustainability and Ethical Sourcing Shaping the Nubuck Leather Treatment Market?

As the global conversation around sustainability intensifies, ethical sourcing is becoming a crucial consideration for B2B buyers in the nubuck leather sector. The environmental impact of leather production, particularly the use of harmful chemicals in tanning processes, has prompted many companies to seek out suppliers who prioritize eco-friendly practices. Buyers are increasingly looking for certifications such as the Leather Working Group (LWG) certification, which indicates adherence to environmental standards in leather manufacturing.

Moreover, the demand for ‘green’ materials is shaping the development of innovative nubuck leather treatments. This includes the use of biodegradable waterproofing sprays and conditioners that do not compromise the quality of the leather while minimizing environmental harm. By prioritizing ethical supply chains and sustainable products, businesses can not only meet consumer expectations but also enhance their brand reputation in a competitive market. This shift towards sustainability is particularly pronounced in Europe, where regulatory frameworks and consumer awareness are driving the adoption of environmentally responsible practices.

What Is the Historical Context of Nubuck Leather Treatment?

Nubuck leather, characterized by its soft, velvety texture, has a storied history dating back centuries. Initially developed as a luxury material for the upper class, it has evolved to become a staple in both high-end fashion and everyday products. The treatment of nubuck leather has also transformed over time; early methods relied heavily on traditional oils and waxes, while modern techniques now incorporate advanced chemical solutions designed to enhance durability and appearance without sacrificing the leather’s natural properties.

This evolution reflects broader trends in the leather industry, including a growing emphasis on quality and craftsmanship. Today, B2B buyers must navigate a landscape where the historical prestige of nubuck is matched by contemporary innovations in care and treatment, ensuring that this timeless material continues to meet the demands of discerning consumers worldwide. Understanding this historical context can provide valuable insights for buyers looking to source high-quality nubuck leather and its treatments effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of how to treat nubuck leather

-

1. How do I solve common cleaning issues with nubuck leather?

To address cleaning issues with nubuck leather, start by using a soft-bristled nubuck brush to gently lift dirt and restore the nap. For stains, blot the area with a damp cloth to remove excess moisture, then apply a nubuck-specific cleaner following manufacturer instructions. If the stain persists, a nubuck eraser can help with tougher marks. Always conduct a patch test on an inconspicuous area before applying any cleaner to avoid discoloration. Regular maintenance, including brushing and conditioning, can prevent many common cleaning problems. -

2. What is the best method to protect nubuck leather from stains?

The best method to protect nubuck leather from stains is to apply a high-quality, nubuck-friendly waterproofing spray. This should be done on clean and dry leather and repeated every 2-3 months, especially before wet seasons. Additionally, avoid exposing nubuck to liquids and promptly blot any spills with a dry cloth to minimize absorption. Regular brushing also helps maintain the leather’s texture and resilience against stains, ensuring your nubuck items remain in pristine condition. -

3. How can I ensure the quality of nubuck leather from suppliers?

To ensure the quality of nubuck leather from suppliers, request samples before placing bulk orders. Look for certifications that demonstrate compliance with international quality standards. Engage in thorough supplier vetting, checking their history, customer reviews, and production processes. Conduct factory visits if possible, or utilize third-party inspection services. Establishing a clear quality assurance protocol with your suppliers will also help maintain consistent standards in your orders. -

4. What are the typical minimum order quantities (MOQ) for nubuck leather?

Minimum order quantities (MOQ) for nubuck leather can vary significantly by supplier and region. Generally, MOQs may range from 100 to 1,000 square feet, depending on the type and grade of leather. For bulk orders, suppliers may offer reduced pricing, but it’s essential to clarify these terms upfront. Discuss your specific needs with suppliers and inquire if they can accommodate lower MOQs for first-time orders or samples, especially when testing new markets or products. -

5. What payment terms should I expect when sourcing nubuck leather?

Payment terms when sourcing nubuck leather can vary widely, but common practices include a 30% deposit upfront and the balance before shipment. Some suppliers may offer net 30 or net 60 terms for established relationships. It’s crucial to negotiate these terms in advance and ensure they are documented in the purchase agreement. Consider using secure payment methods, such as letters of credit, to mitigate risks associated with international transactions. -

6. How can I customize nubuck leather products for my business?

Customizing nubuck leather products typically involves discussing specific design requirements with your supplier, including color, texture, and branding elements. Many suppliers offer options for embossing, stitching styles, and custom sizes. Ensure to provide clear specifications and, if possible, prototypes to align expectations. Be aware that custom orders may have higher MOQs and longer lead times, so plan your production schedule accordingly to avoid delays. -

7. What are the logistics considerations when importing nubuck leather?

Logistics considerations when importing nubuck leather include selecting reliable shipping methods and understanding customs regulations in your destination country. Coordinate with suppliers to ensure timely dispatch and secure appropriate packaging to prevent damage during transit. Familiarize yourself with import duties, taxes, and any documentation required for customs clearance. Partnering with a logistics provider experienced in handling leather goods can streamline the process and minimize potential delays. -

8. How can I maintain the longevity of nubuck leather products in my inventory?

To maintain the longevity of nubuck leather products in your inventory, store them in a cool, dry environment away from direct sunlight and humidity. Regularly brush the items to keep the nap raised and clean. Use protective sprays to shield against moisture and stains before storage. Conduct periodic inspections to catch any issues early, and ensure that your inventory management system tracks the age and condition of each item, facilitating timely care and maintenance.

Top 5 How To Treat Nubuck Leather Manufacturers & Suppliers List

1. Jim Green – African Ranger Boots

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Jim Green African Ranger boots in crazy horse leather; recommended care includes dry brushing, using suede saddle soap, suede cleaner, and waterproofing spray; specific products mentioned include Saphir spatula suede brush, Saphir gommadin suede cleaner, Saphir MDO super invulner waterproofing spray, Saphir omninettoyant suede shampoo, and Saphir suede renovateur; care steps involve removing dirt,…

2. Red Wing Shoes – Care Kit

Domain: redwingshoes.com

Registered: 1998 (27 years)

Introduction: Red Wing Shoes Care Kit includes essential products for maintaining and protecting your footwear. The kit features a cleaner, conditioner, and a brush, designed to keep leather shoes looking their best. Ideal for all Red Wing leather products, it helps to extend the life of your shoes and maintain their appearance.

3. Leather Honey – Leather Care Essentials

Domain: leatherhoney.com

Registered: 2010 (15 years)

Introduction: Leather Conditioner: from $27.99 (originally $68.95)

Leather Cleaner: from $18.99 (originally $33.99)

Leather Care Kit: $43.99 (originally $70.99)

Products are safe for all leathers and contain non-toxic ingredients. The conditioner lasts up to six months and protects against stains and water damage. The cleaner effectively removes dirt and grime without leaving residue.

4. Marlborough of England – Nubuck Leather

Domain: marlboroughofengland.com

Registered: 2014 (11 years)

Introduction: Nubuck leather is a highly sought-after product known for its soft, velvety surface texture. It is made from the top part of the animal’s skin (full grain), making it more durable than suede. Nubuck is vulnerable to wear and staining due to its lack of a protective coating. Care tips include: 1) Protection: Use an industrial quality waterproofing and stain-resistant spray, applying two or three co…

5. Picard – Nubuck Leather Care Guide

Domain: picard-fashion.com

Registered: 2021 (4 years)

Introduction: Nubuck leather is a type of suede made from cow or calf skin, known for its velvety soft texture, high breathability, and durability. It is water-repellent when properly impregnated. Care instructions include: 1) Regularly remove dust with a nubuck leather brush. 2) For light soiling, use a mixture of dishwashing liquid and water. 3) For grease stains, apply baby powder or baking soda. 4) Use a nu…

Strategic Sourcing Conclusion and Outlook for how to treat nubuck leather

In conclusion, understanding how to effectively treat and maintain nubuck leather is crucial for international B2B buyers looking to enhance their product offerings. Key takeaways include the importance of regular brushing to preserve the nap, utilizing nubuck-specific cleaning solutions, and applying protective sprays to guard against moisture and stains. By investing in high-quality care products, businesses can extend the lifespan of their nubuck items, ensuring customer satisfaction and repeat purchases.

Illustrative image related to how to treat nubuck leather

Strategic sourcing plays a pivotal role in this process. By partnering with reliable suppliers who understand the nuances of nubuck leather care, companies can secure the best products and practices for their markets. This ensures that they not only meet but exceed customer expectations, particularly in regions such as Africa, South America, the Middle East, and Europe.

As the demand for luxurious and durable leather products continues to rise, now is the time for businesses to enhance their sourcing strategies. Embrace the future of nubuck leather care and position your brand as a leader in quality and customer trust. Explore innovative solutions and build partnerships that drive your success in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.